#Haas CNC Milling Machine

Explore tagged Tumblr posts

Text

𝐑𝐞𝐯𝐞𝐚𝐥𝐢𝐧𝐠 𝐭𝐡𝐞 𝐇𝐞𝐚𝐫𝐭 𝐨𝐟 𝐭𝐡𝐞 𝐂𝐚𝐫: 𝐇𝐨𝐰 𝐂𝐍𝐂 𝐂𝐚𝐫𝐯𝐞𝐬 𝐚 𝐒𝐭𝐞𝐞𝐫𝐢𝐧𝐠 𝐊𝐧𝐮𝐜𝐤𝐥𝐞

From a rough blank to a precision-finished product, every step in the machining process is a testament to the perfect fusion of technology and craftsmanship. In this post, we take you behind the scenes to explore:

🔩 How CNC machines transform raw materials with unparalleled precision.

🔩 The intricate steps involved in carving a steering knuckle.

🔩 The role of advanced tools and meticulous craftsmanship in achieving perfection.

Whether you’re passionate about automotive engineering or intrigued by manufacturing technologies, this deep dive showcases the artistry and innovation behind every steering knuckle.

𝐃𝐢𝐝 𝐲𝐨𝐮 𝐤𝐧𝐨𝐰? Precision machining ensures not just durability but also optimal performance for critical automotive components.

Check out the video and tell us: What part of the CNC machining process fascinates you the most? Share your thoughts in the comments below!

Contact Us Get More Info:

GreatLight Metal Technology Co., Ltd

✅ Website: https://glcncmachining.com/ ✅ Website: https://cnc-5-axis.com/ ✅ #10, Xinrong Street, Chongtou Community, Chang'an Town, Dongguan City, Guangdong, China, 523845 ✅ + 86 180 2756 7310 ✅ + 86 180 2756 7310(whatsapp) ✅ [email protected]

#Machining #CNC #ThreadTapping #Metalworking #Manufacturing #cncmachine #cncmachining #cncmachinist #cncmilling #cncturning #cncprogramming #foryou

#CNC Machining For Medical Imaging#CNC Milling Machine For Sale#CNC Routers Machines#CNC Screw-Machining For Aviation#Diy CNC Machine#Haas CNC Milling Machine#Laser CNC Machine#Mazak CNC Machine#Mini CNC Milling Machine#What Is CNC Milling Machine#What Is CNC Routers Machine#5 Axis CNC Milling Machine#Advantages Of CNC Machine#Budget CNC Machine

0 notes

Text

Enhance Precision with APEC Aerospace Milling: The Future of Aerospace Manufacturing

In the aerospace industry, precision and reliability are non-negotiable. The components used in aircraft, satellites, and other aerospace applications must meet the highest standards of quality and performance. APEC Aerospace Milling solutions provide cutting-edge technology designed to meet these stringent demands. With unmatched precision, durability, and versatility, APEC Aerospace Milling ensures that manufacturers can produce high-quality aerospace components efficiently and cost-effectively. In this blog, we will explore the benefits of APEC Aerospace Milling and why it is a top choice for the aerospace industry.

What is APEC Aerospace Milling?

APEC Aerospace Milling refers to the advanced milling technology specifically designed for aerospace manufacturing. Milling is a machining process where rotating tools are used to remove material from a workpiece to create complex shapes. APEC Aerospace Milling machines are equipped with the latest CNC (Computer Numerical Control) technology, offering exceptional accuracy and speed in producing parts with extremely tight tolerances. These machines are crucial for producing aerospace components such as turbine blades, engine parts, structural elements, and other complex components.

Why Choose APEC Aerospace Milling?

Unparalleled Precision

Precision is the cornerstone of aerospace manufacturing. Even the smallest deviation in measurements can have catastrophic consequences, especially in critical components like engine parts and structural components. APEC Aerospace Milling machines offer exceptional accuracy, with the ability to produce parts with tolerances as tight as a few micrometers. The high-precision milling ensures that every part meets the exact specifications required, ensuring safety and reliability in every aircraft, satellite, and other aerospace systems.

Advanced CNC Technology

APEC Aerospace Milling machines are powered by advanced CNC technology, which allows for automated, highly accurate milling operations. CNC milling machines are programmed with precise instructions to guide the cutting tools, reducing human error and ensuring consistency across multiple parts. With this level of automation, APEC Aerospace Milling not only improves accuracy but also boosts productivity, as the machines can operate for long hours with minimal downtime. Additionally, CNC technology allows for complex 3D designs to be milled with ease, enhancing flexibility and design options for aerospace engineers.

High-Quality Materials Compatibility

The aerospace industry requires the use of materials that can withstand extreme temperatures, pressures, and environmental conditions. APEC Aerospace Milling machines are built to work with a wide range of materials, including high-strength alloys, titanium, and composites. These materials are commonly used in the aerospace industry due to their durability and lightweight properties. APEC machines are designed to handle these tough materials efficiently, ensuring that the finished parts maintain the strength, performance, and durability required for aerospace applications.

Versatility in Aerospace Applications

APEC Aerospace Milling machines are versatile and capable of handling a wide variety of milling operations. Whether it's drilling, tapping, contouring, or producing complex 3D shapes, these machines can perform multiple tasks in a single setup. This versatility makes them ideal for the production of a diverse range of aerospace components, including engine parts, landing gear, turbine blades, brackets, and structural components. This flexibility allows aerospace manufacturers to optimize their production processes and meet the unique demands of different aerospace applications.

Increased Efficiency and Reduced Lead Times

APEC Aerospace Milling solutions are designed for high-speed performance, ensuring that manufacturing processes are completed efficiently without sacrificing quality. The advanced capabilities of these machines allow for faster processing times and reduced lead times, enabling aerospace manufacturers to meet tight production schedules. With quicker turnaround times, manufacturers can bring their products to market faster, increasing their competitiveness in the industry.

Cost-Effectiveness

While the initial investment in APEC Aerospace Milling machines may seem high, the long-term cost savings far outweigh the upfront costs. These machines are designed to optimize efficiency, reduce material waste, and minimize the need for secondary operations, all of which contribute to cost savings. Furthermore, the exceptional durability and reliability of APEC Aerospace Milling machines mean that manufacturers will have a long-lasting solution, reducing maintenance and repair costs over time.

Key Features of APEC Aerospace Milling Machines

High-Speed Spindles: APEC Aerospace Milling machines come equipped with high-speed spindles that ensure rapid material removal, improving overall production efficiency.

Advanced Control Systems: The machines feature sophisticated CNC control systems that enable real-time adjustments and precise control over the milling process, ensuring consistent quality.

Robust Construction: APEC machines are designed with a rigid construction that reduces vibrations during operation, improving the accuracy and surface finish of the parts.

Automated Tool Change: The machines come with automated tool changers that help reduce downtime between operations, boosting productivity and efficiency.

Customizable Solutions: APEC Aerospace Milling machines can be customized to meet specific needs, ensuring manufacturers have the tools required for their unique production processes.

Applications of APEC Aerospace Milling

APEC Aerospace Milling machines are used to manufacture a wide range of aerospace components. Some of the most common applications include:

Turbine Blades and Engine Components: APEC Aerospace Milling machines are used to produce turbine blades, compressor parts, and other critical engine components. These parts require extreme precision to ensure the safe and efficient operation of aircraft engines.

Aircraft Structural Components: From wing brackets to fuselage parts, APEC machines are used to create the structural components of aircraft. These parts must meet rigorous standards for strength, weight, and durability.

Landing Gear Components: The landing gear of an aircraft is one of the most critical parts, and it must be manufactured with the highest levels of precision. APEC Aerospace Milling machines are used to produce these components to ensure their strength and reliability.

Satellite Parts: APEC Aerospace Milling machines are used to produce components for satellites, including housings, brackets, and structural elements. These parts must be lightweight yet durable to withstand harsh environmental conditions.

Aerospace Tooling: APEC milling machines are also used to create precision tooling for aerospace applications, ensuring that all parts are manufactured to exact specifications.

Conclusion

APEC Aerospace Milling solutions are revolutionizing the aerospace industry by providing manufacturers with the tools needed to produce high-quality, high-precision components efficiently. With their advanced CNC technology, versatility, and compatibility with a wide range of materials, APEC Aerospace Milling machines are the ideal choice for manufacturers looking to enhance their aerospace production capabilities.

If you're looking to improve precision, reduce lead times, and stay competitive in the aerospace industry, investing in APEC Aerospace Milling machines is a step toward future-proofing your business. Reach out today to discover how APEC Aerospace Milling can transform your manufacturing processes and elevate the quality of your aerospace components.

0 notes

Note

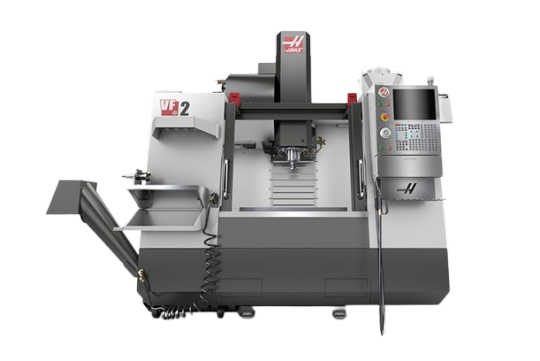

Is it something like this? Look at this guy, he's just a little baybey. Just a cute little guy. That's just how mills are idk what to tell you.

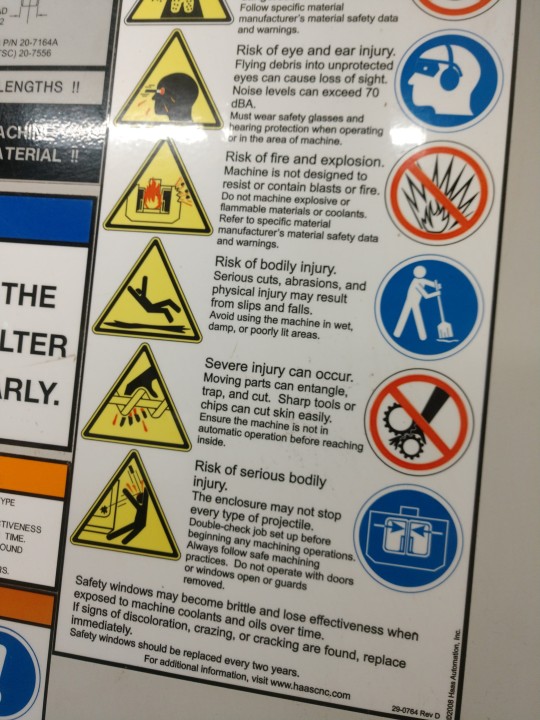

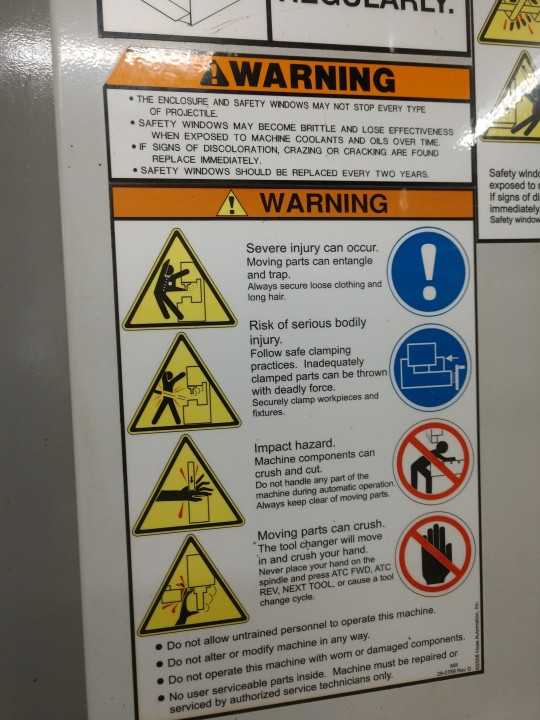

hey heres the whole warning panel from one of the HAAS mini mills at my job, that only like 2 engineers are allowed to touch. personal fav is 3rd image 2 triangles down. owned lmao

splashes of red… very good…

#Did you know that HAAS has a F1 team? I just learned that I think it's kinda cool#HAAS#CNC mill#manufacturing#I like HAAS machines! my high school had two HAAS cnc mills

204 notes

·

View notes

Text

How much does a CNC operator earn?

How much can a CNC operator earn? It’s a question a lot of tradies and aspiring machinists find themselves asking, especially with skilled manufacturing jobs back on the rise. Here's the quick version: In Australia, CNC operators typically earn anywhere from $60,000 to $85,000 a year, with experienced operators or those working in specialised sectors commanding more. Globally, the figure fluctuates—strongly influenced by geography, industry, and the level of automation involved.

Let’s cut deeper and see what actually drives those numbers—and whether the role stacks up financially in today’s tech-savvy trades landscape.

What does a CNC operator actually do?

First, it’s worth clearing up what this role involves. CNC stands for Computer Numerical Control. Operators run computerised machines that shape metal, plastic, and other materials into precision parts. These aren’t your average workshop drills. We're talking high-torque, micro-precise mills, lathes, and routers—automated by code, not calloused hands.

A CNC operator doesn’t just press “start” and walk off. Their job includes:

Reading blueprints or CAD designs

Setting up tooling and machinery

Monitoring and tweaking production runs

Inspecting the finished parts for defects

Performing maintenance or minor repairs on the equipment

Some operators evolve into programmers or machinists, roles that blend both coding and hands-on work.

How much do CNC operators earn in Australia?

In 2025, average CNC operator salaries in Australia look something like this: Experience LevelAnnual Salary (AUD)Entry-level (0–2 yrs)$55,000 – $65,000Mid-level (2–5 yrs)$65,000 – $75,000Senior/Skilled (5+ yrs)$75,000 – $90,000+

Salaries tend to be higher in mining, aerospace, and defence, where tolerances are tighter and materials more exotic. If you’re operating 5-axis CNCs in Perth for an aerospace contractor, you’re probably doing better than someone running 3-axis setups for custom furniture in suburban Melbourne.

Hourly rates typically sit between $30 to $42/hour, depending on shift patterns, penalties, and overtime agreements.

What’s the CNC operator pay like overseas?

Globally, here’s how CNC operator pay shapes up (converted to AUD for easy comparison): CountryAverage Annual SalaryUSA$55,000 – $70,000Canada$50,000 – $65,000UK$45,000 – $60,000Germany$60,000 – $75,000Singapore$40,000 – $55,000

Australian operators fare relatively well in this landscape—largely due to higher living costs and stronger award protections in manufacturing. That said, if you’re certified and adventurous, expat gigs in Germany or the US offer rich opportunities, especially with defence contractors or in automotive prototyping.

What factors affect a CNC operator’s pay?

Like most trades, it’s not just about turning up and clocking on. Pay fluctuates based on:

Machine complexity: 5-axis CNCs or multi-head setups pay more than basic rigs.

Programming knowledge: Operators who can write or tweak G-code earn more.

Industry demand: Mining boom? Expect higher pay in WA. Aerospace expansion? NSW and Victoria benefit.

Shift work: Overnight and rotating shifts usually include penalty rates.

Certifications: TAFE certs and manufacturer training programs can bump your base pay.

And here’s where authority kicks in: employers trust those with proven uptime, clean defect records, and adaptability. A senior CNC hand with a knack for diagnosing issues mid-run is worth their weight in titanium.

Is it hard to become a CNC operator?

Not particularly. You don’t need a uni degree—just the right TAFE certificate (usually Certificate III in Engineering – Mechanical Trade) and on-the-job training. Most operators start as apprentices or machine assistants and work their way up.

Here’s a rough pathway:

Get your TAFE Cert III – This usually takes 3–4 years through an apprenticeship.

Gain hands-on experience – Learn setup, monitoring, and inspection.

Upskill – Get familiar with programming (G-code, FANUC, HAAS interfaces).

Specialise – Move into specific sectors (like defence, aerospace, or medical).

The real skill is in repetition and precision. Anyone who’s tried cutting hardened steel to 5-micron tolerances knows: there’s no faking it.

Are there real opportunities for career growth?

Yes—especially as Australia pushes advanced manufacturing initiatives.

You can level up to:

CNC programmer – Writing and optimising machine code

Toolmaker – Designing and fabricating specialised machine tools

Workshop supervisor – Managing teams and production flow

Quality assurance specialist – Overseeing inspection and compliance

CNC work also builds a pathway into robotics, automation, and additive manufacturing. That puts you on the front line of Industry 4.0, not stuck in a dusty corner of the workshop.

What’s the job outlook like?

Pretty healthy. While some worry automation is replacing operators, the reality’s a bit different. Automation still needs operators—just smarter ones.

In fact, Job Outlook data from the Australian Government shows CNC roles are holding steady, with modest growth predicted through 2026.

There’s also a skilled labour gap in regional areas. If you’re willing to relocate, there’s serious earning potential—especially when coupled with living allowances and regional incentives.

FAQs

Q: Do CNC operators need a licence in Australia? No, but formal qualifications via TAFE or registered apprenticeships are strongly preferred by employers.

Q: Can CNC operators work remotely? Not really. It’s a hands-on job—though remote monitoring and digital twins are changing how some advanced factories operate.

Q: Is CNC machining dangerous? It can be if safety procedures aren’t followed. But with proper PPE and training, risks are minimal.

CNC machining isn’t glamorous, but for people who love working with their hands and minds in sync, it’s rewarding—both in terms of pay and pride. And if you're curious about how salaries vary or want a more in-depth view, this breakdown gives a closer look at CNC machining wages across different roles and locations.

In a world racing toward automation, there’s still something deeply satisfying about shaping real, tangible things—and getting paid well to do it.

0 notes

Text

What Should I Look for in the Best CNC Machine for Precision Manufacturing?

When choosing the best CNC machine, consider factors like accuracy, spindle speed, rigidity, and compatibility with advanced software. High-end machines from brands like Haas or DMG Mori offer multi-axis capabilities, ensuring complex geometries are machined flawlessly. For industries like aerospace or medical devices, investing in machines with micron-level precision is crucial.

At AMS Vietnam, we use state-of-the-art CNC machining centers equipped with automated tool changers and real-time monitoring to deliver consistent quality. Whether you need milling, turning, or 5-axis machining, our machines are calibrated for high-performance precision machining tailored to your specifications.

0 notes

Text

CNC Machines Refurbishment Services Maharashtra – Restoring Precision and Performance

In the dynamic world of manufacturing, efficiency and precision are non-negotiable. Over time, even the most robust CNC (Computer Numerical Control) machines experience wear and tear, leading to reduced accuracy and productivity. However, purchasing new machinery is not always financially feasible. That’s where CNC Machines Refurbishment Services in Maharashtra come into play, offering a cost-effective solution to restore aging equipment to its original or even better performance.

Maharashtra, a hub of industrial activity with cities like Pune, Mumbai, Nashik, Aurangabad, and Nagpur, has emerged as a leader in the CNC refurbishment industry. Whether you operate in automotive, aerospace, die/mold, fabrication, or electronics — these services offer unmatched value and reliability.

What is CNC Machine Refurbishment?

CNC machine refurbishment involves restoring a used or worn CNC machine to its optimal working condition. This is done by overhauling mechanical components, upgrading control systems, recalibrating axes, and ensuring the machine performs like new.

Key Services Include:

🔧 Mechanical reconditioning

⚙️ Replacement of ball screws, guideways, and bearings

💡 Electrical rewiring and control panel upgrades

🖥️ CNC control system and software updates

📏 Axis alignment and geometric accuracy calibration

🔍 Functional testing and certification

With professional CNC machines refurbishment services in Maharashtra, businesses can significantly increase the lifespan and accuracy of their machines at a fraction of the cost of new purchases.

Why Choose CNC Machines Refurbishment Services in Maharashtra?

Maharashtra is India's industrial powerhouse with a highly developed engineering ecosystem. Choosing a CNC refurbishment provider in this region ensures:

✅ Technical Expertise:

Pune and Mumbai boast a dense cluster of skilled engineers and CNC specialists with decades of experience in servicing world-class machinery like Mazak, Haas, Siemens, Fanuc, DMG Mori, and more.

✅ Access to Latest Technology:

Service providers in Maharashtra use cutting-edge tools and diagnostic equipment to carry out precise refurbishments that meet global standards.

✅ Wide Industry Reach:

From automotive giants in Pune to fabrication units in Aurangabad, refurbishment services cater to every sector, ensuring tailored solutions.

✅ Cost-Efficiency:

Refurbishment is 40–70% more affordable than purchasing new CNC machines, offering maximum ROI.

Key Benefits of CNC Refurbishment

Partnering with a professional CNC machines refurbishment service provider in Maharashtra brings numerous advantages:

🔄 Extended Machine Life: Refurbished machines gain an additional 5–10 years of operation.

📈 Enhanced Productivity: Improved spindle speeds, feed rates, and axis response.

🛡️ Improved Safety and Compliance: Electrical and mechanical safety standards are re-evaluated and upgraded.

💰 Significant Cost Savings: No need for capital investment in new equipment.

⚙️ Up-to-date Technology: Integration of the latest CNC controllers and automation options.

Industries Served

Refurbishment services are widely used across Maharashtra’s diverse industrial base:

🚗 Automotive:

Engine component manufacturers refurbish their CNC machining centers to maintain tight tolerances.

✈️ Aerospace:

Precision milling and drilling machines used in aerospace part production are refurbished to achieve micron-level accuracy.

🔩 Die & Mould:

Toolmakers rely on refurbished CNC EDM and VMC machines to meet intricate mold design requirements.

🏗️ Heavy Engineering:

Lathes, boring machines, and horizontal machining centers are restored for large-scale operations.

🧰 General Manufacturing:

Job shops and MSMEs benefit from refurbished CNC routers, turning centers, and vertical machining centers.

CNC Machine Types Commonly Refurbished

🛠️ CNC Turning Centers

🧲 CNC Milling Machines (VMC/HMC)

🔧 CNC Boring Machines

🧵 CNC EDM/Wirecut Machines

📐 CNC Routers and Plasma Cutters

🪛 CNC Grinding Machines

Each refurbishment process is tailored to the machine type, application, and required performance level.

Top Cities Offering CNC Refurbishment in Maharashtra

1. Pune

Known for high-end CNC and automation industries.

Major hub for Fanuc, Siemens, and Mitsubishi system upgrades.

2. Mumbai

Offers full-scale refurbishment for CNC machines used in electronics, textiles, and aerospace.

3. Nashik

Specializes in machine calibration and high-precision spindle refurbishment.

4. Aurangabad

Industrial growth center with numerous refurbishment workshops for heavy-duty CNC machines.

5. Nagpur

Fast-growing location for CNC retrofitting, panel rewiring, and servo upgrades.

How to Choose the Right CNC Refurbishment Service Provider?

Before selecting a CNC machines refurbishment service in Maharashtra, evaluate these factors:

✅ Years of experience in CNC machine restoration

✅ Expertise in your specific machine brand (Fanuc, Haas, Siemens, etc.)

✅ Availability of genuine spare parts

✅ On-site diagnosis and breakdown support

✅ Post-refurbishment warranty and service contracts

Make sure to ask for a performance report and machine test results before approving the refurbished unit.

Conclusion

CNC machine refurbishment is a smart, sustainable, and cost-effective solution for manufacturers looking to optimize operations without investing in new machinery. Maharashtra stands out as a leader in this domain, offering technically sound and value-driven CNC Machines Refurbishment Services across its major industrial cities.

Whether you're facing issues with accuracy, system lag, or mechanical failures, a professional refurbishment can breathe new life into your CNC systems — restoring performance, boosting output, and saving costs.

If you're located in Maharashtra or planning to outsource your CNC refurbishment work, now is the perfect time to explore these services and partner with a trusted local expert.

Frequently Asked Questions (FAQs)

Q1: What is the typical cost of CNC machine refurbishment in Maharashtra? A: The cost can range between ₹75,000 to ₹8,00,000 depending on the machine model, age, and components required.

Q2: How long does it take to refurbish a CNC machine? A: A complete refurbishment usually takes 2 to 4 weeks, depending on the complexity and part availability.

Q3: Can refurbished CNC machines perform like new ones? A: Yes, when properly done, refurbished machines can deliver accuracy and performance similar to brand-new machines.

Q4: Is there a warranty on refurbished machines? A: Most reputed service providers offer a 6–12 month warranty on refurbished machines and components.

Q5: Do CNC refurbishment services include control system upgrades? A: Absolutely. Many providers upgrade the CNC controller, HMI, servo motors, and drives to modern standards.

#CNC Machines Refurbishment Services Maharastra#CNC Machine Reconditioning Service Maharastra#CNC Plano Milling Machine Maharastra#CNC Tube Sheet Drilling Machine Maharastra

0 notes

Text

this is where the glory of cnc milling machines comes in. look at the beautiful control panel of a haas cnc milling machine.

god i love machining sm. she is gorgeous

nobody:

the most obnoxious idiot on the planet: "what if we replaced the buttons with a touch interface"

29K notes

·

View notes

Text

CNC Certification: Your Path to a Thriving Career in Manufacturing

In today’s advanced manufacturing landscape, CNC (Computer Numerical Control) programming is a high-demand skill that powers precision machining across industries like aerospace, automotive, and medical device production. Earning a CNC programming certification can open doors to rewarding careers with competitive salaries, often starting at $60,000 annually. Certifications validate your expertise in G-Code, CAD/CAM software, and machine operation, making you a standout candidate for roles like CNC programmer or machinist.

Online CNC certification courses offer flexibility for beginners and experienced machinists alike. Platforms like CADCAM Teacher provide comprehensive training, covering G-Code fundamentals, milling, lathe operations, and toolpath optimization. Their self-paced courses include video tutorials, printable workbooks, and exercises, ideal for preparing for certifications like NIMS or Mastercam. CADCAM Teacher’s focus on practical, industry-relevant skills ensures you’re job-ready, with simulations mimicking real-world CNC machines. Other notable programs include Titans of CNC Academy and Haas Automation, which often require a hands-on test for certification.

A CNC certification not only boosts your resume but also equips you with skills to innovate in manufacturing. Start your journey with CADCAM Teacher to master CNC programming and secure a stable, high-paying career in this dynamic field. Enroll today and shape your future in precision engineering!

0 notes

Text

HAAS Brushless Servo Motor: Ultimate Choice For CNC Performance

In today’s manufacturing world, where precision, speed, and reliability determine competitive edge, the machinery behind production lines plays a critical role. CNC machines have become the backbone of modern fabrication, relied upon by industries ranging from aerospace to automotive. At the heart of many CNC systems lies the servo motor, responsible for accurate motion control, speed regulation, and torque management.

As technological standards rise, more workshops and manufacturers are shifting toward brushless servo motors for better performance and lower maintenance demands. With brands like HAAS leading the way, the integration of advanced motors is no longer optional; it's essential.

HAAS Brushless Servo Motor

A servo motor is a key component of CNC machines, controlling precise linear or rotational movement. Unlike brushed motors, which rely on physical brushes to transmit current, brushless servo motors operate electronically. This not only reduces wear but also improves efficiency and performance over time.

The HAAS Brushless Servo Motor stands out for its engineering precision and reliable performance under continuous operational stress. These motors are designed for machines that require fine-tuned control and consistent operation, delivering responsive movement without overheating or stalling.

Features of HAAS Brushless Servo Motors

Superior Torque and Speed Control These motors deliver high torque at variable speeds, allowing CNC machines to maintain accuracy even during high-load tasks.

Maintenance-Free OperationWithout brushes to replace, wear and tear are minimized, saving businesses time and money on repairs and downtime.

High Efficiency and Low Heat OutputBrushless motors are more efficient, meaning they convert more energy into motion, reducing energy costs and improving overall system performance.

Advanced Feedback SystemsIntegrated encoders and sensors enable real-time feedback, helping systems adjust instantly to maintain exact positioning.

Benefits for CNC Workshops and Manufacturers

Investing in a HAAS Brushless Servo Motor offers multiple long-term advantages:

Consistent Machining Accuracy: Perfect for applications that require detailed and repetitive cuts. Extended Lifespan: Less friction and lower maintenance mean longer operational life. Operational Savings: Reduced maintenance, lower energy consumption, and fewer part replacements help improve bottom-line efficiency. Higher Productivity: Faster cycle times and fewer disruptions translate to better output with fewer resources.

Industries That Rely on HAAS Servo Motors

From precision metal fabrication shops to full-scale industrial production plants, businesses rely on the power and reliability of HAAS components. Applications include:

CNC milling and turning centers

Robotics and automation systems

Aerospace and defense manufacturing

Automotive parts production

For example, small-to-midsize workshops have benefited from upgrading legacy motors to modern brushless options, achieving faster production with minimal reinvestment.

Choose Refurbished HAAS Brushless Servo Motors

While brand-new equipment offers cutting-edge technology, refurbished motors present an excellent balance of performance and affordability.

Purchasing a HAAS Brushless Servo Motor in refurbished condition can provide:

Significant cost savings

Verified performance with professional testing

Quick availability compared to long lead times for new units

Environmentally conscious purchasing by reducing industrial waste

However, it’s important to source these parts from trusted suppliers to ensure quality and reliability.

Final Thoughts

For manufacturers looking to elevate their CNC systems' efficiency, accuracy, and reliability, the HAAS Brushless Servo Motor is a smart investment. Its combination of high-performance engineering, minimal maintenance, and adaptability to various applications makes it a top choice for modern production environments.

Explore reliable, performance-tested options available now. Visit CNC TOOLS LLC to view refurbished HAAS servo motors and upgrade your system with confidence.

0 notes

Text

Machine Tools Market Size, Share, Trends, Key Drivers, Demand and Opportunity Analysis

Machine Tools Market Segmentation, By Product Type (Milling Machines, Drilling Machines, Grinding Machines, and Electrical Discharge Machines), Automotive (CNC Machine Tools and Conventional Machine Tools), Industry Segment (Automotive and Transportation, Sheet Metals, Capital Goods, and Energy), Sales Channel (Events and Exhibitions and Dealers and Distributors) - Industry Trends and Forecast to 2032

The global machine tools market was valued at USD 80.35 billion in 2024 and is expected to reach USD 106.62 billion by 2032 During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 3.60%, primarily driven by industrialization in emerging economies.

An influential Machine Tools Market report looks over the market with respect to general market conditions, market improvement, market scenarios, development, cost and profit of the specified market regions, position, and comparative pricing between major players. To get knowledge of all the above factors, a transparent, extensive, and supreme-quality report is created. This market document has been prepared with the thorough market analysis carried out by a team of industry experts, dynamic analysts, skillful forecasters, and well-informed researchers. Key players in the market, major collaborations, merger and acquisitions along with trending innovation and business policies are also reviewed in Machine Tools Market report.

Market research covered in the winning Machine Tools Market business report helps the management of a firm in planning by providing precise and up- to-date information about the consumer’s demands, their changing tastes, attitudes, preferences, and buying intentions etc. The report also includes a comprehensive evaluation of the market’s growth prospects and restrictions. The industry analysis report provides guidelines about planning of advertising and sales promotion efforts. With the data covered in this report, Market of goods can be made efficient and economical which leads to elimination of all type of wase. Thus, Machine Tools Market report is a crucial model to have increments in business activities, qualitative work done, and enhanced profits.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Machine Tools Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-machine-tools-market

Machine Tools Market Overview

**Segments**

- By Type: The global machine tools market can be segmented by type into cutting machines, drilling machines, grinding machines, electrical discharge machines, and others. Cutting machines are expected to dominate the market due to the increasing demand for precision cutting in industries such as automotive, aerospace, and construction. - By Application: Based on application, the market can be categorized into automotive, aerospace, electronics, healthcare, and others. The automotive sector is anticipated to have a significant market share as machine tools are extensively used in manufacturing parts and components for vehicles. - By Region: Geographically, the market is divided into North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific is expected to lead the market owing to the rapid industrialization and growing manufacturing sector in countries like China and India.

**Market Players**

- Trumpf - Amada Machine Tools Co., Ltd. - DMG Mori Co., Ltd. - Okuma Corporation - GF Machining Solutions Management SA - Haas Automation, Inc. - Hyundai WIA - Makino - JTEKT Corporation - Komatsu Ltd.

These key market players are focusing on innovation, technological advancements, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product portfolio. The competitive landscape of the global machine tools market is highly fragmented with the presence of numerous players. The market is characterized by intense competition, rapid technological advancements, and changing consumer preferences.

The global machine tools market is witnessing significant growth propelled by the increasing demand for precision cutting, drilling, and grinding machines across various industries. The segmentation of the market by type into cutting machines, drilling machines, grinding machines, electrical discharge machines, and others reflects the diverse applications of machine tools in industrial settings. Cutting machines, in particular, are expected to dominate the market due to the need for precise cutting in sectors such as automotive, aerospace, and construction, where the quality of components is crucial for overall performance. This trend is driving innovation and technological advancements among market players to meet the evolving needs of customers.

When considering the segmentation of the market by application, industries such as automotive, aerospace, electronics, healthcare, and others stand out as key drivers of demand for machine tools. The automotive sector, in particular, is anticipated to hold a significant market share as machine tools play a critical role in the manufacturing of vehicle components and parts. As the automotive industry continues to evolve with advancements in electric vehicles and autonomous technologies, the demand for highly efficient and precise machine tools is expected to rise.

Geographically, Asia-Pacific is positioned as a leading region in the global machine tools market, driven by rapid industrialization and a growing manufacturing sector in countries like China and India. The region's robust industrial infrastructure, coupled with the increasing uptake of automation and CNC technologies, is fueling the demand for advanced machine tools. As key market players focus on expanding their presence in Asian markets through strategic partnerships and investments in research and development, the competitive landscape of the industry is intensifying.

Market players such as Trumpf, Amada Machine Tools Co., Ltd., DMG Mori Co., Ltd., and others are at the forefront of driving innovation and technological advancements in the machine tools market. These companies are leveraging their expertise in precision engineering and automation to develop cutting-edge solutions that cater to the evolving needs of industries like automotive, aerospace, and electronics. Strategic collaborations and mergers and acquisitions are also shaping the competitive dynamics of the market, as players seek to enhance their product portfolios and strengthen their market positions.

One of the significant trends shaping the machine tools market is the increasing demand for precision and efficiency in cutting, drilling, and grinding processes. This trend is driven by the requirements of industries like automotive, aerospace, and construction, where the quality of components directly impacts performance and safety standards. As a result, market players are focused on developing cutting-edge solutions that offer high precision, automation capabilities, and enhanced productivity to meet the stringent requirements of these industries. The emphasis on innovation and technological advancements is critical in enabling manufacturers to optimize production processes, reduce manufacturing costs, and improve overall product quality.

Furthermore, the market segmentation based on application highlights the diverse industries that rely on machine tools for their manufacturing processes. The automotive sector emerges as a key driver of market demand, given the crucial role of machine tools in producing vehicle parts and components. As the automotive industry experiences transformative changes with the rise of electric vehicles, autonomous technologies, and lightweight materials, the need for advanced machine tools continues to grow. This trend creates opportunities for market players to innovate and develop specialized solutions that cater to the specific needs of the automotive sector, reinforcing their competitive positioning in the market.

Geographically, Asia-Pacific stands out as a leading region in the global machine tools market, fueled by rapid industrialization and a thriving manufacturing sector in countries like China and India. The region's robust industrial infrastructure, coupled with investments in automation technologies, drives the adoption of advanced machine tools for increased efficiency and productivity. Market players are actively targeting the Asia-Pacific region to capitalize on the growing market opportunities and establish a strong presence in key industrial markets. This strategic focus on geographic expansion underscores the competitive dynamics of the market and the importance of catering to regional demands and preferences.

In conclusion, the global machine tools market continues to evolve, driven by technological innovation, changing industry requirements, and competitive strategies adopted by market players. The market's segmentation by type, application, and region provides valuable insights into the diverse dynamics shaping the industry landscape. As market players navigate these trends and challenges, the focus on innovation, collaboration, and customer-centric solutions will be instrumental in driving sustainable growth and differentiation in the competitive marketplace.

The Machine Tools Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-machine-tools-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Key questions answered in the report:

What will the market development pace of the Machine Tools Market?

What are the key factors driving the Global Machine Tools Market?

Who are the key manufacturers in the Machine Tools Marketspace?

What are the market openings, market hazard and market outline of the Machine Tools Market?

What are sales, revenue, and price analysis of top manufacturers of Machine Tools Market?

Who are the distributors, traders, and dealers of Machine Tools Market?

What are the Machine Tools Market opportunities and threats faced by the vendors in the Global Machine Tools Marketindustries?

What are deals, income, and value examination by types and utilizations of the Machine Tools Market?

What are deals, income, and value examination by areas of enterprises?

Browse More Reports:

Global Multi-Mode Optical Transceiver Market Global Organic Pea Protein Market Global Clean Label Plant-Based Supplements Market Global Seaweed Extracts Biostimulant Market Global Systemic Lupus Erythematosus (SLE) and Lupus Nephritis (LN) Market Global Recycled Glass Market Middle East and Africa Audio Critical Communication Market Global Washing Machine Market Global Collation Shrink Films Market Global Becker Muscular Dystrophy Treatment Market Global Cardiovascular Small Molecule API Market Europe Latex Mattress Market Global Pleurisy Disease Market Global Smart Cameras Market Global Networked Sound Masking System Market Global Mandibular Osteomyelitis Treatment Market North America Surgical Sealants and Adhesives Market Global Immunoassay Reagents and Devices Market Global Wireless Mesh Network Market Global Electric Surface Heaters Market North America Cold Chain Monitoring Market Asia-Pacific Rapid Diagnostic Tests (RDT) Market Europe Insoluble Sulfur Market for Automotive Sector – Industry Trends and Forecast to 2030 Global Overhead Conveyor Market Global 1-Decene Market Asia-Pacific Rubber Peptizers Market Global Primary Antibodies Market Global Mini Brew Fermenter Market Middle East and Africa Gas Equipment Market Global Fermented Chymosin Market Global Paper Coating Materials Market Asia-Pacific Contract Manufacturing Market Global Hyaluronic Acid Based Dermal Fillers Market Global Earplugs Market Global Cancer Supportive Care Products Market Global Acoustic Neuroma Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

0 notes

Text

🔥Year-end sprint! The 5-axis CNC machine is running at full capacity, working overtime to rush the New Year's orders, and every cut is ingenious! 🎉Can you guess what masterpiece we are working on? #CNCProcessing #CraftsmanSpirit #NewYearNewAtmosphere

#CNC Machine Plywood#CNC Machine Programming Course#CNC Machining Center#CNC Machining For Medical Imaging#CNC Milling Machine For Sale#CNC Routers Machines#CNC Screw-Machining For Aviation#Diy CNC Machine#Haas CNC Milling Machine#Laser CNC Machine#Mazak CNC Machine#Mini CNC Milling Machine#What Is CNC Milling Machine#What Is CNC Routers Machine#5 Axis CNC Milling Machine

0 notes

Text

Horizontal Milling Machines: The Key to Efficient and Precise Manufacturing

In the competitive world of manufacturing, efficiency, precision, and speed are crucial. Horizontal milling machines have become essential tools in achieving these goals, particularly for high-volume production and larger workpieces. These machines offer distinct advantages, making them an ideal choice for industries such as automotive, aerospace, and heavy equipment manufacturing.

At Phillips Corporation Middle East, we provide top-quality horizontal milling machines designed to improve productivity while maintaining exceptional levels of precision. Let’s dive deeper into why horizontal milling machines are an essential addition to modern manufacturing setups.

What Are Horizontal Milling Machines?

Horizontal milling machines are advanced CNC (Computer Numerical Control) tools that use a horizontal spindle to cut materials. The workpiece is typically placed on a horizontal surface, and the cutter moves along multiple axes to remove material, creating the desired shape. Unlike vertical mills, which have a spindle positioned vertically, horizontal mills utilize a horizontally oriented spindle, offering unique benefits for certain machining tasks.

These machines are especially well-suited for larger, heavier workpieces and high-volume production. They also allow for improved chip removal and greater stability, leading to better performance during longer machining cycles.

Key Benefits of Horizontal Milling Machines

Increased Stability and Efficiency

Horizontal milling machines offer enhanced stability compared to vertical mills. The horizontal spindle position provides better support, making them ideal for heavy-duty tasks and larger workpieces. Additionally, horizontal milling machines can be equipped with multiple cutting tools, reducing the need for tool changes and improving efficiency during long production runs.

Superior Chip Removal

One of the standout features of horizontal milling machines is their superior chip removal capability. The horizontal orientation allows gravity to assist in the removal of chips, preventing them from accumulating and interfering with the cutting process. This improves the overall machining quality and ensures that the tool operates at optimal efficiency, even in heavy-duty applications.

Versatility in Operations

Horizontal milling machines are versatile and can perform a wide range of operations, including slotting, boring, drilling, and tapping. This versatility allows manufacturers to use horizontal mills for various tasks, whether it's creating complex geometries or performing basic tasks on large workpieces. They are also compatible with various materials, including metals, plastics, and composites, providing manufacturers with the flexibility to work on diverse projects.

Better Tooling and Automation

Horizontal milling machines can support automatic tool changers (ATC) that make production processes more efficient. An ATC allows the machine to automatically switch between different cutting tools without operator intervention, reducing downtime and increasing productivity. These automated systems are perfect for tasks requiring multiple tools, further enhancing the machine's capabilities in high-volume manufacturing.

Higher Precision for Large Workpieces

Horizontal milling machines excel in machining large parts that require high precision. Their rigid design and horizontal cutting orientation make them ideal for maintaining tight tolerances, especially when working with large and heavy components. This makes horizontal mills an excellent choice for industries like aerospace, automotive, and heavy machinery, where precision is critical for safety and performance.

Types of Horizontal Milling Machines

At Phillips Corporation Middle East, we offer a wide range of horizontal milling machines to meet various manufacturing needs. Some of the most common types include:

Universal Horizontal Milling Machines: These machines are versatile and can be used for a wide range of operations. They feature a table that can be adjusted to different angles, allowing the machine to perform more complex tasks.

Ram-Type Horizontal Milling Machines: This type of machine features a horizontal spindle that is mounted on a movable ram. These machines are suitable for operations that require high flexibility and the ability to handle larger workpieces.

Plain Horizontal Milling Machines: These are designed for simpler tasks and are often used in high-volume production. They are typically equipped with a single spindle and are ideal for cutting large parts with straightforward geometries.

Bed-Type Horizontal Milling Machines: Bed-type mills are designed for heavy-duty operations and are suitable for large, complex components. The workpiece is mounted on a bed that moves along the X, Y, and Z axes, providing increased stability and support during machining.

How to Choose the Right Horizontal Milling Machine

Selecting the right horizontal milling machine for your business depends on several factors:

Workpiece Size and Complexity: If you work with large, heavy workpieces, a bed-type or ram-type horizontal mill may be the best option. For smaller, more intricate parts, a universal or plain horizontal milling machine may suffice.

Production Volume: For high-volume production, choosing a machine with automated features such as an automatic tool changer can significantly improve efficiency.

Material Compatibility: Ensure that the milling machine can handle the materials you plan to work with. Horizontal mills are compatible with a wide range of materials, including tough metals and composites.

Precision Requirements: For industries like aerospace or automotive, where tight tolerances are crucial, opt for a machine known for its precision and stability during long machining cycles.

Why Choose Phillips Corporation Middle East for Your Horizontal Milling Machines?

At Phillips Corporation Middle East, we pride ourselves on offering premium horizontal milling machines that help businesses improve their manufacturing processes. Our machines are built for reliability, efficiency, and precision, ensuring that you can meet the demands of even the most challenging projects.

We offer a comprehensive range of machines tailored to your specific needs, from simple milling operations to complex multi-axis machining tasks. Additionally, our team of experts provides full support, training, and after-sales service, ensuring that your investment continues to deliver outstanding results.

Get Started with Phillips Corporation Middle East Today!

Are you ready to enhance your manufacturing capabilities with a top-quality horizontal milling machine? Contact Phillips Corporation Middle East today to learn more about our machines and how they can transform your production processes. Our team is ready to help you find the perfect solution for your business.

0 notes

Text

CNC Machinist Course: Building Skills for the Future of Manufacturing.

In today’s rapidly evolving manufacturing landscape, skilled machinists are in higher demand than ever. As companies invest in advanced technologies to boost efficiency and precision, the need for well-trained CNC operators continues to grow. One of the most effective ways to enter or advance in this field is by enrolling in a CNC Machinist Course. These programs are designed to equip individuals with the hands-on training and technical knowledge needed to succeed in modern machine shops.

With the support of Phillips Commercial, one of the nation’s leading names in CNC machinery and training partnerships, many schools and training centers are delivering comprehensive courses tailored to the demands of today’s industry.

What is a CNC Machinist Course?

A CNC Machinist Course is a specialized training program that teaches students how to operate, program, and maintain CNC (Computer Numerical Control) machines. These machines are used to produce high-precision parts for industries ranging from aerospace and automotive to medical devices and defense.

The course typically covers:

Reading and interpreting blueprints and technical drawings

G-code programming and editing

Operating CNC milling and turning centers

Machine setup and tooling

Quality control and inspection techniques

Safety procedures in a machining environment

Whether someone is just starting their career or looking to upskill, these courses provide a strong foundation in both theory and practice.

Why CNC Machinist Training Matters.

Machining is no longer just about turning knobs and watching chips fly. Today’s CNC machinists are expected to understand digital programming, tooling systems, and real-time problem-solving. That’s why a CNC Machinist Course goes beyond simple machine operation—it trains individuals to think critically, interpret technical data, and make informed adjustments during the production process.

Completing such a course gives students a competitive edge in the job market. Employers are more inclined to hire candidates who are job-ready and have received training on modern equipment, especially when the curriculum is supported by leaders in the industry such as Phillips Commercial.

The Role of Phillips Commercial.

Phillips Commercial is deeply invested in advancing CNC education across the United States. As a trusted partner of Haas Automation and a leader in CNC solutions, Phillips collaborates with technical colleges, training institutions, and workforce development centers to offer hands-on learning experiences that align with industry standards.

Through its partnerships, Phillips helps ensure that each CNC Machinist Course includes access to state-of-the-art Haas CNC machines, experienced instructors, and up-to-date curriculum. Their involvement guarantees that students gain real-world experience with the same tools and systems used in today’s manufacturing plants.

In addition, Phillips offers ongoing support through maintenance training, machine setup assistance, and operator certification programs. This long-term commitment allows graduates to remain competitive even as technology evolves.

Who Should Take a CNC Machinist Course?

The versatility of a CNC machinist career makes it appealing to a wide range of individuals:

High school graduates exploring technical career paths

Veterans transitioning to civilian roles in manufacturing

Workers in traditional manufacturing who want to retrain for CNC roles

Engineering or industrial students seeking hands-on experience

Most programs are designed with flexibility in mind, offering full-time, part-time, or evening classes. This makes it easier for working adults to upskill while continuing their current jobs.

Career Opportunities After Completing the Course

Graduates of a CNC Machinist Course are qualified for a variety of entry- and mid-level positions in manufacturing, such as:

CNC Machine Operator

CNC Setup Technician

CNC Programmer (with additional experience)

Quality Control Inspector

Maintenance Technician

As machinists gain experience, they can advance to supervisory roles or transition into CNC programming, CAD/CAM design, or process engineering. The long-term earning potential in this field is strong, and job security remains high due to ongoing demand across industries.

Final Thoughts

A CNC Machinist Course is more than just an educational program—it’s a gateway to a stable, rewarding, and future-proof career. In a world where precision and efficiency are everything, the role of the CNC machinist is absolutely vital.

With the backing of industry leaders like Phillips Commercial, training centers are better equipped than ever to prepare the next generation of machinists. Students don’t just walk away with a certificate—they gain real-world skills that translate into lasting careers. For anyone looking to break into modern manufacturing or take their machining skills to the next level, this is the place to start.

0 notes

Text

I've been thinking about buying a used mill and lathe for my basement. I work for a major manufacturer of metal cutting machines and would love to use / tinker with them in my spare time. One thing I've tried to search for / look into on youtube & elsewhere is cutting wood using a metal cutting cnc like a Haas or Makino. I find hardly an info on it. There must be a reason, no?

Is it because of price? Most of my "wood cnc" search results come up with routers that appear to cut mostly flat items. Nothing very 3d.

With some of the medium size horizontal cnc's I deal with, you could take a giant 3' diameter 4' high log and cut out a life size bust of Trump if you wanted to. It might not have any practical use but it could be a real attention getter.

0 notes

Text

What is the Best CNC Machine for Precision Manufacturing?

The best CNC machine depends on your project requirements, but high-precision industries often opt for multi-axis machining centers like 5-axis CNC mills or Swiss-style lathes. These machines offer superior accuracy, repeatability, and the ability to handle complex geometries, making them ideal for aerospace, medical, and automotive applications.

At AMS Vietnam, we use advanced CNC machining centers from leading brands like Haas, DMG Mori, and Mazak. Our machines are equipped with real-time monitoring and rigid tooling systems to ensure tight tolerances (up to ±0.005mm) and flawless surface finishes. Whether you need milling, turning, or grinding, we provide the best CNC machine solutions tailored to your needs.

1 note

·

View note

Text

Comprehensive Analysis of Machine Tools Market Growth: US$ 114.3 Bn by 2031

Astute Analytica, a prominent market research firm, has recently published a comprehensive report that offers an extensive analysis of the global Machine Tools market. This report goes beyond mere statistics, providing deep insights into various critical aspects such as market segmentation, key players, market valuation, and regional overviews. It serves as a valuable resource for businesses and stakeholders seeking to navigate this evolving industry landscape.

Market Valuation

The report includes a thorough evaluation of the market valuation, drawing from historical data, current trends, and future projections. By employing rigorous analytical methods, it effectively captures the growth trajectory of the market. This detailed assessment allows businesses to understand the factors driving growth and make informed decisions regarding investments and strategic initiatives.

Global machine tools market is estimated to generate a revenue of US$ 114.3 Bn by 2031 from US$ 75.2 bn in 2022, registering a CAGR of 4.7% over the period 2023-2031.

A Request of this Sample PDF File@- https://www.astuteanalytica.com/request-sample/machine-tools-market

Comprehensive Market Overview

Astute Analytica's report provides a holistic overview of the global Machine Tools market. It encapsulates a wide array of information related to market dynamics, including growth drivers, challenges, and opportunities. Stakeholders can leverage these insights to formulate effective strategies and maintain a competitive edge in the market.

Key Players in the Market

The report identifies and profiles the major players who are influencing the global Machine Tools market. Through meticulous research, it presents a clear view of the competitive landscape, detailing the strategies, market presence, and significant developments of leading companies. This section is vital for stakeholders who wish to understand the positioning and actions of their competitors.

Key Companies:

Ace Micromatic Group

Amada Co. Ltd.

CHIRON Group

Dalian Machine Tool Group Corporation (DMTG)

DMG MORI

Doosan Machine Tools Co. Ltd.

Electronica Hitech Engineering Pvt. Ltd.

Georg Fischer Ltd

Gleason Corporation

GROB-WERKE GmbH & Co. KG

Haas Automation Inc.

Hyundai WIA

JTKET Corporation

Komatsu Ltd.

MAG IAS GmbH

Makino

Okuma Corporation

Schuler AG

Spinner Machine Tools

Yamazaki Mazak Corporation

Other Prominent Players

For Purchase Enquiry: https://www.astuteanalytica.com/industry-report/machine-tools-market

Segmentation Analysis

A crucial component of the report is the segmentation analysis, which delves into various market segments based on industry verticals, applications, and geographic regions. This detailed examination provides stakeholders with a nuanced understanding of market dynamics, enabling them to identify opportunities for growth and areas for investment.

Market Segmentation:

By Product

Milling Machine

Lathe Machine

Laser Machine

Drilling Machine

Turning Machine

Grinding Machine

Electrical Discharge Machine

Machining Centers

By Automation Type

CNC Machine Tools

Conventional Machine Tools

By Industry

Automotive

Aerospace and Defense

Construction Equipment

Power and Energy

Industrial

Others

By Sales Channel

Dealers and Distributors

Events and Exhibitions

By Region

North America

The U.S.

Canada

Mexico

Europe

Western Europe

The UK

Germany

France

Italy

Spain

Rest of Western Europe

Eastern Europe

Poland

Russia

Rest of Eastern Europe

Asia Pacific

China

India

Japan

Australia & New Zealand

ASEAN

Malaysia

Singapore

Thailand

Indonesia

Cambodia

Vietnam

Rest of ASEAN

Rest of Asia Pacific

Middle East & Africa

UAE

Saudi Arabia

Turkey

Egypt

South Africa

Nigeria

Rest of MEA

South America

Argentina

Brazil

Columbia

Rest of South America

Research Methodology

Astute Analytica is recognized for its rigorous research methodology and dedication to delivering actionable insights. The firm has rapidly established a solid reputation by providing tangible outcomes to clients. The report is built on a foundation of both primary and secondary research, offering a granular perspective on market demand and business environments across various segments.

Beneficiaries of the Report

The insights presented in this report are invaluable for a range of stakeholders, including:

Industry Value Chain Participants: Those directly or indirectly involved in the Machine Tools market need to stay informed about leading competitors and current market trends.

Analysts and Suppliers: Individuals seeking up-to-date insights into this dynamic market will find the report particularly beneficial.

Competitors: Companies looking to benchmark their performance and assess their market positions can leverage the data and analysis provided in this research.

Astute Analytica's report on the global Machine Tools market is an essential resource that empowers stakeholders with the knowledge needed to navigate and thrive in this competitive landscape.

Download Sample PDF Report@- https://www.astuteanalytica.com/request-sample/machine-tools-market

About Astute Analytica:

Astute Analytica is a global analytics and advisory company that has built a solid reputation in a short period, thanks to the tangible outcomes we have delivered to our clients. We pride ourselves in generating unparalleled, in-depth, and uncannily accurate estimates and projections for our very demanding clients spread across different verticals. We have a long list of satisfied and repeat clients from a wide spectrum including technology, healthcare, chemicals, semiconductors, FMCG, and many more. These happy customers come to us from all across the globe.

They are able to make well-calibrated decisions and leverage highly lucrative opportunities while surmounting the fierce challenges all because we analyse for them the complex business environment, segment-wise existing and emerging possibilities, technology formations, growth estimates, and even the strategic choices available. In short, a complete package. All this is possible because we have a highly qualified, competent, and experienced team of professionals comprising business analysts, economists, consultants, and technology experts. In our list of priorities, you-our patron-come at the top. You can be sure of the best cost-effective, value-added package from us, should you decide to engage with us.

Get in touch with us

Phone number: +18884296757

Email: [email protected]

Visit our website: https://www.astuteanalytica.com/

LinkedIn | Twitter | YouTube | Facebook | Pinterest

0 notes