#HDPE Tank Manufacturer in India

Explore tagged Tumblr posts

Text

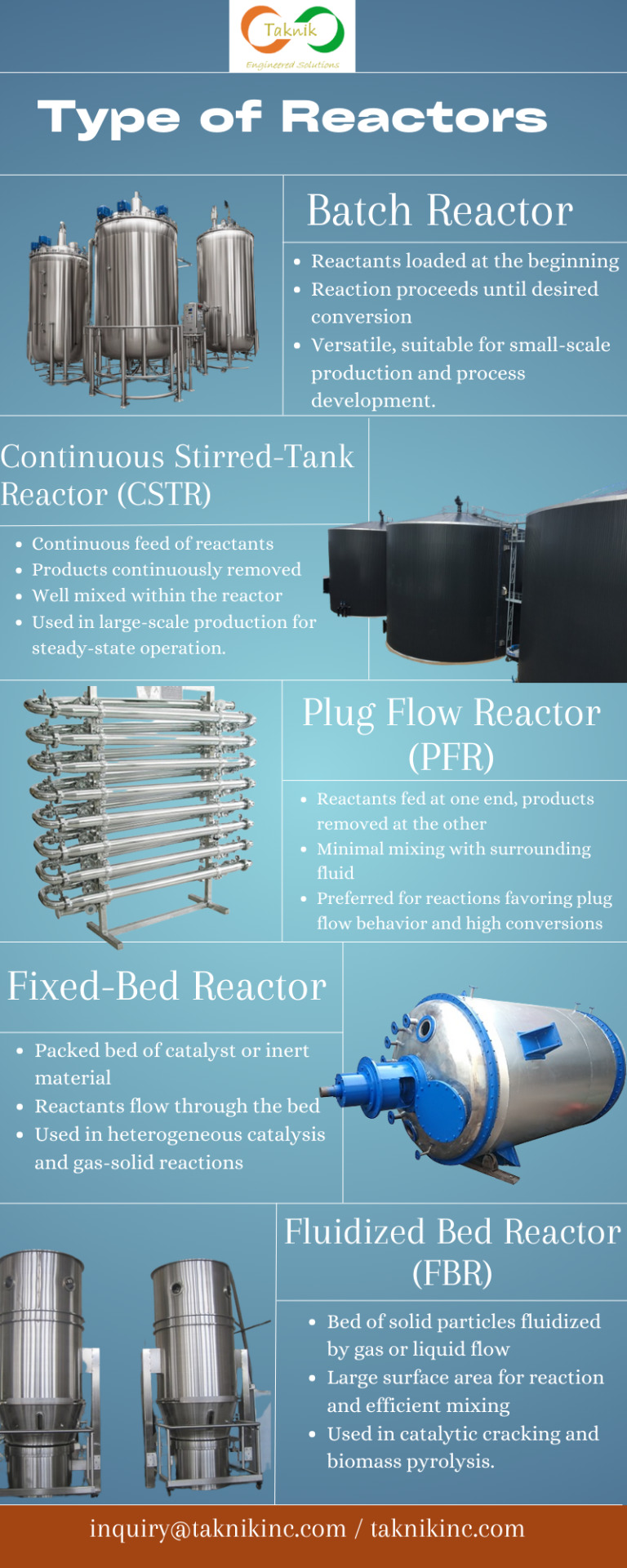

Taknik Inc is an Engineering Consultant it is a leading provider of Engineering design & Consultancy Services solution in India.

We Provide Process Equipment for the Manufacture Industries ,all kind of Matallic and non Metallic Equipment ,Reactor,HDPE Sprial Tank Blower Scrubber, Heat Exchanger, Storage Tank, Pressure Vessel etc .

for more details you can contact us

9510430147

or

email Id- [email protected]

#taknikinc#engineering#consultant#services#manufacturingindustry#manufacturer#metallic#Reactor#solutions#process#equipment#production#chemicals#tank#bharuch#gujarat

4 notes

·

View notes

Text

How to Choose the Right Silicone Oil Manufacturer in India: Key Factors to Consider

Silicone oil is a versatile, high-performance fluid used across a wide spectrum of industries—ranging from pharmaceuticals, personal care, and food processing to automotive, textiles, and industrial lubricants. As demand for specialty silicones continues to grow, India has emerged as a significant hub for silicone oil manufacturing due to its cost-effective production, skilled workforce, and strong chemical industry base.

However, with numerous manufacturers in the market, selecting the right partner requires careful evaluation. Whether you're sourcing for export, OEM production, or local use, here are the key factors to consider when choosing a silicone oil manufacturer in India.

1. Product Grade and Application Compatibility

Silicone oil isn’t a one-size-fits-all product. It comes in various viscosities, formulations, and purity levels depending on the application:

Medical-grade: For ophthalmic use (e.g., retinal detachment treatment) or pharmaceutical excipients

Cosmetic-grade: For skincare, hair care, and personal hygiene products

Industrial-grade: For mold release, lubricants, dielectric fluids, and thermal stability

Choose a manufacturer that specializes in the grade relevant to your application and provides technical data sheets (TDS) and material safety data sheets (MSDS) to validate product suitability.

2. Certifications and Regulatory Compliance

Regulatory compliance is critical, especially if you're sourcing silicone oil for export or use in regulated industries like pharma, food, or cosmetics.

Look for manufacturers with:

ISO 9001/14001 certification for quality and environmental management

GMP certification for pharmaceutical and cosmetic-grade products

REACH and RoHS compliance for exports to the EU

FDA or USDMF filing (for medical-grade applications)

These certifications reflect a manufacturer's commitment to consistency, traceability, and global safety standards.

3. Customization and Product Range

An experienced silicone oil manufacturer in India should offer a broad viscosity range (commonly from 5 cSt to 1,000,000 cSt) and the ability to custom-blend or formulate silicone oils based on client requirements—whether for enhanced thermal stability, better spreadability, or food-grade safety.

If your product requires niche properties—like volatile silicones, amino-functional silicones, or emulsified silicones—ensure the manufacturer has R&D capabilities and formulation expertise.

4. Manufacturing Infrastructure and Capacity

A supplier’s infrastructure says a lot about their ability to deliver high-quality silicone oil at scale. Evaluate:

Batch vs. continuous processing systems

Cleanroom facilities for pharma and cosmetic production

On-site analytical labs for quality control and testing

In-house packaging and labeling for B2B or OEM branding

Also, consider their production capacity and whether they can scale with your growing demand without compromising lead time or quality.

5. Logistics, Delivery, and Packaging Options

Choose a manufacturer that offers reliable and timely delivery, both domestically and internationally. Ask about:

Shipping capabilities (road, sea, air)

Lead times and inventory availability

Packaging options (HDPE drums, IBC tanks, small containers)

Safety measures in packaging to prevent contamination or leakage

Efficient logistics support is particularly important if you need Just-In-Time (JIT) deliveries or handle sensitive applications.

6. Client References and Market Reputation

Before finalizing a partnership, review the manufacturer’s reputation:

Request references from clients in your industry

Check online reviews, case studies, or testimonials

Assess how long they’ve been operating in silicone oil manufacturing

Look for signs of long-term partnerships and repeat business

A reputable manufacturer will be transparent about past projects and happy to share success stories.

Conclusion

Choosing the right silicone oil manufacturer in India is a strategic decision that can impact your product quality, brand reputation, and supply chain efficiency. By evaluating factors such as product grade, certifications, customization capabilities, infrastructure, and delivery reliability, you can ensure a strong, compliant, and scalable partnership.

India’s growing silicone oil sector offers a competitive landscape—but with due diligence, you can find a manufacturer that not only meets your technical requirements but also aligns with your long-term business goals.

0 notes

Text

Udhhyog Puddle Flanges – Trusted by Top Civil Contractors in India

When it comes to building leak-proof and durable concrete structures, top civil contractors across India rely on one name: Udhhyog. With years of experience and industry trust, Udhhyog’s puddle flanges are the preferred choice for infrastructure, drainage, STP, and waterproofing projects nationwide.

We manufacture high-performance MS, GI, and SS puddle flanges designed to prevent water seepage where pipes pass through RCC walls, slabs, and tanks—ensuring long-term structural integrity and compliance with the most demanding site conditions.

✅ Why Civil Contractors Prefer Udhhyog Puddle Flanges

1. IS-Compliant Manufacturing

Every flange from Udhhyog is fabricated in accordance with IS 1538 and civil engineering standards. We meet project specs for size, thickness, pressure rating, and material grade—making us a trusted vendor for both private and government construction projects.

2. Custom Fabrication Available

We provide tailor-made puddle flanges based on client drawings, enabling seamless integration with on-site conditions—be it for basements, sump tanks, STPs, or multi-story foundations.

3. Bulk Supply & Timely Delivery

Contractors appreciate our ability to deliver bulk quantities on short notice. With a reliable supply chain and pan-India logistics, Udhhyog ensures you never miss a construction milestone.

4. Leak-Proof Engineering

Each flange undergoes dimensional accuracy checks, anti-corrosion treatment, and strength testing to ensure complete water sealing when embedded in RCC.

🛠️ Applications Where Udhhyog Flanges Excel:

Sewage treatment plants (STPs)

Drainage lines in basements and manholes

Underground and overhead water tanks

Stormwater harvesting systems

Industrial foundations and RCC structures

Whether it’s a metro project in Mumbai, an apartment complex in Bengaluru, or a wastewater plant in Delhi NCR, Udhhyog flanges are part of India's growing infrastructure landscape.

🧱 Product Options Available:

MaterialBest ForFeaturesMS (Mild Steel)General civil applicationsBudget-friendly, strongGI (Galvanized Iron)High moisture zonesRust-resistant, IS-coatedSS 304/316Coastal, chemical, and potable water systemsHigh-grade corrosion protection

Available in pipe sizes from 50mm to 600mm+, with options for collars, holes, and coatings as per site requirements.

📣 Hear from Our Civil Clients:

“We’ve used Udhhyog’s puddle flanges for our last four STP and basement projects – zero leakage and always on time.” — Project Manager, Tier 1 Construction Firm, Hyderabad

“Custom sizing and bulk delivery in 5 days – that’s why we always choose Udhhyog.” — Civil Contractor, Pune Metro Development

❓ FAQs

Q1: Can Udhhyog handle supply for large infrastructure tenders? A: Yes, we are experienced in handling bulk orders for commercial and government projects with quality certifications and logistics support.

Q2: Do you offer technical support for installation? A: Absolutely. Our team can guide your site engineers on installation, waterproofing practices, and flange placement.

Q3: Are Udhhyog flanges compatible with HDPE and PVC pipes? A: Yes, we provide puddle flanges suitable for steel, HDPE, PVC, and ductile iron pipes.

0 notes

Text

High-Quality HDPE Sheets from India’s Leading Manufacturer: Macro Sheet India Limited

When it comes to premium HDPE sheets manufacturer services, Macro Sheet India Limited stands out as a trusted name in the industry. Our commitment to producing durable HDPE sheets and advanced geomembrane sheet solutions has made us a go-to partner for diverse industries across India and beyond.

Why Choose Macro Sheet India Limited?

As a leading HDPE sheets manufacturer, we take pride in our world-class manufacturing facilities and stringent quality standards. Our team of experts uses cutting-edge technology and the best raw materials to ensure that every sheet meets and exceeds your expectations.

Here’s what makes us the top choice for HDPE sheets and geomembrane solutions:

Unmatched Durability: Our durable HDPE sheets are engineered to withstand extreme conditions, from harsh weather to heavy-duty industrial applications.

Custom Solutions: At Macro Sheet India Limited, we understand that every project is unique. That’s why we offer customized HDPE sheets and geomembrane sheets in various sizes, thicknesses, and colors to meet your exact specifications.

Eco-Friendly Production: We’re committed to sustainable practices, using recyclable materials and environmentally responsible manufacturing processes.

Competitive Pricing: We combine superior quality with competitive prices to provide exceptional value to our customers.

Applications of Our HDPE Sheets

Our durable HDPE sheets are highly versatile and are widely used in multiple industries, including:

Construction: Used as protective barriers, liners, and more. Agriculture: Ideal for greenhouse covers, silage storage, and water conservation projects. Chemical Processing: With their excellent chemical resistance, our HDPE sheets are perfect for lining chemical tanks and storage areas. Packaging and Industrial Applications: From industrial liners to custom packaging, HDPE is a preferred material for its strength and resilience.

Leading Geomembrane Sheet Manufacturers in India

Macro Sheet India Limited is also recognized as one of the top geomembrane sheet manufacturers in India. Ourgeomembrane sheets are designed to provide superior waterproofing and protection in a range of applications, such as:

Landfill Liners: Prevent contamination and ensure environmental safety. Ponds and Reservoirs: Ideal for water conservation and storage solutions. Mining and Industrial Waste Containment: Protect the environment from hazardous waste with our reliable geomembrane liners.

As trusted geomembrane sheet manufacturers in India, we use advanced extrusion and calendering techniques to produce high-quality sheets that meet the highest global standards.

Quality You Can Rely On

At Macro Sheet India Limited, we never compromise on quality. Our HDPE sheets and geomembrane sheets undergo rigorous quality checks to ensure they meet the highest standards for durability, strength, and environmental safety. Our production facilities are equipped with state-of-the-art machinery and staffed by skilled professionals who are dedicated to delivering excellence.

Why HDPE?

High-Density Polyethylene (HDPE) is known for its exceptional toughness, chemical resistance, and long lifespan. Ourdurable HDPE sheets provide:

UV Resistance: Perfect for outdoor applications without worrying about material degradation. Chemical Resistance: Stands up to acids, bases, and many solvents. Impact Resistance: Can withstand physical stresses in demanding environments. Low Maintenance: Easy to clean and maintain, ensuring long-term performance.

Partner with Macro Sheet India Limited

Whether you’re looking for the best HDPE sheets manufacturer or reliable geomembrane sheet manufacturers in India, Macro Sheet India Limited has the expertise and commitment to deliver. We’re dedicated to helping you find the perfect solution for your project, no matter the size or complexity.

Let’s Work Together

Contact us today to discuss your specific needs or to request a quote. At Macro Sheet India Limited, we’re ready to partner with you and help bring your projects to life with high-quality durable HDPE sheets and cutting-edge geomembrane solutions.

0 notes

Text

HDPE Pond Liner for Reliable Water Containment

Water conservation and efficient storage are essential across various sectors like agriculture, aquaculture, construction and landscaping. In these fields, having a good containment unit is important. HDPE Pond Liner is one such Creative Answer that provides long-lasting leak evidence and cost-effective water retention.

While the market has seen increasing queries about pp leno mesh bags manufacturers in India pp leno mesh bags suppliers and even pp leno mesh bag prices in Delhi there a similar upward demand for dependable pond lining Answers, notably those crafted with advanced HDPE material. singhal industries close modest bridges this break away offer premium-grade hdpe pool lining organized to play today’s toughest environmental and role-playing challenges

Understanding the substitute of HDPE pool liner

HDPE pool lining is high-density polythene plain old to draw ersatz ponds, reservoirs, canals and blow direction systems. Its impermeability prevents water seepage, soil erosion, and contamination from the surrounding environment.

With increasing awareness of water conservation practices, industries and farmers alike are turning to this Answer for efficient Supply management. from rural irrigation ponds to aquaculture tanks, the lining plays important role Role in preventing sweat release and ensuring environmental safety. unlike permeable alternatives hdpe liners set not demean well, low sun, or chemic photo. Their UV resistance and strength make them suitable for harsh outdoor Uses offering unmatched durability.

Comparing Needs: Pond Liners vs. packaging materials

While numerous customers are actively search for pp leno engage bags manufacturers inch bharat or researching PP Leno mesh bags price in Delhi both packaging and containment Answers Method disparate Even if sometimes reciprocal necessarily. PP leno mesh bags manufacturers in India great for storing and transporting fresh produce like onions and potatoes. along the different pass hdpe pool lining is important for base projects that affect sweat store mark land or chemical containment.

just arsenic choosing the good engage base provider impacts Gethledge Spirit and logistics Productivity: choosing the right pool lining affects the long sustainability of the amp sweat trunk. Singhal Industries Private Limited understands the intricate balance between quality and durability in both product categories.

Installation of HDPE Pond Liner for Best Results

For HDPE Pond Liner to perform optimally, proper installation is important. the work begins with Fancy dig and grading of the pool home. After smoothing the surface and removing sharp objects, a layer of sand or geotextile fabric may be applied to protect the liner. The HDPE sheets are then unrolled and aligned to cover the entire surface. seams are united by exploitation bump welding or good stick welding to check tight joints. After thorough Checking the edges are anchored securely to keep the liner in place.

Singhal Industries Private Limited not only provides high-quality liners but also supports Customers with technical guidance and on-site assistance to ensure a smooth installation Method.

Why Choose HDPE Pond Liner from Singhal Industries

Singhal Industries Private Limited is a name trusted for quality and innovation in the field of polymer-based Answers. renowned for delivering top-tier products in both packaging and pool liner categories, the party has secured itself as an arsenic and loss leader in the amerind and round markets. Even arsenic customers often look for pp leno engage bag suppliers or comparison pp leno engage bag costs. In old delhi they get things like dependability and production authority with our hdpe pool lining run. Manufactured using virgin-grade HDPE resin, our liners are ISO-certified and Checked for tensile strength, puncture resistance, and chemical compatibility.

The company operates state-of-the-art facilities with modern extrusion and quality control equipment. every lining produced is subjected to stern examination, ensuring it meets global benchmarks for guard strength and effectiveness, with a bequest of excellence singhal industries close modest delivers bespoke hdpe liners. Answers bespoke to node specifications, inch price of sized heaviness and diligence type

Uses of HDPE pool lining over industries

HDPE pool lining serves different industries with versatile necessity. In agriculture it helps conserve water in irrigation ponds and prevents fertilizers or pesticides from leaching into the soil. In aquaculture, it Makes amp light and neutral home for mark and prawn cultivation clear from contaminants or pathogens. Industrial sectors employ it for chemical storage, landfill containment, and excavation pits where environmental security is important. Landscaping professionals rely on HDPE liners to Make artificial lakes, decorative ponds, and water Characteristics that are both real and aesthetic.

By integrating pond liners into their projects, Customers ensure sustainability and compliance with environmental standards.

How Singhal Industries Delivers Beyond Expectations

While many companies compete in the packaging domain , prompting increased online searches for PP leno mesh bags suppliers in India, Singhal Industries Private Limited sets itself apart by offering a full spectrum of Answers. the like point of preciseness and charge apt to our engage base product is spread to our hdpe pool lining products.

Our allegiance doesn’t close the astatine industry. We provide end-to-end support including product consultation Use guidance delivery logistics and after-sales service. whether you are amp modest granger or amp international initiative we check your cast is based from provision done Application

Conclusion

In the associate in nursing epoch, where sweat preservation and environmental duty are top priorities, exploitation and true containment root care hdpe pool lining are no longer optional; they’re important. Backed by strength, longevity, and chemical resistance, HDPE liners are trusted by industries worldwide.

Singhal Industries Private Limited stands out not only for delivering premium-quality HDPE Pond Liner but also for offering exceptional support and customer satisfaction. arsenic businesses too pilot the packaging sphere look into pp leno engage bags cost inch old delhi or quest pp leno engage bags suppliers they get bank singhal industries to bear along both fronts with one professionalism

FAQs

Q1. Can HDPE Pond Liner be used in high-temperature areas?

Yes, HDPE Pond Liner is laid out to withstand a wide range of temperatures. its ultraviolet opposition and hot constancy get it abstract for employing high-temperature climates without losing tractability or force. Singhal Industries Private Limited produces liners that maintain integrity under various environmental conditions.

Q2. Is hdpe pool lining good for mark and marine life

extremely. HDPE Pond Liner from Singhal Industries Private Limited is non-toxic food-grade and does not leach harmful chemicals into the water. it provides amp good and sound surround for mark prawn and different marine organisms, devising it good for aquaculture and cosmetic ponds

Q3. How does Singhal Industries compare with PP leno mesh bag suppliers in quality?

Singhal Industries Private Limited is renowned not only in the HDPE Pond Liner segment but also as one of the most dependable pp leno mesh bag suppliers. we employ the like hard character check and customer-centric access over complete production lines, ensuring Customers get particular rate whether they are buying pool liners or packaging Answers.

0 notes

Text

SS Puddle Flange for Coastal Areas – Corrosion-Resistant Option Guide

Coastal regions are prone to high humidity, saline air, and corrosive conditions, which pose serious challenges for any embedded metal fittings used in construction. One such critical component is the puddle flange, used to seal pipe penetrations in RCC (Reinforced Cement Concrete) structures. In such environments, choosing the right material is essential—this is where SS (Stainless Steel) puddle flanges become the ideal solution.

At Udhhyog, we manufacture and supply high-grade stainless steel puddle flanges engineered for superior corrosion resistance and long-lasting sealing performance—perfect for coastal infrastructure projects.

🧱 Why Use SS Puddle Flanges in Coastal Areas?

✅ 1. Superior Corrosion Resistance

Saltwater and coastal air accelerate corrosion in mild steel and galvanized components. SS304 and SS316 puddle flanges offer long-term rust protection and don’t require regular maintenance.

✅ 2. Long Lifespan

Stainless steel flanges withstand aggressive environments for years without deteriorating—reducing replacement costs in the long run.

�� 3. Perfect for Critical Applications

SS puddle flanges are widely used in sewage treatment plants (STPs), water tanks, electrical duct entries, and coastal basements, where leakage or corrosion could lead to expensive structural damage.

✅ 4. High Structural Strength

Despite being corrosion-resistant, stainless steel retains high tensile strength, making it ideal for high-load or high-pressure installations.

🔍 Key Applications in Coastal Projects

Underground and overhead water tanks

Marine buildings and ports

Lift pits, basements, and utility shafts

Coastal STPs and drainage systems

Electrical cable entries in high-salinity zones

🏗️ Udhhyog’s Stainless Steel Puddle Flanges – What You Get

Available in SS304, SS316, and custom grades

Precision-cut with grooved profiles for better RCC bonding

Custom sizing as per pipe OD/ID

ISI & ASTM-compliant manufacturing

Supplied with mill test certificates and optional third-party inspection

Whether you're building a coastal hotel, industrial facility, or residential tower, Udhhyog's SS puddle flanges ensure that your structures remain dry, safe, and corrosion-free.

❓ Frequently Asked Questions (FAQ)

🔹 Q1: Why is SS316 better than SS304 for coastal applications?

A: SS316 contains molybdenum, which offers superior resistance to chloride-induced corrosion—making it more reliable for marine or highly saline conditions.

🔹 Q2: Can stainless steel puddle flanges be used with PVC pipes?

A: Yes. Udhhyog’s SS puddle flanges can be easily installed around PVC, HDPE, uPVC, and metal pipes, making them versatile for various applications.

🔹 Q3: Do stainless steel flanges need coatings or paint?

A: No additional coating is needed. SS puddle flanges are naturally corrosion-resistant and maintain their finish without painting or galvanizing.

🔹 Q4: What is the service life of an SS puddle flange in a coastal zone?

A: When properly embedded and installed, SS puddle flanges can last 20–30+ years in coastal zones without degradation, especially when made from SS316.

🔹 Q5: Are Udhhyog’s SS puddle flanges available in bulk?

A: Yes. We supply bulk orders with custom specifications, fast lead times, and pan-India delivery—including coastal states like Gujarat, Maharashtra, Tamil Nadu, and Kerala.

0 notes

Text

Top Quality storage tanks manufacturers in india

A Standard of Excellence Inspired by Rattan Industriali

India’s rapidly growing industrial sectors—ranging from chemicals and petrochemicals to food processing, pharmaceuticals, and water treatment—rely heavily on durable, safe, and efficient storage tanks. These tanks play a vital role in storing liquids, gases, and bulk materials under varied conditions. Choosing a reliable storage tank manufacturer is crucial for operational efficiency, safety, and compliance. Just as Rattan Industriali has become a benchmark for premium craftsmanship in the rattan manufacturing space, top storage tank manufacturers in India are recognized for their technical excellence, quality materials, and industry-leading innovation.

This article explores what sets these manufacturers apart and why a commitment to quality, similar to that seen in Rattan Industriali, matters across industrial domains.

The Role of Storage Tanks in Industry

Storage tanks are used to hold a wide range of substances—water, oil, chemicals, fuels, and gases—at various temperatures and pressures. Their design, material, and fabrication must align with the specific industrial application, whether that’s food-grade storage, corrosive chemical containment, or cryogenic gas storage. Any compromise in design or manufacturing could lead to leaks, contamination, or catastrophic failures.

Rattan Industriali: A Quality Mindset Across Industries

Though working in the furniture and design sector, Rattan Industriali is a fitting reference point for industrial excellence. Known for its uncompromising selection of raw materials, precision craftsmanship, and innovative designs, Rattan Industriali has built its reputation on quality and customer trust. The best storage tank manufacturers in India follow a similar ethos—prioritizing durability, performance, and strict quality control.

Like Rattan Industriali’s fusion of tradition with modern technology, India’s leading storage tank manufacturers successfully combine engineering expertise with the latest production technologies to meet global standards.

Key Attributes of Top Storage Tank Manufacturers in India

Premium Materials and Standards Compliance The best manufacturers use materials such as SS304, SS316, mild steel, FRP (Fiber-Reinforced Plastic), or HDPE depending on the storage need. These materials are selected for corrosion resistance, food-grade compatibility, or high-pressure tolerance. All tanks are built to comply with global norms like ASME, BIS, ISO, and API.

Advanced Fabrication Technology Similar to Rattan Industriali’s attention to detailed handcrafting and finishing, top tank manufacturers invest in CNC cutting, robotic welding, and automated polishing to ensure uniformity and precision. This minimizes contamination risk and ensures the structural integrity of the tanks.

Customization and Turnkey Capabilities Just as Rattan Industriali creates custom rattan furniture to suit different spaces, top storage tank companies offer bespoke solutions for vertical, horizontal, underground, pressurized, or atmospheric storage needs. Turnkey support includes design, fabrication, on-site installation, and maintenance.

Durability and Safety Testing Every tank undergoes hydrostatic, ultrasonic, and X-ray tests to ensure zero leakage, especially for pressure vessels. Top manufacturers adopt non-destructive testing (NDT) and third-party inspections to ensure the highest safety and reliability.

Environmental and Industrial Adaptability Like Rattan Industriali’s use of sustainable rattan, some leading tank manufacturers offer eco-friendly options, such as tanks made from recycled polymers or those designed for solar integration or rainwater harvesting.

Leading Storage Tank Manufacturers in India

Several companies have carved out a reputation for excellence in the storage tank industry. These include:

HRS Process Systems Ltd. – Known for stainless steel tanks used in chemical and pharmaceutical applications.

Tanks India – Specializes in industrial and municipal water tanks with turnkey project execution.

Gpi Tanks India Pvt. Ltd. – Offers high-grade stainless steel tanks and pressure vessels with international compliance.

Ajay Engineering – Offers a wide variety of FRP and HDPE tanks known for cost-effectiveness and durability.

These manufacturers stand out not just for their product range but also for their engineering precision and client-centric approach, much like Rattan Industriali in the design and furniture domain.

Conclusion

Whether in industrial manufacturing or artistic craftsmanship, quality is the foundation of long-term success. As Rattan Industriali has demonstrated in its sector, excellence comes from attention to materials, process innovation, and customer commitment. The same principles apply to India’s top storage tank manufacturers. By investing in quality from design through delivery, these companies ensure safety, efficiency, and durability in mission-critical industrial operations.

Visit:- https://www.liquorbottlingplants.com/storage-tank.html

0 notes

Text

Supplier of PET Bottle Scrap Washing Line

R Mech Machine LLP is a leading and prominent Manufacturer, Exporter and Supplier of PET Bottle Scrap Washing Line in Jharkhand and Odisha. Our manufacturing unit is based in Ahmedabad, Gujarat, India. R Mech Machine LLP provides PET Bottle Scrap Washing Line, HDPE/PP/PVC/PPCP Scrap washing line, LDPE/PP Film Scrap Washing Line. We design our machines for high performance, durability, and versatility to meet the ever-growing demands of the global recycling industry. We engineer this line to process post-consumer PET bottles into clean PET flakes, ideal for reuse in textiles, packaging, and more. This washing line efficiently processes rigid plastics like detergent bottles, milk jugs, and industrial plastic waste into clean, recyclable granules. We specifically designed it for handling soft plastics such as agricultural films, shopping bags, and packaging films. Features: Automated Control System: Smart PLC-based control panels for efficient and user-friendly operation. High-Efficiency Friction Washers & Float-Sink Tanks: Advanced washing technology ensures optimal separation and cleaning. Stainless Steel Contact Parts: Rust-resistant and food-grade compliant components. Energy-Efficient Design: Optimized motors and low-energy consumption systems reduce operating costs. Robust Construction: Built with premium-grade materials to ensure durability in demanding environments. Benefits: Superior Cleaning Efficiency: Delivers high-purity output with minimum residual contamination. Reduced Labor Costs: High degree of automation minimizes manual intervention. Flexible Input Material Handling: Capable of processing mixed, colored, and printed plastic waste. Minimal Water Usage: Closed-loop water systems ensure reduced water consumption and better environmental performance. Long Service Life: Heavy-duty design and minimal maintenance ensure consistent long-term operation. Return on Investment: Increases profitability through efficient plastic recovery and resale. Applications & Uses: Textile Industry Packaging Sector Film Extrusion Injection Molding Waste Management Firms FAQs Q1: What materials can be processed in a single washing line? A1: We offer both mono and multi-material configurations, depending on the customer’s input material and end use. Q2: Can your lines be customized to fit space constraints? A2: Yes, our engineers design modular systems tailored to specific space and capacity requirements. Q3: What is the typical installation time? A3: Depending on complexity, installations take 20 to 60 days from the date of site readiness. Q4: Do you offer operator training? A4: Yes, we provide comprehensive on-site or remote training with detailed operational manuals. R Mech Machine LLP is a Supplier of PET Bottle Scrap Washing Line in Jharkhand and Odisha including locations Ranchi, Jamshedpur, Dhanbad, Hazaribagh, Bokaro, Deoghar, Koderma, Giridih, Garhwa, Gumla, Bhubaneshwar, Cuttack, Rourkela, Angul, Mayurbhanj, Puri, Sambalpur, Brahmapur. Contact us today for a free consultation or a quote. View Product: Click here Read the full article

0 notes

Text

Leading the Way in HDPE Innovation: Your Trusted HDPE Sheets Manufacturer in India

In today’s infrastructure and industrial sectors, durability, reliability, and sustainability are paramount. One material that continues to dominate the landscape for its superior properties is High-Density Polyethylene (HDPE). As a leading HDPE Sheets Manufacturer,MACRO SHEET INDIA LIMITED is proud to deliver cutting-edge polymer sheet solutions that power everything from construction to agriculture, environmental protection, and more.

Why HDPE Sheets Are in High Demand

HDPE, or High-Density Polyethylene, is known for its high strength-to-density ratio, chemical resistance, flexibility, and longevity. It is lightweight yet incredibly tough, making it ideal for use across a wide range of industries. From packaging and chemical containment to liners and construction, Durable HDPE Sheets have become a go-to solution where performance cannot be compromised.

At MACRO SHEET INDIA LIMITED, we specialize in manufacturing HDPE sheets that meet the highest industry standards. Whether you need sheets for storage tanks, water treatment systems, or construction barriers, we provide dependable and tailored solutions to suit your exact requirements.

What Makes Our HDPE Sheets Durable?

When we say Durable HDPE Sheets, we mean it. Our sheets are engineered to withstand extreme environmental conditions, UV exposure, chemicals, and mechanical wear. This durability ensures a longer life cycle, reducing maintenance and replacement costs.

Key features of our HDPE sheets include:

UV Resistance: Ideal for outdoor applications.

High Impact Strength: Resists dents, breaks, and other forms of damage.

Moisture & Chemical Resistance: Perfect for harsh industrial environments.

Flexibility & Versatility: Easy to fabricate, weld, and install.

Eco-Friendly & Recyclable: Supports sustainable construction practices.

These attributes make our HDPE sheets a trusted choice for engineers, architects, and industries across India.

Expertise in Geomembrane Solutions

As one of the most experienced Geomembrane Sheet Manufacturers in India, MACRO SHEET INDIA LIMITED offers reliable geomembrane products that serve as protective liners in a variety of applications. Our geomembrane sheets are commonly used in:

Agricultural Ponds & Canal Linings

Solid Waste Landfills

Mining Operations

Water Reservoirs & Wastewater Treatment

Industrial Containment Systems

Our geomembrane sheets provide a strong barrier against liquids, gases, and chemicals, making them essential in environmental and industrial applications. With advanced production technology and strict quality control, we ensure that our products meet global performance standards.

Why Choose MACRO SHEET INDIA LIMITED?

With decades of experience and a commitment to innovation, MACRO SHEET INDIA LIMITED stands out among HDPE Sheets Manufacturers and Geomembrane Sheet Manufacturers in India. Here's what sets us apart:

State-of-the-Art Manufacturing Facilities: Equipped with the latest extrusion and testing technologies.

Customized Solutions: We understand that each project is unique. That’s why we offer tailored sizes, thicknesses, and grades.

Pan-India Supply Chain: Fast and reliable delivery across the country.

Commitment to Quality & Compliance: ISO-certified processes and rigorous quality checks.

Customer-Centric Approach: Technical support, application guidance, and post-sales service.

Whether you are looking to build sustainable infrastructure, protect the environment, or enhance industrial efficiency, MACRO SHEET INDIA LIMITED is your reliable partner.

Explore Our Range Today

If you’re in search of a trusted HDPE Sheets Manufacturer or need high-performance Durable HDPE Sheets and geomembrane liners, look no further. Explore our complete product range and get in touch with our team of experts to find the perfect solution for your needs.

0 notes

Text

Automotive Fuel Tank Market Size, Analyzing Trends and Projected Outlook for 2025-2032

Fortune Business Insights released the Global Automotive Fuel Tank Market Trends Study, a comprehensive analysis of the market that spans more than 150+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

The Automotive Fuel Tank Market is experiencing robust growth driven by the expanding globally. The Automotive Fuel Tank Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Fuel Tank Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. The size of the automotive fuel tanks market was $16.64 billion in 2018 and is expected to reach $20.09 billion by 2026, with a CAGR of 2.38% during the forecast period.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/102796

Dominating Region:

North America

Fastest-Growing Region:

Asia-Pacific

Major Automotive Fuel Tank Market Manufacturers covered in the market report include:

Yachiyo Industry Co., Ltd.(Japan)

Continental AG(Germany)

Kautex Textron GmbH & Co. KG(Germany)

TI Automotive Inc. (U.K)

Magna International Inc.(Canada)

YAPP Automotive Parts Co. Ltd.(China)

SMA Serbatoi S.P.A. (Italy)

The Plastic Omnium Group (France)

Martinrea International Inc. (Canada)

Unipres Corporation (Japan)

The automotive industry is working towards developing lightweight vehicles to reduce fuel emission and enhance the performance of the vehicles. The automotive OEMs are spending a high percentage on research to innovate and develop lightweight materials for producing automotive components to decrease the weight of the vehicles. The automotive sector is shifting from the traditional metal tanks to plastic tanks since the recent past. Plastic tanks have become the preferred choice of automotive manufacturing companies owing to its various inherent advantages over metal fuel tanks and is gaining high popularity in the market. These tanks are produced using High-Density Polyethylene (HDPE). Owing to the flexible property of the plastic tanks, they can be customized according to the requirement of the OEMs.

Geographically, the detailed analysis of consumption, revenue, market share, and growth rate of the following regions:

The Middle East and Africa (South Africa, Saudi Arabia, UAE, Israel, Egypt, etc.)

North America (United States, Mexico & Canada)

South America (Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, etc.)

Europe (Turkey, Spain, Turkey, Netherlands Denmark, Belgium, Switzerland, Germany, Russia UK, Italy, France, etc.)

Asia-Pacific (Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia).

Automotive Fuel Tank Market Research Objectives:

- Focuses on the key manufacturers, to define, pronounce and examine the value, sales volume, market share, market competition landscape, SWOT analysis, and development plans in the next few years.

- To share comprehensive information about the key factors influencing the growth of the market (opportunities, drivers, growth potential, industry-specific challenges and risks).

- To analyze the with respect to individual future prospects, growth trends and their involvement to the total market.

- To analyze reasonable developments such as agreements, expansions new product launches, and acquisitions in the market.

- To deliberately profile the key players and systematically examine their growth strategies.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive Fuel Tank Market?

► Who are the prominent players in the Global Automotive Fuel Tank Market?

► What is the consumer perspective in the Global Automotive Fuel Tank Market?

► What are the key demand-side and supply-side trends in the Global Automotive Fuel Tank Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Fuel Tank Market?

FIVE FORCES & PESTLE ANALYSIS:

In order to better understand market conditions five forces analysis is conducted that includes the Bargaining power of buyers, Bargaining power of suppliers, Threat of new entrants, Threat of substitutes, and Threat of rivalry.

Political (Political policy and stability as well as trade, fiscal, and taxation policies)

Economical (Interest rates, employment or unemployment rates, raw material costs, and foreign exchange rates)

Social (Changing family demographics, education levels, cultural trends, attitude changes, and changes in lifestyles)

Technological (Changes in digital or mobile technology, automation, research, and development)

Legal (Employment legislation, consumer law, health, and safety, international as well as trade regulation and restrictions)

Environmental (Climate, recycling procedures, carbon footprint, waste disposal, and sustainability)

Points Covered in Table of Content of Global Automotive Fuel Tank Market:

Chapter 01 - Automotive Fuel Tank Market for Automotive Executive Summary

Chapter 02 - Market Overview

Chapter 03 - Key Success Factors

Chapter 04 - Global Automotive Fuel Tank Market - Pricing Analysis

Chapter 05 - Global Automotive Fuel Tank Market Background or History

Chapter 06 - Global Automotive Fuel Tank Market Segmentation (e.g. Type, Application)

Chapter 07 - Key and Emerging Countries Analysis Worldwide Automotive Fuel Tank Market.

Chapter 08 - Global Automotive Fuel Tank Market Structure & worth Analysis

Chapter 09 - Global Automotive Fuel Tank Market Competitive Analysis & Challenges

Chapter 10 - Assumptions and Acronyms

Chapter 11 - Automotive Fuel Tank Market Research Methodology

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

0 notes

Text

The Best Tanks Fabrication in India

Particularly in the field of tank fabrication, India has become a significant center for commercial and industrial fabrication services. The need for premium, long-lasting, and specially made tanks is continuously growing, regardless of the application—water storage, chemical processing, oil and gas, or agriculture. A few notable businesses among the numerous others in the sector are raising the bar for quality, making India a top choice for tank fabrication.

To satisfy the various demands of industries, the top tank fabrication firms in India provide a broad range of solutions. These include the production of HDPE (high-density polyethylene), FRP (fiber-reinforced plastic), SS (stainless steel), and MS (mild steel) tanks. The capacity to produce custom tanks with outstanding construction quality, corrosion resistance, and conformity to strict industry standards like ASME, IS codes, and API is what distinguishes these fabricators.

India's trained labor and access to cutting-edge manufacturing technologies are two important reasons that have contributed to the country's prominence in tank fabrication. Cutting-edge machinery like CNC plasma cutters, automatic welding machines, and precise forming tools are used by top businesses. In addition to guaranteeing precision and uniformity in fabrication, this helps clients save money and get faster turnaround times.

The top tank fabrication firms in India also place a high priority on quality control throughout the entire manufacturing process. Quality control teams carry out stringent testing to guarantee structural integrity, leak-proof performance, and long-term durability from raw material selection to final inspection. In keeping with their dedication to international standards, many businesses are also ISO certified and use ecologically friendly procedures.

0 notes

Text

"What Is a GI Puddle Flange Used for in Stormwater Management?"

In modern stormwater management systems, one of the critical components for maintaining waterproof integrity is the GI puddle flange. Short for Galvanized Iron puddle flange, this product plays a vital role in preventing water leakage where pipes pass through concrete structures such as basements, culverts, tanks, retaining walls, and manholes.

🔧 Purpose of GI Puddle Flanges in Stormwater Management:

GI puddle flanges are designed to seal the gap between a pipe and the concrete it penetrates. During heavy rainfall or drainage flow, water tends to seep along the outer wall of the pipe. This water can eventually find its way into structural concrete if not properly sealed. A GI puddle flange acts as a physical barrier, stopping this flow path and ensuring a watertight connection.

✅ Key Benefits of Using Udhhyog GI Puddle Flanges:

Corrosion Resistance: Galvanized iron is coated to withstand moisture and rust, ideal for underground drainage environments.

Leak Prevention: Eliminates capillary paths around pipe entry points in concrete walls and slabs.

Durability: Can handle soil pressure, water force, and harsh environmental conditions common in drainage systems.

Easy Installation: Installed during the RCC (Reinforced Cement Concrete) pour, forming a solid bond with the structure.

Versatility: Suitable for various pipe materials like PVC, HDPE, MS, and concrete.

🌧️ Applications in Stormwater Infrastructure:

Drainage pipes in RCC basements and substructures

Stormwater outfalls and trench drains

Rainwater harvesting tanks

Concrete culverts and overflow pits

Wet utility vaults and utility corridors

🏭 Why Choose Udhhyog GI Puddle Flanges?

Udhhyog is one of India’s leading manufacturers of GI puddle flanges, offering ISI-compliant products designed for heavy-duty infrastructure. With precision engineering, bulk availability, and nationwide delivery, our flanges are trusted in stormwater projects across cities and rural development zones.

If your project involves stormwater drainage, rainwater harvesting, or sub-ground waterproofing, choose Udhhyog GI puddle flanges for proven leak-proof protection.

0 notes

Text

HDPE Pond Liners: A Sustainable Solution for Water Conservation and Aquaculture

Gujarat, with its robust supply chain and technological expertise, is leading the way, thanks to reliable pond liners suppliers in Gujarat and specialized pond lining manufacturers in Ahmedabad. Whether you're building a farm pond, fish tank, or rainwater harvesting system, working with an experienced pond liner manufacturer in India ensures peace of mind and value for money.

HDPE Pond Liners: A Sustainable Solution for Water Conservation and Aquaculture

0 notes

Text

BIS Registration in India for Polyethylene: Ensuring Quality and Compliance

Polyethylene is a versatile and widely used plastic material in industries such as packaging, agriculture, construction, and consumer goods. Increased demand for improved plastic products in India makes product safety and quality more critical than ever. The ongoing regulation and maintenance by the Bureau of Indian Standards (BIS) are responsible for such materials as polyethylene.

Against all odds, obtaining BIS Registration in India is sustained credibly, applicable also among product manufacturers and importers dealing in polyethylene items. Further in this article, one can go through what is BIS certification, the reasons making it mandatory for polyethylene, and how well to go about it, acquiring professional assistance in the process.

What is BIS Certification?

In order to provide certification, Bureau of Indian Standards uses BIS certification to ensure that a product meets some specifications according to Indian standards regarding quality, safety, performance, etc. This mandatory process applies to various products, among which there are certain grades and applications concerning polyethylene-much more so as they pertain to different sensitive sectors-such as food packaging, water supply, and agriculture.

BIS accredited the products with an ISI mark that states quality and compliance in a product. Without BIS certification, such products cannot be sold in the Indian market.

BIS Registration in India for Polyethylene Products

BIS Registration in India is applicable to various types of polyethylene materials, including High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE). These materials are mainly governed by the following Indian Standards:

IS 7328: High-Density Polyethylene (HDPE) Material for Moulding and Extrusion

IS 12701: Polyethylene tanks for water storage

IS 4984: HDPE pipes for water supply

BIS certification so that polyethylene used in such applications meets requirements as laid down by standards for strength, durability, chemical resistance, and safety.

Why BIS Certification is Important for Polyethylene

Mandatory Compliance To market polyethylene products under compulsory certification, it is mandatory to issue BIS certificate. Default, if detected, will lead to severe legal penalties and market restrictions.

Consumer Safety Polyethylene being an ingredient in packaging and water supply-related applications impacts directly on contamination and leakage, as well as health hazards. BIS helps to avoid these problems via assuring product quality.

Market Access Most retailers, distributors, and government agencies require BIS certification. With certification, your products acquire reputability and haste access to larger contracts and tenders.

Brand Trust The ISI mark in its product is reflected as one where the organization conforms to certain standards both in quality and safety, all of which build trust from customers in the organization.

BIS Registration Process for Polyethylene

Most steps are involved in the process of BIS Registration in India for polyethylene products.

Step 1: Identify Applicable Indian Standards

Determine which BIS standard applies to your polyethylene product. This will depend on the application and type of polyethylene.

Step 2: Preparation of Documents

Collect the required documents as:

Business license

Manufacturing process details

Product specifications

Test reports from BIS-approved laboratory.

Step 3: Product Testing

Send product samples to a BIS-recognized lab for testing. The product must meet the requirements of the relevant Indian Standard.

Step 4: Application Submission

All documents and test reports accompanying the application should also be submitted online for BIS registration.

Step 5: Factory Inspection for Foreign Manufacturers

If the product is manufactured outside India, a BIS team may visit the production site to get aware of the quality control process.

Step 6: Certification and ISI Marking

On successful verification, a certification license is issued by BIS. The manufacturer can then put the ISI mark on polyethylene products.

How Fusion Compliance Services Can Help

Fusion Compliance Services is the best BIS Registration solution, from end to end, in India. The expert team assists in:

Product standard assessment

Filing of Documentation and Application

Coordination with BIS approved labs

Assistance during factory audits

BIS certification renewals and update assistance.

We do the certification process smooth, speed up the time period and save you from expensive mistakes. Whether you are a domestic manufacturer or an international exporter, we ensure that you meet the whole requirements of regulations for polyethylene-based goods.

Industries We Serve

Manufacturers of plastic packaging

Manufacturers of HDPE and LLDPE pipes

Producers of agricultural film

Manufacturers of water storage tanks

Importers of polyethylene resins and goods

Contact Us

For obtaining BIS Registrations in India for polyethylene products, Fusion Compliance Services is the right partner to be with. Let us handle the compliance processes while you concentrate on business growth.

Fusion Compliance Services Office No. S1 520, Cloud-9, Vaishali Sector 1, Near Mahagun Metro Mall, Ghaziabad, Uttar Pradesh - 201012 📞 +91-9696966665

www.fusioncomplianceservices.com

#BISRegistrationInIndia#BISCertification#PolyethyleneBISStandards#BISForPlasticMaterials#BISForPolyethylene#BISCertificationOnline#BureauOfIndianStandards#PlasticProductCertification#ISIMarkForPolyethylene#BISComplianceIndia#BISApprovedMaterials#BISLicenseForPlastics#IndianStandardCertification#BISTestingForPolyethylene#PolymerProductCertificationIndia

0 notes

Text

🧴 Plastic Power Surge: HDPE Blow Molded Products Market Eyes $6.9B by 2034

HDPE Large Blow Molded Products Market is on the rise, transforming how industries package, transport, and build with durable, lightweight, and recyclable materials. From automotive fuel tanks to industrial drums and household products, HDPE is powering the future of sustainable design and industrial efficiency. 🌱🏭 In 2024, the market reached a massive 320 million metric tons, with projections climbing to 500 million metric tons by 2028. 🔥 The automotive segment leads with a 45% share — thanks to the growing demand for lightweight components that improve fuel efficiency. Packaging is next, capturing 30% of the market, while consumer goods round it out with 25%, boosted by urbanization and rising household demand. 🚗📦🏠

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS26174 &utm_source=SnehaPatil&utm_medium=Article

🌍 Regionally, Asia-Pacific dominates, with China and India driving demand through rapid industrialization, urbanization, and government support. Europe follows with a strong automotive base and eco-focused regulations, while the U.S. shows strong potential with cutting-edge manufacturing innovations. 🔧🇨🇳🇮🇳🇺🇸🇪🇺

💡 Advancements like 3D printing integration, advanced automation, and sustainable tech are reshaping this landscape. Whether it’s recycled HDPE or UV/chemical-resistant solutions, this market is all about innovation, resilience, and sustainability. The future of HDPE blow molding is smart, green, and unstoppable. 💪♻️

#hdpeproducts #blowmolding #industrialpackaging #automotivecomponents #sustainablematerials #lightweightdesign #recycledplastics #urbanizationimpact #packagingtrends #durablegoods #manufacturingtech #3dprintingintegration #automotiveinnovation #consumerpackaging #smartmanufacturing #greenplastics #hdpecontainers #industrialsolutions #materialscience #engineeringplastics #futureofpackaging #ecoindustrial #highdensitypolyethylene #plasticsinnovation #impactresistant #uvresistantproducts #chemicalresistant #costeffectivematerials #constructionindustry #retailpackaging #agritechsolutions #urbanlivingtrends #plasticengineering #sustainabletech #asiaindustrialboom

Research Scope:

· Estimates and forecast the overall market size for the total market, across type, application, and region

· Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

· Identify factors influencing market growth and challenges, opportunities, drivers, and restraints

· Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

· Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Plastmax : Delivers Customized Recycled Plastic Raw Materials for Diverse Industries

At Plastmax Thailand, we specialize in providing top-tier recycled plastic raw materials to a wide range of industries worldwide. Whether you require durable plastic granules for automotive parts, flexible materials for packaging or strong grades for consumer goods, Plastmax ensures that you receive the perfect material tailored to your exact specifications.

Our mission is to offer customized plastic raw materials that drive performance and efficiency in every industry we serve. By working closely with our clients, we ensure that the materials we provide are not only reliable but also innovative, enabling businesses to thrive in today’s competitive market.

Plastmax, managed by Wiwat Plastic, is a registered company that has established itself as a leader in the recycled plastic industry since 1997, in Thailand. We have continuously innovated and adapted to meet the evolving needs of businesses in Thailand, India, Bangladesh, Africa, Ghana, Tanzania, Kenya, South Africa and around the world. Our success is built on our commitment to delivering high-quality plastic materials, customized solutions and unparalleled customer service.

With state-of-the-art production facilities and a team of highly skilled professionals, we are capable of producing up to 30 tons of plastic materials per day. This allows us to meet the growing demand for customized recycled plastic granules and deliver solutions efficiently, no matter the size or complexity of the order.

Our Product Range: Tailored Plastic Solutions for Every Industry

At Plastmax, we recognize that every industry has distinct needs when it comes to recycled plastic materials. To ensure the highest level of satisfaction, we offer a comprehensive range of customized plastic granules designed to meet specific performance requirements. Here’s a closer look at the diverse products we provide:

LDPE Plastic Granules

Low-Density Polyethylene (LDPE) is valued for its flexibility and resilience. Our LDPE Plastic Granules are ideal for films, bags and flexible packaging. These granules are easy to process and provide excellent flexibility for various applications.

LLDPE Plastic Granules: Superior Flexibility Meets Enhanced Strength Linear Low-Density Polyethylene (LLDPE) stands out with its improved mechanical traits compared to traditional LDPE. Its unique molecular structure provides greater tensile strength without sacrificing flexibility. Plastmax’s LLDPE granules are ideal for applications that demand a perfect balance of durability and pliability, delivering reliable performance in flexible yet tough end products.

HDPE Blow Molding Granules: Built for Endurance and Tough Environments Renowned for its excellent strength-to-density ratio, High-Density Polyethylene (HDPE) remains a top choice across industries. Plastmax’s HDPE blow molding granules are specifically tailored for manufacturing hollow items such as bottles, storage tanks, and large containers. These granules offer exceptional resilience, making them ideal for products subjected to rigorous use and harsh environments.

PC / Polycarbonate Granules: Clarity and Strength for Demanding Applications Polycarbonate is an advanced material valued for its remarkable clarity, impact resistance, and structural stability. Plastmax offers premium PC plastic granules engineered for transparent applications that require both toughness and aesthetic appeal—ideal for eyewear lenses, automotive components, and optical media.

GPPS Granules: High Clarity and Rigidity for Premium Finishes General Purpose Polystyrene (GPPS) is known for its stiffness, ease of processing, and polished surface quality. Plastmax’s GPPS granules are perfect for crafting rigid products with a glossy, smooth appearance. Their excellent optical clarity makes them a top choice for transparent applications where both form and function matter.

PP Injection Grade Plastic Granules

Polypropylene (PP) is a versatile material used across various industries. Plastmax’s PP Injection Grade Granules are engineered for injection molding applications, offering excellent mechanical strength and long-lasting durability. These granules are used to manufacture a wide variety of products, from furniture and containers to packaging materials.

ABS Plastic Granules

Acrylonitrile Butadiene Styrene (ABS) is known for its strength and impact resistance. Our ABS Plastic Granules are perfect for electronics, automotive and consumer goods industries. They provide reliability and aesthetic quality, making them ideal for the production of enclosures, automotive parts and other high-performance applications.

HDPE Injection Grade Plastic Granules

High-Density Polyethylene (HDPE) is one of the most widely used plastics. Our HDPE Injection Grade Plastic Granules offer the perfect combination of strength, flexibility and chemical resistance, making them ideal for a wide range of applications, including packaging, construction and household products.

HIPS Plastic Granules

HIPS (High Impact Polystyrene) is renowned for its toughness and impact resistance. Plastmax’s HIPS Plastic Granules are commonly used for producing food packaging, storage containers and durable household items. The high impact resistance ensures the materials perform well in tough environments.

TPU Repro and Compounding

Thermoplastic Polyurethane (TPU) is a durable and highly flexible material used in a variety of demanding applications. Plastmax offers TPU Repro and Compoundingservices that allow us to create tailored materials for industries such as footwear, medical devices and automotive parts. By customizing the granules, we ensure that our clients receive materials suited to its specific needs.

Meeting Industry-Specific Needs with Customized Plastic Solutions

Plastmax’s core strength lies in our ability to provide customized recycled plastic solutions that meet the unique needs of each industry we serve. Our products are used across a wide range of industries, including automotive, packaging and consumer goods. Here’s how we serve each sector:

Automotive Industry

Our ABS, HDPE and HIPS granules are commonly used in the automotive industry to produce high-performance components. These materials are essential for creating dashboards, bumpers and interior panels. Its durability, impact resistance and lightweight properties make them ideal for enhancing the performance and safety of vehicles.

Packaging Industry

In the packaging sector, we provide PP and LDPE granules that are used to create containers, bottles and flexible packaging. These granules are engineered to meet the industry’s need for strength, flexibility and cost-effectiveness, ensuring that manufacturers can deliver high-quality packaging solutions to its customers.

Consumer Goods Industry

Our HIPS, ABS and PP granules are frequently used in the consumer goods industry to manufacture products like household items, toys and storage containers. These materials offer a perfect blend of durability and aesthetic appeal, helping manufacturers create products that meet both functional and design requirements.

Plastmax's Commitment to Customization and Quality

We understand that one size doesn’t fit all, which is why we offer customized plastic solutions designed to meet the exact specifications of our clients. Our process involves the following key stages:

Material Selection: We collaborate with clients to identify the best plastic grade for its applications, ensuring that the material meets its specific requirements.

Advanced Manufacturing: Our cutting-edge machinery and production techniques allow us to produce high-quality plastic granules with consistent results.

Compounding and Additives: We provide compounding services, adding custom colorants, stabilizers and other additives to modify the properties of the material as needed.

Quality Control: Plastmax adheres to strict quality control measures, ensuring that each batch of granules meets the highest standards for performance, strength and durability.

On-Time Delivery: We pride ourselves on our reliable delivery service, ensuring that our products reach our clients on time to meet its production schedules.

Why Plastmax is the Ideal Partner for Your Recycled Plastic Needs

Plastmax is a trusted name in the recycled plastic industry. Here are just few reasons:

Expertise and Experience: With over 20 years of experience, we have developed deep industry knowledge and the technical know-how to provide tailored solutions.

Custom Solutions: We specialize in offering customized plastic grades and compounding services that perfectly match the needs of our clients.

Commitment to Quality: We prioritize quality control throughout the entire production process, ensuring consistent, high-quality products that meet the highest standards.

Global Reach: With an international client base, we can deliver high-quality recycled plastic materials to businesses across the globe.

Conclusion

At Plastmax, we provide high-quality recycled plastic materials that cater to the unique needs of various industries. Whether you're looking for customized plastic granules for automotive, packaging or consumer goods, we have the expertise and capabilities to deliver exactly what you need. With over many years of experience, a commitment to innovation and a focus on customer satisfaction, Plastmax is your trusted partner for recycled plastic solutions.

1 note

·

View note