#LOTOProcedure

Explore tagged Tumblr posts

Text

OSHA Lockout Tagout Standard 1910.147(c) - Employee Retraining

While the employer is required to provide effective training for all employees covered by the LOTO standard, under section (c)(7)(iii) Retraining must be provided to all the authorized as well as affected employees depending upon the circumstances mentioned above.

There are three types of employees which must receive Training & Retraining: authorized, affected, and other. The amount and type of training/retraining that each employee receives is based upon the relationship of that employee's job to the machine and upon the degree of knowledge relevant to hazardous energies.

In addition, retraining must be conducted if an inspection reveals a lack of understanding of LOTO procedures by the employees. This is called Additional Retraining.

Whenever a periodic inspection discloses any deviations or inadequacies in the employees' understanding, additional retraining becomes mandatory.

Under section (c)(7)(iv) Employers are required to certify that effective training and retraining has been provided to all employees covered by the standard. The certification must contain each employee's name and dates of training.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#EmployeeRetraining#LockoutTagoutTraining#LOTOTraining#LOTOCertification#Safety#WorkplaceSafety#LockoutTagoutOSHA#OSHAGuidelines#LOTO#OSHAStandard#SafetyTips#LOTOProgram#OSHARegulations#OSHALockoutTagout#LOTOProcedure#ESquare#ESquareAlliance

0 notes

Text

Lockout Tagout - 8 Steps of LOTO Procedure for Workplace Safety

Our comprehensive lockout tagout guide focuses on 8 essential steps to implement LOTO procedure for critical safety. Learn how to identify hazardous energy sources, prepare for shutdown, isolate energy sources, ground and bond equipment, verify energy isolation, apply lockout devices, test for residual energy, and authorize work and release.

Follow these Lockout Tagout steps to minimize accidents and create a safer working environment for everyone.

#LockoutTagout#LOTOSteps#LockoutTagoutProcedure#8StepstoApplyLockoutTagout#LOTOProcedure#LockoutTagoutGuide#WorkplaceSafety#ESquareAlliance

0 notes

Text

OSHA 1910.147(c)(4) Energy Control Procedure

Most of the OSHA Violations are due to the unavailability of Energy Control Procedures (ECP) or Machine Specific Procedures (MSP) in organisations. Companies buy Local products, just to become LOTO compliant, but they do not know the correct procedure for safe isolation and control of Hazardous energies. Successful implementation of Energy Control Program requires an understanding and awareness of Hazardous energy types and magnitude, the methods, techniques, and devices used to control that energy.

To provide guidance to employees for putting the program into practice, written Energy Control Procedures should be developed. These procedures must define the purpose, scope, and application of the program, deploy the responsibilities of the managers, supervisors, and employees for implementing a systematic Lockout Tagout program.

A written Energy Control procedures (ECP) / Machine Specific procedures (MSP) needs to be developed, documented as it clearly and specifically outlines the steps to be followed, techniques to be used, and measures to be applied for the control of potentially Hazardous Energy.

This includes specific steps to shut down, isolate, block, secure, place, and remove lockout or tagout devices, and to determine the effectiveness of those devices by following verification steps.

The written ECP/MSP must have pictorial representation for isolation, installed images of LOTO devices that specifies procedural steps for the placement, removal and transfer of Lockout Devices or tagout devices.

Lack of compliance can lead to serious disciplinary actions. Industries need to mention the consequences in case of non-compliance of Lockout Tagout due to any reason, whatsoever.

Periodic inspections are mandatory to help ensure that the energy control procedures and the requirements of the standard are being followed.

Services of LOTO can be taken for developing ECPs/MSPs as they have vast industrial knowledge to prescribe the proper steps for the safe isolation by the correct use of Lockout Tagout.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-documentation/

#OSHA#EnergyControlProcedure#LockoutTagoutProcedure#LOTOProcedure#LockoutTagout#OSHAViolations#OSHAGuidelines#LOTO#LockoutTagoutProgram#OSHAStandard#OSHALockoutTagout#ESquare#ESquareAlliance

0 notes

Text

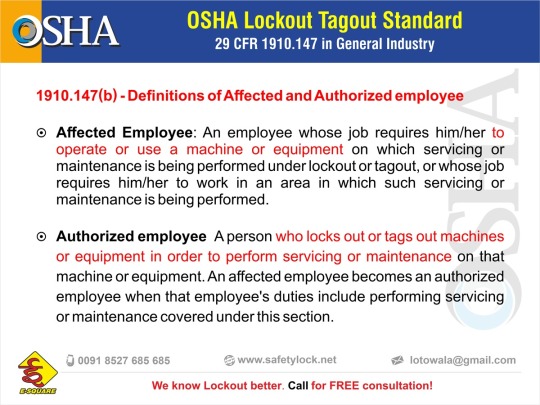

OSHA Lockout Tagout Standard 1910.147(b) - Definition of Affected and Authorized Employee

OSHA Lockout Tagout standard 1910.147(b) defines authorized and affected employees as:

An Authorized employee, by definition, is a person who locks out or tags out machines or equipment in order to perform servicing and maintenance on that machine or equipment. Authorized employees are those who are charged with the responsibility for implementing the energy control procedure prior to performing servicing and maintenance, and thus require the highest level of training.

Whereas, an Affected employee, by definition, is an employee whose job requires him/her to operate or use a machine or equipment on which servicing or maintenance is to be performed. Affected employees are generally the machine operators or users. An affected employee becomes an authorized employee when that employee’s duties include performing servicing and maintenance.

Check OSHA guidelines in detail - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-explained/

#OSHA#LockoutTagout#AuthorizedEmployee#AffectedEmployee#OSHALockoutTagout#OSHAGuidelines#OSHAStandard#LOTO#LockoutTagoutDevice#LOTODevices#LOTOProcedure#LockoutTagoutProcedure#WorkplaceSafety#Safety#LockoutTagoutAccidents#ESquare#ESquareAlliance#EsquareTrainingAcademy

0 notes

Text

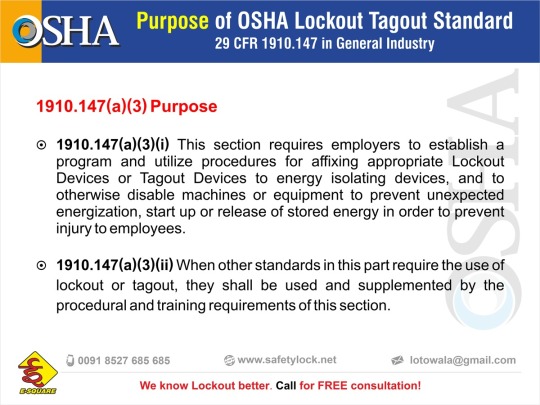

Purpose of OSHA Lockout Tagout Standard - 29 CFR 1910.147 in General Industry

More than half of the fatalities occur due to mishappenings caused while workers carry out service or maintenance related tasks. So, to avert these accidents and mishappenings OSHA Lockout Tagout Standard requires that employers must establish a well-defined LOTO Program which should have a complete Lockout Tagout planning, responsibilities and procedures for systematic application & removal of Lockout Tagout isolating devices to prevent unexpected energization, start up or release of Stored Energy that can cause serious injuries to employees working on it.

It should be supported by trainings, procedural reviews, retraining etc. to make it sustainable and effective in the long run.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#LockoutTagout#OSHALockoutTagout#OSHAGuidelines#OSHAStandard#LOTO#LockoutTagoutDevice#LOTODevices#LOTOProcedure#LockoutTagoutProcedure#ESquare#ESquareAlliance

0 notes

Text

LOTO Services - Energy Source Identification and Hazard Isolation

The most essential task associated with launching a Lockout Tagout Program includes, performance of a workplace survey and hazard assessment to identify the equipment and machines with Hazardous Energy, along with their isolation points.

LOTO can be accomplished easily and effectively if the surveyors study all the types of energies present, the hazards to be controlled, and the method of energy control, including the stored energies as well.

· Survey of the workplace should be performed to identify the machines and equipment that could accidentally energize, start up or release hazardous energies. Also, check that the machines are capable of being locked out.

· Access the Hazards and the Hazardous points of the equipment to be serviced or maintained.

· Understand the input of the employees, as they are the most affected ones, and they are often the ones most familiar with the equipment.

· Hazards should be labelled properly. Labelling of the isolating points & isolating devices is also of great benefit to the employees in assuring that energy control devices can be quickly and properly applied.

· Communication with and feedback from employees should be sought continuously to identify deficiencies and to detect opportunities for improvement.

· Right kind of Lockout Devices for different isolation points like electrical switches, isolators, ball valves, gate valves, butterfly valves, etc. need to be assessed carefully by someone who is experienced & is well aware of all kinds of Lockout devices available.

· A comprehensive report needs to be made and presented before the management, defining all the hazards with their locations & methods of their energy isolation, along with the prescription of Lockout Tagout Devices required.

A thorough study of all Hazard Isolations and the complete documentation is the base of a Successful LOTO System. So, it is essential that we seek the help of a LOTO Expert or get professional guidance for the same.

For professional Lockout Tagout hazard isolation at your premises, please send your request - https://www.safetylock.net/lockout-tagout-services/

#LockoutTagout#HazardIsolations#HazardousEnergy#LOTO#LOTOSurvey#LOTOProcedure#LockoutDevices#LockoutTagoutProgram#WorkplaceSafety#Safety#ESquare#ESquareAlliance

0 notes

Text

Lockout Tagout Gap Analysis and Audit

Success of the Lockout system requires a commitment to a sustained effort highlighted by continuous improvement. Audits, reviews & LOTO Gap Analysis are most important for having a successful LOTO system in place. A lapse in implementing energy control processes, can lead to serious injuries if not checked, audited and verified.

To ensure that energy control measures are adequate and being properly and consistently applied, a Lockout Tagout Program must be reviewed periodically and revised if needed. Besides meeting the OSHA requirements, annual audits help companies ensure that they have the up-to-date and accurate devices and procedures that allow employees of the companies to safely de-energize equipment using the appropriate steps of disconnects.

E-Square helps its customers in gap analysis and internal audits to ensure the accuracy of LOTO Procedures; Meet the OSHA Compliance; ensure Employee Safety and save time and resources. This also ensures that new or overhauled equipment is capable of being locked out. These audit dates are specifically marked on all the MSPs installed in the industry at all the locations as well as in the internal binding copies available with the plant head.

For professional Lockout Tagout Audit at your premises, visit - https://www.safetylock.net/services/lockout-tagout-gap-analysis-audit/

#LockoutTagoutAudit#GapAnalysis#LOTOAudit#LOTOSurvey#LOTOProcedure#WorkplaceSafety#LockoutTagout#LOTO#Audit#OSHA#OSHALockoutTagout#WorkplaceAudit#ESquare#ESquareAlliance

0 notes

Text

Preserving Lives and Assets - The Art of Effective Lockout Tagout Implementation

Efficient lockout tagout procedures can enhance your unit's productivity and efficiency. The process of implementing lockout tagout involves critical aspects related to safely de-energising machines or equipment.

A proactive technique for maintenance safety is much needed in today’s fast-paced world. Regulatory compliances, safety processes and enforced guidelines create a sense of safety and protection for both employees and employers.

#LockoutTagoutImplementation#LockoutTagout#LOTOInstallation#LOTO#LOTOProcedure#ESquare#EsquareAlliance

0 notes

Text

E-Square Lockout Tagout Compliance Manual

Maintenance is every day’s job in the workplaces, so is the use of Lockout Tagout for ensuring employees safety. Though the Lockout Tagout OSHA standard is expected to prevent fatalities and injuries, yet accidents associated with the release of hazardous energies continue to occur. Despite the alarming number of machine related accidents and OSHA’s enforcement efforts, companies are unable to implement successful lockout tagout systems in their premises. Sometimes, these companies face heavy fines and risk the occurrence of serious and costly machine related accidents which are entirely preventable with effective LOTO System in place.

The success of Lockout System requires a commitment to a sustained effort: Although the process seems to be burdensome, taxing and time-consuming - but with E-Square Lockout/Tagout Compliance Manual - one can easily prepare their own internal plan of Lockout Tagout Procedure for implementing a successful LOTO System.

We at E-Square are known worldwide for helping our customers in developing their in-house, Lockout Tagout System.

*Lockout Tagout Compliance Manual is only for Corporates/Companies.

To get more information on Lockout Tagout compliance manual, visit - https://www.safetylock.net/services/lockout-tagout-policy-and-procedure/

#LockoutTagout#LockoutTagoutProcedure#LockoutTagoutPolicy#LotoProcedure#LOTOServices#LOTCompliance#OSHA#OSHALockoutTagout#OSHAGuidelines#HazardousEnergy#Safetylock#ESquare#ESquareAlliance

0 notes