#Light Steel Framing Software

Explore tagged Tumblr posts

Text

Solutions for Light Steel Framing Design with SteelSmart System

Explore the Light Steel Framing Software by SteelSmart System, engineered to streamline the design and analysis of light steel framing projects. This software offers a comprehensive suite of tools tailored for precision, efficiency, and innovation in structural engineering. With advanced features, users can optimize their designs, ensuring compliance with industry standards and enhancing project outcomes. Visit their website to discover the full potential of their Framing Software and elevate your engineering solutions.

0 notes

Text

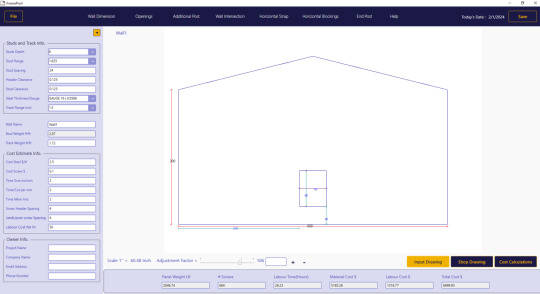

Make Use Of Light Gauge Steel Design Software Without Having 3D Modeling Skills

Did you know? Now you no longer need to have a thorough understanding of CAD design or acquire specialized 3D modeling abilities. With your basic knowledge of evaluating architectural dimensions and structural standards, you can easily enter your data into our light gauge steel design software program. After that, FrameProX instantly generates detailed shop drawings along with comprehensive cost calculation, for constructing the particular wall.

#light gauge steel design software#light gauge steel framing#3d modeling software construction#3d modeling software for buildings#3d steel detailing software#architecture 3d modeling software#building construction software#best steel detailing software#building structural analysis software

1 note

·

View note

Text

Warframe: Tandem

Short fic on how the Operator works with her favourite Warframe. This is just kind of a rough drabble, but maybe you'll dig it.

Freefall. Blood pressure behind her ears. Sloane wakes up with a jolt through her systems. The lurch in her chest like a redirection of gravity and then - suddenly - steel under her boots and a holographic display that lights her features in capital-cult blue.

Chaos. Alarms blare. Officers bark orders. Bots respond in warbled, digital tones. A spray of energy fire singes the wall either side of Sloane, a horizontal line interrupted by the protective shielding provided by her Warframe. Hildryn stands stalwart, arms crossed, shoulders squared and stance tall. Energy shimmers around the frame, bands of light peel from this field whenever Corpus security gets too close.

Sloane is used to this. Flitting between dreaming of the world and existing within it. "Tenno." And the Lotus helps, her voice calm in Sloane's ear. Both mother and commander. Soothing authority. "The alarms have been triggered. If you do not retrieve this data now, it will be lost forever."

After a beat of mild static the line cuts and Sloane mutters, "Yeah, yeah... We got this."

She gets to work. Personal Parazon injected into the data-port just below the main console. It forces the holo to obey, display filtering out unnecessary junk. Sloane is in a tertiary data vault two decks below topside on a Corpus War and Commerce Supercruiser. There is an R&D sector - highlighted, honed in on, read-out unspooling on the display, a near infinite scroll of raw data - that needs to be plundered.

An explosion. A burst of light and wave of heat. Sparks fly, officers hit the deck, Corpus MOA internal gyros just barely hold on. Sloane doesn't even blink. Hildryn's shields have her back. She's focused on the task at hand.

Technically, Sloane can not read the Corpus alphabet. Nor the stock-Sign that half of this data is written in. Yet she knows what is important. An intrinsic feeling, the imprint of her Warframe's translation software like muscle memory for her mind. "There." The data package is identified, the de-encryption software is pushed and resolved in the same second. Transfer is instantaneous. "Got it."

Sloane closes her eyes, crosses her arms over her chest, and falls backwards into sleep.

Panic ripples through the Corpus communications. The Warframe finally moves. First her fingers flex, then she rolls her shoulders, then her neuroptics hone in on the security team captain.

The ground below Hildryn - a proprietary metal alloy found only on ship models personally approved by the board - warps and melts. Hildryn's energy field is directed downwards and gives her lift. Heatwaves roll across the floor - it's already too late for the enemy to run. They are caught in the radioactive flare, held aloft in a pillar of balefire that fries their gear. The officers scream and flail. The MOAs fall apart completely.

Then comes the drop. Hildryn hits the dark hard with a three-point landing that shudders the entire section. Corpus security slams into the floor a half-second later, bodies broken, robots destroyed.

This is what Sloane dreams of. Her consciousness safe in Hildryn's frame. Her sleeping will translated into Warframe action. In this state - this dream that is real - Sloane and Hildryn are one and the same. Working in tandem.

Hildryn's body tenses and Sloane feels the tension. Hildryn launches into a horizontal bullet-jump and Sloane feels the rush.

"Our operative has looked over the data," The Lotus' voice is just as clear in this dream and now tinged with pride. "You have retrieved what you came here for. We are done here. Move on to extraction."

"[Intruder is on the move. Fall in on--]" An officer's communications are cut short by Hildryn slamming into him. Sparks fly from the floor as she skids to a halt and redirects at the junction, chasing now a green blip the Lotus had supplied her HUD. She launches again, gliding forward with an arm outstretched. Sloane feels this too. Anatomy that doesn't exist on her own body. Like a pleasant itch.

Hildryn's wrist-mounted launcher hums with power and unleashes a hot pink burst of radioactive energy against a security team attempting to make a blockade. They are obliterated.

Past the felled team and into a docking bay, landing with a low slide that carries Hildryn underneath one antigrav loader. Then she pushes up immediately into another bullet-jump. From here she gets a wide-band view of the space. More MOAs positioning to take shots. A trio of officers setting up an energy turret. Drones flying in from ceiling mounted housing.

Sloane wakes up. A child tumbling from the Warframe's body. It's a practiced move, Hildryn left tucked and entering freefall while Sloane herself taps into the pull of the Void. She is given a second of suspension where no shots can hit her, targeting systems simply slipping past her presence. She uses this time to conceptualize where she is now and where she is going to be.

Void sling. The point to point translation of a child from where she was to where she will be. The time and space between those points turned to nil.

Where she was: Twenty five meters above the main docking bay deck.

Where she will be and so is: Rapidly approaching the floor of the personal craft landing bay, already past the security checkpoint.

Sloane squeezes her eyes shut and Hildryn lands in her place. Sleeping again, the Warframe pulled to her position (it was always there) like a protective shell. Or warm blanket. The remaining Corpus are left shooting dead air and scratching their heads at the sudden loss of their target.

"Mission complete," The Lotus says. Hildryn settles into the extraction alcove, liset already powered up and ready to depart. "Good job, Tenno."

7 notes

·

View notes

Text

@haematophiliac

02:12 on the clock.

The pair had been working together in silence, leaning over the autopsy table for nearly two hours. This was not an unusual place to find Executive Proton and Admin Jax-- in fact, the two of them regularly worked alongside one another in the basement levels of the executive's workshop.

Whenever Fragmentation Syndrome was involved anything pertaining to a Rocket member, individuals with previous experience handling the condition were pulled and assigned to the issue at hand. In this scenario, a grunt had been inflicted with the anomalous syndrome, and was showing symptoms for the past 72 hours. Fragmentation develops quickly-- and aggressively. Without intervention, it can devastate any body, either organic or artificial.

Autopsying these bodies was vital in order to better understand the condition, and in order to prevent further spread. Of course, the ongoing treatments that Executive Proton received for his own illness, was paramount as well.

Of course, he was still very symptomatic, despite being stable.

And unfortunately, when one anomaly meets another, reactions occur.

The room had been silent, until Proton's scalpel cut into the vagus nerve of the cadaver. Once steel cut through the delicate strand, an awful, screeching sound erupted, and Proton's arm was rendered temporarily useless-- within seconds, the body in front of the pair distorted, as did the executive's arm. Frozen in place, Proton twitches some, that horrid screeching piercing his cranium, and causing the man to hunch over as he made an awful sound of his own. It only lasts for a moment-- but in that moment, some of the exposed organs and muscle tissue on the cadaver simply-- pixelate and vanish.

Cussing under his breath, Proton leans up-- and then turns his head to Jax. His own movements were still lagging, like that of outdated software.

❝ Well that was fucked up. ❞

His frame flickers, just like the dingey yellow lights overhead, and he lowers his hand down from his face. Proton smiles, his calmness rather unnerving. His voice is off, more akin to a radio signal.

❝ Jaaax? Are you oͦᵏkͣaͣaͣaͣʸay? ❞

#➤ 《 𝟗𝟎 𝐃𝐚𝐲𝐬 𝐃𝐞𝐥𝐢𝐧𝐪𝐮𝐞𝐧𝐭; 𝐆𝐞𝐭 𝐓𝐡𝐞 𝐑𝐞𝐩𝐨 𝐓𝐫𝐞𝐚𝐭𝐦𝐞𝐧𝐭 》 In Character#➤ 《 𝐒𝐞𝐫𝐩𝐞𝐧𝐭 𝐁𝐞𝐧𝐞𝐚𝐭𝐡 𝐓𝐡𝐞 𝐒𝐡𝐫𝐢𝐧𝐞 》 Verse One#haematophiliac

2 notes

·

View notes

Text

Best Tensile Structure manufacturer in Delhi

If you’re planning to upgrade your space with something modern, stylish, and durable, tensile structures are the perfect choice. Be it a car parking area, garden canopy, terrace shade, or a large-scale commercial project—tensile structures not only provide protection from sun and rain but also give a beautiful, contemporary touch to your surroundings.

But here’s the real question—how do you choose the Best Tensile Structure Manufacturer in Delhi who can bring your vision to life with top quality and perfect design? Let’s break it down in the simplest and most practical way so you can make a smart, confident decision for your project.

Why Tensile Structures Are a Smart Investment

Tensile structures have become a popular choice today because they blend strength, flexibility, and style perfectly. Unlike traditional constructions that block your space with multiple pillars, tensile structures give you wide open spaces with fewer supports, allowing more light and air to flow freely.

These structures can be customized into various attractive shapes like cones, arches, domes, or waves, adding uniqueness to your property. Whether you want something simple or a bold statement design, tensile structures can easily match your vision.

In a city like Delhi, where summers bring extreme heat and monsoons bring heavy rain, tensile structures offer practical protection. Made from high-quality, UV-resistant, waterproof fabric and strong steel frames, they stay durable and require very little maintenance. The frames are treated to resist rust, so you can be assured of long-lasting performance.

What Makes the Best Tensile Structure Manufacturer in Delhi Stand Out

The Best Tensile Structure Manufacturer in Delhi isn’t just about selling you a structure—it’s about delivering a complete solution. The right manufacturer will start by understanding your space, your style preferences, and your purpose. From there, they will design a structure that not only fits perfectly but also enhances the look of your property.

Professional manufacturers use advanced tools like CAD software to create precise, flawless designs. Their production units follow strict quality standards, ensuring that every part is strong, safe, and reliable. You’ll have the flexibility to choose from a variety of fabric types, colors, and shapes to suit your specific needs.

Installation is another area where top manufacturers shine. They have trained and experienced teams who install the structure with great care, making sure it’s safe and secure. Plus, the best companies provide excellent after-sales support so that if you ever need assistance, they’re just a call away.

Why Choosing a Professional Matters

Sometimes people are tempted by cheap offers from local vendors. But when it comes to tensile structures, quality and safety should always come first. A professional and reputed manufacturer ensures that your structure not only looks good but also meets high safety standards. You get honest advice, clear pricing without hidden charges, and a timeline that’s respected—no unnecessary delays or surprises.

Ready to Transform Your Space? Let’s Connect

If you’re looking for the Best Tensile Structure Manufacturer in Delhi, one who combines creativity, quality materials, precision design, and reliable service—we’re here to help you every step of the way. Our team is passionate about creating tensile structures that are strong, stylish, and built to last.

👉 Contact us today to share your ideas and see how we can help you create a structure that perfectly fits your space and budget. Whether you need a small canopy or a large commercial setup, we promise customized solutions that exceed your expectations.

📞 Phone No: 9625651202 📧 Email ID: [email protected]

0 notes

Text

Mactec: Pioneering Excellence in High Mast Pole Manufacturing

In the realm of outdoor lighting and large-scale infrastructure, high mast poles play a pivotal role in ensuring visibility, safety, and operational efficiency. Among the leading names in the industry, Mactec has established itself as a trusted and innovative high mast pole manufacturer, delivering superior quality and precision-engineered solutions across various sectors including highways, airports, ports, sports arenas, and industrial facilities.

Founded on the principles of engineering excellence and customer satisfaction, Mactec has consistently set new benchmarks in the manufacturing of high mast poles. Their advanced manufacturing facility is equipped with state-of-the-art machinery and quality control systems, allowing the company to produce poles that meet international standards such as ISO, ASTM, and BSEN. From design to fabrication and final finishing, every stage of the production process is meticulously managed to ensure structural integrity, durability, and performance.

Mactec’s high mast poles manufacturers are designed to withstand harsh environmental conditions, including strong winds, heavy rains, and extreme temperatures. Using high-grade galvanized steel and superior corrosion-resistant coatings, the poles are built for long-term reliability with minimal maintenance. The company offers a wide range of customizations in terms of height, head frame design, and raising/lowering systems to suit the specific needs of each project.

What sets Mactec apart is not just the quality of its products, but also its comprehensive approach to client service. From initial consultation to post-installation support, the Mactec team works closely with clients to ensure optimal design, ease of installation, and cost-efficiency. Their in-house design and engineering team utilizes the latest software tools like STAAD.Pro and AutoCAD to create precise models and simulations, helping clients visualize the final outcome before execution.

Moreover, Mactec emphasizes safety and compliance in all its manufacturing and installation processes. Each pole undergoes rigorous testing, including load testing and weld inspections, to ensure it meets both functional and safety requirements. This commitment to excellence has earned Mactec a reputation for reliability and professionalism in both domestic and international markets.

In addition to serving government infrastructure projects, Mactec is also a preferred partner for private sector developments seeking high-performance lighting systems. The company has successfully completed numerous turnkey projects across India and overseas, consistently meeting delivery timelines and quality expectations.

As urbanization and infrastructural development continue to rise globally, the demand for robust lighting solutions is set to grow. Mactec, with its unwavering dedication to innovation, quality, and customer satisfaction, remains at the forefront of this evolution. For anyone looking to invest in top-tier high mast pole manufacturer lighting systems, Mactec stands out as a name synonymous with trust, performance, and lasting value.

Visit:- https://www.mactec.in/high-mast-pole.html

#flag mast pole manufacturer#puf sandwich panels manufacturer#octagonal pole manufacturers#conical pole manufacturer#High Mast Pole Manufacturer

0 notes

Text

Revolutionizing Construction with CFS Software and Cold Formed Steel

Cold Formed Steel (CFS) is quickly becoming the preferred material in modern construction due to its high strength-to-weight ratio, resistance to corrosion, and design flexibility. Unlike traditional materials, CFS is manufactured through a cold-forming process at room temperature, resulting in precise, lightweight components that are ideal for both commercial and residential structures. Its ability to reduce structural weight without sacrificing integrity makes it an excellent choice for cost-effective and sustainable building projects.

As CFS continues to grow in popularity, the complexity of designing and detailing these structures also increases. That’s where CFS Software plays a crucial role. Tailored specifically for engineers, architects, and fabricators working with Cold Formed Steel, this software provides advanced tools for structural analysis, member sizing, and automatic code checks. It not only speeds up the design process but also enhances accuracy and ensures compliance with building standards—something that manual calculations or general-purpose tools often struggle to achieve.

Incorporating CFS Software into your design workflow means you can confidently deliver precise drawings, optimize material usage, and collaborate more effectively with your team. Whether you're working on light-gauge steel framing, modular buildings, or steel trusses, this software simplifies complex tasks and reduces the risk of costly errors. As construction moves toward greater efficiency and digital integration, CFS Software has become an essential resource for anyone working with Cold Formed Steel.

Discover more on the topic by visiting our blog - https://steelsmart.blogspot.com/2025/06/revolutionizing-construction-with-cfs.html

0 notes

Text

Revolutionize Your Ride with the Alter Hub Motor Kit: The Smart Way to Go Electric

Meta Description

Convert any bike to electric with the Alter Hub Motor Kit – smart, fast, and eco-friendly.

.

Introduction:

In today’s fast-paced urban world, electric mobility isn’t just a trend—it’s a necessity. Rising fuel prices, growing environmental concerns, and daily traffic congestion are pushing more people to seek smarter, cleaner ways to commute. Enter Alter Hub Motor Kits, a game-changing innovation from Alter Bikes, a pioneering electric mobility brand based in Ludhiana, India.

With Alter's hub motor kits, you can convert your traditional bicycle into a powerful electric cycle—quickly, affordably, and sustainably. Whether you're a daily commuter, a student, or an eco-conscious rider, this guide will walk you through the world of Alter Hub Motor Kits, explain how they work, and help you understand why they're the future of urban mobility.

What is the Alter Hub Motor Kit?

The Alter Hub Motor Kit is a complete electric conversion package that replaces your cycle’s front or rear wheel hub with an electric motor. It includes essential components such as:

Hub Motor Wheel (front or rear)

Battery Pack (typically Lithium-Ion)

Throttle and Display Unit

Controller

Wiring Harness and Connectors

Pedal Assist Sensor (PAS)

Brake Levers with Cutoff

This kit allows your bicycle to gain electric power assist, making your rides smoother, faster, and less physically demanding—perfect for commuting or leisure.

Why Choose Alter Hub Motor Kits?

✅ 1. Plug-and-Play Simplicity

Alter kits are designed for easy installation. Most users can convert their cycle within a few hours, using basic tools. Whether you're a DIY enthusiast or a beginner, the instructions are straightforward.

✅ 2. Affordable & Scalable

Instead of buying a brand-new e-bike, the kit lets you upgrade your existing cycle, making it a budget-friendly option. Kits come in 250W to 500W variants, suitable for city rides or slightly rugged routes.

✅ 3. High Performance

Alter hub motors are brushless and gearless, offering:

Quiet operation

Efficient torque delivery

Speeds up to 25–40 km/h (depending on model and local laws)

Up to 40–60 km range per charge

✅ 4. Customizable Options

Choose between front or rear hub motors based on your riding style:

Front hub: Easier to install, better for flat terrain.

Rear hub: Offers more traction and performance on inclines.

✅ 5. Eco-Friendly Commuting

Each electric conversion reduces your carbon footprint by miles, helping the planet while saving on fuel and maintenance costs.

Real-Life Example 1: Ramesh, Office Commuter from Delhi

Ramesh, a 32-year-old software engineer, used to spend nearly ₹2,500 a month on fuel. After installing an Alter rear hub motor kit on his hybrid bicycle, his monthly commute cost dropped to just ₹150 in electricity.

“I reach work without sweating, save time in traffic, and don’t worry about parking,” he says.

Real-Life Example 2: Anjali, Student in Pune

Anjali converted her old steel-frame bicycle using Alter’s front hub motor kit. She now covers 10–15 km daily for classes and errands.

“Installation took just a morning with a friend’s help. It's fun, light, and clean!”

Types of Alter Hub Motor Kits

🔄 1. Front Hub Motor Kit

Easiest to install

Suitable for city commuters

Lightweight, with decent power (250W)

Ideal for riders new to e-bikes

🔄 2. Rear Hub Motor Kit

Better torque and traction

Preferred for hilly routes or heavier loads

Supports up to 500W motors

🔋 Battery Options:

36V 7.8Ah for city commutes (up to 30 km range)

36V 10.4Ah and 13Ah for longer rides (up to 60 km)

🔧 Most kits come with smart BMS (Battery Management System) for safe charging and discharging.

What’s Included in the Kit?

Component

Function

Hub Motor Wheel

Provides electric power to rotate the wheel

Battery

Powers the motor (removable or fixed)

Controller

Regulates power flow and motor behavior

Display (LCD/LED)

Shows speed, battery level, and PAS mode

Throttle

Twist or thumb lever for manual speed control

PAS Sensor

Enables pedal-assist mode

Brake Cut-off Levers

Ensures safety by cutting motor power when braking

Wiring + Connectors

Pre-wired for easy plug-and-play setup

Installation Tips for Beginners

Choose the Right Wheel Size: Alter kits are available in 26", 27.5", and 700c sizes to match your cycle.

Mount the Motor Wheel: Replace the existing wheel with the motorized one.

Install Battery Mount & Controller: Most riders attach the battery to the frame’s bottle holder or rear carrier.

Connect Display, Throttle & Sensors: Route cables neatly using zip ties. Use waterproof connectors.

Test the System: Before riding, lift the wheel and test throttle/PAS response to ensure proper setup.

FAQs

❓ Is the kit waterproof?

Yes, most components are weather-resistant, but avoid heavy waterlogging or submersion.

❓ Does it require a license?

For 250W kits (under 25 km/h), no license or registration is required in India.

❓ Can it climb hills?

The 500W rear motor kits handle moderate inclines well, especially when paired with pedal assist.

❓ What is the warranty?

Alter provides 1-year warranty on most components and offers responsive after-sales support.

Maintenance and Care Tips

Keep connectors dry and clean

Charge battery regularly (don’t let it drop below 20%)

Lubricate your chain and brakes like on regular cycles

Get an occasional check-up from local bike mechanics familiar with e-bikes

Real-Life Example 3: Delivery Rider from Chandigarh

Ravinder, a Zomato delivery rider, used to rent petrol bikes daily. After investing in an Alter 500W rear hub kit, his delivery efficiency went up, and he saves ₹4,000–₹5,000 monthly.

“My Alter bike is light, fast, and always reliable—even during peak hours.”

Where to Buy the Alter Hub Motor Kit

You can purchase directly from:

👉 Official Website: www.alterbikes.com 👉 Flipkart & Amazon (select models) 👉 Local authorized dealers across India

Conclusion: Power Your Pedals with Purpose

The Alter Hub Motor Kit is more than a product—it’s a movement toward cleaner, smarter, and more affordable commuting. Whether you're tired of sweating through traffic, paying fuel bills, or simply want a greener lifestyle, this kit offers the perfect balance between performance, price, and practicality.

Take your existing bike and give it a new lease of life—with silent power and guilt-free speed. Go electric, go Alter!

Link: https://alterbikes.com/

0 notes

Text

Advanced Guide to Installation of LED Display Boards

LED display panels have become the star of commercial spaces, conference rooms, exhibition halls and even home decorations for their high brightness, bright colors and flexibility. The LED display panel installed on the ceiling can save space, enhance the sense of technology, and bring shocking visual effects. However, installing an LED display panel is not just about hanging it up, it involves multiple links such as structure, electrical and debugging. This article will provide you with an installation guide from entry to proficient, helping you create a safe and cool visual feast, with the word count controlled within 1,000 words, which is easy to understand and professional.

Preparation: Lay a solid foundation and achieve twice the result with half the effort

Clarify requirements and budgets

Before installation, figure out the purpose: whether to play advertisements, display artistic content, or conference presentation? The purpose determines the screen specifications, such as P2 (pixel spacing 2mm) is suitable for close viewing, while P4 is more suitable for long distances. The budget is also very important. Ordinary indoor screens are about 5,000-10,000 yuan per square meter. With the frame and installation fee, the total cost may be between 8,000-15,000 yuan per square meter. How to reduce the installation cost of LED walls?

Check equipment and tools

When counting the equipment, confirm whether the LED module, control card, power supply and cable models match. Prepare professional tools: torque wrench ensures uniform screw fixation; anti-static bracelets and pads protect sensitive components; cable testers check line faults. These details can greatly improve installation efficiency.

Assess the ceiling and environment

Ceiling load-bearing is the top priority! The LED display panel weighs 20-50 kilograms per square meter, and structural engineers need to be asked to evaluate whether the ceiling needs to be reinforced. Consider environmental factors: choose a screen with IP54 or above protection level in places with high humidity; choose a high-brightness model (≥1000 nits) in strong light environments. Don't forget to reserve maintenance space for future maintenance.

Installation steps: Make every step and strive for excellence

Design a solid framework

The core of ceiling installation is a fixed frame, usually made of steel structure or aluminum alloy, and needs to be customized according to the screen weight and size. The frame and the ceiling are connected with expansion bolts or embedded parts to ensure stability. Outdoor screens also need to consider factors such as wind load and snow load, and welding and anti-rust treatment must also be in place. Give you a steel frame LED screen: key features, case studies and buying tips.

Electrical wiring and safety

The power supply and signal wiring should be standardized to avoid cross-entanglement and meet fire protection requirements. The power cord diameter must match the screen power, and it is recommended to be equipped with a UPS to prevent power outage. The signal line is made of high-quality materials, and long-distance transmission can be used to consider optical fiber to reduce interference. The metal housing and power supply system must be well grounded to prevent leakage or static electricity.

Module splicing and debugging

During installation, the modules should be spliced piece by piece, and leveling is used to ensure smoothness, and fine-tuning screws or gaskets to eliminate height differences. The cable connection should be aligned with the interface to lock it to prevent loosening. After the installation is completed, debug the brightness, color and white balance to ensure that the picture is uniform and has no color difference. Large screens may require correction of software optimization display effects.

Post-maintenance: Make the screen shine for a long time

Regular inspection

Check the frame, cooling system and cables every six months to prevent loosening or aging. Pay special attention to whether the waterproof joints and sealing tape are intact when outdoor screens are available.

Cleaning and Maintenance

Wipe the screen gently with a soft cloth to avoid using a damp cloth or chemical cleaner to avoid damage to the surface coating. Clean the dust regularly to maintain the display effect.

Content Management

Update play content regularly, combining festival or event themes to keep the screen attractive. Choose a system that supports remote control to facilitate content updates and troubleshooting.

Fees and supplier selection

The cost varies from project to project. The total cost of screen, frame and installation is about 8,000-15,000 yuan/square meter. Creative styling or high-end control systems will be more expensive. When choosing a supplier, don’t just look at the price! The qualifications, cases and after-sales service are inspected, and a reliable supplier will provide full-process support and a 3-5-year warranty. After installation, please ask for drawings and maintenance manuals for easy management. China LED screen factory, this is more reliable!

Conclusion

The ceiling-mounted LED display panel can give the space a technological charm, but the key to success lies in preliminary planning, fine construction and continuous maintenance. From demand analysis to debugging and optimization, you can’t be careless in every step. I hope this guide can help you create a safe and cool visual space from getting started to master! Have a question? Find a professional team to consult and let your LED display panel shine in the audience!

Thank you for watching. I hope we can solve your problems. Sostron is a professional LED display manufacturer. We provide all kinds of displays, display leasing and display solutions around the world. If you want to know: Small-pitch LED large screen: illuminates the vista, not just "small". Please click read.

Follow me! Take you to know more about led display knowledge.

Contact us on WhatsApp:https://api.whatsapp.com/send?phone=+8613510652873&text=Hello

0 notes

Text

Top Benefits of Using Structural Framing Software for Design

When tackling the complexities of light steel and cold-formed steel floor framing, using specialized software can revolutionize your design approach. Managing design tasks manually can be both time-consuming and error-prone. With Light Steel Framing Software, many tasks are automated, making the design process more streamlined. This software enables quick model generation and effortless adjustments, which reduces the need for extensive manual calculations and updates. As a result, you can complete projects faster and with greater efficiency.

Designing floor systems using Floor Framing Design software offers precise and detailed design capabilities. This software helps ensure that each component is accurately sized and positioned, adhering to all necessary specifications. Accuracy is crucial in structural design significantly enhances this aspect by automating many of the calculations and design checks. Structural framing software design often involves intricate calculations that can be challenging to perform manually. Advanced software handles these calculations quickly and accurately, allowing you to focus on other aspects of the project. This not only speeds up the design process but also provides a solid foundation for making well-informed decisions.

Incorporating framing software into your design process can greatly benefit your approach to light steel and CFS floor framing. Steel Smart System provides innovative software solutions designed to streamline structural framing tasks. Their tools are designed to optimize light steel and CFS floor framing design, improving both efficiency and precision in your designs. To learn more and enhance your design capabilities, read the full blog:

0 notes

Text

A specialised casting technique has emerged as a trusted solution, particularly for reinforcing high-stress areas like structural corners. This article explores how this process supports various industries—from construction to logistics—by improving strength, ensuring consistency, and enhancing performance while aligning with sustainability and cost-efficiency goals.

Strength at the Core of Structural Design

In structural engineering and heavy manufacturing, the integrity of joint areas plays a pivotal role in determining overall durability. These connection points are regularly exposed to mechanical pressure, vibrations, and environmental elements. Strengthening these areas ensures the long-term performance of equipment, buildings, or containers. Corner Casting is widely used in such applications, as it provides a reinforced solution specifically designed to handle concentrated stress. By incorporating Corner Casting in high-load zones, manufacturers can deliver structures with a stronger core, especially where failure is least tolerated.

Why Moulded Reinforcement Makes a Difference

Precision casting enables manufacturers to create solid, seamless parts that outperform traditionally welded or fabricated joints. The absence of seams reduces the risk of stress fractures, and the uniform density of the material provides excellent load-bearing capacity. These reinforcements offer peace of mind in critical applications such as building supports, lifting frames, or marine platforms, where absolute reliability is essential.

Selecting the right material is crucial. Cast steel remains a popular choice due to its strength, resistance to deformation, and ability to withstand harsh elements. For industries that demand peak mechanical performance, such as marine construction, oil rigs, or shipping containers, steel provides a trusted foundation. In addition, its compatibility with post-processing techniques like welding, painting, and machining makes it a versatile option.

Meeting Industrial Standards and Safety

The transportation and construction industries are governed by strict global standards. Shipping containers, for instance, must safely endure stacking, lifting, and shifting in unpredictable conditions. Their support structures are often produced using cast components that conform to these standards, ensuring durability during loading and unloading. In construction, these parts serve as dependable links between beams and panels, particularly in multistory frameworks.

Shaping Performance Through Design Precision

Modern design tools allow engineers to simulate real-world stress before production even begins. Using CAD software, manufacturers can predict the performance of a component under pressure, adjusting mould dimensions to improve strength or reduce weight. The result is a balance of structural integrity and efficient resource use, giving companies a competitive edge in performance and cost management.

Long-Term Durability in Harsh Conditions

Industrial environments are unforgiving. Components used in outdoor or high-pressure applications must endure continuous exposure to water, chemicals, UV light, and extreme temperatures. Precision-cast components offer enhanced resistance to these factors, maintaining shape and function for years. This makes them indispensable in projects where structural failure is not an option, such as coastal bridges, offshore platforms, or power facilities.

Consistency and Quality You Can Count On

Mass production demands consistency. Each unit must meet the same specifications, especially in industries where parts are installed interchangeably. The casting process allows for reliable repetition without quality degradation, thanks to reusable moulds and strict controls. Advanced inspection techniques like X-ray imaging or ultrasonic testing verify structural integrity before distribution, ensuring every piece is ready for performance. One of the most appealing aspects of this manufacturing method is its long service life. By minimising wear and tear in high-stress areas, companies benefit from fewer maintenance interventions and less frequent part replacements. This not only enhances operational uptime but also contributes to reduced lifetime costs—a major benefit for industries operating under tight margins or continuous production cycles.

Sustainability in Modern Manufacturing

Environmental responsibility is a growing concern in heavy industry. Today’s foundries incorporate eco-conscious practices like recycling excess materials, using energy-efficient furnaces, and adopting closed-loop cooling systems. Because these components last longer and require fewer replacements, they help reduce industrial waste. The combination of durability and low environmental impact adds significant value to any sustainable engineering project. From construction to aerospace, this production technique supports a wide range of industries. It is vital in the logistics industry, where containers must maintain their integrity during global transport. It supports mining equipment subjected to constant movement and impact. It also plays a key role in architectural structures that combine aesthetic appeal with strength. This wide range of applications highlights the process’s adaptability and importance in modern manufacturing.

Conclusion As engineering evolves, so do the methods that define precision and durability. Casting processes designed for structural enhancement remain at the forefront of reliable component manufacturing. Their ability to withstand pressure, maintain shape, and deliver consistent results across countless applications has made them a cornerstone of modern production. In particular, Corner Casting continues to be a preferred solution in industries that prioritise safety, efficiency, and performance, helping build the strong, sustainable structures of tomorrow. The increasing demand for high-performance infrastructure has placed a spotlight on components that provide structural integrity without compromising on design. From shipping containers and trailers to architectural frameworks and machinery, the corners often bear the brunt of stress. By incorporating robust casting techniques at these pressure points, manufacturers enhance both safety and longevity. This focus not only reduces repair costs but also ensures that structures remain reliable over decades of use. As materials and methods continue to improve, the reliance on expertly cast parts, especially at crucial joints, will become even more pronounced in the global industrial landscape.

0 notes

Text

Elmalo, let’s dive deeper into the hardware specifications that will form the foundation of Iron Spine’s sensor fusion capabilities. This detailed look will cover sensor choices, ruggedization strategies for extreme environments, and considerations for optimizing edge computing performance.

1. Sensor Choices

A diverse sensor suite is crucial for a system designed to operate across space, deep sea, underground, and more. Here are some categories and specific choices to consider:

Environmental Sensors:

Radiation Detectors:

Example: Semiconductor-based sensors (e.g., Silicon PIN diode detectors) or Geiger-Müller tubes.

Key Considerations: Sensitivity range, calibration for cosmic or deep-sea radiation, and response time.

Pressure Sensors:

Example: Piezoresistive or capacitive sensors like those used in underwater applications.

Key Considerations: Depth ratings, response time, and temperature compensation.

Temperature & Humidity Sensors:

Example: Bosch BME280 or Sensirion SHT series.

Key Considerations: Accuracy under varying environmental conditions, low power consumption, and integration ease.

Motion & Optical Sensors:

Insect-Inspired Motion Sensors:

Example: MEMS-based inertial measurement units (e.g., InvenSense MPU-9250 or similar) that capture acceleration, angular velocity, and magnetic field data with high resolution.

Key Considerations: Minimal latency, low drift, and high sensitivity for subtle movements.

High-Resolution Cameras:

Example: Industrial-grade camera modules (such as those designed for robotics or autonomous vehicles) that can perform in varied lighting.

Key Considerations: Frame rate, resolution, and the ability to operate in low-light or high-contrast conditions.

LIDAR/Optical Ranging:

Example: Compact, time-of-flight sensors or structured light systems.

Key Considerations: Range, environmental adaptability, and integration with visual feeds.

Acoustic & RF Sensors:

Acoustic Sensors:

Example: MEMS microphone arrays or specialized underwater hydrophones for sonar applications.

Key Considerations: Frequency sensitivity (audible versus ultrasonic), noise cancellation, and dynamic range.

RF Sensors:

Example: Software-defined radio (SDR) modules or narrow-band receivers capable of picking up anomalous electromagnetic signals.

Key Considerations: Frequency range, sensitivity, and resistance to interference.

2. Device Ruggedization

Operating in extreme environments demands that each edge device and sensor module be hardened for durability and reliability. Consider these strategies:

Enclosures & Packaging:

IP-Rated Cases: Use industrial enclosures rated at least IP67 or higher to protect against dust, water ingress, and contaminants.

Shock & Vibration Dampening: Implement mounting solutions with shock-absorbing materials (such as silicone inserts or rubber gaskets) to reduce the effects of mechanical impacts and vibrations common in harsh environments.

Temperature Control:

Thermal Management: Integrate active cooling (mini fans or heat sinks) or passive solutions (thermal conductive materials) to maintain optimal operating temperatures across extreme conditions.

Heaters or Insulation: In cold or high-altitude settings, built-in heaters or insulation can prevent sensor malfunctions and maintain performance.

Material Selection:

Robust Circuitry: Use components rated for wide temperature ranges and shock tests. Consider industrial-grade microcontrollers (like those used in aerospace) along with robust soldering and PCB design techniques.

Corrosion Resistance: For deep-sea or subterranean applications, use corrosion-resistant materials (e.g., conformal coatings, stainless steel housings) to extend the lifetime of the sensors and board-level components.

3. Edge Computing Performance

At the edge, the processing unit must handle a high throughput of sensor data in real time. Consider these platforms and configurations:

Primary Edge Devices:

NVIDIA Jetson Series:

AGX Xavier: Offers high computational power with an 8-core ARM CPU, 512-core GPU, and accelerated deep learning inference capabilities. Ideal for implementing sophisticated preprocessing and fusion algorithms.

Jetson Nano: A cost-effective alternative when power is limited, capable of running streamlined models and basic sensor fusion tasks.

Key Advantages:

Real-Time Processing: GPU acceleration and support for frameworks like TensorRT enable fast, in-situ data analysis and decision-making.

Modular Scalability: Easily integrated with additional sensor inputs and can run multiple fusion algorithms concurrently.

Supplementary Controllers:

Raspberry Pi Compute Modules & Arduino Boards:

Roles: Act as microcontroller units (MCUs) for simpler sensor tasks such as data acquisition, local filtering, or secondary processing.

Interfacing: Use standardized communication protocols (SPI, I2C, UART) to easily integrate with primary edge devices.

Communication & Connectivity:

Protocols for Inter-Device Communication: Consider MQTT for lightweight messaging and LoRaWAN for long-range, low-power communication in areas with intermittent connectivity.

Latency & Bandwidth Considerations: Properly balance between local processing (minimizing transmission delays) and cloud synchronization for historical data analysis.

Power Considerations:

Energy Efficient Design: Optimize both hardware and software to balance high performance with reasonable power consumption, especially critical in remote field deployments.

Battery Solutions: Explore rugged, high-capacity battery units or renewable energy options (solar panels) for prolonged, autonomous operation.

Summarized Blueprint Table

This comprehensive hardware specification not only outlines your sensor choices but also integrates strategies for device ruggedization and robust edge computing performance—ensuring Iron Spine’s sensor network is resilient, precise, and ready for extreme, real-world applications.

Would you like to further explore specific sensor integration techniques, or do you have additional requirements or constraints—perhaps environmental limits or power consumption targets—we should account for in the current blueprint?

0 notes

Text

Best Sheet Metal Components Manufacturer in Ahmedabad

Sheet metal components are integral parts in various industries, crafted by shaping metal sheets into desired forms through processes like cutting, bending, stamping, and welding. These components are typically made from stainless steel, aluminum, brass, or copper and are known for their strength, durability, and light weight. Their applications span across industries such as automotive, aerospace, construction, electronics, and household appliances. From engine parts to structural frames and electronic enclosures, sheet metal components deliver both structural integrity and aesthetic appeal. Modern manufacturing techniques, including CNC machining, laser cutting, and automated stamping, allow for high precision and repeatability in producing sheet metal parts. Manufacturers also offer tailored solutions to meet specific industrial needs, including prototyping and large-scale production. High-quality finishing processes such as powder coating, anodizing, and galvanization enhance the components’ resistance to corrosion and wear. As design requirements evolve, manufacturers integrate CAD/CAM software to ensure every product is optimized for function, fit, and finish. With the rising demand for lightweight yet strong materials, sheet metal components continue to play a crucial role in industrial innovation. The growing emphasis on sustainability also favors sheet metal, as most materials used are recyclable, reducing environmental impact. Moreover, their reusability and long lifespan contribute to cost-efficiency in production and maintenance. As industries adopt smart manufacturing and lean production, sheet metal components remain essential for building resilient, efficient, and eco-conscious systems.

For More Details Click Here: https://www.indiantradebird.com/product/sheet-metal-components

0 notes

Text

Realme GT 7 Price, Availability, Design And Performance

Realme GT 7

The China-released Realme GT 7 improved smartphone performance on April 23, 2025. The GT 7's power, performance, and futuristic design reveal Realme's determination to challenge Samsung, Xiaomi, and OnePlus flagships.

The Realme GT 7's design, hardware, camera, and global release are addressed.

Display & Design

Like its predecessors, the Realme GT 7 is stylish and useful. The smartphone has a polished steel frame and a Nebula Blue and Starry Night Black glass back.

A 6.78-inch AMOLED screen with 144 Hz refresh rate and 1.5K resolution fronts the GT 7. Bright colours, deep blacks, and smooth scrolling make this screen spectacular. The display's 2,160Hz PWM dimming enhances low-light gaming, binge-watching, and everyday use.

Performance

The GT 7's next-generation MediaTek Dimensity 9400+ chipset and 3nm CPU are major advancements. Higher CPU and GPU speeds, efficiency, and AI processing than prior generations.

Realme promises rapid multitasking, app opening, and data transfer with up to 16GB of LPDDR5X RAM and 1TB of UFS 4.0 storage. Game visuals and productivity are good on Realme GT 7.

Advanced vapour chamber cooling lowers phone temperature after long usage or intense gaming.

Batteries and charging

Battery life is another GT 7 highlight. Its 7,200mAh battery is one of the largest on a premium phone. One charge gives this massive capacity over two days of constant use.

Realme doesn't lose battery capacity for charging speed. GT 7 can be charged from 0% to 50% in 15 minutes with 100W SuperVOOC quick charging. For busy individuals, its durability and rapid charging is groundbreaking.

Cam System

Realme invested much on the GT 7's camera. The phone has three cameras:

50MP Sony IMX890 OIS primary sensor.

Ultra-Wide 8MP Lens.

2-megapixel macro.

The main sensor captures sharp, color-accurate photos in bright and dim light. HDR, night photography, and scene detection benefit from AI. Even though they're not innovative, macro and ultra-wide lenses provide casual photographers additional alternatives.

A punch-hole hides a 32MP selfie camera on the front. Real-time beautification, 4K video capturing, and AI-powered social media photo enhancements are available.

AI, Software Features

Realme GT 7 comes with Realme UI 6.0 on Android 15. The UI is simple, fast, and customisable.

The way this device integrates AI-enhanced functionality is unique. This includes:

AI-based scene recognition.

Instant AI translation.

Performance and battery management using AI resource allocation. Picture filters, AI Night Mode.

These features enhance smartphone use and productivity by making it more fluid and intelligent.

Additional Features & Connectivity

Features of Realme GT 7:

5G and global band support.

WiFi 7 for lightning-fast internet.

5.4 Bluetooth.

screen-mounted fingerprint scanner.

HD audio and stereo speakers.

Realme also has IP65 water and dust protection, making it more durable in difficult environments.

Differences between Realme GT 7 and GT 7 Pro

Despite many similarities, the GT 7 Pro is the ultra-premium option with enhancements like:

Generation 4 Snapdragon 8.

Periscope zoom.

Vegan leather or ceramic.

Fast 120-watt charging.

An LPTO AMOLED display.

The GT 7 is more balanced, prioritising performance above luxury.

Available Worldwide

Realme GT 7, released on April 23, 2025, is only available in China. The company has not declared a global or Indian release date.

Due to the GT series' popularity and the GT 7 Pro's global success, the Realme GT 7 is expected to launch in India, Europe, and Southeast Asia in May or June 2025.

The cost in China

CNY 2,799 (~$385) for 8GB+256GB.

CNY 3,199 ($440) for 12GB+512GB.

CNY 3,799 ($520) for 16GB + 1TB.

The GT 7 will undercut rivals while offering equivalent top specifications, although costs may vary internationally.

Concluding

Realme GT 7 is another flagship and upper mid-range attempt by Realme to rule the market. With its powerful Dimensity 9400+ processor, huge battery, AI-enhanced camera, and smooth AMOLED display, the GT 7 may be one of the most cheap smartphones of 2025.

If Realme prices the GT 7 competitively internationally, it may become the top choice for budget-conscious flagship users.

#RealmeGT7#RealmeGT7pro#Android15#smartphone#LPDDR5XRAM#Dimensity9400#News#Technews#Technology#Technologynews#Technologytrends#govindhtech

0 notes

Text

Light Gauge Steel Machine: A Game-Changer in Modern Construction

In the dynamic world of construction, speed, precision, and sustainability are no longer optional—they’re essential. As the industry shifts toward modular construction and prefabricated solutions, the Light Gauge Steel Machine has emerged as one of the most impactful tools for builders and manufacturers alike.

Whether you’re building residential homes, commercial complexes, or prefabricated units, a Light Gauge Steel Machine can dramatically enhance your workflow, reduce costs, and deliver exceptional quality with structural integrity. In this blog, we’ll explore everything you need to know about light gauge steel machines—from how they work to why they matter.

What is a Light Gauge Steel Machine? A Light Gauge Steel Machine is a high-precision roll forming system designed to produce cold-formed steel framing components. These machines transform galvanized steel coils into structural elements such as studs, tracks, joists, and trusses, which are used for framing walls, ceilings, and floors in light steel construction systems.

These machines are fully automated and programmable, making them ideal for high-volume production of framing systems with minimal human intervention.

Why Light Gauge Steel is Gaining Popularity Before diving deeper into the machine, let’s understand why light gauge steel (LGS) is becoming a top choice in construction:

Lightweight yet Strong: LGS offers excellent strength-to-weight ratio.

Non-Combustible: Steel does not burn, making it a safer alternative to timber in fire-prone areas.

Sustainable: Steel is 100% recyclable and leaves minimal waste during production.

Dimensionally Stable: No warping, shrinking, or rotting—ensuring long-lasting structures.

Faster Construction: LGS buildings can be assembled quickly with prefabricated parts.

All these advantages are maximized when produced using a Light Gauge Steel Machine.

How Does a Light Gauge Steel Machine Work? The machine process is designed for speed and accuracy. Here’s how it works step-by-step:

Coil Loading A galvanized steel coil is placed onto a hydraulic decoiler which unwinds the coil and feeds it into the machine.

Leveling and Straightening The steel passes through straighteners that remove coil memory and flatten the material.

Punching & Notching Precision punches create service holes for electrical wiring, plumbing, and HVAC installations based on the design.

Roll Forming The core of the machine features multiple stations of roll forming dies that shape the steel into C, U, or custom profiles.

Cutting An automated flying shear or saw cuts the profiles to exact lengths as specified in the building plan.

Labeling & Stacking Optional modules label the parts for easy assembly and stack them for delivery or on-site use.

The entire process is controlled via CNC or PLC systems and can integrate with BIM or CAD software.

Key Features of a Modern Light Gauge Steel Machine ✅ Automated Operation – Reduces human error and labor cost.

✅ CAD/BIM Compatibility – Import architectural designs directly into the machine.

✅ Multiple Profile Options – Easily switch between stud, track, joist, and truss production.

✅ High-Speed Production – Capable of producing 10–25 meters per minute or more.

✅ Precision Punching – Custom hole placement for MEP systems.

✅ Material Efficiency – Minimizes scrap and maximizes yield.

Applications of Light Gauge Steel Machines These machines have a wide range of applications across multiple sectors:

🏠 Residential Construction From single-family homes to multi-story buildings, light gauge steel frames provide structural components for walls, floors, and roofs.

🏢 Commercial Interiors LGS is widely used in office buildings, malls, and hospitals for partitions, suspended ceilings, and support walls.

🛠️ Modular and Prefab Buildings Light gauge steel machines are the cornerstone of prefab housing factories that require fast and repeatable production.

🏭 Industrial Buildings Warehouses, cold storage units, and logistics centers rely on light steel framing for flexible design and durability.

🌍 Disaster Relief and Remote Housing Due to their lightweight and easy assembly, LGS structures are perfect for rapid deployment in disaster zones or remote areas.

Benefits of Using a Light Gauge Steel Machine

Faster Construction Timelines Manufacture and pre-assemble framing systems off-site and reduce on-site work significantly.

Consistent Quality Eliminate variability and errors common in manual fabrication.

Reduced Labor Dependency One machine operator can manage production for large-scale projects.

Flexible Design Options Easily switch between different steel thicknesses and profiles.

Sustainability Precise cuts and digital control minimize waste, contributing to eco-friendly building practices.

Integration with BIM & CAD Software One of the standout features of the Light Gauge Steel Machine is its seamless integration with BIM (Building Information Modeling) and CAD platforms. This allows designers and architects to:

Upload building models directly to the machine

Reduce design-to-production time

Ensure accurate part labeling and coordination

Detect and correct clashes before construction

This digital-to-physical workflow significantly improves project coordination and efficiency.

What to Look for When Buying a Light Gauge Steel Machine If you're considering investing in a Light Gauge Steel Machine, here are a few things to keep in mind:

Feature Why It Matters Profile Range Can the machine produce all the profiles you need (C, U, Sigma, etc.)? Software Integration Supports your existing CAD/BIM ecosystem? Punching Flexibility Are the punching dies easily adjustable or replaceable? Speed and Output Does it meet your volume demands? After-Sales Support Is training, maintenance, and troubleshooting support available? The Future of Light Gauge Steel Machines As the construction industry continues to embrace digitalization and prefabrication, we can expect even smarter and more versatile LGS machines:

AI and Machine Learning for predictive maintenance and adaptive production

IoT-Connected Machines for real-time performance monitoring

3D Framing Capabilities for more complex structural systems

On-Site Compact Machines for localized production in remote projects

Conclusion: Build Smart with a Light Gauge Steel Machine In an era where time is money and quality is non-negotiable, the Light Gauge Steel Machine is more than just a piece of equipment—it’s a strategic investment. From reducing costs to enhancing precision and accelerating construction timelines, this machine plays a vital role in modernizing the building industry.

Whether you’re a contractor, prefab builder, or steel product manufacturer, adopting a Light Gauge Steel Machine can help you deliver superior results while staying ahead of the competition.

Looking to upgrade your production line? Explore our high-performance Light Gauge Steel Machines designed for builders who demand the best in speed, accuracy, and flexibility. Contact us now for a free consultation and quote. roll forming machine in india purlin machine light steel frame machine

0 notes