#High Voltage DC DC Converter

Explore tagged Tumblr posts

Text

PAA300F-15 COSEL AC-DC Power Supply – Compact, Reliable, and Efficient!

The PAA300F-15 AC-DC Power Supply from COSEL is a high-performance solution for applications requiring reliable and stable power conversion. With an output power of 300W and a voltage rating of 15V, this power supply is engineered to meet the demands of industrial automation, medical equipment, communications, and instrumentation systems. Its compact design allows for easy integration into tight spaces, while its high efficiency ensures minimal energy loss during operation.

Designed with durability in mind, the PAA300F-15 features comprehensive protection mechanisms, including overcurrent, overvoltage, and thermal safeguards. Its high-quality components and robust build make it a dependable choice for applications that require continuous and stable operation. Backed by COSEL's reputation for excellence in power solutions, this power supply delivers consistent performance you can count on. As the official distributor of COSEL products, USComponent offers authentic PAA300F-15 units with exceptional service and competitive pricing. Upgrade your power systems with COSEL's trusted innovation! Order now and learn more https://www.uscomponent.com/buy/COSEL/PAA300F-15.

#AC DC Power Supplies#AC To DC Converter#DC DC Converters#DC Converter#High Voltage DC DC Converter#DC To DC Power Supply#COSEL Power Supply#COSEL#Cosel Distributor#Cosel Electronics#Cosel Power#Cosel DC DC Converters#Cosel DC DC#Cosel AC DC#PAA300F-15

0 notes

Text

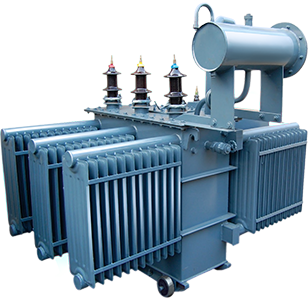

Power Transformer — 63 Kva aluminum Energy Efficient Distribution Transformer Manufacturer from Lucknow

Manufacturer of Power Transformer — 63 Kva aluminum Energy Efficient Distribution Transformer, 400kVA Three Phase Copper Wound Distribution Transformer, 16kVA Single Phase AI wound Distribution Transformer and CCI Power Transformers offered by CCI Transformers Private Limited, Lucknow, Uttar Pradesh.

Contact us:

Call us: 8318455691

Email us: [email protected]

Address: D 242, Sector 63 Rd, D Block, Sector 63, Noida, Uttar Pradesh 201301

For more information visit: http://www.ccitransformer.co.in/

#power transformer#110v to 220v converter#12v transformer#24v transformer#dc transformer#led transformer#ac transformer#240v to 12v transformer#120v to 12v converter#control transformer#voltage converter 110 to 220#110v to 12v converter#220 to 110 voltage converter#110 to 220 voltage converter#step down voltage converter#transformer manufacturers#120v to 220v converter#high frequency transformer#ac to dc transformer#step up voltage converter#like power transformer#120v converter#36v transformer#5 amp transformer price#led power supply transformer#240v to 5v transformer#dc step down transformer#240v to 12v dc transformer#1000w inverter transformer#220v to 100v converter

2 notes

·

View notes

Text

How to Build a Small Solar Power System - Low-tech Magazine

Readers have told me they like to build small-scale photovoltaic installations like those that power Low-tech Magazine’s website and office. However, they don’t know where to start and what components to buy. This guide brings all the information together: what you need, how to wire everything, what your design choices are, where to put solar panels, how to fix them in place (or not), how to split power and install measuring instruments. It deals with solar energy systems that charge batteries and simpler configurations that provide direct solar power. Conventional solar PV installations are installed on a rooftop or in a field. They convert the low voltage direct current (DC) power produced by solar panels into high voltage alternate (AC) power for use by main appliances and rely on the power grid during the night and in bad weather. None of this holds for the small-scale systems we build in this manual. They are completely independent of the power grid, run entirely on low voltage power, and are not powering a whole household or city but rather a room, a collection of devices, or a specific device. Small-scale solar is decentralized power production taken to its extremes. Most of the work in building a small-scale solar system is deciding the size of the components and the building of the supporting structure for the solar panel. Wiring is pretty straightforward unless you want a sophisticated control panel. You only need a limited set of tools: a wire stripper, some screwdrivers (including small ones), and a wood saw are the only essentials. A soldering iron, pliers, and a multimeter are handy, but you can do without them.

243 notes

·

View notes

Text

Can a halogen headlight be converted to LED?

Technically, yes, but there are some key issues with legality, safety, and performance. Here’s what you need to know:

🔧 How the conversion works Plug and Play (PnP) LED bulbs

Fit into halogen sockets (H1, H4, H7, 9005, etc.).

Built-in driver to convert 12V DC to LED voltage.

Example: “Halogen to LED” bulb kit.

⚠️ Key Disadvantages and Risks Issue Importance

🗲 Illegal in most areas Non-compliant LED bulbs in halogen housings scatter light excessively → glare other drivers. This violates DOT/FMVSS 108 (US) and ECE (Europe) standards. ☢ Poor beam pattern Halogen housings have reflectors designed to the shape/size of the halogen filament. No adjustable light pattern LEDs emit light differently → produce dark spots/scattering (“moth effect”). 🚨 Safety Hazard: Due to the uneven beam, your visibility is reduced and the risk of dazzling oncoming vehicles → accidents is increased. 🔌 CanBus Error: Modern cars detect low LED power draw as "bulb burnt out" and trigger a dashboard warning. Resistor may be required. 📛 Inspection Failure: Most states/provinces will fail your vehicle inspection for non-compliant lamps.

🔬 Technical Challenges Heat Dissipation: LEDs require heat sinks, which are too long/fans too large (may not fit in a sealed housing).

Bulb Orientation: LEDs require precise rotational alignment (many bulbs do not adjust well).

Vibration Damage: Improperly secured LEDs may fail prematurely.

✅ Safer, legal alternatives Solution Pros Cons

🔦 High-performance halogen lamps (Philips X-tremeVision, OSRAM Night Breaker) Legal, plug-and-play, 20-30% brighter, shorter life (400-600 hours) 💡 OEM LED/Projector lamp conversion Replaces complete headlight assembly → Legal, beam pattern optimized Expensive ($500-$2000+ per pair) ⚙️ Professional projector lamp conversion Custom HID/LED projector lamps installed into housing Expensive ($130-$800+), requires expertise

⚖️ Decision checklist

Before conversion: Check local laws (must be DOT/ECE compliant).

Ask your insurance company if conversion will affect insurance.

Test beam pattern: Install LED lamps in a dark garage - do not drive if beam cutoff is blurry or uneven.

Consider warranty - aftermarket LEDs may void your headlight warranty.

💎 KEY ADVICE

Avoid plug-and-play LED bulbs in halogen housings. Recommended choices: High-output halogens for economical performance.

Full factory LED assemblies for superior performance.

If pursuing a custom upgrade, have it professionally retrofitted.

🌟 Bottom line: While physically possible, inferior LED bulbs in halogen housings compromise safety and legality. Prioritize compliant solutions to avoid fines, incidents, or inspection failures. If you proceed, use only reputable brands (e.g. Philips, SNGL) with a proper fan/heatsink design and turn your headlights down to reduce glare.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#race cars#cars#electric cars#classic cars#car#carlos sainz#porsche#truck#automobile#lamborghini#bmw#autonomous vehicle headlights#older vehicles#overtake another vehicle#vehicle#automobiles#autos#automotive#autowreckers#chrysler

8 notes

·

View notes

Text

Are solar power systems prone to cyberattacks?

“Like any technological revolution, digitalisation presents incredible opportunity, for example, energy system cost savings of €160 billion per year,”

“It also comes with new challenges, like cybersecurity. We didn’t need anti-virus protection for a typewriter - but we do need it for our laptops. As a responsible, forward-looking sector, we have mapped the cybersecurity challenge, and we’re rising to meet it with clear, comprehensive solutions.”

The report, written by risk management organisation DNV.

Europe’s move away from an energy system dependent on a few high-impact targets to a more decentralised system offers clear energy security benefits, the report states. Ukraine has learnt this in a particularly brutal way, following repeated cyberattacks on its power grid by Russia.

But to realise these benefits, cybersecurity laws, which focus on old, centralised infrastructure, need to be updated, the experts say. New legislation must address the specific security needs of distributed energy sources, like smaller rooftop solar installations.

Though on a much smaller scale than the strikes on other parts of the energy sector, the solar sector has faced attacks and interference, too.

In 2023, a group of Romanian solar customers modified mandatory inverter settings - which convert DC electricity generated by panels into the AC electricity used by homes - to disable the voltage-active power function.

This function is required by the grid operators to reduce active power at high grid voltage, in order to keep the power system running efficiently and safely.

Modifying this grid support function enabled the customers to make more money by not limiting their solar systems during high-voltage events, potentially jeopardising grid integrity as a result.

In a more pernicious incident, pro-Russian hacktivist group Just Evil stole credentials for 22 client sites in Lithuania and posted them on the Dark Web last year. This opened up access to the management portal of these solar sites, although access was not used to carry out further attacks on that occasion.

Analysing risk, the report found that these large utility-scale solar installations are more secure, since they are often managed by experienced utilities and covered by the EU’s Network and Information Security (NIS2) Directive.

Small-scale solar systems, meanwhile, which are often rooftop installations on people’s homes or businesses, lack strict cyber rules. They are connected to the clouds of manufacturers, installers, or service providers.

And while the impact of compromising a single installation is low, when grouped together for power system efficiency, they become virtual power plants of significant scale.

#solarpunk#solarpunk business#solar punk#solar power#cyber security#new laws#new rules#new ways to think about decentralized energy security

10 notes

·

View notes

Text

High energy particles are absorbed by luminescent particles that re-emit them as visible light. Similar type of luminescent particles (derivable from certain fruits and vegetables) were suspended in a resin substrate and is used as the core technology on both devices. When hit by UV light, the particles absorb and re-emit visible light along the edges due to internal reflectance. PV cells are placed along the edges to capture the visible light emitted. The captured visible light are then converted to DC electricity. Regulating circuits will process the voltage output to allow battery charging, storage, or direct utilization of electricity

Solar Farms are built horizontally and never vertically, until now. Since AuREUS captures UV, it can produce electricity even when not facing the sun. Buildings clad on all sides with AuREUS become vertical solar farms. Crops easily spoil and cause losses to farmers. With this tech, wastes can now be upcycled.

3 notes

·

View notes

Text

The Ultimate Guide to Choosing the Right Power Supply for Your Needs

When it comes to building or upgrading a computer, one of the most critical components you need to consider is the power supply. Often overlooked, the power supply is the backbone of your system, ensuring that all other components receive the necessary power to function correctly. In this comprehensive guide, we’ll explore everything you need to know about power supply units (PSUs), including how to choose the right one for your needs, the different types available, and why it’s essential to invest in a high-quality power supply.

Why is a Power Supply Important?

The power supply is responsible for converting the alternating current (AC) from your wall outlet into direct current (DC) that your computer’s components can use. Without a reliable power supply, your system could experience instability, crashes, or even permanent damage to its components. A high-quality power supply ensures that your computer runs smoothly, efficiently, and safely.

Key Functions of a Power Supply

Voltage Regulation: A good power supply maintains a consistent voltage level, preventing fluctuations that could harm your components.

Efficiency: Efficient PSUs convert more of the AC power into DC power, reducing energy waste and lowering your electricity bills.

Protection Features: Modern power supply units come with built-in protections such as over-voltage, under-voltage, over-current, and short-circuit protection to safeguard your system.

Types of Power Supply Units

There are several types of power supply units available, each designed for specific needs and applications. Understanding the differences between them can help you make an informed decision.

1. ATX Power Supplies

ATX (Advanced Technology Extended) power supply units are the most common type used in desktop computers. They come in various wattages and form factors, making them suitable for a wide range of systems, from basic office PCs to high-end gaming rigs.

2. SFX Power Supplies

SFX (Small Form Factor) power supply units are designed for compact PCs, such as mini-ITX builds. Despite their smaller size, they still offer sufficient power for most components, making them ideal for space-constrained setups.

3. Modular Power Supplies

Modular power supply units allow you to connect only the cables you need, reducing clutter and improving airflow within your case. This type of PSU is particularly popular among enthusiasts who prioritize cable management and aesthetics.

4. Non-Modular Power Supplies

Non-modular power supply units come with all cables permanently attached. While they are generally more affordable, they can be challenging to manage, especially in smaller cases.

5. Semi-Modular Power Supplies

Semi-modular power supply units offer a middle ground between modular and non-modular PSUs. They come with essential cables permanently attached, while additional cables can be connected as needed.

How to Choose the Right Power Supply

Selecting the right power supply for your system involves considering several factors, including wattage, efficiency, form factor, and additional features. Here’s a step-by-step guide to help you make the best choice.

1. Determine Your Power Requirements

The first step in choosing a power supply is to determine how much power your system needs. You can use online PSU calculators to estimate the wattage required based on your components. It’s essential to choose a PSU with a wattage rating that exceeds your system’s requirements to ensure stability and allow for future upgrades.

2. Consider Efficiency Ratings

Power supply efficiency is measured by its 80 PLUS certification, which indicates how effectively the PSU converts AC power to DC power. The higher the certification (e.g., 80 PLUS Bronze, Silver, Gold, Platinum, Titanium), the more efficient the PSU. A more efficient power supply not only reduces energy consumption but also generates less heat, leading to a quieter and cooler system.

3. Choose the Right Form Factor

Ensure that the power supply you choose fits your case. Most standard ATX cases accommodate ATX PSUs, but smaller cases may require SFX or other form factors. Always check your case’s specifications before purchasing a PSU.

4. Look for Additional Features

Modern power supply units come with various features that can enhance your system’s performance and longevity. Some of these features include:

Modular Cabling: As mentioned earlier, modular PSUs allow for better cable management and improved airflow.

Silent Operation: Some PSUs are designed to operate quietly, making them ideal for noise-sensitive environments.

High-Quality Components: PSUs with high-quality capacitors and other components tend to be more reliable and durable.

5. Consider Future Upgrades

If you plan to upgrade your system in the future, it’s wise to choose a power supply with a higher wattage than you currently need. This will ensure that your PSU can handle additional components, such as a more powerful GPU or extra storage drives.

Common Power Supply Mistakes to Avoid

When selecting a power supply, it’s easy to make mistakes that could compromise your system’s performance or even cause damage. Here are some common pitfalls to avoid:

1. Underpowered PSU

Choosing a power supply with insufficient wattage can lead to system instability, crashes, and even hardware failure. Always ensure that your PSU can handle your system’s power requirements.

2. Overlooking Efficiency

While it may be tempting to save money by opting for a less efficient PSU, doing so can result in higher energy bills and increased heat output. Investing in a more efficient power supply can save you money in the long run.

3. Ignoring Cable Management

Poor cable management can obstruct airflow, leading to higher temperatures and reduced system performance. Modular or semi-modular PSUs can help you keep your cables organized and improve airflow.

4. Skipping Research

Not all power supply units are created equal. Some brands and models are more reliable than others. Take the time to read reviews and research different PSUs before making a purchase.

Conclusion

Choosing the right power supply is crucial for the stability, efficiency, and longevity of your computer system. By understanding the different types of PSUs, considering your power requirements, and avoiding common mistakes, you can select a power supply that meets your needs and ensures optimal performance. Remember, a high-quality power supply is an investment in your system’s future, so don’t cut corners when it comes to this essential component.

Whether you’re building a new PC or upgrading an existing one, taking the time to choose the right power supply will pay off in the long run. With the right PSU, you can enjoy a stable, efficient, and reliable system that meets your computing needs for years to come.

2 notes

·

View notes

Text

How does an engine contribute to a car's powertrain?

The powertrain in a vehicle is the system responsible for generating power and delivering it to the wheels to propel the vehicle forward. The operation of a powertrain can vary depending on whether the vehicle is powered by an internal combustion engine (ICE) or an electric motor (in the case of electric vehicles). Here's a general overview of how a powertrain works in both types of vehicles:

Internal Combustion Engine (ICE) Vehicle - Combustion Process: In an ICE vehicle, the powertrain starts with the combustion process in the engine. Fuel (gasoline or diesel) mixes with air in the combustion chamber and is ignited by spark plugs (in gasoline engines) or compression (in diesel engines).

Power Generation: The combustion process generates energy in the form of mechanical power, causing pistons to move up and down within the cylinders of the engine. This motion drives the crankshaft, converting linear motion into rotational motion.

Transmission: The rotational motion from the crankshaft is transmitted to the transmission, which consists of gears that allow the driver to select different ratios (speeds). This enables the engine to operate efficiently across a range of vehicle speeds.

Drivetrain: The transmission sends power to the drivetrain components, including the driveshaft, differential, and axles, which transfer power to the wheels. The differential allows the wheels to rotate at different speeds, enabling smooth turns.

Wheel Movement: The power transmitted through the drivetrain causes the wheels to rotate, propelling the vehicle forward or backward depending on the gear selection and throttle input from the driver.

Electric Vehicle (EV) -

Battery Pack: The primary source of power for the EV, storing electricity in chemical form.Powers the electric motor and provides electricity for all electronic devices within the EV.

Battery Management System (BMS): Monitors battery cell conditions, including voltage, current, temperature, and state of charge (SoC).It protects the battery against overcharging, deep discharging, and overheating and helps balance the charge across cells. Ensures optimal performance and longevity of the battery by regulating its environment.

Inverter: Converts DC from the battery pack into AC to drive the electric motor.Adjusts the frequency and amplitude of the AC output to control the motor’s speed and torque. Critical for translating electrical energy into mechanical energy efficiently.

Onboard Charger: Facilitates the conversion of external AC (from the grid) to DC to charge the battery pack. Integrated within the vehicle, allowing for charging from standard electrical outlets or specialized EV charging stations. Manages charging rate based on battery status to ensure safe and efficient charging.

DC-DC Converter: Steps down the high-voltage DC from the battery pack to the lower-voltage DC needed for the vehicle's auxiliary systems, such as lighting, infotainment, and climate control. Ensures compatibility between the high-voltage battery system and low-voltage electronic components.

Electric Motor: Converts electrical energy into mechanical energy to propel the vehicle. It can be of various types, such as induction motors or permanent magnet synchronous motors, each offering different efficiencies and characteristics. Typically provides instant torque, resulting in rapid acceleration.

Vehicle Control Unit (VCU): The central computer or electronic control unit (ECU) that governs the EV's systems. Processes inputs from the vehicle’s sensors and driver inputs to manage power delivery, regenerative braking, and vehicle dynamics. Ensures optimal performance, energy efficiency, and safety.

Power Distribution Unit (PDU): Manages electrical power distribution from the battery to the EV’s various systems. Ensures that components such as the electric motor, onboard charger, and DC-DC converter receive the power they need to operate efficiently. Protects the vehicle's electrical systems by regulating current flow and preventing electrical faults.

In both ICE vehicles and EVs, the powertrain's components work together to convert energy into motion, enabling the vehicle to move efficiently and effectively. However, the specific technologies and processes involved differ significantly between the two propulsion systems.

#electric powertrain technology#conventional powertrain#Electric vehicle components#revolo hybrid car kit#ev powertrain development services#software (SW) platforms for all Electric vehicles components#Battery Management Systems#Inverter#Smart Charger#VCU solutions

5 notes

·

View notes

Text

The XL4005 Power supply module is based on the XL4005 Dc-Dc converter IC. The module can step-down and regulate a voltage from 0.8V to 32V based on the position of the potentiometer. The Potentiometer used here is a 25-turn potentiometer that provides easy adjustment of the output of the module to exactly the voltage application needs. The maximum output current can go as high as 5A making it suitable to power heavy loads like CNC machines, Robotic Arms or even to charge batteries.

6 notes

·

View notes

Text

Boost Your Power Solutions with the COSEL CBS504812 DC-DC Converter

In the fast-evolving world of electronics, a reliable power supply is vital for optimal performance. The COSEL CBS504812 DC-DC Converter is crafted to ensure efficient and stable power conversion, making it an ideal option for a wide range of applications. As an authorized distributor, USComponent is pleased to provide this advanced converter to enhance your projects.

Key Features and Benefits

High Efficiency: The CBS504812 is designed for maximum efficiency, ensuring minimal energy loss during conversion. This feature is crucial for applications that demand reliable power without compromising on performance.

Wide Input Range: With its versatile input voltage range, the CBS504812 can accommodate various power requirements, making it suitable for a broad spectrum of applications, from industrial equipment to telecommunications.

Compact Design: The converter's compact footprint allows for easy integration into space-constrained environments. This makes it an ideal choice for modern applications where size and efficiency are critical.

Robust Performance: Built to withstand demanding conditions, the CBS504812 offers reliable operation under various loads. Its robust design ensures consistent performance, providing peace of mind for your power needs.

Why Choose USComponent.com?

As an authorized distributor of COSEL products, USComponent is committed to providing:

Expert Guidance: Our knowledgeable team is available to help you select the right components and offer technical support tailored to your needs.

Competitive Pricing: We provide competitive pricing on all products, ensuring you receive excellent value for your investment.

Timely Delivery: With efficient inventory management and fast shipping, we guarantee that your components arrive on time, keeping your projects on track.

Conclusion

The COSEL CBS504812 DC-DC Converter is an excellent solution for those seeking reliable and efficient power conversion. With its high efficiency, wide input range, and compact design, it’s perfectly suited for a variety of applications. Partner with USComponent to access this exceptional converter and elevate your projects to new heights. Visit our website today to learn more and place your order!

#AC DC Power Supplies#AC To DC Converter#DC DC Converters#DC Converter#DC DC Converter 12v#High Voltage DC DC Converter#DC To DC Power Supply#COSEL Power Supply#COSEL#Cosel Distributor#Cosel Electronics#Cosel Power#Cosel DC DC Converters#Cosel DC DC#COSEL CBS504812#CBS504812

0 notes

Text

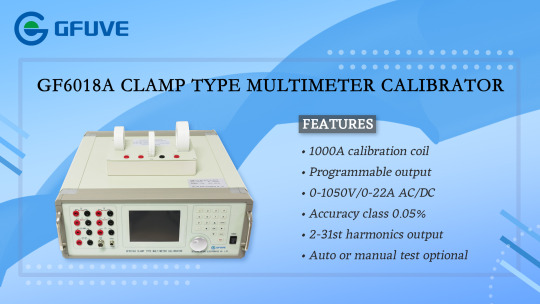

GF6018A High precisition 6.5bit portable AC DC multi product calibrator for multimeter calibrator

This GF6018A high precision multi-product calibrator is compliance with national verification regulation: JJG124-2005 Ammeter, voltmeter, power meter and resistance meter verification rules" and related national standards. 0.05% single-phase standard AC/DC voltage and current source, can verify level 0.2 and the following AC/DC voltmeter, ammeter, frequency meter, resistance meter & clamp meter. The source signals by using DSP and 16-bit high-speed A/D converters of controllable sine wave, the distorted wave signal source. Multifunction calibrator GF6018A is designed as universal calibration tool for electrical calibration laboratories. Measurement range from 0-1050V and 0-20A AC/DC;With 200A, 600A, 1000A calibration coil. The GF6018A clamp type multimeter calibrator with RS-232 port, it can be connected with PC to control, become automatic verification system. It has precise interface and multi-functions including verification, storage and query. The GF6018A multimeter calibrator adopts color LCD screen, chart character display is clear, with high precision, stable and reliable, convenient operation and flexible characteristics. It fully meets ISO17025 laboratory standards and is a good ideal test equipment for electrical engineers. APPLICATION ■ Power plant; ■ Universities; ■ Panel manufacturer; ■ Research institutes; ■ Electrical testing center; ■ Multimeter manufacturers; ■ Oscilloscope manufacturer; ■ Clamp meter manufacturers; ■ Digital meter manufacturers; ■ ISO17025 Electrical laboratory; ■ Electricity power bureau & power company; ■ Power engineering commissioning company; ■ Electrical Department of industrial and mining enterprises;

2 notes

·

View notes

Note

Sydney Trains K set

Class of electric train operating in Sydney, Australia

The Sydney Trains K sets are a class of electric multiple units that currently operate on the Sydney Trains network. Built by A Goninan & Co, the K sets first entered service in 1981 operating under the State Rail Authority, and later CityRail. The carriages are of stainless steel, double deck construction and share much of their design with the older S sets. All of the 40 K sets originally built (160 carriages) remain in service and are currently the oldest in the Sydney Trains fleet.

Quick Facts K set, In service ...

K set

K81 departing Summer Hill station

Refurbished vestibule

In service

1981–present

Manufacturer

A Goninan & Co

Built at

Broadmeadow

Constructed

1981–1985

Refurbished

late 1990s

Number built

160 carriages

Number in service

160 carriages

Successor

Converted H sets

Formation

4-car sets

Fleet numbers

C3501–C3580

D4096–D4099

T4171–T4246

K60–K99 (full 4-car sets)

Capacity

452 (108 in power cars, 118 in trailers)

Operators

Sydney Trains

Depots

Flemington

Lines served

Inner West & Leppington

Bankstown

Airport & South

Specifications

Train length

81.54 m (267 ft 6+1⁄4 in)

Car length

20,385 mm (66 ft 10+1⁄2 in)

Width

3,036 mm (9 ft 11+1⁄2 in)

Height

4,368 mm (14 ft 4 in)

Doors

Sliding pocket, 2 per side

Maximum speed

115 km/h (71 mph)

Weight

188 t (185 long tons; 207 short tons)

Traction system

Mitsubishi camshaft resistance control

Traction motors

4 × Mitsubishi 150 kW (201 hp) series wound DC motor

Power output

1.2 MW (1,609 hp)

Electric system(s)

1,500 V DC (nominal) from overhead catenary

Current collector(s)

Pantograph

UIC classification

Bo′Bo′+2′2′+2′2′+Bo′Bo′

Track gauge

1,435 mm (4 ft 8+1⁄2 in) standard gauge

Close

Design and construction

The K sets were the first New South Wales suburban trains to be air conditioned and have headlights.

Two orders were placed for the K sets with all manufactured between 1981 and 1985 by A Goninan & Co in Broadmeadow:

Order 1

More information Qty, Class ...

Qty Class Carriage numbers Notes

50 Power cars C3501–C3550

4 Driving trailers D4096–D4099 converted to trailer cars 2014

46 Trailer cars T4171–T4216

Close

Order 2

More information Qty, Class ...

Qty Class Carriage numbers

30 Power cars C3551–C3580

30 Trailer cars T4217–T4246

Close

A K set in its original State Rail Authority livery in the 1980s. Some sets were originally classified as R sets.

The first order featured low mounted upper deck windows, off-white and sagebrush grey interiors, and unpainted fronts. The second order featured higher mounted upper deck windows, yellow and mustard interiors and State Rail Authority candy livery fronts. The first four trailers were built as driving trailers allowing them to operate in two-car formation, although in practice they were formed into four carriage sets and often ran together as one eight-car set until 1988. These also differed in the subsequent deliveries in being fitted with air conditioning from new, rather than pressure ventilation. To provide a spare, C3550 & T4216 were also built with air conditioning. All ten carriages were fitted with different windows, being sheet glass with small opening hoppers. This was replaced with sheet glass in 1993.

To accommodate the air conditioning and associated equipment, the pantograph had to be shifted to the adjacent trailer car to which the power car is semi-permanently coupled with high voltage cables connecting the two cars. Although some power cars and trailers have been broken up and married with others during periods of heavy maintenance, many original combinations remain.

The control carriages have a flat front, with headlights at the top. They were built with four sets of marker lights, standard at the time. Different combinations of white marker lights were used to indicate different destinations. Flip-dot destination displays were installed later on, which covered the upper middle marker light. Since destination displays have been installed, marker light combinations are no longer necessary, so usually only the two upper marker lights are used. However, some trains still retain the switch for the lower marker light. The front of the train also has an emergency door for the guard compartment and windscreen wipers for the driver window only. Hoses and receptacles are provided below the windows to connect another set, since, unlike newer trains, the coupler does not carry electrical or air connections.

Like other trains of the time, the crew compartment contains a smaller compartment for the driver on the left side (in direction of travel). The guard uses the area outside of the driver's compartment, with two manual hinged doors on either side providing access to platforms. Above these doors, on the outside are blue lights indicating which compartment the guard is in.

Each vestibule has two-panel sliding doors on either side. Each door also has a vent underneath the window, which was covered when air-conditioning was installed. The doors cannot detect obstacles and continue pushing against the obstruction until it is removed or the guard reopens the doors. Small orange LEDs are located above the doors on the outside that flash when the doors are closing. They assist the guard in locating doors that haven't closed successfully. All trains were retrofitted with traction interlocking, meaning the driver cannot apply power when the doors are open.

In service

All K sets are crewed with a driver and guard. The guard uses the rear cab on a two or four-car train. On eight car trains, the guard usually uses the 5th carriage so that the entire platform can be seen. However the 4th carriage cab can also be used if there is a problem with the 5th carriage one.

All the K sets were delivered to either Hornsby or Punchbowl depots. With the trials on the ten experimental carriages judged successful, in 1986 a programme commenced to retrofit air conditioning to the second order. This saw the Beclawat windows replaced with sheet glass. It would be July 1990 before the programme was completed.

In April 1989, K sets commenced operating peak-hour services via the North Shore line to Gosford. This was extended to Wyong in January 1992. In September 1990, all Punchbowl based sets were transferred to Hornsby.

In January 1991, four sets were transferred to Flemington Maintenance Depot to operate peak-hour Illawarra line services to Port Kembla.

To replace U sets on stopping services between Gosford and Newcastle, the sets with driving trailers were re-marshaled as two-car sets from October 1996.

Following the delivery of the outer suburban Tangara sets in 1994, the K sets ceased operating the Central Coast and Illawarra services.

Upper deck after the CityDecker refurbishment of the 1990s.

During the late 1990s, all were refurbished by A Goninan & Co as part of the CityDecker program. This saw the interiors refurbished with white walls and ceilings, grey floors and blue seats. Power cars received a destination indicator and had yellow applied to the lower half of their fronts. Sliding Beclawat windows on the pressure ventilated cars were replaced with hopper windows and doors painted yellow. The first order was finally retrofitted with air conditioning just prior to the Sydney 2000 Olympics. These cars retained the hopper windows until the late 2000s, but were sealed shut with an adhesive to avoid the loss of air conditioning.

After the introduction of a new timetable in October 2009, all K sets were allocated to Hornsby to operate North Shore, Northern & Western line services, operating in 8-car formations. This was due to the noise levels inside trains when operating on the Epping to Chatswood segment. Older S sets lack sufficient sound insulation for passengers, while newer Tangara sets don't have sufficient cooling in the dynamic braking system to deal with extended shuttle runs through the tunnel.

In mid-2014, K sets are gradually transferred from Hornsby to Flemington resulting in their resumption of service on the Airport, Inner West & South, Bankstown, Carlingford and Olympic Park lines. K60 to K86 were previously running these lines, based out of Flemington Depot. Prior to 2017, K87–99 continued to run part-time on the T1 North Shore, Northern & Western lines.

In October 2013, the 2 car K Sets (K1–4) were withdrawn from NSW TrainLink Gosford to Newcastle services. The four driving trailers were converted to ordinary trailers at Hornsby and the sets returned to service on Sydney Trains services in March 2014 as K98 and K99. The existing K98 was re-numbered K91. The driver cabins in these carriages were stripped of controls however the actual walls were kept intact. The doors to the driver cabin are kept locked and the blinds are kept down. There are no passenger seats where the crew compartment used to be. Also, unlike converted S set cars, the round window on the crew compartment doors were removed and covered with a metal plate.

In July 2017, asbestos was found in the circuit breaker panels, which is inside the driver compartment of the K sets, with all withdrawn for inspection for a few weeks. All have since returned to service.

After the introduction of a new timetable in November 2017, all K sets were transferred to Sector 2.

In late 2017 and early 2018, all K sets and C sets were slightly refurbished with all poles and other safety features repainted yellow.

In 2019, set K96 was withdrawn from passenger service and had Automatic Train Protection (ATP) equipment installed. It has conducted ATP testing since then and will be retained following the retirement of the rest of the fleet for this purpose.

K sets operate on the following lines:

T2 Inner West & Leppington Line: Leppington or Parramatta to City Circle via Granville

T3 Bankstown Line: Liverpool or Lidcombe to City Circle via Bankstown

T8 Airport and South Line: Macarthur to City Circle via Airport or Sydenham

They were formerly in operation on the T6 Carlingford line until it was closed in January 2020.

Preservation

While at the moment there are no developed plans for the preservation of any K set cars, Sydney Electric Train Society has expressed interest in preserving at least one. K96 will likely be retained for the purposes of ATP testing after the K sets are withdrawn from revenue service.

Several heritage tours have used K sets prior to retirement, these have been:

-the girl who sent the k set wiki

Damn I'm doing some sick train studying today thanks for the facts and history! /gen

4 notes

·

View notes

Note

I've had experiences in Europe where (high quality!) laptops made for US/JP markets had similarly poor noise isolation, with or without voltage adapters; my theory is that a lot of companies in those places test for noise on 100/110V, and don't notice minor flaws at 110 that become major flaws at 220/240. Lenovo laptops, meanwhile, don't tend to have those problems in my experience, probably because China's grid is 220.

this is a Lenovo, and perplexingly it comes from the internal power distribution hardware not the AC supply since it's still there when the whole thing is unplugged.

Given that it is probably from the DC-DC converters, might just be bad filtering hardware on the DC-DC side, or bad components like a cracked inductor or bad capacitor might be causing unwanted resonance or leaks.

4 notes

·

View notes

Text

How do Teslas manage power differently from traditional cars, especially regarding overnight features like headlights?

Teslas manage power fundamentally differently from traditional internal combustion engine (ICE) cars—especially for "always-on" features like headlights—through architectural differences in their electrical systems, intelligent power management, and energy source prioritization. Here’s how they do it:

⚡ 1. Core Power Architecture Differences Component Traditional ICE Car Tesla

Primary Energy Source Alternator (belt-driven) recharges the 12V battery High-voltage (400V) battery pack → powers everything 12V System Power Source Lead-acid battery (depletes quickly) DC-DC converter taps HV pack to charge 12V lithium battery Headlights/Electronics Run only off 12V battery → drains in hours Prioritized LV loads → HV pack replenishes 12V as needed

🔋 2. Overnight Power Management

Teslas avoid dead batteries via layered power optimization: Deep Sleep Mode:

After 15-30 mins idle, Tesla shuts down non-essential systems (sentry mode, infotainment), cutting power draw to ~10-50W (vs. 200W+ in ICE idling).

Adaptive 12V Charging:

The DC-DC converter tops up the 12V battery only when its voltage drops → minimizes HV pack cycles.

Lithium 12V Battery (2021+ models):

Replaced lead-acid → 4x longer lifespan, faster charging, lighter weight.

Example: Headlights Left On ICE Car: Drains 12V battery in ~4-8 hours (500W draw).

Tesla:

Headlights auto-shutoff after delay (or via app).

If left on: HV pack feeds DC-DC converter → powers lights for days (~0.1% HV pack loss/hour).

🌙 3. Tesla-Specific "Overnight" Features Feature Power Source ICE Equivalent

Sentry Mode HV pack → 12V system (~200W) N/A – ICE battery dies fast Climate Keep HV pack → heat pump (1-3kW) Engine must idle (1-2L fuel/hr) Software Updates HV pack → compute (300W+) Drains 12V battery rapidly

HV battery sustains all features without idling an engine.

🔧 4. Real-World Efficiency Data Vampire Drain:

Tesla loses ~1-2% battery/day with sentry/climate off.

ICE cars lose 0.5–1L/day in fuel to keep 12V alive during shipping/storage.

Headlight Overnight Draw:

Tesla LED headlights: ~50W total.

ICE halogen headlights: 110W+.

⚠️ Why Tesla’s System Wins No Parasitic Losses: No alternator constantly burning fuel to charge a 12V system.

Energy Scale: Tapping a 75kWh HV pack for 12V loads is like "using an ocean to fill a bathtub."

Predictive Shutdown: Tesla sleeps deeply unless explicitly woken (via app or key).

🛠️ Edge Cases & Fail-Safes 12V Battery Failure:

Tesla alerts drivers weeks in advance → DC-DC converter keeps it charged proactively. HV Pack Depletion:

If HV pack hits 0%, the car uses reserve energy to boot critical systems for recovery. Frozen Temperatures:

HV pack self-heats to maintain efficiency (ICE batteries struggle below -10°C).

Bottom Line: Teslas treat electricity like a data network—intelligently routed, prioritized, and scalable—while ICE cars rely on wasteful "always-on" generation. This allows features like headlights, sentry mode, and climate control to run indefinitely overnight without stranding the driver. 🔋💡

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#Tesla#tesla cars#tesla cybertruck#boycott tesla#nikola tesla#cybertruck#swasticars#cars#car light#race cars#electric cars#classic cars#car#porsche#truck#carlos sainz#automobile#lamborghini#bmw#auto mode

3 notes

·

View notes

Text

What is UPS?

What is UPS?

In this block we see following points

What is UPS?

UPS block diagram

How UPS works?

UPS power range and backup time

Now we will discuss

What is UPS and its functionality?

UPS stands for Uninterruptable Power Supply. It is an electronic power supply which leads for enable some load for short period of time when electricity goes off.

There are Two Types of UPS system

Offline UPS

Online UPS

How UPS Works?

Simply UPS means provides uninterrupted power to the AC load. This AC load converts into DC power. It is also known as standby or emergency power supply and standby generator. After light shut down it switch into the battery bank power and provides 10-15 minutes standard backup time at full load.

In operating conditions, the current is drawn from the main AC power supply or power grid, while Online UPS provides load current in case of a power failure. Here the battery is used as the backup source to transfer power to the load in case of power break.

UPS power range and backup time

Each UPS have different output power, which is designed and calculated according to the connected load. Usually, the output power is shown in the volt-ampere (VA) unit. The common online or offline UPS output power in the market are 600VA, 1kVA, 1.5kVA, 2kVA, 6kVA, 10kVA, 15kVA, and 20kVA and also available in higher kva e.g30Ka, 100Kva etc. Backup time is the time that UPS can provide the connected load/loads and depends on how many batteries UPS has.

Advantages of UPS

Here are some advantages of Uninterruptable Power Supply

Highly reliable

Better protection

Noise free

Offers continuous power

In case of main power failure, no need to change the operation mode.

Negligible transfer time.

Wide Input voltage range

Disadvantages of UPS

Every machine has own drawbacks.

It generates more heat because of continuous power on

Complex design

High Power Loss

We Sycom Power Protection Pvt. Ltd provides all range of online and line interactive UPS. We provide Pan India service of batteries, UPS, Inverters and stabilizer. For more details please contact us www.sycompower.com

#online ups#UPS#Uninterruptable Power Supply#sales#Sycom Power Protection#line interactive UPS#batteries#battery#voltage stabilizer#offline UPS

2 notes

·

View notes

Text

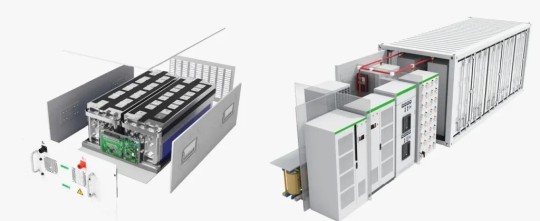

Basic understanding of battery energy storage system: battery, PCS, BMS

With the increasingly serious global energy crisis and the increasing awareness of environmental protection, energy storage technology has become one of the important means to solve energy problems.

Battery energy storage systems are currently one of the most common and practical energy storage technologies. In the battery energy storage system, the battery, PCS, and BMS are its most basic components. Let’s take a look at these three basic concepts.

Battery

The battery is the core part of the battery energy storage system. It is a device that converts chemical energy into electrical energy. It consists of four parts: positive electrode, negative electrode, electrolyte and separator. There are many types of batteries, the common ones include lead-acid batteries, nickel-metal hydride batteries, lithium-ion batteries, etc. Among them, lithium-ion batteries have become the most commonly used battery type in current battery energy storage systems due to their high energy density, long life, and environmental protection.

PCS

PCS is the core equipment in the battery energy storage system. It is a device that converts the electric energy stored in the battery into AC electric energy and supplies it to the grid or users. PCS mainly consists of inverters, transformers, controllers, etc. Its main function is to convert DC power into AC power, control the input and output of power, and ensure the safety and stability of the system. The performance of PCS directly affects the operating efficiency and service life of the battery energy storage system.

BMS

BMS is the abbreviation of battery management system and is an important part of the battery energy storage system. BMS is mainly composed of monitoring module, control module, communication module and other parts. Its main function is to monitor and control the status of the battery in real time, including battery voltage, current, temperature, SOC and other parameters. At the same time, BMS can also protect and control the battery, such as overcharge, over-discharge, over-current, etc., to ensure the safety and life of the battery.

To sum up, batteries, PCS, and BMS are the three basic components of battery energy storage systems. As the core part, the battery is responsible for storing energy; PCS converts the electric energy stored in the battery into AC electric energy; BMS monitors and protects the battery in real time to ensure the safety and life of the battery. In the design and operation of battery energy storage systems, the coordination of the three is crucial. Only in this way can the efficient, stable and safe operation of the battery energy storage system be achieved.

2 notes

·

View notes