#Moldflow Service

Explore tagged Tumblr posts

Text

Unlocking Efficiency in Manufacturing: The Power of Mold Flow Analysis

Imagine a world where every plastic part is flawless, embodying perfection in both form and function. Thanks to this vision, the reality is near. Advanced technologies like Mold Flow Analysis. This method not only enhances the quality of plastic parts but also optimizes the manufacturing process, resulting in major cost reductions and better product durability. The essence of Mold Flow Analysis lies in its ability to predict and solve injection molding challenges before they become costly problems.

Understanding Mold Flow Analysis

Mold Flow Analysis is a critical tool used in the injection molding industry to simulate the flow of plastic materials through a mold. This analysis helps manufacturers predict potential defects and determine the optimal mold design and processing parameters to guarantee the output's quality at last. By analyzing how the molten plastic flows, cools and solidifies within the mold, engineers can make informed decisions that enhance mold design, reduce waste, and improve the overall efficiency of production.

The Role of Moldflow in Modern Manufacturing

As sectors aim for higher accuracy and efficiency, software solutions like Moldflow become indispensable. Moldflow software provides detailed insights into the molding process, offering predictions on how the plastic will behave, which in turn allows for adjustments before committing to a full-scale production. This preemptive approach is vital in avoiding costly design errors and in ensuring that the products meet rigorous quality standards.

Advancing with Technology: Integration in Manufacturing

Integrating Moldflow Service into manufacturing processes represents a proactive approach to quality assurance. Utilizing Moldflow Service early in the design phase helps in identifying the ideal materials, the most effective mold design, and the optimal processing conditions. This integration results in a smoother production flow, minimal downtime, and a faster turnaround from design to final product, which is crucial in today's fast-paced market environments.

The Impact of Moldflow on Industry Standards

The influence of Moldflow Service extends beyond just enhancing individual products. It sets new industry standards for quality and efficiency, encouraging manufacturers to adopt more sophisticated and technologically advanced practices. This service not only aids in complying with industry regulations but also pushes the boundaries of what can be achieved in plastic manufacturing, ensuring that every product is not only high-quality but also manufactured in an environmentally responsible way.

Conclusion

In conclusion, the strategic implementation of technologies like Mold Flow Analysis and Moldflow Service is transforming the manufacturing landscape. These tools are pivotal in refining product design, enhancing quality, and optimizing production efficiency. For those interested in exploring these services, visiting the website FEAmax.com provides extensive resources and expert insights into how these analyses can be integrated into manufacturing processes. Embracing these advanced solutions equips manufacturers with the tools necessary to thrive in a competitive industry, making every production step more predictable, controlled, and efficient.

Blog Source Url:-

0 notes

Text

Automotive Interior Design & Simulation Services | HVAC CFD Analysis Services

Satven's automotive interior design and simulation services include HVAC CFD analysis to ensure optimal comfort and safety. Learn more about our expertise in interiors.

Competencies: Development of 3D geometry including B-surface, attachment/assembly features and GD&T drawings from Class-A surface from OEM Statutory studies – Head impact study & Veiling glare index study Development of fit & finish sections 3D tolerance analysis for gap & flush requirement Reverse engineering – development of surfaces from scan data Moldflow studies Tool & fixture design – injection molds, assembly fixtures and inspection fixtures

Domains: IP, Door trims, Pillar trims, Console, Front & Rear bumpers, Fascia

1 note

·

View note

Text

product engineering services

The process of turning a concept into a fully working product is called product engineering. Typically, the product development process is broken down into phases, with several project team members focusing on distinct topics. The hardware design is finished by CAD engineers hired by Product Engineering Services in India, while the software is finished by software engineers.

Each project often receives a team of dedicated product engineers, whose job it is to steer the product concept through the different product development stages and into mass production so that it may be marketed. In certain businesses, a project manager—who need not be an engineer by training—fills this role.

Product engineering phases cover the whole lifespan of a product, from conception through disposal. Therefore, it is essential to comprehend the different stages of product engineering while dealing with product engineering. Listed below are the many phases of product development:

The conception of an idea

This is the initial phase, which entails both conceptualising and outlining the idea's requirements and specifications. To determine if moving forward is worthwhile, additional research is intended. Even though a topic seems intriguing at first, it may not be worthwhile to pursue.

Designing:

The next step is to create engineering drawings to make the notion a reality when it has been finalised. This stage is when any adjustments and updates are made before the design is finalized.

Development:

The next step involves the development or assembly of the final product. The project's implementation, cost control, and optimization are all carefully considered.

Testing and validation:

To ensure that a developed product is error-free and suitable for use as intended, it must consistently pass stringent quality tests. Before the product is made available, any issues must be found and any necessary changes, alterations, or fixes must be made.

Introduction to the Market:

Following development, the product is made available to the public. Users' opinions must be gathered in order to enhance the product in next iterations. Additionally, it can be sent to outside product testers to help them comprehend the user experience.

Maintenance/Re-engineering:

The product will undergo regular updates, improvements, and maintenance once it is put on the market. It is necessary to build a support system in order to handle customer issues and swiftly fix them. Food must be available during the anticipated lifespan of the product. Re-engineering is often required since goods need to be scaled to meet future customer demands. This not only helps to satisfy customer needs, but it also makes it possible for products to advance.

The following technologies are used by Rheomold's Product Engineering Services: To examine, evaluate, and finalise design concepts digitally nowadays, designers from across the world use 3D design tools.With Rheomold's enhanced product designing services, designers may streamline and optimise their work processes, boost output, enhance design quality, enhance communications, and help build a sustainable manufacturing process.

Rheomold's process-driven methodology aids clients with anything from design concepts to industry-specific iteration processes. Other engineering support organisations, such FEA and manufacturing simulations like moldflow, can assist customers in identifying potential issues early in the design phase and resolving them. As a result, our clients are able to cut costs, avoid redoing work, and accelerate their time to market.

Packaging and Conceptualization are a crucial area that also has to be given careful consideration, along with Product Engineering.

Conceptualization is an inventive process in which product designers use their imaginations to generate countless alternatives. After extensive discussion with the client, a final design that satisfies both aesthetic and functional objectives was produced.

Best-in-class product engineering services are provided by Rheomold in India, enabling any product to be created to seamlessly blend into a current or brand-new environment. Rheomold designs are consistently verified for manufacturing simulation. During the engineering design process, all dimensional factors—including tolerance, stack-up, and GD&T—are taken into consideration.

0 notes

Text

Autodesk Moldflow Adviser Ultimate 2021.2 Latest File Patch

Autodesk Moldflow Adviser Ultimate 2021.2 Latest File Patch

Autodesk Moldflow Adviser Ultimate 2021.2 Patch Key Visual Communication & Rendering. Download Autodesk Moldflow Adviser Ultimate 2021.2 Download Latest Version. The app features even some services that are not easily used on the full standalone version of the app.One such feature is a GPS locator, which can showcase the exact position of the user within a drawing or architectural plan, thus…

View On WordPress

0 notes

Text

Fusion 360 Moldflow

Fusion 360 Download

Technical Support Specialist, Moldflow and Fusion 360 Autodesk Construction Solutions Portland, OR 2 weeks ago Be among the first 25 applicants. Fusion 360 โปรแกรมเดียวที่รวม CAD, CAM, CAE ไว้ด้วยกัน รวบรวมการออกแบบ การผลิต และ การตรวจสอบไว้ในโปรแกรมเดียว เหมาะสำหรับงานออกแบบ. We at Mechman Solution provide wide-ranging Autodesk line of products such as fusion 360, powershape, featureCAM, Moldflow, Netfab etc. Software Features Links PowerMill Features. On October 22, 2020, the latest Autodesk Moldflow Insight, Moldflow Synergy, and Moldflow Adviser releases became available for subscribers! Some users were able to participate earlier this year in the Moldflow Insight & Synergy 2021 Beta program to help the developers test many of the great new features and functionalities within this latest release.

The principal products are Fusion 360, and its family (Fusion 360 with FeatureCAM, PowerMill, PowerShape, or PowerInspect), Autodesk Alias, Autodesk Inventor, Autodesk Vault, Autodesk CFD (formerly Autodesk Simulation CFD), Moldflow, Netfabb, VRED, and the Product Design & Manufacturing Collection, which includes Inventor Nastran (formerly.

Autodesk® Moldflow® software provides a broad range of simulation tools for injection mold design, plastic part design, and the injection molding design process to help engineers and analysts create better products by enabling them to make crucial decisions earlier in the design process.

Autodesk® Moldflow Features

Autodesk Moldflow has features and tools that allow you to:

Validate and optimize plastic part and mold designs before manufacturing—increasing efficiency, minimizing reliance on physical prototypes, reducing costs, and improving product quality.

Optimize the position of the gates and runner designs to optimize product quality and minimize costs.

Evaluate and optimize plastic part and injection mold designs to help control shrinkage and warpage based on grade-specific materials and processing parameters. You can output accurately compensated models for tooling or further geometry modification.

Calculate the effect of fiber orientation, in fiber re-enforced plastics, on product shrinkage and warpage and make these effects available to structural analysis products to evaluate the performance of the molded part.

Optimize the layout of the cooling system and evaluate the impact of different mold materials to improve product quality and reduce the cycle time. Moldflow Insight supports state of the art cooling technologies, including rapid-temperature cycling, conformal cooling technologies and Induction Heating.

Optimize the injection molding process and part design with Moldflow® Insight’s Design of Experiments (DOE) capabilities.

Use Moldflow Insight to simulate the standard thermoplastic and thermoset molding processes, as well as many variations (e.g. two-shot overmolding, injection compression molding, compression molding, bi-injection molding, MicroCellular injection molding etc.)

Simulate with confidence using precise material data on more than 10,000 grade-specific plastics. Get additional materials tested, expert data-fitting services, and extensive material databases with the Moldflow Plastics Labs.

Moldflow Insight provides direct editing tools in Synergy to evaluate different variations of part designs and the resulting impacts on manufacturability on the fly.

Fusion 360, included with Moldflow Synergy and Adviser subscriptions, enables quick CAD model simplification, cleanup, and editing that can help any user save time on model preparation, improve mesh quality, and explore the impact of design changes more quickly. Fusion 360 can import CAD data in a variety of native and neutral CAD formats, identify potential problems before they occur, and help you quickly remove excess detail.

Moldflow Insight provided cloud enabled options that offers the benefit of expanded solve capacity. Solve many simulations in parallel in the cloud, while freeing up local resources. These cloud capabilities allow the analysis of scenarios and designs overcoming local resource restrictions.

Helius PFA included with Moldflow Insight Ultimate subscription to pass as-manufactured inputs in to a structural analysis.

Purchasing Autodesk Moldflow

Fusion 360 Download

Call or e-mail us if you are interested in purchasing Autodesk® Moldflow™. Applied Engineering is authorized to sell Autodesk products throughout the United States and has offices in Minnesota, North Dakota, South Dakota and Wisconsin.

0 notes

Photo

New Post has been published on https://www.injectionmouldchina.com/shrinkage-prediction/

Shrinkage Prediction

PC reenactment is an undeniably basic in plastics item and form plan for china injection molded parts factory, with Autodesk/Moldflow, Core Iech/Moldex3D, and Sigma Engineering/Sigmasoft giving shrinkage assessment to shaped parts. To exhibit the examination for the bezel, Autodesk/Moldlow (Molding Plastics Insight, MPI 2014 [8]) was performed for Cycolac MG47. The isotropic shrinkage rates anticipated by the recreation are given in injection mold services china expecting similar conditions as the earlier investigation: a mid-range liquefy temperature, mid-range coolant temperature, a steady pressing weight of 66 MPa for a period of6 s, and a cooling season of 20 s.

The outcomes demonstrate that the shrinkage changes generally over the form hole. Low shrinkage rates (on the request for 0.3 % and underneath) are anticipated in the slight territories around the edge that freeze at high dissolve pressures. Specifically, the most minimal shrinkage of 0.1 % adjoining the door is anticipated as this region of the hole totally freezes at high soften pressures over 100 MPa while the polymer liquefy is filling the rest of the pit. Moderate shrinkage rates (around 0.6%) are anticipated in the majority of the part, which is more than the 0.31 % shrinkage recently anticipated by the manual investigation. High shrinkage rates (over 1 %) are anticipated close to the furthest limit of fill. The high shrinkage rate toward the finish of fill is because of the way that the material closer the entryway is hardening and forestalling extra polymer liquefy from arriving at the finish of stream to make up for volumetric shrinkage.

The outcomes show a critical issue for the shape planner and the end-client: what shrinkage worth ought to be utilized? In the event that a normal shrinkage of 0.6% is utilized, at that point the part width might be out of detail due to the exorbitant unaccounted shrinkage along the top and base edges.

There are a few unique procedures that can be utilized by the shape planner if nonuniform shrinkage happens. One progressively regular technique, which is upheld by the joint utilization of PC reproduction and CNC machining, is for the form planner to utilize distinctive shrinkage esteems in various parts of the shape. For the PC bezel appeared in oem/odm injection mould factory, the decay may pick a shrinkage estimation of 0.7% for the left and right sides and a shrinkage esteem over 1 % for the top and base sides. In this model, this procedure is moderately simple to utilize and would probably be fruitful since the calculation is generally straightforward. For more unpredictable item calculation with a firmly interconnected surface, in any case, the utilization of non-uniform shrinkage esteems can turn into an intricate and hazardous undertaking.

Another regular way to deal with acquiring tight resistances is to guarantee more uniform shrinkage over the form hole through the expansion of various entryways. By expanding the quantity of entryways for the PC bezel from two to four as appeared in china plastic injection molding, the filling and pressing weights and in this way the shrinkage rate are completely made more uniform over the form pit. In this model, the extra two entryways have diminished the greatest shrinkage from 1.3 % at the focal point of the top edge in Fig. 10.8 to 0.74% at the corners in high precision plastic injection mould factory. Besides, the normal shrinkage in the hole has been decreased from 0.7 % for the twogated shape plan to 0.65% for the four-gated form plan.

#china injection mold maker#china injection molded parts factory#china plastic injection molding#china tooling-building services#custom plastic moulding#factory injection mould#high precision mould china#high precision plastic injection mould factory#injection mold services china#injection mould quotation#injection mould tooling china#injection moulder services#injection moulding services#medical devices mould china#oem/odm automotives injection mold factory#oem/odm industrial injection moulding factory#oem/odm industrial mould factory#oem/odm injection mould factory#pipe mould china#plastic precision injection mould pricelist#pp joint fitting mould manufacturers#stainless steel metal injection moulding housing manufacturers china#Plastic Mold

0 notes

Text

CNC Milling Part

Model Manufacturing CNC Services 24/7

We offer various completion alternatives and higher-level completions for every model assembling administration. We can have you

models in as meager as a couple of days, giving you an opportunity to test the item's fit, structure and work and permitting you to quick come into creation. At xytmachinedparts, we give fast assembling and complete item improvement administrations. These contributions include: structure thinks about, practical, and visual verification of rule models. We can construct tests in 3D printing, SLA model, CNC exactness machining, CNC turning, and quick tooling techniques. Our accomplished building staff work with, Pro-E, UG, Solid Works, and MoldFlow demonstrating projects to create parts for usefulness and xytmachinedparts We can

help customers all through the item advancement process from model to large scale manufacturing. We take extraordinary pride in giving its customers exceptional fast prototyping administrations and CNC machining. Our in-house tooling enables us to expertly process, drill, tap, bore, turn, propose, counter bore and string your metals (titanium, aluminum, steel, metal, copper .and so on) and plastic polymers (Delrin, ABS, PE .and so forth) all while holding resistances down to 0.01MM all through the assembling procedure. We realize that speed is basic all through the whole item advancement arrange. We sincerely need to be your accomplice in item advancement!Injection part, tooling, rapid tool, machined part, CNC machining part, CNC lathing part, CNC Milling Part, Rubber Part, Prototype Supplier, Stamping and laser. Visit here for More info- www.xytmachinedparts.com

Our Services 24/7

Casting part

Casting parts

Rapid tool

Temporary mold

Mould

Moulding

Prototype

CNC prototype

0 notes

Text

Why We Choose Plastic Injection Molding ?

Making of top quality plastic injection molds is the main business of Loxin. The company is well equipped with many professional mold designers with great experience in mold structures and plastic properties, offer top plastic injection molding for close to 10 years. This makes Loxin Company the best plastic molding company in the market.

What’s more, the designers consider each case very important, before structuring begins, the company architect starts with running Mold Flow Analysis, then goes to a specialized meet for each form with the injection depth and tool shop in order to keep away from potential production issue and troubleshoot. This is done to certify the high caliber as well as short lead time

The company designers are ready to provide the suitors with appearance design, industrial design, structure design, mold flow analysis, Design For Manufacturability and mold design with high quality.

Loxin provides is determined to provide quality services and products as well with less cost within the shortest time. Making the company very standard to stand firm the competition in today’s market, hence outdoing the competitors easily. Each molded plastics part should run easily through product configuration, instrument building, tryouts, assembly, fabricating, field applications. Our mastery in computer-aided engineering in combination with the experience of many formed items gives an important connection to achieving the objective of delivering quality items at the most reduced expense and in the briefest time.

Our architects will analyze well the mold filling, the deformation and cooling for each part using the tooling configuration and experimentally validating key steps in making your product successfully designed and built. The unmatched way of dealing with each venture gives the best and is cost-effective and time short.

Contents

Designing

Our Project Management

Management Objectives

How Much China Plastic Injection Mold Cost?

How Much Cost For Quality China Plastic Injection Mold ?

How LOXIN’s Plastic Injection Molding Process Works

Your Unmateched Partner in Mold Making-LOXIN Mold

Your Reliable China Plastic Mold Manufacturers

Designing

We give a wide scope of services to assist customers with front-end work that a product needs before production begins. A portion of those services incorporate fundamental structure, material selection, cost estimating, shape plan, evaluation and procurement, surface modeling, and good communication with the clients building department. For every part, we fabricate we guarantee the DFM study as well as mold flow examination which improves and bolster the mold structure design. We present to you the best assets accessible including quality workmanship, high technology equipment, and product development methods that are sufficiently adaptable to address the issues of your exceptional prerequisites that can help the worker spare cost and time.

Our Project Management

Good project management is the way to the achievement and quality of the items. A Project Engineer with rich knowledge in tooling and plastic injection mold is selected for each project. The task specialists will be dependable in engineering the project progress including the tooling plan and management ofother workers. The project engineer additionally ensures that clients specialized requirement is pursued.

Management Objectives

The company has highlighted project management objectives to easily meet customer objectives. The objectives are based on on-time delivery, keeping good communication between engineers and clients, assurance to clients that the products are made to customers standards and proper inspection of all produced products before release.

Lastly, due to the great expertize of the workers, the company relies on software like Moldflow, Surfcam, CATIA, Solidworks, Autocad, Mastercam, Unigraphics and Animatronics to ensure high-quality products. Hence Loxin choosesplastic mold injection for you.

#plastic injection molding#injection moulding#injection mold maker#plastic injection molding company#plastic mold maker

0 notes

Text

Precision and Innovation: Exploring the Role of Engineering Design and CAD Drawing Services

Imagine constructing a skyscraper or designing a complex machine without a detailed plan. This is where Engineering Design Services come into play, transforming abstract ideas into detailed blueprints. These services are essential in laying the groundwork for successful engineering projects, ensuring every aspect is meticulously planned and executed with precision.

Strategic Impact of Engineering Design Services

In the competitive world of engineering, Engineering Design Services provide a significant edge. They refine not only the aesthetic appeal of a project but also its functionality and sustainability. By collaborating with clients and stakeholders, these services ensure that every element of a project aligns with technical specifications and overall vision, setting the stage for successful implementation and long-term success.

The Role of CAD Drawing Services in Modern Engineering

Once the design phase is complete, the focus shifts to detailed visualizations provided by CAD Drawing Services. These services are indispensable in modern engineering, allowing for the creation of precise and detailed drawings. By visualizing every component in three dimensions, engineers and architects can ensure that all parts fit together seamlessly, reducing the risk of errors during the construction phase.

Enhancing Precision with CAD Drawing Services

The advancements in CAD Drawing Services have revolutionized the way engineering projects are visualized and executed. These services allow for the manipulation of intricate 3D models, providing a virtual simulation of the final product. This not only enhances the precision of the design but also allows for modifications to be made easily, ensuring that the final product meets all requirements and standards.

Navigating Future Challenges with Advanced Design Techniques

As technology continues to evolve, the integration of AI and machine learning with Engineering Design Services is becoming increasingly important. These advanced techniques provide predictive insights and automated design adjustments, which are crucial for managing complex projects. Similarly, CAD Drawing Services are evolving to include virtual reality and augmented reality, offering immersive experiences that allow for better design comprehension and client engagement.

Ensuring Compliance and Global Standards

In the evolving landscape of global industries, adhering to international standards and regulations is crucial for success. Engineering Design Services and CAD Drawing Servicesplay a pivotal role in ensuring that projects meet these stringent requirements. By incorporating global best practices and standards into the design and drafting processes, these services help companies expand their reach and maintain competitiveness in international markets. This focus on compliance not only ensures safety and quality but also enhances the credibility and reputation of businesses in the global arena.

Conclusion

In a world where precision and efficiency are paramount, the roles of Engineering Design Services and CAD Drawing Services are more critical than ever. For businesses looking to leverage these advanced services, visitingfeamax.comoffers a gateway to industry-leading expertise and innovative solutions. Whether it’s refining a complex design or ensuring that every component fits perfectly, the right design services can transform potential into reality, driving success in every project.

Blog Source URL :

#Computational Fluid Dynamics Consulting#CFD Consulting Services#Cad Design Services#Computer Aided Design Services#Engineering Design Services#Cad Drawing Services#FEA Consulting Services#Finite Element Analysis Consultants#FEA Simulation Services#Engineering Manufacturing Services#Manufacturing Sourcing Services#Mold Flow Analysis#Moldflow Service#Moldflow And Casting Analysis

0 notes

Link

0 notes

Text

Inno Molding Company Limited Manufactures World-class Injection Mold And Plastic Molding Products For Its Global Clients

Inno Molding Company Limited is a national leader in China which manufactures injection molded and other plastic components for its global clients. It possesses over two decades of valuable experience in this commerce.

Most of the items people use on a daily basis are made from injection molding. For the technically uninitiated, It is a widely used method in the polymer industry for the purpose of mass production of any plastic items (trays, buttons for clothes, water bottles, etc.) and those plastic derivatives which partly constitute other items (electric switch coatings, mechanical gear covers, automobile parts, etc.). Inno Molding Company Limited is a leading plastic injection mold company in China which employs the aforementioned techniques to produce premium grade plastic, and injection molded components for its global clientele; which order from far-flung places like Australia, Canada, USA, UK, Russia, and Germany.

Among all the indigenous injection mold manufacturers in China, Inno Molding Company Limited has the most comprehensive and richest experience in this trade, a jaw-dropping twenty years. They have routinely fine-tuned their production processes to gain an edge over their competitors by offering plastic and injection molded deliverables at rock bottom sticker prices and without compromising the performance, durability, quality as well as the safety standards of their product offerings. Laptop plastic parts, smartphone covers, pen stands, battery cases, sofa arms, DVD covers, ring case, master box, automotive thermoplastic components are just a few names from their wide array of products.

Their plastic mold factory located in China’s Shenzhen, makes rubber injection molds, outer covers, slider mounts, base covers, mainframes, cylinder tanks, body compartments, socket covers and electric albums as well. Presently their arsenal contains five CNC machine sets, ten EDM sets, five slow-feed linear cutters, twenty injectors, eight wire cutter sets, eighteen milling machine sets, three lathe sets and six grinder sets. All their machines are imported from USA, Germany, and Switzerland. Their in-house design and prototyping studio are well-stocked with latest versions of Moldflow, Auto CAD, UG, PRO/E and Master CAM for all the experimentation, sketching and simulation requirements for creating new molds and test models.

The Quality inspectors, senior project managers, as well as design evangelists work together as a team to perform DFM analysis and FMEA risk assessment using Moldflow to eliminate design errors even before getting started with a new project. If they are awarded a turnkey project; they meticulously take care of the much required 3D modeling, drawing, and 2D prototyping pre-requisites. They’re after sales service is best-in-class. As they manage the packaging and national or international shipping on behalf of their esteemed clients as well, their customers only need to concentrate on marketing and product promotion, and this is the USP of Inno Molding Company Limited.

About Inno Molding Company Limited:

Inno Molding Company Limited is a nationally reputed Chinese injection molding and plastic molding products maker and has a world-class factory that serves their global clients coming from USA, UK, Germany, Russia, Canada, Australia and many other technologically advanced countries.

Media Contact Company Name: Inno Molding Co.,ltd Contact Person: James Yu Email: [email protected] Phone: +86-13590208318 Country: China Website: http://www.mouldingchina.com

The post Inno Molding Company Limited Manufactures World-class Injection Mold And Plastic Molding Products For Its Global Clients appeared first on Daily Press Release News To Whole World.

from Daily Press Release News To Whole World https://www.dailyprnews.com/inno-molding-company-limited-manufactures-world-class-injection-mold-and-plastic-molding-products-for-its-global-clients/

0 notes

Link

The company has moved from Tangxia Sicun to Tangxia Lincun since 2018. Factory floor area is over 10,000 square meters and Wing Tat has installed a great deal of imported and high-precision manufacturing machines and testing equipements, together with advanced CAD/CAM software systems such as UG NX12 and MoldFlow analysis system and also some sophisticated processing technologies.

We have developed into a modern enterprise integrating product design, plastic injection mold design, plastic mold manufacturing, product assembly, spray painting, pad printing and packaging operations. So far, it has more than 70 injection molding machines from Japan, Germany, Taiwan, China, etc., which can fully meet the high quality and high efficiency requirements of customers and continuously provide our best service.

0 notes

Photo

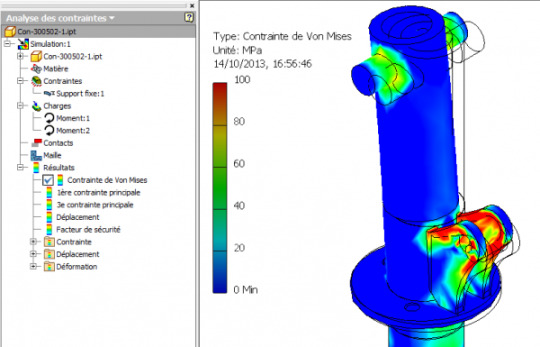

Rheomold is a product-based service provider Company Headquartered in Pune, India. Founded with an intention to provide cost effective and world class engineering solutions.

Rheomold, a leading Engineering Service Provider in Computer Aided Design-CAD, Computer Aided Engineering-CAE (Structural, NHV & Thermal Analysis) and Computational fluid dynamics-CFD, Tool Design & Development (Plastics, Sheet Metal & Die Casting) and Manufacturing Simulation (Moldflow, Forming & Casting) all under one roof, was founded in the year 2010. In simple terms, Rheomold can help customers with everything from design through manufacturing.

We have outstanding competence in offering our customers with efficient and cost-effective solutions.

Rheomold has always been in the forefront of providing cutting-edge, innovative solutions, establishing a competitive benchmark across all service industries. We are dedicated to providing high-quality solutions in a timely manner.

Visit us: https://www.rheomold.com/about-us.html

0 notes

Text

Simple ABS injection moulding

Simple ABS injection moulding through to specialist medical injection moulding. Once a tool is made, diy injection molders is the fastest and most cost-effective way to make up to hundreds of thousands of finished parts. For more than 50 years, Universal Plastic Mold has been a leading manufacturer of high tonnage custom and large part injection molding thanks to our one-stop facility. From its purpose built 40,000 sq ft facility in Rochester, Kent, ICM has a history of producing the most technically demanding Injection moulded and compression moulded components for a wide range of industries. Blow molding, also called blow forming, is a manufacturing process which is conducted by using thermoplastics by which hollow plastic profiles are formed. The mold itself can be highly intricate to facilitate the molding of a wide range of products. We fully understand the impact of tolerance management on your product assembly process and ensure that the service we provide is of the highest standard. We have been doing injection molding and manufacturing for over 24 years. We have 25 Plastic injection molding machines from 90 Ton to 2000Ton, that could solve all of your plastic molding manufacturing requirement. Material, molding, and on-site assembly services. As plastic injection moulding manufacturers, we are able to offer a full turn-key solution and support you in a number of post moulding operations such as sub and full assembly, heat staking and ultrasonic welding. Leveraging on our affluent industry proficiency, we provide Electrical Switches Moulding Service. With the advent of newer higher strength materials and fillers such as glass and carbon fiber, parts previously made out of metal are being replaced wit molded parts to save weight and fight corrosion. We can create high-quality, multi-material parts by injecting a thermoplastic elastomer or silicone rubber material directly onto a rigid plastic substrate. Cornick & Morris have the facilities to manufacture & control a wide range of plastic injection mouldings in technical material grades to tight tolerances. We will consult and select the best possible steel material which suit the functionality of customers products. Lastly, different injection molding processes, such as overmolding and insert molding, allow you to create plastic parts with unique characteristics such as enhanced strength, soft-grip surfaces, or added flexibility. With P.I.M.S you have the security of a supplier who will meet your quality and delivery requirements, as a small company you will receive a very personal service. Xometry utilizes a network of over a thousand top plastic injection molding companies - including a wide range of rapid Injection Molding machines - to provide services from tool design, to manufacturing feasibility, to production runs of simple and complex parts and multi-component assemblies. Injection molding produces parts by forcing molten material into a mold where it cools and hardens to the mold's shape.

All of this supplied by a company that is able to offer a high quality comprehensive plastic injection moulding service at ISO 9001 & ISO 14001 standards. Injection blow moulding is best for affordable manufacturing one-piece designs and hollow objects in large quantity. Rubber plastics are well suited for injection molding because they can easily be brought to molten state and poured into molds. Injection molding is the process of making custom plastic parts by injecting molten plastic material at high pressure into a metal mold. For a list of 10 common injection molding defects and how to fix or prevent them read here Consider gate locations and run simulations using moldflow software like Solidworks Plastics. The mold is then opened and ejector pins help to remove the plastic part from the tooling. Delivering a quality manufacturing service customized for you from our 20 years of experience in the industry. Use the icons below to easily navigate to additional Injection Molding resources. At OGM, we offer bespoke component assembly and finishing services. Malton Plastics is a UK plastic injection moulding company, providing manufacturing services to companies in the automotive, agriculture, construction, consumer appliances, electronics, floorcare, and home and garden sectors. Thermoset compression, transfer and thermoplastic molding services are available. All of mold parts and manufacturing process are fully inspected before mold assembly. The biggest advantage of working with Broanmain is the fact that the supplier customer relationship is seen as a true partnership which greatly aids all aspects of developing and sourcing products. Based on our diversified experience, we partner with you to offer design assistance, and tailored product development solutions. Established in 1982 Patterson & Rothwell have made thousands of Injection Mould Tools for all types of markets and they have invested over £1m in their toolroom in the past 3 years and can manufacture tooling up to 6 tons in weight. The success of A-T Mould is attributed to its young group of qualified engineers and competent technical staff and its mission to provide reliable services to its customers. For this same reason injection molding can be a poor choice for low volume production. With a rotary table on the B-half” of the tool that spins around 180���, this machine can utilize two B-half's”, allowing for more molded parts to be created high productivity. A company may choose to make a single cavity tool of that part to make sure all of the features will mold as desired. The injection moulding cost is also very low. Custom manufacturer of short run injection molded plastics. Note: waste plastic from injection molding manufacturing typically comes consistently from four areas: the sprue, the runners, the gate locations, and any overflow material that leaks out of the part cavity itself (a condition called flash ”). We also work with a number of tool makers both in the UK and overseas to to ensure your receive quality products from an affordable mould tool, while also adhering to your time schedule. So, whether you are looking for an ISO certified contract manufacturer specializing in custom injection molding or a global supplier of injection and blow molded thermoplastics, our directory can connect you with the ideal source. Our team is skilled in producing high-precision and durable plastic injection moulded parts. Plastic injection moulding will offer the ideal solution for your needs. Learn what product designers must consider when designing a part for injection molding, including: warp, surface finish, stress, resin additives, and more. Some thermosets and liquid silicones are also compatible with the injection molding process. Plastic Molding Service for Medical Industry is capable of high capacity production with a speedy turnaround. Injection molding process needs to use mold tool, injection molding machine, and raw plastic material. A runner is a system of channels that meet up with the sprue, typically within or as part of the mold tool, that guides the molten plastic into the part cavities within the mold tool.

Materials used include thermoset polyester, vinyl ester, melamine, bulk molding and sheet molding compounds, diallyl phthalate and epoxy. We monitor color and gloss, and use other analytical or custom testing to ensure all finished products meet your specifications. To be clear, we produce molded parts using standard injection molding equipment with the resins our customers specify in two state of the art facilities in the United States. The professionals at Leomuovi and the modern machinery they use guarantee high-quality products and customer satisfaction. Our people have many years of experience in plastic mould manufacturing and the production of plastic molding parts. Components ranging from consumer products to medical rely on our plastic injection moulding services. Maxell Moulding Services, the chosen manufacturer of Rapstrap, as featured on `Dragons Den on Tour` BBC2. You are welcome to consult on our technical team, we will suggest you the best solution to assist you with better design, low cost for plastic tooling making, plastic molding manufacturing. We offer competitive, innovative plastic manufacturing solutions for customers of all sizes, as a company we are passionate about what we do and we proudly offer services from concept, product design, and tooling to production. We take pride in reacting quickly to customer needs offering flexible production schedules to cater all service the packaging, electrical, building, medical, toy, household, garden, electronics, defense and automotive industries - a complete range of customers. And to complement these services we also offer special surface finishing including electro (chrome) plating, vacuum metalising, graphic surface treatments, pad printing, hot foiling, ultra sonic welding, RFI shielding and a full range of wet paint finishing facilities. Zeal Injection Molding Services and plastic molding manufacturing services additionally offers its clients an extensive variety of auxiliary administration alternatives that incorporate machining, powder covering, silk screening, painting and ultrasonic welding. The plastic cools in the mold, taking the shape of the product, and is ejected. Call and speak to our project manager today - you'll be surprised what Maxell can do for your plastic components production. UK plastic injection moulders, Rutland Plastics, can help whatever your requirements. We work with a range of thermoplastics and are ISO 13485 certified for medical device component manufacturing. During the injection molding process, the melted plastic material is forced to inject into the mold tooling, where it cools and solidifies to obtain the desired parts or products. When you're looking for a plastic injection molding company, look no further than IMI. We are proud of being one of the top custom injection moulding suppliers for manufacturers whose injection moulding cost is lower than any market. Injection molding allows for the use of a large diversity of materials — plastic pellets can be premixed, or mixed directly into the hopper of a molding machine, to meet virtually any specification. At its core, the injection molding process is a relatively simple one. We undertake all custom, technical & precision production, through to trade & sub-contract mouldings. Injection molds are precisely CNC milled and polished, which gives the parts terrific surface, customizable treatments are also available. As you can imagine, all of the iteration required to get the tool correct prior to mass production requires both time and money. With over 22 years experience in manufacturing and packaging precision moulded plastic components, Maxell Moulding Services are your ideal resource for OEM plastic components. Plastic blow molds, aluminum and steel tooling, 2-shot and 3-shot molding are also available. SMW specializes in custom injection molding of simple & complicated shapes. Plastic molding began in the late 1800's to fill the need for plastic billiard balls as opposed to the commonly used ivory billiard balls of the time.

0 notes

Text

CAE Services Named Primary Reseller of AutoDesk Moldflow Simulation Software

http://dlvr.it/RGYHHK

0 notes

Link

0 notes