#Motorized Pallet Racking Systems

Explore tagged Tumblr posts

Text

#Pallet Racks#Pallet Storage Systems#System Storage Racks#Vertical Storage Solutions#Warehousing Equipments#Warehouse Storage Systems#Material Handling Storage Solutions#Conventional Pallet Racks#Warehouse Storage Solutions#Vertical Storage Systems#Vertical Carousel Systems#Storage Solution Consultancy Services#Storage Shelving Systems#Radio Shuttle Storage Systems#Racking Storage Systems#Motorized Pallet Racking Systems#Motorized Mobile Racks#Mobile Storage Systems#Manufacturer#Supplier#Exporter#Service Provider#Consultant#Training#AMC Services#Kolhapur#Maharashtra#India#Asia#Africa

0 notes

Text

The Ultimate Guide to Choosing the Right Pallet Truck for Your Business

Introduction

Pallet trucks, also known as pallet jacks, are essential tools for businesses that require efficient material handling. Whether you operate a warehouse, retail store, or manufacturing unit, choosing the right pallet truck can increase productivity, reduce manual labor, and enhance workplace safety. However, with various types and features available, selecting the right pallet truck can be challenging.

This ultimate guide will walk you through the types, key features, and factors to consider before purchasing a pallet truck for your business.

1. Understanding Different Types of Pallet Trucks

Before selecting a pallet truck, it’s important to understand the different types available in the market.

A. Manual Pallet Trucks

Operated by hand-pumping the hydraulic system to lift loads.

Ideal for small warehouses and short-distance transport.

Cost-effective and easy to maintain.

Best for businesses handling light to medium loads (up to 2500 kg).

B. Electric Pallet Trucks

Powered by a battery-operated motor.

Reduces manual effort and speeds up operations.

Suitable for medium to large warehouses handling frequent material movement.

Can handle heavier loads, typically up to 3000 kg.

C. Semi-Electric Pallet Trucks

Combines manual lifting with an electric drive system.

More affordable than fully electric models.

Great for businesses transitioning from manual to powered equipment.

D. High-Lift Pallet Trucks

Designed to lift pallets to a higher height.

Useful for loading/unloading trucks and stacking.

Prevents strain on workers by reducing excessive bending.

E. Weighing Scale Pallet Trucks

Equipped with a built-in scale to weigh loads instantly.

Useful in warehouses, shipping, and production units.

F. Rough Terrain Pallet Trucks

Designed for outdoor and uneven surfaces.

Features large, durable wheels for stability.

Ideal for construction sites and agricultural businesses.

2. Key Factors to Consider Before Choosing a Pallet Truck

Once you understand the types, consider the following factors to select the best pallet truck for your business needs:

A. Load Capacity

Choose a pallet truck with a capacity that matches or exceeds your typical load weight.

Standard pallet trucks support 1500–3000 kg.

Overloading can cause wear and tear and reduce the truck’s lifespan.

B. Fork Length & Width

Standard fork length: 1150mm (suitable for standard pallets).

Short forks: Ideal for small pallets and confined spaces.

Wide forks: Better for handling large or custom-sized pallets.

C. Lift Height

Standard pallet trucks lift up to 200mm.

High-lift pallet trucks can reach 800mm or more.

Consider lift height based on your racking and storage requirements.

D. Material & Build Quality

Opt for high-quality steel construction for durability.

Galvanized or stainless-steel models are ideal for corrosive environments (e.g., food & chemical industries).

E. Wheels & Manoeuvrability

Polyurethane wheels: Quiet, smooth rolling, and floor-friendly.

Nylon wheels: Ideal for rough surfaces and wet environments.

Rubber wheels: Provide better grip and shock absorption.

Consider 360-degree swivel wheels for enhanced maneuverability in tight spaces.

F. Ease of Use & Ergonomics

Look for ergonomic handles to reduce strain on workers.

Electric models with easy-to-use control panels improve efficiency.

Low-resistance pumps and smooth-rolling wheels make manual handling easier.

G. Battery Life (For Electric Pallet Trucks)

Ensure long-lasting battery performance for uninterrupted operations.

Lithium-ion batteries offer faster charging and longer life.

Check for easy battery replacement and charging options.

3. Benefits of Choosing the Right Pallet Truck

Investing in the correct pallet truck can benefit your business in several ways:

✅ Increases efficiency – Faster material handling reduces downtime. ✅ Enhances worker safety – Reduces the risk of injuries from manual lifting. ✅ Saves operational costs – Reduces labor costs and increases productivity. ✅ Improves space utilization – Enables better storage management. ✅ Extends equipment lifespan – Choosing the right model reduces wear and maintenance costs.

4. Best Practices for Maintaining Your Pallet Truck

To maximize your pallet truck’s lifespan, follow these maintenance tips:

🔹 Regularly inspect wheels for wear and tear. 🔹 Check hydraulic fluid levels and top up when necessary.

🔹 Lubricate moving parts to ensure smooth operation.

🔹 Keep the forks clean and free from debris.

🔹 Store electric pallet trucks properly and charge batteries as required.

5. Where to Buy the Best Pallet Trucks Online?

If you are looking to buy a pallet truck online, consider the following tips:

🔸 Choose a trusted supplier with positive customer reviews. 🔸 Compare features, warranties, and after-sales support. 🔸 Check if the seller offers fast shipping and easy returns. 🔸 Look for discounts and bulk purchase deals.

Conclusion

Selecting the right pallet truck for your business involves understanding your operational needs, load capacity, terrain, and budget. Whether you need a high-lift, electric, or manual hand pallet truck, choosing the correct model will boost efficiency, enhance safety, and save costs in the long run.

Take your time to assess your requirements and invest in a high-quality pallet truck to improve material handling operations.

Looking to buy the best pallet truck online? Explore top-rated models from leading suppliers and make an informed decision today!

0 notes

Text

Power Up Your Warehouse: Choosing Between Electric and Semi-Electric Pallet Stackers

Efficiently moving and stacking heavy pallets is essential for smooth operations in any warehouse or distribution center. While manual pallet jacks have been a staple for decades, advancements in technology have introduced powered options that significantly improve productivity and reduce worker strain. This guide focuses on two such solutions: electric pallet stackers and semi-electric pallet stackers. By understanding their differences and considering your specific needs, you can choose the perfect equipment to optimize your material handling processes.

Electric Pallet Stackers: Fully Powered for Maximum Efficiency

Electric pallet stackers are versatile machines designed to lift and move pallets with minimal manual effort. They are powered by an electric motor and battery, allowing operators to raise, lower, and transport pallets with ease.

Key Features:

Fully Powered Lift and Travel: Both the lifting and horizontal movement are powered by the electric motor, reducing operator fatigue and increasing efficiency.

Higher Lifting Heights: Can typically reach greater heights compared to semi-electric pallet stackers, making them suitable for high racking systems.

Increased Load Capacity: Often have higher load capacities, allowing them to handle heavier pallets.

Enhanced Safety Features: May include advanced safety features like automatic braking systems and overload protection.

Ideal Applications:

Warehouses with high racking systems

Frequent lifting and moving of heavy pallets

Operations prioritizing speed and efficiency

Environments where operator fatigue is a concern

Semi-Electric Pallet Stackers: A Balance of Power and Affordability

Semi-electric pallet stackers offer a blend of manual and electric operation. They utilize an electric motor for lifting pallets but rely on manual effort for horizontal movement. This hybrid design provides a cost-effective solution while still reducing operator strain.

Key Features:

Electric Lift, Manual Travel: The lifting mechanism is powered by an electric motor, while the operator manually pushes or pulls the stacker for horizontal movement.

Cost-Effective: Generally less expensive than fully electric pallet stackers.

Maneuverability: The manual movement allows for greater maneuverability in tight spaces.

Reduced Operator Strain: Electric lifting minimizes the physical effort required to raise pallets.

Ideal Applications:

Operations with moderate lifting needs

Warehouses with limited aisle space

Businesses seeking a balance of affordability and efficiency

Tasks involving both lifting and transporting pallets over shorter distances

Factors to Consider When Choosing a Pallet Stacker

Frequency of Use: How often will the stacker be used? For frequent use, a fully electric model might be more efficient.

Load Capacity: What is the maximum weight of the pallets you need to lift?

Lifting Height: How high do you need to lift pallets?

Aisle Space: How much space is available for maneuvering the stacker?

Budget: What is your budget for purchasing and maintaining the equipment?

Operator Training: Ensure your operators are adequately trained to safely operate the chosen stacker.

Electric pallet stackers and semi-electric pallet stackers offer significant advantages over manual pallet trucks, improving efficiency, reducing operator strain, and enhancing safety. By carefully considering your specific needs and the key features of each type, you can choose the right equipment to optimize your warehouse operations and boost productivity.

0 notes

Text

How Pallet Flow Racks Improve Warehouse Efficiency

In the fast-paced world of warehousing, efficiency is key to ensuring smooth operations and keeping costs under control. One of the most revolutionary systems that has been improving warehouse efficiency is the pallet flow rack. But what exactly is a pallet flow rack, and why has it become a go-to solution for many warehouses? Let’s dive in!

What are Pallet Flow Racks?

Pallet flow racks are a type of racking system designed to streamline inventory management in warehouses by utilizing gravity and sloped rails. These racks allow pallets to move from one end of the shelf to another, helping with the easy retrieval of products. Think of them like a conveyor belt that moves goods automatically, but with a more storage-oriented twist. Products are loaded from one side, and as items are removed from the other side, the remaining pallets gradually move forward, ready to be picked up.

Why are Pallet Flow Racks Important?

Pallet flow racks are more than just a space-saving mechanism. They’re essential in optimizing storage capacity, reducing labor costs, and ensuring quick inventory turnover. The importance of pallet flow racks lies in their ability to create a more organized, efficient workflow, which can have a significant impact on the overall performance of a warehouse.

How Pallet Flow Racks Work

Understanding how pallet flow racks function is essential to appreciating their value. These racks are designed with a slight incline, and gravity takes care of the rest. When pallets are placed on the rack, they gradually move toward the picking area as items are removed.

The Mechanics Behind Pallet Flow Racks

Pallet flow racks rely on rollers or wheels positioned along sloped tracks to create a controlled flow of pallets. When a new pallet is placed in the racking system, it automatically moves toward the picking position as the previous pallet is retrieved. This means that the system is always “on the go,” with new stock entering and old stock leaving in an efficient and seamless process.

Gravity-Driven Systems: Simplifying Storage and Retrieval

One of the standout features of pallet flow racks is the use of gravity-driven technology. Gravity is an inexpensive and efficient tool that automatically moves the pallets, which helps eliminate the need for motorized conveyors or excessive manual labor. By harnessing the natural force of gravity, pallet flow racks simplify the storage and retrieval process while reducing both energy costs and human error.

Benefits of Using Pallet Flow Racks in Warehouses

So, why should warehouses invest in pallet flow racks? Let’s break down some of the key benefits that make these systems a must-have.

Maximizing Storage Space

Space is always at a premium in warehouses, and pallet flow racks help optimize the use of vertical and horizontal space. Since the system uses gravity to move pallets from one point to another, it allows for dense storage, which in turn maximizes the available square footage. The ability to store more items in less space is a huge advantage, especially for businesses looking to expand or manage inventory more effectively.

Enhancing Warehouse Efficiency and Speed

Think of how much time warehouse workers spend walking up and down aisles, searching for items or manually moving pallets from one place to another. With pallet flow racks, those days are over. Since the system automatically brings pallets to the picking area, it speeds up the process of locating and retrieving items. This increased efficiency means faster order fulfillment, quicker shipments, and ultimately, a more agile warehouse.

Reducing Labor Costs and Errors

In any warehouse, labor costs can make up a significant portion of overall expenses. Pallet flow racks help to reduce these costs by minimizing the amount of manual labor required to retrieve and store items. Additionally, the automated nature of pallet flow systems means there is less chance of human error—pallets move automatically without the risk of misplaced inventory or confusion. This makes the entire system more reliable and cost-effective in the long run.

Improving Inventory Control

Effective inventory control is crucial for businesses, and pallet flow racks can significantly enhance tracking and management of stock. The FIFO (First-In-First-Out) principle is automatically applied with pallet flow racks, ensuring that older stock is picked before newer stock. This reduces the risk of inventory spoilage, ensures stock turnover, and helps businesses maintain optimal inventory levels.

Factors to Consider Before Installing Pallet Flow Racks

Before jumping into a pallet flow rack installation, there are a few things to keep in mind. While the benefits are clear, it’s important to evaluate the specific needs of your warehouse before making a decision.

Types of Pallet Flow Racks Available

Pallet flow racks come in a variety of designs, each suited to different types of products, warehouse layouts, and storage requirements. For example, you can choose between single-deep or double-deep systems, depending on the level of access you need for picking and stocking. Make sure to select a system that best fits the size and shape of your inventory to maximize storage and efficiency.

Warehouse Layout and Space Optimization

Before installing pallet flow racks, it’s crucial to assess the layout of your warehouse. Is there enough space to incorporate this system without disrupting existing workflows? Are the aisles wide enough for pallets to move smoothly through the racks? A well-planned layout ensures that pallet flow racks will work optimally, improving efficiency and reducing congestion.

Budget Considerations

Pallet flow racks represent a significant investment, so it's essential to consider your budget and long-term goals. While the initial cost of installation can be high, the savings in labor and operational efficiency can more than justify the expenditure over time. Take into account both the upfront costs and the ongoing savings when making your decision.

Conclusion: Are Pallet Flow Racks Worth the Investment?

In conclusion, pallet flow racks are an incredibly effective tool for improving warehouse efficiency. From maximizing storage space to reducing labour costs and minimizing errors, they can revolutionize the way warehouses operate. By utilizing gravity, these systems provide a fast, reliable, and cost-effective solution for managing inventory and streamlining warehouse workflows.

Meatco Distributor

3265 Gateway Rd, Suite 350, Brookfield, WI

800–558–5104

0 notes

Text

Understanding Rack and Pinion Systems: Mechanisms of Precision

Introduction

Rack and pinion systems are essential mechanical components that convert rotational motion into linear motion, playing a vital role in various applications across different industries. Whether in automotive steering systems, industrial machinery, or even amusement park rides, the principles behind rack and pinion mechanisms are crucial for ensuring precise and efficient operation. In this article, we’ll delve into the workings of rack and pinion systems, their applications, advantages, and considerations when selecting them for your projects.

What is a Rack and Pinion System?

A rack and pinion system consists of two main components: the rack, which is a flat, straight bar with teeth cut into it, and the pinion, a cylindrical gear that meshes with the teeth of the rack. When the pinion rotates, its teeth engage with the rack, causing the rack to move linearly. This simple yet effective mechanism is widely used for converting rotational motion to linear motion.

How It Works

Pinion Rotation: When the pinion gear is rotated by a motor or manual input, its teeth push against the teeth of the rack.

Linear Motion: As the pinion turns, the movement of its teeth translates into linear movement along the rack.

Direction Control: The direction of the rack's movement depends on the direction in which the pinion is rotated. Reversing the rotation of the pinion will move the rack in the opposite direction.

Applications of Rack and Pinion Systems

Rack and pinion systems are versatile and can be found in numerous applications, including:

1. Automotive Steering Systems

One of the most common applications of rack and pinion mechanisms is in automotive steering systems. The rack converts the rotational motion of the steering wheel into lateral movement of the wheels, providing precise control and responsiveness.

2. Industrial Machinery

In manufacturing and automation, rack and pinion systems are used in conveyor belts, CNC machines, and robotic arms. Their ability to provide accurate linear movement makes them essential for tasks that require high precision.

3. Material Handling Equipment

In warehouse and distribution centers, rack and pinion systems are often found in lift systems and pallet movers. They enable smooth and efficient movement of heavy loads.

4. Amusement Park Rides

Rack and pinion mechanisms are also used in various amusement park rides, providing the necessary motion to lift or move riders safely and reliably.

5. Home Appliances

Certain home appliances, such as reclining chairs and adjustable beds, utilize rack and pinion systems to facilitate smooth movement and positioning.

Advantages of Rack and Pinion Systems

1. Precision and Accuracy

Rack and pinion systems are known for their ability to provide precise linear motion, making them ideal for applications where accuracy is crucial.

2. Simplicity of Design

The straightforward design of rack and pinion systems makes them easy to understand and implement. Fewer components mean lower chances of failure and easier maintenance.

3. High Load Capacity

These systems can handle significant loads, making them suitable for heavy-duty applications in industrial settings.

4. Versatility

Rack and pinion systems can be customized for various applications, including different sizes and tooth configurations, allowing for flexibility in design.

5. Cost-Effective Solution

With relatively simple manufacturing processes, rack and pinion systems can be produced at a lower cost compared to other motion transfer systems.

Considerations When Selecting Rack and Pinion Systems

1. Material Selection

Choosing the right materials for the rack and pinion is crucial. Steel is commonly used for heavy-duty applications, while lighter materials like aluminum or plastics may be suitable for less demanding environments.

2. Tooth Design

The design of the teeth (shape, size, and pitch) impacts the efficiency and smoothness of operation. Depending on the application, you may need to consider different tooth profiles, such as straight or helical.

3. Lubrication

Proper lubrication is essential to reduce friction and wear, prolonging the life of the system. Regular maintenance and the use of appropriate lubricants are vital.

4. Alignment

Ensure proper alignment between the pinion and rack to prevent premature wear or failure. Misalignment can lead to increased friction and reduce the system's efficiency.

5. Load Requirements

Evaluate the load requirements of your application to select a rack and pinion system that can handle the necessary forces without compromising performance.

Conclusion

Rack and pinion systems are a fundamental mechanism in mechanical engineering, providing efficient and reliable motion transfer in various applications. Their simplicity, precision, and versatility make them a preferred choice in many industries, from automotive to robotics.

0 notes

Text

Choosing the Right Electric Forklift for Your Business

Discover how selecting the perfect electric forklift can elevate your operational efficiency and sustainability.

Understanding the Basics of Electric Forklifts

Electric forklifts are essential tools in modern warehousing and manufacturing. They differ from traditional internal combustion forklifts by using electric motors powered by rechargeable batteries. This results in a quieter, cleaner operation with fewer emissions and often lower operating costs. Understanding the basics includes grasping the types of batteries used, charging requirements, maintenance needs, and the impact of electric forklifts on workplace safety and efficiency.

Additionally, the versatility of electric forklifts makes them suitable for a variety of indoor tasks. They can range from simple pallet lifting to complex order picking operations. With advancements in technology, these forklifts have become more powerful and reliable, capable of handling a wide range of load weights and sizes, making them a go-to choice for many businesses.

Evaluating Your Business Needs

When evaluating your business needs for an electric forklift, consider the size and nature of your operations. Assess the weight and dimensions of the typical loads, the height requirements for stacking, and the aisle width in your storage area. It's also important to consider the frequency and duration of use to determine the battery life and charging solutions needed. Analyzing your current and future business needs will help guide your decision in selecting a forklift that can grow with your company.

Furthermore, think about the ergonomics and comfort for the operator. Features such as adjustable seats, controls, and visibility can impact operator fatigue and productivity. A thorough needs assessment will ensure that you choose a forklift that not only meets today's requirements but is also scalable for future demands.

Comparing Types of Electric Forklifts

There are several types of electric forklifts available, each suited to different working environments and tasks. Three-wheel counterbalance forklifts, for instance, are known for their maneuverability in tight spaces. Reach trucks are ideal for high rack storage, while pallet jacks are perfect for horizontal transport and low-level lifting. Understanding the specific capabilities and limitations of each type of forklift is crucial in making an informed decision that aligns with your operational needs.

The decision should be based on the specific job requirements, such as lifting capacity and height, aisle width, and the type of material handling involved. Some electric forklifts are designed for specialty tasks, such as order picking or working in narrow aisles, so it's important to compare the various models and features to find the one that best fits the unique demands of your business.

Key Features to Consider in an Electric Forklift

When selecting an electric forklift, key features to consider include battery life, charging time, and overall energy efficiency. Look for models with regenerative braking systems that can help to extend battery life. The forklift's lift capacity and the ease of maintenance should also be top considerations. Features like programmable performance settings can be beneficial for customizing the forklift to specific tasks or operator preferences.

Safety features are paramount. This includes automatic braking systems, warning signals, and good visibility. Forklifts with advanced safety technology can greatly reduce the risk of accidents in the workplace. Additionally, consider the availability of after-sale support and parts, as this can significantly affect the long-term value and usability of the forklift.

Implementing Your Electric Forklift for Maximum Efficiency

Once you have selected the right electric forklift, implementing it into your operations effectively is key to maximizing efficiency. This involves training your staff on the proper use and maintenance of the forklift to ensure long-term reliability. Additionally, analyze your workflow to optimize the use of the forklift, including storage layout, charging station placement, and work schedules.

Consider implementing a fleet management system to track forklift usage and maintenance schedules. Regularly reviewing performance data can lead to improvements in operation efficiency and the prevention of downtime. By strategically integrating your electric forklift into your business operations, you can achieve improved productivity, reduced operational costs, and a stronger return on your investment.

Keywords: Bendi Forklift Training, Narrow Aisle Forklift, Order Picker, Mini Forklifts, Electric Forklift

Website:

https://translift-bendi.co.uk/

https://translift-bendi.co.uk/driver-training/

https://translift-bendi.co.uk/ep-equipment/

https://translift-bendi.co.uk/order-pickers/

https://translift-bendi.co.uk/mini-bendi-pedestrian-articulated-forklift/

https://translift-bendi.co.uk/drexel-narrow-aisle-longloader-forklifts/

Source: https://seoe2zblogs.medium.com/choosing-the-right-electric-forklift-for-your-business-6393a8be7085

0 notes

Text

A Guide to Warehouse Racking

Warehouse organization is not just about storing goods; it's a critical component of effective supply chain management. A well-designed racking system is essential for maximizing warehouse efficiency and ensuring the quality and safety of stored goods. In this guide, we will explore the different types of racking systems and provide tips on choosing the right one for your needs.

The Importance of Effective Warehouse Racking Imagine running out of storage space in your warehouse. The options for expanding space, such as renting additional space or building a new facility, are time-consuming and costly. A more efficient solution is to maximize the existing space with a well-planned racking system, which not only saves time and money but also enhances the overall functionality of your warehouse.

FAST Principle & Approach in Warehouse Designing

The FAST Principle in Warehouse Design The FAST principle is a systematic approach to warehouse design, focusing on four key aspects:

F for Flow: Ensuring a smooth flow of goods in and out of the warehouse.

A for Accessibility: Making sure all items are easily accessible for efficient operation.

S for Space: Utilizing the available space to its fullest potential.

T for Throughput: Optimizing the warehouse's capacity to handle goods efficiently.

Applying the FAST principle helps in creating a racking system that optimizes storage, ensures safety for both products and employees, and provides timely access to resources.

Types of Warehouse Racking System

In the realm of warehouse management, the strategic selection of a racking system can greatly enhance operational efficiency. Each type of racking system offers unique advantages and is suitable for specific kinds of inventory and warehouse operations. Here's an expanded overview of various warehouse racking systems, illustrated with examples to provide a clearer understanding of their applications:

Selective Racking: This is the most versatile and widely used racking system, offering easy access to every pallet. It is particularly beneficial for warehouses that store a wide variety of items, each in relatively low volumes. For instance, a distributor dealing with diverse but limited consumer goods like electronics or household items would benefit from selective racking, as it facilitates quick access and easy stock management.

Static Racking: Ideal for items that require long-term storage without frequent access, static racking is a stable solution that keeps goods securely in one place. For example, a company storing backup equipment or archival materials that are not needed regularly would find static racking advantageous due to its sturdy and immobile design.

Mobile Racking: These are mounted on motorized carriages and can be compacted together to save space, then expanded as needed. This type of racking is perfect for storage environments where space is at a premium but access is still occasionally required. An example could be a retail stockroom where seasonal items are stored compactly during off-seasons and accessed only when the season changes.

Industrial Wire Partition Racking: This system enhances the security and safety of stored items, making it ideal for valuable or hazardous materials. For instance, a pharmaceutical company might use industrial wire partition racking to securely store sensitive drugs that need to be protected from unauthorized access while ensuring ventilation and visibility.

Drive-In Rack: These are designed for storing large quantities of similar items and utilize a LIFO (last in, first out) storage method. This system is best suited for items that are not date-sensitive, such as canned goods or materials that do not expire. A beverage manufacturer could use drive-in racks to store bulk quantities of bottled products, maximizing storage density and space.

Multi-Tier Racking: By utilizing vertical space, multi-tier racking systems are perfect for operations with limited floor space but sufficient ceiling height. This system can effectively double or triple the available storage area. For example, auto parts stores often use multi-tier racking to organize small parts across different levels, making efficient use of vertical space.

Push-Back Racking System: This system allows for storing pallets 2-5 deep and operates on a LIFO basis, offering higher density storage. It's particularly useful in scenarios where space is constrained but batch volume storage is necessary. A food distributor, for example, might use push-back racking to store multiple pallets of the same product, allowing older items to be used first while newer stock is pushed to the back.

youtube

Things to Consider Before Designing Your Warehouse Racking System

Each of these racking systems can be tailored to the specific needs of a warehouse, ensuring that the space is used efficiently and that inventory is managed effectively. When choosing a racking system, it is crucial to consider not just the current requirements but also potential future needs to ensure scalability and adaptability.

When planning to design your warehouse racking system, it’s crucial to consider several key factors to ensure you select the most suitable system for your operations. Here’s an expanded description of the considerations you should keep in mind:

Budget: Before embarking on the installation of a new racking system, it's essential to thoroughly evaluate your financial capacity. This includes not only the upfront costs of purchasing and installing the racking system but also ongoing maintenance expenses. These costs can vary significantly depending on the complexity and scalability of the system you choose. Planning your budget carefully will help you avoid overextending your financial resources and ensure that the system you select offers the best value for the investment.

Safety Requirements: Safety is paramount in warehouse operations to protect both your inventory and your workforce. Assess the specific safety requirements needed for your operations, considering the weight and nature of the goods stored. Ensure that the racking system adheres to local safety standards and regulations. This might include features like seismic rating for earthquake-prone areas, fire safety compliance, and the strength to safely bear the loaded weight. Regular safety audits and training for your staff on how to properly use and maintain the racking system are also crucial components to consider.

Flooring Inspection: The integrity and capacity of your warehouse floor are fundamental to the success of your racking system. Inspect the flooring to ensure it can support the weight of the racking units fully loaded with goods. This might involve professional assessment of the floor’s load-bearing capacity and the installation of reinforcements if necessary. The levelness and condition of the floor can also affect the stability of the racking system, so addressing any irregularities or damage is vital before installation.

Forklift Accessibility: Efficient material handling is critical to warehouse operations. Ensure that the layout of your racking system is accessible for forklifts or other machinery used in your operations. This includes considering aisle width to accommodate turning radii, overhead clearance, and ensuring that load and unload zones are optimally positioned to reduce traffic and potential bottlenecks. The type of forklifts used (e.g., reach trucks, side loaders) will also influence the design of the system, particularly the aisle width and rack configuration.

Versatility & Flexibility: The needs of your business will inevitably evolve over time, so choosing a racking system that can adapt to changing demands is beneficial. Consider modular or adjustable racking systems that can be reconfigured as needed without significant disruption or additional costs. This flexibility can accommodate changes in the type of products stored, fluctuations in inventory levels, or shifts in operational strategy. Furthermore, scalability is essential; the racking system should allow for easy expansion, either vertically or horizontally, to increase storage capacity as your business grows.

Maximize Your Warehouse Storage by Choosing the Right Racking system

Choosing the best racking system is a significant part of inventory management. It helps you optimize your storage and control expenditure on warehouse management by avoiding frequent maintenance and alterations.

When it comes to warehouse optimization and installation, you might be spending a huge amount to make it beneficial in the long run. So for choosing the best method you need to consider the factors that are mentioned below. If you are concerned about installing the right racking technology into your warehouse unit, you don't need to worry, 3PL partners will help you efficiently manage your warehouse by understanding your storage requirements. So, get in touch with a full-fledged 3PL provider to make your warehouse management quick & hassle-free.

0 notes

Text

Why Do You Think Compactus Brisbane Is Highly Demanding?

The warehouse owners always need to look for ways to help them keep space optimised and efficiently organised. Traditional storage systems are not in vogue these days, so business workers are searching for more innovative options. They preferably like to embrace storage systems that are less cumbersome and won’t take up much of the floor space. That is why Compactus Brisbane is gaining popularity.

What do you mean by Compactus shelving solutions?

The Compactus Brisbane is one of the most demanding brands that is known for its flexible storage system. They consist of shelves Brisbane mounted on movable bases designed to run along the tracks. You can move the shelves With the help of a motor or crank. Thus, you can create the storage space as and when needed. This lets you increase the storage space without wasting a single inch.

What are the different pros of using the Compactus Brisbane

Increasing the storage space

The Compactus Brisbane helps you double the storage capacity in that respective footprint.

Access any items faster

You can access any item faster with the help of a movable racking solution. Thus, it saves both your effort and time.

Optimising the space

The Compactus Brisbane is designed to let you fruitfully use the floor space, like when used for production areas or workstations.

Enhancing the organisation

The Compactus Brisbane is customised to meet the particular needs of the users. Thus help in efficiently arranging inventories.

Secured options

The Compactus Brisbane is crafted to accommodate all sorts of sensitive items as well.

How to find the right sort of Compactus Solution Brisbane

To get the right kind of Compactus Brisbane, you need to consider the following ● Understand your need ● Research on the suppliers ● Compare all the available options ● Take some expert advice

Final thought

Well, Compactus Brisbane is the modern-day solution for those seeking composed storage options. So you can opt for the Pallet rack shelving or Warehouse rack if needed as perconvenience.

#Compactus#Compactus Units#Compactus Brisbane#Shelves Brisbane#Shelving Brisbane#Shelving Racks Brisbane#Pallet Racking Suppliers#Racking and Shelving Suppliers

0 notes

Text

Pallet Rack Moving System

Pallet Rack Moving Systems

In the fast-paced world of logistics and warehouse management, the need for efficient and flexible storage solutions is more critical than ever. Pallet rack moving systems have emerged as a game-changer, offering a revolutionary approach to optimizing warehouse space and streamlining operations.

Traditional static pallet racking systems often pose challenges when it comes to adapting to changing inventory needs. However, the introduction of pallet rack moving systems has transformed the landscape by providing a dynamic and customizable solution. These systems allow warehouse managers to reconfigure their storage layout quickly and easily, adapting to fluctuating stock levels and operational requirements.

The key innovation lies in the design of these movable pallet racks. Mounted on rails or tracks embedded in the warehouse floor, the racks can be effortlessly repositioned with the help of a motorized system or manual effort. This flexibility enables warehouses to maximize space utilization, accommodating varying inventory sizes and optimizing the layout for improved accessibility.

One of the primary advantages of pallet rack moving systems is their ability to enhance operational efficiency. With traditional static racks, rearranging inventory or making space for new stock can be a time-consuming and labor-intensive process. In contrast, the dynamic nature of movable pallet racks allows for quick adjustments, minimizing downtime and improving overall workflow efficiency.

Additionally, the adaptability of these systems contributes to better inventory management. Warehouse managers can easily segregate fast-moving items from slow-moving ones, optimizing picking and restocking processes. This adaptability is especially valuable in industries where product turnover rates vary significantly.

Furthermore, pallet rack moving systems contribute to a more sustainable approach to warehouse management. By maximizing space utilization, businesses can reduce the need for additional warehouse construction, ultimately lowering their environmental impact.

In conclusion, pallet rack moving systems represent a paradigm shift in warehouse management. Their dynamic and customizable nature allows businesses to stay agile in the face of changing demands, leading to improved efficiency, better inventory management, and a more sustainable approach to storage solutions. As industries continue to evolve, the adoption of these innovative systems is poised to become a cornerstone of modern warehouse management practices.

0 notes

Text

#motorized mobile storage rack manufacturers#motorized mobile rack manufacturer#motorized pallet racking system manufacturer in india#warehouse pallet rack manufacturer#pallet rack manufacturers#warehouse rack manufacturers

0 notes

Text

Key Components of an Efficient Cargo Handling System

Efficient cargo handling systems are the backbone of logistics and transportation industries, enabling the smooth flow of goods from one point to another. Whether it's at a bustling port, a busy airport, or a well-organized warehouse, the effectiveness of cargo handling systems plays a critical role in the success of supply chains and the overall economy. In this article, we will explore the key components that make up an efficient cargo handling system.

1. Conveyors and Conveyor Belts

Conveyors are the workhorses of cargo handling systems. These motorized systems consist of belts, rollers, or chains that move cargo from one location to another, whether it's loading cargo onto a ship, moving baggage at an airport, or transporting goods within a warehouse. Conveyors can be customized to accommodate various types of cargo and are designed to optimize the flow of materials, minimizing manual handling and reducing the risk of damage.

2. Cranes and Lifts

Cranes and lifts are essential for handling heavy and oversized cargo. They come in various types, including gantry cranes, overhead cranes, and forklifts, each designed for specific tasks. For instance, container cranes are used at ports to load and unload shipping containers from vessels, while forklifts are commonly used in warehouses to move pallets of goods. The efficiency of cargo handling greatly depends on the availability and proper operation of these lifting devices.

3. Storage and Warehousing Systems

Effective storage and warehousing systems are crucial for the temporary storage of cargo before it is loaded onto transportation vehicles or shipped to its final destination. Pallet racking systems, automated storage and retrieval systems (AS/RS), and bulk storage solutions all contribute to efficient cargo management by maximizing space utilization and providing easy access to stored items.

4. Automated Guided Vehicles (AGVs)

AGVs are autonomous vehicles used in cargo handling systems to transport goods within warehouses or across large facilities. They are equipped with sensors and navigation systems, allowing them to move materials without human intervention. AGVs are particularly valuable in large-scale operations, where they can navigate predefined paths and optimize material flow, reducing labor costs and improving efficiency.

5. Sorting and Conveyor Systems

Sorting systems are critical in cargo handling operations, particularly in distribution centers and logistics hubs. These systems automatically identify, categorize, and route packages or items to their designated destinations. Optical sensors, barcode scanners, and computer software work in tandem to ensure that each piece of cargo is directed to the correct conveyor or transport vehicle, minimizing errors and delays.

6. Control and Management Software

Efficient cargo handling systems rely on advanced software solutions to manage and control various components. Warehouse management systems (WMS), transportation management systems (TMS), and cargo tracking software are just a few examples. These systems enable real-time monitoring, optimization of routes, inventory management, and visibility into the movement of goods, leading to better decision-making and resource allocation.

7. Safety and Security Measures

Safety is paramount in cargo handling operations. Safety measures, including personnel training, safety barriers, emergency stop buttons, and warning signs, are essential to protect workers and prevent accidents. Additionally, cargo handling facilities often employ security measures such as surveillance cameras, access control systems, and alarms to safeguard valuable or sensitive cargo.

8. Environmental Considerations

Efficiency in cargo handling extends beyond speed and productivity; it also encompasses sustainability. Many modern cargo handling systems are designed with environmental concerns in mind. For example, electric-powered equipment and vehicles are becoming more common to reduce emissions and minimize the carbon footprint of cargo operations. Additionally, smart energy management systems help optimize energy use, reducing both costs and environmental impact.

9. Integration and Communication

Efficiency is enhanced when cargo handling components can communicate and work seamlessly together. Integration between different systems, such as the conveyor system, warehouse management software, and vehicle control systems, is essential to ensure that cargo moves smoothly from the point of origin to its destination.

10. Continuous Improvement and Adaptability

Efficiency in cargo handling is an ongoing process. Systems should be regularly evaluated and improved to accommodate changing needs and technology advancements. The ability to adapt to evolving cargo types, volumes, and logistics requirements is crucial for maintaining efficiency.

In conclusion, efficient cargo handling systems are a complex network of components and technologies that work together to streamline the movement of goods. From conveyors and cranes to software systems and safety measures, each component plays a vital role in ensuring that cargo is handled efficiently, safely, and sustainably. As technology continues to advance, the future of cargo handling will likely see further automation, increased connectivity, and a continued commitment to environmental responsibility.

0 notes

Text

Power Up Your Productivity: A Guide to Pallet Trucks

Moving heavy pallets around your warehouse or facility can be a backbreaking task. Luckily, there's a range of pallet trucks designed to make the job easier and more efficient. From manual hand pallet trucks to powerful electric models, there's a solution for every need and budget. Let's break down the different types and help you choose the right one for your business.

Hand Pallet Trucks: The Classic Workhorse

The humble hand pallet truck, also known as a pallet jack, is a staple in warehouses worldwide. It's a simple, cost-effective solution for moving pallets short distances.

How it works: Using hydraulics, you pump the handle to lift the pallet slightly off the ground, allowing you to maneuver it with ease.

Pros: Affordable, easy to use, requires no power source, and highly maneuverable in tight spaces.

Cons: Limited lifting capacity, best suited for short distances, and can be physically demanding for heavy loads.

Electric Pallet Trucks: Effortless Efficiency

Electric pallet trucks take the strain out of moving heavy pallets. Powered by batteries, these trucks offer increased efficiency and reduced operator fatigue.

How they work: An electric motor powers the hydraulic pump, lifting and lowering pallets with the push of a button.

Pros: Higher lifting capacity, reduced operator effort, increased productivity, and can cover longer distances.

Cons: Higher initial cost, requires battery charging and maintenance, and may be less maneuverable in confined spaces.

Battery-Operated Pallet Trucks: Cordless Convenience

Battery-operated pallet trucks offer the power of electric models with the added convenience of cordless operation.

How they work: Similar to electric pallet trucks, but with rechargeable batteries that provide freedom from power cords.

Pros: Combines the benefits of electric power with increased maneuverability, ideal for both indoor and outdoor use.

Cons: Battery life can be a consideration, and may require battery swaps or charging downtime.

Semi-Electric Stackers: Reaching New Heights

For operations that require lifting pallets to higher levels, semi-electric stackers are a versatile solution.

How they work: These trucks combine electric lifting with manual pushing or pulling for movement.

Pros: Cost-effective compared to fully electric stackers, allows for vertical lifting, and suitable for stacking pallets in racking systems.

Cons: Manual movement can be physically demanding for heavy loads or long distances.

Choosing the Right Pallet Truck: Key Considerations

Load capacity: Determine the maximum weight you need to lift.

Frequency of use: How often will you be using the pallet truck?

Distance: How far do you need to move pallets?

Terrain: Will you be operating on smooth floors or uneven surfaces?

Budget: Consider your initial investment and ongoing maintenance costs.

Maximize Your Material Handling

Investing in the right pallet truck can significantly improve efficiency and reduce the risk of injuries in your workplace. Whether you opt for a manual hand pallet truck, a powerful electric model, or a versatile semi-electric stacker, choose the solution that best meets your specific needs and helps you power up your productivity.

#semi electric stacker#hand pallet trucks#Battery operated pallet trucks#semi electric pallet stackers#best pallet stackers#Stacker

0 notes

Text

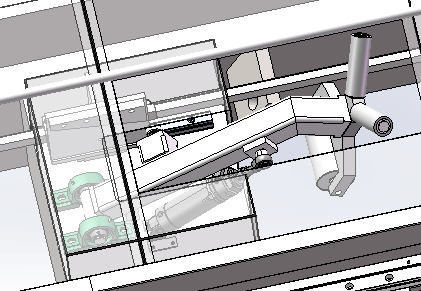

Remcor Apollo BK series three chuck tube fiber laser cutting machine can cut all types of metal tubes, from mild steel to stainless and also non-ferrous metals. It is also valid for cutting some reflective metals like aluminum, brass and copper, etc. The thickness of the metal can be anywhere up to 30 mm. The diameters can be up to Ø 350mm tubes. Can cut different shapes on the surface of square tubes, oval tubes, U tubes or rectangular tubes or other special shape tube products. The most outstanding feature of our BK system is that can realize the real Zero-tailing cutting. And our automatic loading system freedom operator from the hard and heavy pipe loading problem.

Apollo BK Three-chuck Tube Laser Cutting Machine 1000w-6000w Features

Different shapes & Different sizes

1. All kinds of pipe processing, no need to change clamping scheme.

2. Match the three-dimension head to solve all kinds of the pipe inflection points.

3. CNC and CAM can calculate complex profile sections. Φ8-Φ440 mm range.

Max weight

600kgs load and unload maximum length up to 12M.

Raw material waste

Unique 3 chucks technology, zero tailing, high pipe utilization Average material can reduce up to 30%.

Labor cost

Real time, high precision, fast troubleshooting servo motor control automatic and semi load can be chosen.

Environment pollution

Dust collection box included full sealing chuck to prevent dust into chuck to have a longer lifetime.

Low efficiency

1. Simple to operate, new upgraded system with servo motor to realize the high automation and simplication.

2. High-precision chuck to make sure high speed, stability, high quality cutting.

3. Automatic loading and unloading to improve efficiency.

Apollo BK Three-chuck Tube Laser Cutting Machine 1000w-6000w Parameter Details

Item

6020-BK

7025-BK

9025-BK

9034-BK

Power range

1500-6000W

Chuck structure

3 chucks

Tube size

Round Type: Φ15-200mm

Round Type: Φ15-245mm

Round Type: Φ15-245mm

Round Type: Φ15-330mm

Square Type:15-140mm

Square Type:15-175mm

Square Type:15-175mm

Square Type:15-230mm

Positioning accuracy of x& y

±0.05mm/m

Max positioning speed x&y

100m/min

80m/min

Max cutting length

6000mm

7000mm

9000mm

9000mm

Tail length

≥ 0mm

Max weight single tube

135KG

260KG

260KG

500KG

Max loading length

6000mm

7000mm

9000mm

9000mm

Fully Annealed Table

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time. The table is equipped with automatic lubrication device, which ensure the moving parts operate in good condition and improve the service life of guide rails, gears and rack.

Follower Support

The follower support device will be optional. The follower support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

Smart Auto Focus Laser Head

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Intelligent CNC Operating System

tube laser cutting machine intelligent cnc operating system

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic Clamp Chucks

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed. Suitable for cutting a range of tube diameters from Ø20 mm to Ø220 mm and various wall thicknesses.

Front chuck

tube laser cutting machine front chuck

Back chuck

tube laser cutting machine back chuck

Fractional Automatic Support Technology

Applies the intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Equipped with two sets of variable-diameter support structures, which are automatically lifted by the cylinder to avoid the rear chuck in processing. When processing profiles with different diameters, manually turn the variable-diameter wheels to achieve fit and support for different-sized profiles. The variable-diameter wheels It can be supported every two degrees of rotation to reduce the diameter of the circumscribed circular tube by 2mm

0 notes

Link

Storage rack shelf production line

Roll forming machine for production pallet stud,upright shelf, rack shelf, metal frame.

Customized Rack Frame

Rack shelf production line process

Uncoiler straightener 2 in 1 →Servo feeder→ Guide device → Hydraulic Punch → roll forming machine →shear device (including knife)→ finished product rack

Machines List

2 in 1 Uncoiler straightener

1, Type Manual Expansion

2, Parameter

1) Passive discharge

2) Coil weight:< 2T

3) Coil inner D.:φ450mm-φ530mm

4) Max. Width.200mm

5) Thickness .0.4-1.6mm

6) Straightener roller :7 pcs

7) Power.1.5kw

Servo Feeder 3.1 Max. feeding width:200mm 3.2 Feeding thickess: 0.4-1.6mm

3.3 Motor , 0.85KW(Yaskawa)

Hydraulic hole punching system

3.1 Function:Hydraulic punch breach 3.2 Structure: set the length, automatic length measurement, automatic positioning reaches the set distance stop action , hydraulic cylinder driven punching die, stamping automatic shutdown. 3.3 Hydraulic system working pressure:16MPa 3.4 Hydraulic station:15KW( Hydraulic punch hole/shear use same station)

Guide device

Main Forming machines (for panel width 36mm)

5.1 Forming Roller:14 stations,and add Rub-roll, To make sure the surface profile no scratches.

5.2 Side Panel:T.18mm ,A3 steel Heavy duty 。

5.3 Rolling speeding: 2-8 m/min。

5.4 Roller material:#45,overall quenching, hardness HRC56-62 ℃. 5.5 Motor power:4KW。 5.6 Main Roller :¢65mm,45 #。 5.7 Equipment base: 45 # H type using welded steel plate. 5.8 Transmission: chain drive. 5.9 Security: across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operator safety. And other gear in the chain and the staff could easily lead to injury transmission section covered with protective cover, to ensure the safety of workers.

5 notes

·

View notes

Text

Here are Different Types of Heavy Load Handling System used in Industries

The term “material handling equipment or heavy load handling system” is quite broad. There are numerous situations where it becomes essential to move large and heavy equipment in a production environment. Any piece of equipment that is used in such an application can be labeled as heavy load handling system.

There are plenty of items that fall under the definition of the heavy load handling system, such as storage units, tools, vehicles, and appliances. Any equipment that deals with the storage, transportation, and control at any stage of the processing of materials can be termed as material handling equipment.

There are four main categories of heavy load handling equipment, these includes:

1. Engineered system

2. Industrial trucks

3. Bulk material handling

4. Storage and handling equipment

Let’s understand each type in detail:

1. Bulk Handling Material Equipment:

Bulk handling material refers to control, storage and transportation of materials by bulk and in loose form. Bulk handling material equipment is mainly used in handling beverages, metal items, food.

Conveyor belts, bucket, and grain elevators, hoppers, silos, reclaimers, and stackers are common examples of bulk handling material equipment.

These equipment are primarily used to handle the good when it is loose. In addition to this, you can also integrate these systems with other stages of the production process, so that you can offer as much as automation as possible.

2. Industrial Trucks:

Industrial trucks are also another broad definition that you can apply to different types of equipment. All the type of industrial truck equipment is known to provide transportation.

Industrial trucks mainly include both large-scale motorized vehicles and hand-operated devices. Some items can be driven, while others like mecanum wheel movers and pallet trucks add mobility to the materials.

Type of industrial trucks mainly include side loaders, orders pickers, platform, and pallet jacks, walking stackers and Automated Guided Vehicles (AGVs).

3. Storage and Handling Equipment:

Types of equipment that are used for storage and handling mainly include items that are not automated. Storage and handling equipment that is automated falls under different category termed as “engineered systems”

Storage equipment is that equipment, which is used to hold when they are not being used or when they are entering or leaving the production process. These periods could be short-term or long-term both, which allow the suitable build-up of stock items.

Drive-through or drive-in trucks, shelving, stacking frames, push-back racks, pallet racks, and sliding racks are the most common type of storage and handling equipment.

4. Engineered System:

The engineered system is mostly the one that is automated and such a system is usually created combining a variety of units. When combined, engineered system work to enable both storages and transportation.

An Automated Storage and Retrieval System is a typical example of an engineered system. This is a largely automated device that comes along with shelves, aisles, and racks. These storage solutions are mainly accessed by a shuttle, which is a mechanized device that is similar to a cherry picker.

Types of the engineered system mainly include conveyor system, robotic delivery system, Automated Guided Vehicles and more.

For more information about the heavy load handling system, get in touch with us. http://oimtec.com/

1 note

·

View note

Text

The Top factors to consider when choosing storage rack Manufactures.

The Top factors to consider when choosing storage rack Manufactures.

Over the past decades, industrial evolution attained a revolutionary change and took the business to a new era. With growing industrial sector along with e-commerce platforms makes the manufacturer and supplier move parallel to maintaining an uninterrupted supply chain effectively.

E-commerce is the fastest-growing supply chain system in India focusing on the manufacturers and warehouse owners to handle logistics with adequate guidelines and safety measures. Increasing demand for warehouses, industrial racking systems gained more importance which boosts better supply chain management from cold storage to logistics handling.

Storage rack plays a major role in material handling, space utilization, and ease of transportation of goods. Selection of the best industrial storage rack manufacturers for your kind of business is the most important role and the choice can differ in terms of goods that you are going to handle and store.

Choosing the right storage rack system and Manufacturer.

Each storage rack manufacturer differs in terms of their business model, Selecting the best choice depends on major factors like the nature of goods, the budget allocated for the business and rack system installation, material handling, the size and place available for storage, quality, and durability of materials used for a racking system.

Different racking systems are available in the market like pallet racks, flow racks, pushback racks which are suitable for warehouse storage systems where goods can be stored both in vertical and horizontal patterns. Conti-lever racks and rolling racks are mechanical storage rack systems that are suitable for moving lengthy and wide goods like metals, rods, and woods. These storage racks are suitable for metal handling industries where storage and production lines are set parallel for easy movement which consumes less energy when loading and unloading of materials.

Tier pallet racking system reduces space utilization and provides ample storage area which is a more efficient and economic rack option for a business-like cold storage and E-commerce. Forklift plays a role in loading and unloading pallets from the racks which is a typical mode of cargo transportation. Other racking systems like store display racks, supermarket display racks, tyre holding racks are useful for easy storage and retrieval of things.

Mobile rack system gains importance these days for their conventional storage and easy access. In the mobile racking system, the pallets are moved with help of chassis fixed to the truck on the floor operated through motors and rails at the base level of the floor area. These mobile pallet racking systems are useful for the maximum utilization of storage space. The loading and unloading of cargo can be done at any point of storage either through FIFO or LIFO methodology.

Mobile racks are much suited for healthcare facilities for storage and retrieval of medical records, pharmacies, and firms that store a huge set of documents. Proper technical and automation support is needed for the smooth operation and maintenance of the mobile racking system. Mobile storage rack manufacturers produce advanced storage racking system that are more useful, durable, secure, and versatile than ever.

Things to consider when selecting the Manufacturer.

Numerous reputable storage rack manufacturers are available in the market from small-scale to large-scale businesses. Selection of the best suitable rack manufacturer should include your specifications like design and material, the budget of your business, the timeline for installation, periodic maintenance and technical support, warranty of materials, etc.

Design and material:

The beginning of a required storage system starts with a suitable rack design which involves professional engineering and knowledge in material handling to ensure supplier specification requirements and storage rack layout.

The first and most important aspect while planning for a suitable racking system is to get interact with the mobile storage rack manufacturer and discuss the requirement of your business, the scope of material handling and transportation, and your budget allocated for rack installation which will help the manufacturer to produce a suitable design model for your business.

Another important aspect is to consider the type of material used in the construction of racks. Usually, strong metals like stainless steel, aluminum, and titanium are used in the manufacturing of racks which are stronger, and these heavy-duty materials can withstand any temperature conditions and loads. When a customer requires lightweight and less durable materials they can consider alternative sources like wood, fiber plastics, metal sheets, etc, for rack manufacturing.

Periodic maintenance and Support:

As your business grows in the future and you are planning to expand the storage capacity. The storage rack manufacturer must be able to adjust and modify the changes as required for further expansion. Technical and mechanical support should be provided round the clock in case of mobile pallet racking systems which require continuous monitoring.

The mobile storage rack manufacturer should inspect the warehouse for safety measures to safeguard materials by ensuring proper ventilation, Clear flooring, sanitization, pest control, and occupational safety of staff. Inspection of racks and replacement of damaged, crushed frames, bent columns, and beams as part of occupational safety measures.

Proper maintenance ensures the life and durability of racks. Loading and unloading of materials and goods are to be monitored whether excessive or unequal loads are kept which cause damage to the racks.

Finally, it is important to ensure the proper operation of a forklift as a prevention measure for damage to racks in the warehouse. Every load is to be handled and operated by a forklift to ensure the safety of racks.

Conclusion:

Finding the right industrial storage rack manufacturer is the most important task while starting a successful business. Mobile storage rack manufacturers are very few in industry to provide consistent support to the clients. Finally, choose your manufacturer in terms of commitment to your storage facilitation and not in terms of budget constraints.

0 notes