#Halogen-Free Films

Explore tagged Tumblr posts

Text

The Environmental Benefits of Halogen-Free Flame Retardant BOPET Films in Packaging

Introduction: The global Halogen-Free Flame Retardant BOPET Films Market is poised to attain a substantial valuation of USD 1.98 billion by 2024. This growth trajectory is underpinned by the escalating demand for eco-conscious, fire-resistant materials across a spectrum of industries. The market is projected to burgeon at a compound annual growth rate (CAGR) of 6.2% between 2025 and 2032, propelled by the widespread integration of flame-retardant films within sectors like electronics, automotive, packaging, and construction. Current BOPET market trends underscore a discernible shift toward sustainable, halogen-free alternatives, as industries move away from conventional flame retardants in favor of safer, more environmentally benign solutions. This surge is indicative of an intensifying demand for fire-resistant films that comply with increasingly stringent safety and environmental standards.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40636-global-halogen-free-flame-retardant-bopet-films-market

Halogen-Free Flame Retardant BOPET Films Market Dynamics: The Halogen-Free Flame Retardant BOPET Films Market is undergoing a dynamic expansion due to tightening regulations surrounding halogenated materials and the growing need for flame-resistant films in industries such as electronics, automotive, and construction. This transformation reflects a broader market transition toward eco-friendly, high-performance films that excel in fire resistance while emitting minimal harmful substances. In particular, the mounting enforcement of fire safety regulations across industries has acted as a critical catalyst for the adoption of halogen-free flame-retardant materials. Certifications such as UL 94 VTM-0, RoHS, and REACH have become indispensable for manufacturers, fueling the demand for specialized films.

Technological breakthroughs, particularly in nano-coating technologies, present significant avenues for market growth. These nano-coatings enhance thermal stability, fire resistance, and mechanical integrity, thereby fortifying BOPET films against extreme conditions. Moreover, they offer superior barrier protection against moisture, oxygen, and ultraviolet radiation, which in turn augments the durability and longevity of the products. As companies invest in cutting-edge research and development, they are well-positioned to secure a competitive edge in this rapidly evolving market.

Despite its promise, the market faces challenges, notably the high production costs associated with these advanced materials. The manufacturing of halogen-free flame-retardant BOPET films involves specialized raw materials and sophisticated processing methods, rendering the production process more costly than traditional plastic films. Additionally, the need to integrate flame-retardant additives and adhere to stringent fire safety regulations further inflates manufacturing costs, presenting a potential hurdle to broader adoption.

A key trend driving the Halogen-Free Flame Retardant BOPET Films Market forward is the continual enhancement of BOPET films' thermal stability and fire resistance. New formulations offering self-extinguishing capabilities and superior heat resistance are particularly well-suited for use in high-temperature industrial applications, including EV batteries and aerospace insulation.

Get up to 30% Discount: https://www.statsandresearch.com/check-discount/40636-global-halogen-free-flame-retardant-bopet-films-market

Halogen-Free Flame Retardant BOPET Films Market Segmental Analysis: The Halogen-Free Flame Retardant BOPET Films Market is segmented into several categories, each exhibiting distinct growth trajectories shaped by unique demand drivers and industry specifications. Among these, the Polyethylene Terephthalate (PET) sub-segment remains the market leader, valued at USD 1.2 billion in 2024. PET's dominance is attributable to its broad application base across electronics, packaging, and automotive sectors. Conversely, the Polyethylene Furanoate (PEF) sub-segment is forecast to experience robust growth, with a CAGR of 7.5% through 2032, thanks to its eco-friendly properties and expanding role in sustainable packaging solutions.

In terms of flame-retardancy ratings, the V-0 rating sub-segment commands the lion's share of the market, valued at USD 900 million in 2024, owing to its superior fire resistance. Meanwhile, the V-1 rated sub-segment is expected to register significant growth, with a projected CAGR of 6.3% between 2025 and 2032. This segment's appeal lies in its optimal balance of flame resistance and cost-effectiveness, making it particularly attractive to the automotive and electronics industries.

The Polyvinylidene Chloride (PVDC) coating segment is the largest within the market, valued at USD 550 million in 2024, due to its outstanding barrier properties and extensive use in packaging. The Silicon Oxide (SiO2) coating segment is anticipated to grow at a CAGR of 6.8% until 2032, benefiting from its enhanced fire resistance and durability, especially in high-performance applications like electronics and aerospace.

As for end-user applications, Packaging dominates the market with a valuation of USD 700 million in 2024, driven by the growing demand for fire-resistant packaging solutions in sectors such as food, pharmaceuticals, and industrial goods. The Electronics sector, in particular, is set for considerable expansion, with a forecasted CAGR of 7.0% between 2025 and 2032, fueled by the rising deployment of flame-retardant films in components like printed circuit boards (PCBs), capacitors, and wiring.

Halogen-Free Flame Retardant BOPET Films Market Regional Outlook: The Halogen-Free Flame Retardant BOPET Films Market is witnessing pronounced growth across various global regions, with Asia-Pacific at the forefront due to its rapid industrialization and the burgeoning electronics and automotive sectors. This region is expected to achieve a CAGR of 7.5% from 2025 to 2032. North America follows closely, with a 6.0% CAGR projection, spurred by stringent fire safety regulations and an increasing demand for sustainable packaging solutions, particularly in the electronics and automotive industries. Europe is also experiencing robust growth, with a CAGR of 6.8%, driven by regulatory pressures favoring eco-friendly materials and fire-resistant solutions in construction and packaging.

The Middle East & Africa and South America are anticipated to register promising growth rates of 6.3% and 5.2%, respectively, owing to ongoing infrastructure development and rising demand for fire-resistant packaging, particularly in the food and pharmaceutical industries.

Competitive Landscape: The Halogen-Free Flame Retardant BOPET Films Market is marked by the strategic initiatives of leading players such as Toray Industries, Inc. and DuPont de Nemours, Inc., both of whom are making substantial strides to meet the escalating demand for sustainable, fire-resistant materials.

Noteworthy developments in this space include Toray Industries' February 2024 launch of a new halogen-free flame-retardant BOPET film, designed specifically for automotive and electronics applications. This product innovation aligns with the growing regulatory emphasis on environmental sustainability and fire safety, positioning Toray as a leader in this rapidly evolving market.

Similarly, DuPont de Nemours has bolstered its market presence with the November 2023 launch of a next-generation halogen-free flame-retardant film, targeting electronics and packaging applications. Leveraging phosphorus-based flame retardants, this new film offers superior fire safety while meeting rigorous RoHS and REACH standards, thereby strengthening DuPont's position in the highly competitive BOPET market.

Conclusion: In conclusion, the Halogen-Free Flame Retardant BOPET Films Market is poised for significant growth, driven by an increasing appetite for fire-resistant, eco-friendly materials across industries ranging from electronics and automotive to construction and packaging. Regulatory pressures, particularly in North America and Europe, are propelling the demand for halogen-free solutions, making them a sought-after alternative. Asia-Pacific, propelled by rapid industrialization, remains the dominant region, while continuous technological advancements and innovations in flame-retardant compositions are set to further fuel market expansion. With the escalating prioritization of sustainability and fire safety across industries, the market for halogen-free flame-retardant BOPET films is primed for continued growth through 2032 and beyond.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40636-global-halogen-free-flame-retardant-bopet-films-market

Market Segmentation:

By Composition:

Cyclic Olefin Copolymer (COC)

Polyethylene Terephthalate (PET)

Polyethylene Naphthalate (PEN)

Polyethylene Furanoate (PEF)

Polybutylene Succinate (PBS)

By Flame Retardancy:

V-0

V-1

V-2

HB

By Coating:

Polyvinylidene Chloride (PVDC)

Polyethylene (PE)

Polypropylene (PP)

Ethylene Vinyl Alcohol (EVOH)

Silicon Oxide (SiO2)

By Application:

Construction

Automotive

Packaging

Electronics

Aerospace

By Region:

North America

Europe

Asia Pacific

South America

Middle East & Africa

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Halogen-Free BOPET Films#Flame Retardant BOPET Films#BOPET Films Market#Halogen-Free Films#Flame Retardant Films#BOPET Films#Fire Resistant Films#Sustainable BOPET Films#BOPET Film Market Growth#Flame Retardant Materials#Eco-friendly BOPET Films#Global BOPET Films Market#BOPET Film Industry Trends#Flame Retardant Packaging Films#Market for BOPET Films#Halogen-Free Materials#Fire-Resistant Packaging#BOPET Film Applications#Chemical-Free BOPET Films#BOPET Films for Electronics#BOPET Films in Automotive#Renewable BOPET Films

1 note

·

View note

Text

Sketch-Verse Lore:Life on the XXX side & Tier Systems

With the particular quirk and kinky nature of their respective wives or girlfriends and how often they get around with other women, it stands to reason that Krillin, Kirishima and Moxxie would somehow halogen to wind up finding themselves working in the porn industry. But of course the studios to work for her are professional as much as they are erotic in nature and the owners and operators of these establishments have a fond appreciation for the natural talents of their rookie studs, even obliging their need for a little anonymity to protect their identities and prevent from being recognised out on public streets. To say nothing of how much their co-stars just love and look forward to working with them for filming and photoshoots.

From the dragonball verse’s ZigZag studios aka Double Z studios we have Don Juan Sanchez (Krillin), to date the current sole human male star in the anthro occupied roster. Naturally this has seen him build up a steady growing body of work in its newly arisen human male on furry female tag demographic as well as a sizeable fanbase among women. Most chalk this up to the slight resemblance he has to the line of Warrior Monk sex dolls and his modest, humble charisma and debate rages I he would look better without the beard and tattoo (which are temporary). His most notable streak thus far has been the series of shoots he has performed with retired veteran stars who’ve made thir comebacks in a new career renaissance just to have another round with him. Rumours say he’s gotten up to more sexual hijinks off camera than on but nothing has been confirmed or denied….

In the Heo Aca verse, we present ManaWorld Pictures’ Mr.R often referred to by his common character name Red (Kirishima), who Syx herself has come to consider her personal favourite rookie to date and she even has that statement in writing. This modest beefcake has made quite the body of work thanks to his Plus Ultra stamina and his personal drive and dedication on the ideal that a real man never leaves a woman sexually unfullfilled or unsatisfied. His Ikemen vibes have certainly also helped in not only being well built and quite well endowed but also the right blend of cute and handsome and his teddy bear like nature has made for quite good chemistry with some of his co-stars. One can only imagine his age and skill will only increase in age as his career runs on....

In the peculiar Hellverse, we have the Lust ring based Skullfuck Productions' talented rookie imp sensation known only as Mysterious M, an enigmatic demon of sophisticated theatrical taste and culture and an appreciation for the arts. This silver tongued sweetheart has made quite a name for himself with his ever growing body of work seeing him woo many a fine pretty sexy thing in Hell and even the living world and Heaven itself!! This has seen sales of his movies and views on the SFP website hit numbers mathmeticians have never even possibly heard of and that's not changing anytime soon. Many a woman has sent fan letters sharing intimate details they've had fantasizing about this masked imp visting them in their dreams to work his demonic magic on them....which has inspired the scriptwriters much to Mr.Sketch's delight...

Rumours say that Demon Queen Chloe with her vast amount of free time and ultimate omnipotence and a few individuals made up a tier systems of studs & bull on what particular girls really like and want in a man. those who've qualified are all equal in endowment but it’s particularly ranked by emotional maturity . There are 4 tiers in total as follows as well examples of the guys who fall within each.

Tier 1 is the Lovable Every man Himbo: these guys are the every regular men who poses huge cocks and a level of relative maturity but in some way foreign to the Lewd occurrences . These are some who fall in this tier. Jon Herron, Dipper Pines, Izuku Midoriya, and Jaune Arc.

Tier 2 is the Reluctant Bull Moose: These are the guys who are thrusted in the lewd direction by random chance and fate. These are the ones who does it cause it’s the only choice or tricked.

Tier 3 is the Crutch Crotch. These are the emotional support dogs of the endowed hunks and himbos who attracts the laddies with their eagerness to listen and be courteous towards the women who they fuck

Tier 4 is the Trifecta Ratio Casanova: these are the hunks who are all three tiers in a perfect ratio of personality and skill. These of course are Kirishima, Krillin and Moxxie.

#sketchfan#sketchfanda#sketchfan85#kirimina#helluva boss#my hero academia#kirishima eijirou#kirishima

29 notes

·

View notes

Text

0 notes

Text

Thermoplastic Polyurethane Adhesive Market Size, Innovations, Market Growth & Drivers 2032

Global Thermoplastic Polyurethane Adhesive Market Overview The global thermoplastic polyurethane (TPU) adhesive market was valued at about USD 1.3 billion in 2024 and is forecast to reach nearly USD 1.9 billion by 2029, expanding at a compound annual growth rate (CAGR) of roughly 6.5 % over the next five years. Robust demand from automotive lightweighting, high‑performance footwear, flexible electronics, and sustainable packaging is accelerating adoption. OEM preferences for solvent‑free hot‑melt TPU systems, superior elasticity, and excellent low‑temperature bonding further reinforce growth. Regionally, Asia‑Pacific dominates on the back of booming consumer‑goods production and battery‑electric vehicle output, while North America and Europe invest heavily in bio‑based polyurethane chemistries that comply with circular‑economy goals. Global Thermoplastic Polyurethane Adhesive Market Dynamics Drivers — Stringent VOC regulations favor solvent‑less bonding technologies; rising e‑mobility and electronics miniaturization require flexible, vibration‑resistant joints; and the shift toward lightweight composites in transport fuels TPU adhesive uptake.Restraints — Price volatility in MDI/TDI feedstocks, limited large‑scale bio‑based TPU supply, and processing‑temperature sensitivity can hinder penetration in mass‑production lines.Opportunities — Advances in reactive hot‑melt formulations, laser‑activatable grades for smart manufacturing, and recycling‑compatible TPU blends open new revenue streams. Government incentives for green buildings and medical‑grade wearables also widen addressable space.Technology, Regulation & Sustainability — Industry 4.0 dispensing robots, digital rheology monitoring, and UV‑curable TPU hybrids cut cycle times. Global frameworks such as REACH, the European Green Deal, and China’s RoHS 2.0 promote low‑toxicity, halogen‑free chemistries, while life‑cycle analysis (LCA) pushes suppliers to introduce bio‑polyol content and closed‑loop take‑back programs. Download Full PDF Sample Copy of Global Thermoplastic Polyurethane Adhesive Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=491507&utm_source=PR-News&utm_medium=380 Global Thermoplastic Polyurethane Adhesive Market Trends and Innovations Emerging trends include carbon‑negative polyols sourced from captured CO2, nano‑reinforced TPU dispersions delivering 30 % higher shear strength, and 3‑D printable adhesive filaments enabling mass‑customization. Collaborative ventures between chemical majors and smartphone OEMs are driving ultra‑thin, heat‑resistant films for foldable displays. Start‑ups are piloting enzymatically depolymerizable TPU systems that simplify end‑of‑life recycling. In footwear, in‑mold color‑shift adhesives integrate aesthetics with structural bonding, while the packaging sector embraces low‑temperature hot‑melt sticks to minimize energy use. Cloud‑based formulation databases and AI‑driven property prediction shorten development cycles and speed commercialization. Global Thermoplastic Polyurethane Adhesive Market Challenges and Solutions Supply‑chain disruptions—notably in isocyanate logistics—have created lead‑time fluctuations. Diversifying raw‑material sourcing to regional suppliers and boosting on‑site storage cushions volatility. Pricing pressures from commodity adhesive alternatives can be mitigated through value‑added services such as joint durability simulation and application‑specific technical support. Regulatory barriers surrounding residual monomer limits are addressed via ultra‑low‑free‑isocyanate grades and real‑time emissions monitoring. To counter limited recyclability perceptions, manufacturers are deploying thermomechanical debonding techniques that separate TPU layers from substrates without damaging base materials. Global Thermoplastic Polyurethane Adhesive Market Future Outlook Through 2030, the market is expected to maintain a mid‑single‑digit CAGR, propelled by electrified mobility, smart wearable adoption, and aggressive sustainability mandates.

Asia‑Pacific will retain the largest share, yet Latin America and the Middle East are poised for above‑average growth as industrial diversification accelerates. The convergence of bio‑based chemistry, additive manufacturing, and circular‑economy legislation will redefine competitive advantage, favoring suppliers that can deliver high‑performance, low‑carbon bonding solutions. Companies investing in recyclable TPU formulations, AI‑enabled process optimization, and strategic OEM partnerships are likely to capture outsized market share over the next decade. Global Thermoplastic Polyurethane Adhesive Market Competitive Landscape The Global Thermoplastic Polyurethane Adhesive Market competitive landscape is characterized by intense rivalry among key players striving to gain market share through innovation, strategic partnerships, and expansion initiatives. Companies in this market vary from established global leaders to emerging regional firms, all competing on parameters such as product quality, pricing, technology, and customer service. Continuous investments in research and development, along with a focus on sustainability and digital transformation, are common strategies. Mergers and acquisitions further intensify the competition, allowing companies to broaden their portfolios and geographic presence. Market dynamics are influenced by evolving consumer preferences, regulatory frameworks, and technological advancements. Overall, the competitive environment fosters innovation and drives continuous improvement across the Global Thermoplastic Polyurethane Adhesive Market ecosystem. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=491507&utm_source=PR-News&utm_medium=380 Global Thermoplastic Polyurethane Adhesive Market Segmentation Analysis The Global Thermoplastic Polyurethane Adhesive Market segmentation analysis categorizes the market based on key parameters such as product type, application, end-user, and region. This approach helps identify specific consumer needs, preferences, and purchasing behavior across different segments. By analyzing each segment, companies can tailor their strategies to target high-growth areas, optimize resource allocation, and improve customer engagement. Product-based segmentation highlights variations in offerings, while application and end-user segmentation reveal usage patterns across industries or demographics. Regional segmentation uncovers geographical trends and market potential in emerging and developed areas. This comprehensive analysis enables stakeholders to make informed decisions, enhance competitive positioning, and capture new opportunities. Ultimately, segmentation serves as a critical tool for driving focused marketing, innovation, and strategic growth within the Global Thermoplastic Polyurethane Adhesive Market. Global Thermoplastic Polyurethane Adhesive Market, By Type Global Thermoplastic Polyurethane Adhesive Market, By Application Global Thermoplastic Polyurethane Adhesive Market, By End User Global Thermoplastic Polyurethane Adhesive Market, By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/thermoplastic-polyurethane-adhesive-market/ About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies. We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research

methodology, expertise, and years of collective experience to produce informative and accurate research. Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768 Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/japan-dram-market/ https://www.verifiedmarketresearch.com/ko/product/europe-drilling-rig-market/ https://www.verifiedmarketresearch.com/ko/product/europe-ict-market/ https://www.verifiedmarketresearch.com/ko/product/mea-facility-management-market/ https://www.verifiedmarketresearch.com/ko/product/luxembourg-pos-terminals-market/

0 notes

Text

Material Structure and Selection in Rigid-Flex PCBs

Rigid-Flex PCBs combine the stability of rigid boards with the adaptability of flexible circuits. But the key to a successful design lies in material selection and stack-up structure. Choosing the right materials impacts everything from electrical performance and mechanical flexibility to cost and manufacturability.

Below is a breakdown of essential materials used in Rigid-Flex PCBs and considerations for selecting them.

1. Rigid Section Materials

The rigid part of a Rigid-Flex PCB usually serves as the component-mounting area. It uses materials similar to traditional multilayer PCBs.

Common rigid materials:

FR-4 (Standard epoxy-glass laminate) Cost-effective and widely available, suitable for most applications with moderate thermal and electrical requirements.

High-Tg FR-4 Used in designs with higher operating temperatures or lead-free soldering.

Halogen-free FR-4 Chosen for environmental compliance (RoHS, REACH) and flame retardance.

Key properties to consider:

Glass transition temperature (Tg)

Coefficient of thermal expansion (CTE)

Dielectric constant (Dk) and loss tangent (Df)

Thickness tolerance and layer uniformity

2. Flex Section Materials

The flexible part of the PCB must endure bending, folding, and vibration without failure. Flex materials must be thin, strong, and highly resistant to cracking.

Core flex materials:

Polyimide film (PI) The most commonly used dielectric material in flex sections, due to excellent thermal, chemical, and mechanical properties.

Adhesive-based vs adhesiveless polyimide laminates Adhesiveless: Thinner, better dimensional stability, and higher reliability. Adhesive-based: Slightly lower cost, but more prone to delamination under heat or flexing.

Copper types used in flex:

Rolled Annealed (RA) copper High ductility, ideal for repeated bending applications.

Electrodeposited (ED) copper Lower cost, better suited for static flex or one-time folding designs.

3. Coverlay vs Solder Mask

The flexible solder resist layer is typically made from polyimide-based coverlay, not traditional solder mask.

Coverlay: A polyimide film laminated with adhesive, providing insulation and mechanical protection in flex areas.

Flexible solder mask: Can be screen-printed like in rigid boards, but less durable in dynamic bending conditions.

Use coverlay in all bend zones for improved reliability and better protection against cracking or delamination.

4. Stiffener Materials

Stiffeners are added under flex areas to provide mechanical support for connectors or SMT components.

Common stiffener options:

FR-4: Adds thickness and support under connector pads.

Polyimide film: Maintains flexibility while giving local stiffness.

Stainless steel or aluminum: Used when high rigidity is needed in limited space.

Stiffeners are not part of the electrical structure, but must be specified accurately in mechanical drawings.

5. Adhesive Systems

The adhesives used in Rigid-Flex PCBs bond copper to polyimide and help laminate multiple layers together. Adhesive performance directly affects heat resistance, delamination resistance, and bend lifespan.

Adhesives must:

Be compatible with lead-free processing temperatures

Withstand dynamic mechanical stress

Maintain integrity under humidity and thermal cycling

For better thermal and mechanical stability, adhesiveless constructions are preferred in high-reliability or dynamic-flex designs.

6. Material Matching and CTE Compatibility

In Rigid-Flex designs, mismatched materials can lead to mechanical stress, warping, or cracking during lamination or soldering.

Tips for compatibility:

Use materials with similar CTEs across rigid and flex zones

Avoid combining low-Tg and high-Tg materials in one board

Choose laminates tested for multilayer Rigid-Flex constructions

Final Thoughts

The materials chosen for a Rigid-Flex PCB form the backbone of the entire structure — influencing everything from mechanical durability to signal integrity and cost.

A well-designed material stack-up:

Supports complex bending and 3D assembly

Ensures thermal and electrical stability

Reduces risk of failure in critical environments

Enables long-term reliability even under stress

0 notes

Text

Copper Clad Flexible Laminate Market 2025-2032

MARKET INSIGHTS

The global Copper Clad Flexible Laminate Market size was valued at US$ 1.89 billion in 2024 and is projected to reach US$ 3.12 billion by 2032, at a CAGR of 7.5% during the forecast period 2025-2032.

Copper Clad Flexible Laminates (CCFL) are specialized composite materials consisting of a flexible polymer film laminated with thin copper foil. These materials enable three-dimensional wiring configurations while maintaining excellent electrical conductivity and mechanical flexibility. Key product variants include FR4 Board, Halogen-free Board, and Special Board types, each serving distinct application requirements in electronics manufacturing.

The market growth is propelled by increasing demand for lightweight, compact electronics and the proliferation of flexible printed circuits in consumer devices. The FR4 Board segment dominates with 42% market share in 2024, driven by its cost-effectiveness in standard applications. However, halogen-free variants are gaining traction due to environmental regulations, projected to grow at 9.1% CAGR through 2032. Major manufacturers like Kingboard Laminates Group and Panasonic are expanding production capacities in Asia to meet rising demand from automotive and 5G infrastructure sectors.

Download Your Free Copy of the Sample Report-https://semiconductorinsight.com/download-sample-report/?product_id=97530

Key Industry Players

Market Leaders Expand Production Capacities to Capture Growing Demand for Flexible Electronics

The global copper clad flexible laminate (CCFL) market features a competitive environment where established manufacturers compete through technological innovation and strategic expansions. Kingboard Laminates Group currently dominates the market, with its extensive portfolio spanning FR4, halogen-free, and high-frequency laminates serving diverse industries like automotive electronics and 5G infrastructure. The company’s market leadership stems from its vertically integrated supply chain and strong foothold in Asia-Pacific.

Meanwhile, DuPont and Panasonic have maintained significant market shares through their advanced material science capabilities. DuPont’s Pyralux® flexible circuit materials continue gaining traction in aerospace applications, while Panasonic’s Megtron® series remains popular for high-speed communication devices. Both companies recently announced expansions in their Asian manufacturing facilities to meet growing regional demand.

The market also sees intense competition from specialized manufacturers like Rogers Corporation and Isola Group, who focus on high-performance solutions for mission-critical applications. Rogers Corporation’s recent acquisition of a PCB materials company strengthened its position in the automotive radar segment, demonstrating how strategic moves are reshaping the competitive dynamics.

Chinese manufacturers including SYTECH and Nanya New Material Technology are rapidly gaining ground by offering cost-competitive alternatives without compromising quality standards. Their growth reflects the broader industry shift toward localization of supply chains in the electronics manufacturing sector.

List of Key Copper Clad Flexible Laminate Companies

Kingboard Laminates Group (Hong Kong)

DuPont (U.S.)

SYTECH (China)

Panasonic (Japan)

Nan Ya Plastic (Taiwan)

EMC (U.S.)

ITEQ (Taiwan)

DOOSAN (South Korea)

TUC (Taiwan)

GDM International Technology Ltd. (China)

Hitachi Chemical (Japan)

Isola Group (U.S.)

Nanya New Material Technology Co., Ltd. (China)

Rogers Corporation (U.S.)

Segment Analysis:

By Type

FR4 Board Segment Dominates Due to High Demand in Electronics Manufacturing

The market is segmented based on type into:

FR4 Board

Subtypes: Standard FR4, High Tg FR4, Halogen-free FR4

Halogen-free Board

Special Board

Subtypes: High-frequency laminates, High-speed laminates, Others

Others

By Application

Consumer Electronics Leads Market Share Due to Proliferation of Smart Devices

The market is segmented based on application into:

Communication

Consumer Electronics

Automotive Electronics

Others

Click to Access Your Free Sample Report-https://semiconductorinsight.com/download-sample-report/?product_id=97530

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Copper Clad Flexible Laminate Market?

-> The global Copper Clad Flexible Laminate Market size was valued at US$ 1.89 billion in 2024 and is projected to reach US$ 3.12 billion by 2032, at a CAGR of 7.5% during the forecast period 2025-2032.

Which key companies operate in this market?

-> Key players include Kingboard Laminates Group, Dupont, Panasonic, Nan Ya Plastic, Rogers Corporation, ITEQ, and Mitsubishi, with the top 5 holding 45% market share.

What are the key growth drivers?

-> Growth is driven by 5G infrastructure rollout (projected 1.2 million base stations by 2025), automotive electronics (15% annual growth), and flexible display adoption (28% CAGR).

Which region dominates the market?

-> Asia-Pacific accounts for 62% of global demand, with China alone representing 38% market share by 2032.

What are the emerging trends?

-> Emerging trends include ultra-thin flexible laminates (under 25μm), high-frequency materials for 5G/6G, and sustainable halogen-free alternatives.

Related URL

0 notes

Text

Why does touching the bulbs from headlights damage them but most other light bulbs are fine to touch?

Touching a car headlight bulb (especially a halogen bulb) can cause damage, while ordinary household incandescent or LED bulbs are usually safe to touch, which is mainly determined by the material properties, operating temperature and environmental design differences. Here is a detailed explanation:

1. Core reason: bulb surface contamination and high temperature reaction

Special features of halogen bulbs:

Car halogen bulbs operate at high temperatures (the surface can reach 250–600°C), and their quartz glass lampshades are designed to allow ultraviolet light to penetrate to improve luminous efficiency.

Grease carbonization: Finger contact will leave grease (containing sodium ions and organic acids), which will carbonize into black spots at high temperatures, causing local overheating of the glass (temperature difference stress) and rupture.

Quartz glass weaknesses: Although quartz glass (SiO₂ amorphous) is resistant to high temperatures, it has poor anti-pollution ability, and pollutants will cause microcracks to expand.

Ordinary incandescent lamp:

The operating temperature is low (about 80–120°C), the glass material is soda-lime glass (containing Na₂O·CaO·SiO₂), it is not sensitive to oil and grease, and pollutants will evaporate slowly at low temperature.

2. Comparison of materials and design Bulb type Lampshade material Maximum temperature Sensitivity to contaminants Touchability Automotive halogen bulbs Quartz glass 600°C Very high (carbonization risk) ❌ Do not touch Household incandescent lamps Soda-lime glass 120°C Low ✅ Safe LED headlights Polycarbonate/aluminum housing 60–80°C None ✅ Safe HID xenon lamps Quartz glass (coated) 800°C Medium ⚠️ Wear gloves

3. Physical mechanisms: thermal stress and light efficiency degradation

Thermal stress cracking (halogen bulbs):

$$ \Delta T = \frac{Q \cdot t}{k \cdot A} $$ (Q=heat, k=thermal conductivity, A=surface area, t=time) Grease carbonization area (k value decreases) causes a sharp increase in local ΔT, which exceeds the fracture toughness of quartz glass (~0.7 MPa√m).

Decreased light efficiency:

Grease spots absorb light, the halogen cycle (tungsten regeneration reaction) is blocked, and the brightness decreases by 10–30%.

4. Correct operation and alternative solutions

Rules to follow when replacing halogen bulbs:

Wear fiber-free gloves (such as nitrile gloves) or wrap the bulb with a clean cloth.

If accidentally touched, wipe the surface with isopropyl alcohol (IPA) to thoroughly remove grease.

Upgrade options:

LED bulbs: solid-state light emission, no glass lampshade, vibration-resistant and touch-resistant.

HID xenon lamps: gloves are required for installation, but some modern models have anti-fouling coatings.

5. Exceptions and scientific trivia

Infrared halogen lamps: Some industrial halogen lamps are allowed to be touched because they are coated with a titanium dioxide (TiO₂) anti-fouling layer.

Spacecraft halogen lamps: NASA mixes platinum group metals into satellite lamps to sublimate pollutants in a vacuum and avoid carbonization.

When the surface of LED lamp beads is contaminated with oil, it will cause the following multi-dimensional effects, which need to be comprehensively analyzed based on the composition of the oil, contact time and environmental conditions:

1. Quantum-level attenuation of optical performance Fresnel loss multiplication The oil film (refractive index n≈1.4-1.5) forms a refractive index gradient at the interface of the LED silicone encapsulation layer (n=1.53), resulting incascade total internal reflectionwhen photons escape. Experimental data show that a 0.1mm thick edible oil film can reduce the transmittance of 450nm blue light by 22-37% (ASTM E903 test). Color coordinate shift

Conjugated double bond compounds in oil stains (such as acrylamide in frying oil) selectively absorb short-wavelength light, causing the CIE 1931 coordinates of the LED to shift to the yellow zone by Δx=0.015, causing the color rendering index CRI to drop from 80 to 65. 2. Thermodynamic collapse critical point

Nanoscale thermal barrier effect

The oil film forms a barrier layer with a thermal conductivity of only 0.15 W/m·K between the LED chip and the air (237 W/m·K for aluminum substrate), causing the junction temperature Tj to rise at a rate of 8-12°C/μm. When Tj>150°C, carrier leakage occurs in the InGaN quantum well, and the light efficiency drops sharply. Thermal stress cracking The oil stains are carbonized by heat to produce micro-area expansion stress, which causes the crack propagation rate in the silicone encapsulation layer to reach 1.2×10⁻⁶ m/cycle (Paris formula), and eventually causes moisture to invade the chip bonding point. Third, electrochemical corrosion path Ion migration dendrites Edible oil containing Na⁺ (such as vegetable oil containing Na 50-200ppm) forms an electrolyte film at 85% humidity, which triggers electrochemical migration of the Ag reflective layer. The dendrite growth rate reaches 3μm/h, causing LED micro-short circuits. Sulfidation corrosion Sulfur-containing amino acids (such as cysteine in frying oil) react with Cu wires to generate Cu₂S, and the resistivity soars from 1.7×10⁻⁸ Ω·m to 10⁻⁴ Ω·m, causing local overheating and melting. Fourth, cleaning scheme and material science countermeasures Supercritical CO₂ cleaning Under the conditions of 30MPa and 50°C, supercritical CO₂ (density 0.6g/cm³) can dissolve non-polar oil stains, and the contact angle with LED silicone is ≤5°, without residue. However, the equipment cost is high and suitable for industrial-grade maintenance. Plasma activation treatment Use 13.56MHz radio frequency plasma (Ar/O₂=4:1) to bombard the surface of oil stains, and the carboxylic acid groups are oxidized to CO₂, the surface energy is increased to 72mN/m, and the light extraction efficiency is restored to 98%. Oleophobic nano-coating Coated with perfluoropolyether (PFPE) self-assembled film, the surface energy is reduced to 12mN/m, the oil stain contact angle is >150°, and self-cleaning (lotus effect) is achieved. V. Failure time prediction model According to the oil thickness d (μm), salt content C (ppm), humidity RH (%), the LED life attenuation coefficient λ can be expressed as:

As shown below

When λ>1, MTTF (mean time to failure) is shortened from 50,000 hours to <5,000 hours.

Operation Guide:

Mild oil pollution: Use a microfiber cloth dipped in anhydrous ethanol (water content <0.5%) to wipe in a spiral. Acetone is prohibited (it will swell silica gel).

Severe pollution: After disassembly, place it in a 60°C vacuum oven (-0.1MPa) for 2 hours to thermally decompose and volatilize the oil.

Preventive measures: Magnetron sputtering 10nm thick Al₂O₇ barrier film on the surface of the LED lens to prevent oil penetration.

Note: Carbonized oil pollution needs to be ablated with Nd:YAG laser (wavelength 1064nm, pulse width 10ns) to avoid mechanical scratches and damage to the anti-reflection film.

Summary: Automotive halogen bulbs are taboo to touch due to high temperature and quartz glass characteristics, while household incandescent lamps and LEDs (with housings or protective materials) can be safely operated due to material and temperature differences. Understanding these principles can avoid bulb damage and extend its service life.

#led lights#car lights#led car light#youtube#led headlights#led auto light#led light#led headlight bulbs#ledlighting#young artist#lamp#lighting#lights#led light bulbs#american cars#cars#car culture#classic cars#car#suv#vehicle#automobile#headlight#headlight bulb#headlamp#halogen#xenon#car lamp

1 note

·

View note

Text

Comparing LED vs. Halogen Options in Light Equipment on Rent

When planners look for Light Equipment on Rent, the discussion inevitably turns to LED and halogen fixtures. Both technologies illuminate event spaces, film sets, fashion ramps, and corporate expos across Chennai, yet they differ in energy draw, color accuracy, fixture weight, and long‑term economics. Understanding those differences helps event professionals book the right inventory—avoiding surplus costs while delivering an unforgettable visual experience.

1. Energy Efficiency and Power Logistics

A single 100 W LED PAR can produce the same luminous output as a 500 W halogen PAR can. Because rental venues often impose power limits, shaving 80 % off consumption frees amperage for audio consoles or high‑definition LED walls. Less current also means lighter‑gauge cabling, smaller generators, and reduced diesel rentals—hidden savings that matter when you invoice clients.

From a sustainability angle, LEDs convert most of their draw into visible light, whereas halogens waste roughly 90 % as radiant heat. Green‑conscious brands increasingly ask production houses to document their carbon footprint; specifying LED fixtures for Light Equipment on Rent becomes an automatic talking point in RFPs.

2. Heat Management and Audience Comfort

Halogen filaments reach 250 °C in seconds. On a packed wedding mandapam or conference stage, that heat radiates toward performers, wilts floral décor, and hikes HVAC bills. LEDs run cool to the touch, allowing truss technicians to reposition heads even after hours of use—minimising downtime during tight turnarounds.

Cool operation is especially critical for fashion shows where models stand inches from back‑light bars, or for product launches featuring delicate cosmetics that cannot melt under focus spots. When budget and ambience both matter, LED wins the thermal debate hands‑down.

3. Color Quality and Artistic Control

Halogen’s natural warm output (≈ 3200 K) flatters skin tones and wood finishes, which explains its enduring presence in theatre. Designers often dim halogen fixtures for romantic amber washes; tungsten filaments maintain consistent color even at 40 % intensity.

LED engines, by contrast, mix discrete red, green, blue, amber, white, and UV diodes to create nearly any hue without external gels. Modern RGBAL fixtures now exceed 90 CRI, rivaling halogen on fidelity while offering instantaneous color bumps for DJ drops or award‑night stings. In rental scenarios where one rig must cover gala dinners, keynote sessions, and DJ after‑parties, LED’s versatility reduces fixture count and truck space—key metrics for Light Equipment on Rent providers.

4. Rigging Weight and Setup Speed

Halogen PAR cans are metal workhorses but tip the scales at 3 – 4 kg each, plus the bulkier dimmer racks they rely on. An equivalent LED PAR weighs 1.5 – 2 kg and runs directly from DMX‑addressable drivers. Lighter weight lessens the load on ballrooms with limited rigging points and speeds up load‑in, translating to lower labor hours—a direct benefit reflected on the client’s quote for Light Equipment on Rent.

5. Total Cost of Ownership (TCO) in Rental Context

Purchasing inventory is the rental firm’s capital expenditure; clients essentially fund depreciation through daily hire charges. A halogen lamp lasts 75–100 hours; a single three‑day conference could blow a bulb, forcing replacement stock. LED source life exceeds 25,000 hours, so rental houses spread the purchase cost across hundreds of shows, allowing competitive rental rates without margin erosion.

For the client, that translates to fewer consumable surcharges and reduced risk of mid‑show failures—a selling point every event company leverages when pitching cost‑conscious procurement teams.

6. Use‑Case Matrix: When Halogen Still Shines

Application Recommended Source Rationale Classical dance recitals Halogen Rich warm spectrum, flattering for skin and silk sarees Budget‑limited village fairs Halogen Low upfront rental price, simple dimmer control High‑end corporate galas LED Energy limits, color branding, silent operation Outdoor concerts LED Weather‑sealed IP65 fixtures, low power from gensets

Even with LED dominance, seasoned lighting designers keep halogen profiles in their design palette—for nostalgia or specific artistic warmth. The key is matching the source to the story you want the stage to tell and balancing that choice with the logistical realities of Light Equipment on Rent.

7. Emerging Trends Influencing Rental Decisions

Hybrid fixtures combining tungsten and LED chips allow designers to cross‑fade between classic warmth and saturated color looks, giving rental catalogues a flexible, one‑SKU solution.

Wireless DMX and battery‑powered uplights shrink setup times for boutique venues where cable runs are visually intrusive.

Cloud‑based fixture monitoring lets rental crews track remaining lamp hours and proactively service gear, reducing on‑site failures. Providers who adopt such tech will own the premium market for Light Equipment on Rent in 2025 and beyond.

Conclusion

Choosing between LED and halogen in Light Equipment on Rent isn’t a one‑size‑fits‑all decision; it’s a strategic balance of energy efficiency, heat output, color requirements, rigging logistics, and TCO. Savvy planners collaborate with an experienced event management company in Chennai that stocks both technologies and knows when to deploy each.

That’s where G Productions excels. With an extensive in‑house inventory of cutting‑edge LED fixtures and meticulously maintained halogen classics, the team crafts lighting landscapes that elevate concerts, weddings, and corporate spectacles alike—all while safeguarding budgets and sustainability goals. By entrusting your next show to G Productions, you gain a partner whose commitment to technical quality, creative vision, and on‑time delivery sets the benchmark for the industry.

0 notes

Text

Top 10 Advantages of PVDF Coated Aluminum Panels

In the modern day, the PVDF coatings have been highly used for the non-reactive and pure thermoplastic fluoropolymer. The Polyvinylidene Fluoride coating is added with several benefits, such as low thermal conductivity. It is also known for its exceptional wear and abrasion resistance.

What are PVDF coatings?

PVDF coating is the organic coating on the steel and aluminum panels, which offers excellent color retention. These also provide a better range of corrosion resistance as they are made with 70% fluorocarbon resin. PVDF coating is also made using 30% Acrylic resin along with a special weathering pigment.

Top 10 Advantages of PVDF-coated Aluminum Panels:

Heat resistance:

PVDF coated aluminum panels would be retaining the strength even at the temperature of 280°F. PVDF is high enough to withstand the high-temp sanitation processes and they are designed for sterilizing the surface. It allows PVDF to be used for varied applications and even melts with other materials.

2. Chemical resistance:

PVDF coating is also highly resistant to acids and alkalis. Normally, the acids and alkalis are not typically equal and ensure in providing resistance. PVDF is resistant to most acids, organic solvents, and even bases. These are also resistant to the other halogen compounds.

3. Tensile strength:

PVDF also involves with tensile strength of about 50 MPa or 7,251 psi. It would be an efficient option for making materials completely stronger when compared to other fluoropolymers. Polypropylene especially has a tensile strength of about 33 MPa or 4,800 psi.

4. Surface hardness:

PVDF coated aluminum panels also become highly harness on surface with rated 100 on the Rockwell Hardness “R” scale. It also extensively enables materials to be added with semi-rigid coatings. These are slightly harder when compared to the polypropylene. It would be definitely making aluminum panels flexible to absorb impacts.

5. Ultraviolet light resistance:

PVDF coated aluminum panels also involved with Ultraviolet Light Resistance and these are suitable for withstanding even with higher UV radiation. It would be making useful for the coating as basket for storing outdoor areas.

6. Gloss range:

Normally, the Gloss range can be called the level of a paint finish in a glossy manner. For example, Metallic coatings are also available with a range of gloss options. PVDF formulations are also available with the standard gloss level.

7. Color retention:

The PVDF coating involves with Inorganic pigments which are combined with quality resins. These would be determining color, aesthetic qualities and durability of finished coatings. Normally, the Pigments will be the key component on the metal coatings. These would be creating colour imaginable based on requirements.

8. Weather resistance:

PVDF coating on the aluminum panels contains 70% fluorocarbon resin. These also involve with larger numbers of F-C bonds and they are determined with awesome stability. These also involves with excellent resistance to weathering based on UV, temperature or moisture.

9. Coating adhesion quality:

The Film integrity, as well as coating adhesion quality, is maintained to the highest for PVDF-coated aluminum panels. PVDF coatings also have an erosion rate or amount of time for the coating to degrade. These also involves relatively lower erosion rate of PVDF coatings which acts as amazing design life.

10. Maintenance-free and easy cleaning:

PVDF coating surface is completely Maintenance-free as surface dust can be easily cleaned. The maximum water absorption rate will be 5% as well as minimum coefficient friction will be 0.15 to 0.17. These do not adhere to dirt or oil.

Conclusion

PVDF involves the fluorocarbon resin, which acts as the main film-forming material. It is an ideal option for protective coating on steel, aluminum as well as other metal building panels. PVDF also requires the Kynar coating as chemical processing equipment, and this does not affect the coating.

0 notes

Text

1 note

·

View note

Text

Flexible Packaging Market by Regions, Type & Applications During 2024-2030

Flexible Packaging Industry Overview

The global flexible packaging market size was estimated at USD 270.96 billion in 2023 and is expected to expand at a CAGR of 4.8% from 2024 to 2030. Increasing consumption of flexible packaging products in medical and pharmaceutical sectors is driving their demand. These products offer various advantages, such as container variety, need for less raw materials, ease of disposal, and lightweight nature, which are expected to fuel their demand over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Flexible Packaging Market

According to the Flexible Packaging Association, nearly 34.7 million tons of all produced food is sent to landfills annually. Food waste generates 27.0 million tons of carbon dioxide. In addition, there are other indirect effects of food production on the environment, which include the greenhouse gases generated from cattle breeding, farm machinery, vehicles that transport food, and nutrient runoff from fertilizers that often lead to water pollution.

Extending food shelf life is necessary to reduce the amount of food waste dumped in landfills. Oxygen and moisture affect the freshness of food products, thereby rendering them unsafe for consumption due to mold formation on food products. The shelf life of food products depends on factors such as storage conditions, packaging material, and exposure to microorganisms, oxygen, light, and moisture.

The flexible packaging consists of plastic films with high barrier properties. The high-barrier properties efficiently block the transmission of moisture, light, and oxygen from contacting sensitive foods. Furthermore, the reseal closure products featured by flexible packaging allow users to securely close the bags or pouches, ensuring the freshness of the packaged food products over several uses.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global phthalic anhydride market size was valued at USD 4.52 billion in 2023 and is projected to grow at a CAGR of 3.8% from 2024 to 2030. This growth is driven by significant industrial chemicals used as starting materials for manufacturing various chemicals and polymers.

• The global low smoke halogen free flame retardant polypropylene market size was valued at USD 637.1 million in 2023 and is projected to grow at a CAGR of 9.5% from 2024 to 2030. The market growth is attributed to the increased adoption of low-smoking halogen-free flame retardant polypropylene due to its low-smoking emission and environment-favoring properties.

Flexible Packaging Market Segmentation

Grand View Research has segmented the global flexible packaging market report based on material, product, application, and region

Flexible Packaging Material Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • Plastics o Polyethylene (PE) o Polypropylene (PP) o Polyamide (PA) o Polyvinyl Chloride (PVC) o Polystyrene (PS) o Others • Paper • Metal • Bioplastics

Flexible Packaging Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • Bags • Pouches o Retort Pouches o Refill Pouches • Rollstock • Films & Wraps • Others

Flexible Packaging Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • Food • Beverages • Pharmaceutical & Healthcare • Personal Care & Cosmetics • Others

Flexible Packaging Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030) • North America o US o Canada o Mexico • Europe o Germany o UK o France o Italy o Spain • Asia Pacific o China o India o Japan o South Korea o Australia o Indonesia o Malaysia o Philippines o Thailand o Vietnam o Myanmar • Central & South America o Brazil o Argentina • Middle East & Africa o Saudi Arabia o UAE o South Africa

Order a free sample PDF of the Flexible Packaging Market Intelligence Study, published by Grand View Research.

Key Companies profiled: • Amcor plc • Mondi Group • Huhtamaki Flexible Packaging • Sonoco Products Company • Sealed Air • DS Smith • Berry Global • Constantia Flexibles • Bemis Manufacturing Company • UkrMetal • ProAmpac • Wipak Group • FlexPak Services • Transcontinental Inc. • Coveris Holdings • American Packaging Corporation • InterFlex Group • FLEX-PACK ENGINEERING, INC. • Innovia Films • Cosmo Films • Novolex • Sigma Plastics Group • Graphic Packaging International, LLC • Bischof+Klein SE & Co. KG • Südpack

Recent Developments

• In May 2024, Amcor and AVON both combinedly launch the AmPrima Plus refill pouch for the AVON Little Black Dress classic shower gels in China. The recycle-ready packaging will result in an 83% reduction in carbon footprint, and 88% and 79% reduction in water consumption and renewable energy respectively when it's recycled.

• In August 2023, Amcor acquired Phoenix Flexibles, expanding its capacity in Indian market. Phoenix Flexibles is situated in Gujarat, India, and generates revenue of approximately USD 20 Mn per year from the sale of flexible packaging for food, home care and personal care applications. The acquisition also adds advanced film technology, enabling local production of a broader range of more sustainable packaging solutions, and brings capabilities allowing Amcor to expand its product offering in attractive high-value segments.

• In February 2023, Sealed Air acquired Liquibox for a purchase price of USD 1.15 Bn on a cash and debt-free basis. Liquibox is a pioneer, innovator and manufacturer of Bag-in-Box sustainable fluids & liquids packaging and dispensing solutions for fresh food, beverage, consumer goods and industrial end-markets.

0 notes

Text

White Shirt

HND 2 2020 – 21

Health and safety in the studio.

STUDIO CHECKLIST: Health and safety in the studio due to covid 19

Please refer to this before and after all shoots

Activity: White Shirts

Does this activity require the use of a photographic studio?

Y

Are you free of all symptoms attributed to covid – 19?

Y

Are you wearing a face mask? (unless exempt)

Y

Are you able to maintain a safe social distance of 2m?

Y

Have you made sure it is only you and your studio partner that are in your studio space?

Y

Have you access to hand sanitizer?

Y

Is your equipment clean?

Y

If borrowing or lending equipment have you used hand sanitizer before and after use?

Y

If working with studio equipment have you cleaned the work area and kit before and after use?

Y

Have you read the most recent government and college guidelines on social distancing?

Y

Have you effectively pre planned your shoot?

50

50

I could have planned it more effectively a lot of time was lost at the beginning of the day.

Have you effectively planned your time in the studio, to make the most of your studio day?

As above

NWhite balance

Find a diagram that explains colour temperature, in relation to photography

https://medium.com/the-coffeelicious/a-photographers-guide-to-color-temperature-6bbc882d1524

Sourced online 17.09.2020

Explain the difference between colour correction and colour grading.

Colour correction is when an adjustment is made to an image to compensate for the colour cast caused by the light, either natural or man-made and to make the image look as natural as possible. This gives you a neutral starting point for any editing.

Lights such as candles, halogen or studio lights emanate a warm light which usually produces a red or yellow glow. Lights such as strong bright winter days, halogen lights and “daylight strip lights cause a blue, colder, colour cast.

These can be corrected in camera by adjusting the white balance, or post production during editing. One of the simplest was to correct postproduction is by taking a test shot in the same lighting of a piece of white card or paper, or to use a colour passport and shoot the neutral 18% Grey.

Colour grading on the other hand is more about the feel of the picture and can be used to take a themed approach to images. Both photographers and cinematographers take this approach to create strong images.

Obvious examples include Wes Anderson’s “The Grand Budapest Hotel” with his stylistic Art Nouveau colour palette. Pedro Almodóvar’s “Pain and Glory” with his characters carrying a colour board that is specifically theirs throughout the film, or, Tarantino’s “Once Upon a Time in Hollywood” with its vintage 1960’s Colombia Pictures colours permeating the entire movie.

Once Upon a Time in Hollywood – Quintin Tarantino

The Grand Budapest Hotel – Wes Anderson

https://medium.com/the-coffeelicious/a-photographers-guide-to-color-temperature-6bbc882d1524

Sourced online 17.09.2020

Explain or show diagram of how you correct white balance using your camera.

Sourced from The Olympus E-M1X user manual, pages 207,208.

Your own shoot.

Explain your editing workflow to correct colour casts.

After importing to Adobe Bridge, I did a batch rename and added some info to the metadata.

Once I had reduced the numbers down a bit, I was able to take a little time and look through each one in a bit more detail.

I then went into review and did an initial rating of the shots.

This one for example looked fine at first glance, but the models spectacle lens correction made it look like there was a little chunk of face missing so I went through them and discarded a few.

I was then able to adjust the slightly yellow colour cast using the adjustment sliders on the right-hand side. Once I had adjusted the white to my liking, I Synched my images and applied this to all of them before going on to individually optimising each of my final shots.

This left me with a selection of 19 to work with.

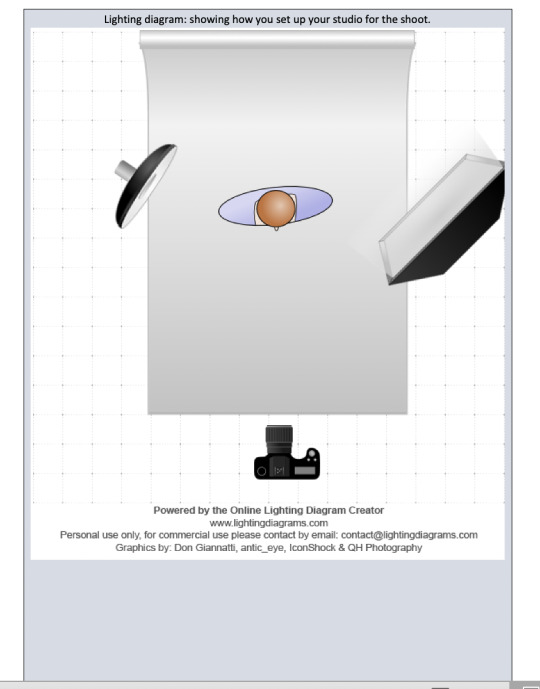

Lighting diagram: showing how you set up your studio for the shoot.

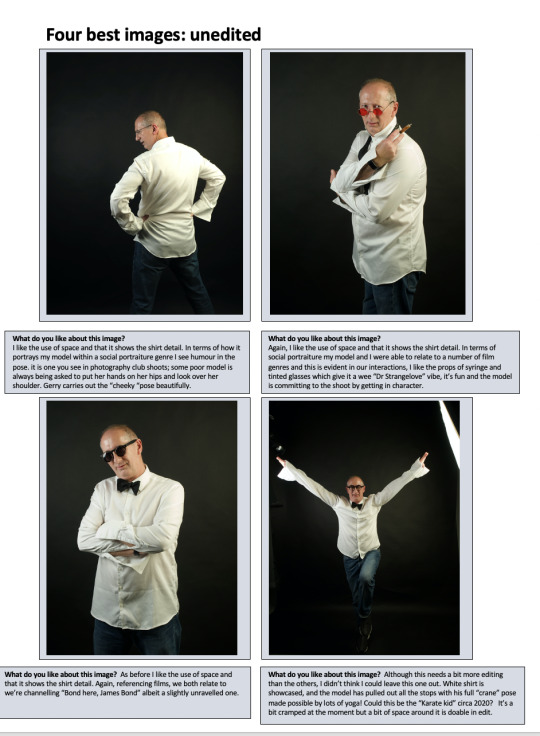

Four best images: unedited

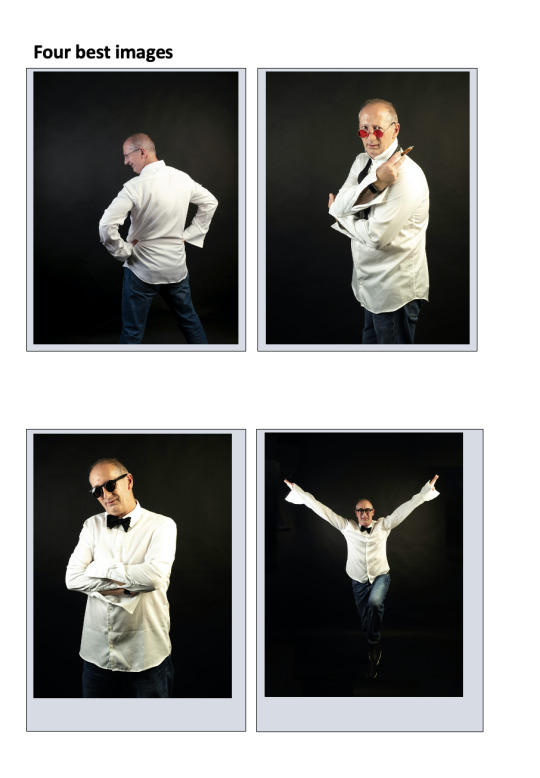

Four best images

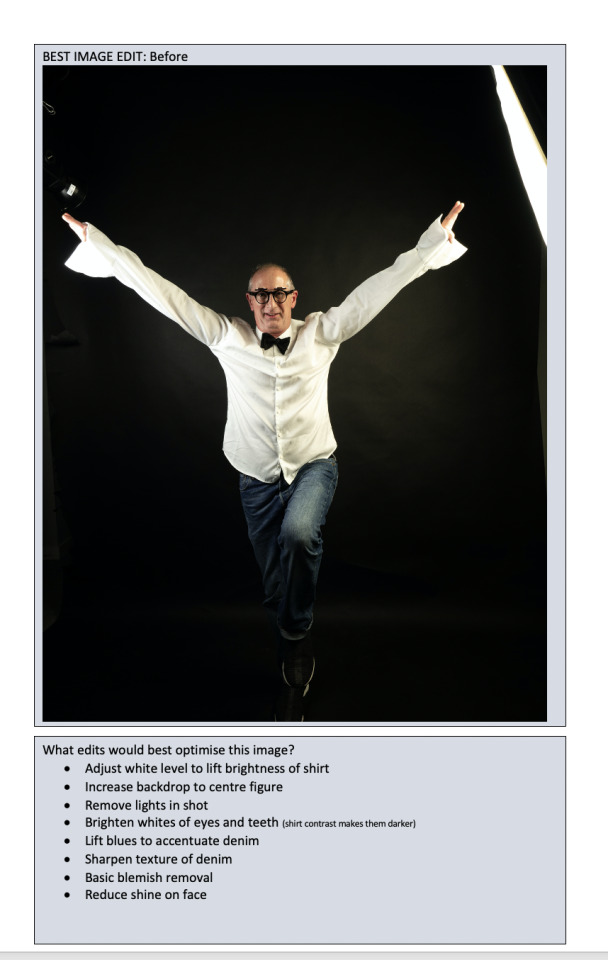

BEST IMAGE EDIT: Before

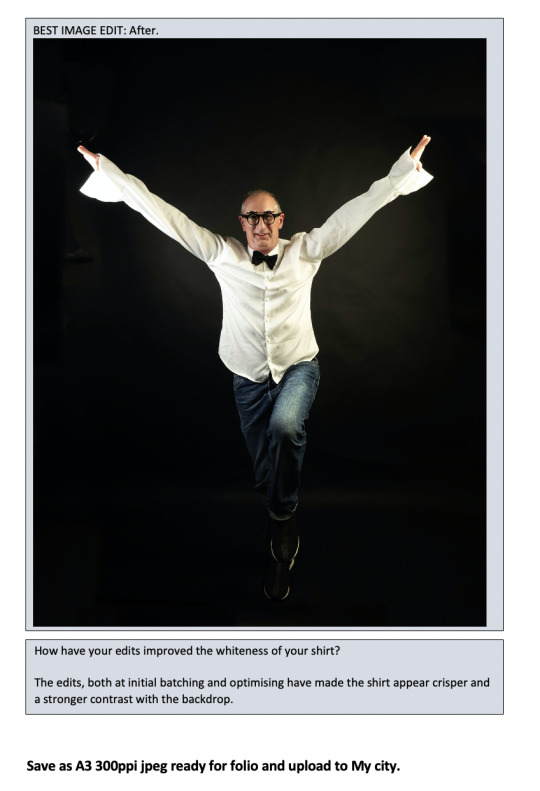

How have your edits improved the whiteness of your shirt?

The edits, both at initial batching and optimising have made the shirt appear crisper and a stronger contrast with the backdrop.

What edits would best optimise this image?

· Adjust white level to lift brightness of shirt

· Increase backdrop to centre figure

· Remove lights in shot

· Brighten whites of eyes and teeth (shirt contrast makes them darker)

· Lift blues to accentuate denim

· Sharpen texture of denim

· Basic blemish removal

· Reduce shine on face

Save as A3 300ppi jpeg ready for folio and upload to My city.

1 note

·

View note

Photo

Lattice anchoring: A neoteric approach to phase stabilization

A group of researchers at the University of Toronto have recently come up with a very successful approach to stabilize solution processed semiconductors. These types of semiconductors have several advantages over other semiconductors (including the ease of processing, scalable fabrication, and compatibility with flexible substrates) that allow for a strong argument that they might be the next generation of optoelectronic materials. However, in spite of their steadily increasing performance in sensing, light emission, and photovoltaic applications, their stability is still a concern and commercial applications are few and far between.

Two of the most common solution processed ceramic semiconductor materials are colloidal quantum dots (CQDs) and perovskites, but past approaches to stabilize these materials (by doping, or adding ligands) have not always been satisfactory. Perovskite materials in particular have near room temperature phase transitions that alter their properties, while CQDs are prone to oxidation. The University of Toronto researchers have hypothesized that these phase transitions can instead be controlled by incorporating CQD inclusions into the crystal lattice of the perovskite materials. The lattice match between the two resulting phases would obstruct lattice rearrangement, granting stability.

The cubic, alpha-phase of perovskites (specifically CsPbX3 wherein X is a halogen) is the phase which has a bandgap most suitable for solar cells, and its stability is dependent upon two parameters:

First, the Br to I ratio. This ratio controls the degree of mismatch within the lattice. Minimal mismatch creates strain free grains, which are more energetically favorable.

Second, the CQD concentration. CQD surfaces act as defect centers, and an increasing concentration leads to a decrease in the lifetime of the material. However, when the dot-to-dot distance is small enough to keep the strain energy below the formation energy of dislocations, stability is increased.

To give an example, ambient condition stability of CsPbBrI2 is enhanced from three days to over six months by the incorporation of 13 volume percent CQDs. Incorporating the CQDs in a matrix also raises the oxidation temperature to over 100 C, as compared to 40 C in matrix free CQDs.

Overall, the higher stability leads to better photoluminescent and photovoltaic properties. Such films sustain 90% of their initial photoluminescence after annealing and generate higher current densities. The success of this approach lays the foundation for future work in phase stabilization in more diverse systems through lattice anchoring.

Source/Further Reading. More on solution processed semiconductors.

Written by: @deepesttheoristlady; Edited by this blog.

#Materials Science#Science#Semiconductors#Colloidal quantum dots#Quantum dots#Colloids#Perovskites#Crystal structure

10 notes

·

View notes

Text

Operating shadowless lamp main performance requirements

1.Sufficient illumination.

The shadowless lamp's illumination has reached more than 150,000 LUX, close to the brightness under sunny days in summer.The actual illumination is generally appropriate to 40,000 ~ 100,000 LUX, too bright will affect the vision.While providing sufficient illumination, the beam should be avoided to produce glare on the surgical instrument.Glare affects vision and vision, easy to cause eye fatigue.For operations with less favorable conditions to surgeons, the illumination of shadowless lamps should not be too different from that of the operating room. Some standards stipulate that the overall illumination should be less than 1/10 of the local illumination.The overall illumination of the operating room should be more than 1000LUX.

2. High opacity during surgery.

HOECARE Shadowless lamp is an important feature and performance indicators.Any shadow formed in the operating field will hinder the doctor's observation, judgment and operation.In addition to providing sufficient illumination, the shadowless lamp should also have a high shadowless degree to ensure the luminosity of the surgical field surface and deep tissue.Shadowless degree test, the use of a 50 x75mm black garden tube, is 1 meter above the disposal of the light source, the bottom a photometer, the measured light ratio shall not be less than 10%, the actual use of the product is in the 50-100 cm in diameter of chimney device several or a dozen into circular uniform arrangement of the globe, the globe bulb and reflectors, the special light beam reflected from a different location through the filter to the intersection point, to provide a balanced, smooth and no shadow of bright light.

3 low temperature.

The improvement of illumination will inevitably lead to the increase of the temperature of the lamp body and the beam, which will affect the temperature of the doctor's head and the tissue of the surgical site, thus affecting the efficiency and quality of surgery.Therefore, the operating room control within 10 ℃ temperature requirements.The main method adopted is to make the visible light generated by the light source pass through the reflector which can filter 70% of the infrared ray. The remaining infrared ray is mostly isolated and filtered by the glass cover.The light beam that has been processed is called cold light.

4.Good light quality.

Good light quality means that the provided light beam can truly reflect the color and changes of blood and tissues.This property is generally known as color rendering, which is represented by the color rendering index calculated by the spectral distribution of the light source, and the best color rendering index is 100.Color rendering is closely related to color temperature.The required color temperature is 6000K, the true color rendering is about 70-90, and the effective color rendering is nearly 100.

5. Easy operation.

HOECARE Operating shadowless lamp should be able to continuously change position and direction during operation, and the operation must be simple, flexible, light, fast and effective.The central part of the lamp body should be equipped with sterilization handle, advanced products also equipped with light guide fiber deep cold light, color television photography device and ventilation device.

6. Economy and safety.

Economy mainly refers to high luminous efficiency, low power consumption and long service life.Abroad already used halogen bulb mostly.The lamp body shall be made of materials that are difficult to adhere to dust.Considering the safety of shadowless lamps is very important since their structures tend to be bulky and complex.This mainly refers to the electrical safety performance, lamp structural strength and weight.

In recent years, in order to improve the light quality, HOECARE have developed and produced a multi-layer dielectric film anti-lens with hard glass as the reflection surface and infrared ray transmission, namely cold light reflector, whose illumination can reach more than 100,000 LUX.The mirror surface of the mirror is coated with multiple layers of high-purity zinc sulfide and magnesium fluoride coating or titanium dioxide and silicon dioxide coating in vacuum. The coating is uniform and free from impurities.In order to adapt to the needs of the operation, we also set the photometric adjustment device on the shadowless lamp.The Angle of light can vary according to the position and range of the surgeon.HOECARE Shadowless lamps are developing towards the direction of high efficiency, multi-function and economic ratio, and strive to provide high-quality uniform beams with sufficient illumination, good color rendering, high shadowless degree and less infrared ray to meet the needs of modern surgery.

HOECARE In the sharing.

www.hopesgz.com Email:[email protected]

1 note

·

View note

Text

What products work to clean headlights?

Cleaning car lights (especially halogen/plastic lampshades that are oxidized, yellowed, or blurred) requires targeted products and the right methods. The following are proven effective cleaning solutions, covering DIY home recipes, professional products, and tools:

1. Light cleaning (daily maintenance)

Soapy water + soft cloth

Applicable situations: surface dust, shellac.

Steps: Warm water + car-specific car wash liquid (such as Meguiar's Gold Class), brush gently with a soft brush and rinse.

Note: Avoid using car wash liquid containing wax (may accelerate oxidation).

Isopropyl alcohol (IPA) solution

Formula: 70% isopropyl alcohol + 30% distilled water.

Function: Remove grease and sap residues to prepare for subsequent deep cleaning.

Method: Let stand for 2 minutes after spraying and wipe with a microfiber cloth. 2. Moderate oxidation cleaning (yellowing/fogging) 1. Toothpaste grinding method Principle: Calcium carbonate (abrasive) in toothpaste polishes the surface oxidation layer. Steps: Preliminary grinding with 2000 grit sandpaper (wet grinding).

Apply fluoride toothpaste (such as Colgate Total) and polish in a circular motion for 5 minutes.

Rinse with clean water and wipe dry. Effect: Temporary restoration of 80% transparency, lasting 1-3 months. 2. Professional headlight restoration kit Recommended products: 3M Headlight Restoration Kit: Contains sandpaper (500-3000 grit), polishing paste, and UV sealant. Meguiar's G2980 Heavy Duty Kit: Double-ended drill bit adapter, suitable for heavy oxidation. Steps: Mask the area around the lampshade. Wet grinding (500→800→1000→3000 mesh, step by step). Apply oxidation remover (containing Teflon). Spray UV protective layer (to prevent secondary oxidation). Effect: Restore more than 90% transparency, lasting 1-2 years. III. Severe oxidation/scratch repair

Two-component polyurethane coating (2K Clear Coat)

Principle: Spray-type clear coating fills deep cracks. Tools:

Spraymax 2K Clear (with hardener spray can). Spray mask, dust-free environment. Steps:

Grind until the lampshade is matte (1500 mesh). Spray 2-3 layers after cleaning, 10 minutes apart. Curing for 24 hours. Effect: Close to the original new lamp, lasting 3-5 years. 2. Professional refurbishment service Cost: 50–150 (4S shop or professional auto beauty shop). Advantages: Use industrial-grade polisher (such as Rupes LHR15) + ceramic coating (such as CarPro CQuartz). Fourth, natural/home alternatives Baking soda + white vinegar: Mix into a paste, wipe and rinse (only for very mild oxidation). Insect repellent (WD-40): Spray and wipe to temporarily brighten (contains petroleum solvent, use with caution). Five, pit avoidance guide Prohibited products: Ammonia glass cleaner (corrodes plastic). Steel wool/hard brush (causes scratches). Sandpaper selection: Wet sandpaper (avoid dry grinding to generate static electricity to attract debris). Necessity of sealing: Polishing without UV coating will accelerate oxidation (recurrence within 3 months). Six, preventive measures for oxidation Regular maintenance: Apply 303 Automotive Protectant to the lampshade every month. Car cover/PPF film: Physically block ultraviolet rays (such as XPEL Ultimate). Parking habits: Avoid long-term exposure to the sun and use a car cover. Summary: Choose according to needs Limited budget: Toothpaste + sandpaper (temporary first aid). Moderate oxidation: 3M/Meguiar's set (best value for money). Severe damage: 2K Clear Coat or professional refurbishment. Cleaned headlights can improve night lighting safety and vehicle aesthetics, and the investment will have significant results!

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#car culture#car#cars#classic cars#american cars#car light#headlight bulb#headlight restoration#headlamp#headlight#headcanon

0 notes

Text

DOTSLASER-UV Lasers And Their Applications in Laser Processing

First, UV laser characteristics description

The ultraviolet laser wavelength is short, energy concentration, high resolution, especially has the characteristic of "cold processing", can directly destroy the connection material chemical bond, without producing to the peripheral heating, therefore becomes the ideal tool of processing fragile material, and can carry on the perforation, cutting, ablation to many kinds of materials, has the wide application in the field of micromachining.

1. Gas UV laser

Gas UV lasers are excimer lasers, argon ion lasers, nitrogen molecule lasers, fluorine molecule lasers, helium cadmium lasers and so on. The gas ultraviolet laser used for laser processing mainly has the excimer laser.

Excimer is a kind of excimer in the excited state composite into molecules, in the base state dissociation into atomic unstable connective matter. In excimer laser systems, the leap occurs from the bound excited to the repelled fundamental state, and is therefore a free leap of bound origin. Excimer laser is a kind of pulsed laser, the working medium is generally a certain proportion of mixed inert gas and strong electron halogen element gas, when the base state of the inert gas atom is excited, the extra-nuclear electron is excited to a higher orbit and thus change the electronic shell layer all filled state, so that it and other atoms to form an excimer, when the excited state of the molecule leaps back to the base state, immediately decomposed, reverted to the original properties! The laser emits high energy ultraviolet laser, which is amplified by the resonant cavity and releases photons at the same time.

2. Solid-state ultraviolet laser

The general produce ultraviolet excitation spectral line method has two kinds: one is directly using infrared all solid-state laser triplex frequency or quadruple frequency obtain 355nm or 266nm ultraviolet excitation spectral line, another kind of method is first use frequency doubling technology to get the second harmonic, then use and frequency technology to get ultraviolet excitation spectral line. The former method effective nonlinear coefficient is small, the conversion efficiency is low, the latter method because of the use of the second nonlinear polarization rate, the conversion efficiency is going to be higher than the former kind many. The solid ultraviolet laser relative to the excimer laser has the advantages of compact volume, easy maintenance, easy operation and so on.

3. Application advantages

There are three advantages of UV lasers in laser processing: first, the shorter wavelength of UV lasers can process very small parts; Two is the ultraviolet laser for laser processing directly destroy material chemical bond, is "cold" processing, has a small heat affected area; Three is most materials can effectively absorb ultraviolet light, can process many infrared and visible light laser processing can't material, and the ultraviolet laser especially solid-state UV lasers are becoming increasingly compact, high average power, easy to maintain, easy to operate, low cost and high productivity. Therefore, it has been widely used in laser processing fields such as bioengineering, material preparation, all-optical optical device production, integrated circuit board and semiconductor industry.

4. Industry Applications

Application area Legend Brief description

Chip processing

(Bioengineering) Laser excimer fabrication of polymer microfluidic chips for analysis, synthesis and cell culture, DNA sequencing, gene mutation and other applications.

Material Preparation

Nano Si film