#Linear Displacement Transducer

Explore tagged Tumblr posts

Text

27mm Waterproof Incremental Linear Draw Wire and Cable Displacement Sensor Transducer | NPN/PNP/Line Driver ABZ Outputs/IP68 rated

Key features

Exceptional Durability: Designed for 5 million fatigue cycles, ensuring long-lasting performance.

Advanced Incremental Output Options: Supports NPN Output, PNP Output, Voltage Output, Linear Drive Output, and Push-Pull Output for versatile integration.

Durable Wire Outlet: Ceramic material enhances wear resistance, extending the life of the steel wire rope.

High-Quality Construction: Features a 0.8mm diameter, imported flexible stainless steel wire rope with a nylon coating for reduced friction and enhanced durability.

Visit https://briterencoder.com/product/27mm-waterproof-incremental-linear-draw-wire-and-cable-displacement-sensor-transducer-npn-pnp-line-driver-abz-outputs/ for more.

#Waterproof Incremental Linear Draw Wire#Cable Displacement Sensor Transducer#Cable Displacement Sensor

0 notes

Text

How LVDTs Revolutionize Precision Measurement Systems

Opening Up the Concept

If you've ever wondered how machines “know” the exact position of a moving object, the answer often lies in a smart piece of tech called an LVDT. Used in everything from aircraft to industrial robots, these devices are silent heroes in the automation world.

The Basic Science Behind It

LVDTs function through electromagnetic induction. A small coil arrangement and a core that slides within them help convert mechanical movement into a digital signal.

The Design Breakdown

Three-Coil Configuration: A primary coil in the center flanked by two secondary coils.

Ferromagnetic Core: The moving part that modulates voltage.

Output Signal: A differential AC voltage proportional to the displacement.

Key Features

No physical contact

Robust against shock and vibration

Can operate in harsh environments

Highly accurate across temperature ranges

Types of LVDTs

Standard LVDTs: For general industrial use

Miniature LVDTs: Ideal for tight spaces

High-Temperature LVDTs: Built for aerospace and power plants

Application Areas

Machine tool calibration

Nuclear reactor control rods

Bridge structural monitoring

Testing labs for material strength

Major Benefits

Wear-free design

High output stability

Broad measurement range

No signal drift over time

Challenges in Usage

Despite their many strengths, proper alignment is crucial. Also, signal conditioning circuits may be needed in complex setups.

Closing Thoughts

In a world increasingly driven by automation and data, the linear variable differential transducer stands as a cornerstone of accurate measurement and control.

0 notes

Text

How Transducers Power Modern Automation Systems?

In today’s fast-paced industrial landscape, automation systems are the backbone of efficiency, safety, and productivity. But what connects the physical world to digital control systems? Transducers - the often-unsung heroes of automation - play a vital role in this transformation.

Let’s explore how transducers power modern automation systems, what types are commonly used, and why they are so essential in today’s industries.

What Is a Transducer?

A transducer is a device that converts one form of energy into another. In automation, it usually refers to a sensor that converts a physical quantity (such as temperature, pressure, or displacement) into an electrical signal. This signal is then interpreted by a controller, display, or monitoring system to take action.

How Transducers Work in Automation Systems?

Automation systems rely on feedback loops to perform operations accurately. These loops consist of:

1. Input – A physical change (temperature, motion, pressure, etc.)

2. Transducer/Sensor – Detects the change and converts it to an electrical signal.

3. Controller – Processes the signal and decides on action.

4. Actuator – Takes physical action (e.g., turning on a fan, moving a valve).

5. Feedback – Monitors the outcome to maintain control.

Transducers are critical at the input stage, providing real-time data to control units and enabling automated responses.

Types of Transducers Used in Automation

1. Temperature Transducers

Example: Thermocouples, RTDs

Use: In HVAC, food processing, plastic molding, and chemical plants.

Function: Measure heat and help maintain temperature stability in processes.

2. Pressure Transducers

Example: Strain gauge-based sensors

Use: Oil & gas, hydraulic systems, marine equipment.

Function: Monitor and control fluid or air pressure in real-time.

3. Displacement/Position Transducers

Example: LVDTs (Linear Variable Differential Transformers)

Use: Robotics, CNC machines, packaging.

Function: Track motion or position of machine parts for precision control.

4. Force Transducers

Example: Load cells

Use: Weighing systems, industrial presses, material testing.

Function: Convert force or load into measurable signals.

5. Flow Transducers

Example: Turbine meters, magnetic flow meters

Use: Water treatment, chemical flow, oil pipelines.

Function: Measure flow rate of liquids or gases for volume control.

6. Light/Photoelectric Transducers

Example: Photodiodes, phototransistors

Use: Conveyor belt item detection, safety doors, counting systems.

Function: Convert light intensity into electrical signals.

Applications Across Industries

Transducers are used in virtually every industry:

1. Manufacturing

In smart factories, transducers track everything from spindle speed to ambient humidity, helping to maintain optimal production conditions.

2. Marine & Offshore

Transducers help monitor engine pressure, ballast tank levels, and environmental sensors, ensuring safety at sea.

3. Energy & Utilities

Power plants use temperature and pressure transducers to maintain turbine efficiency and prevent failures.

4. Automotive

From throttle control to airbag deployment, cars are filled with transducers that communicate with onboard computers.

5. Healthcare & Labs

Medical devices rely on pressure and temperature transducers for accurate diagnostics and monitoring.

Why Transducers Are So Important?

1. Precision: They deliver accurate data critical for automation decisions.

2. Speed: They enable real-time feedback, reducing lag and inefficiency.

3. Safety: They help detect abnormal conditions (like overpressure or overheating) early.

4. Efficiency: They optimize energy usage and material waste.

5. Remote Monitoring: With IIoT (Industrial Internet of Things), transducers allow remote supervision and predictive maintenance.

The Future of Transducers in Automation

As industries move toward smart factories and Industry 4.0, transducers are becoming smarter, smaller, and more network-connected.

Wireless Transducers: Reduce wiring and simplify installations.

Digital Signal Output: Direct communication with PLCs or IoT systems.

Self-Calibrating Sensors: Lower maintenance requirements.

Integration with AI: Help analyze trends and automate maintenance alerts.

0 notes

Text

0 notes

Text

0 notes

Text

UniMeasure Inc

UniMeasure Inc

UniMeasure, Inc. has been manufacturing position and velocity sensors in Corvallis, Oregon since 1987. The company has steadily grown over the years to become a leader in the linear and rotary transducer industry with a focus on customer service, innovative design, and high-quality products. The Corvallis facility is ISO 9001:2015 certified with many raw materials and vendor services sourced in the local area. With a core group of long-standing employees, UniMeasure is dedicated to manufacturing position sensors in the USA and providing high-quality solutions while further enhancing customer experience.

UNIMEASURE LINEAR POSITION TRANSDUCERS

String Potentiometer

Often referred to as string pot, yo-yo pot, draw wire transducer, cable extension transducer, cable actuated transducer, UniMeasure extending wire rope linear position transducers have proven to be an attractive approach for a multitude of applications in many different industries. With relatively non-critical alignment requirements, compact size, and ease of installation wire rope actuated transducers are the linear position measurement system of choice in applications as diverse as bone densitometers in the medical industry, crash testing in the automobile industry, pump jacks in the crude oil extraction industry and irrigation and flood control in the water management industry. With a wide variety of electrical outputs, UniMeasure linear displacement measuring and position sensor products provide an extremely cost effective method for linear position feedback.

UNIMEASURE ROTARY POSITION TRANSDUCERS

Position Sensor

UniMeasure rotary position transducers provide an analog output signal that is directly proportional to the angle of rotation of the shaft of the device. With a voltage or 4 to 20 mA analog electrical output, UniMeasure rotary position transducers are also known as angle sensors, analog rotary shaft encoders and analog multiturn analog shaft encoders and absolute angle encoders. These position sensor devices are commonly used in applications where an absolute output signal is a must. Typical use occurs in closed loop process control and in testing applications where oscillatory rotary motion occurs. UniMeasure absolute analog rotary position transducers have proven to be an extremely cost effective alternative for measuring rotational positioning.

CONTACT US

UniMeasure Inc https://unimeasure.com/ ADDRESS: 4175 SW Research Way Corvallis, OR 97333 PHONE: (541) 757-3158

Facebook

1 note

·

View note

Text

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts Sold by YOYIK. Deyang YOYIK is a professional production, development, sale of power plant dedicated spare parts and accessories processing company. Through more than 20 years of efforts, the majority of customers have been fully recognized. Limited space, and look forward to your calls for consultation, we will sincerely for your service, your satisfaction is our greatest comfort! Yoyik can offer many spare parts for power plants as below: #DF-MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B-DF Signal Converter ADAM4520 Magnetic Proximity Sensors DF2018 Analog Linear Displacement Sensor ZDET-20B Shaft Speed Sensors CS-1-G-100-05-00 Digital display AC ammeter PA194I-3X1 rpm sensor indicator G-065-05-01 Magnetic Pick-up Speed Sensor DF2012 angular displacement sensor B151.36.09G09 displacement sensor FRD.WJA2.301H lvdt linear position sensor TDZ-1E-31 temperature measurement sensor pt100 WZP2-014s PT100 2M lvdt transducer displacement LVDT-400-6 rtd cable WZPK-646 displacement transducer TDZ-1E-32 rotation sensor D-100-02-01 lvdt transducer displacement HL-3-100-15 LVDT Displacement Transducer Sensors B151.36.09.04.15 thermocouple machine WRN-332NM rtd probe WZPM2 lvdt full form B151.36.09G32 Platinum Thermocouple Wire WRN2-630 LX1=225*76 rpm speed meter DF9011-B dc speed control sensor G-090-02-01 replace thermocouple WRN2-239 0-600℃ linear variable displacement transducer B151.36.09G08 full form of lvdt ZDET1000B pressure switch black 396725-LKTS16 speed meter sensor HZSP-475-50-10-HL celsius thermometer WSS-461 0~350℃ non-contact displacement sensor ZD-7000TDB oil pressure sensor SPB424BXCC RPM Sensor magnetic GSH5 RPM Sensor magnetic CS-1 L=100 Thermocouple Type-K TE-109 tachometer price DF9011-B Type K Thermocouple Cartridge WRNKB-446S/TG MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B rtd cable WZP-201 LVDT Position Sensors K156.36.06.004 vacuum pressure gauge 1201901 lvdt 20mm sensor LVDT-35-3 furnace thermocouple TE-305 Rotary Torque Sensor ZS-02 L=65 element cartridge heaters ZJ-14.5-180 rpm sensor generator DF2018 Surface Thermocouple TC03A2-KY-2B/S13 lvdt-sensor ZDET-25B thermocouples extension lead wires TE-303 linear displacement sensor FRD.WJA2.308 LVDT Position Sensors A191.36.09.03 lvdt 0-300 TDZ-1G-32 pt100 rtd probe thermowell WRNK2 pt100 rtd WZP-221 rotational speed sensor CS-1-G-100-02-01 lvdt displacement transducer B151.36.06(1)G02 thermal resistance tester WZP2M-201 thermocouple k-type WRNK2-294 non-contact displacement sensor TDZ-1E-12 lvdt working principle 400TD non-contact displacement sensor TDZ-1E-22 BENTLY Cable 330130-040-12-00 Tacho RPM sensor CS-3 M16-L60 cartridge heater electric heating heater DJ-22-2/ZBK54019-88 liquid level gauge UTG2005C Displacement sensor 5000TDG 0-250mm LVDT Position Sensors TDZ-1-21 lvdt full form TDZ-1-33 pt100 thermocouple machine WRNK2-292 lvdt displacement sensor inductive sensor HL-6-20-15 thermowell flange TC03A2-KY-2B/S3 Gear speed sensor CS-3-M16-L120 Shaft Rotation Speed Sensors DF6202-005-050-04-00-10-000 lvdt 20mm sensor B151.36.09G42 MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B DFYLSYC-2024-6-17-A

0 notes

Text

0 notes

Text

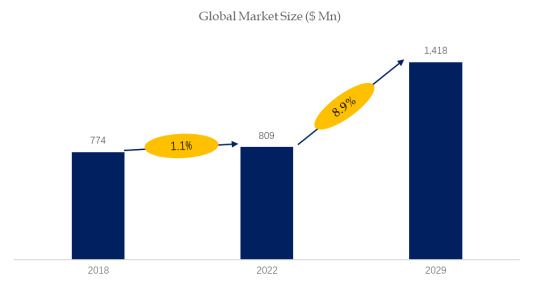

Linear Variable Differential Transformer (LVDT) Sensors, Global Key Players Rank and Market Share, Top Twelve Companies Hold 39.18% (2022)

Linear Variable Differential Transformer (LVDT) Sensors Market Summary

LVDT is an acronym for Linear Variable Differential Transformer. It is a common type of electromechanical transducer that can convert the rectilinear motion of an object to which it is coupled mechanically into a corresponding electrical signal.

According to the new market research report “Global Linear Variable Differential Transformer (LVDT) Sensors Market Report 2023-2029”, published by QYResearch, the global Linear Variable Differential Transformer (LVDT) Sensors market size is projected to reach USD 1.42 billion by 2029, at a CAGR of 8.9% during the forecast period.

Figure. Global Linear Variable Differential Transformer (LVDT) Sensors Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Linear Variable Differential Transformer (LVDT) Sensors Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

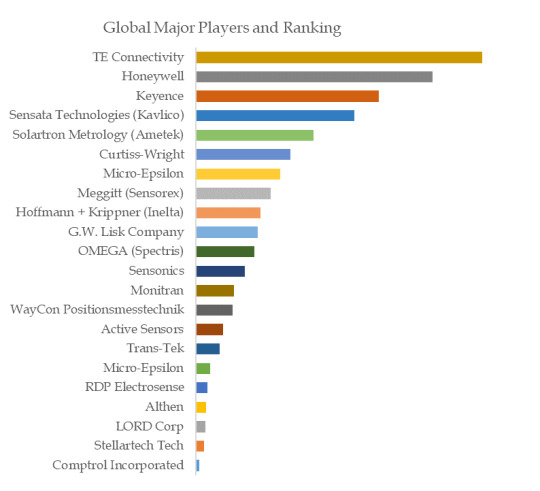

Figure. Global Linear Variable Differential Transformer (LVDT) Sensors Top Twelve Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Linear Variable Differential Transformer (LVDT) Sensors Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Linear Variable Differential Transformer (LVDT) Sensors include Comptrol Incorporated, Stellartech Tech, LORD Corp, Althen, RDP Electrosense, Micro-Epsilon, Trans-Tek, Active Sensors, WayCon Positionsmesstechnik, Monitran, etc.

In 2022, the global top 12 players had a share approximately 39.18% in terms of revenue.

Market Drivers:

1. The product has its own advantages: the LVDT sensor is a non-contact displacement sensor. There is no frictional contact between the coil and the iron core, and no wear will occur. Regardless of the level conversion and conditioning modules, the sensor body is a mechanical structure, which has the advantages of extremely high reliability, high precision, impact resistance and good dynamic performance, and is widely used in industrial and military fields.

2. Demand for industrial automation and smart manufacturing: With the advancement of Industry 4.0 and smart manufacturing, the demand for accurate, stable and reliable displacement measurement increases. LVDT sensors are widely used in automated production lines, due to their high accuracy, durability and wide operating temperature range. It is widely used in robotics, heavy machinery and precision manufacturing.

3. Aerospace and defense industry: In the aerospace and defense industry, precise displacement measurement of key parts of mechanical systems such as engines, flight control systems, missile guidance systems, etc. is crucial. LVDT sensors are used due to their high stability and harsh conditions. It is widely used due to its ability to adapt to the environment.

4. Technological innovation and product upgrades: With the continuous development of LVDT sensor technology, smaller, more efficient, and higher-precision products have emerged, meeting the market's demand for miniaturization and integration, and promoting further expansion of the market.

About The Authors

Analyst: Ran xinrong

Email: [email protected]

Website: www.qyresearch.com Hot Line:4006068865

QYResearch focus on Market Survey and Research

US: +1-888-365-4458(US) +1-202-499-1434(Int'L)

EU: +44-808-111-0143(UK) +44-203-734-8135(EU)

Asia: +86-10-8294-5717(CN) +852-30628839(HK)

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Analog 4-20mA Linear Draw Wire and Cable Displacement Sensor Transducer

Key features

Exceptional Durability: Designed for 5 million fatigue cycles, ensuring long-lasting performance.

Advanced Analog Communication: Provides absolute position sensing with power-off memory for reliable data retention.

Durable Wire Outlet: Ceramic material enhances wear resistance, extending the life of the steel wire rope.

Data Interfaces: Equipped with a 4-20mA output for seamless data integration and communication.

High-Quality Construction: Features a 0.8mm diameter, imported flexible stainless steel wire rope with a nylon coating for reduced friction and enhanced durability.

Superior Pull Head Design: Special fixation method with a tensile limit 10 times greater than competitors, allowing a 15° angle deviation.

User-Friendly Configuration: Easily set parameters via communication protocol or software, offering intuitive and straightforward operation.

Versatile Operation Modes: Supports query and auto-return modes with feedback on position and speed. Programmable for various functions including positioning and speed feedback.

Visit https://briterencoder.com/product/displacement-draw-wire-encoder-and-sensor-with-analog-4-20ma-output/ for more.

0 notes

Text

Harnessing Ono Sokki's Linear Gauge Sensor for Accurate Data

Precision and reliability are crucial factors in the measurement of displacement, particularly in today's dynamic industrial environment. Our Linear Gauge Sensor are recognized as leading-edge tools for obtaining precise data across diverse applications. Let's explore the exceptional features of these sensors and their effective utilization.

Our device is meticulously engineered to deliver unparalleled accuracy in displacement measurement. The sensor utilize cutting-edge technology to ensure precise readings, making them indispensable in industries where even the slightest deviation can have significant repercussions.

Features of the sensor

High Precision: It's boast high precision, allowing for precise measurement of displacement with minimal margin for error.

Reliability: Built to withstand demanding industrial environments, these sensor offer consistent and reliable performance under various conditions.

Versatility: With a range of models available, Ono Sokki caters to diverse applications, ensuring that there's a sensor suitable for every need.

Digital Interface: The GS series Digital Linear Gauges feature advanced digital interfaces, enabling seamless integration with modern measurement systems.

Applications of the Device

The versatility of the sensor makes it ideal for a wide array of applications across industries. Here are some key areas where these sensor excel:

Manufacturing and Quality Control

In manufacturing processes where precision is paramount, our sensor play a crucial role in ensuring product quality. From automotive to aerospace industries, these sensor help maintain tight tolerances and uphold stringent quality standards.

Automotive Testing

In automotive testing applications, such as chassis testing and suspension analysis, linear variable differential transducer provide precise displacement measurement, enabling engineers to fine-tune vehicle performance and safety parameters.

Research and Development

In research and development environments where innovation thrives on accurate data, further facilitate groundbreaking discoveries by providing researchers with reliable displacement measurements.

Harnessing The Power

To harness the full potential, it's essential to employ best practices in sensor installation, calibration, and data interpretation. Here are some tips for maximizing the effectiveness of these sensor:

Proper Installation

Ensure that the sensor is installed securely and aligned correctly with the target object to obtain accurate measurements consistently.

Calibration

Regular calibration is crucial to maintaining the accuracy of the sensor over time. Follow the manufacturer's guidelines for calibration procedures and frequency.

Data Analysis

Invest in software tools or systems that allow for a thorough analysis of the data collected by the sensor. Extract valuable insights to optimize processes and improve overall efficiency.

Quality Assurance

Ono Sokki's sensor represents the pinnacle of precision and reliability in displacement measurement technology. With their advanced features and versatile applications, these sensor empower industries to achieve new heights of accuracy and efficiency. By harnessing the capabilities of LVDT sensors and implementing best practices, businesses can unlock a world of possibilities and stay ahead in today's competitive landscape.

For any clarifications or queries, please feel free to contact us:

Mobile: +91–92055–92194 or +91–92055–92195

Email ID: [email protected]

Website: www.onosokki.co.in

#Linear Gauge Sensor#LVDT#Linear Variable Differential Transducer#sound level meter#noise level meter#class 2 sound level meter#class 1 sound level meter#db meter#ono sokki india

0 notes

Link

Intek Instruments is engaged in offering Rectilinear Displacement Transducer / Linear Transducer / LVDT Transducer / Linear Scale / Linear Potentiometer. We are Distributor, Dealer, Supplier, Traders and Wholesaler for GEFRAN Italy, NOVOTECHNIK, OPKON, MINOR, MYAN, BALLUFF, and WAYCON. Our offer Displacement Transducer in Delhi, Uttarakhand, Haryana, Punjab, Uttar Pradesh, Andhra Pradesh, Rajasthan, Jammu and Kashmir, Arunachal Pradesh, Madhya Pradesh, Maharashtra, Kerala, West Bengal, Karnataka, Gujarat, Tamil Nadu, Telangana, India, Nepal.

#Displacement Transducers#Linear Transducers#LVDT Transducers#Linear Scales#Linear Potentiometers#Gefran Displacement Transducer#Gefran Linear Transducer#Gefran LVDT Transducer#Gefran Linear Scale#Gefran Linear Potentiometer#Gefran Italy#INTEK INSTRUMENTS#Displacement Transducer Indicators#Gefran Rectilinear Displacement Transducer#Rectilinear Displacement Transducer#Displacement Transducer Contactless Measurement Using Magnetostriction#Contactless Magnetostrictive Linear Position Transducer#Rectilinear Displacement Transducer with Cylinderical Case#Signal Conditioner For Linear Displacement Transducers#Linear Displacement Transducer#Rodless Rectilinear Displacement Transducer#Rotative Position Transducers in Conductive Plastic#Gefran Distributors#Gefran Dealers#Gefran Traders#Gefran Suppliers#Gefran Manufacturers#Gefran Distributor in Baddi#Gefran Dealer in Uttarakhand#Gefran Trader in Rudrapur

0 notes

Text

Linear Variable Displacement Transducers Market Consumption Analysis, Business Overview and Upcoming Trends|TE Commectivity, Honeywell, Sensata Technologies (Kavlico), AMETEK, etc

The linear variable displacement transducers (LVDT) market refers to the market for devices that are used to measure linear displacement or position changes. LVDTs are electromechanical devices that convert linear motion into an electrical signal for measurement and control purposes.

LVDTs are widely used in various industries and applications where precise and accurate measurements of linear displacement are required. They consist of a coil assembly and a core that moves within the coil. As the core moves, it induces changes in the output voltage of the coil, which can be measured and converted into a displacement value.

Free Download Link:-https://www.marketinforeports.com/Market-Reports/Request-Sample/342102

The LVDT market is driven by the increasing demand for high-precision measurement and control systems in industries such as automotive, aerospace, manufacturing, healthcare, and robotics. LVDTs offer several advantages over other displacement sensing technologies, including high resolution, excellent linearity, wide measurement range, and long-term stability.

The market for LVDTs is competitive, with several manufacturers offering a wide range of products tailored to different application requirements. LVDTs are available in various sizes, measurement ranges, and mounting options to accommodate different installation and integration needs. Major players in the market include sensor manufacturers, automation solution providers, and specialized LVDT manufacturers.

The LVDT market is influenced by factors such as technological advancements, industry regulations, and the need for accurate position feedback in critical applications. With advancements in LVDT design and manufacturing processes, newer models offer improved performance, higher accuracy, and increased durability.

The market is also driven by the growing trend towards automation and the need for precise positioning and motion control in various industries. LVDTs play a crucial role in automation systems, ensuring accurate feedback for positioning, leveling, and control applications.

Furthermore, the market is impacted by the integration of LVDTs with advanced technologies such as digital interfaces, wireless connectivity, and smart functionalities. This allows for easier integration with control systems, data logging, and remote monitoring, enhancing overall system efficiency and functionality.

As industries continue to demand higher accuracy and reliability in displacement measurement, the LVDT market is expected to witness further advancements. This may include the development of LVDTs with miniaturized form factors, improved resistance to harsh environmental conditions, and enhanced measurement capabilities in extreme temperature or pressure conditions.

In conclusion, the LVDT market caters to the demand for precise and accurate linear displacement measurement in various industries. With their high-resolution measurement capabilities and versatility, LVDTs play a critical role in applications requiring position sensing and control. The market is driven by industry demands for automation, accuracy, and reliability, leading to ongoing technological advancements in LVDT design and integration.

0 notes

Photo

To know about slide type linear scale visit: https://yantong-injection.com/slide-type-linear-scale/

#linear potentiomater#linear transducer#linear scale sale#linear scale supplier#linear scale displacement

0 notes

Link

Elmec Heaters India offers a wide range of linear displacement transducers or linear transducer – linear sensors from 30mm to infinity length works under the principle of Resistive and Magnetic encoding method. These sensors are widely used in Plastic injection moulding machines, Hydraulic press, Sheet metal working machines, CNC machines and etc. Our linear sensors, linear potentiometer, press brake linear scale are cost economic and reliable.

Linear Transducer,

Linear Potentiometer

0 notes

Text

linear scale rod | injection molding linear scale | linear position sensors | linear potentiometers

The linear scale will help you to fix the length of the plastic mold and injection machine distance. It has two types of measures are Linear scale rod and linear scale slide type. We provide injection molding linear scale for measuring length and if need any information can contact us – 9566097688.

0 notes