#JIS L1076...

Explore tagged Tumblr posts

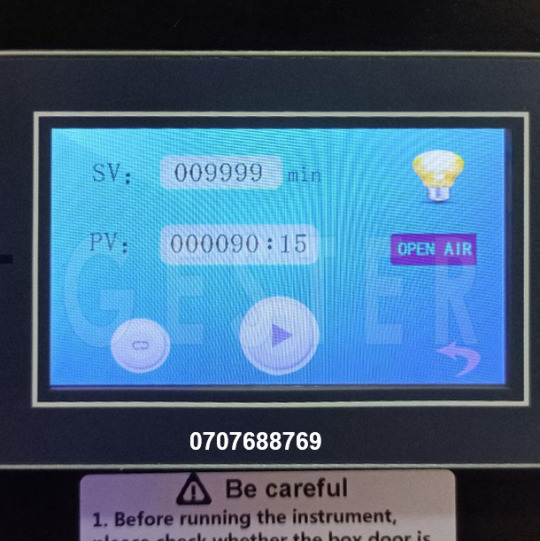

Text

#🌾 Máy kiểm tra độ đóng cục ngẫu nhiên GT-C19A được thiết kế để kiểm tra độ bền bong tróc giữa đế và phần trên của toàn bộ chiếc giày hoặc gi#🌾 Thiết bị đáp ứng theo tiêu chuẩn ASTM D3512#DIN 53867#JIS L1076...#👉 Hàng được nhập khẩu v�� phân phối trực tiếp tại công ty Viên Viên.#Tel: 0707688769#Email: [email protected]#Website: www.vienvienco.com

0 notes

Text

Fabric Pilling Testing for Industrial and Workwear Fabrics: Why It Matters?

Industrial and workwear fabrics are designed to withstand harsh environments, frequent usage, and extreme conditions. Durability, performance, and comfort are crucial factors for these fabrics, and one significant aspect that impacts their longevity is fabric pilling. Pilling—small fiber balls forming on fabric surfaces—can compromise the integrity, aesthetic, and functionality of workwear and industrial textiles. Fabric pilling testing ensures that these textiles maintain their high standards, meeting industry requirements and worker expectations.

This blog explores why fabric pilling test is essential for industrial and workwear fabrics, the testing methods used, global standards, and best practices for achieving durable, high-quality textiles.

The Importance of Fabric Pilling Testing in Industrial and Workwear Fabrics

1. Ensuring Long-Lasting Durability

Workwear fabrics endure repeated washing, friction, and rough handling. Pilling can weaken fabric fibers, reducing their strength and making garments more prone to tearing. Testing helps manufacturers select materials that resist pilling, ensuring long-lasting apparel.

2. Maintaining a Professional Appearance

Industrial and corporate uniforms are part of a company’s brand identity. Excessive pilling can make workwear look old, unkempt, and unprofessional. Conducting pilling tests ensures fabrics retain a neat and polished look even after multiple washes and heavy use.

3. Enhancing Worker Comfort

Comfort is a priority for workwear, especially in physically demanding jobs. Pilled fabric can feel rough, causing discomfort and irritation to the skin. By preventing excessive pilling, manufacturers can produce workwear that remains smooth and comfortable over time.

4. Meeting Industry Standards and Compliance

Certain industries, such as construction, manufacturing, and healthcare, have strict textile requirements. Fabric pilling testing helps brands meet these standards, ensuring compliance with safety and performance regulations.

5. Reducing Costs and Customer Complaints

Pilling can lead to premature replacement of workwear, increasing costs for businesses. By selecting high-quality, pilling-resistant fabrics through rigorous testing, companies can reduce replacement frequency and improve customer satisfaction.

Fabric Pilling Test Methods for Workwear Fabrics

To assess pilling resistance, manufacturers use standardized testing methods that replicate real-world wear and tear.

1. Martindale Pilling Test (ISO 12945-2, ASTM D4970)

Fabric samples are subjected to circular rubbing motions under controlled conditions.

The degree of pilling is evaluated visually using a grading scale.

Ideal for assessing woven and knitted industrial fabrics.

2. Random Tumble Pilling Test (ASTM D3512)

Fabric samples are placed inside a rotating drum with cork or rubber balls.

The tumbling action mimics everyday wear, assessing the fabric’s ability to resist pilling.

Commonly used for knitwear and soft workwear fabrics.

3. ICI Pilling Box Test (ISO 12945-1)

Fabric samples are placed in a rotating cork-lined box.

The number of rotations determines the extent of pilling.

Best suited for industrial uniforms and heavy-duty fabrics.

4. Brush and Sponge Pilling Test (JIS L1076)

A brush and sponge apply controlled friction to fabric samples.

Used to test delicate industrial fabrics, ensuring they resist pilling over extended use.

Industry Standards for Fabric Pilling Testing

To ensure consistent fabric quality, manufacturers adhere to international testing standards, including:

ISO 12945-1 & ISO 12945-2 – International standards for pilling resistance.

ASTM D4970 – Standard Martindale pilling test.

ASTM D3512 – Standard for Random Tumble Pilling Tests.

JIS L1076 – Japanese standard for brush and sponge testing.

Following these guidelines helps manufacturers maintain uniform product quality and meet industry requirements.

Best Practices for Conducting Fabric Pilling Tests in Workwear Manufacturing

1. Choose High-Quality Fabrics

Selecting workwear materials with tightly woven or knitted structures minimizes pilling. High-quality polyester, cotton blends, and treated synthetic fabrics offer superior resistance.

2. Conduct Multiple Pilling Tests

Using a combination of testing methods provides a more accurate assessment of a fabric’s pilling resistance. Conducting multiple tests helps manufacturers identify weak points before production.

3. Control Environmental Factors

Testing should be conducted under controlled temperature and humidity levels. Environmental fluctuations can impact results and lead to inconsistencies.

4. Apply Fabric Finishing Treatments

Advanced treatments, such as enzyme washes, fabric coatings, and singeing (removing protruding fibers), can improve pilling resistance and extend the life of workwear fabrics.

5. Train Quality Control Teams

Well-trained quality control teams ensure that fabric pilling tests are performed accurately and consistently. Regular training ensures adherence to testing standards.

6. Partner with Certified Testing Laboratories

Collaborating with accredited testing labs ensures that pilling test results are reliable and meet international benchmarks. Certified labs provide third-party validation of fabric performance.

Conclusion

For industrial and workwear fabrics, fabric pilling testing plays a crucial role in ensuring durability, comfort, and a professional appearance. Pilling-resistant fabrics extend garment longevity, enhance worker satisfaction, and reduce maintenance costs for businesses.

By employing rigorous testing methods, following industry standards, and implementing best practices, manufacturers can produce high-performance workwear that meets the demands of various industries. Investing in fabric pilling testing not only enhances textile quality but also reinforces a brand’s commitment to excellence.

0 notes

Text

#🌻Máy kiểm tra chất liệu vải GT-C19B được cuốn ngẫu nhiên#sử dụng để xác định các đặc tính đóng vón và xù lông của vải dệt.#🌻Thiết bị đáp ứng theo tiêu chuẩn ASTM D3512#DIN 53867#JIS L1076...#✈️✈️Hàng hoá được nhập khẩu và phân phối trực tiếp tại Công Ty TNHH TM DV VIÊN VIÊN#Tel: 0707688769#Email: [email protected]#Website: www.vienvienco.com

0 notes

Text

#🌻Máy kiểm tra độ vón cục ngẫu nhiên GT-C19B được sử dụng để xác định đặc tính vón và xù lông của vải dệt. Bánh công tác tốc độ cao chính xác#🌻Thiết bị đáp ứng theo tiêu chuẩn ASTM D3512#DIN 53867#JIS L1076...#✈️✈️Hàng hoá được nhập khẩu và phân phối trực tiếp tại Công Ty TNHH TM DV VIÊN VIÊN#Tel: 0707688769#Email: [email protected]#Website: www.vienvienco.com

0 notes

Text

#🌾Máy kiểm tra độ vón cục ngẫu nhiên RF3194N#đưa các loại vải thử nghiệm và mảnh bông vào buồng thử nghiệm được hỗ trợ bằng lớp lót liên kết#các cánh quạt bằng thép quay với tốc độ cao không đổi#cùng với việc bơm khí nén vào buồng#làm cho các loại vải thử nghiệm va chạm với các lớp lót liên kết#để xác định các đặc tính vón và xù lông của vải dệt.#🌾Thiết bị đáp ứng theo tiêu chuẩn: ASTM D3512#DIN 53867#ISO DIS 12945-3#JIS L1076-D#GB/T 4802.4...#✈️✈️Hàng hoá được nhập khẩu và phân phối trực tiếp tại Công Ty TNHH TM DV VIÊN VIÊN#Tel: 0707688769#Email: [email protected]#Website: www.vienvienco.com

0 notes