#Lithium-ion cell sorting and packaging

Explore tagged Tumblr posts

Text

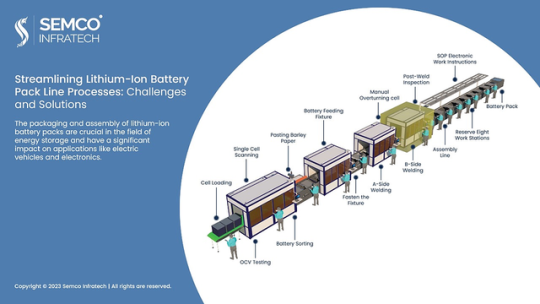

Streamlining Lithium-Ion Battery Pack Line Processes: Challenges and Solutions

The packaging and assembly of lithium-ion battery packs are crucial in the field of energy storage and have a significant impact on applications like electric vehicles and electronics.

The pack line process consists of three main phases: production, assembly, and packaging.

The pack is a complex system comprising battery packs, shunts, soft connections, protective boards, outer packaging, output components (such as connectors), insulating materials like barley paper, plastic brackets, and other auxiliary materials. These components come together to form a complete pack unit. This blog discusses the challenges faced in the Lithium-Ion Battery Pack Line Processes and offers potential solutions.

The Core Functions of a Pack Line

A typical production line for battery packs serves two main purposes: transmission and testing. In the industry, it is common to use semi-automatic assembly lines for pack production. These lines handle tasks such as launching, offline operations, testing, in-plant transmission, and packaging. The processes involved in a lithium battery pack production line are relatively simple, including feeding, attaching brackets, welding, and conducting thorough testing, among other steps.

Challenges in Meeting Pack Line Requirements

Highly Customized Demands: The power battery system pack requires targeted research and development tailored to the specific requirements of vehicle manufacturers. Each automaker has unique specifications and needs, leading to a high degree of customization in the assembly process. These drive increased demand for automated production lines that can efficiently adapt to these variations.

Stringent Safety and Stability Prerequisites: The core challenge in creating a power battery system pack lies in accommodating the customized market demands of different vehicle models. This customization process addresses various aspects, including BMS design, thermal management, space constraints, structural strength, system interfaces, IP ratings, and safety measures. These custom requirements are vital for ensuring the safety and stability of the battery pack.

Precise Control of Production Rate: Modern battery pack production requires a different approach to maintain a high and efficient production rate while meeting market supply and demand. This involves refining the process to manage the “whole line beat,” focusing on average workstation working time rather than a sequential production line.

Enhanced Compatibility: The evolving lithium battery industry adds complexity to the production process. With non-standardized modules, incoming cells, shells, PCB boards, and connecting components, compatibility across the production line becomes crucial. Adapting to these changes and ensuring efficiency and compatibility is vital.

Embracing Automation and Innovation: In response to the growing lithium power industry, leaders are expanding production capacity, optimizing pack line processes, and incorporating smart technologies. This includes integrating intelligent equipment, robotic arms, collaborative robots, mobile robots, and other advanced technologies to improve efficiency.

The lithium battery manufacturing process requires highly reliable, stable, and precise equipment for process control. It also demands intelligent data processing capabilities for effective production data management. This drives the need for automation and intelligent upgrades to meet the evolving demands of the industry.

As the energy storage landscape evolves, automating and enhancing pack line processes is crucial to ensure reliable, stable, and precise equipment. This streamlines production for the intelligent and data-driven future of lithium-ion battery manufacturing.

#Battery cell assembly#Battery management systems#EV battery pack production line#lithium battery industry#lithium-ion battery#lithium-ion battery industry#lithium-ion battery pack#lithium-ion battery pack line#Lithium-ion battery pack assembly#Lithium-ion cell sorting and packaging

0 notes

Text

New energy, optical fiber and other four major markets, this year's curing leaders will focus on

UV LED is a new technology emerging with LED. Compared with traditional curing sources such as high-pressure mercury lamps and metal halide lamps, UVA-LED can provide faster, more consistent and more reliable curing results. Although traditional mercury lamps in the industry are still There is use, but more and more curing equipment is moving to UV LED technology. It is understood that at present, UV LED light source curing has basically completely replaced mercury lamps in the fields of electronic components, medical consumables and other adhesive curing fields, as well as consumer curing fields represented by nail art curing. In many fields such as silk screen printing, optical fiber coating, wood curing, and automobile curing, there is still a huge room for UV LED replacement. Among them, the application of these four curing scenarios is worthy of attention. According to experts, UV is not completely sorted out, and similar companies such as Youweixin, Yongcheng, Phoseon Technology, etc. are involved in these fields. New energy, optical fiber and other four major markets, this year's curing leaders will focus on New energy vehicle field It is understood that the current application of UV LED light curing in the automotive industry mainly involves the production of automotive lamp lenses, reflectors, instrument panels, steering wheels, reversing images, wheel windows, new energy battery modules, electronic components, sensors, etc. manufacture. Especially for new energy battery packs, one of the most critical and expensive components in electric vehicles is the lithium-ion battery pack (LIB). Electric vehicle battery packs are subject to extreme environments such as heat, corrosion and vibration. The securing of individual cells, the vibration resistance of the welds between cells (for electrical connections), and the precise assembly of electrodes within cells all require more robust processes to complete. New energy, optical fiber and other four major markets, this year's curing leaders will focus on According to the official microblog of Good Lide, it has already set foot in the business of vehicle wiring harness material curing and battery packaging. Using self-produced UVA chips has more stable performance and super power density, and the airing time of batteries after packaging has been reduced from traditional methods. 3-7 days shortened to 3-5 seconds. In addition, Unicore, Heraeus, and Excelida Technology also have related products involved in the field of new energy vehicle manufacturing. According to the latest data from the Passenger Federation since 2022, major car companies will actively promote sales before the end of subsidies in December 2022. In December, the retail sales of new energy vehicles completed 640,000 units, a year-on-year increase of 35.2% and a month-on-month increase of 7.0%. In 2022, the annual retail sales will be 5.674 million, a year-on-year increase of 90.0%, and the penetration rate will reach 27.6%. The target of 25% penetration rate of new energy vehicles will be completed three years ahead of schedule. According to the latest statistics from the China Association of Automobile Manufacturers, my country's new energy vehicles will continue to grow explosively in 2022, with production and sales of 7.058 million and 6.887 million vehicles, respectively, a year-on-year increase of 96.9% and 93.4%, ranking first in the world for eight consecutive years. Taken together, new energy vehicles are still growing rapidly. Optical fiber and cable field According to the optical fiber market, it is expected to grow at a compound annual growth rate of 10% between 2019 and 2024, reaching a value of US$6.9 billion (approximately RMB 49.4 billion) in 2024. Investments in new information technology and telecommunications industries, as well as development needs and project investments in the United States, China, India, Brazil, Western and Eastern European countries, drove the growth in demand. Therefore, it is particularly important to rapidly mass-produce optical fibers. To achieve faster, higher-volume production, fiber optic manufacturers are turning to high-irradiance UV LED curing systems that can maintain high product quality and throughput speed. The high efficiency, long life and low operating costs of UV LED curing systems also contribute to significantly lower manufacturing costs. New energy, optical fiber and other four major markets, this year's curing leaders will focus on Shanghai Zhenhui Optoelectronics Technology Co., Ltd. strives to launch the 6th generation UV LED optical fiber coating curing system. Compared with the 5th generation, the 6th generation has a new breakthrough in the supported wire drawing speed. There are also significant improvements in UV irradiation intensity, power and application flexibility. The specific 10 characteristics are as follows: 1) Better compatibility with different types of coatings; 2) The product has stronger UV irradiance; 3) Supports higher drawing speed, up to 3500-3800 m/min; 4) Innovative optical design It can produce more efficient focusing; 5) Increase the temperature of the focusing area and reduce the amount of volatile oil; 6) By reducing the operating current of each LED chip, the decay rate can be reduced to prolong the life of the chip; 7) Mixed spectrum can be provided to provide more flexible 8) Make the curing lamp run at a lower temperature to prolong the service life of the light source; 9) The design is more compact, saving a lot of space; 10) The old tower is rebuilt to increase the drawing speed in a limited space. New energy, optical fiber and other four major markets, this year's curing leaders will focus on And the OmniCure® AC9225-F UV LED curing system from Excelitas Technologies with custom lenses and optimized LED light engine can provide extremely focused high-irradiance UV light for fast curing of fiber optic coating materials. OmniCure AC Series UV LED systems feature custom front-end optics to maximize irradiance at the curing site at a specified working distance. A custom lens produces a highly focused beam (line) from the LED, optimizing curing efficiency by maximizing the focus of the UV energy onto a very thin fiber optic bundle. The OmniCure AC8225-F+ and AC9225-F further enhance the output beam of previous OmniCure systems by incorporating a technologically advanced custom LED light engine design. Meanwhile, the custom optics of the OmniCure AC9225-F system maintain irradiance (>20W/cm²) virtually constant over a range of 10 to 18 mm, a typical working distance for fiber optic coating applications.

0 notes

Text

How battery chargers work

If you've read our main article on batteries, you'll know all about these portable power plants. An example of what scientists refer to as electrochemistry, they use the power of chemistry to release stored electricity very gradually.

What happens inside a typical battery—like the one in a flashlight? When you click the power switch, you're giving the green light to chemical reactions inside the battery. As the current starts flowing, the cells (power-generating compartments) inside the battery begin to transform themselves in startling but entirely invisible ways. The chemicals from which their components are made begin to rearrange themselves. Inside each cell, chemical reactions take place involving the two electrical terminals (or electrodes) and a chemical known as the electrolyte that separate them. These chemical reactions cause electrons (the tiny particles inside atoms that carry electricity) to pump around the circuit the battery is connected to, providing power to the flashlight. But the cells inside a battery contain only limited supplies of chemicals so the reactions cannot continue indefinitely. Once the chemicals are depleted, the reactions stop, the electrons cease flowing through the outer circuit, the battery is effectively flat—and your lamp goes out.

That's the bad news. The good news is that if you're using a rechargeable battery, you can make the chemical reactions run in reverse using a battery charger. Charging up a battery is the exact opposite of discharging it: where discharging gives out energy, charging takes energy in and stores it by resetting the battery chemicals to how they were originally. In theory, you can charge and discharge a rechargeable battery any number of times; in practice, even rechargeable batteries degrade over time and there eventually comes a point where they're no longer willing to store charge. At that point, you have to recycle them or throw them away.

All battery chargers have one thing in common: they work by feeding an electric current through batteries for a period of time in the hope that the cells inside will hold on to some of the energy passing through them. That's roughly where the similarity between chargers begins and ends!

The cheapest, crudest chargers use either a constant voltage or constant current and apply that to the batteries until you switch them off. Forget, and you'll overcharge the batteries; take the waterproof battery charger off too soon and you won't charge them enough, so they'll run flat more quickly. Better chargers use a much lower, gentler "trickle" charge (maybe 3–5 percent of the battery's maximum rated current) for a much longer period of time.

Batteries are a bit like suitcases: the more you pack in, the harder it is to pack in any more—and the longer it takes. That's easy to understand if you remember that charging a battery essentially involves reversing the chemical reactions that take place when it discharges. In a laptop battery, for example, charging and discharging involve shunting lithium ions (atoms missing electrons) back and forth, from one electrode (where there are many of them) to another electrode (where there are few). Since the ions all carry a positive charge, it's easier to move them to the "empty" electrode at the start. As they start to build up there, it gets harder to pack more of them in, making the later stages of charging harder work than the earlier ones.

Overcharging is generally worse than undercharging. If batteries are fully charged and you don't switch off the charger, they'll have to get rid of the extra energy you're feeding in to them. They do that by heating up and building up pressure inside, which can make them rupture, leak chemicals or gas, and even explode. (Think of overcharging as overcooking a battery and you might just remember not to do it!)

Slightly more sophisticated timer chargers switch themselves off after a set period, though that doesn't necessarily prevent overcharging or undercharging because the ideal charging time varies for all sorts of reasons (how much charge the battery held to begin with, how hot it is, how old it is, whether one cell is performing better than others, and so on). The best chargers work intelligently, using microchip-based electronic circuits to sense how much charge is stored in the batteries, figuring out from such things as changes in the battery voltage (technically called delta V or ΔV) and cell temperature (delta T or ΔT) when the charging is likely to be "done," and then switching off the current or changing to a low trickle charge at the appropriate time; in theory, it's impossible to overcharge with an intelligent waterproof car charger.

Nickel cadmium (also called "nicad" or NiCd), the oldest and perhaps still best known type of rechargeable batteries, respond best either to fairly rapid charging (providing it doesn't make them hot) or slow trickle charging.

Nickel metal hydride (NiMH) batteries use newer technology and look exactly the same as nicads, but they're generally more expensive because they can store more charge (shown on the battery packaging as a higher rating in mAH or milliampere-hours). NiMH batteries can be fast charged (on high current for several hours, at the risk of overheating), slow charged (for about 12–16 hours using a lower current), or trickle charged (with a much lower current than nicad), but they should really be charged only with an NiMH charger: a rapid nicad charger may overcharge NiMH batteries.

Expert opinions seem to differ on whether nickel batteries experience what's widely known as the memory effect. This is the well-reported phenomenon where failure to discharge a nickel-based battery before charging (when you're "topping up" a partly discharged battery with a quick recharge) reputedly causes permanent chemical changes that reduce how much charge the battery will accept in future. Some people swear the memory effort is real; others are equally insistent that it's a myth. The real explanation for an apparent memory effect is voltage depression, where a battery that hasn't been fully discharged before charging temporarily "thinks" it has a lower voltage and charge-storing capacity than it should have. Battery experts insist you can cure this problem by charging and discharging a battery fully a few times more.

It's generally agreed that nickel-based batteries need to be "primed" (charged fully before they're used for the first time), so be sure to follow exactly what the manufacturers say when you take your new batteries out of the packet.

There are two simple reasons why there are so many different sizes and types of batteries: a bigger battery has more chemicals inside it so it can store more energy and release it for longer; bigger batteries also tend to have more cells inside them so they can produce a higher voltage and current to power bigger things (brighter flashlight bulbs or higher-powered motors). By the same token, bigger rechargeable batteries need charging for longer. The more energy you expect to get out of a rechargeable battery (the longer you expect it to last), the longer you'll need to charge it (or the higher the charging current you'll need to use). A basic law of physics called the conservation of energy tells us you can't get more energy out of a battery than you put into it.

Most people tend to put things on to charge "overnight" without paying too much attention to exactly what that means—but your batteries will work better and last longer if you charge them for the right number of hours. How long is that? It can be very confusing, especially if you use batteries that didn't come supplied with your waterproof marine charger. Never fear! All you have to do is read what it says on your batteries and you should find (often in tiny writing) the recommended charging current and charge times. If you have a basic charger, simply check its current rating and adjust the charge time accordingly. Bear in mind what we've said elsewhere about matching your charger to your batteries, however.

Lithium-ion rechargeable batteries are usually built into gadgets such as cellphones, MP3 players, digital cameras, and laptops. Typically they come with their own chargers, which automatically sense when charging is complete and cut off the power supply at the right time. Lithium-ion batteries can become dangerously unstable when the battery voltage is either too high or too low, so they're designed never to operate under those conditions. If the voltage gets too low (if the battery discharges too much during use), the appliance should cut out automatically; if the voltage gets too high (during charging), the electric transportation battery charger will cut out instead. Although lithium-ion batteries don't show a memory effect, they do degrade as they get older. A typical symptom of aging is gradual discharge for a period of time (maybe an hour or so) followed by a sudden, dramatic, and completely unexpected cut-out of the appliance after that. Read more about how lithium ion batteries work.

Lead-acid batteries are popular because they're simple, cheap, reliable, and use well-proven technology that dates back to the middle of the 19th century. Generally they last for several years, though that depends entirely on how well they are maintained—in other words, charged and discharged. They do take quite a long time to charge (typically up to 16 hours—several times longer than they take to fully discharge), and that can lead to a tendency both to undercharge (if you don't have time to charge them properly before you next use them) or overcharge (if you put them on charge and forget all about them). Undercharging, charging with the wrong voltage, or leaving batteries unused causes a problem known as sulfation (the formation of hard lead sulfate crystals), while overcharging causes corrosion (permanent degradation of the positive lead plate through oxidation, analogous to rusting in iron and steel). Both will affect the performance and life of a lead-acid battery. Overcharging also tends to degrade the electrolyte, decomposing water (by electrolysis) into hydrogen and oxygen, which are given off as gases and therefore lost to the battery. That makes the acid stronger and more likely to attack the plates, which will reduce the battery's performance. It also means there's less electrolyte available to interact with the plates, also reducing the performance. From time to time, batteries like this have to be topped up with distilled water (not ordinary water) to keep the acid at the optimum strength and at a high enough level to cover the plates.

0 notes

Text

The Role Of Battery Recycling In The Circular Economy: Part 1

New Post has been published on https://tattlepress.com/economy/the-role-of-battery-recycling-in-the-circular-economy-part-1/

The Role Of Battery Recycling In The Circular Economy: Part 1

Editor’s Note: The Role Of Battery Recycling In The Circular Economy is a three-part series. Part 1 focuses on Key Technologies. Part 2 focuses on the Battery Supply Chain, Logistics and Profitability. Part 3 focuses on Challenges and the Role of Policy.

Only a few major battery innovations (Lead Acid by Plante, Nickel Cadmium by Jungner, Lithium-ion by Goodenough/Sony) have reached significant market penetration since the 1800s. As of 2018, over 90% of large‐scale battery storage power capacity in the US was provided by batteries based on Lithium‐ion (Li-ion) chemistries [1]. The demand for Li-ion batteries for consumer electronics and electric vehicles (EVs) is projected to grow about tenfold until the next decade. By 2025, the global revenue from Li-ion batteries is expected to reach $71 billion USD [2]. The volume of retired batteries follows an S-like curve, with less end-of-life Li-ion batteries today, but an estimated 315 GWh (1,619,000 tons) available for recycling by 2030 (assuming a lifetime of 10 years) [3], a volume roughly equivalent to current annual battery production [4].

Recycling Li-ion batteries is critical to address safety, environmental, and supply considerations. Retired batteries pose a fire hazard due to volatile components such as the electrolyte, particularly dangerous given the possibility of HF formation [5]. Additionally, an EV battery can be responsible for up to a third of the vehicle’s life-cycle emissions from cradle to grave [6]. Mining of raw materials for Li-ion batteries can be environmentally costly, as the process consumes excessive amounts of water, uses strong acids, and can contaminate underground stores of fresh water. Finally, there are varying predictions of critical supply shortages such as lithium, nickel, cobalt, and copper to meet EV demand. Recovering and recycling allows for more independence from geological mining and potentially a reduced cost of raw materials.

Many companies see the opportunity to turn the Li-ion battery waste problem into profit given to the increasing prices for Li-ion battery raw materials such as lithium, nickel, and cobalt. Currently, the Chinese market is well advanced in recycling (for example, Ganfeng has a capacity of 100,000 tons/year), followed by the European market (30,000-40,000 tons/year which includes Umicore and Glencore). The US needs to catch up in battery supply, refining, and recycling in order to be competitive. This article focuses on companies and organizations and how they fit into the Li-ion battery recycling ecosystem.

Key Technologies in Recycling

Li-ion batteries consist of a cathode, anode, electrolyte, separator, current collector foils, and packaging. Today’s Li-ion battery recycling companies primarily rely on some combination of two well-established processes, pyrometallurgy and hydrometallurgy. Direct recycling is a research-stage approach promising a shorter recycling loop at lower cost (see Figure 1). Electro-extraction (not shown) is in the early stages of deployment, focused on modularity and reduced costs and emissions by providing upgraded feedstock for the final stages of hydrometallurgy.

Pyrometallurgy, or smelting, is the process of melting battery packs or the shredded and separated cathode materials and reacting the molten metal oxides with carbon, which acts as a reducing agent to decompose the ore into metal, slag and carbon dioxide. Smelting has been used for centuries to refine ores into metals. In the context of Li-ion battery recycling, it is used today to recover elements such as copper, nickel, and cobalt. The benefits of smelting are that it is well-tested and simple, eliminating the need to shred or separate the Li-ion battery components. However, the process is very energy-intensive and materials recovery rates are significantly lower than competing processes. In particular, smelting is not suitable for the recovery of elements such as aluminum and lithium or the plastic packaging.

Further, the treatment of toxic air emissions (such as fluorine, phosphorus, sulfur, and particulates containing heavy metals) during smelting is costly. Pyrometallurgy is the predominant recycling technology used in China and Europe. In the US, Redwood Materials first collects batteries from a variety of partners. Rather than relying on fossil fuels for smelting, Redwood uses residual energy in the batteries to produce an alloy [8]. Afterwards, Redwood employs hydrometallurgical methods to reach recovery rates of 95-98% for nickel and cobalt (80% for lithium) [9]. This allows them to reach the quality necessary to sell their output raw materials to battery manufacturers.

“Today the EU [using pyrometallurgy] can achieve a Recycling Efficiency Rate (RER) of 50% (targeting 65-75%)…compare this to the Functional Material Recovery Rate (FMRR), which can be optimized economically but if you volatilize other components, like graphite and plastics, the RER will go down,” says Ajay Kochhar, CEO, Li-Cycle.

Figure 1. ReCell Center is focused on closed-loop recycling by directly recovering materials from spent batteries for manufacturing in a process that minimizes energy use and waste. ReCell Center’s main goal is to improve the economics via direct recycling [7].

Hydrometallurgical methods, also known as chemical leaching and extraction, are less capital- and energy-intensive and can recover lithium, but rely on large volumes of potentially environmentally harmful chemicals. Various companies, such as Accurec and Toxco Inc. (now Retriev Technologies Inc.), have developed leaching and extraction processes using these technologies. Spent Li-ion batteries are recycled through the following steps: pretreatment, leaching (typically using sulfuric acid), solvent extraction (typically using large amounts of sodium hydroxide for neutralization and additional acid for stripping), and precipitation. Multiple solvent extraction steps are necessary to separate all raw materials, and the process flow must be optimized to obtain high recovery rates (>90%) for each material. For example, Neometals first shreds batteries to obtain plastic, steel casings, and metal foil.

Next, they implement hydrometallurgy to leach and extract in the following order: copper sulfate, aluminum and iron oxide, manganese sulfate, nickel sulfate, and finally cobalt sulfate. It is possible to collect byproducts for additional sources of revenue. For instance, Neometals collects their ammonium sulfate ‘tailing,’ concentrates the material, and sells it as a liquid fertilizer. After each of the desired products and byproducts are recovered, there is generally a large amount of wastewater remaining (>10 times the amount of feedstock initially fed into the process on a mass basis). Costly processes are then needed to treat and dispose of this water and the constituent contaminants. As a result, reuse and recovery of solvents can dramatically impact the economics of the process (Neometals has an 85% solvent recovery rate). Nevertheless, these processes still require large economies of scale to have compelling unit economics (on the order of 20,000-60,000 tons).

Direct recycling is still under development, but typically relies on physical separation of battery components (such as crushing the cell) and then recovering materials based on density. Automation of sorting, disassembly, and recovery would increase efficiency. The value from directly recycled Li-ion batteries could be significantly higher by relithiating cathodes rather than fully dissolving or smelting cathodes and recovering the individual elements to then remanufacture the cathode structures. ReCell Center is pioneering the technology. Direct recycling has high potential as a cost-effective route to recover lithium iron phosphate (LFP) batteries, which offer almost no economic value because they are composed of relatively low-cost base materials. These batteries are widespread today in hand-held tools and EVs in China. LFP batteries are expected to increase in EVs in North America and Europe in the coming years for lower-cost models. The challenge of direct recycling is the fast turnover cycles of next-generation material and the high rate of change predicted for cathode technologies. It will be difficult to forecast changes in chemistry over the next 8-10 years, and consumers are likely not willing to buy EVs with dated battery chemistries and performance. Additionally, while re-lithiation of cathodes has been shown to be successful with defective or lightly-aged cathode materials, it is unclear if these regeneration processes will be able to sufficiently repair cathode structures that have undergone severe degradation over a full vehicle lifetime. Nth Cycle employs a unique electro-extraction flow-through process that uses carbon filters and electricity to recover the metals of interest. This process is inherently more energy-efficient than pyrometallurgy and hydrometallurgy and requires less volume of material to achieve profitability.

This translates to higher margins and lower price sensitivity in the short term given their lower upfront CAPEX requirements and operating costs. In particular, Nth Cycle’s modular approach can be placed onsite at existing recycling locations (separating copper, cobalt, nickel, manganese, and graphite from black mass) to improve economics and lower emissions for the final hydrometallurgy stages, or at mines to upgrade ore before transportation. Their output material (high grade hydroxides) are sold to late stage refineries to be converted into sulfates for cathode manufacturing.

References

[1] Sylvia, T. (2020, July 15). Battery adoption skyrocketed in the 2010s and lithium-ion reigns supreme. pv magazine USA. https://pv-magazine-usa.com/2020/07/15/battery-adoption-skyrocketed-in-the-2010s-and-lithium-ionreigns- supreme/.

[2] Statista. (2021, February 5). Global lithium-ion battery market 2020–2025. https://www.statista.com/statistics/1011187/projected-global-lithium-ion-battery-market-size/

[3] Circular Energy Storage Research & Consulting. (2020, December). The lithium-ion battery life cycle report 2021. https://circularenergystorage.com/reports

[4] Statista. (2020, July 3). Lithium-ion batteries – statistics & facts. https://www.statista.com/topics/2049/lithium-ion-battery-industry/

[5] Anderson, M. (2013b, March 1). Potential Hazards at Both Ends of the Lithium-Ion Life Cycle. IEEE Spectrum. https://spectrum.ieee.org/green-tech/fuel-cells/potential-hazards-at-both-ends-of-the-lithiumion-life-c ycle

[6] Union of Concerned Scientists, & Nealer, R. (2015, November). Cleaner Cars from Cradle to Grave: How Electric Cars Beat Gasoline Cars on Lifetime Global Warming Emissions. https://www.ucsusa.org/sites/default/files/attach/2015/11/Cleaner-Cars-from-Cradle-to-Grave-full-rep ort.pdf

[7] Kuntz, T. (2019, February 15). DOE launches its first lithium-ion battery recycling R&D center: ReCell | Argonne National Laboratory. Argonne National Laboratory. https://www.anl.gov/article/doe-launches-its-first-lithiumion-battery-recycling-rd-center-recell

[8] Oberhaus, D. (2020, December 3). The Race To Crack Battery Recycling—Before It’s Too Late. Wired. https://www.wired.com/story/the-race-to-crack-battery-recycling-before-its-too-late/

[9] Former Tesla CTO JB Straubel tackles battery recycling with Redwood Materials. (2021, April 10). CNBC.

Source link

0 notes

Text

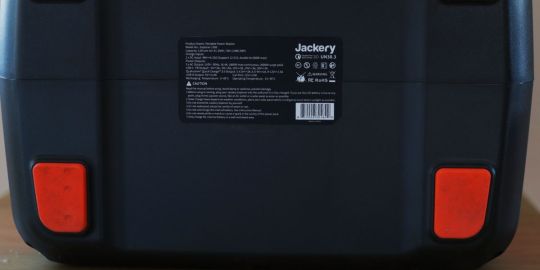

Is the Jackery Explorer 1500 the Best Portable Power Station of 2021?

Jakcery Explorer 1500

9.50 / 10

Read Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Read More Reviews

Shop Now

For lovers of portable power, the Explorer 1500 is just about perfect.

Key Features

Dual MPPT DC inputs (48V)

Maintenance-free design

Onboard Battery Management System

Overcharge Protection/Short Circuit Protection

Multiple charging methods

Smart LCD display with estimated remaining runtime

LED Flashlight

Specifications

Brand: Jackery

Weight: 33lbs (15KG)

Size: 14” x 10.4” x 12.7” (35.6 x 26.5 x 32.3 cm)

Capacity: 1488.2Wh (41.34Ah, 36V)

Maximum Discharge: 1800W continuous / 3600W peak

Maximum Charge: 500W

Solar Controller: Yes

Ports: 7 outputs, 2 inputs

Ports: 3 x AC, 2 x 12V DC, USB-C, 2 x USB-A, 12V Carport

Pros

Solar support is fantastic

Easily powers high wattage devices

All-day capacity

7 outputs

Sturdy build quality

Colorful LCD display

Cons

Heavy

Solar panel option is expensive

No Anderson connections

Buy This Product

Jakcery Explorer 1500 other

Shop

// Bottom var galleryThumbs1 = new Swiper('.gallery-thumbs-1', { spaceBetween: 10, slidesPerView: 10, freeMode: true, watchSlidesVisibility: true, watchSlidesProgress: true, centerInsufficientSlides: true, allowTouchMove: false, preventClicks: false, breakpoints: { 1024: { slidesPerView: 6, } }, }); // Top var galleryTop1 = new Swiper('.gallery-top-1', { spaceBetween: 10, allowTouchMove: false, loop: true, preventClicks: false, breakpoints: { 1024: { allowTouchMove: true, } }, navigation: { nextEl: '.swiper-button-next', prevEl: '.swiper-button-prev', }, thumbs: { swiper: galleryThumbs1 } });

There's just something about going off the grid. Maybe it's drinking that first cup of coffee as you bask in the morning quiet of the woods. Or perhaps it's swapping stories around the orange glow of a smoky campfire. Whatever it is, eschewing the busy world and getting back to nature is something we should all do from time to time. Just ask Thoreau.

But, if old Hank were around today, he'd probably have a cell phone. He'd also probably have a laptop, and he'd need a way to charge that puppy while pontificating out on Walden Pond. In other words, he'd need some portable power.

Well, Jackery has heard this siren song and created the Explorer 1500 portable solar generator. This beastly unit promises 1800 watts of continuous AC power and a generous 1488 watt-hour capacity. But is it any good? That's what we're going to find out in today's Jackery Explorer 1500 review.

youtube

Meet the Jackery Explorer 1500

The Jackery Explorer 1500 is a portable "solar generator" used to power your various electronic devices. Think of it as a giant battery bank with enough juice to take out to the campsite or use for emergency electricity, which can be charged from a variety of sources, including solar.

The Explorer features three ways to charge the unit, including a 12-volt auxiliary power adapter, AC power, and optional solar panels (not included). The Explorer houses a lithium-ion battery rated at 41.34 amp hours and 36 volts. It also offers 1488.2 watt-hours of total capacity.

The Explorer 1500 is available for $1599 on Jackery’s website and can be packaged with four SolarSaga 100W solar panels for $2699.

Technical Specifications

Dimensionst: 14 x 10.4 x 12.7 inches (35.6 x 26.5 x 32.3 cm)

Weight: 33.1 lbs (15 Kg)

Battery: Lithium-ion

Capacity: 1488.2Wh (41.34Ah, 36V)

Input: 2 SolarPeak MPPT DC 48V inputs

Outputs: 7 total.

3 Pure Sine Wave AC outputs (110v ~60Hz)

USB-C (60W PD)

Qualcomm Quick Charge USB-A 3.0,

USB-A (5v, 2.4A)

Carport (12V, 10A)

Inverter: 1800W AC (3600W surge peak)

Display: LCD

Certifications: RoHS, UN38.3, FCC, Qualcomm Quick Charge 3.0

Operating Temperature: 14 - 104F (-10C - 40C)

Recharge Temperature: 32 - 104F (0 - 40C)

Warranty: 24 Months (extended to 3 years if registered)

Extras: LED Flashlight

Cost: Battery alone $1599.99 US, and as tested $2699.99

What’s in the Box?

In the box for the Jackery Explorer 1500, you’ll get:

The Explorer 1500

2 Jackery Parallel Solar Power Cable Adapters

12-Volt Power Cable

AC Power Cable with Power Brick

Neoprene Pouch For Power Cable Storage

The Explorer 1500 Instruction Manual and Warranty Information

Who is the Jackery Explorer For?

There are two types of consumers who might be interested in the beefy Explorer 1500. The first is looking for a way to power their devices in case of an emergency. For example, sustained power outages, natural disasters, or the odd one-off zombie apocalypse. For these folks, the Jackery Explorer 1500 offers a few benefits over a gas generator.

The second type of consumer who will appreciate the Jackery Explorer is the outdoor type. Jackery’s motto is “Power Outdoors,” which demonstrates the kind of consumer Jackery is targeting.

Campers who enjoy periodically going off-grid, weekend-warriors, and vehicle-based nomads will all love the freedom that the Explorer 1500 provides. This category also includes people like me, who need to power photography equipment, lighting, computers, tablets, phones, and other mobile content creation gear outside my home studio.

Related: Camping Apps for the Perfect Camping Getaway

Key Features

The most important key feature of the Jackery Explorer 1500 is its high wattage capability. Devices like hairdryers, countertop microwaves, and electric tea kettles use high wattage to operate. Jackery states that this unit should accommodate up to 85% of all electronic devices.

As long as your device doesn’t go above 1800 running watts for a sustained period, then the Explorer 1500 should power it. They can peak at up to 3600 watts, but not for long.

The all-in-one design of the Explorer 1500 is safer than a gas generator and requires very little maintenance. There's also absolutely no risk of carbon monoxide poisoning with this unit.

Plus, the Jackery is much quieter than your standard gas generator and will likely draw less attention from folks who might want to borrow power in an emergency. The device doesn’t need gas to function, and the giant battery will juice up all sorts of household items.

The onboard battery management system keeps the Explorer 1500 from overcharging, and Jackery states that you can leave the device plugged into AC power without any ill effects. The internal lithium-ion battery is rated for 800 cycles. That means you’ll have power when you need it, and you can use the Explorer 1500 for years without killing it.

Recharging the unit is accomplished by plugging it into AC power, using the solar panels, or using the supplied 12-volt car charger. Using these charging methods results in different overall recharge times. The 12-volt car charger is the slowest, taking around 13 hours to recharge the unit thoroughly.

With two SolarSaga 100W panels, a full charge takes around nine hours. With four SolarSaga panels, the total time to fully charge is approximately five hours. Finally, charging the Explorer 1500 with two Jackery AC power adapters takes around two hours to get to 80% power. In this case, you’ll have to purchase another AC power brick, but if you need to fast charge the Explorer 1500, then dual AC is the speediest way to go.

Using the single AC charger supplied with the unit takes around six hours to charge the Explorer 1500 to maximum. This time is relatively fast considering the size of the unit.

Something possible, though not recommended for extended periods, is pass-thru charging. With pass-thru charging, you can charge your devices while you’re charging the Explorer 1500.

Testing the Jackery Explorer 1500

On Jackery’s website, there's a list of appliances that the Explorer 1500 can power and the approximate times the Explorer can run them continuously. Included are a mini cooler for 21 hours, a coffee maker for 68 minutes, a pressure cooker for 75 minutes, an electric grill for 60 minutes, and a microwave for 68 minutes.

To see which household devices the Explorer 1500 would power, I decided to put some of them to the test. I didn’t have a mini-cooler, but I do have a mini chest freezer in my garage, so I hooked the Jackery up to that to see what kind of power it drew. The chest freezer pulled between 300-350 watts when the compressor cycled on, but the wattage output on the Jackery Explorer sank to zero when it stopped.

Some people might ask if the Explorer 1500 will power a camp freezer or mini-fridge. I attempted to answer that question with my tests. Unfortunately, I don't have a camp-sized fridge, but I do have a full-sized home fridge that I plugged into the solar generator.

With the fridge plugged in and running, the Explorer reported around 265 watts being drawn and around 7.1 hours of possible run-time. If you’ve ever experienced a multiple-day power outage, then this device would be great to have around the house as backup power.

As for other appliances, I also tested a 1200W toaster, a 1000W blender, and a 1000W tea kettle. The Jackery Explorer 1500 allowed all of these appliances to function well. Using all three within a short time also only resulted in a 10% reduction in overall charge. This test indicates that the Explorer 1500 is fully capable of powering small kitchen appliances with high wattage requirements.

I also used the Explorer 1500 to power a small 15-amp Ryobi circular saw for a weekend project. Unfortunately, I wasn’t able to get power output readings for the saw, but the Jackery had more than enough chutzpah to help me finish the job.

The ability to provide power to carpentry tools indicates another potential use case for the Explorer 1500—as portable power for a small worksite. Would I use the unit on a big project with heavy power needs? Probably not. But for minor home repair work, this power station is perfect.

Testing the SolarSaga 100W Solar Panels

I also wanted to test the solar charging potential of the Explorer 1500. Setting up the SolarSaga 100W panels involves plugging the panels into the parallel solar power cable adapters and then plugging those adapters into the two MPPT input ports at the top of the device.

These 8mm connectors are standard on many other Jackery units, such as the Explorer 500 and 1000. Unlike those units, however, the 1500 does not include any Anderson connectors. That means if you’re planning on using the Explorer 1500 with solar panels that aren’t the SolarSaga 100W, you’ll likely need an adapter. Fortunately, you can pick up these adapters relatively inexpensively.

The third version of these SolarSaga 100W panels have some exciting features, such as the included built-in stands, ETFE surfaces, and USB-A and USB-C charging ports, which you can use for on-the-go device top-ups.

Using the panels in direct sun, I was able only to achieve around 60W of power input per panel. But it was around 3 pm and somewhat overcast during testing. So, I was expecting input wattage to fall short of the maximum.

Now, if you’re planning on over-paneling this unit, understand that the Explorer 1500 is only rated for 12-51 volts. The top-end of that range is a hard cap, and if you exceed that voltage on either of the input ports, then the unit will stop charging.

What Do We Love About the Jackery Explorer 1500?

The best part of the Jackery Explorer 1500 is the sheer amount of stuff you can power with the unit. The massive 1488Wh capacity of this unit is also something remarkable. While other generators of this type, such as the Bluetti EB150, and EB240 offer similar or higher watt-hour capacity, these devices can’t touch the Explorer 1500’s muscular 1800W inverter performance.

Then there’s solar power. If you can afford it, solar is your ticket to nomadic off-grid bliss. The SolarSaga 100W panels fold up into an ultra-thin package and are only slightly larger than an extra-large pizza box. Packing these panels into your camper or RV will take up only a tiny amount of space.

The panels’ magnetic clasps are also well made, and each time you close the panels, they snap shut with confidence. But, these panels are pricey. On the other hand, if you’re going to invest in a solar generator like the Explorer 1500, add-on solar is undoubtedly worth the bump in cost.

The unit also has the benefit of being equipped to charge seven devices at once. That means no fighting your kids for a spot on the Explorer when they want to charge up their mobile devices. (Your Nintendo Switch is just as important!) And pass-thru charging is a boon, even if you only use it occasionally.

The build quality of the Explorer 1500 is top-notch, and it’s clear that Jackery wasn’t aiming to cut corners. Or, maybe the company was, because there are no sharp corners on this unit. While that might not seem like it matters, try smacking yourself in the back of your leg with 33 lbs. of pointed object, and you’ll understand why this attention to detail is important.

Finally, the unit’s LCD is bright and colorful, and it looks much better than Jackery’s previous Explorer 1000 iteration. The display is easy to read, and even in the dark, you’ll always know how much juice you have or how much power you’re using.

What’s Not to Love?

There are only a few issues with the Explorer 1500 that prevent it from earning a perfect score. The first is the noise of the fan. This fan is noticeably loud. Will that be a problem for some people? Maybe.

For someone like me, who uses the Explorer in a videography setting, as long as my microphones don’t pick up the generator’s noise, then I’ll be happy. And at this point, I haven’t had much trouble. But don’t expect a unit that is whisper-quiet if you’re thinking about buying the Explorer.

Next is the weight. This unit is ultra-portable, but I would not consider it light. It’s 33 lbs of dead weight that will take some muscle to move over long distances. Again, this might not bother you, but if carrying the equivalent of a car battery around with you on your camping trip sounds agonizing, then you might want to search out some smaller power generation options.

There are also no Anderson connectors on the Explorer 1500. For those folks who already have solar panels with Anderson connectors, this might be a bit frustrating. But, you can solve this frustration by purchasing an Anderson adapter for the Jackery. For this, you’ll have to go to the aftermarket, but these adapters are certainly less money than buying all new solar panels.

Finally, the cost of this unit is going to be hard to swallow for some folks. With a complete set of solar panels, the Explorer 1500 will set you back around $2700. That’s a lot of money for someone who is just looking for supplemental weekend power. But, if you’re a serious outdoor person or a digital nomad, then this price may be perfectly justifiable.

Should You Buy the Jackery Explorer 1500?

If the cost of this unit fits your budget, then the Explorer 1500 is a great buy. While I’d recommend it more for its outdoor uses, there is viability to keeping this device charged up in your basement in case of disaster. And, if you’re the type of person who is vehicle-based and in search of portable power, then the Explorer 1500 by Jackery is a no-brainer.

This device is compact, easy to use, and eliminates one of the major problems of “roughing it.” Namely, the lack of portable electricity. The unit is fantastic, and for us, the Explorer 1500 is forging some new and exciting territory in the mobile power market.

Is the Jackery Explorer 1500 the Best Portable Power Station of 2021? published first on http://droneseco.tumblr.com/

0 notes

Text

The Best Solar Lanterns You Can Find

Laterns seem like a throwback - the sort of thing you imagine a gold prospector carrying around, along with his pickaxe, all while sporting a massive beard. But they are essential when you want illumination when there's no electricity. The problem is that you have to rely on kerosene or batteries. Kerosene smells terrible and is flammable. And even the best lithium ion batteries run out. The solution is solar lanterns.

One of the most transformative technologies that has yet to reach those who need it most are solar lanternst. An estimated 1.1 billion people – 14% of the global population – do not have access to electricity. They have to rely on kerosene or other dangerous forms of fuel that are a fire hazard and threaten smoke inhalation damage. A solar light can be a boon to off-grid families in need so they can live safer, brighter and more productive lives

Solar Lamp 50

This portable solar light provides 50 lumen of light. The lower setting provides 20 lumens of light for more than 6 hours; a perfect solar lantern which is ideal for reading, cooking or lighting up your home.

Weighs only 6 ounces - great for backpacking and camping

full day of sunshine will completely recharge the battery

Solar Cabin System

Light the home, cabin, or outdoors with the Solar Cabin System. This package offers light for up to four rooms. Mobile phone charging is supported via USB output.

Comes with an 8W solar panel and can be setup in minutes to run for many years. Integrated LFP battery is ready to serve 5+ years fully backed up by GoSun's 1 Year Warranty.

5+ years LFP long life battery

2 brightness modes

15 ft. cable for lamps

4 lamps

8W solar panel

Mobile phone charging

Solar Home Light

GoSun's Fusion has been getting plenty of buzz for its ability to cook food with solar energy even when the Sun is down. But you still need to see what you're doing if solar night cooking is your thing. And those LED headlamps definitely don't use solar energy.

But the Solar Home Light does. This is a solar-panel powered light with a 360-degree tilt. The Pico is compact and reliable, providing up to 72 hours of light from a full charge.

5x brighter than kerosene

Integrated solar design

72 hours of light on low mode

The Solar Home Light defines the industry's gold standard in affordable solar-powered lanterns with a 360-degree tilt and mobile device charging capability. Sun King Pro features phone charging capacity, and a leading level of brightness, in the industry. The Sun King Pro is an ideal home or travel accessory, that provides up to 45 hours of light per day on a full charge.

Uses: Camping, boating, shed, garages, cottages

Solar Light Flashlight

his rechargeable flashlight packs 280 lumens of on demand light. With an integrated solar cell, it has the ability to recharge using solar energy alone, but can also be recharged with the included USB cord. It has a lantern mode, spotlight ability and a red strobe emergency setting. A magnetic back allows for hands free use.

Uses: Camping, backpacking, and emergency

Weight: 0.3 lb

Lumens: 280

Charges USB devices

Multiple modes: Lantern, Spotlight, and Emergency

For faster re-charging use: SolarFlex 10 or Powerbank

Features

Multi-Functional: This device works as a flashlight, power bank, working light, and warning light

Charge Electronics: Connect other electronic devices to the flashlight to charge them via the integrated USB port

Magnetic Bottom: Attach to surfaces for hands free use

Vertical Lantern Mode: An illuminating bright white light allows the flashlight to double as a lantern

Emergency Strobe Function: The side lantern doubles as an emergency red strobe light

Weather Resistant: Rain, sleet, and snow won’t hold this flashlight back. This is a reliable light for any weather scenario.

Drop Resistant: Durable no matter how rough the road gets

40x brighter than kerosene

USB charging port

100 hours of light on low mode

To know more about Solar light and solar flashlight Please visit our website.

0 notes

Text

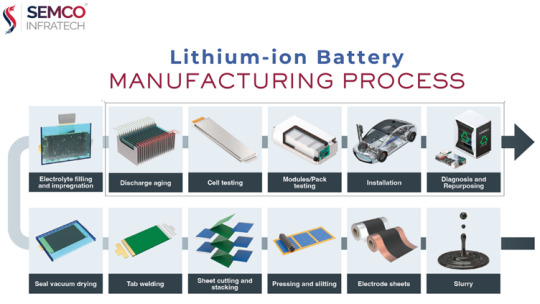

Step-by-Step Guide to Lithium Battery Pack Assembly and Cell Making Equipment

The rise of electric vehicles, renewable energy systems, and portable electronics has significantly increased the demand for lithium-ion batteries. But behind these powerful energy sources lies a highly intricate and controlled manufacturing process.

From raw materials to finished products, battery making machines and advanced battery making equipment are essential in ensuring efficiency, precision, and safety at every stage.

Understanding the Fundamentals

Before diving into the production process, it's crucial to understand the core components of a lithium-ion battery:

Positive Electrode: Made from materials such as lithium cobalt oxide (LCO), lithium nickel manganese cobalt oxide (NMC), or lithium iron phosphate (LFP).

Negative Electrode: Typically composed of graphite.

Separator: A porous membrane that separates the electrodes while allowing lithium ions to flow.

Electrolyte: A gel or liquid that enables ion movement between electrodes.

Current Collectors: Usually, aluminium for the positive electrode and copper for the negative, these provide a conductive path for electrons.

The battery works through the reversible movement of lithium ions between electrodes. During charging, lithium ions migrate to the negative electrode; during discharge, they return to the positive side—producing electrical energy.

The Lithium-Ion Battery Assembly Process: A Multi-Stage Journey

The lithium-ion battery assembly process can be categorized into three key stages:

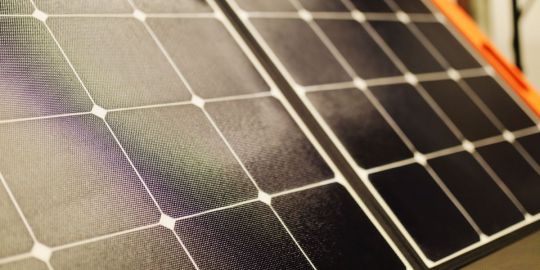

1. Front-End: Electrode Manufacturing

This initial phase focuses on producing high-performance electrodes, a critical step in the battery cell making machine workflow.

Slurry Preparation: Active materials (e.g., LCO or graphite) are mixed with binders like PVDF and conductive agents to form a uniform slurry.

Coating: The slurry is precisely applied to metal foils using high-precision battery-making equipment, ensuring uniform thickness.

Drying & Calendaring: Coated electrodes are dried to eliminate solvents and then compressed for better conductivity.

Slitting & Die Cutting: Electrodes are cut into specific dimensions to fit the battery cell, making machine specifications.

2. Middle-End: Cell Assembly

The second stage of the lithium-ion battery assembly process involves assembling the core components.

Winding/Stacking: Positive and negative electrodes are alternately layered with separators to form a cell stack.

Electrolyte Filling: The electrolyte is carefully injected into the cells to enable ion movement.

Sealing: The cells are sealed using heat or ultrasonic sealing to avoid leakage and ensure safety.

3. Back-End: Formation and Packaging

The final stage is about bringing the battery to life.

Formation: Cells undergo multiple charge-discharge cycles to stabilize their chemistry.

Testing & Sorting: Advanced battery making machines test each cell for voltage, capacity, and other parameters. Cells are then sorted accordingly.

Packaging: Assembled cells move into the lithium battery pack assembly stage, where they are configured into packs, enclosed, and prepared for shipment.

Key Challenges in Lithium Battery Manufacturing

Quality Control: Every step, from mixing to testing, demands extreme precision.

Safety: Mishandling materials or processes can result in thermal runaways or fire hazards.

Environmental Responsibility: Managing chemical waste and emissions is critical for sustainability.

Technological Advancements: The demand for higher capacity and faster charging batteries drives constant innovation in battery making equipment.

Conclusion

The lithium-ion battery assembly process is a sophisticated, multi-layered operation that relies heavily on precision, quality, and cutting-edge technology. With growing applications in EVs, consumer electronics, and energy storage, understanding this process—and the role of battery-making machines—is vital. As innovations continue to emerge, the evolution of lithium battery pack assembly will remain central to the future of sustainable energy solutions.

#battery making machine#battery making equipment#battery cell making machine#lithium ion battery assembly#lithium battery pack assembly#lithium ion battery assembly process#lithium ion battery manufacturing process

0 notes

Text

Don’t toss that vape!

Kristen Lewis is the assistant principal at Boulder High School in Colorado. A large cardboard box sits in her office. It’s where she tosses the spoils of her ongoing battle with the newest student addiction: vaping. “This is what I call the Box of Death,” she explains. Inside it “is everything that we’ve confiscated.”

There are vape pens, such as JUULs (the leading brand of e-cigarettes). You also can see dozens of disposable pods that once were full of flavored, nicotine-rich liquids. There is even a lonely box of Marlboros.

Students aren’t allowed to smoke or vape on school grounds. But Lewis and other school employees still regularly pluck e-cigs from students’ hands or find vape-related trash littering the halls and restrooms.

E-cigarettes don’t need nicotine to be toxic

In the school parking lot, Lewis spots discarded packaging. “This one,” she says, is from “an Orion vape device, it looks like.” A little further on, she spots a pile of JUUL pods. More vaping trash shows up in the yards of homes across from the school and along the edge of nearby Boulder Creek.

This trash reveals “how much [vaping] has become a part of our students’ lives,” Lewis says. “And that’s what’s scary… It really has become an epidemic.” She notes, “every high school in the nation is really dealing with this.”

Colorado recently topped the national list for teen vaping. That’s based on data reported in June 2018 by the U.S. Centers for Disease Control and Prevention. Boulder, it turns out, is a Colorado hot spot. The surge in vaping here, as elsewhere, has led to health problems. Less obvious, this new teen obsession is creating a new environmental problem. Discarded vape pens and pods now litter city streets and schools across the nation.

And they’re not just unsightly. They also can be toxic. Indeed, cities are beginning to argue that this trash is really hazardous waste.

Vaping waste removal strategies

The disposable pod is a small plastic cartridge holding a flavored, nicotine-rich liquid. It snaps onto a base, often called a “vape pen.” This may can look like an actual pen or even a small thumb drive. In 2017, people bought more than 16 million of the devices in the United States. That’s according to a report by the Truth Initiative. It’s a nonprofit group dedicated to ending tobacco use. And its 2017 figure — now long out of date — doesn’t include the disposable e-liquid pods. For JUUL, those pods often are sold in packs of four.

Boulder High custodian Allen Chavez points to hole in wall of boy’s bathroom where students deposit finished pods. He said he finds pods thrown away all over the school, including between furniture cushions.John Daley/Colorado Public Radio

At Boulder High, custodian Allen Chavez points to where he often finds empty e-cig pods. Some have been stuffed between furniture cushions. In a boy’s bathroom, he points to a small hole in the wall. That’s where he’s seen students stick empty pods.

“I’ve caught a couple of guys [putting them there],” says Chavez. But most time students simply tell him, ‘It wasn’t me!'”

Angel Ocon played football at Boulder High. He’s seen plenty of discarded e-cig pods under the school bleachers. “If you use vapor or juul or something, all you’re going to think about is, like, getting the buzz,” Ocon says. He explains that users are not worried about “where you’re going to throw away your stuff.”

Shelly Fuller manages the local county’s hazardous-waste program. No e-cig device or its parts should ever be tossed in the trash, she says. Instead, vapers should collect them for disposal at a hazardous-waste or recycling center.

At a battery-sorting table, Fuller shows off a bucket of vape trash. This new part of the waste stream only emerged about two years ago, she says. Now people regularly drop off vaporizers, pods and batteries. Such items also show up in household trash.

Shelly Fuller manages Boulder County’s hazardous-materials program. Vaping devices should never be dumped in the trash, but instead should be dropped off at a facility like hers for proper disposal.John Daley/Colorado Public Radio

Different parts of an e-cig must be managed separately, she explains. These devices have batteries, usually the lithium-ion type. Fuller ships them to a recycling facility in Arizona. She sends e-liquid pods instead to a facility in eastern Colorado. Those pods hold traces of concentrated nicotine. It’s an acutely hazardous waste, she says. Even small doses can be lethal to people or small animals. And the nicotine needn’t be eaten or inhaled. It can pass right through the skin. That’s why “we’re shipping it off with our poisons or toxics,” she says. It needs to be recycled or incinerated.

Risks of poisoning or contamination

A recent study of a dozen high schools in the San Francisco Bay Area in California found trash from vaping, smoking and cannabis products in and near area high schools.

At higher-income high schools, the researchers reported finding “substantial quantities of JUUL and JUUL-compatible e-cigarette waste.” Most came from pods with flavored liquids “other than tobacco flavor.” At lower-income schools, the researchers found a different mix of wastes, including remnants of small flavored cigars. At all the high schools, large quantities of butts turned up from menthol-flavored cigarettes.

Brittany Carpenter is a Boulder County tobacco-education specialist. One e-cig pod can start out with as much or more nicotine than a pack of cigarettes, she notes. And there’s more to be concerned about in an e-liquid than its nicotine. Some types contain heavy metals, Carpenter notes, “including lead, tin and nickel.”

E-cigarette packaging and JUUL pods litter the parking lot at Boulder High School.John Daley/Colorado Public Radio

All of these things can end up in the ground or water if they’re not disposed of properly, says John Volckens. He’s an environmental health researcher at Colorado State University in Fort Collins. “As the battery degrades, the compounds in the battery can leach into water nearby,” he says. Wastes from a discarded e-cig or pod, then, doesn’t really go away, he says. It just goes somewhere else.

And to date, the vaping industry has done little to push for a recycling of its products, he adds.

In fact, some vaping advocates claim these pollution concerns are overblown.

“Compared to all of the household products that we throw out in the garbage every day,” says Gregory Conley, “there is no environmental damage [from vaping wastes]. Conley is president of the American Vaping Association. It’s based in Stamford, Conn. He says, “Most pods, by the time someone wants to recklessly throw them on the ground, they’ve been vaped.” As a result, he claims, “there’s little to no liquid left in that pod.” And in the end, he argues, it’s really up to vapers to pick up their wastes.

JUUL, the market leader, declined interview requests. The company website states that its pods are not meant to be refilled and can be thrown away. That is contrary to what Boulder County advises. The county website recommends that a JUUL’s battery-powered base should be disposed of in the same manner as other electronics, such as cell phones.

Stephanie Faren directs health services for the Boulder Valley School District. She says, “This is a whole new thing that, really.” People talk about vape risks. But the pollution, she says, that’s something “I don’t think many people have even given any thought to.”

Don’t toss that vape! published first on https://triviaqaweb.tumblr.com/

0 notes

Text

How Do You Charge a Helicopter?

This allows the battery to cool down before every charging cycle. I might confirm the battery is cool before I recharge it, however, quarter-hour ought to be ok.

1: If the battery is hot once use, this can be a decent sign that the battery is obtaining recently.

Anything hotter than concerning a hundred and forty degrees is dangerous. If your battery is thus heating once flying, you'll have to be compelled to replace it. I might not use it any longer thus it doesn't explode. this can be a decent indication that you just ought to be trying to find a replacement one within the close to future. I might advocate the next quality / mAh battery (but maintain identical voltage) once the battery is dead. Get more information about RC helicopter-- Follow Us.

2: Battery terms to be understood once shopping for associate RC battery.

mAh:

current unit hour. this can be primarily the electrical charge that's transmitted for one hour with a current of 1 current unit. I am not an electrical genius, however the upper the mAh, the longer electric battery can last per charge. this {can be} a part of electric battery that you just can amendment while not damaging the whirlybird.

Volt:

The electrical pressure. Basically, this determines what proportion of power will flow to the engine. For Lipo batteries, the voltage could be a multiple of three.7 volts or three.7 volts per cell.

Cell:

associate freelance three.7 potential unit battery.

If you would like a lot of careful rationalization, I found this text useful.

Lithium particle (Li-Ion):

a sort of battery that incorporates a rigid cell structure and form. it's safer than a Lipo battery, however not thus economical.

Lithium chemical compound (Lipo): electric battery sort with versatile cell structure and form. Lipos will ignite and explode if slapped or born on a tough surface. ATTENTION! though a lot of dangerous, they're a lot of economical than Li-ion batteries and might settle for just about any form with identical cell count.

See below to examine however the Li-ion (right) has 2 outlined cylindrical shapes within the packaging, whereas the left lip is simply a parallelogram with no visible curvature or cells.

3: Discard (properly) batteries that are swelled once the flight.

This is a decent indication that the battery is simply too recent to prevent exploitation. If you fly with the electric battery that balloons, there's a heavy risk of associate explosion that would destroy your whirlybird. The overuse of associate recent battery during this method prices a lot of within the end of the day than shopping for a replacement one.

4: ne'er discharge the battery over eighty-fifth.

Discharging (or in alternative words, exploitation in flight) the battery on the far side an exact purpose will injury the battery and considerably shorten its life. ne'er unload over eighty-fifth.

Normally flying with over eighty-fifth discharge doesn't enable us to fly over a foot higher than the bottom. you'll tell if the battery is low, as a result of the electronic speed governor (ESC) limits the voltage on the motors. In alternative words, you'll fly lower with an identical throttle setting. I notice that the whirlybird continues to be concerning one foot higher than the bottom at eighty-fifth discharge and nearly full throttle.

In this case, land, wait fifteen minutes and recharge the battery. If you are tempted to wing till the ESC mechanically shuts off the whirlybird, don't tell yourself that you are let alone thirty seconds for dozens or many flights within the future.

Case study: The average 9053 Volitation user gets 10-15 charges with the quality Li-Ion battery. Following these rules has strictly allowed Pine Tree State to fly over sixty times with the quality battery, while not noticeable performance degradation, that equates to a saving of four-hundredth - 600%. In alternative words, I actually have an identical flight time as if I had bought 3-5 a lot of stock batteries. That saves concerning 30-60 bucks. For me, it pays to lose twenty seconds for every pointless flight for this sort of savings.

5: don't overcharge the battery

Overcharging a Lipo battery is harmful and might cause explosions. With the battery and charger that comes with a whirlybird, you would like not to worry concerning it, however, once shopping for a replacement charger or battery, it's vital to understand.

Conclusion

Take the mAh rating (eg on the mCP x this is able to be two hundred mAh). Divide this range by one thousand to induce the fundamental charge of the electronic equipment. for instance 200/1000 = zero.2 amps Charge batteries with a temperature below twenty ° C solely with the fundamental charge of the electronic equipment or less. If your battery incorporates a C rating of over twenty-five, it's okay to charge it at double the bottom rating (0.4 amps).

youtube

0 notes

Photo

Question of the day: We are looking for suitable packaging for "small" batteries according to SP 188 for: UN 3090 Lithium metal batteries without equipment + UN 3091 Lithium metal batteries contained in equipment UN 3480 lithium ion batteries without equipment + UN 3481 Lithium ion batteries contained in equipment Which packaging is suitable for "small" lithium cells and lithium batteries? For road transport according to ADR we would like to use a suitable type of packaging, if possible small and regulation compliant. How big does the box have to be? Must the label fit completely on one side of the package? What must the inside look like? Non-flammable? e.g. Bubble wrap or can you also use padding paper? The large online store starting with A… often uses the following packaging solutions for lithium cells and batteries as per SP 188. Is such a packaging permissible at all? Our answer: Suitable packaging has the following specifications: For the inside of the package according to SP 188, there is only the requirement that the inner packaging must completely enclose the lithium cell resp. lithium battery. This can be an inner cardboard box or a plastic bag. The lithium cells / lithium batteries must be protected against short circuits and against electrically conductive materials. For the outer packaging the following applies: -The inner packaging must be placed in a strong outer packaging. Strong means that it may not be bent by a sorting machine. - The material must be compatible. - The inner packaging must not be able move in the outer packaging. Cushioning material may be used to ensure that. - The readily prepared package must not exceed 30 kg Gross for UN 3090 and UN 3480. A cardboard packaging would be OK. The air cushion envelopes definitely is not. Of course the packaging must bear the respective Lithium Battery Mark. The minimum dimensions for the package would therefore be 10.5 cm x 7.4 cm, so that the reduced size lithium battery mark can still be placed on one package side. The prepared package must withstand a drop test of 1.2 m. According to SP 188 this drop test is required for lithium cells / lithium batteries without equipment UN 3090 and UN 3480 and for lithium cells / lithium batteries packed with equipment. The manufacturer of your package will surely assist you here. For safety reasons this test of course is not carried out with real lithium cells / lithium batteries but with article dummies of the same size and weight. If you do not have an unyielding surface then the manufacturer of your packaging will assist you with this drop test. If you get lithium cells / lithium batteries in air cushioning envelopes then please always send a notification of complaint to the shipper. And by no means relabel these air cushion envelopes for further forwarding. Every lithium cell and every lithium battery must be manufactured according to the quality management program described in the transport regulations, including prototypes. And that they have successfully passed the UN Test series 38.3 described in the UN Manual of Tests and Criteria. What this Quality Management Program includes, you can find here: https://www.lithium-batterie-service.de/de/qualitaetsmanagement-programm The UN test series 38.3 includes the following: https://www.lithium-batterie-service.de/en/un-38.3-test-series Our checklist articles include in addition to the checklist for transport preparation all the required marks and labels for your transport case and if necessary an example of the required transport documents. The checklist article for your transport case you can find via FIND A SINGLE CHECKLIST: https://www.lithium-batterie-service.de/en/checklist Our Supplier Inquiry Form can assist you to obtain all necessary information for logistics from the manufacturer or supplier: https://www.lithium-batterie-service.de/files/552211cce724117c3178e3d22bec532ec/downloads/UN38-3-Test-Summary-and-Supplier-Inquiry-Form-Lithium-Battery-Service-2019-04-02.pdf From 01.01.2020 onwards a UN 38.3 Test Summary needs to be provided by the manufacturer and any subsequent supplier on request. We have included all required details of the UN 38.3 Test Summary in our Supplier Inquiry Form.

#small batteries#Li-ion#li-ion battery#UN3090#UN3091#UN3480#UN3481#special provision 188#packaging#UN test 38.3#question of the day

0 notes

Text

Batteries? What For?

This is a guest blog post from Andrew Shepherd. Andrew has been studying electronics in earnest for over a decade and loves working with his mind and hands. He specializes in analog electronics, but his interests are eclectic and span seemingly unrelated areas.

If you need a project to be portable, here’s a small crash course on some of the batteries that are available and what situations they are good for.

Types:

There are two main types of batteries: primary and secondary – batteries that can be recharged and those that are one-use-only. Today we'll cover only the most relevant and available types for the sake of brevity, as the full catalog of battery types could fill pages. We will also only explore certain secondary batteries.

Lead-Acid - This is the oldest type of rechargeable battery. They can supply a lot of current but are also very heavy compared to newer types. They tend to be used in cars and stationary equipment, like UPSs (Uninterruptible Power Supplies), due to their durability and tolerance for low temperatures. Cell voltage is ~2.1 V each, but they typically come in 6V or 12V packs. Charging and discharging is quite simple, as long as the upper and lower voltage bounds are not grossly exceeded and the charge current is not too high. If they are abused they can outgas hydrogen and potentially explode.

added to your cart!

Lead Acid Battery - 12V 7.2Ah

In stock PRT-15066

This is a Panasonic Sealed Lead Acid Battery. It is a valve regulated rechargeable battery. These units are designed to provi…

$47.95

Favorited Favorite 0

Wish List

NiMH - These are an improvement on the NiCd batteries, and are a proven and reliable battery technology. They are more power dense than lead-acids, but have a lower cell voltage of ~1.2V under load. Recharging and discharging is also fairly simple given that you don’t draw current below a certain voltage. If abused they can overheat and lose a lot of their capacity.

added to your cart!

2500 mAh NiMH Battery - AA

In stock PRT-00335

2500mAh 1.2V Nickel Metal Hydride rechargeable 'AA' batteries. [NiMH technology](http://en.wikipedia.org/wiki/Nickel_metal_hy…

$2.95

Favorited Favorite 3

Wish List

-

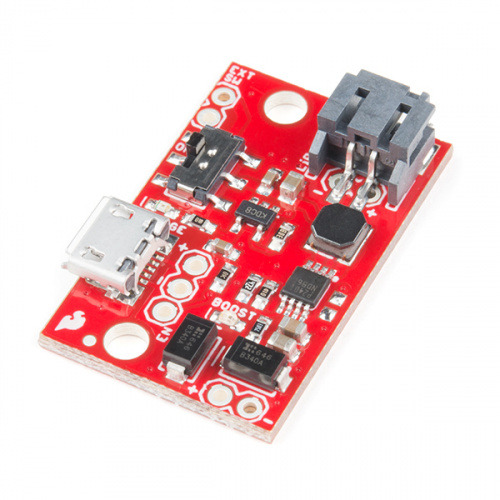

LiPo/Li-Ion - The difference between LiPo and Li-Ion is subtle and the technologies are typically combined for most batteries, so they will be regarded together. These are lightweight, high power density, high cell voltage (3.7V under load). Their output current capability is consistently better than NiMH for a given size. Their disadvantage is they are less stable than other batteries and care must be taken when charging or discharging. The charging process is more complicated and requires a special process to avoid damage. For multi-cell systems, cell balancing is required for charging and discharging. If these batteries are abused, they can explode and shoot flames and fluoride gas everywhere.

Types of LiPos

These things come in all shapes and sizes and can be used for many applications due to their high power density.

Small Li-Ion Flat Packs - These are useful for small projects and most can interface directly with many SparkFun products. Paper-thin, flexible batteries also exist and may be best for wearables.

added to your cart!

Lithium Ion Battery - 850mAh

In stock PRT-13854

These are very slim, extremely light weight batteries based on Lithium Ion chemistry. Each cell outputs a nominal 3.7V at 850…

$9.95

2

Favorited Favorite 6

Wish List

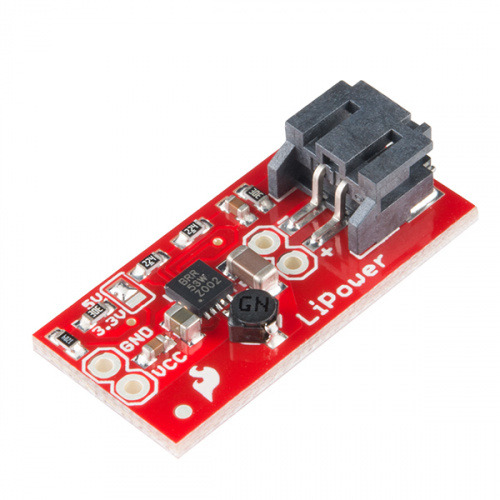

<-