#HDPE bags

Explore tagged Tumblr posts

Text

How Do HDPE Woven Bags Contribute to Sustainable Packaging?

High-Density Polyethylene (HDPE) woven bags have become an integral part of sustainable packaging solutions. Known for their durability, recyclability, and versatility, HDPE woven bags are extensively used across industries such as agriculture, construction, and retail. This blog explores the key ways in which these bags contribute to sustainable packaging and their broader environmental benefits.

What Are HDPE Woven Bags?

HDPE woven bags are made from strips of high-density polyethylene that are woven together to create a strong, lightweight fabric. These bags are often used for packaging bulk goods, such as grains, fertilizers, and construction materials, due to their robustness and cost-effectiveness.

Contribution to Sustainable Packaging

Recyclability

HDPE woven bags are 100% recyclable, making them an eco-friendly alternative to single-use plastics.

They can be reprocessed into new products, such as pipes, crates, or even new woven bags, reducing the demand for virgin materials.

Durability and Reusability

These bags are designed to withstand heavy loads and harsh conditions, allowing for multiple uses before disposal.

Their extended lifespan reduces the need for frequent replacements, minimizing waste.

Lightweight Material

The lightweight nature of HDPE woven bags reduces transportation emissions, contributing to a lower carbon footprint during shipping and logistics.

Energy-Efficient Manufacturing

The production of HDPE woven bags requires less energy compared to other types of packaging materials, such as rigid plastics or metal containers.

Reduction in Food Waste

HDPE woven bags offer excellent protection against moisture, pests, and contamination, ensuring the safe storage and transport of food products. This helps reduce food spoilage and waste.

Customizable Design

These bags can be tailored to specific needs, such as UV-resistant coatings or laminated finishes, enhancing their utility while minimizing the use of additional packaging materials.

Environmental Benefits of HDPE Woven Bags

Waste Diversion: By encouraging recycling and reuse, HDPE woven bags help divert plastic waste from landfills and oceans.

Resource Conservation: Using recycled HDPE material reduces reliance on fossil fuels and other non-renewable resources.

Lower Greenhouse Gas Emissions: The reduced energy requirement for production and transportation translates to lower greenhouse gas emissions compared to traditional packaging materials.

Support for Circular Economy: HDPE woven bags align with the principles of a circular economy, where materials are reused and recycled to extend their lifecycle.

Challenges and Opportunities

Despite their benefits, HDPE woven bags face challenges such as improper disposal and contamination in recycling streams. Addressing these issues can unlock their full potential as a sustainable packaging solution.

Improved Recycling Infrastructure: Expanding recycling facilities and technologies can ensure efficient processing of HDPE bags.

Consumer Awareness: Educating consumers on proper disposal and recycling practices can reduce contamination and increase recycling rates.

Innovation in Materials: Research into biodegradable HDPE alternatives can further enhance the environmental credentials of these bags.

Conclusion

HDPE woven bags are a versatile and sustainable choice for packaging needs across industries. Their recyclability, durability, and energy-efficient production make them an eco-friendly alternative to traditional packaging materials. By addressing challenges and investing in innovative solutions, HDPE woven bags can play a significant role in advancing sustainable packaging practices and reducing environmental impact.

0 notes

Text

One of the most common uses of HDPE bags is in grocery stores. High-density polyethylene bags have become a staple for customers due to their lightweight yet sturdy nature. These bags can hold heavy items such as bottles, canned goods, and fresh produce without tearing or stretching. For plastic sack suppliers, producing HDPE bags for grocery stores remains one of the most profitable and high-demand markets.

0 notes

Text

https://homment.com/lBUy057jlxMK15E7yuZi

HDPE Bags: Versatile, Durable, and Eco-Friendly Packaging Solutions

In the realm of packaging and storage, High-Density Polyethylene (HDPE) bags stand out as a reliable, versatile, and eco-friendly option. These bags, known for their strength and resilience, are used in a myriad of applications, from grocery shopping to industrial storage. Here’s a comprehensive look at HDPE bags, their benefits, and their diverse uses.

0 notes

Text

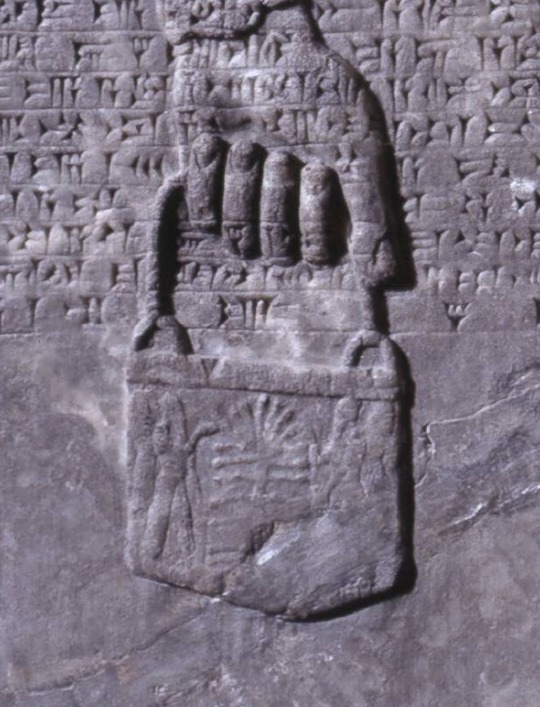

Apkulla Bucket Bag moodboard, from the Apkullacore Capsule Collection

images: the walters museum; british museum; ashmolean museum; some saint laurent purse flipper site; klein tools

#apkullacore#apkulla bucket bag#wet-molded leather#vacuum-formed hdpe#saint laurent#klein tools#capsule collection#handbag of the gods#ea nasir gtfo

4 notes

·

View notes

Text

#hdpe bag filling system#hdpe bag filling & packaging system#hdpe bag filling line#integrated packaging systems.#automatic hdpe filling & packaging system

0 notes

Text

Zubairi Plastics Reinforces Its Market Leadership with Premium HDPE Solutions

In the ever-evolving packaging industry, material matters. And few materials offer the resilience and versatility of HDPE—High-Density Polyethylene. Known for its incredible strength-to-density ratio, HDPE has become the gold standard for manufacturing robust, reliable, and eco-conscious packaging. At the forefront of this innovation stands Zubairi Plastics, a leader in delivering tailored HDPE packaging solutions for diverse industries across the UAE and beyond.

As industries seek packaging that balances durability with sustainability, Zubairi Plastics continues to invest in advanced production technologies to create high-quality HDPE products. Whether it’s bags, films, or sheets, their offerings are engineered for maximum performance under challenging conditions—moisture, weight, chemical exposure, and transportation stress.

What makes HDPE such a powerful material is its ability to be both lightweight and incredibly tough. This reduces material consumption without sacrificing strength, leading to more efficient and sustainable packaging outcomes. Zubairi Plastics uses food-grade and recyclable HDPE in many of its products, ensuring client needs are met with both safety and environmental responsibility in mind.

Zubairi Plastics' commitment to customization also shines through in their HDPE line. Clients can choose from a wide range of sizes, gauges, colors, and printing options, helping businesses brand themselves effectively through practical packaging. Whether you're in retail, logistics, agriculture, or pharmaceuticals, the adaptability of HDPE makes it a preferred choice.

Beyond functionality, Zubairi Plastics' strength lies in its customer-first approach. As a trusted HDPE manufacturer, they offer personalized consultation and rapid turnaround times, helping businesses stay ahead of the curve in a competitive marketplace.

For companies seeking packaging that ticks all the boxes—strong, safe, sustainable, and customizable—Zubairi Plastics' HDPE solutions represent the future of smart, responsible manufacturing.

0 notes

Text

Grow bags for gardening

Get gardening more fun and easy with grow bags. The gardening bags are of light weight, easy to handle, available in all the sizes required, durable, UV stabilized and comes with proper drainage holes. Get grow bags at myecomart.com to save your money as they provide bags at wholesale price.

1 note

·

View note

Text

More Than Meets the Eye: Unveiling the Essential Role of Plastic Tubing

We often overlook the simple things that make our lives easier, and plastic tubing is a perfect example. This humble product, often hidden from view, plays a vital role in countless applications, from the medical field to our everyday home appliances. But what exactly makes plastic tubing so versatile and indispensable? Let’s delve into the fascinating world of this unsung hero.

Beyond the Basics: A Material of Many Faces

Plastic tubing isn’t just one thing. It’s a broad category encompassing a wide range of materials, each with its own unique properties. This diversity allows us to tailor the tubing to specific needs.

Polyethylene (PE): A common and affordable choice, PE tubing is known for its flexibility and chemical resistance, making it ideal for low-pressure applications like irrigation and beverage dispensing.

Polyvinyl Chloride (PVC): Rigid and durable, PVC tubing is often used in plumbing and construction due to its resistance to chemicals and weathering.

Silicone: Highly flexible and temperature resistant, silicone tubing is a popular choice for medical and food-grade applications.

Nylon: Known for its strength and abrasion resistance, nylon tubing is often used in pneumatic and hydraulic systems.

Polyurethane (PU): Offering excellent flexibility and kink resistance, PU tubing is ideal for applications requiring tight bends and frequent movement.

A World of Applications: From Life-Saving to Everyday Convenience

The versatility of plastic tubing translates into a vast range of applications:

Medical: From IV lines and catheters to dialysis tubing, plastic tubing plays a critical role in delivering fluids and medications, saving lives every day.

Automotive: Used in fuel lines, vacuum systems, and windshield washer systems, plastic tubing ensures the smooth operation of our vehicles.

Industrial: From chemical transfer to pneumatic systems, plastic tubing is essential for various industrial processes.

Food and Beverage: Used in beverage dispensing, food processing, and packaging, food-grade plastic tubing ensures the safe and hygienic transport of consumables.

Home and Garden: From irrigation systems to aquarium air lines, plastic tubing helps us maintain our homes and gardens efficiently.

Choosing the Right Tubing: A Matter of Matching Properties to Needs

With so many options available, selecting the right plastic tubing for a specific application is crucial. Factors to consider include:

Material: The chemical compatibility, temperature resistance, and flexibility of the material are paramount.

Size: The inner and outer diameter of the tubing will determine its flow rate and compatibility with fittings.

Pressure Rating: The tubing must be able to withstand the operating pressure of the system.

Flexibility: The required flexibility will depend on the application and the routing of the tubing.

Temperature Range: The plastic tubing must be able to withstand the operating temperature of the system.

The Future of Plastic Tubing: Innovation and Sustainability

As technology advances, we can expect to see further innovation in plastic tubing, including:

Development of new materials: Researchers are constantly exploring new materials with enhanced properties, such as improved chemical resistance and biocompatibility.

Advanced manufacturing techniques: New manufacturing techniques are enabling the production of tubing with tighter tolerances and more complex geometries.

Sustainable solutions: Efforts are underway to develop biodegradable and recyclable plastic tubing.

Plastic tubing, though often overlooked, is a vital component in countless applications that impact our lives daily. Its versatility, affordability, and adaptability make it an indispensable material for a wide range of industries. As technology continues to evolve, we can expect to see even more innovative applications for this unsung hero.

So, the next time you see a piece of plastic tubing, take a moment to appreciate its simplicity and the crucial role it plays in our modern world. It’s a testament to the power of simple solutions to solve complex problems.

#plastic bags#printed plastic bags#plastic bags south africa#plastic tubing#plasticmanufacturer#plastic sheeting#clear plastic bags#plastictubing#plasticbags#plasticsheeting#plastic tubing johannesburg#plastic pipe durban#plastic hosepipe cape-town#PVC tubing pretoria#PVC pipe gauteng#HDPE tubing

0 notes

Text

Food Packaging Bags Wholesale

Looking for high-quality food packaging bags at wholesale prices? Choose from a wide variety of durable, eco-friendly, and customizable options for restaurants, bakeries, and food businesses. Our bulk packaging solutions ensure freshness, compliance, and affordability. Order now for reliable and cost-effective food storage and presentation!

#seed bags manufacturers in india#fertilizer bags manufacturers in india#flexo printed hdpe/pp woven bags manufacturers

0 notes

Text

HDPE Bags Manufacturers: A Durable and Eco-Friendly Packaging Solution

Introduction to HDPE Bags

High-Density Polyethylene (HDPE) bags are one of the most versatile and durable plastic packaging solutions available today. Known for their strength, lightweight properties, and resistance to chemicals and moisture, HDPE bags are used across various industries, including retail, agriculture, food packaging, and industrial applications. With the growing demand for eco-friendly and sustainable packaging solutions, HDPE bags, which are recyclable and reusable, have become a popular choice for manufacturers and consumers alike.

In this blog, we’ll dive into the benefits of HDPE bags, the manufacturing process, and why it’s important to partner with reliable HDPE bag manufacturers for high-quality packaging solutions.

What Are HDPE Bags?

HDPE bags are made from high-density polyethylene, a thermoplastic polymer known for its superior strength and resistance to wear and tear. Compared to low-density polyethylene (LDPE), HDPE has a more rigid structure, making it ideal for applications that require durable and robust packaging.

HDPE bags are characterized by their stiffness, chemical resistance, and ability to withstand higher temperatures compared to other types of plastic bags. They are used in a wide range of applications, from grocery bags and food packaging to industrial liners and agricultural sacks.

Manufacturing Process of HDPE Bags

The manufacturing process for HDPE bags involves several steps, ensuring the final product meets the required standards of durability and performance. Here’s an overview of the key stages:

Extrusion: The manufacturing process starts by heating HDPE granules until they melt. The melted plastic is then forced through a die to create a thin film or sheet of HDPE.

Blown Film Process: In many cases, the extrusion process is followed by a blown film process. The extruded plastic is inflated like a bubble, forming a thin, uniform plastic film, which is then cooled and flattened.

Printing and Cutting: Once the film is created, it can be printed with custom designs, logos, or product information, depending on the customer’s requirements. Afterward, the film is cut and sealed to form individual bags.

Testing and Quality Control: High-quality HDPE bags undergo strict quality testing to ensure they meet industry standards. This includes testing for tensile strength, puncture resistance, and chemical resistance to guarantee the bags can handle various loads and conditions.

Why Choose HDPE Bag Manufacturers?

Selecting a reputable HDPE bag manufacturer is essential for ensuring your bags are durable, safe, and compliant with environmental regulations. Here are some reasons why choosing the right HDPE manufacturer matters:

Customizable Solutions: HDPE manufacturers can create bags tailored to specific customer needs, such as size, thickness, color, and printing options. Whether you need food-grade packaging or heavy-duty industrial liners, reliable manufacturers can offer customized solutions to meet your requirements.

Quality Control: A trusted manufacturer will have robust quality control processes in place, ensuring each bag meets industry standards for strength, durability, and performance. Consistent quality is especially important in applications such as food packaging or hazardous material handling.

Sustainability: Many HDPE manufacturers are focusing on sustainability by using eco-friendly production processes and materials. Partnering with a manufacturer that prioritizes sustainability ensures that your packaging solutions align with environmental goals, such as using recyclable materials or producing biodegradable options.

Compliance with Regulations: HDPE bags used for food packaging or industrial applications must meet specific safety and regulatory standards. A reliable manufacturer will ensure their products are compliant with FDA, EU, and other local standards for safe and responsible use.

Competitive Pricing: The right manufacturer will balance quality and affordability, providing cost-effective solutions that don’t compromise on performance. Bulk orders can often lead to significant savings without sacrificing quality.

Applications of HDPE Bags

HDPE bags are used across a variety of industries due to their versatility and strength. Here are some common applications:

Retail Bags: HDPE bags are widely used in grocery stores, retail shops, and supermarkets. Their lightweight yet durable nature makes them perfect for carrying groceries, clothes, and other retail products.

Food Packaging: HDPE bags are food-safe and used for packaging fresh produce, frozen food, and other perishable goods. The material’s moisture and chemical resistance help protect the contents from spoilage.

Industrial Packaging: HDPE bags are often used as liners for drums, containers, and other storage vessels in industrial settings. They are also commonly used to package chemicals, fertilizers, and construction materials.

Agricultural Use: Farmers and agricultural suppliers use HDPE bags to store and transport grains, seeds, and fertilizers. The bags’ durability and resistance to weather conditions make them ideal for outdoor use.

Waste Management: HDPE bags are frequently used for waste collection, including garbage bags and bin liners. Their puncture-resistant properties make them suitable for managing heavy or sharp waste materials.

Benefits of Using HDPE Bags

Strength and Durability: HDPE bags offer high tensile strength, making them suitable for carrying heavy loads without tearing or breaking. Their durability ensures they can be reused multiple times, reducing the need for single-use plastic.

Moisture and Chemical Resistance: HDPE is highly resistant to moisture, chemicals, and other environmental factors, making it ideal for packaging goods that require protection from external elements.

Recyclable and Eco-Friendly: One of the major advantages of HDPE bags is their recyclability. They can be repurposed into other products, reducing plastic waste. Additionally, manufacturers are increasingly offering biodegradable HDPE options, contributing to a more sustainable packaging solution.

Cost-Effective: HDPE bags are affordable and offer an excellent balance between cost and durability. Their lightweight structure helps reduce shipping costs, making them a cost-effective packaging option for businesses.

Versatility: HDPE bags come in a wide range of sizes and thicknesses, making them suitable for a variety of applications, from small retail bags to large industrial liners.

Challenges of HDPE Bags

Environmental Concerns: Although HDPE bags are recyclable, they are not biodegradable, which can contribute to plastic pollution if not properly disposed of. However, many manufacturers are working on producing biodegradable HDPE bags to mitigate this issue.

Stiffness: HDPE bags tend to be stiffer compared to LDPE or other plastic materials, which might limit their use in certain applications that require more flexibility.

Conclusion

HDPE bags are an essential packaging solution in many industries, offering a unique combination of strength, durability, and affordability. From retail and food packaging to industrial and agricultural use, HDPE bags provide reliable protection for various products.

Choosing a reliable HDPE manufacturer ensures that you get high-quality, customizable, and sustainable packaging solutions for your specific needs. As the demand for eco-friendly and recyclable packaging grows, HDPE bags continue to be a smart choice for businesses looking to reduce their environmental footprint while maintaining high-performance standards in their packaging.

0 notes

Text

The Green Revolution: How HDPE Bags Are Leading the Way in Sustainable Packaging

The global packaging industry is undergoing a profound transformation, driven by the urgent need for sustainable practices. Among the many innovations in this field, high-density polyethylene (HDPE) bags have emerged as a key player in the shift toward eco-friendly packaging solutions. These versatile and durable bags offer a range of benefits that make them a preferred choice for various industries. This article explores how HDPE bags are leading the way in sustainable packaging, highlighting their advantages, their role in the market, and the importance of collaboration with plastic sack suppliers and plastic sack manufacturers.

Understanding HDPE Bags

High-Density Polyethylene Bags are produced from high-density polyethylene, a thermoplastic made from petroleum. Known for their strength and durability, HDPE bags have become increasingly popular for packaging in several sectors, including agriculture, retail, and food service. Their resilience allows them to withstand wear and tear, making them suitable for heavy items while remaining lightweight, which is essential for reducing transportation costs and carbon footprints.

Advantages of HDPE Bags

The adoption of HDPE bags comes with numerous advantages that make them an appealing choice for businesses seeking sustainable packaging solutions. First and foremost, HDPE is recyclable. Many local recycling programs accept HDPE products, allowing consumers to recycle these bags and reduce their impact on landfills. This attribute aligns with the principles of a circular economy, where products are designed for reuse and recycling.

Moreover, HDPE bags are resistant to moisture, chemicals, and UV radiation. This resistance is vital in industries like agriculture, where bags are often used to store and transport fertilizers and pesticides. The longevity of HDPE bags ensures that they protect their contents effectively, thus minimizing waste due to spoilage or degradation.

Environmental Impact of HDPE Bags

As the world grapples with the environmental consequences of plastic waste, the focus has shifted to the life cycle of packaging materials. Traditional plastic bags contribute significantly to pollution and harm wildlife. In contrast, high-density polyethylene bags offer a more sustainable alternative, especially when produced by environmentally conscious plastic sack manufacturers. Many of these manufacturers are implementing practices that minimize energy consumption and emissions during production, further enhancing the eco-friendliness of HDPE bags.

Additionally, the production of HDPE bags requires less energy compared to other plastic materials. This lower energy consumption contributes to reduced greenhouse gas emissions, making HDPE bags a more environmentally friendly option. Furthermore, the ability to recycle HDPE means that the material can have a second life, diverting waste from landfills and conserving natural resources.

The Role of Plastic Sack Suppliers

The role of plastic sack suppliers in promoting HDPE bags cannot be overstated. These suppliers play a crucial role in the distribution and accessibility of sustainable packaging options. By prioritizing HDPE bags, they contribute to a growing market demand for environmentally responsible products.

Plastic sack suppliers are increasingly collaborating with manufacturers to ensure that the production process adheres to sustainability standards. This collaboration often involves sourcing recycled materials for bag production or implementing practices that reduce waste and energy consumption. As more consumers become aware of the environmental impact of packaging, the demand for sustainable options like HDPE bags is expected to rise, pushing suppliers to adapt and expand their offerings.

Industry Applications of HDPE Bags

The versatility of HDPE bags allows them to be used in various industries, making them a vital component of sustainable packaging strategies. In the agricultural sector, these bags are often used for bulk storage and transportation of grains, seeds, and fertilizers. Their resistance to moisture and pests ensures that the contents remain intact during transit.

In retail, HDPE bags have become a popular choice for shopping bags due to their strength and reusability. Many retailers are transitioning away from single-use plastic bags and embracing HDPE options as part of their commitment to sustainability. The aesthetic appeal of HDPE bags, which can be customized with branding and designs, further enhances their popularity among businesses looking to promote their eco-friendly practices.

Additionally, the food service industry utilizes HDPE bags for packaging groceries, takeout, and prepared foods. The bags’ ability to resist contamination ensures that food products remain safe for consumption, making them a reliable choice for businesses committed to quality and safety.

Challenges and Future Directions

While HDPE bags are a step in the right direction toward sustainable packaging, challenges remain. The perception of plastic as inherently harmful can hinder widespread acceptance of even eco-friendly options like HDPE. To combat this perception, educational campaigns are needed to inform consumers about the recyclability and benefits of HDPE bags.

Furthermore, the industry must focus on enhancing the recycling infrastructure for HDPE products. Although many communities accept HDPE for recycling, improving the collection and processing systems is crucial to ensure that these bags are effectively reused and repurposed.

As technology continues to advance, the future of HDPE bags looks promising. Innovations in material science may lead to even more sustainable options, such as biodegradable alternatives or products made from renewable resources. Collaborations between Plastic sack manufacturers and researchers can drive this innovation, ensuring that the industry continues to evolve in response to environmental concerns.

Conclusion

The Green Revolution in packaging is well underway, with high-density polyethylene bags leading the charge toward sustainability. Their numerous advantages, from recyclability to durability, make them an ideal choice for various industries. As plastic sack suppliers and plastic sack manufacturers work together to promote these eco-friendly options, the future of packaging looks brighter. By embracing HDPE bags, businesses can take significant strides toward reducing their environmental impact while meeting the growing consumer demand for sustainable practices. The journey toward a greener future is just beginning, and HDPE bags are at the forefront of this vital movement.

FAQs about HDPE Bags and Sustainable Packaging

1. What are HDPE bags?

HDPE bags, or high-density polyethylene bags, are made from a strong, durable plastic known for its resistance to moisture, chemicals, and UV radiation. They are commonly used for packaging in various industries, including agriculture, retail, and food service.

2. Are HDPE bags recyclable?

Yes, HDPE bags are recyclable. Many local recycling programs accept them, allowing consumers to recycle these bags and reduce their environmental impact. Recycling helps conserve resources and reduces waste in landfills.

3. How do HDPE bags compare to traditional plastic bags?

HDPE bags are generally more durable and stronger than traditional plastic bags. They also have a lower environmental impact, as they require less energy to produce and can be recycled, promoting a circular economy.

0 notes

Text

As leading PP HDPE Woven Sacks Manufacturers, we specialize in producing high-quality, durable sacks suitable for packaging and transporting a variety of products. Our sacks are made from premium polypropylene and high-density polyethylene, ensuring strength and resistance to wear and tear. Available in customizable sizes and designs, we cater to diverse industries, providing reliable and eco-friendly solutions for all your packaging needs.

0 notes

Text

HDPE Bags: A Comprehensive Guide

High-Density Polyethylene (HDPE) Bags have gained immense popularity in various industries due to their strength, durability, and versatility. These bags are widely used for packaging, carrying goods, and protecting products from moisture and contamination. In this article, we will explore the role of HDPE Bag Manufacturers and Suppliers in providing quality HDPE Bags that meet diverse consumer needs.

0 notes

Text

0 notes

Text

Exploring HDPE Bags: A Comprehensive Guide to 50 kg HDPE Bags from Leading Manufacturers in Hyderabad

Introduction

High-Density Polyethylene (HDPE) bags have emerged as a popular choice for packaging across various industries due to their durability, versatility, and cost-effectiveness. These bags are particularly favored for their ability to handle substantial weights, with the HDPE Bags 50 kg being a standard for bulk packaging needs. This article delves into the world of HDPE bags, focusing on 50 kg variants and highlighting top manufacturers in Hyderabad. We'll explore their advantages, benefits, and answer some frequently asked questions. Advantages of HDPE bags

HDPE bags are renowned for their numerous advantages which make them ideal for a wide range of applications. Here are some key benefits:

Durability: HDPE bags are highly durable and resistant to punctures and tears. This makes them suitable for packaging heavy and sharp-edged items without the risk of breakage.

Moisture resistance: One of the standout features of HDPE bags is their excellent resistance to moisture. This makes them ideal for storing and transporting goods that need to be kept dry, such as grains, fertilizers, and chemicals.

Chemical resistance: HDPE bags do not react with most chemicals, which ensures the safe storage and transportation of various chemical products.

Lightweight: Despite their strength and durability, HDPE bags are lightweight. This reduces transportation costs and makes handling easier.

Environmental impact: HDPE bags are recyclable, contributing to environmental sustainability. With proper recycling processes, the environmental footprint of HDPE Bags Manufacturer can be significantly minimized. Benefits of using 50 kg HDPE bags:

50 kg HDPE bags offer specific benefits that cater to bulk packaging needs:

Economical packaging solution: For industries that require bulk packaging, 50 kg HDPE bags offer a cost-effective solution. Their durability reduces the need for double packaging, saving costs.

Versatility: These bags can be used across various industries, including agriculture, chemicals, construction, and food processing. Their ability to handle a wide range of products makes them a versatile packaging option.

Ease of storage and transport: The 50 kg capacity strikes a balance between ease of handling and the need for bulk packaging. These bags are easy to stack, store, and transport, optimizing logistics and storage space.

Customization options: Manufacturers offer customization options for 50 kg HDPE bags, including printing and color variations. This allows businesses to tailor the bags to their branding and product requirements. Conclusion: HDPE bags, particularly the 50 kg variants, play a crucial role in the packaging industry due to their durability, versatility, and cost-effectiveness. HDPE Bags Manufacturers in Hyderabad are at the forefront of producing high-quality HDPE bags that meet diverse industrial needs. By choosing these bags, businesses can ensure safe, economical, and sustainable packaging solutions. As the demand for efficient and eco-friendly packaging continues to grow, HDPE bags remain a pivotal choice for industries worldwide. FAQs:

Q. What are HDPE bags? A. HDPE bags are made from High-Density Polyethylene, a strong and durable plastic material known for its resistance to moisture, chemicals, and wear and tear.

Q. What are the uses of 50 kg HDPE bags? A. These bags are used for packaging bulk materials such as grains, chemicals, fertilizers, and construction materials due to their high strength and capacity.

Q. Why choose HDPE bags over other types of bags? A. HDPE bags offer superior durability, moisture and chemical resistance, and are lightweight. They are also recyclable, making them an environmentally friendly option.

1 note

·

View note