#IECEx

Explore tagged Tumblr posts

Text

HydITEx Corporation is a research company primarily focused on Research and Development (R&D) in explosion-proof technologies and hydrogen energy.

#HydITEx#ex#explosion-proof#explosionproof#iecex#R&D#research#technology#hydrogen#geological#bioprotein#IT#IndyIndustry40#IndyIndustry50#ethernet#antenna#USB#peripheral#19-inchrack#enclosure#IEMS#Intrinsic#flameproof

1 note

·

View note

Text

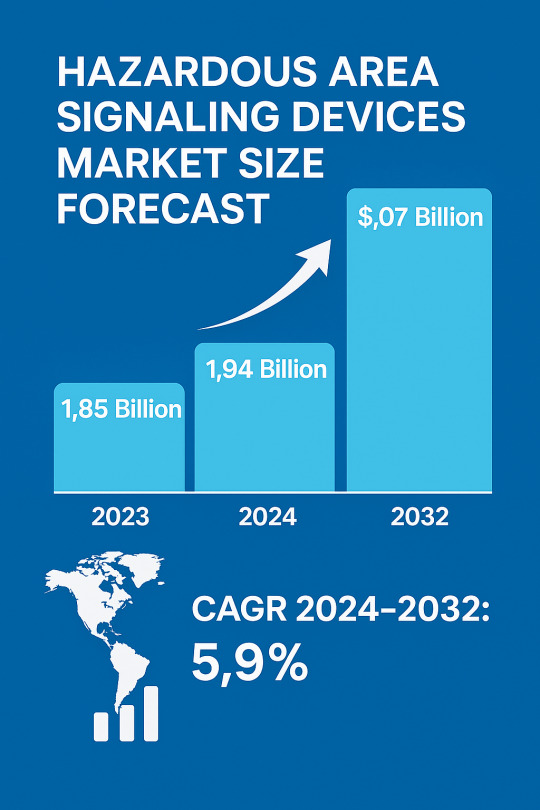

Hazardous Area Signaling Devices Market Set to Cross $3 Billion by 2032. Here’s What’s Powering the Rise

Just came across some compelling numbers on the hazardous area signaling devices industry — and if you’re in industrial safety, automation, or infrastructure, this one’s worth a deeper dive.

📊 Market Forecast (2024–2032)

💰 2023 Market Size: $1.85 billion 🔮 2024 Projection: $1.94 billion 🚀 2032 Forecast: $3.07 billion 📈 CAGR (2024–2032): 5.9%

That’s over 58% growth in just under a decade.

��� Safety First — And Everywhere

Hazardous area signaling devices are a critical piece of infrastructure in industries like oil & gas, mining, chemicals, and food processing — basically, anywhere explosive or dangerous environments require high-performance alerts and compliance with ATEX/IECEx norms.

🔑 Key Trends Fueling the Growth:

🚨 1. Industrial Safety Regulations Are Tightening

Governments and regulators worldwide are ramping up safety codes, especially in high-risk environments. That means more demand for reliable alarms, strobes, horns, and beacons designed for hazardous zones.

🏗️ 2. Expansion of Oil & Gas and Chemical Processing

As energy infrastructure expands — particularly in the Middle East, North America, and Asia — the need for certified signaling devices in explosive atmospheres is scaling accordingly.

⚙️ 3. Rise of Smart & Connected Devices

We're seeing the integration of IoT, diagnostics, and remote monitoring into signaling systems. These “smart alerts” improve incident response times and reduce maintenance downtime.

📦 4. Demand in Food & Pharma Cleanrooms

Signaling systems aren’t just for explosive zones — they’re increasingly deployed in sterile and contamination-sensitive spaces like pharmaceutical manufacturing and food processing, where audible/visual alerts ensure regulatory compliance.

🌐 5. Emerging Markets Are Catching Up

Developing economies are now building out their industrial safety frameworks. As factories and energy plants come online, the market for ATEX- and IECEx-compliant signaling devices is set to boom.

🧠 What Does This Mean for Industry Players?

We’re moving toward automation-ready, network-integrated safety ecosystems. Whether you’re a manufacturer or investor, now’s the time to focus on scalable, smart, and regulation-driven solutions.

🔧 If you’re building: Prioritize interoperability with PLC/DCS systems, cloud diagnostics, and fail-safe compliance certifications.

💼 If you’re investing: Long-term demand will favor companies innovating in smart industrial safety, modular device design, and emerging economy installations.

0 notes

Text

𝗥𝗲𝘃𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝗶𝘇𝗶𝗻𝗴 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝗦𝗮𝗳𝗲𝘁𝘆: 𝗧𝗵𝗲 𝗘𝘅𝗽𝗹𝗼𝘀𝗶𝗼𝗻 𝗣𝗿𝗼𝗼𝗳 𝗘𝗾𝘂𝗶𝗽𝗺𝗲𝗻𝘁 𝗢𝗽𝗽𝗼𝗿𝘁𝘂𝗻𝗶𝘁𝘆

The global Explosion Proof Equipment Market size is forecasted to reach $14.5 billion by 2030, growing at a CAGR of 5.7% during the forecast period from 2024-2030.

📥 𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝘁𝗵𝗲 ��𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁 𝗦𝗮𝗺𝗽𝗹𝗲: 👉 https://lnkd.in/gM39ggDF

🌡️ 𝗞𝗲𝘆 𝗖𝗼𝗼𝗹𝗶𝗻𝗴 𝗧𝗲𝗰𝗵𝗻𝗼𝗹𝗼𝗴𝗶𝗲𝘀:

𝗥𝗲𝗴𝘂𝗹𝗮𝘁𝗼𝗿𝘆 𝗖𝗼𝗺𝗽𝗹𝗶𝗮𝗻𝗰𝗲 & 𝗥𝗶𝘀𝗸 𝗠𝗶𝘁𝗶𝗴𝗮𝘁𝗶𝗼𝗻:With #international standards such as ATEX, IECEx, and NFPA driving product certification, companies are compelled to #upgrade to advanced explosion-proof #solutions to ensure operational safety and minimize downtime.

𝗧𝗲𝗰𝗵𝗻𝗼𝗹𝗼𝗴𝗶𝗰𝗮𝗹 𝗜𝗻𝗻𝗼𝘃𝗮𝘁𝗶𝗼𝗻: Advancements in #smart #monitoring, IoT-enabled sensors, and #AI-driven predictive maintenance are redefining explosion proof equipment. These innovations not only enhance safety but also drive operational efficiency and reduce #long-term maintenance costs.

𝗘𝗻𝗵𝗮𝗻𝗰𝗲𝗱 𝗥𝗢𝗜 & 𝗖𝗼𝗺𝗽𝗲𝘁𝗶𝘁𝗶𝘃𝗲 𝗘𝗱𝗴𝗲: Investing in high-quality explosion-proof systems translates into fewer #operational interruptions, reduced liability risks, and improved employee productivity. Forward-thinking companies #leveraging these #technologies set themselves apart as leaders in industrial safety and efficiency.

📊 𝗞𝗲𝘆 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀: Emerson | Honeywell | Rockwell Automation

Eaton | Siemens | ABB | Schneider Electric | Parker Hannifin | GE | Johnson Controls | Intertek | Pepperl+Fuchs Group | Bosch Rexroth | Phoenix Contact | Danfoss | Mitsubishi Electric | Fuji Electric Co., Ltd.

Legrand | Baker Hughes | Ingersoll Rand | Cummins Inc. | ITT Inc. | Flowserve Corporation | NOV | Siemens Energy | Dover Corporation

AMETEK | Fluke Corporation | Alfa Laval

📖 𝗚𝗲𝘁 𝗠𝗼𝗿𝗲 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀: 👉 https://lnkd.in/gx8dQNAw

✨ (𝐂𝐫𝐞𝐝𝐢𝐭 𝐂𝐚𝐫𝐝 𝐃𝐢𝐬𝐜𝐨𝐮𝐧𝐭 𝐨𝐟 𝟏𝟎𝟎𝟎$ 𝐨𝐧 𝐚𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐏𝐮𝐫𝐜𝐡𝐚𝐬𝐞𝐬 | 𝐔𝐬𝐞 𝐂𝐨𝐝𝐞: 𝐅𝐋𝐀𝐓𝟏𝟎𝟎𝟎 𝐚𝐭 𝐜𝐡𝐞𝐜𝐤𝐨𝐮𝐭) https://lnkd.in/g6e9u3vX

#ExplosionProof#IndustrialSafety#HazardousEnvironments#ATEX#IECEx#NFPA#OilAndGas#Mining#ChemicalIndustry#PharmaceuticalIndustry#RiskManagement

0 notes

Text

Benefits of Using IECEX Cable Glands?

Discover the multitude of advantages offered by IECEX cable glands for your industrial applications. Engineered to meet stringent safety standards, IECEX cable glands ensure reliable cable entry points in hazardous environments. These specialized glands provide superior ingress protection, preventing the intrusion of dust, moisture, and gases, thus safeguarding sensitive electrical components. With robust construction and compatibility with various cable types, IECEX cable glands offer ease of installation and maintenance, enhancing operational efficiency. Embrace the assurance of safety and reliability with IECEX cable glands, essential components for hazardous area installations.

0 notes

Text

Signs You Should Invest in an Explosion-Proof Junction Box

In dangerous environments where flammable gases or dust are present, safety is a top priority. Electrical components, such as junction boxes and control panels, must be designed to withstand potentially explosive conditions. An explosion proof junction box is essential in such settings to prevent accidents. But how do you know when you need one? Let’s explore the key signs that indicate it’s time to invest in explosion-proof electrical equipment.

Presence of Flammable Gases or Vapors

One of the most obvious signs that you need an explosion junction box is the presence of flammable fumes, vapors, or liquids in the environment. Industries like oil & gas, chemical processing, and pharmaceuticals often work with materials that are highly volatile.

Signs: Unprotected wiring and electrical components in areas with gas leaks or vapors can create sparks or heat, leading to explosions.

Solution: Explosion-proof electrical enclosures, such as junction boxes, ensure that sparks or heat generated inside the box do not ignite the surrounding environment.

High Risk of Dust Explosions

Another indicator that you may require explosion-proof equipment is the presence of combustible dust in the atmosphere. This is common in industries such as mining, food processing, and woodworking.

Signs: If dust accumulates in your work area and is flammable, it can create an explosive mixture with air.

Solution: Explosion junction boxes are designed to contain any sparks or heat within the box, preventing ignition of dust and minimizing the risk of explosions.

Increased Electrical Load or Equipment Stress

If your electrical systems are operating under higher-than-normal load or experiencing frequent electrical surges, this could create an environment where components might overheat, potentially causing an explosion.

Signs: Frequent overheating, melting, or burning of wires or terminals.

Solution: An explosion junction box ensures that any internal overheating does not spread to the surrounding environment, providing a layer of safety.

Improper Ventilation or Environmental Conditions

In many industrial environments, ventilation may not be adequate, increasing the risk of gas, vapors, or dust accumulation. In these settings, electrical components are at greater risk of sparking and causing an explosion.

Signs: Poor ventilation, confined spaces, and low air circulation increase the risk of hazardous conditions.

Solution: Explosion proof control panels and junction boxes can contain and protect electrical components from igniting volatile substances in poorly ventilated environments.

Compliance with Industry Standards and Regulations

Certain industries are subject to strict protection regulations that mandate the use of explosion-proof equipment. For example, facilities that handle volatile materials or operate in hazardous zones are required by law to use explosion-proof enclosures to comply with safety standards such as ATEX, IECEx, or NEC.

Signs: Regulations and safety standards require the use of explosion-proof electrical equipment in certain environments.

Solution: To comply with these standards and avoid legal penalties, investing in an explosion proof junction box is essential.

In Conclusion

Recognizing the signs that indicate you need an explosion proof control panels is crucial for maintaining safety in hazardous work environments. From the occurrence of flammable gases or dust to compliance with industry regulations, these protective enclosures are designed to prevent accidents & ensure that your electrical systems are functioning safely.

For high-quality, reliable explosion-proof solutions, trust Prolux International LLC to provide the best products tailored to meet your safety needs.

0 notes

Text

Explosion proof portable work light - ATEX approved

Explosion-Proof Work Lights are attached with movable wheels below the gadget and may be moved from one location to another. They are very practical and simple to move. Due to the outside aluminum die-casting, polished surface, and epoxy coating of these lights, they are also quite durable. These 360-degree adjustable lights are perfect for Zones 1&2 and 21&22 and offer improved illumination. The device incorporates an easily adjustable manual valve that controls the lift for simpler operation. Work lights that are portable, strong, and explosion-proof are perfect for explosive conditions.

Key Features

Zones 1 & 2, Zones 21 & 22

Housing made of die-cast aluminum with an epoxy coating for a lovely appearance; lighting angle is adjustable by 120 degrees. Wheels that are simple to move are attached to the bottom of the light box.

Upward and downward adjustment, 360-degree rotation, and complete lighting

Control the lift by using a manual valve or an air pump.

The generator set's bottom has universal wheels that can be used on the pit's train lines and paved surface. Small and lightweight, making it simple to carry.

#Explosion Proof Work Light#Explosion Proof Work LED Light#Intrinsically safe work lighting#ATEX/IECEx LED WORKLITE#ATEX Work Lights

0 notes

Text

iDOL 46 ATEX sensor

iDOL 46 ATEX sensor is approved according to ATEX directive 2014/34/ EU and IECEx for operation in potentially explosive dust atmospheres. The sensor is classified for explosion group II, which concerns all remaining risk areas but mines. iDOL 46 ATEX is classified as equipment for use in atmospheres with continuous presence of explosive dust with an ignition temperature above 85 oC. The ATEX approval makes the sensor suitable for installations where dust poses an imminent explosion risk classified according to Zone 20 and 21. iDOL 46 ATEX sensor has a robust design with plastic housing with 7 joule shock/impact test.

Serving pig farming, chicken farming. Contact us in Vietnam.

1 note

·

View note

Text

Explosion Proof Searchlight Market - Key Players, Size, Trends, Growth Opportunities, Analysis and Forecast

Explosion Proof Searchlight Market, Trends, Business Strategies 2025-2032

The global Explosion Proof Searchlight Market size was valued at US$ 345 million in 2024 and is projected to reach US$ 478 million by 2032, at a CAGR of 4.2% during the forecast period 2025-2032.

Explosion proof searchlights are specialized lighting devices designed for hazardous environments where flammable gases, vapors, or combustible dust may be present. These rugged luminaires feature reinforced housings and intrinsic safety designs that prevent ignition sources, making them critical for applications in oil & gas, mining, chemical processing, and military operations. The product range includes explosion-proof floodlights with illumination ranges exceeding 3500 meters and projection lamps for fixed installations in high-risk areas.

The market growth is driven by stringent industrial safety regulations and increasing investments in hazardous location lighting solutions. While the oil & gas sector remains the dominant end-user, emerging applications in renewable energy installations and port operations are creating new opportunities. Recent product innovations include LED-based searchlights with IoT connectivity for remote monitoring. Key players like Emerson Electric and Eaton are expanding their portfolios through strategic acquisitions, with the top five companies accounting for approximately 42% of global revenue in 2024.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://semiconductorinsight.com/download-sample-report/?product_id=103087

Segment Analysis:

By Type

Explosion-Proof Floodlight Segment Dominates Due to High Demand in Industrial Safety Applications

The market is segmented based on type into:

Explosion-Proof Floodlight

Subtypes: Halogen, LED, and others

Explosion-Proof Projection Lamp

Portable Explosion-Proof Searchlight

Fixed Mount Explosion-Proof Lighting

Others

By Application

Oil & Gas Sector Leads Consumption Owing to High-Risk Operating Environments

The market is segmented based on application into:

Oil & Gas

Smelting and Chemical Industry

Railway

Mining

Others (Firefighting, Military, etc.)

By End User

Industrial Sector Accounts for Majority Usage Due to Critical Safety Requirements

The market is segmented based on end user into:

Industrial

Petrochemical plants

Refineries

Manufacturing facilities

Commercial

Government & Defense

Others

By Protection Level

ATEX Certified Products Are Most Sought After in Hazardous Locations

The market is segmented based on protection level into:

ATEX Certified

IECEx Certified

UL Certified

Others

Regional Analysis: Explosion Proof Searchlight Market

North America The North American market for explosion-proof searchlights is driven by stringent safety standards, particularly in industries like oil & gas, mining, and petrochemicals. Regulatory bodies such as OSHA and NFPA mandate the use of certified explosion-proof lighting solutions, creating steady demand. Investments in energy infrastructure, including the expansion of LNG facilities and offshore drilling operations, further stimulate market growth. The U.S. dominates regional demand, accounting for approximately 65% of North America’s market share, with strong adoption of high-performance LED-based explosion-proof searchlights that offer longer lifespans and energy efficiency. However, pricing pressures from Asian manufacturers pose competitive challenges for domestic suppliers.

Europe Europe’s mature industrial sector and rigorous ATEX directives govern the explosion-proof searchlight market, ensuring high product standards across EU member states. Germany and the UK lead in adoption, particularly for hazardous area applications in chemical plants and pharmaceutical facilities. The shift toward smart lighting solutions with IoT integration represents a growing trend, though premium pricing limits penetration in cost-sensitive Eastern European markets. Recent emphasis on renewable energy infrastructure, particularly offshore wind farms, presents new application opportunities for rugged searchlight solutions. European manufacturers differentiate through technical innovation and after-sales service networks rather than price competition.

Asia-Pacific As the fastest-growing regional market, Asia-Pacific benefits from rapid industrialization and infrastructure development across China, India, and Southeast Asia. China alone comprises over 45% of regional demand, driven by its massive petrochemical sector and expanding oil refinery capacities. While price sensitivity favors local manufacturers, international brands gain traction through joint ventures and technology transfers. The proliferation of special economic zones containing hazardous processing facilities fuels steady demand, though inconsistent enforcement of safety standards across developing markets creates quality concerns. Japan and South Korea represent premium markets favoring high-tech solutions, while emerging ASEAN nations prioritize cost-effective alternatives.

South America Market growth in South America correlates with regional investments in mining and oil production, particularly in Brazil and Argentina. However, economic instability and currency fluctuations disrupt procurement cycles for explosion-proof equipment. The Brazilian offshore oil sector offers promising opportunities, though local content requirements complicate market entry for international suppliers. While awareness of safety standards improves, budget constraints often lead to the purchase of non-certified alternatives, creating challenges for legitimate manufacturers. Infrastructure modernization projects in Chile and Peru present pockets of growth potential for suppliers who can navigate complex regulatory environments.

Middle East & Africa This region demonstrates significant variation in market maturity, with GCC countries driving demand through large-scale oil & gas projects requiring ATEX/IECEx certified equipment. The UAE and Saudi Arabia account for nearly 60% of regional market value, with extensive usage in refinery and desalination plant applications. Sub-Saharan Africa presents growth opportunities in the mining sector, though limited electrification and infrastructure hinder broader adoption. Political instability and inconsistent regulation enforcement remain barriers, while major industrial projects along the East African coast begin driving localized demand. The market exhibits strong potential for modular, portable explosion-proof lighting solutions suited to temporary installations.

List of Key Explosion Proof Searchlight Manufacturers

Emerson Electric (U.S.)

Eaton (Ireland)

Hubbell Incorporated (U.S.)

Iwasaki Electric (Japan)

Phoenix Products Company (U.S.)

AZZ Inc. (U.S.)

Western Technology (UK)

AtomSvet (Russia)

Adolf Schuch GmbH (Germany)

LDPI (U.S.)

Shenzhen Nibbe Technology (China)

WorkSite Lighting (Canada)

Oxley Group (UK)

Zhejiang Tormin Electrical (China)

Unimar (Turkey)

Stringent safety mandates across hazardous industries are propelling the explosion-proof searchlight market forward. Government agencies worldwide have intensified workplace safety standards, particularly in oil & gas and chemical sectors where explosion risks are prevalent. For instance, updated ATEX directives in Europe and NEC standards in North America now require specialized lighting solutions in Zone 1 and Zone 2 hazardous areas. These regulations mandate certified equipment that prevents ignition of flammable substances, creating sustained demand for explosion-proof lighting solutions. The market has responded with technologically advanced products meeting IECEx and UL 844 certifications, driving a projected 6-8% annual growth in compliance-driven purchases.

The global offshore energy sector’s resurgence is creating substantial demand for rugged lighting solutions. With offshore drilling activities projected to increase by 23% through 2030, operators require specialized searchlights capable of withstanding saltwater corrosion and methane-rich environments. Modern explosion-proof searchlights now incorporate marine-grade aluminum housings and advanced LED arrays delivering over 50,000 lumens, making them indispensable for rig lighting, underwater inspection, and emergency response operations. Recent contracts in the North Sea and Gulf of Mexico demonstrate this trend, where operators are allocating 12-15% of safety budgets to explosion-proof lighting upgrades.

The convergence of IIoT technologies with explosion-proof lighting presents transformative opportunities. Next-generation smart searchlights now incorporate built-in condition monitoring, automatic brightness adjustment, and wireless mesh networking capabilities. This enables predictive maintenance and centralized control across large industrial facilities – features that justify premium pricing while reducing operational costs. Early adopters in LNG terminals report 30% maintenance cost reductions using these smart systems. With industrial IoT investments projected to grow at 11% CAGR through 2030, connected explosion-proof lighting represents one of the most promising market segments.

As renewable energy facilities expand globally, their unique lighting requirements create fresh demand. Hydrogen production plants and battery storage facilities present new hazardous zones requiring explosion-proof lighting solutions. Manufacturers are developing specialized products for these applications, including methane-resistant fixtures for biogas plants and corrosion-resistant models for offshore wind platforms. The renewable sector’s lighting needs are expected to account for 18-22% of total explosion-proof market revenues by 2028, up from just 8% in 2024.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=103087

Key Questions Answered by the Explosion Proof Searchlight Market Report:

What is the current market size of Global Explosion Proof Searchlight Market?

Which key companies operate in Global Explosion Proof Searchlight Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Browse More Reports:

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014

[+91 8087992013]

0 notes

Text

Offshore Oil Platform Lighting: Why It's a Bright Idea to Get It Right?

Have you ever wondered how oil rigs operate safely 24/7 in the middle of the ocean? What kind of lighting systems can survive extreme saltwater, storms, and explosive atmospheres? Why does lighting matter so much offshore, anyway? When you think of offshore oil platforms, you probably imagine massive steel giants rising from the sea, pumping oil and gas nonstop. But behind the scenes, there's a critical yet often overlooked element that keeps everything running smoothly—offshore oil platform lighting. Let's shine a light on why proper illumination is more than just a convenience—it's a key player in safety, productivity, and operational success.

Why Is Offshore Lighting So Important?

Offshore oil platforms are hostile environments. You're dealing with salt-laden air, high winds, heavy rain, and complete isolation. In these conditions, offshore oil platform lighting solutions go far beyond basic visibility—it needs to ensure:

Safe 24/7 operations

Accident prevention

Accurate navigation

Emergency readiness

Regulatory compliance

A single lighting failure can pose serious risks—from injuring crew members to halting production. That's why specialized, rugged, and reliable lighting systems are essential.

1. Built for the Harshest Conditions

Standard oil platform lighting won't cut it offshore. Lighting systems here must be marine-grade and corrosion-resistant. Exposure to saltwater is constant, and any rust or degradation can quickly lead to failures.

Most offshore oil platform lighting is made from materials like:

Marine-grade stainless steel

Anodized aluminum

Durable polycarbonate lenses

They're also sealed tight, with IP66 or higher ratings to keep out water, dust, and debris.

2. Explosion-Proof and ATEX-Certified

Oil platforms deal with flammable gases and vapors. That means lighting must be explosion-proof, preventing any spark or heat source from igniting a disaster.

Look for offshore oil platform lighting certified under ATEX or IECEx standards. These perform safely in Zone 1 or Zone 2 hazardous areas, where explosive atmospheres are either likely or possible.

Explosion-proof lights have reinforced enclosures that contain any internal fault, ensuring nothing dangerous escapes into the surrounding environment.

3. Energy-Efficient with LED Technology

Offshore operations rely on generators or limited power supply, so energy efficiency is a must. That's where LED lighting comes in. LEDs are the gold standard for offshore oil platform lighting because they:

Use up to 80% less energy than halogens or fluorescents

Last 50,000+ hours

Produce low heat, reducing fire risks

Require less maintenance

The result? Lower operational costs and less time spent replacing lights in hard-to-reach places.

4. Tailored Light for Every Task

Offshore platforms are like floating cities—each area requires different lighting.

Floodlights illuminate broad deck areas and walkways

Spotlights are used for cranes and helipads

Emergency lights kick in during power failures

Task lights help workers perform precision work safely

Offshore oil platform lighting plays a significant role in helicopter landings, vessel docking, and night operations. So intensity, beam angle, and color temperature must be customized.

5. Compliance Is Non-Negotiable

In the offshore industry, regulatory compliance isn't optional—it's the law. Offshore oil platform lighting must meet strict safety standards set by organizations such as:

OSHA

ABS (American Bureau of Shipping)

DNV

IMO (International Maritime Organization)

Failing to comply could result in shutdowns, fines, or more severe consequences. Choosing certified lighting systems ensures that your operation remains safe and compliant with rules.

6. Built-In Redundancy & Smart Controls

Modern offshore lighting systems now feature built-in redundancy—backup circuits that kick in automatically during failures. Some even include smart controls that monitor usage, temperature, and voltage to prevent malfunctions.

These smart systems can be controlled remotely. Thus making diagnostics and energy management easier than ever—even when the platform is hundreds of miles from land.

7. Maintenance Made Simple

Maintaining equipment offshore is no easy task. That's why lighting systems are modular, tool-free, and easily accessible. Less time spent on maintenance means:

Reduced safety risks

Less downtime

More focus on core operations

Final Thoughts:

Offshore oil platform lighting isn't just about seeing—it's about surviving and succeeding in one of the world's most demanding workplaces. Whether you're managing an oil rig, outfitting a new platform, or upgrading existing systems, don't overlook the impact of innovative, efficient, and compliant lighting. Because when the storm rolls in, and the deck gets slick, the right light can save lives. Shop for efficient and cost-effective offshore oil platform lighting from CR Control Systems Inc and illuminate your workspace.

#Marine Aids to Navigation#Marine Lighting Manufacturer USA#Daylight Control Sensors#Offshore Oil Platform Lighting#Side-Emitting Lens Technology

0 notes

Text

Earth Tag Washer: An Essential Safety Component for Electrical Grounding in 2025

In modern industrial and electrical systems, earth tag washers are small yet essential components that play a vital role in ensuring electrical safety. They are specifically designed to provide a secure and low-resistance path for fault currents in cable gland assemblies, particularly for armored cables. As safety regulations and standards evolve in 2025, the demand for high-quality earth tag washers is steadily rising in industrial, commercial, and hazardous applications.

⚡ What is an Earth Tag Washer?

An earth tag washer is a flat, metallic washer with a grounding terminal or lug. It is installed between the cable gland and the equipment enclosure to create an earth connection from the cable armor to the enclosure or grounding system. This ensures that in case of a fault or short circuit, the electrical current is safely directed to the ground, preventing electrical shock, equipment damage, or fire.

Made commonly from brass, tinned copper, or stainless steel, earth tag washers are corrosion-resistant and suitable for high-temperature or hazardous environments.

🔧 Functions of Earth Tag Washers

Provides Electrical Grounding:

The main function of an earth tag washer is to connect the metal sheath or armor of a cable to the earth, reducing the risk of shock or fire.

Supports Compliance:

Earth tag washers are essential for meeting ATEX, IECEx, and IP-rated safety standards, especially in explosive or flammable zones.

Complements Cable Glands:

Used in conjunction with cable glands, locknuts, and shrouds, they enhance the mechanical and electrical performance of the gland installation.

🏭 Industrial Applications of Earth Tag Washers

In 2025, earth tag washers are used across industries such as:

Oil & gas refineries

Power plants and switchgear

Automation and control systems

Data centers and telecom

Marine and offshore platforms

Renewable energy installations

They are particularly vital in Zone 1 and Zone 2 hazardous environments, where grounding of equipment is not just recommended, but mandatory for operational safety.

🔍 Benefits of Using Earth Tag Washers

✅ Improves Electrical Safety

They prevent electrical hazards by ensuring fault current is grounded efficiently.

✅ Corrosion-Resistant

Most earth tags are made with anti-corrosive materials, suitable for humid, saline, and chemical environments.

✅ Easy Installation

Simple to install with standard cable gland accessories like locknuts and sealing washers.

✅ Compliance-Ready

Helps meet international standards such as IEC 62444, BS EN 50262, and ATEX directives.

📌 How to Choose the Right Earth Tag Washer

When selecting an earth tag washer, consider:

Cable gland size (metric or PG thread)

Material compatibility (brass, copper, SS)

Application environment (indoor, outdoor, hazardous)

Certification needs (ATEX/IECEx/IP ratings)

Preferred brands like CMP, Hummel, LAPP, and Dowells

🔚 Conclusion

An earth tag washer may appear small, but it is a powerful safeguard in any electrical installation. By enabling effective grounding, it enhances electrical safety, ensures compliance, and protects personnel and equipment. As industries in 2025 move toward smarter, safer, and more sustainable operations, integrating certified earth tag washers into your cable gland assemblies is not just a choice—it’s a necessity.

0 notes

Text

Hazardous Area Lighting | Hazardous Area Lights - SharpEagle

Explore our range of ATEX & IECEx certified hazardous area lighting solutions. Durable, safe, and ideal for explosive environments. Trusted by industries globally.

0 notes

Text

Benefits of IECEX Cable Gland?

Discover the unparalleled advantages of IECEX cable gland technology with our comprehensive guide on the "Benefits of IECEX Cable Gland." This informative resource delves into the superior features and safety standards that make IECEX cable glands a preferred choice in hazardous environments. From enhanced durability to rigorous compliance with international regulations, explore how IECEX cable glands provide a reliable and secure solution for ensuring the integrity of electrical installations in potentially explosive atmospheres. Stay informed and safeguard your operations with the reliability and peace of mind that IECEX cable glands bring to the forefront of industrial safety.

0 notes

Text

⚠️ Patlayıcı gaz ve toz riskinin yüksek olduğu alanlarda, doğru armatür hayat kurtarır!

📌 Zone 1 – Zone 21 Ex-Proof armatürler; kimyasal üretim tesisleri, LPG dolum istasyonları, boya atölyeleri, un siloları, gıda fabrikaları gibi yüksek riskli alanlarda güvenli aydınlatma sağlar.

💡 ATEX & IECEx sertifikalı ürünler 💡 Alüminyum gövde + temperli cam yapı 💡 Patlamaya dayanıklı, kıvılcım sızdırmaz tasarım 💡 Acil kitli ve sensörlü seçenekler 💡 IP66 – IK10 koruma standartları

🔐 Zone 1 (gaz riski) ve Zone 21 (toz riski) ortamlar için %100 uyumlu bu çözümlerle projelerinizde iş sağlığı ve güvenliği standartlarını eksiksiz karşılayın.

#dekmarled#zone1armatür#zone21armatür#atexexproof#patlayiciortamaydınlatma#dekmarlight#guvenlikaydınlatması#lpgistasyonaydinlatma#boyahaneaydınlatması#unfabrikasiarmatur#endustriyelled#ip66armatür#kıvılcımsızaydınlatma#exproofacilkit#yanicigazortami#tozpatlamasi#isiklandirmadaguvenlik#atexsertifikaliurun#zoneaydınlatmacozumleri#endustriyellogistic#endustriyelguvenlikled

1 note

·

View note

Text

What to Expect from a Quality Gas Sensors Manufacturer

What to Expect from a Quality Gas Sensors Manufacturer

In today's safety-first age, gas detection is an industrial process, consumer product, and environmental monitoring requirement. Quality gas sensors are essential to keeping air quality levels or worker safety in check. The result, therefore, of seeking out an appropriate Gas Sensors Manufacturer being a critical choice. Yet what exactly can purchasers reasonably expect from a quality Gas Sensors Manufacturer? In this new market, the following article speaks about the usual traits, technology, and warranties that distinguish a good Gas Sensors Manufacturer.

Innovation and Technological Capability

The fundamental requirement of a leading Gas Sensors Manufacturer is that it must be capable of research and development. Performance, reliability, and miniaturization — the four key attributes in today's gas sensing technology — are fueled by innovation. Those organizations that provide a wide range of metal oxide sensors (MOS), electrochemical sensors, photoionization detectors (PID), and infrared (IR) sensors clearly reflect the industry demand.

One of the most recognized Gas Sensors Manufacturers also tracks emerging technologies like MEMS-based sensors, which provide high accuracy in small packaging. In addition, integration with IoT devices and wireless communications platforms like LoRa or NB-IoT is becoming the new standard for innovative manufacturers.

Customization for Industry Applications

Various industries have totally different sensing requirements. A best-fit Gas Sensors Manufacturer delivers customized solutions for some of the industries like oil and gas, chemicals, automotive, food processing, HVAC, and even smart homes. Adjustable sensor modules, different detection ranges, temperature compensation capability, and rugged environment housings are a few examples of industry-specific customization.

This customization not only achieves gas detection safety but also minimizes false alarms, optimizes maintenance cycles, and increases safety.

Global Compliance

Compliance and certification is another very crucial factor of a well-established Gas Sensors Manufacturer. While as much as certifications such as ATEX, UL, CSA, IECEx, and RoHS certification are voluntary, they actually prove safety, reliability, and integrity in risk-critical environments.

The buyers have to go search for certification reports that confirm such standards. A company with a sound record of meeting international standards shows that the company is serious about providing trustworthy, secure, and excellent products.

Quality Control and Testing Procedures

Accurate gas detection is impossible without assumptions. Quality assurance is the essence of every good Gas Sensors Manufacturer because of this. From raw material inspection to end-level calibration, every process in the production line has to have strict regulations.

Seek those organizations with automated test beds, simulated environments, and real-time calibration software. Batch testing, life testing, and test performance at a wide range of temperature and humidity levels also reflect strict quality control.

Open Customer Support and Documentation

Post-sales service is an afterthought but really the key while selecting a Gas Sensors Manufacturer. As an end-user or system integrator, prompt technical support, sensor calibration processes, guarantee support, and product quality information are a requirement.

A good maker publishes datasheets, calibration reports, integration manuals, and user manuals that support engineers and procurement managers to make sound judgments. Customer-focused companies also have open communication and prompt response to questions.

Environmental and Sustainable Production Practices

With the environmental rules becoming increasingly stringent across the world, new-world manufacturers anticipate sustainability to be a major one. A leading Gas Sensors Manufacturer adopts green manufacturing practices and recycled products wherever feasible.

As crucial as product capability is scalability. Be it 100 or 100,000 sensors, the firm should be able to scale production without sacrificing quality or lead time. Robust manufacturing lines, efficient logistics, and scalable models of production all point toward a partner you can rely on.

Global Presence and Market Reputation

A well-established Gas Sensors Manufacturer will typically have an established global presence. Established global presence typically means established credibility, repeat quality, and responsiveness to varied regulatory regimes.

Certifications, awards, customer feedback, and online reviews all potentially are a reflection of a manufacturer's reputation within the marketplace. Established manufacturers typically deal with industrial leaders, utility players, and government entities in the long term, authenticating their credentials.

Project Highlight: IMAT CVD

A specimen of this type in a company is the IMAT CVD project on which a highly acclaimed Gas Sensors Manufacturer has collaborated to develop sensitive solutions for monitoring chemical vapor deposition. The gas sensors that are developed with precision are such that trace gases utilized in thin-film processing methods adopted by the electronics and solar industries can be traced. With great sensitivity, short response times, and extended life cycles, the sensors supplied under the scope of IMAT CVD show the kind of high-quality and advanced technologies quality suppliers introduce into the marketplace. The cooperation demonstrates how customized sensor technology can be employed for optimal process support and safety in advanced technologies. Final Thoughts

Final Thoughts

Selecting a Gas Sensors Manufacturer is more than shopping for specs. It's innovation, compliance, long-term reliability, and trust. A satisfactory supplier not only meets but surpasses expectations with state-of-the-art technology, a well-informed customer support team, environmentally conscious practices, and industry knowledge.

From startups seeking compact sensors for smart devices to large-scale industries requiring explosion-proof units, the role of a reliable Gas Sensors Manufacturer is pivotal. By knowing what to expect, buyers can form stronger, more successful partnerships in the critical field of gas detection.

Let me know if you'd like this turned into a PDF or customized for a specific audience (e.g., HVAC buyers, automotive companies, or industrial safety engineers).

0 notes

Text

ATEX Work Lights - Explosion proof | UK | UAE | Saudi

SharpEagle’s ATEX approved intrinsically safe work lights are 360-degree adjustable lights, perfect for Zones 1 and 2 and 21 and 22 and offer improved illumination. You can call us at +971-45549547 or mail us at [email protected]

#Explosion Proof Work LED Light#Intrinsically safe work lighting#ATEX/IECEx LED WORKLITE#ATEX Work Lights

0 notes

Text

Explosion-Proof Electrical Safety Barrier Market: Technological Innovations and Future Roadmap 2025–2032

Explosion-Proof Electrical Safety Barrier Market, Trends, Business Strategies 2025-2032

Explosion-Proof Electrical Safety Barrier Market size was valued at US$ 187.6 million in 2024 and is projected to reach US$ 267.8 million by 2032, at a CAGR of 4.6% during the forecast period 2025-2032

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis https://semiconductorinsight.com/download-sample-report/?product_id=103398

MARKET INSIGHTS

The global Explosion-Proof Electrical Safety Barrier Market size was valued at US$ 187.6 million in 2024 and is projected to reach US$ 267.8 million by 2032, at a CAGR of 4.6% during the forecast period 2025-2032.

Explosion-proof electrical safety barriers are critical components designed to prevent ignition of flammable gases, vapors, or dust in hazardous industrial environments. These devices limit electrical energy to safe levels through intrinsic safety principles, using either Zener diode barriers or galvanic isolation techniques. They find primary application in Zone 0, 1, and 2 hazardous areas as classified by IEC 60079 standards.

The market growth is driven by stringent industrial safety regulations such as ATEX in Europe and NEC in North America, coupled with increasing automation in oil & gas facilities. However, the emergence of alternative protection methods like explosion-proof enclosures presents competitive challenges. Recent technological advancements include smart barriers with IoT-enabled condition monitoring, with companies like Pepperl+Fuchs and Eaton Corporation leading innovation in this space.

List of Key Explosion-Proof Safety Barrier Companies

Pepperl+Fuchs (Germany)

Eaton Corporation (Ireland)

R. STAHL (Germany)

Phoenix Contact (Germany)

PR ELECTRONICS (Denmark)

DATEXEL SRL (Italy)

TURCK (Germany)

Panasonic Eco Solutions (Japan)

FineTek (Taiwan)

Adalet Inc. (U.S.)

Recent competitive dynamics reveal three strategic patterns: established players are divesting non-core safety businesses to focus on explosion-proof technologies, mid-market competitors are forming consortiums to pool R&D resources, and regional specialists are expanding certification portfolios to meet multinational client demands. The market’s technical complexity creates high barriers to entry, but also rewards companies that continuously advance their safety and connectivity features.

Segment Analysis:

By Type

Multi-Channel Segment Leads Due to High Demand in Complex Industrial Setups

The market is segmented based on type into:

Single Channel

Subtypes: Basic, Smart-connected, and others

Multi-Channel

Subtypes: Dual-channel, Four-channel, and others

By Application

Oil and Gas Industry Dominates Due to Stringent Safety Requirements in Hazardous Environments

The market is segmented based on application into:

Oil and Gas

Chemical Processing

Mining

Pharmaceutical

Others

By Technology

Smart Barriers Gain Traction With IoT Integration for Remote Monitoring Capabilities

The market is segmented based on technology into:

Conventional Barriers

Smart Barriers

Subtypes: Wireless-enabled, IoT-connected, and others

By Certification

ATEX-Certified Barriers Lead Due to European Market Dominance

The market is segmented based on certification standards into:

ATEX

IECEx

NEC

Others

Regional Analysis: Explosion-Proof Electrical Safety Barrier Market

North America North America dominates the explosion-proof electrical safety barrier market due to stringent safety regulations, particularly in high-risk industries like oil & gas, chemical processing, and mining. The region’s well-established regulatory framework, including standards set by OSHA (Occupational Safety and Health Administration) and NEC (National Electrical Code), drives the adoption of advanced safety solutions. The United States remains the largest market, accounting for approximately 65% of the regional revenue, with Canada following due to its expanding industrial sector. Investments in digital transformation and industrial automation further stimulate demand for IoT-enabled safety barriers that offer real-time monitoring capabilities. Leading manufacturers like Eaton Corporation and Cooper Crouse-Hinds continue to innovate, focusing on energy efficiency and compliance with ATEX directives.

Europe Europe’s market is characterized by strict compliance requirements under ATEX and IECEx regulations, ensuring high safety standards across hazardous environments. Countries like Germany, France, and the UK lead in adoption due to advanced manufacturing and energy sectors. The EU’s emphasis on Industry 4.0 has accelerated the integration of smart safety barriers capable of predictive maintenance and remote diagnostics. While Western Europe remains the largest consumer, Eastern Europe shows gradual growth, driven by industrial modernization in nations like Poland. Pepperl+Fuchs and R. STAHL are key players, leveraging their expertise to cater to specialized applications such as offshore wind farms and pharmaceutical manufacturing. However, high costs associated with certification and installation pose challenges for SMEs.

Asia-Pacific Asia-Pacific is the fastest-growing market, propelled by rapid industrialization in China, India, and Southeast Asia. China alone contributes over 40% of regional demand, supported by its booming oil & gas and chemical industries. Governments across the region are enforcing stricter workplace safety regulations, spurring the need for explosion-proof solutions. However, price sensitivity leads to a preference for cost-effective, single-channel barriers, particularly in developing markets. Japan and South Korea focus on high-end, multi-channel barriers for precision manufacturing and semiconductor industries. Leading suppliers include Panasonic Eco Solutions and FineTek, who are expanding their distribution networks. The rise of automotive electrification and smart factories further fuels long-term growth prospects.

South America South America presents moderate but steady demand, primarily driven by Brazil’s oil & gas and mining sectors. The region struggles with economic volatility, which limits investments in high-cost safety infrastructure. Local manufacturers often prioritize basic explosion-proof solutions due to budget constraints, while multinational corporations opt for certified ATEX barriers in critical facilities. Argentina and Colombia show nascent growth, supported by small-scale industrial expansions. The lack of uniform safety regulations across countries remains a hurdle, though initiatives like MERCOSUR safety standards aim to harmonize requirements. Partnerships with global players such as TURCK and Phoenix Contact are helping bridge the technology gap.

Middle East & Africa The Middle East’s market is fueled by oil-rich GCC nations (Saudi Arabia, UAE), where stringent safety norms in refineries and petrochemical plants drive adoption. Israel and Turkey are emerging markets due to growing electronics and automotive sectors. Africa faces slower adoption due to limited industrial development, though mining operations in South Africa and Nigeria create localized demand. Infrastructure gaps and lack of skilled labor for installation remain barriers, but foreign investments in energy projects could unlock potential. Companies like Adalet Inc. and DATEXEL SRL are targeting niche applications in desalination plants and LNG facilities, leveraging the region’s energy diversification efforts.

MARKET DYNAMICS

The lack of harmonization between regional certification requirements poses significant hurdles for manufacturers and end-users alike. While ATEX dominates in Europe and NEC in North America, emerging markets often develop their own evolving standards. A single product might require separate certifications for Brazil (INMETRO), Russia (EAC), and China (CCC), each with different testing protocols. This regulatory fragmentation forces manufacturers to maintain multiple product versions, increasing inventory costs by an estimated 15-20%. The challenge intensifies with recent geopolitical shifts, as trade restrictions alter certification reciprocity agreements between regions. Multinational corporations must navigate this complex landscape while ensuring all facilities maintain equivalent safety standards.

Retrofitting Legacy Systems Many industrial facilities operate aging infrastructure where integrating modern safety barriers proves technically challenging and cost-prohibitive. Retrofitting often requires complete electrical system overhauls rather than simple component replacements.

Material Compatibility Issues Certain industrial environments contain corrosive chemicals that degrade standard enclosure materials. Finding safety barriers that withstand both explosion risks and chemical exposure remains an ongoing engineering challenge.

The development of modular, scalable safety solutions creates opportunities in previously underserved markets. Compact barriers designed for confined spaces are gaining traction in pharmaceutical clean rooms and semiconductor fabrication plants. Plug-and-play systems now allow facilities to incrementally upgrade protection as operations expand. This flexibility makes explosion-proof technology accessible to smaller specialty chemical producers and research laboratories handling volatile compounds. The modular approach reduces total cost of ownership by enabling selective rather than complete system replacements during facility upgrades.

Advanced diagnostics embedded in modern safety barriers create new revenue streams for manufacturers through value-added services. Cloud-connected systems can predict component failures before they occur, transforming the traditional break-fix model into proactive maintenance programs. Early adopters report these services improve system uptime by over 95% while reducing emergency service calls. The data collected also helps manufacturers optimize future designs, creating a feedback loop that continually enhances product reliability. This shift toward service-based offerings represents a strategic opportunity to deepen customer relationships beyond equipment sales.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=103398

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Explosion-Proof Electrical Safety Barrier Market?

Which key companies operate in this market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Related Reports:

https://semiconductorblogs21.blogspot.com/2025/07/gas-scrubbers-for-semiconductor-market_14.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/sequential-linker-market-economic.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/lever-actuator-market-swot-analysis-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/probe-station-micropositioners-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/gesture-recognition-sensors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/multi-channel-piezo-driver-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/video-sync-separator-market-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/tv-tuner-ic-market-investment-analysis.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/single-channel-video-encoder-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/sic-ion-implanters-market-revenue.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/quad-flat-no-lead-packaging-qfn-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/ntc-thermistor-chip-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/low-dropout-ldo-linear-voltage.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/logic-test-probe-card-market-strategic.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/led-display-module-market-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/industrial-led-lighting-market-trends.html

CONTACT US: City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 [+91 8087992013] [email protected]

0 notes