#LDPE Pricing

Explore tagged Tumblr posts

Text

LDPE Prices: Market Analysis, Trend, News, Graph and Demand

Low Density Polyethylene (LDPE) is a thermoplastic polymer that plays a crucial role in various industries, particularly in packaging, agriculture, and construction. Over the past few years, the LDPE market has experienced significant price fluctuations driven by several factors, including raw material costs, supply-demand dynamics, global trade patterns, and geopolitical events. LDPE prices are closely tied to the cost of ethylene, its primary feedstock, and any changes in the crude oil market typically have a direct impact on LDPE price trends. When crude oil prices rise, the cost of producing ethylene increases, pushing LDPE prices upward. Conversely, a drop in crude oil prices can offer relief to manufacturers and consumers, resulting in lower LDPE prices.

Demand-side factors also play a pivotal role in shaping LDPE market prices. The packaging sector, which consumes a significant portion of LDPE, has seen steady growth owing to the boom in e-commerce and increased consumer awareness of hygiene and food safety. Flexible packaging, LDPE films, and plastic bags remain in high demand, particularly in emerging economies. This rising demand supports price stability, but it can also lead to price hikes during periods of tight supply. Furthermore, seasonal demand variations, such as increased agricultural film usage during planting seasons, can temporarily influence LDPE pricing trends.

Get Real time Prices for Low Density Polyethylene (LDPE): https://www.chemanalyst.com/Pricing-data/low-density-polyethylene-ldpe-24

Global trade dynamics further complicate the LDPE pricing landscape. Major producers like the United States, China, and countries in the Middle East have significant influence over the global supply. When large-scale producers increase output or offer competitive prices in international markets, global LDPE prices tend to adjust accordingly. On the other hand, import restrictions, anti-dumping duties, or trade disputes can limit availability in specific regions, thereby escalating local prices. For instance, protectionist policies in India or tariffs imposed on polyethylene imports in some European nations have led to regional price variations that diverge from global trends.

Another key factor influencing LDPE market prices is the growing emphasis on sustainability and environmental regulations. Governments around the world are tightening policies around plastic usage and encouraging the use of biodegradable alternatives. While this shift promotes long-term environmental goals, it has a short-term impact on LDPE demand. The introduction of plastic bans in several countries has caused demand to fluctuate, impacting overall market pricing. However, technological advancements in recycling and circular economy initiatives have opened new avenues for LDPE reuse, potentially stabilizing demand and influencing long-term price behavior.

Production capacity expansions and plant turnarounds also contribute to LDPE market dynamics. Investments in new petrochemical facilities, especially in Asia and the Middle East, have increased global LDPE supply capacity. This expansion has the potential to reduce prices by improving availability. However, planned and unplanned shutdowns of manufacturing units for maintenance or upgrades can create temporary supply shortages, causing price spikes. The timing and scale of these operational changes are often monitored closely by market analysts and traders to predict potential price movements.

In the current market landscape, LDPE prices are showing signs of moderate recovery following previous periods of high volatility. Supply chains have gradually stabilized, and raw material costs have become more predictable. However, market participants remain cautious as economic uncertainty, inflationary pressures, and changes in consumer behavior continue to influence overall demand. While short-term price movements may remain uncertain, the long-term outlook for LDPE prices appears relatively balanced, driven by steady demand from key industries and expanding production capabilities.

Technological innovations in polymer processing and packaging have also had a subtle yet meaningful impact on LDPE pricing. The development of more efficient manufacturing processes and the use of advanced catalysts have improved production yields, helping manufacturers lower costs. At the same time, the shift toward value-added LDPE grades, including those used in specialized applications like medical packaging or high-barrier films, has created niche markets with distinct pricing patterns. As a result, market segmentation is becoming more prominent, with standard LDPE grades following broader commodity trends, while specialty grades experience different pricing dynamics.

Digitalization and data analytics are increasingly being used by market participants to forecast LDPE prices and manage procurement more effectively. Real-time tracking of raw material prices, global inventory levels, and shipping logistics allows companies to anticipate market changes and adjust their strategies accordingly. This level of market intelligence contributes to more efficient pricing mechanisms and better risk management, which ultimately helps stabilize LDPE price trends over time.

Looking ahead, the LDPE market is expected to remain influenced by a combination of macroeconomic indicators, industry-specific demand patterns, regulatory changes, and technological developments. While prices may continue to experience short-term fluctuations due to external shocks or market speculation, the underlying fundamentals point toward a gradually stabilizing market. For businesses involved in LDPE production, trade, or consumption, staying informed about market trends and maintaining supply chain resilience will be key strategies for navigating future price movements. With growing applications and ongoing innovations, LDPE is likely to retain its vital role in the global polymer market, supported by a pricing environment that reflects both evolving challenges and emerging opportunities.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#LDPE Price#LDPE Price Monitor#LDPE Pricing#Low Density Polyethylene#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

LDPE Decking Market to Hit $3.9 Billion by 2032

The global LDPE Decking Market was valued at USD 1.9 Billion in 2024 and it is estimated to garner USD 3.9 Billion by 2032 with a registered CAGR of 11.2% during the forecast period 2024 to 2032.

The report throws light on the competitive scenario of the global LDPE Decking Market to know the competition at global levels. Market experts also provided the outline of each leading player of the global LDPE Decking Market for the market, considering the key aspects such as the areas of operation, production, and product portfolio. In addition, the companies in the report are studied based on vital factors such as company size, market share, market growth, revenue, production volume, and profit.

The global LDPE Decking Market is fragmented with various key players. Some of the key players identified across the value chain of the global LDPE Decking Market include Certainteed Corporation, Universal Forest Products, Advanced Environmental Recycling Technologies, Azek Building Products, Fiberon, Green Bay Decking, UPM Kymmene, Duralife Decking and Railing Systems, Cardinal Building Products, Tamko Building Products, etc. Considering the increasing demand from global markets various new entries are expected in the LDPE Decking Market at regional as well as global levels.

Download LDPE Decking Market Sample Report PDF: https://www.vantagemarketresearch.com/ldpe-decking-market-0935/request-sample

Top Competitors:

Certainteed Corporation, Universal Forest Products, Advanced Environmental Recycling Technologies, Azek Building Products, Fiberon, Green Bay Decking, UPM Kymmene, Duralife Decking and Railing Systems, Cardinal Building Products, Tamko Building Products,

Understanding the Industry's Growth, has released an Updated report on the LDPE Decking Market. The report is mixed with crucial market insights that will support the clients to make the right business decisions. This research will help new players in the global LDPE Decking Market to sort out and study market needs, market size, and competition. The report provides information on the supply and market situation, the competitive situation and the challenges to the market growth, the market opportunities, and the threats faced by the major players.

Regional Analysis

-North America [United States, Canada, Mexico]

-South America [Brazil, Argentina, Columbia, Chile, Peru]

-Europe [Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland]

-Middle East & Africa [GCC, North Africa, South Africa]

-Asia-Pacific [China, Southeast Asia, India, Japan, Korea, Western Asia]

You Can Buy This Report From Here: https://www.vantagemarketresearch.com/buy-now/ldpe-decking-market-0935/0

Full Analysis Of The LDPE Decking Market:

Key findings and recommendations point to vital progressive industry trends in the global LDPE Decking Market, empowering players to improve effective long-term policies.

The report makes a full analysis of the factors driving the development of the market.

Analyzing the market opportunities for stakeholders by categorizing the high-growth divisions of the market.

Questions answered in the report

-Who are the top five players in the global LDPE Decking Market?

-How will the global LDPE Decking Market change in the next five years?

-Which product and application will take the lion's share of the global LDPE Decking Market?

-What are the drivers and restraints of the global LDPE Decking Market?

-Which regional market will show the highest growth?

-What will be the CAGR and size of the global LDPE Decking Market during the forecast period?

Read Full Research Report with [TOC] @ https://www.vantagemarketresearch.com/industry-report/ldpe-decking-market-0935

Reasons to Purchase this LDPE Decking Market Report:

-Analysis of the market outlook on current trends and SWOT analysis.

-The geographic and country level is designed to integrate the supply and demand organizations that drive industry growth.

-LDPE Decking Industry dynamics along with market growth opportunities in the coming years.

-LDPE Decking Market value (million USD) and volume (million units) data for each segment and sub-segment.

1 year consulting for analysts along with development data support in Excel. Competitive landscape including market share of major players along with various projects and strategies adopted by players in the last five years.

Market segmentation analysis including qualitative and quantitative analysis including the impact on financial and non-economic aspects.

Complete company profiles that include performance presentations, key financial overviews, current developments, SWOT analyzes and strategies used by major LDPE Decking Market players.

Check Out More Reports

Global Cannabis Testing Market: Report Forecast by 2032

Global Herbal Supplements Market: Report Forecast by 2032

Global Marché des produits chimiques de construction: Report Forecast by 2032

Global E-Bike Market: Report Forecast by 2032

Global Small Satellite Market: Report Forecast by 2032

#LDPE Decking Market#LDPE Decking Market 2024#Global LDPE Decking Market#LDPE Decking Market outlook#LDPE Decking Market Trend#LDPE Decking Market Size & Share#LDPE Decking Market Forecast#LDPE Decking Market Demand#LDPE Decking Market sales & price

0 notes

Text

LDPE Sheets: An Essential Material in Industrial Applications

Introduction to LDPE Sheets Low-Density Polyethylene (LDPE) sheets are among the most versatile and widely used materials in various industrial applications. Known for their flexibility, durability, and chemical resistance, LDPE sheets are favored in numerous sectors, including construction, packaging, and agriculture. Their unique properties make them indispensable for many industrial processes, providing solutions that are both cost-effective and efficient.

Properties and Advantages of LDPE Sheets LDPE sheets are characterized by their low density, which gives them a high degree of flexibility and toughness. The flexibility of LDPE sheets allows them to be easily formed and molded, catering to a wide range of applications. Moreover, they possess excellent insulating properties, which is crucial in electrical and thermal applications.

Applications in Construction In the construction industry, LDPE sheets are highly valued for their durability and versatility. LDPE sheet for construction are used for moisture barriers, vapor retarders, and as protective covers. They are commonly employed in roofing, flooring, and wall protection to prevent moisture infiltration and damage. Additionally, these sheets serve as an effective barrier against dust and debris during construction activities, ensuring a cleaner and safer work environment.

Packaging Solutions LDPE sheets play a significant role in the packaging industry due to their lightweight and durable nature. These sheets are used to manufacture a variety of packaging materials, including bags, wraps, and liners. The flexibility of LDPE allows it to be used for shrink wrapping, providing a secure and protective layer for goods during transportation and storage. The LDPE plastic sheet suppliers offer customized solutions to meet the specific needs of different industries, ensuring that products are adequately protected.

Agricultural Uses The sheets help in maintaining soil moisture, controlling weed growth, and protecting crops from adverse weather conditions. The durability and resistance to chemicals make LDPE sheets ideal for use in harsh agricultural environments. Farmers and agricultural professionals rely on LDPE sheet manufacturers to provide high-quality materials that enhance crop productivity and sustainability.

Electrical and Thermal Insulation LDPE sheets are excellent insulators, making them suitable for electrical and thermal applications. They are used in the production of insulating layers for cables and wires, providing protection against electrical currents and heat. The insulating properties of LDPE sheets also make them ideal for use in thermal insulation, helping to maintain temperature control in various industrial processes.

Manufacturing and Fabrication The manufacturing and fabrication processes benefit significantly from the use of LDPE sheets. These sheets can be easily cut, welded, and formed into various shapes and sizes, making them suitable for a wide range of applications. The LDPE sheet manufacturer price is competitive, providing cost-effective solutions for industries that require high-quality materials. The ease of fabrication and the ability to customize LDPE sheets to specific requirements make them a preferred choice for manufacturers.

Environmental Considerations

The production and disposal of plastic materials have raised concerns about pollution and waste management. However, advancements in recycling technologies have made it possible to recycle LDPE sheets, reducing their environmental footprint. Industries are increasingly adopting sustainable practices, such as using recycled LDPE materials, to minimize their impact on the environment.

Innovations and Future Trends The continuous development of new technologies and materials is driving innovations in the use of LDPE sheets. Researchers and manufacturers are exploring ways to enhance the properties of LDPE, such as improving its strength, flexibility, and resistance to environmental factors. The integration of advanced manufacturing techniques, such as 3D printing, is opening up new possibilities for the application of LDPE sheets in various industries. The future of LDPE sheets looks promising, with ongoing efforts to make them more sustainable and efficient.

Choosing the Right LDPE Sheet Supplier Selecting the right supplier is crucial for ensuring the quality and reliability of LDPE sheets. LDPE plastic sheet suppliers must adhere to strict quality standards and provide materials that meet the specific needs of their customers. It is essential to consider factors such as the supplier's reputation, experience, and ability to offer customized solutions. A reliable supplier will ensure that the LDPE sheets are manufactured using high-quality raw materials and advanced production techniques, providing consistent performance and durability.

Cost-Effectiveness and Value One of the key advantages of LDPE sheets is their cost-effectiveness. The LDPE sheet manufacturer price is competitive, making them an affordable option for various industrial applications. Despite their affordability, LDPE sheets do not compromise on quality and performance. They offer excellent value for money, providing long-lasting and reliable solutions that meet the demands of different industries. The ability to source high-quality LDPE sheets at reasonable prices makes them an attractive choice for businesses looking to optimize their operations.

Conclusion

LDPE sheets have established themselves as an essential material in industrial applications due to their unique properties and versatility. From construction and packaging to agriculture and electrical insulation, LDPE sheets offer reliable and cost-effective solutions for a wide range of industries. As technology continues to advance, the applications and benefits of LDPE sheets are expected to grow, making them an integral part of modern industrial processes. By choosing the right suppliers and adopting sustainable practices, industries can maximize the advantages of LDPE sheets while minimizing their environmental impact.

Frequently Asked Questions (FAQs)

How do LDPE sheets benefit agricultural practices? In agriculture, LDPE sheets help in weed control, soil temperature regulation, and moisture retention through mulching. They also provide optimal conditions for plant growth when used as greenhouse covers and are effective in water management as pond liners.

Are LDPE sheets environmentally friendly? While LDPE sheets are a type of plastic, many manufacturers produce recyclable versions to reduce environmental impact. It is important to recycle LDPE sheets and consider eco-friendly alternatives to minimize pollution.

What factors should be considered when choosing an LDPE sheet supplier? When choosing an LDPE sheet supplier, consider factors such as the supplier’s reputation, the range of products offered, pricing, and the availability of customizable options to meet specific industrial needs.

0 notes

Text

LDPE Shrink Films: A Comprehensive Guide to Uses, Benefits, and Manufacturers

Introduction LDPE (Low-Density Polyethylene) shrink films have become a staple in the packaging industry due to their versatile and LDPE Shrink Film Price cost-effective nature. Whether you're a business owner looking to secure your products for transport or a consumer seeking durable packaging options, understanding the nuances of LDPE shrink films can be incredibly beneficial. In this article, we will delve into what LDPE shrink films are, their advantages, the benefits they offer, and insights into pricing and manufacturers. What Are LDPE shrink films? LDPE shrink films are plastic films made from low-density polyethylene, a type of thermoplastic derived from the polymerization of ethylene. These films are known for their flexibility, toughness, and ability to shrink tightly over items when heat is applied. This makes them an excellent choice for wrapping and protecting various goods, from food products to industrial materials. Advantages of LDPE shrink films Durability and strength One of the primary advantages of LDPE shrink films is their durability. These films provide a robust barrier against external factors such as moisture, dust, and other contaminants. Their strength ensures that the packaged products remain secure and intact during transit and storage.

Flexibility and conformability LDPE shrink films are highly flexible, allowing them to conform to the shape of the items they are wrapping. This flexibility is particularly useful for packaging irregularly shaped items, ensuring a snug fit and optimal protection.

Transparency These films offer excellent clarity, which is an essential factor for product visibility. Transparent shrink films allow consumers to see the product without needing to open the packaging, enhancing the product's shelf appeal and aiding in marketing efforts.

Cost-effectiveness When it comes to cost, LDPE shrink films are an economical choice. Their efficiency in terms of material usage and energy consumption during the shrink process makes them a budget-friendly option for businesses looking to reduce packaging costs without compromising on quality. Benefits of using LDPE shrink films Protection and preservation LDPE Shrink Film Manufacturer provide superior protection against physical damage, contamination, and environmental factors. They are especially effective in preserving perishable goods by creating an airtight seal that helps extend the shelf life of food products.

Versatility The versatility of LDPE shrink films is unmatched. They can be used across various industries, including food and beverage, pharmaceuticals, electronics, and more. This adaptability makes them a valuable packaging solution for a wide range of products.

Ease of use The application process for LDPE shrink films is straightforward. With the use of shrink tunnels or heat guns, these films can be easily applied to products. This ease of use not only speeds up the packaging process but also reduces labor costs.

Sustainability Many manufacturers are now producing LDPE shrink films with a focus on sustainability. These films can be recycled, which helps reduce the environmental impact. Moreover, innovations in manufacturing processes are continually improving the eco-friendliness of these films. Conclusion LDPE Shrink Film Manufacturers are a versatile and cost-effective solution for a wide range of packaging needs. Their durability, flexibility, and clarity make them an ideal choice for businesses looking to protect their products while maintaining a professional appearance. By understanding the advantages and benefits of these films, and selecting the right manufacturer, you can ensure your packaging solutions are both efficient and effective. FAQs Q1: What is LDPE shrink film made of? LDPE shrink film is made from low-density polyethylene, a type of thermoplastic derived from the polymerization of ethylene.

Q2: How does LDPE shrink film work? LDPE shrink film shrinks tightly over items when heat is applied, providing a secure and protective packaging solution.

Q3: Can LDPE shrink films be recycled? Yes, many LDPE shrink films are recyclable, contributing to more sustainable packaging practices.

0 notes

Photo

Top HDPE Sheet Manufacturers in India - Top HDPE Sheet Manufacturers (on Wattpad) https://www.wattpad.com/1402323370-top-hdpe-sheet-manufacturers-in-india-top-hdpe?utm_source=web&utm_medium=tumblr&utm_content=share_reading&wp_uname=monoindustries2&wp_originator=%2B%2Fom4EhXfKzBFgiJGO5v3l5Bau9DoYfyqwGFb96XPyJt2SlaAm327EYCNZxwUFfJEnPbL9jFB%2FHVmDg5JtVzlh6gc2zibBYZ5GJJxRgujj5W7nUR9ParEpY9UnOdJhLV In the realm of industrial materials, High-Density Polyethylene (HDPE) sheets stand as versatile and indispensable components across diverse sectors. This blog delves into the intricate world of HDPE sheets, spotlighting the journey of a manufacturer dedicated to excellence, innovation, and the seamless integration of HDPE sheets into various applications.

#best#geomembrane#hdpe#hdpesheets#ldpe#lining#manufacturer#plastic#polythene#pond#price#quality#sheet#sheets#supplier#top#adventure#books#wattpad#amreading

0 notes

Text

Polyethylene market Poised for Growth Amidst Rising Demand Across Industries

The Polyethylene Market is witnessing significant momentum as global demand for versatile plastic materials continues to surge. As a cornerstone of modern industrial applications, Polyethylene—the most widely produced plastic globally—plays a vital role in packaging, construction, automotive, electronics, and healthcare sectors. The expanding applications of polyethylene are fueling an uptick in market volume, prompting stakeholders to assess opportunities and challenges more strategically.

Global Polyethylene Market Size: Analysis By Type (High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE)), By Industry (Packaging Industry, Construction Industry, Automotive Industry, Electrical and Electronics Industry, Consumer Goods Industry, Agriculture Industry, Healthcare Industry): Global and Regional Demand Supply Trends and Forecast-2025-2030

Growing Industry Segments Fuel Market Expansion

The polyethylene industry is categorized primarily into HDPE, LDPE, and LLDPE—each with distinct characteristics and industry use cases. HDPE, known for its high tensile strength and rigidity, is extensively used in construction and automotive applications. LDPE and LLDPE, with their flexibility and toughness, dominate the packaging and consumer goods segments. The polyethylene market report shows an increase in demand from emerging economies, particularly in Asia-Pacific, where rapid industrialization and urbanization drive consumption.

Packaging Industry Dominates Demand

According to recent polyethylene market analysis, the packaging industry continues to be the largest consumer of polyethylene, driven by the growth of e-commerce, FMCG sectors, and increasing demand for food-safe materials. Flexible and rigid packaging solutions are seeing innovation, contributing to rising polyethylene market share. The polyethylene market forecast suggests packaging applications will continue to dominate through 2030, especially for HDPE and LLDPE variants.

Sustainability Trends and Market Drivers

One of the most notable polyethylene market trends is the rising demand for sustainable and recyclable materials. As regulatory pressures mount and consumer preferences shift toward eco-friendly solutions, manufacturers are investing in circular economy strategies and chemical recycling techniques. This sustainability shift is both a polyethylene market opportunity and a challenge, requiring innovation and capital investments.

Key polyethylene market drivers include growing urban infrastructure, increased automotive production, and the proliferation of electronic devices requiring durable and insulating materials. However, polyethylene market restraints such as fluctuating crude oil prices, environmental concerns, and stringent regulations in some regions may impact production and profitability.

Outlook and Strategic Insights

The global polyethylene market is expected to grow steadily from 2025 to 2030, backed by technological advancements and robust demand from diverse sectors. A comprehensive polyethylene market study reveals strong potential in the Asia-Pacific and Middle East regions, while North America and Europe continue to focus on recycling technologies and high-performance polymers.

In conclusion, strategic investments in research, recycling infrastructure, and regional expansions are critical for tapping into the evolving polyethylene market size and capturing long-term growth. Stakeholders across the value chain must remain agile to navigate the fast-changing landscape of the polyethylene industry.

For more detailed polyethylene market insights, keep an eye on industry reports and forecasts that highlight granular polyethylene market statistics and segmentation opportunities.

0 notes

Text

Low Density Polyethylene (LDPE) Prices, News, Trend, Graph, Chart, Monitor and Forecast

Low-Density Polyethylene (LDPE) is a widely used thermoplastic that plays a crucial role in various industries, including packaging, agriculture, construction, and consumer goods. The global market for LDPE is heavily influenced by factors such as crude oil prices, feedstock availability, supply-demand dynamics, geopolitical events, and regulatory changes. Over recent years, the price trends of LDPE have been highly volatile, shaped by fluctuations in raw material costs and global economic conditions. As a derivative of ethylene, LDPE pricing is directly impacted by the movement of crude oil and natural gas prices, which serve as primary feedstocks for ethylene production. Any significant shift in the energy market, such as supply chain disruptions, geopolitical tensions, or OPEC decisions, can have an immediate and lasting effect on LDPE price movements worldwide.

Global supply chain challenges have also played a vital role in influencing LDPE prices. While the post-pandemic recovery has gradually stabilized certain market conditions, intermittent supply chain bottlenecks, such as port congestion, raw material shortages, and freight cost increases, have kept LDPE prices unpredictable. Additionally, regulatory changes related to plastic waste management and sustainability concerns have altered market dynamics. Many governments are imposing restrictions on single-use plastics, pushing manufacturers to invest in bio-based or recycled alternatives. This shift is gradually reshaping demand patterns, as businesses look for sustainable solutions while still relying on LDPE for flexible packaging, films, and industrial applications.

Get Real time Prices for Low Density Polyethylene (LDPE): https://www.chemanalyst.com/Pricing-data/low-density-polyethylene-ldpe-24

Another significant factor affecting LDPE pricing is regional capacity expansion and plant shutdowns. Major LDPE-producing regions such as North America, Europe, and Asia-Pacific witness periodic capacity additions, influencing supply levels. The United States and China, in particular, have been increasing their production capacities due to rising domestic demand and export opportunities. Meanwhile, planned and unplanned plant shutdowns due to maintenance, weather-related disruptions, or technical failures often result in temporary supply shortages, driving prices upward. Additionally, the level of imports and exports between key trading hubs influences regional price fluctuations. For instance, China's growing demand for LDPE has resulted in increased imports from the Middle East, affecting global price equilibrium.

Seasonal demand fluctuations are another critical component in LDPE price trends. Demand for LDPE films, particularly in the agricultural and packaging sectors, tends to rise during certain seasons, leading to price hikes. Conversely, demand may drop during off-peak seasons, resulting in lower prices. Industrial activities, consumer spending trends, and festival seasons also contribute to temporary price variations. In recent years, global inflation and economic slowdowns have impacted LDPE demand, as businesses and consumers adjust their spending habits. Inflation-driven cost increases in transportation, energy, and labor have further added pressure on LDPE producers, influencing overall pricing strategies.

Sustainability and recycling trends are becoming increasingly important in shaping LDPE prices. With mounting pressure from environmental organizations and regulatory authorities, companies are adopting more recycled polyethylene and alternative packaging solutions. The rising adoption of circular economy principles is expected to influence virgin LDPE demand in the coming years. Additionally, technological advancements in polymer processing and recycling are enabling companies to create high-quality recycled LDPE, which could gradually shift pricing dynamics as businesses look for cost-effective and environmentally friendly alternatives.

The outlook for LDPE prices remains uncertain, with multiple factors at play. Crude oil price fluctuations, geopolitical developments, economic growth patterns, and technological innovations will continue to shape the LDPE market in the foreseeable future. Industry participants, including manufacturers, suppliers, and consumers, must stay vigilant about emerging market trends and global developments to make informed decisions. With sustainability gaining prominence, future LDPE prices may also be influenced by regulatory shifts and consumer preferences toward eco-friendly materials. As the industry navigates evolving challenges, market players need to adopt flexible pricing strategies, enhance supply chain resilience, and invest in research and development to remain competitive in the dynamic LDPE landscape.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#LDPE Price#LDPE Price Monitor#LDPE Pricing#Low Density Polyethylene#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Transform your balcony into a haven of relaxation with the exquisite offerings from Bhairav Store. Our Chairs and Center Table set not only adds flair to your outdoor space but also provides ultimate comfort for both indoor and outdoor lounging. Crafted by highly skilled designers, our Balcony Dining Coffee Set boasts durability like no other, thanks to its UV-resistant materials. Resilient against the elements, this set is both lightweight and durable, promising longevity even in the face of sun and rain. The elegant finish adds a touch of sophistication, making it ideal for outdoor entertaining. Whether it's a cozy gathering or a lively soirée, Bhairav Store's furniture set ensures comfort and style. With an ingenious design that seamlessly blends with any decor, and multi-purpose functionality ranging from coffee tables to utility tables, each piece undergoes rigorous quality checks, ensuring top-notch performance for years to come. Experience the epitome of outdoor luxury with Bhairav Store. ✔💞 Garden Furniture Set || 2 Chairs || 1 Table with Glass Top || Table Size ( 24 Inch X 24 Inch ) ✔💞 Upper Material - PU Wicker, Frame Material- Mild Steel, Base - PU Solids, Foam Density - 40 Density || Weight Carrying Capacity of Chairs 120 Kg ✔💞 Chair Dimensions: (L x W x H) Seating - 18-inch x Width 22-inch x Height -30-inch, Weight: 6kg | Table Dimensions: (L x W x H) 24-inch x 24-inch x 26-inch Table | Weight: 6 kg /Powder coated frame made of MS ✔💞 High quality A class durable HDPE/LDPE|UV Protected wicker hands woven by professionals Craftsmen || 1 Year Manufacturing defect & Wicker warranty |T&C Apply (Warranty Terms) ✔? 100% in-house production, For Any Product customization like Size /Color of (Chair/Table/Cushion) |kindly Contact us before dispatched on - 9205238511 [ad_2]

0 notes

Text

High-Density Polyethylene (HDPE) Trends and Forecast (2024–2034)

Market Overview

The Polyethylene Market plays a foundational role in modern manufacturing, serving as one of the most widely used plastics globally. From grocery bags and food packaging to industrial containers and medical devices, polyethylene’s versatility makes it indispensable. The market was valued at approximately USD 125.4 billion in 2023 and is projected to reach USD 182.7 billion by 2033, growing at a CAGR of 3.9% during the forecast period.

Polyethylene (PE) is a polymer primarily derived from ethylene, available in various types including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE). Each type has distinct properties, enabling its use across multiple applications ranging from flexible films to rigid packaging and durable industrial goods. This adaptability, combined with low production costs and excellent chemical resistance, continues to fuel demand across industries.

Click to Request a Sample of this Report for Additional Market Insights: https://infinitymarketresearch.com/request-sample/1168

Market Dynamics

The growth of the polyethylene market is driven by expanding applications in packaging, construction, automotive, agriculture, and healthcare. Among these, packaging remains the dominant segment due to polyethylene’s lightweight, moisture-resistant, and flexible characteristics. As e-commerce and online food delivery boom worldwide, the demand for protective, tamper-proof plastic packaging is surging.

In the construction sector, HDPE is used in pipes, geomembranes, and insulation products. Its strength, durability, and chemical inertness make it ideal for water transportation and infrastructure applications. Similarly, the agriculture industry leverages LDPE films for mulching, greenhouse covers, and irrigation components.

The automotive sector utilizes polyethylene in fuel tanks, interior trims, and insulation, helping manufacturers reduce vehicle weight and improve fuel efficiency. In healthcare, PE is valued for its safety and sterility in disposable gloves, tubing, and containers.

Despite its widespread use, the polyethylene industry faces growing scrutiny due to plastic waste and environmental concerns. Regulatory bans on single-use plastics in several countries are pressuring manufacturers to adopt recyclable, biodegradable, and bio-based alternatives. This has led to innovation in sustainable PE production, such as bio-PE derived from sugarcane and PE grades optimized for recyclability.

Volatility in crude oil prices, a key raw material source, also impacts polyethylene pricing and margins. Supply chain disruptions and geopolitical tensions further influence the market dynamics, requiring manufacturers to diversify sourcing and invest in more resilient production systems.

Key Players Analysis

The polyethylene market is highly competitive and includes several major global players. Leading companies include LyondellBasell Industries, ExxonMobil Corporation, SABIC, Dow Inc., INEOS Group, Chevron Phillips Chemical, Borealis AG, and Braskem.

These companies focus on expanding their production capacities, developing sustainable product lines, and forming strategic partnerships. LyondellBasell is known for its advanced polymer technologies and global production footprint. ExxonMobil continues to invest in high-performance polyethylene grades for specialty applications.

Dow Inc. emphasizes circular economy initiatives, including the development of recyclable PE films. SABIC and Braskem are leading the charge in bio-based and recycled polyethylene innovations. Braskem, in particular, is notable for its "I'm Green" bio-polyethylene, made from renewable sugarcane ethanol.

Mergers, acquisitions, and technological collaborations are shaping the competitive landscape as companies look to strengthen their market presence and product portfolios.

Regional Analysis

Asia-Pacific dominates the global polyethylene market, accounting for the largest share due to its massive manufacturing base, rising population, and rapid urbanization. China, India, and Southeast Asian countries are key growth engines, supported by government investments in infrastructure and industrialization.

North America remains a mature but robust market, driven by demand from packaging, construction, and automotive sectors. The shale gas revolution in the U.S. has provided a cost advantage in ethylene production, making the region a hub for polyethylene exports.

Europe is witnessing moderate growth, with increasing emphasis on sustainability, recycling, and the circular economy. EU directives targeting plastic waste are reshaping the way polyethylene is produced and consumed, pushing companies to innovate eco-friendly solutions.

Latin America, Middle East, and Africa are emerging as important regions, offering growth potential due to rising disposable incomes, urban development, and a growing consumer goods sector. Middle Eastern countries, notably Saudi Arabia and the UAE, benefit from access to raw materials and expanding polymer production capacity.

Recent News & Developments

Recent developments in the polyethylene market reflect the industry’s shift toward sustainability and circularity. In 2024, Dow and Lucro Plastecycle collaborated on developing post-consumer recycled (PCR) polyethylene for flexible packaging applications in India. Similarly, SABIC introduced TRUCIRCLE, a portfolio of circular polymers made through advanced recycling technologies.

LyondellBasell announced the opening of a new mechanical recycling facility in the Netherlands, boosting its recycled PE output. ExxonMobil unveiled Exxtend™ technology, aimed at producing virgin-quality polyethylene from plastic waste, marking a significant milestone in molecular recycling.

In North America, Chevron Phillips Chemical and QatarEnergy launched a joint venture to build a new integrated polymers facility in Texas, reinforcing the region’s supply capability. Meanwhile, Braskem expanded its bio-based PE capacity in Brazil to meet rising global demand for greener plastics.

Governments are also playing a crucial role. Many nations have introduced incentives for recycling infrastructure and taxes on virgin plastic usage, driving momentum toward sustainable material innovation.

Browse Full Report: https://infinitymarketresearch.com/polyethylene-market/1168

Scope of the Report

This comprehensive report on the Polyethylene Market explores key types (HDPE, LDPE, LLDPE), applications (packaging, construction, automotive, agriculture, healthcare), and forms (films, sheets, pipes, containers). It analyzes production trends, regional outlooks, pricing strategies, competitive benchmarking, and future forecasts.

With sustainability at the core of industry transformation, the polyethylene market is evolving rapidly. The focus is shifting from merely producing more to producing smarter—where recyclability, bio-content, and energy efficiency define the next phase of growth. The coming years will witness a stronger alignment between polyethylene innovation and environmental responsibility.

Discover Additional Market Insights from Infinity Market Research:

The global Gadolinium Market size was USD 5.7 billion in 2023 to USD 9.5 billion by 2033, exhibiting a CAGR of 5.3% during the forecast period from 2023-2033

Global Recovered Carbon Black Market size is expected to be worth around USD 9.5 Billion by 2033 from USD 0.6 Billion in 2023, growing at a CAGR of 32.8% during the forecast period from 2023 to 2033.

Global 3D Printing Filament Market size is expected to be worth around USD 12.8 Billion by 2033 from USD 1.4 Billion in 2023, growing at a CAGR of 23.4% during the forecast period from 2023 to 2033.

Global Ethylene Market size is expected to be worth around USD 304.6 Billion by 2033 from USD 177.7 Billion in 2023, growing at a CAGR of 5.6% during the forecast period from 2023 to 2033.

Global Sulfuric Acid Market size is expected to be worth around USD 25.4 Billion by 2033 from USD 16.0 Billion in 2023, growing at a CAGR of 4.6% during the forecast period from 2023 to 2033.

About Us

We at Infinity Market Research hold expertise in providing up-to-date, authentic, and reliable information across all industry verticals. Our diverse database consists of information gathered from trusted and authorized data sources.

We take pride in offering high-quality and comprehensive research solutions to our clients. Our research solutions will help the clients in making an informed move and planning their business strategies. We strive to provide excellent and dedicated market research reports so that our clients can focus on growth and business development plans. We have a domain-wise expert research team that works on client-specific custom projects. We understand the diverse requirements of our clients and keep our reports updated based on the market scenario.

Contact US:

Pune, Maharashtra, India

Mail: [email protected]

Website: https://infinitymarketresearch.com

For More Insights, follow us on LinkedIn- https://www.linkedin.com/company/imrreports

0 notes

Text

Plastic Recycling Market Insights 2025–2033: Comprehensive Analysis of Size, Trends, and Future Forecasts

The "Plastic Recycling Market" report delivers crucial insights for businesses, covering key elements like market size, share, growth, and emerging trends. It equips companies with the knowledge needed to make strategic decisions and drive growth. The report examines technological innovations, shifting sales approaches, market expansion opportunities, production enhancements, and potential revenue sources. With its in-depth analysis, it helps businesses remain competitive and capitalize on new opportunities.

Get a sample PDF of the report at - https://www.proficientmarketinsights.com/enquiry/request-sample/2603

Who are the largest manufacturers of Plastic Recycling Market worldwide?

Greentech

KW Plastics

Vogt-Plastic

Biffa

The report analyzes the Plastic Recycling Market from 2019 to 2030, offering data and insights about its development. It provides a global overview, including details on sales, revenue, and market growth rates. Additionally, the report segments the market by region, product type, and customer demographics, allowing readers to gain a comprehensive understanding of the market from various perspectives.

Plastic Recycling Market Dynamics Covers:

The dynamics of the keyword market involve analyzing the factors that affect market behavior and pricing. These factors include changes in supply and demand, actions taken by competitors, prevailing market trends, and economic frameworks. Together, they shape the overall structure and movement of the market.

Key Elements of Market Dynamics:

Supply and Demand: At the heart of market dynamics is the interaction between supply and demand, which directly impacts pricing and availability.

Market Positioning: This refers to identifying a product’s place in the market relative to competitors, emphasizing its unique value or differentiators.

Competitive Analysis: Evaluating competitors’ strengths, weaknesses, and market standing enables businesses to uncover potential opportunities and anticipate challenges.

Understanding Plastic Recycling Market Dynamics: Involves examining the various factors that shape market behavior and pricing. This analysis supports businesses in remaining competitive, adapting to market shifts, optimizing resource use, and improving product development.

What are the factors driving the growth of the Plastic Recycling Market?

Plastic Recycling Market Segmented by Types:

PET

PP

HDPE

LDPE

and Others.

Plastic Recycling Market Segmented by Applications:

Packaging & Consumer Goods

Construction

Textile Fiber / Clothing

Landscaping/Street Furniture

and Other Uses.

Regional Segmentation:

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

Key Takeaways from the Global Plastic Recycling Market Report:

Market Size Estimates: Estimation of the Plastic Recycling market size in terms of value and sales volume from 2018 to 2028.

Market Trends and Dynamics: Analysis of Plastic Recycling market drivers, opportunities, challenges, and risks.

Macro-economy and Regional Conflict: Impact of global inflation and the Russia-Ukraine conflict on the Plastic Recycling market.

Segment Market Analysis: Plastic Recycling market value and sales volume by type and application from 2018 to 2028.

Regional Market Analysis: Current situations and prospects of the Plastic Recycling market in North America, Asia Pacific, Europe, Latin America, the Middle East, and Africa.

Country-level Studies on the Plastic Recycling Market: Revenue and sales volume data for major countries within each region.

Plastic Recycling Market Competitive Landscape and Major Players: Analysis of 10-15 leading market players, including sales, price, revenue, gross margin, product profile, and application.

Trade Flow: Import and export volumes of the Plastic Recycling market in key regions.

Plastic Recycling Industry Value Chain: Overview of raw materials and suppliers, manufacturing processes, distributors, and downstream customers in the Plastic Recycling market.

Plastic Recycling Industry News, Policies, and Regulations: Updates on relevant industry news, policies, and regulations.

Reasons to Purchase This Report:

Comprehensive Analysis: Gain access to extensive quantitative and qualitative analysis covering a research period from 2019 to 2030.

Market Overview: Understand the global Plastic Recycling market through detailed metrics on sales, revenue, and growth rates.

Segmented Insights: Benefit from segmented market analysis by region, product type, and downstream industry for a nuanced understanding of market distribution.

Competitive Landscape: Stay ahead with insights into the competitive landscape, including key players and their market strategies.

Future Prospects: Make informed decisions with projections and future market prospects.

Regional Analysis: Gain insights into regional growth trends and market status.

Emerging Trends: Identify and understand emerging market trends and opportunities.

Strategic Planning: Utilize the report’s insights for strategic planning and market positioning.

Get a sample PDF of the report at - https://www.proficientmarketinsights.com/enquiry/request-sample/2603

0 notes

Text

Polymer Granules Supplier India: Your Trusted Partner for Quality Polyethylene Materials

The demand for high-quality plastics and polymers in India is growing rapidly, and at the heart of this growth lies polymer granules—the raw materials used to manufacture everyday plastic products. Whether you're in the packaging, construction, agriculture, or automotive industries, sourcing the right polymer granules supplier in India can make a significant difference in product quality, cost, and performance.

In this blog post, we’ll help you understand everything you need to know about polymer granules, the types of polyethylene available (HDPE, LDPE, and LLDPE), and how to choose the best supplier in India.

What Are Polymer Granules?

Polymer granules are small, solid plastic particles made from synthetic resins. These granules are melted and molded into various plastic products. They serve as the primary raw material for plastic manufacturing across multiple industries.

Depending on your requirements, you can choose from different types of polyethylene granules like:

HDPE Polyethylene in India (High-Density Polyethylene)

LDPE Polyethylene in India (Low-Density Polyethylene)

LLDPE Polyethylene in India (Linear Low-Density Polyethylene)

Each type has unique properties, making it suitable for specific applications.

Types of Polyethylene Granules in India

1. HDPE Polyethylene in India

HDPE (High-Density Polyethylene) is known for its strength, stiffness, and durability. It is used for making:

Pipes and fittings

Bottles and containers

Chemical drums

Crates and bins

Advantages:

High tensile strength

Chemical and UV resistant

Excellent durability

Recyclable

Top HDPE polyethylene suppliers in India provide virgin as well as recycled HDPE granules in various grades suitable for blow molding, injection molding, and film applications.

2. LDPE Polyethylene in India

LDPE (Low-Density Polyethylene) is a softer and more flexible polymer. It’s ideal for manufacturing:

Grocery bags

Flexible lids

Shrink wraps

Cable insulation

Advantages:

Good impact resistance

Excellent moisture barrier

Flexible and lightweight

Cost-effective

LDPE polyethylene in India is widely used in packaging, electrical, and agricultural industries due to its lightweight and flexible nature.

3. LLDPE Polyethylene in India

LLDPE (Linear Low-Density Polyethylene) offers a balance of flexibility, strength, and puncture resistance. Common uses include:

Stretch film

Agricultural film

Liners and covers

Toys and flexible tubing

Advantages:

High impact strength

Excellent tear resistance

Versatile for molding and film production

Better toughness than LDPE

LLDPE polyethylene in India is gaining popularity for packaging and protective applications.

Why Choose a Reliable Polymer Granules Supplier in India?

Partnering with a trusted polymer granules supplier in India ensures consistent quality, timely delivery, and competitive pricing. Here’s why choosing the right supplier matters:

Quality Assurance

A good supplier ensures that granules like ISO, REACH, and ROHS meet international standards. Quality materials result in fewer defects and better end products.

Wide Range of Products

Top suppliers offer a variety of polymer grades—HDPE, LDPE, and LLDPE—for different manufacturing processes like blow molding, extrusion, and injection molding.

Pan-India Delivery

A well-established supplier should have a strong logistics network to deliver polymer granules across India efficiently.

Technical Support

Leading suppliers offer technical guidance to help clients select the right grade and optimize manufacturing performance.

Sustainability

Recycled polymer granules are often available to help businesses reduce their carbon footprint while maintaining quality.

Applications of Polymer Granules in India

Polymer granules are essential for several sectors, including:

Packaging: Flexible films, containers, shrink wraps

Automotive: Fuel tanks, bumpers, dashboards

Agriculture: Irrigation pipes, greenhouse films, mulch covers

Construction: Water tanks, insulation boards, fittings

Consumer Goods: Toys, storage boxes, homeware

Choosing the right polymer granules supplier in India means ensuring uninterrupted production, lower material waste, and high customer satisfaction.

Related FAQs: Polymer Granules Supplier India

Q1. What is the best type of polyethylene for packaging?

A: For flexible packaging, LLDPE and LDPE polyethylene in India are widely used due to their flexibility, transparency, and puncture resistance.

Q2. What’s the difference between HDPE and LDPE granules?

A: HDPE is stronger and more rigid, making it ideal for pipes and containers. LDPE is softer and more flexible, suitable for bags and films.

Q3. Can I buy recycled polymer granules in India?

A: Yes, many polymer granule suppliers in India offer recycled HDPE, LDPE, and LLDPE granules at cost-effective prices.

Q4. What certifications should a polymer granules supplier have?

A: Look for suppliers with ISO, REACH, ROHS, and BIS certifications to ensure product quality and compliance with safety standards.

Q5. Are polymer granules customizable for specific applications?

A: Yes, many suppliers provide customized grades and color masterbatches to suit specific industry requirements.

Q6. Where can I find polymer granule suppliers near me?

A: Most suppliers have pan-India logistics. You can easily connect with top polymer granules suppliers in India through B2B platforms or supplier directories.

Conclusion

Whether you're a manufacturer of plastic packaging, construction parts, or automotive components, selecting the right polymer granules supplier in India is critical for consistent production quality. Make sure your supplier offers a wide range of materials, including HDPE polyethylene in India, LDPE polyethylene in India, and LLDPE polyethylene in India, backed by quality certifications and prompt delivery.

Choose wisely, and your manufacturing process will be more efficient, cost-effective, and sustainable.If you need help connecting with trusted polymer granule suppliers in India or want personalized recommendations based on your industry, feel free to reach out to our team.

0 notes

Text

Top LD Poly Bags Manufacturers in Delhi – Quality You Can Trust.

Looking for top LD poly bags manufacturers in Delhi? We provide high-quality LDPE plastic bags suitable for packaging across industries. Our LD poly bags are known for their durability, flexibility, and eco-friendliness. As a trusted LDPE bags supplier in Delhi, we offer custom sizes, thickness, and printing options to meet your specific needs. Whether you need plain or printed LD plastic bags, we deliver in bulk with timely service and competitive pricing. Our advanced manufacturing process ensures strong sealing and reliable packaging solutions. Choose us for LD plastic bag manufacturing in Delhi and experience quality you can trust. Contact now for the best deals on LD poly packaging bags in Delhi NCR.

0 notes

Text

LDPE prices are growing in Delhi market

A surge in demand has pushed LDPE(124FS040) prices high in Delhi. As per Indian Petrochem analysts, the polymer was priced at Rs. 122/kg on July 17, 2025, marking a firm stance in the domestic market. LDPE, a versatile polymer, is extensively used in various industries, including packaging, agriculture, and consumer goods, making its price trends critical for multiple sectors. In India, major producers of LDPE include Reliance Industries Limited (RIL), Indian Oil Corporation Limited (IOCL), GAIL (India) Limited, and Haldia Petrochemicals Ltd. These companies cater to the growing domestic demand for LDPE in sectors such as food packaging, greenhouse films, and industrial coatings. Globally, prominent producers include ExxonMobil, SABIC, Dow Chemicals, LyondellBasell, and Sinopec, which supply LDPE for diverse applications across industrial, agricultural, and consumer markets. The global LDPE market, valued at approximately $44 billion in 2024, is projected to grow to $55 billion by 2030, with a compound annual growth rate (CAGR) of 4.2%. Growth is driven by rising demand for flexible packaging, expanding use in agriculture, and the increasing adoption of light weight materials in the automotive and construction sectors, LDPE Prices in India, Indian LDPE Prices, Indian Prices LDPE, IndianPetrochem.

0 notes

Text

Waterproof & UV-Resistant Tarpaulins: Why They’re Essential for Modern Businesses

Understanding Tarpaulins in Today’s Industry

What Are Tarpaulins?

Think of tarpaulins as the shield your business didn’t know it needed—heavy-duty, flexible sheets that protect your precious assets from every curveball Mother Nature throws your way. More than just a piece of plastic, tarps today are tailored, engineered, and built to outlast the fiercest storms and scorching sun.

Key Types of Industrial Tarps

From sturdy HDPE (High-Density Polyethylene) to rugged PVC and lightweight LDPE, the options suit every need—agriculture, logistics, construction, and much more.

Unique Properties of Waterproof & UV-Resistant Tarpaulins

Advanced Material Science

Not all tarps are created equal! Waterproof and UV-resistant variants go through specialized treatments. Imagine a raincoat and sunglasses for your cargo—all in one!

What Makes Them Waterproof?

Special coatings and tightly woven fibers seal out water, preventing leaks even during the most relentless downpours. This means no nasty surprises when you open your stored goods after the monsoon.

How Do UV Inhibitors Work?

These tarps contain additives that absorb or reflect UV rays, stopping sunlight from degrading the material or the products beneath. Sun-cracked, brittle tarps are a thing of the past.

Weather Challenges for Indian Businesses

India’s High-Impact Climate

From sweltering summers to ceaseless monsoons and even bouts of hail, the Indian subcontinent is unpredictable. A single storm or persistent humidity can ruin crops, halt construction, or damage goods in transit.

Cost of Weather-Related Losses

Yearly, businesses lose crores due to inadequate protection—spoiled grain, corroded metal, waterlogged products, and construction delays. Investing a little in prevention saves a fortune on recovery.

Agriculture: Protecting India’s Backbone

Shielding Crops and Livestock

Farmers battle not only pests but also erratic weather. Imagine stacks of harvested paddy or wheat left exposed—just a day of rain can destroy months of effort!

Real-World Example: Monsoon-Proof Storage

Many Indian farmers now use UV-resistant tarpaulins to create makeshift storage sheds in the field, saving entire harvests from monsoon onslaughts. This simple solution is boosting rural incomes and reducing food waste.

Preventing Post-Harvest Damage

Beyond shielding from rain, these tarps block harmful UV rays that degrade nutrients. Fresher produce, higher market prices, and happier customers.

Cloudland Impex LLP

Logistics: Keeping Goods Safe Across Miles

Secure Transportation of Goods

Every truck on the highway with a colorful cover is most likely using a tarpaulin. It’s not just for show—it’s the first line of defense against road spray, sun, and dust.

Rail, Road, and Coastal Shipping Needs

Whether crisscrossing India’s highways or plying coastal routes, goods run the risk of rain, salty air, and intense sunlight. Quality tarps prevent ruined shipments and angry customers.

Cutting Losses Due to Water and Sun

Without waterproof and UV protection, bulky goods, electronics, and textiles arrive soggy or faded—never a good look for your business.

Construction: Safeguarding Sites and Materials

Covering Machinery and Building Supplies

Construction sites are vulnerable to sudden showers and relentless sun. Moisture can rust steel or warp wood overnight, leading to expensive delays.

Case Study: UV Protection on High-Rise Projects

Many leading construction firms cover scaffolding, poured concrete, and even entire floors with UV-resistant tarps during summer. This shields workers and materials, keeping projects on time and on budget.

Ensuring Worker Safety and Workflow

Shaded tarpaulin canopies protect workers from heatstroke and provide a safer, more comfortable environment—helping keep work uninterrupted even during adverse weather.

Benefits Beyond Weather Protection

Cost-Efficiency for Modern Enterprises

A quality tarp pays for itself by preventing losses and cutting the cost of repairs or wasted inventory.

Durability and Longer Lifespan

Thanks to robust construction, these tarps withstand countless weather cycles without tearing, fading, or leaking.

Ease of Installation and Maintenance

Lightweight yet tough, today’s tarps are easy to set up, take down, and move—no more wrestling with unwieldy covers.

Making the Right Choice: What to Look For

GSM, GSM, GSM—Why Thickness Matters

GSM (grams per square meter) is your magic number. The higher the GSM, the thicker and stronger the tarp—perfect for heavy-duty applications.

Quality Certifications and Standards

Look for ISI or ISO marks that signal industry-approved manufacturing and safety standards.

Caring for Your Tarpaulin Investment

Best Practices for Maintenance

Clean regularly with mild soap—no harsh chemicals.

Dry completely before storing to prevent mold.

Common Mistakes to Avoid

Folding when wet (leads to mildew)

Placing in direct contact with sharp edges (causes punctures)

The Future of Business Protection: Smart Tarps & Sustainable Materials

Innovation is on the rise—think tarps with sensor-based damage alerts or made from recycled plastics. As the world goes green, your next tarp could be as smart as your smartphone!

Conclusion: Why No Business Should Ignore Weatherproof Tarps

No matter your industry, weatherproof and UV-resistant tarpaulins offer peace of mind, business continuity, and serious savings. They aren’t just an expense—they’re a shield, an investment, and a silent business partner that works 24/7.

FAQs About Waterproof & UV-Resistant Tarpaulins

How long do waterproof and UV-resistant tarpaulins last? With proper care, many premium tarps can last upwards of 5 years, even in extreme climates.

Are higher GSM tarpaulins always better? Not always! Choose GSM based on your needs—heavy goods need higher GSM, but for light use, lower GSM is easier to handle.

Can tarpaulins be custom-sized for unique applications? Absolutely. Most manufacturers offer custom sizing, grommet placement, and even color options.

Are these tarps safe for food storage in agriculture? Yes—just make sure to choose food-grade, non-toxic products certified for agricultural use.

What’s the best way to repair a torn tarp? Use compatible tarp tape or patches, and replace badly damaged covers—duct tape is only a short-term fix!

0 notes

Text

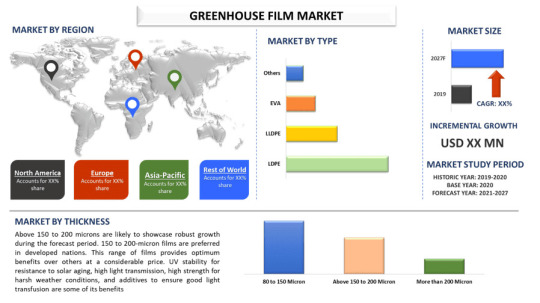

Greenhouse Film Market Trends, Agricultural Demand and Global Forecast (2021-2027) |UnivDatos

A comprehensive overview of the global Greenhouse Film market is recently added by UnivDatos to its humongous database. The report has been aggregated by collecting informative data from various dynamics such as market drivers, restraints, and opportunities.

Access sample report (including graphs, charts, and figures) https://univdatos.com/reports/greenhouse-film-market?popup=report-enquiry

This innovative report makes use of several analyses to get a closer outlook on the Greenhouse Film market globally. This report offers a detailed analysis of the latest industry developments and trending factors that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the global Greenhouse Film market at regional and country levels. The global greenhouse film market is likely to showcase a growth of 8% during the forecast period.

Market Overview

The growing population and increasing awareness for healthy food are some of the driving forces behind the horticulture industry’s increasing focus on sustainable production and higher profit margins. Greenhouse farming is one of the sustainable solutions to provide high productivity resulting in high-profit margins. These farming systems use films that provide a closed structure for the maintenance of a controlled growing environment for crops. The films help in trapping the sun’s rays and create a warm humid atmosphere for the efficient growth of crops. Reduction in agricultural arable land is further supporting the market of greenhouse films market. By using greenhouse films farmers can improve their productivity without the requirement of additional land. However, the high initial requirement is one of the key factors which resist the growth of the market mainly in developing nations. Setting up a greenhouse facility would necessitate a significant cash commitment as well as prior planning. Apart from the establishment of the primary facility, there are various other components that require money and financial assistance in order to work as a whole system.

The global greenhouse film market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

By type, the market is primarily divided into:

· LDPE

· LLDPE

· EVA

· Others

Based on type, the market is categorized into LDPE, LLDPE, EVA, and others. Among these, LDPE accounted for a significant share in the market and is expected to showcase significant growth during the forecast period. This can be attributed to the low cost of LDPE film. Further, the film provides better thickness, optical properties, and resistance to excess sunlight and the external environment. As a result of which both consumers and manufacturers focus more on LDPE base greenhouse films.

By thickness, the market is primarily divided into:

· 80 to 150 Micron

· Above 150 to 200 Micron

· More than 200 Micron

Based on thickness, the market is categorized into 80 to 150 micron, above 150 to 200 micron, and more than 200 microns. Among these, above 150 to 200 microns are likely to showcase robust growth during the forecast period. 150 to 200-micron films are preferred in developed nations of Europe. This range of films provides optimum benefits over others at a considerable price. UV stability for resistance to solar aging, high light transmission, high strength for harsh weather conditions, and additives to ensure good light transfusion are some of its benefits.

Global Greenhouse Film Market Geographical Segmentation Includes:

· North America (United States, Canada, Rest of North America)

· Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

· Asia-Pacific (China, Japan, India, Australia, Rest of APAC)

· Rest of the World

Asia-Pacific accounted for a significant portion of the global greenhouse films market and is expected to showcase robust growth during the forecast period. Countries like China and India are among the largest agricultural crops producers. Further, the large and growing population of the region is increasing the pressure to improve agricultural productivity in order to meet the growing demand. Thereby, creating a large opportunity for the greenhouse farming system and films providers. However, less mechanization rate, low wages in farming activities, and less awareness regarding unconventional techniques are some of the factors which are providing resistance to the market. Although, governments in many countries are supporting greenhouse farming techniques by offering several schemes. In India, the central as well as state or local governments and agriculture bodies provide subsidies. For instance, National Horticulture Board, the regulatory body in India for greenhouse farming, provides a subsidy of 50% on a project of USD 0.15 million (INR 112 lakhs) maximum ceiling per beneficiary. Further, Gujarat Agro Industries Corporation provides a 6% subsidy on loan interest to a maximum limit of USD 5.26 thousand (INR 4 lakhs).

· Ginegar Plastic Products Ltd.

· PLASTIKA KRITIS S.A.

· RKW Group

· Berry Global Inc.

· Grupo Armando Alvarez

· Polifilm Extrusion GmbH

· Essen Multipack Limited

· Agriplast

· EIFFEL S.P.A.

· Mitsubishi Chemical Agri Dream Co. Ltd.

Competitive Landscape

The degree of competition among prominent companies has been elaborated by analyzing several leading key players operating globally. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the global Greenhouse Film market. The major players have been analyzed by using research methodologies for getting insight views on market competition.

Click here to view the Report Description & TOC https://univdatos.com/reports/greenhouse-film-market

Key questions resolved through this analytical market research report include:

What are the latest trends, new patterns, and technological advancements in the global Greenhouse Film market?

Which factors are influencing the global Greenhouse Film market over the forecast period?

What are the global challenges, threats, and risks in the global Greenhouse Film market?

Which factors are propelling and restraining the global Greenhouse Film market?

What are the demanding global regions of the global Greenhouse Film market?

What will be the market size in the upcoming years?

What are the crucial market acquisition strategies and policies applied by the companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature. Please let us know if you have any custom needs.

Contact Us:

UnivDatos

Contact Number - +1 978 733 0253

Email - [email protected]

Website - www.univdatos.com

LinkedIn- https://www.linkedin.com/company/univ-datos-market-insight/mycompany/

0 notes

Text

Polyethylene Market

Polyethylene Market Poised for Growth Amidst Rising Demand Across Industries

The Polyethylene market is witnessing significant momentum as global demand for versatile plastic materials continues to surge. As a cornerstone of modern industrial applications, Polyethylene—the most widely produced plastic globally—plays a vital role in packaging, construction, automotive, electronics, and healthcare sectors. The expanding applications of polyethylene are fueling an uptick in market volume, prompting stakeholders to assess opportunities and challenges more strategically.

Global Polyethylene Market Size: Analysis By Type (High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Linear Low-Density Polyethylene (LLDPE)), By Industry (Packaging Industry, Construction Industry, Automotive Industry, Electrical and Electronics Industry, Consumer Goods Industry, Agriculture Industry, Healthcare Industry): Global and Regional Demand Supply Trends and Forecast-2025-2030

Growing Industry Segments Fuel Market Expansion

The polyethylene industry is categorized primarily into HDPE, LDPE, and LLDPE—each with distinct characteristics and industry use cases. HDPE, known for its high tensile strength and rigidity, is extensively used in construction and automotive applications. LDPE and LLDPE, with their flexibility and toughness, dominate the packaging and consumer goods segments. The polyethylene market report shows an increase in demand from emerging economies, particularly in Asia-Pacific, where rapid industrialization and urbanization drive consumption.

Packaging Industry Dominates Demand

According to recent polyethylene market analysis, the packaging industry continues to be the largest consumer of polyethylene, driven by the growth of e-commerce, FMCG sectors, and increasing demand for food-safe materials. Flexible and rigid packaging solutions are seeing innovation, contributing to rising polyethylene market share. The polyethylene market forecast suggests packaging applications will continue to dominate through 2030, especially for HDPE and LLDPE variants.

Sustainability Trends and Market Drivers

One of the most notable polyethylene market trends is the rising demand for sustainable and recyclable materials. As regulatory pressures mount and consumer preferences shift toward eco-friendly solutions, manufacturers are investing in circular economy strategies and chemical recycling techniques. This sustainability shift is both a polyethylene market opportunity and a challenge, requiring innovation and capital investments.

Key polyethylene market drivers include growing urban infrastructure, increased automotive production, and the proliferation of electronic devices requiring durable and insulating materials. However, polyethylene market restraints such as fluctuating crude oil prices, environmental concerns, and stringent regulations in some regions may impact production and profitability.

Outlook and Strategic Insights

The global polyethylene market is expected to grow steadily from 2025 to 2030, backed by technological advancements and robust demand from diverse sectors. A comprehensive polyethylene market study reveals strong potential in the Asia-Pacific and Middle East regions, while North America and Europe continue to focus on recycling technologies and high-performance polymers.

In conclusion, strategic investments in research, recycling infrastructure, and regional expansions are critical for tapping into the evolving polyethylene market size and capturing long-term growth. Stakeholders across the value chain must remain agile to navigate the fast-changing landscape of the polyethylene industry.

For more detailed polyethylene market insights, keep an eye on industry reports and forecasts that highlight granular polyethylene market statistics and segmentation opportunities.

0 notes