#Manufacturing Conveyors

Explore tagged Tumblr posts

Text

#Conveyor System Market#Material Handling Systems#Industrial Conveyors#Automated Conveyor Systems#Conveyor Technology#Warehouse Automation#Manufacturing Conveyors#Logistics Solutions#Conveyor Industry Trends#Conveyor Belt Systems#Packaging Conveyors#Industrial Automation#Conveyor System Innovations#Supply Chain Efficiency#Conveyor Equipment

0 notes

Text

How Toothpaste Is Made

#toothpaste#turtles#ai videos#ai generated#ai art#a.i.#how it's made#tv shows#production#industrial#fake news#conveyor belt#factory#colgate#turtle wax#Soylent Green#manufacturing#industry

8 notes

·

View notes

Text

High-Quality Spindle Tapes for Open-End Spinning Machines | ELGITEX

ELGiTEX spindle tapes have been serving the yarn processing industry since 1985.. Manufactured using the advanced Caprobond technology, these tapes are versatile, designed to suit a wide range of spindle speeds.

#conveyor belt manufacturers in india#conveyor belt companies in india#industrial conveyor belt#power transmission belts#rubber conveyor belt manufacturers in india#spindle tape

2 notes

·

View notes

Text

Tired of bottlenecks and slow production lines? 🙅♂️ Our Inclined Conveyors offer a smooth and efficient transport solution for your materials.

#yontro mechatronic systech#conveyor belt manufacturers in india#conveyor belt#Inclined Conveyor Belt#Inclined Conveyor#yontro

2 notes

·

View notes

Text

Leading SMSR Gear Box manufacturers in India - Shaft Mounted Speed Reducer Manufacturers In Ahmedabad - Nisuka Industries

Nisuka is a renowned name in the industry as one of the top SMSR gear box manufacturers in Ahmedabad, India and trusted Shaft Mounted Speed Reducer manufacturers. We specialize in providing high-quality, durable, and efficient gearboxes designed to meet the demands of various industrial applications. Our products are known for their superior performance, robust construction, and long service life, making them an ideal choice for industries like mining, quarrying, and material handling. At Nisuka, we are committed to delivering innovative solutions that enhance productivity while ensuring reliability and cost-effectiveness for our clients.

#SMSR Gear Box#Manufacturing#SMSR Gear Box manufacturer#Shaft Mounted Gearbox Manufacturer#Conveyor Gearbox Manufacturer

2 notes

·

View notes

Text

Uses and Advantages of Chain Conveyor

A chain conveyor is a mechanical system designed for automated material handling in industrial settings. It consists of interconnected chains running on sprockets, facilitating the continuous and reliable movement of goods or materials. Widely used in manufacturing and distribution, these conveyors are known for their durability, versatility, and ability to handle heavy loads. They offer customization options, reducing manual labor, minimizing downtime, and optimizing material flow, thereby enhancing overall operational efficiency in various industries.

Uses of Chain Conveyors:

Material Handling in Manufacturing: Chain conveyors play a pivotal role in manufacturing processes by efficiently transporting raw materials, components, and finished products from one point to another. They ensure a smooth flow of materials, reducing manual handling and enhancing overall production efficiency.

Automated Assembly Lines: In industries where precision and speed are paramount, chain conveyors are employed to facilitate the movement of products along assembly lines. This helps streamline the production process, allowing for consistent and timely assembly of intricate components.

Distribution and Warehousing: The logistics and distribution sector heavily relies on chain conveyors to handle the seamless movement of packages and goods within warehouses. These systems can be customized to suit the specific needs of different industries, enabling efficient order fulfillment and timely dispatch of products.

Automotive Industry: In the automotive sector, where precision and efficiency are crucial, chain conveyors are used for transporting vehicle parts during the manufacturing process. This ensures a continuous and reliable flow of components, contributing to the overall productivity of the assembly line.

Advantages of Chain Conveyors:

Reliability and Durability: Chain conveyors are known for their robust construction, making them highly reliable in demanding industrial environments. The durable chains and sprockets used in these systems contribute to their long lifespan and minimal maintenance requirements.

Versatility: Chain conveyors are incredibly versatile and can be adapted to suit a wide range of applications. They can handle various types of materials, including bulk items, heavy loads, and irregularly shaped products, making them suitable for diverse industries.

Customization Options: These conveyors offer extensive customization options, allowing businesses to tailor the system to their specific needs. Whether it’s the size, speed, or configuration, chain conveyors can be designed to optimize the workflow within a particular facility.

Efficient Material Flow: The continuous and automated nature of chain conveyors ensures a smooth and efficient flow of materials. This not only reduces the risk of bottlenecks but also enhances overall productivity by minimizing downtime and optimizing resource utilization.

Cost-Effective Solution: Chain conveyors are a cost-effective solution for material handling, especially when compared to alternative methods like manual labor or other conveyor systems. The initial investment is often offset by the long-term savings in labor costs and increased operational efficiency.

Conclusion:

In conclusion, chain conveyors have become indispensable in modern industries, offering a reliable and efficient solution for material handling. Their versatility, durability, and customizable features make them a preferred choice for businesses aiming to enhance their production processes and streamline logistics. As industries continue to evolve, chain conveyors will undoubtedly play a vital role in shaping the future of automated material handling systems.

#chain conveyor#chain conveyor manufacturer#chain conveyor system manufacturer#chain conveyor system supplier#chain conveyor supplier in India#chain conveyor manufacturer in India

2 notes

·

View notes

Text

Liquid Storage Tank Manufacturers in India

Find excellence in liquid storage with leading Liquid Storage Tank Manufacturers in India. From corrosive chemicals to potable water, tanks are engineered for durability and safety. With a commitment to superior craftsmanship, ensure compliance with industry standards and deliver innovative storage solutions. Expertise to provide customizable, efficient, and cost-effective liquid storage tanks that safeguard your valuable liquids. Elevate your storage capabilities with Bhupati Engineering's advanced solutions, setting new benchmarks for reliability and performance in the liquid storage industry.

#Liquid Storage Tank Manufacturers in India#Top Liquid Storage Tank Manufacturers in India#Best Liquid Storage Tank Manufacturers in India#Liquid Storage Tank Manufacturers#Liquid Storage Tanks#Liquid Storage Tank#Storage Solution Providers#Agricultural Storage Tanks#Material Handling Equipment Manufacturers & Suppliers#Grain Storage Silo Manufacturers in india#Industrial Material Handling Equipment Manufacturers in india#Vertical Bucket Elevator Manufacturers in India#"#Conveyor Belt Manufacturers in India

2 notes

·

View notes

Text

The Multifaceted Importance of a High-Quality Heat Resistant Conveyor Belt in Industries

In today’s fast-paced world, the smooth and efficient transportation of goods and materials has become the lifeblood of numerous industries. At the heart of this logistical revolution lies the unsung hero – heat resistant conveyor belts. These unassuming systems have completely transformed the way industries operate, enabling the seamless movement of products, enhancing safety, and bolstering…

View On WordPress

#Heat Resistant conveyor Belt#heat resistant conveyor belt manufacturer#heat resistant conveyor belt supplier#heat resistant conveyor belts

2 notes

·

View notes

Text

Top Belt Conveyor Manufacturers in the UK: Delivering Efficiency and Innovation

In the fast-paced world of logistics, manufacturing, and material handling, belt conveyors have become essential. They offer a cost-effective and reliable way to transport materials across facilities—boosting productivity and reducing manual labor. The UK is home to some of the leading belt conveyor manufacturers who combine decades of engineering excellence with modern-day innovation.

Why Belt Conveyors Are Vital for Your Operations

Whether you're moving bulk materials in a warehouse or handling fragile goods on a production line, belt conveyors streamline the process. They are known for:

Smooth and continuous material flow

Customisable lengths, widths, and materials

Easy integration into automated systems

Low maintenance and long operational life

From food-grade stainless steel belts to heavy-duty rubber systems, UK manufacturers cater to a wide range of industries including food processing, packaging, construction, recycling, and more.

Top Belt Conveyor Manufacturers in the UK

Here are some of the leading names in the UK known for delivering high-quality, bespoke belt conveyor systems:

1. L.A.C. Conveyors & Automation

Based in Nottingham, L.A.C. offers custom conveyor systems and turnkey automation solutions. Their belt conveyors are ideal for warehousing, e-commerce, and production environments.

2. Conveyor Systems Ltd (CSL)

With over 30 years of experience, CSL provides modular and bespoke belt conveyors. Their systems are widely used in retail, pharmaceuticals, and manufacturing.

3. Coveya

Known for robust and portable conveyor systems, Coveya serves construction, demolition, and mining industries. Their customer-focused service and rental options make them highly flexible.

4. Spaceguard Ltd

This Hull-based manufacturer specializes in made-to-order belt conveyors. They offer fast turnaround times and custom designs to suit diverse industrial needs.

5. Amber Industries

Amber has a reputation for delivering reliable material handling systems. Their belt conveyors are known for smooth operation and energy efficiency.

Key Features to Look for When Choosing a Manufacturer

When selecting a belt conveyor manufacturer in the UK, consider:

Material & Build Quality: Stainless steel, aluminium, or mild steel depending on the application

Customisation: Size, load capacity, incline/decline, and speed control

Support & Maintenance: Ongoing technical support and spare parts availability

Compliance: CE marking and compliance with UK health and safety standards

Final Thoughts

Investing in a high-quality belt conveyor system from a trusted UK manufacturer can transform your operational efficiency. With many options on the market, it’s important to choose a provider who understands your industry, offers customization, and provides excellent after-sales support.

If you're looking to upgrade or install a new conveyor system, explore options from the top belt conveyor manufacturers in the UK and bring greater automation and flow to your operations.

0 notes

Text

Trusted Conveyor System Manufacturers – CONOVEY

CONOVEY distinguishes itself among conveyor system manufacturers by providing custom-engineered solutions tailored for various industries. They design, build, and install high-performance conveyor systems that enhance efficiency, minimize downtime, and facilitate smooth operations. To know more, connect with them today.

0 notes

Text

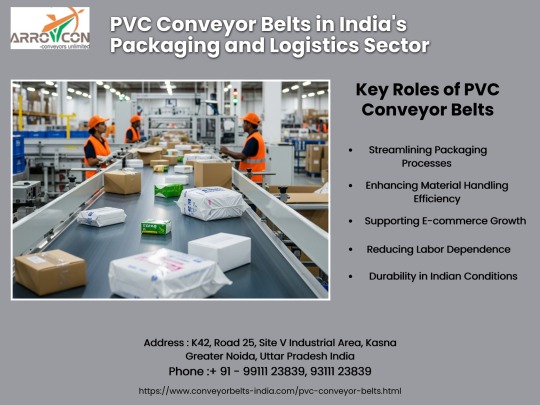

A PVC Conveyor Belt is a robust and bendy belt used to move goods in factories, warehouses, and packaging units. Made from plastic fabric (PVC), it's far easier, smooth to smoother, and works well in specific situations. It allows for conveying items speedily and effectively, making work faster and simpler.

#pvc belts#PVC Conveyor Belts Manufacturer in India#PVC Conveyor Belts#PVC Conveyor Belts Supplier#PVC Conveyor Belts Manufacturer in Noida

0 notes

Text

Boost Efficiency and Productivity with a Garment Sort Conveyor System

The garment sort conveyor system by Alpha Conveyor is a powerful tool for businesses that need to sort large volumes of garments quickly and accurately. Its high sorting capacity, intelligent design, and customizability make it an ideal choice for boosting productivity and reducing operational costs. Whether you're looking to streamline warehouse operations or improve customer order handling, this system offers a smart, scalable solution to meet your needs. For more information please visit: https://www.slideserve.com/Alpha55/boost-efficiency-and-productivity-with-a-garment-sort-conveyor-system

#overhead conveyor case studies#custom manufacturing clothing conveyor#garment warehousing rail systems#apparel and formal wear

0 notes

Text

Screw Conveyors Manufacturers: Precision Engineering for Seamless Bulk Handling

In the world of bulk material handling, screw conveyors stand as essential equipment, renowned for their versatility and reliability across various industries. Whether it’s moving grains, cement, chemicals, or biomass, screw conveyors offer a simple yet highly effective solution for horizontal and inclined conveying. This growing demand has led to the rise of leading screw conveyor manufacturers in India and around the world, who specialize in designing custom-built solutions tailored to diverse industrial needs.

What are Screw Conveyors?

A screw conveyor, also known as an auger conveyor, uses a rotating helical screw blade housed inside a tube or trough to move granular or semi-solid materials. These conveyors are ideal for handling free-flowing materials, such as:

Food grains

Fly ash

Cement

Animal feed

Wastewater sludge

Minerals and chemicals

The design simplicity and enclosed structure make them a go-to option for industries requiring dust-free, efficient, and continuous material transport.

Why Choose Reliable Screw Conveyor Manufacturers?

When it comes to bulk material handling, performance and durability are non-negotiable. Partnering with trusted screw conveyor manufacturers ensures:

Customized Design

Reputed manufacturers offer tailor-made solutions based on material type, density, moisture content, and throughput requirements.

Quality Components

Top manufacturers use high-grade materials like stainless steel or carbon steel for enhanced durability, corrosion resistance, and food safety compliance.

Energy Efficiency

Modern screw conveyors are engineered for optimal energy consumption while ensuring high output with minimal wear and tear.

After-Sales Support

From installation to maintenance and repair, established manufacturers provide full lifecycle support, minimizing downtime and improving ROI.

Applications Across Industries

Screw conveyors are widely used across multiple industries due to their adaptability and robust performance. Key sectors include:

Food Processing: For conveying flour, sugar, grains, and spices.

Cement & Construction: Handling dry bulk cement, sand, and lime.

Chemical Industry: For safe transportation of powders and granules.

Agriculture: Moving feed, grain, and fertilizer.

Waste Management: Transporting sludge or solid waste in treatment plants.

Top Features to Look for in a Screw Conveyor System

When evaluating screw conveyor systems from manufacturers, ensure they offer:

Modular design for easy installation

Dust-tight construction

Variable speed drives

Easy cleanability and maintenance access

Options for horizontal, inclined, or vertical conveying

How to Choose the Right Screw Conveyor Manufacturer

Selecting the best screw conveyor manufacturer requires a careful assessment of their technical expertise, client portfolio, and ability to deliver on time. Look for manufacturers who offer:

In-house design and fabrication capabilities

Compliance with ISO and other industrial standards

Extensive industry experience

Proven track record with successful installations

Conclusion

Screw conveyors are indispensable in bulk handling systems due to their efficiency, reliability, and adaptability. Choosing the right screw conveyors manufacturer ensures your system is optimized for performance, durability, and cost-effectiveness. Whether you're in food, cement, chemical, or agriculture industries, partnering with a skilled manufacturer is the key to seamless material movement and operational efficiency.

0 notes

Text

This type of Incline Conveyor Belt are essentially used to transport material at different elevations. It can be used for moving products between two floors or loading and unloading trucks etc. For the various angle of incline or decline and the wight of the product, the selection of the type of belt is determined. As per the inclination angle, Plain belt, rough-top belt, cleated belt, modular plastic belt with cleats or drag chain conveyors are used.

#yontro mechatronic systech#Incline Conveyor Belt#conveyor belt#conveyor belt manufacturers in india

2 notes

·

View notes

Text

Belt Conveyor System in Ahmedabad, India | Nilkanth Machine Tools

Nilkanth Machine Tools is a trusted manufacturer and supplier of high-performance Belt Conveyor Systems in Ahmedabad, India. Our conveyor systems are engineered for efficient material handling in a wide range of industries, including construction, cement, packaging, and manufacturing. Designed for durability and smooth operation, our belt conveyors support continuous movement of materials with minimal maintenance. We offer customizable solutions based on your operational needs, including size, load capacity, and layout. Whether it’s for transporting aggregates in concrete batching plants or bulk materials in production units, our conveyor systems ensure seamless workflow and enhanced productivity. With years of industry experience and a focus on quality and innovation, Nilkanth Machine Tools delivers reliable, cost-effective, and robust material handling solutions to clients across India and beyond.

Visit: https://nilmac.com/

#Belt Conveyor System#Belt Conveyor Manufacturer in Ahmedabad#Conveyor System Supplier#Industrial Belt Conveyor India

0 notes

Text

No. 1 Conveyor Gearbox Manufacturer in Ahmedabad, India

Introduction

When it comes to smooth and efficient industrial operations, the gearbox is at the heart of any conveyor system. In Ahmedabad, India, Nisuka Industries has earned a solid reputation as the No. 1 Conveyor Gearbox Manufacturer in Ahmedabad, India, delivering precision-engineered, durable, and high-performance gearboxes tailored for heavy-duty applications. Trusted by businesses across India, Nisuka's solutions ensure seamless material handling in industries like mining, cement, and packaging.

This blog highlights why Nisuka Industries is a leader in the field and offers valuable insights into related components such as SMSR gearboxes, V-belt pulleys, gear oil pumps, and more.

Why Conveyor Gearboxes Matter

Conveyor gearboxes are vital for regulating the speed and torque of conveyor belts. They transfer mechanical power from the motor to the conveyor system, enabling the belt to move materials efficiently. A high-quality gearbox reduces wear and tear, increases system lifespan, and boosts operational reliability.

As a Conveyor Gearbox Manufacturer in Ahmedabad, Nisuka Industries offers gearboxes that are compact, energy-efficient, and built to withstand tough working conditions. Their designs allow for easy maintenance, perfect alignment, and long-term performance.

What Makes Nisuka the No. 1 Manufacturer?

Expertise and Engineering Excellence

With decades of experience and a team of skilled engineers, Nisuka Industries develops gearboxes that meet international quality standards. Their conveyor gearboxes are designed with robust housings, precision gears, and durable bearings.

Complete Product Ecosystem

In addition to conveyor gearboxes, Nisuka Industries is also known as a:

SMSR Gearbox Manufacturer in Ahmedabad

SMSR Gearbox Manufacturer in India

Suspension Magnet Manufacturer in India

Gear Oil Pump Manufacturer in India

V Belt Pulley Manufacturer in India

Plummer Block Manufacturer in India

Conveyor Belt Tensioner Manufacturer in India

This wide product range ensures clients get all essential components from one reliable source.

Customization and Support

Every industry has different requirements. Nisuka offers tailored gearbox solutions depending on the load, speed, and type of material handled. They also provide after-sales support, installation guidance, and maintenance services.

What Is an SMSR Gearbox?

An SMSR (Shaft Mounted Speed Reducer) Gearbox is a highly efficient gearbox mounted directly on the drive shaft of the conveyor. It eliminates the need for extra couplings and foundations. These gearboxes are compact, require minimal maintenance, and are ideal for harsh environments.

As a leading SMSR Gearbox Manufacturer in India, Nisuka ensures all their gearboxes come with torque arms, backstops, and oil sealing systems for improved performance.

What Is a V-Belt Pulley?

A V-belt pulley is a wheel with a grooved rim designed to guide a V-belt, which transmits mechanical power between rotating shafts. These pulleys reduce slippage and increase belt efficiency.

Nisuka, a reliable V Belt Pulley Manufacturer in India, manufactures pulleys that ensure excellent grip, alignment, and long service life. Their V-belt pulleys are used in various drive systems, including conveyors, compressors, and pumps.

Types of Gearboxes Used in Industries

Different applications demand different types of gearboxes. Below are the most common:

Helical Gearbox – Known for high efficiency and low noise; ideal for heavy-load applications.

Bevel Gearbox – Suitable for angular drives; commonly used in conveyor and mining operations.

Worm Gearbox – Offers high torque output and compact size; perfect for space-limited applications.

Planetary Gearbox – Compact and powerful; used in robotics and automation.

SMSR Gearbox – Easy to install and maintain; best for conveyors and material handling.

Understanding these types helps industries choose the right gearbox for their needs.

Role of Gear Oil Pumps

A Gear Oil Pump ensures the gearbox is always lubricated for smooth operation. Nisuka, a top Gear Oil Pump Manufacturer in India, offers pumps designed for continuous oil circulation, minimizing friction and heat inside the gearbox. This extends the life of the gearbox and reduces breakdowns.

Why Suspension Magnets Are Crucial

Suspension magnets are essential for separating iron contaminants from conveyor systems. As a trusted Suspension Magnet Manufacturer in India, Nisuka supplies high-grade magnets that ensure product purity and protect downstream equipment from damage.

Conveyor Belt Tensioner:

A conveyor belt tensioner ensures the belt maintains proper tension and alignment, which is key to avoiding slippage and wear. As a Conveyor Belt Tensioner Manufacturer in India, Nisuka offers adjustable and spring-loaded tensioners designed for different belt widths and loads.

Plummer Blocks:

Plummer blocks support rotating shafts and reduce vibration. Being a reputed Plummer Block Manufacturer in India, Nisuka manufactures blocks that are easy to mount, maintain, and suitable for all heavy-duty applications.

Final Thoughts

Nisuka Industries is not just a Conveyor Gearbox Manufacturer in Ahmedabad; it is a one-stop solution for various industrial power transmission products. From SMSR gearboxes to V-belt pulleys, gear oil pumps, plummer blocks, and suspension magnets, Nisuka delivers quality, durability, and innovation.

With their deep expertise, customized solutions, and wide product range, Nisuka Industries has truly earned its place as the No. 1 Conveyor Gearbox Manufacturer in Ahmedabad, India.

#Conveyor Gearbox Manufacturer in Ahmedabad#Conveyor Gearbox supplier in Ahmedabad#Conveyor Gearbox exporter in Ahmedabad

0 notes