#MetalCuttingTechnology

Explore tagged Tumblr posts

Text

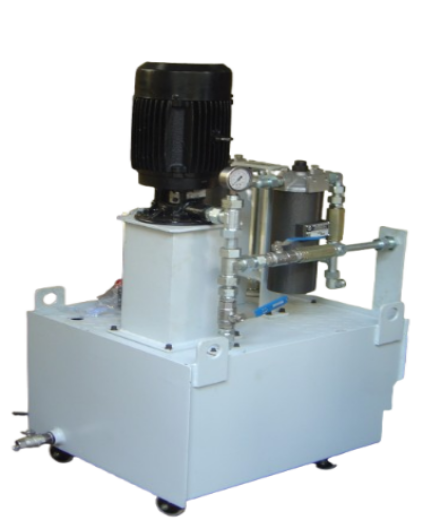

Precision Machining with High Pressure Through Coolant Systems by Lex Technoaid

Lex Technoaid’s High Pressure Through Coolant System enhances CNC machining efficiency by delivering clean, pressurized coolant directly to the cutting zone. Designed for high-performance metal cutting applications, it helps extend tool life, maintain temperature control, and improve surface finish. Ideal for modern manufacturing setups seeking precision and productivity.

#CoolantSystem#HighPressureCoolant#CNCManufacturing#MachiningSolutions#IndustrialFiltration#ToolLifeExtension#PrecisionMachining#MetalCuttingTechnology#ManufacturingInnovation#LexTechnoaid

0 notes

Text

Tube Laser Cutting Machine Manufacturers

Tube laser cutting machine manufacturers specialize in designing, producing, and supplying high-precision laser cutting systems for metal and non-metal tubes or pipes. These machines utilize advanced laser technology to deliver accurate cuts, intricate designs, and seamless finishes on tubular materials such as steel, aluminum, copper, and more.

Manufacturers often focus on innovative features like CNC integration, automated loading and unloading systems, and support for various tube sizes and shapes (round, square, rectangular, or custom profiles). Their products are widely used in industries such as automotive, aerospace, construction, furniture, and metal fabrication, where precision, speed, and efficiency are critical.

Key manufacturers also prioritize offering customized solutions, user-friendly interfaces, energy efficiency, and after-sales services, including maintenance and technical support, to meet diverse client needs.

#TubeLaserCutting#LaserCuttingMachine#PrecisionCutting#TubeFabrication#MetalCuttingTechnology#IndustrialMachinery#MetalFabrication#LaserCuttingExperts#CNCManufacturing#TubeProcessing#AdvancedManufacturing#MetalworkingMachines#InnovativeCuttingSolutions#FabricationTechnology#AutomationInManufacturing

0 notes

Text

The best metal laser cutting machine for precision cuts

This advanced machine uses fiber optic technology to cut various metals with exceptional precision, speed, and versatility. Weldarc India, a leading manufacturer of metal laser cutting machine, offers top-notch solutions for metal fabrication and manufacturing.

Key Features of the Best Metal Laser Cutting Machine:

1. Precision Cutting: Fiber laser cutting machines can create intricate designs and complex shapes with minimal material wastage.

2. High-Speed Production: These machines are known for their high-speed cutting capabilities, increasing productivity without compromising on quality.

3. Versatility: Fiber laser cutting machines can effortlessly cut through a wide range of metal thicknesses, making them suitable for diverse industrial applications.

4. Low Maintenance: These machines require minimal maintenance, resulting in lower operational costs and increased uptime.

5. Energy Efficiency: Fiber laser cutting machines are more energy-efficient than traditional cutting methods, leading to cost savings and environmental sustainability.

Fiber Laser Welding Machines - Enhancing Metal Fabrication Capabilities:

Fiber laser welding machines deliver precise and efficient welding for various metal components, ensuring superior weld quality, minimal distortion, and enhanced productivity.

In conclusion, investing in a high-quality fiber laser cutting and welding machine from Weldarc India can enhance metal fabrication capabilities, meet production demands, and elevate the quality of products. Read more

#BestMetalLaserCuttingMachine#PrecisionCuts#FiberLaserCuttingMachine#MetalFabrication#WeldarcIndia#HighSpeedCutting#VersatileCuttingMachines#LowMaintenanceMachines#EnergyEfficientCutting#LaserWeldingMachines#MetalCuttingSolutions#FiberLaserWelding#MetalIndustryInnovation#MetalCuttingTechnology#MetalManufacturingSolutions#LaserCuttingExperts#WeldQuality#IndustrialCuttingSolutions#AdvancedLaserTechnology#MetalFabricationEfficiency#SustainableCuttingSolutions

0 notes

Photo

We can cut any metal up to three quarters of an inch thick (4 ft by 8 ft) . . . . .

#metalcutting#metalcuttingtools#metalcuttingbandsaw#metalcuttingmachine#metalcuttinglaser#metalcuttingtechnology#metalcuttingdisc#metalcuttingsaw#metalcuttingdie#metalcuttingblade#metalcuttings#metalcuttingtool#metalcuttingservice#metalcuttingmama#metalcuttingmachinery#customcutting#custommetalwork#custommetal#dtla#happeningindtla#dtlaartsdistric#customlosangeles

0 notes