#MetalExtraction

Explore tagged Tumblr posts

Text

Metal Extraction Via Hydrometallurgy

Driving excellence in non-ferrous metal extraction through hydrometallurgy. Discover how our tailored solutions can enhance your extraction process while reducing environmental impact.

For more info, visit https://www.saumitgroup.com/

#SaumitGroup#Hydrometallurgy#MetalExtraction#Sustainability#MetalRecovery#MineralProcessing#solvents#nonferrousmetals

0 notes

Photo

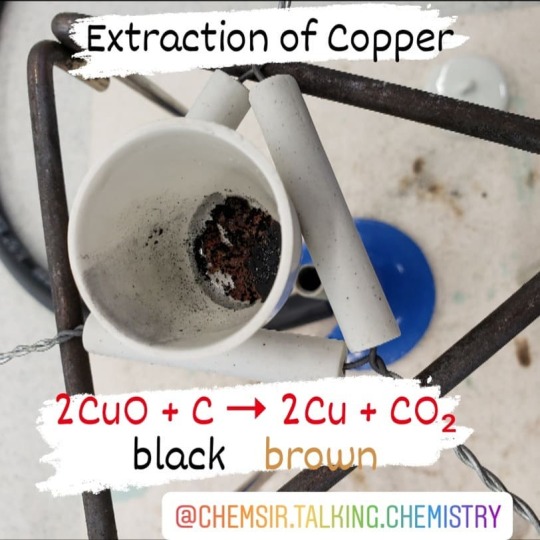

Do you know how to extract copper from copper(II) oxide in the laboratory? 😆 ------------------------------------------------------------------------ 👍Please like, comment and share @chemsir.talking.chemistry and tag your friends. ------------------------------------------------------------------------ 👉Follow @chemsir.talking.chemistry and @chemsir_lee_wai_hon for more chemistry materials. ------------------------------------------------------------------------ 🙏Thank you for your support. Wish you enjoy the page! ------------------------------------------------------------------------ #ChemsirTalkingChemistry #chem #chemistry #science #experiment #copper #Cu #Copper(II)Oxide #CopperOxide #CuO #extraction #extract #MetalExtraction #CarbonReduction #chemistrylover #chemistrylovers #chemistryaddict #chemistryaddicts #hkdse #dse #Chemsir同你講化學 #化學 #科學 #Chemsir做實驗 #銅 #氧化銅 #氧化銅II #金屬提取 #碳還原 #Chemsir https://www.instagram.com/p/CGZ8WXcBpNn/?igshid=bvxab04ftpag

#chemsirtalkingchemistry#chem#chemistry#science#experiment#copper#cu#copperoxide#cuo#extraction#extract#metalextraction#carbonreduction#chemistrylover#chemistrylovers#chemistryaddict#chemistryaddicts#hkdse#dse#chemsir同你講化學#化學#科學#chemsir做實驗#銅#氧化銅#氧化銅ii#金屬提取#碳還原#chemsir

3 notes

·

View notes

Text

Global Regenerative Feedback Conveyors Market Global Market Estimation, Dynamics, Regional Share, Trends

Ore mining continues to follow historic trends, but more recently toward higheraltitudes. Today, altitudes of 3,000 metersto 4,000 meters abovesea level are by no means unusual for new copper mines. This places very heavy stress on personnel.At high altitudes, it is recommended to install onlythose equipmentswhich are directly required for mining the ore.A very attractive solution to this problem is the use of conveyors with downwardbelt mechanisms, which transport the mineral from the mineto the concentrator.

The bidirectional nature of the power flow of electrical machinespermits the transformation of the potential energy of theore in the conveyor into electrical energy that can be regeneratedto the electrical supply of the mine, generating importantenergy savings.When the amount of ore handled is in the range of100,000 tons/day, power produced by a conveyor may surpassseveral megawatts and must be delivered to the electricalutility.A downhill conveyor is mounted between the quarry areaand the raw material section of the plant. Because of the operational requirements, the drive is to beadjustable in speed, and has to be capable of regenerating the power on the downhill section.All operating processes nowadays are monitored, with sophisticated control systems. A huge advantage asserted for Active Front End (AFE) technology is the fact that it is network friendly.

Request to view Brochure Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=6529

Rapid augmentation in the high-altitude metal mining industry combined with increased demand of metals for construction and other industrial applications, make up for growth drivers for regenerative conveyors. Moreoveractive front end solutions result in less stress for personnel due to high altitudes, and theequipment does not need to be highly derated. Despite the positive growth, the industry has been facing certain restrictions in terms of mining extraction methods and the extent of extraction allowed. Government regulations have been put into place over concerns of ecological imbalance and environmental hazards that excavation and mining of metals and non-metals has caused over the years. Mining has had a major impact on agricultural lands as well. Intensive capital requirement and availability of expertise for operations are also some of the factors that have hindered the progress of mining, thereby reducing the demand for regenerative conveyors. Despite all the limitations, new opportunities lie in store. With the advent of new eco-friendly mining technologies, metal mining could see a spur of growth in the near future.

Request for Customization @

https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=6529

For conveyors generating several megawatts of energy per day, medium-voltage drives must be considered.At this voltage level, converter topologies can be segmented based on the type of drive installed, viz. cyclo-converters, current-source inverters (CSIs),three-level voltage-source inverters (VSIs), and cascadedmultilevel (CML) inverters.Conveyors with longer belt length have proven to be a challenge for applications involving drive and control techniques. Depending on material to be transported and regional characteristics, a customized drive system must be installed for each separate condition. In certain areas these drive systems have to be selected based on standards set by local environmental agencies as well.

Geographically, demand for regenerative conveyors is concentrated in mining hotspots across the globe. Most of the world’s mining and production of metals is carried out in Australia in the AsiaPacific region followed by Sri Lanka, Myanmar Thailand, Laos, Malawi and Cambodia. The state of Montana and Arizona in the U.S. lead the market in the North American region. No significant deposits or mines exist nor have they recently been discovered in Europe; hence mining activities there are limited. The African region also boasts a significant metalextraction dominated by Tanzania, Kenya, Nigeria, Madagascar and South Africa.

0 notes

Text

Solvents for Solvent Extraction Process

Saumit Group is a pioneer supplier and importer of Solvents used for the Hydro Metallurgy and Solvent extraction process. We do supply entire range of Solvents to e tract Conalt, Nickel, Lithium, Copper, Zinc, Molybdate to name a few.

For more info, visit www.saumitgroup.com

#SaumitInnovation#HydroMetallurgy#MetalExtraction#SaumitSolutions#AdvancedSolventExtraction#NonFerrousMetal#HydroMetallurgyExperts#ChemicalEngineering#SustainableMetalProcessing

0 notes

Photo

[M.C. Challenge] Which of the following metals can be extracted by heating metal oxide with carbon (i.e. carbon reduction)? A. sodium B. magnesium C. zinc D. aluminium 🤔 Choose the best answer👆 🤔 ------------------------------------------------------------------------ 👍Please like, comment and share @chemsir.talking.chemistry and tag your friends. ------------------------------------------------------------------------ 👉Follow @chemsir.talking.chemistry and @chemsir_lee_wai_hon for more chemistry materials. ------------------------------------------------------------------------ 🙏🏻Thank you for your support. Wish you enjoy the page! ------------------------------------------------------------------------ #ChemsirTalkingChemistry #chem #chemistry #science #ChemsirMCChallenge #extraction #extract #MetalExtraction #CarbonReduction #metal #elements #element #2021dse #2022dse #2023dse #hkdse #dse #dsefighter #dse2021 #dse2022 #dse2023 #Chemsir同你講化學 #化學 #科學 #教育 #金屬提取 #碳還原 #金屬 #元素 #Chemsir https://www.instagram.com/p/CGhhKVwBt0c/?igshid=1gbjlz3ludnpc

#chemsirtalkingchemistry#chem#chemistry#science#chemsirmcchallenge#extraction#extract#metalextraction#carbonreduction#metal#elements#element#2021dse#2022dse#2023dse#hkdse#dse#dsefighter#dse2021#dse2022#dse2023#chemsir同你講化學#化學#科學#教育#金屬提取#碳還原#金屬#元素#chemsir

1 note

·

View note

Text

Regenerative Feedback Conveyors Market Trends, Market Share,Opportunities and Forecast to 2016- 2024

Ore mining continues to follow historic trends, but more recently toward higheraltitudes. Today, altitudes of 3,000 metersto 4,000 meters abovesea level are by no means unusual for new copper mines. This places very heavy stress on personnel.At high altitudes, Regenerative Feedback Conveyors Market is recommended to install onlythose equipmentswhich are directly required for mining the ore.A very attractive solution to this problem is the use of conveyors with downward belt mechanisms, which transport the mineral from the mineto the cconcentrate

The bidirectional nature of the power flow of electrical machinespermits the transformation of the potential energy of theore in the conveyor into electrical energy that can be regeneratedto the electrical supply of the mine, generating importantenergy savings.When the amount of ore handled is in the range of100,000 tons/day, power produced by a conveyor may surpassseveral megawatts and must be delivered to the electricalutility.A downhill conveyor is mounted between the quarry areaand the raw material section of the plant. Because of the operational requirements, the drive is to beadjustable in speed, and has to be capable of regenerating the power on the downhill section.All operating processes nowadays are monitored, with sophisticated control systems. A huge advantage asserted for Active Front End (AFE) technology is the fact that it is network friendly.

Request to view Brochure Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=6529

Rapid augmentation in the high-altitude metal mining industry combined with increased demand of metals for construction and other industrial applications, make up for growth drivers for regenerative conveyors. Moreoveractive front end solutions result in less stress for personnel due to high altitudes, and theequipment does not need to be highly derated. Despite the positive growth, the industry has been facing certain restrictions in terms of mining extraction methods and the extent of extraction allowed. Government regulations have been put into place over concerns of ecological imbalance and environmental hazards that excavation and mining of metals and non-metals has caused over the years. Mining has had a major impact on agricultural lands as well. Intensive capital requirement and availability of expertise for operations are also some of the factors that have hindered the progress of mining, thereby reducing the demand for regenerative conveyors. Despite all the limitations, new opportunities lie in store. With the advent of new eco-friendly mining technologies, metal mining could see a spur of growth in the near future.

Request for Customization @

https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=6529

For conveyors generating several megawatts of energy per day, medium-voltage drives must be considered.At this voltage level, converter topologies can be segmented based on the type of drive installed, viz. cyclo-converters, current-source inverters (CSIs),three-level voltage-source inverters (VSIs), and cascadedmultilevel (CML) inverters.Conveyors with longer belt length have proven to be a challenge for applications involving drive and control techniques. Depending on material to be transported and regional characteristics, a customized drive system must be installed for each separate condition. In certain areas these drive systems have to be selected based on standards set by local environmental agencies as well.

Geographically, demand for regenerative conveyors is concentrated in mining hotspots across the globe. Most of the world’s mining and production of metals is carried out in Australia in the AsiaPacific region followed by Sri Lanka, Myanmar Thailand, Laos, Malawi and Cambodia. The state of Montana and Arizona in the U.S. lead the market in the North American region. No significant deposits or mines exist nor have they recently been discovered in Europe; hence mining activities there are limited. The African region also boasts a significant metalextraction dominated by Tanzania, Kenya, Nigeria, Madagascar and South Africa.

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

Contact

Transparency Market Research

State Tower,90 State Street,Suite 700,

Albany NY - 12207,United States

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Email: [email protected]

Website: http://www.transparencymarketresearch.com

0 notes