#IPC CERTIFICATION

Explore tagged Tumblr posts

Text

Why Join IPC 620 Training and Certification Program

2 notes

·

View notes

Text

youtube

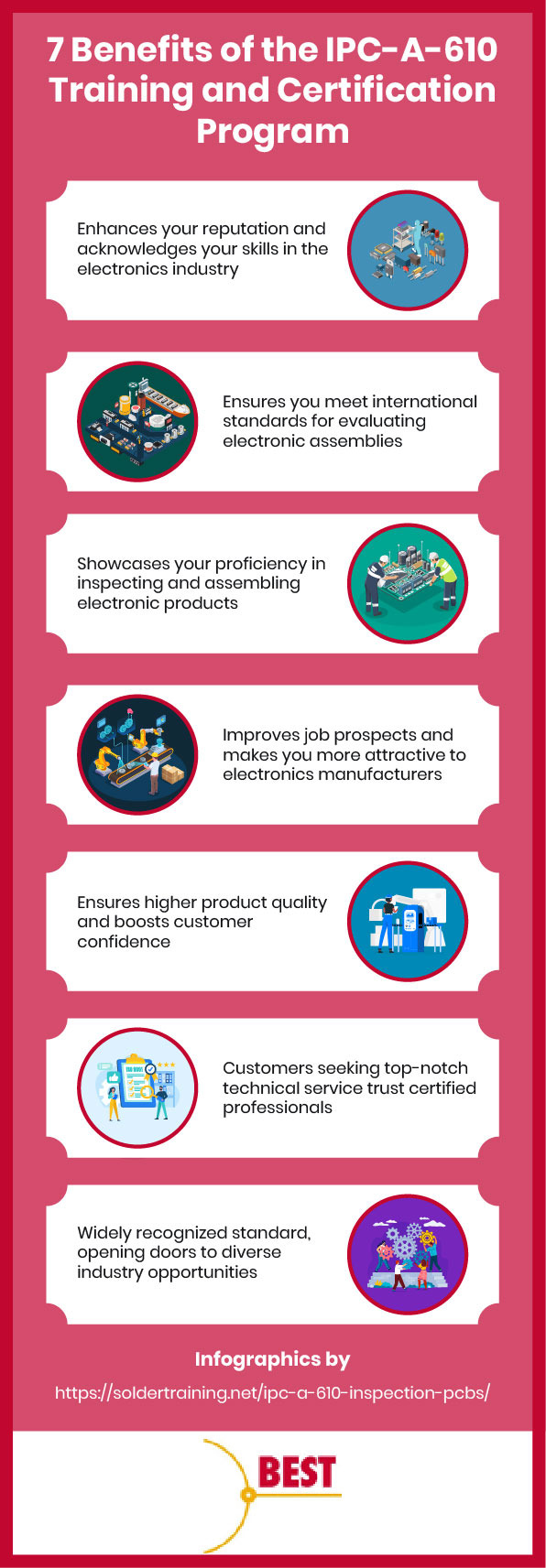

BEST Inc.'s training methods align with industry standards. The electronics company provides technicians with wide-ranging certification courses. Their IPC-A-610 certification program is an industry-consensus program that includes training, certification, and instructional materials that align with IPC-A-610 criteria. This training and certification program is well-known in the electronics industry. Those that want to join IPC A-610 training can contact BEST Inc. To know more, watch this video or visit their website: https://soldertraining.net/ipc-a-610-inspection-pcbs/.

0 notes

Text

youtube

Want to get IPC solder certification? Visit https://www.solder.net/ipc-certification-courses/. BEST Inc. is a trusted electronics company specializing in PCB repair, rework, & assembly services, solder training, and solder training tools and materials. The company is dedicated to providing quality services that align with the needs of its clients. They provide electronics solutions that help their clients work more effectively and stand out among their many competitors. To know more, watch this video.

0 notes

Text

The Kinda Unhinged Ratiorine Fic I Want to Read

In an (admittedly very contrived) AU situation, Dr. Ratio finds out he's about to be cut out of his (mostly estranged) family's inheritance forever because of his complete lack of interest in continuing the family line. Which, all factors considered, does make perfectly logical sense. Investment of capital should go to the branch of the lineage most likely to benefit from it, and Cousin Tiberius has five sons and daughters already. Let the house and the trust fund go to them.

But the library.

There's absolutely no way Veritas could bear to be permanently parted from the staggering assemblage of paper volumes under his collected family's auspices. Not only would being separated from tomes so full of memories be heart-wrenching, but think of the devastating blow to his research! There are records in those archives that no other mortal eyes have ever gazed upon!

So there's only one solution for it: He needs to pass on his family name, immediately.

(Andddd the rest is under a read more because what is brevity?)

Problem 1: Veritas Ratio is very gay.

Problem 2: Statistically, single men have the lowest chance of being selected for adoption placement, and this Child Welfare Agent is looking at his alabaster head very, very strangely.

Think, Ratio, think. What is the most efficient way to solve such a tedious quandary?

The obvious first step is to increase his likelihood of being selected by the adoption agency, and the quickest way to do that is... Eureka! How elegant a design! He just needs to enter into a (temporary) committed and stable partnership to demonstrate a degree of domestic dedication and home-building prowess!

Problem 3: ...Where in the universe is he going to find a stable and committed man willing to marry him?

Ratio does not exactly possess the world's most endearing personality. He might... never have had any form of romantic relationship lasting past a one-night stand even, because it turns out most people don't like being scored a 2/10 on their technique during intercourse.

So he's probably not going to find a stable and committed man.

But... He might at least find someone willing--for the right price.

Enter Aventurine (stage left). He's as expensive as they come, the greatest reward saved for the highest bidder, but despite his festering ambitions, he's still trapped as nothing more than a high-class escort, owned by a company the IPC has on the books as selling everything but what they actually trade in: Avgin slaves.

Sigonians... The reputation--and sleazy men's curiosity--precedes him, and though he only has to get on his knees for the truly bold nowadays, he hasn't yet been able to make the ultimate gamble, pull the last string needed to finally gain his freedom: the freedom to live his life as he pleases--and to enact every ounce of vengeance he's been storing for decades like cards up his sleeves.

Until now.

Until an absolute madman shows up at the underground headquarters waving around an offer that no average person would possibly make: He wants to buy Aventurine and wed him.

(Because marrying a Sigonian thrall is a safe and sane thing that safe and sane people do.)

The offer is far too good to be trusted: A real marriage certificate but a perfectly fake marriage, a no-fault divorce once an adoption is finalized, and a guaranteed sponsor for his citizenship documents. A year or two of fake homemaking, this Veritas Ratio claims, and then Aventurine can walk away a completely free man, no strings--no chains--attached.

Well, Aventurine of the Myriad Stratagems has always held one skill dearer to his heart than any other: a crystal clear knowledge of when to fold--and when to go all in.

(...Problem 4: Amber Lord help him, Aventurine's new husband is the most irritating man in the entire universe.)

Alas, if only that was their biggest problem. Somewhere between learning to navigate the citizenship process, the adoption process, a truly unacceptable level of systemic racism, and also, increasingly, each other, Ratio and Aventurine discover that the circumstances of their lives might be far more entangled than they ever could have imagined from the beginning, and the same shadowy parties that profited off Aventurine's existence might have a vested interest in parting Ratio from valuable research secrets--permanently.

While struggling to maintain a charming and loving facade and struggling not to kill each other behind the scenes, Aventurine and Ratio also end up having to out-roll and out-plan a particularly dangerous enemy; something they can really only do together.

Or, tl;dr: Dr. Ratio chooses the most efficient but most unhinged method of finding a husband that intelligence could possibly contrive, only to determine that marrying a guy whose track record for unexplained deaths matches his track record for card counting really is the encyclopedic opposite of "committed and stable." Ridiculously enough, the trouble they get into is almost entirely Ratio's fault, the only one who is remotely convincing in front of the Child Welfare Agency is Aventurine, and sometimes it turns out the guy you married for the library ends up being the guy you married for life.

#ratiorine#no wait what is the actual ship name#aventio#raturine#hsr fandom kinda wild for that one#dr. ratio#aventurine#honkai star rail#fic ideas#tbh star rail is my 'I don't actually go here' game#because I cannot afford two gachas#but I have been absolutely infected#by social media brainrot#after seeing all the ship content for these two#is this a shitpost?#maybe#but it comes from a place of love#also known as#I think it's really funny to see a ship do everything ass backwards#and still get a happy ending somehow#also remember#comedy is gold

213 notes

·

View notes

Text

Exploring the World of Leading Wire Harness Innovators

Wire harness manufacturers play a crucial role in various industries, providing essential components that ensure seamless connectivity and electrical integration in a wide array of applications. These manufacturers design and produce intricate wire harness systems tailored to specific requirements, adhering to strict quality standards and industry regulations.

For More Information Please visit, top wire harness manufacturers

key aspects of wire harness manufacturing

Industry Overview : Wire harness manufacturers operate in a highly competitive and evolving industry. They serve sectors such as automotive, aerospace, electronics, telecommunications, and healthcare, among others. The demand for custom wire harness solutions continues to grow as industries advance technologically.

Customization and Design : One of the significant aspects of wire harness manufacturing is customization. Manufacturers work closely with their clients to understand their unique needs. This involves designing wire harnesses that meet specific requirements, including size, shape, number of wires, insulation materials, and connector types.

Quality Assurance: Quality is paramount in wire harness manufacturing. Manufacturers invest in state-of-the-art testing equipment and employ skilled technicians to ensure that each harness meets the required standards. Rigorous testing procedures are in place to check for electrical continuity, insulation resistance, and overall durability.

Materials and Components: Wire harnesses consist of various materials and components, including wires, connectors, terminals, tubing, and insulation materials. Manufacturers carefully select these components based on the application's requirements, taking into account factors such as temperature, voltage, and environmental conditions.

Compliance and Certification: Wire harness manufacturers adhere to industry standards and regulations to guarantee the safety and performance of their products. Compliance with standards such as IPC/WHMA-A-620 ensures that the manufactured harnesses meet the necessary criteria for reliability and functionality.

Advanced Manufacturing Techniques : Modern wire harness manufacturing involves advanced techniques such as automated assembly, which enhances efficiency and precision. Computer Numerical Control (CNC) machines are employed for accurate cutting, stripping, and crimping of wires and connectors.

Supply Chain Management : Efficient supply chain management is crucial for timely production and delivery of wire harnesses. Manufacturers work closely with suppliers to source high-quality materials and components, ensuring a seamless flow of production.

Research and Development : Continuous research and development efforts drive innovation in the wire harness industry. Manufacturers invest in developing new materials, manufacturing processes, and technologies to improve the performance and longevity of wire harnesses.

Environmental Sustainability : Many wire harness manufacturers focus on sustainable practices, including the use of eco-friendly materials and recycling initiatives. Sustainability efforts contribute to reducing the environmental impact of manufacturing processes.

Conclusion

Wire harness manufacturers operate at the intersection of technology and precision engineering. Their commitment to quality, innovation, and customer satisfaction drives the industry forward, enabling seamless integration of electrical systems in various applications across the globe.

2 notes

·

View notes

Text

How to Choose the Right Electronic Manufacturer in Chennai

Electronic manufacturing in Chennai is a rapidly growing sector offering vast opportunities for innovation and scale.

If you’re searching for electronic manufacturing services in Chennai, the key is finding a partner with proven capabilities in contract manufacturing, product engineering services, and PCB design and manufacturing. Chennai is one of India’s leading electronics hubs — but choosing the right manufacturer means evaluating more than just location. You need a provider that ensures quality, reliability, scalability, and technical expertise. This guide walks you through exactly what to look for — and how to choose the right electronic manufacturer in Chennai for your next project.

Why Chennai Is a Smart Choice for Electronic Manufacturing

Chennai is more than just a manufacturing destination — it’s a complete ecosystem built for modern electronics production. Here’s why it stands out:

1. Established Manufacturing Ecosystem

Chennai is home to numerous electronics manufacturing clusters such as Sriperumbudur, Oragadam, and Pillaipakkam, where many global and domestic EMS providers operate.

2. Skilled Workforce & Technical Talent

The city produces thousands of engineering graduates annually, providing a skilled workforce for PCB assembly, embedded systems, and precision electronics.

3. Advanced Infrastructure

With access to major ports, industrial parks, and logistics hubs, Chennai offers a ready-made foundation for fast, efficient manufacturing and distribution.

4. Government Support

Policies like the Tamil Nadu Electronics Hardware Manufacturing Policy 2024 and national-level PLI schemes provide tax benefits, funding support, and ease of doing business.

Key Criteria to Choose the Right Electronic Manufacturing in chennai

Before partnering with a manufacturer, make sure they meet these critical criteria:

1. Core Capabilities & Services Offered

Look for providers that offer more than just PCB assembly. A full-service partner will provide:

Product engineering services

PCB design and manufacturing

Prototyping and New Product Introduction (NPI)

Box build and final assembly

Component sourcing and logistics

After-sales support and warranty repair

2. Quality Standards and Certifications

The best manufacturers follow strict quality assurance practices and hold certifications like:

ISO 9001 / ISO 13485 / ISO 14001

RoHS and CE compliance

IPC standards for PCB assembly

3. Technology and Infrastructure

Evaluate their in-house equipment and facilities:

SMT and THT lines

Automated Optical Inspection (AOI)

X-ray and In-Circuit Testing (ICT)

Cleanrooms and ESD-safe environments

4. Scalability and Flexibility

A good manufacturer should easily handle:

Low-volume prototyping

Mid- to high-volume production

Rapid scale-up based on your market demand

5. Transparent Communication

Benefits of Choosing the Right EMS Partner in Chennai

Speed to Market: Faster prototyping and production cycles

Cost Efficiency: Competitive pricing with high-quality output

Customization: Tailored support from design to delivery

Reliability: Long-term partnership with consistent performance

Integrated Services: One-stop solution for design, assembly, and post-sales

Example: What a Full-Service Manufacturing Partner Should Offer

Let’s say you’re building a medical device or IoT product. The ideal Chennai-based partner should help you with:

Design for Manufacturing (DFM) consultation

Prototyping and testing for early validation

Complete PCB design and manufacturing

Mechanical integration through box build

Supply chain and sourcing

Packaging and global shipping

This saves you from managing multiple vendors and allows you to stay focused on core product development.

Final Thoughts: Chennai Is Ready — Are You?

Chennai is already powering the next generation of electronic products — from consumer gadgets to industrial devices. With its talent, infrastructure, and supportive ecosystem, it’s the ideal place to launch or scale your next innovation.

Choosing the right electronic manufacturing partner in Chennai is about more than capabilities — it’s about finding someone who aligns with your goals, understands your product, and is ready to grow with you.

Looking for a Trusted EMS Partner in Chennai?

If you’re ready to take the next step with a dependable electronics manufacturing partner, consider Auckam Technologies. With proven expertise in IoT, healthcare, industrial automation, and drone electronics, Auckam delivers comprehensive electronic manufacturing services — from prototyping and PCB design and manufacturing to full-scale contract manufacturing.

Whether you’re a startup, OEM, or scaling product company, Auckam’s commitment to quality, transparency, and flexibility ensures your innovation moves from idea to market — faster, smarter, and stronger.

Electronic manufacturing in Chennai — Auckam Technologies Pvt Ltd., №26A, Anna Street, Chitlapakkam, Chennai — 600064.

👉 Visit www.auckam.com to learn more or start your project

#electronic manufacturing#ems companies in chennai#pcb design and manufacturing#top ems providers#chennai electronic manufacturing#pcb assembly services chennai

0 notes

Text

PCB Fabrication Company in India – Reliable Solutions for Your Manufacturing Needs

Printed Circuit Boards (PCBs) are the foundation of modern electronics. From mobile devices to industrial equipment, PCBs are essential in powering technology across industries. As demand for high-quality electronics continues to rise, India has become a global hub for PCB fabrication, offering reliable, affordable, and advanced manufacturing solutions.

If you are looking for trusted PCB fabrication company in India, FindingMFG connects you with verified manufacturers ready to deliver quality at every stage of production.

Why Work with a PCB Fabrication Company in India?

India has established itself as a leading destination for electronics manufacturing. Supported by skilled professionals, modern infrastructure, and global certifications, Indian PCB manufacturers deliver products that meet international standards. Here’s why businesses choose PCB fabrication companies in India:

Affordable and Efficient Production

PCB manufacturers in India provide cost-effective solutions, whether you require a prototype or a large-volume order. Competitive pricing combined with strict quality control ensures that you receive reliable products at the right cost.

Advanced Manufacturing Capabilities

With access to modern machinery and production techniques, Indian PCB companies can fabricate single-sided, double-sided, and multilayer boards. They can handle standard designs as well as complex, custom configurations.

Customized Services for Every Requirement

Indian manufacturers specialize in tailored PCB solutions to match your exact project needs. From design specifications to delivery timelines, they offer flexibility for both small and large production runs.

Commitment to Global Standards

Leading PCB fabrication companies in India hold international certifications such as ISO, IPC, UL, and RoHS. These certifications guarantee that every board produced meets high-quality benchmarks for global markets.

Comprehensive PCB Fabrication Services

At FindingMFG, you can easily connect with PCB manufacturers offering a wide range of services, including:

Single-Sided PCBs

Double-Sided PCBs

Multilayer PCBs

Flexible and Rigid-Flex PCBs

High-Density Interconnect (HDI) PCBs

Metal Core PCBs

High-Frequency PCBs

Whether your project is straightforward or highly complex, India’s PCB manufacturers have the capabilities to deliver.

Industries Served by PCB Fabrication Companies in India

Indian PCB manufacturers serve a broad range of industries, including:

Automotive

Aerospace and Defense

Consumer Electronics

Telecommunications

Medical Devices

Industrial Automation

IoT and Smart Technology

This industry expertise allows them to provide solutions that meet the specific needs of diverse applications.

FindingMFG – Connecting You with the Right PCB Fabrication Partner

FindingMFG is India’s trusted online platform for sourcing electronics manufacturing services. We help you discover reliable, verified PCB fabrication companies in India, simplifying the process of finding the right supplier for your project.

What FindingMFG Offers:

Verified suppliers across India

Easy-to-use search filters

Fast, direct quote requests

Transparent communication with manufacturers

Solutions for domestic and international buyers

Start Your PCB Manufacturing Project Today

Choosing the right PCB fabrication partner is a critical step toward building successful electronic products. With FindingMFG, you gain access to India’s best manufacturers who can deliver quality, precision, and value.

Post your requirement on FindingMFG and connect with trusted PCB fabrication companies in India.

Visit FindingMFG.com to get started

#pcb fabrication company#pcb fabrication companies in India#pcb design#pcb manufacturing#manufacturing directory

0 notes

Text

Precision in Every Turn: Get the Best Digital Torque Meter in India at Ascomp Inc

In industries where precision, safety, and quality control are non-negotiable, measuring torque accurately is vital. From electronics assembly and automotive manufacturing to aerospace engineering and medical equipment servicing, a digital torque meter in India is an indispensable tool. At Ascomp Inc, we supply a wide range of high-accuracy digital torque meters designed for modern industrial needs—helping you maintain standards, reduce defects, and ensure reliability.

What is a Digital Torque Meter?

A digital torque meter is a device used to measure the rotational force applied to a fastener such as a screw or bolt. Unlike analog tools, digital torque meters provide real-time numeric readings on a digital display, improving accuracy, traceability, and ease of use. Most models can measure both clockwise and counter-clockwise torque and come with programmable features like alarms, memory storage, and USB/RS232 outputs.

At Ascomp Inc, we bring you industry-grade digital torque meters in India that ensure every tightening operation meets your exact specification.

Applications of Digital Torque Meters

Digital torque meters are widely used in:

Electronics and PCB assembly lines

Automotive component manufacturing

Medical device tightening and testing

Defense and aerospace assembly units

Quality control and R&D labs

Tool calibration and verification centers

Whether you're ensuring screw torque consistency in smartphone production or verifying critical fastener tension in aviation parts, our torque meters deliver accuracy and dependability.

Key Features of Ascomp Inc’s Digital Torque Meters

✅ High-resolution digital display for quick readings

✅ Multiple torque units: N·m, lbf·in, kgf·cm, etc.

✅ Real-time peak and track modes

✅ Memory storage for 1000+ readings

✅ Rechargeable battery with long operating time

✅ Overload alert and data export options

✅ Compact handheld and benchtop models available

Our torque meters undergo stringent calibration and come with certificates for traceability and compliance.

Why Accurate Torque Measurement Matters

🛠️ Avoid over-tightening or under-tightening fasteners

🚫 Prevent product damage and safety failures

📈 Improve quality control and reduce rework

🧪 Meet ISO, IPC, and industry-specific standards

📊 Enable detailed torque data logging and analysis

Investing in a high-quality digital torque meter in India ensures long-term savings, better product performance, and audit-ready compliance.

Why Choose Ascomp Inc?

🧰 ISO-compliant and lab-tested devices

📦 Stock availability and fast delivery across India

💼 Ideal for EMS, OEMs, and repair service providers

🔧 Full support for calibration, usage, and after-sales

🔄 Custom solutions for unique torque requirements

🧑🏫 Training provided for QC and production teams

We help manufacturers maintain a zero-defect policy with tools that measure torque precisely and reliably.

#DigitalTorqueMeterIndia#AscompInc#PrecisionMeasurement#TorqueToolsIndia#QualityControlEquipment#ElectronicsAssemblyTools#ToolCalibrationIndia#IndustrialTorqueSolutions#PCBAssemblyIndia#ProductionLineTools

0 notes

Text

Marck Industries: Trusted Manufacturer of Premium Elevator Spare Parts

Why Reliable Spare Parts Matter in Elevator Systems

Elevators are essential in modern buildings—transporting people and goods swiftly and safely. Downtime due to broken or worn-out parts isn’t just inconvenient—it can impact safety, building efficiency, and tenant satisfaction. That’s why having a dependable source of high-quality spare parts is vital.

What Sets Marck Industries Apart

1. Decades of Expertise

With years of experience in manufacturing elevator components, Marck Industries understands the stringent requirements of vertical transportation—ensuring every part is engineered for precision, durability, and compliance with international safety standards.

2. Comprehensive Product Portfolio

From mechanical to electrical systems, we supply a full range of elevator parts, including:

Controller boards & PCBs

Inverter and VFD units

Proximity switches & sensors

Door lock and safety gear

Brake assemblies & drums

Buffers, rollers, and pulleys

Cabin fixtures: buttons, display panels, handrails

3. Precision Manufacturing

Utilizing CNC machining, injection molding, and automated PCB assembly, each component is produced to exact tolerances—ensuring fit and function with OEM performance or better. Strict quality checks, including EN 81, ASME A17.1, and ISO audits, guarantee consistency.

4. Certified Quality & Safety

Marck operates with certifications to:

ISO 9001 Quality Management

CE marking and compliance

Adherence to EN (Europe) and ASME (North America) elevator safety codes

These credentials ensure safe, global-grade parts.

5. Custom Solutions & Adaptability

Recognizing that every elevator system is unique, Marck Industries excels in custom engineering—from tailored connectors and cables to complete PCB re-engineering—while maintaining cost and lead-time efficiency.

Benefits of Partnering with Marck Industries

Advantage

Impact

High Uptime & Quick Delivery

Minimize downtime with rapid part replacement and fast shipping

Competitive Pricing

Optimized production lowers costs without compromising quality

Global Support Infrastructure

Sales and technical teams available round-the-clock across regions

Extended Product Warranty

Confidence via long-term warranty and support packages

Serving Diverse Market Segments

Residential Buildings: Reliable replacements for passenger-lift maintenance.

Commercial Complexes: Durable components suited for high-traffic usage.

Industrial Facilities: Heavy-duty parts designed for freight and goods lifts.

OEM Collaborations: Contract manufacturing aligned with global elevator brands.

Quality Control & Testing Procedures

Each batch undergoes:

Incoming Material Inspection (IQC)

In-Process Monitoring (IPC)

Performance Testing: Load, endurance, vibration, and electrical tests

Final Audits & Certification

Partnering with Marck: How It Works

Initial Consultation Understand your system specs, OEM models, and usage patterns.

Quotation & Sample Approval We provide detailed proposals and offer test samples for validation.

Order & Production Ranging from small spare lots to mass production, with regular updates.

Technical & After-Sales Support Including troubleshooting, field assistance, and prompt RMA processes.

Ongoing Relationship We offer lifecycle support—even for legacy elevators requiring obsolete part replacements.

Elevate Your Operations with Marck Industries

Your elevator fleet deserves nothing less than reliable, certified parts that stand the test of time. Choose Marck Industries for precision, safety, and peace of mind—backed by technical excellence and global service reach.

Ready to discuss your parts needs? Contact our sales team or request a quote through the Marck Industries website today.

0 notes

Text

IPC-A-610 certification is an industry-standard document published by the Association of Connecting Electronics Industries (IPC). This widely recognized standard establishes the acceptability criteria for the assembly of electronic components, defining what is acceptable and what is not in terms of their artistry. To know more read this infographic: https://soldertraining.net/blog/benefits-of-ipca610-training-certification-program/.

0 notes

Text

Understanding CEM in Modern Electronics: A Practical Insight

Understanding CEM in Modern Electronics: A Practical Insight

In today’s complex electronics landscape, product innovation and efficient manufacturing go hand in hand. For engineers, designers, and procurement professionals, choosing the right electronics partner is no longer a matter of convenience—it’s essential to product success. At Arrival Electronics Limited, a company based in Arundel, West Sussex, clients find an experienced and well-established resource for navigating the ever-changing world of electronic components and contract manufacturing.

Whether you are developing a product prototype or managing large-scale production, understanding the value and structure of CEM—Contract Electronics Manufacturing—is key to maintaining consistency, reliability, and supply chain strength. This article breaks down the concept of contract electronics manufacturing in practical terms, why it matters, and what to consider when selecting the right partner for your business.

CEM Explained: How Outsourced Electronics Manufacturing Supports Product Success

CEM refers to the process where a company outsources some or all of its electronic manufacturing responsibilities to a third-party provider. These services can include the assembly of printed circuit boards (PCBs), box builds, cable assemblies, and even full system integration. For many businesses, this arrangement helps bridge the gap between concept and market delivery without investing in internal production facilities.

But the advantages of outsourcing electronic manufacturing are not limited to infrastructure savings. A seasoned provider brings value through quality control, compliance assurance, procurement efficiency, and reduced lead times. The focus is not just on manufacturing but on delivering consistent results across the entire product lifecycle.

The Role of Contract Manufacturing in Product Development

In the early stages of product development, design and testing cycles can be both time-intensive and cost-sensitive. Working with an experienced manufacturing partner during this phase ensures that designs are ready for production, not just in theory but in practice. This includes:

Design for Manufacture (DfM) input: Ensuring that designs can be replicated reliably at scale.

Component sourcing guidance: Helping identify component availability, pricing trends, and lifecycle risks.

Rapid prototyping: Allowing for multiple iterations and validation cycles before full production.

The value of this support is particularly noticeable in industries with tight regulatory requirements or highly customized designs. Knowing that your product is being assembled by a team familiar with these challenges adds a layer of assurance often missed when production is fragmented or uncoordinated.

Quality Control and Compliance in Electronics Manufacturing

Consistency is everything when it comes to electronics. A single deviation in assembly quality or component specification can compromise an entire batch of products. Reputable manufacturers implement rigorous quality control standards—often including ISO certifications and IPC-A-610 class ratings—to ensure production meets both industry standards and client expectations.

In addition, experienced production partners are frequently tasked with managing regulatory documentation. For sectors like medical, automotive, aerospace, and defence, regulatory compliance is not just about paperwork—it’s a vital part of risk management and long-term reliability.

With experienced providers, clients benefit from:

Traceability systems to track component origins and manufacturing data

Test procedures tailored to the client’s performance standards

Material compliance such as RoHS, REACH, and conflict mineral regulations

This commitment to precision manufacturing and documentation forms the foundation of long-term supply stability.

Supply Chain Management and Procurement

One of the most significant advantages of working with an experienced electronics manufacturing partner is procurement efficiency. The global electronics supply chain can be unpredictable—affected by material shortages, geopolitical issues, and currency fluctuations. A reliable provider has both the scale and supplier relationships to manage these challenges on your behalf.

By centralizing procurement and inventory management, the risk of component obsolescence, stockouts, and delivery delays is greatly reduced. Strategic sourcing, long-term supplier contracts, and access to authorized distribution channels allow clients to focus on core design and development tasks.

In many cases, these providers also help negotiate better pricing through consolidated purchasing volumes, improving overall cost-effectiveness without compromising on quality.

Customization and Flexibility in Electronics Manufacturing

Different companies have different requirements. Some need full assembly and testing; others only need PCB population or logistics support. A flexible production model is one that adapts to these varying levels of engagement.

For example, some clients may request:

Box build and enclosure integration

Cable and wire harness manufacturing

Programming and firmware upload

Functional testing and diagnostics

A well-structured manufacturing relationship allows businesses to adjust their production effort (either up or down) based on demand, without renegotiating contracts or reorganizing supply infrastructure. This adaptability is particularly important for startups, R&D teams, and businesses with seasonal product cycles.

The Importance of Local Manufacturing Support

While many companies consider offshore production due to lower costs, working with a local manufacturing partner still provides key advantages in terms of quality and communication. UK-based providers offer accessible collaboration, faster turnaround times, and streamlined logistics—all important factors in today’s competitive electronics environment.

Local manufacturing also contributes to:

Greater visibility during production runs

Faster issue resolution if engineering changes are required

Reduced transportation risks, especially for fragile or sensitive components

Working with a local partner ensures better control, particularly when dealing with niche products, custom builds, or compliance-heavy applications.

Trends in Electronics Manufacturing for 2025 and Beyond

As the demand for smarter, more integrated electronics continues to grow, so do the expectations placed on modern manufacturing services. Emerging technologies such as IoT-enabled devices, wearable electronics, and electric vehicle systems require a more advanced and flexible approach to assembly and testing.

In response, many manufacturing specialists are expanding their capabilities to include:

Microelectronics assembly

High-frequency RF product support

Environmentally controlled production environments

Long-term product lifecycle support

These advancements are not confined to high-volume production. Niche developers and innovators also benefit from working with partners that understand how to manage intricate designs and deliver dependable, high-quality builds.

Choosing the Right Manufacturing Partner

With so many electronics manufacturing options available, how do you decide which one is right for your project?

Here are five practical factors to consider:

Experience: Look for a provider with a strong track record in your specific industry. Practical experience brings valuable insight, especially when navigating technical designs and regulatory requirements.

Certifications: Confirm that the company holds relevant and current industry certifications, as these reflect adherence to recognized quality standards.

Transparency: A trustworthy partner will be clear about their production capabilities, timelines, and internal processes from the start.

Technical Support: It's beneficial to work with a team that offers design-stage assistance—not just assembly. Early input can prevent delays and reduce costs.

Location: Think about the practical benefits of working with a nearby provider, including easier communication, faster lead times, and simplified logistics.

By considering these factors carefully, you can reduce risk and improve the likelihood of a successful, long-term collaboration.

Why Contract Electronics Manufacturing Still Matters

In a world where electronics innovation is constant, outsourced production remains a vital service for product teams aiming to maintain focus and efficiency. It’s not just about handing off manufacturing—it’s about building the right partnerships. With increasing pressure to deliver quality products on time and within budget, working with a capable electronics manufacturing partner is a smart and strategic move.

This type of collaboration allows businesses to stay agile while drawing on technical expertise, stable supply chains, and reliable assembly processes. It helps bridge the gap between concept and product delivery—without the need for extensive internal infrastructure.

Conclusion

From component sourcing and design guidance to full assembly and product lifecycle support, Arrival Electronics Limited provides the practical expertise and trusted service needed in today’s competitive electronics industry. Located in West Sussex, the team works closely with clients across the UK and beyond, delivering dependable contract manufacturing solutions built on transparency, experience, and technical depth.

If you're looking for a CEM provider who understands your challenges and delivers reliable, detail-oriented service, consider a partner with proven experience and a commitment to quality at every stage of your project.

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions.

If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions. If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions.

If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

Electronic Manufacturing in Chennai — A Complete Industry Overview

If you’re exploring electronic manufacturing in Chennai, you’re looking at one of India’s fastest-growing and most dynamic industrial sectors. Chennai has emerged as a key hub for EMS (Electronics Manufacturing Services) and PCB design, attracting both domestic and international companies seeking quality, efficiency, and innovation.

This comprehensive overview will help you understand why Chennai is a preferred destination for electronics manufacturing, what the local industry offers, and how it can support your product development needs.

Why Chennai is a Leading Electronics Manufacturing Hub

Chennai’s rise as an electronics manufacturing center is driven by several unique advantages:

Strategic Location and Connectivity

Chennai offers excellent access to major ports like Chennai Port and Ennore Port, facilitating smooth import and export of components and finished goods. The city is well-connected via road, rail, and air to key markets across India and globally.

Skilled Workforce and Technical Expertise

Chennai is home to numerous engineering colleges and technical institutes that supply a steady stream of qualified engineers and technicians. This talent pool is well-versed in modern PCB design and electronics manufacturing processes, supporting innovation and quality.

Robust Infrastructure and Industrial Clusters

Dedicated electronics manufacturing zones, such as Sriperumbudur and Oragadam, host advanced industrial parks with reliable power, logistics, and facilities tailored for electronics production.

Government Support and Incentives

Tamil Nadu’s electronics manufacturing policy encourages investments through subsidies, incentives, and streamlined approvals. National initiatives like Production Linked Incentive (PLI) schemes further boost the sector.

Key Components of Electronic Manufacturing in Chennai

Electronics Manufacturing Services (EMS)

EMS companies in Chennai offer end-to-end manufacturing solutions, including:

Prototype development and New Product Introduction (NPI)

Printed Circuit Board Assembly (PCBA) with Surface Mount Technology (SMT) and Through-Hole Technology (THT)

Box build assembly and product integration

Testing, quality control, and compliance assurance

These companies serve diverse sectors such as consumer electronics, automotive, healthcare, industrial automation, and IoT devices.

PCB Design and Manufacturing

Advanced pcb design capabilities are a cornerstone of Chennai’s electronics ecosystem. Local companies specialize in multilayer PCB layout, high-density interconnects (HDI), and design for manufacturability (DFM), enabling efficient production and performance optimization.

PCB manufacturing units support these designs with precise fabrication, assembly, and inspection processes.

Trends Shaping the Electronics Manufacturing Industry in Chennai

IoT and Smart Devices: Increasing demand for connected devices is driving innovation in EMS and PCB design services.

Automation and Industry 4.0: Adoption of robotics and AI-powered quality control is enhancing manufacturing precision.

Sustainability: Growing focus on eco-friendly materials and energy-efficient manufacturing practices.

Export Growth: Chennai’s electronics exports are rising steadily, supported by favorable trade policies and global demand.

How to Choose the Right EMS Partner in Chennai

When selecting an EMS company in Chennai, consider the following factors:

Technical expertise in PCB design and advanced manufacturing technologies

Quality certifications such as ISO and IPC standards compliance

Manufacturing capacity and scalability to support your product lifecycle

Transparent communication and project management for smooth collaboration

Conclusion

Electronic manufacturing in Chennai is a thriving, well-supported industry with strong infrastructure, skilled talent, and innovative EMS providers. Whether you are a startup or an established company, Chennai offers a reliable ecosystem to develop, manufacture, and scale your electronic products efficiently.

Understanding the local capabilities in pcb design and EMS will help you make the best choices and accelerate your product’s journey from concept to market success.

#ElectronicManufacturing#EMSIndia#PCBDesignChennai#ElectronicsInChennai#PCBAIndia#SMTAssembly#ElectronicsManufacturingServices#PCBManufacturingIndia#ChennaiEMS#ManufacturingInChennai

0 notes

Text

Key Capabilities to Look for in a High-Level Assembly (HLA) Manufacturing Partner

Introduction

Choosing the right High-Level Assembly (HLA) manufacturing partner is a vital move that could define the future success of your success of your product development, time to market, and customer satisfaction. Whether you're building complex medical devices, aerospace systems, or industrial automation units, your partner must have the technical expertise and infrastructure to deliver fully integrated, tested, and reliable assemblies.

This article outlines the key capabilities to evaluate when selecting an HLA partner, including mechanical, electrical, and software integration, quality certifications, and robust testing protocols.

1️⃣ Proven Expertise in Mechanical, Electrical, and Software Integration

A capable HLA partner should offer multi-disciplinary integration services, seamlessly combining hardware and software into a fully functional product.

🔧 Mechanical Integration

Experience with enclosures, housings, and thermal management

Precision in component alignment and structural assembly

Capability to handle miniature, complex, or heavy-duty mechanical parts

⚡ Electrical Integration

Assembly of wire harnesses, PCBs, and custom cable systems

Safe routing, insulation, and grounding of components

Knowledge of EMI/EMC management in high-speed electronics

💻 Software & Firmware Integration

Embedded software flashing and functional setup

Compatibility testing across hardware and software systems

Support for device communication protocols (e.g., USB, CAN, Wi-Fi, Bluetooth)

✅ Why it matters: Seamless integration ensures fewer failures, better performance, and faster product validation.

2️⃣ Industry-Specific Knowledge and Standards Compliance

Your HLA partner should understand the regulatory landscape and product requirements specific to your industry.

Examples of Industry Standards:

Medical Devices: ISO 13485, FDA 21 CFR Part 820

Aerospace & Defense: AS9100, MIL-SPEC, ITAR compliance

Industrial & Automation: UL certification, RoHS, CE

Electronics & Telecom: IPC/WHMA-A-620, ISO 9001

✅ Why it matters: Compliance with certifications ensures product safety, smooth global market entry, and regulatory peace of mind.

3️⃣ In-House Testing & Quality Assurance Protocols

A reliable HLA provider should offer comprehensive testing services to verify each unit before shipment.

Types of Testing to Look For:

Functional Testing (FCT): Verifies real-world functionality

In-circuit testing (ICT): Validates electronic performance and integrity

Burn-In Testing: Simulates prolonged use to detect failures

Environmental Stress Screening: Confirms performance under temperature, vibration, or humidity stress

Additional Quality Measures:

Root cause failure analysis

Documentation and traceability systems

Statistical Process Control (SPC)

✅ Why it matters: Thorough testing ensures long-term reliability and reduces the risk of costly field failures or recalls.

4️⃣ Scalable Production Capabilities

Whether you need a small pilot run or high-volume production, your partner should be able to scale operations efficiently.

Look for:

Flexible production lines for low- to high-mix assemblies

Automation capabilities for faster throughput

Supply chain management and component sourcing expertise

Inventory and warehousing support

✅ Why it matters: Scalability supports fast market entry and seamless ramp-up during product launches or demand spikes.

5️⃣ Engineering & Design for Manufacturability (DFM) Support

Top-tier HLA manufacturers offer engineering collaboration during product development.

Key Services:

Design for Manufacturability (DFM) reviews

Design for Testability (DFT) insights

Cost optimization recommendations

Rapid prototyping and iterative feedback

✅ Why it matters: Early engineering support reduces errors, shortens development cycles, and improves product performance and cost efficiency.

6️⃣ Transparent Communication and Project Management

Effective collaboration requires a partner who values clear communication and accountability.

Must-Have Traits:

Dedicated project managers

Regular status updates and milestone tracking

Open communication channels with engineering and QA teams

Responsiveness to design revisions or urgent issues

✅ Why it matters: A responsive partner ensures your project stays on track, financially controlled, and aligned with goals.

Conclusion

Selecting a high-quality, High-Level Assembly manufacturing partner is more than outsourcing—it's forming a strategic relationship. The right partner brings together engineering expertise, regulatory compliance, testing rigor, and scalability, empowering you to build complex products faster, more reliably, and more cost-effectively.

When evaluating HLA partners, prioritize those with proven cross-functional capabilities, strong quality certifications, and a collaborative approach. This will ensure that your innovations make it to market with precision, performance, and confidence.

0 notes