#PCB Board Assembly

Explore tagged Tumblr posts

Text

#circuit board manufacturing#circuit board manufacturing companies#electronics manufacturing company#electronics manufacturing company in delhi#pcb assembly#pcb assembly services#pcb board assembly#pcb board manufacturer#pcb board manufacturers in India#pcb manufacturer in delhi ncr#pcb suppliers in india#printed circuit board manufacturers in India

1 note

·

View note

Text

What is the SMT Process for PCB Board Assembly?

The SMT PCB Board assembly process, or Surface Mount Technology process, is a strategy utilized to mount electronic components straightforwardly onto the surface of a printed circuit board (PCB). This advanced method has generally supplanted the more seasoned through-hole strategy due to its productivity, cost-effectiveness, and capacity to oblige miniaturized components. SMT permits for higher circuit densities and littler gadget profiles, making it the standard in today's hardware fabricating industry.

The SMT prepare includes a few basic steps, each planned to guarantee precision, unwavering quality, and execution of the last PCB assembly. These steps are regularly executed in a exceedingly mechanized environment to keep up accuracy and consistency.

1. Solder Paste Application

The to begin with step in the SMT PCB board assembly prepare is the application of solder paste. Solder paste is a blend of minor patch particles and flux. It is connected to the cushions on the PCB where components will be set utilizing a stencil and squeegee. This step is significant since the quality of solder paste application specifically influences the unwavering quality of patch joints.

2. Pick and Place

After the solder paste is connected, the PCB moves to the pick-and-place machine. This computerized framework precisely picks surface mount devices (SMDs) from component reels or plate and places them onto the solder-pasted cushions on the PCB. The speed and accuracy of this machine permit for quick assembly of thickly pressed circuit boards.

3. Reflow Soldering

Once all components are set on the SMT PCB Board, the assembly enters a reflow broiler. The broiler slowly warms the board through a controlled temperature profile. The solder paste dissolves (reflows) and shapes a solid electrical and mechanical bond between the components and the PCB cushions. The board is at that point cooled, setting the connections.

4. Inspection and Quality Control

Post-reflow, the assembly experiences assessment to confirm the quality of the patch joints and adjust component situation. This step frequently incorporates Automated Optical Inspection (AOI), which employments cameras to identify issues such as misalignment, lost components, or patch bridges. For complex assemblies, X-ray assessment may moreover be utilized, particularly to look at covered up patch joints beneath components like BGAs (Ball Grid Arrays).

5. Rework and Repair (on the off chance that needed)

If any surrenders are found amid review, the SMT PCB board may be sent for adjust. Talented specialists utilize revamp stations to expel, supplant, or resolder components as essential. Progressed devices guarantee that revamp does not harm the board or encompassing components.

6. Functional Testing

Finally, the board may go through utilitarian testing, where it is powered up and tried in conditions comparative to real-world utilize. This guarantees the PCB performs as expecting some time recently it moves on to last item assembly or shipping.

In conclusion, the SMT prepare for PCB board assembly is a profoundly exact and effective strategy that empowers the generation of compact, high-performance electronic devices. From solder paste printing to reflow fastening and testing, each organize plays a crucial part in the creation of dependable and strong SMT PCB sheets that control today’s progressed advances.

0 notes

Text

Navigating the Essentials of Printed Circuit Board Assembly: PCB Board and PC Board Assembly Explained

Some of the most complex systems and components are called Electronics, and probably one of the most critical parts of modern technology is the Printed Circuit Board (PCB). Visit: https://andassemblypcb.livepositively.com/navigating-the-essentials-of-printed-circuit-board-assembly-pcb-board-and-pc-board-assembly-explained/

0 notes

Text

Streamlining Circuit Card Assembly: How PCB Board Assembly Simplifies Electronics Manufacturing

The world is constantly evolving in the field of electronics manufacturing-transforming technologies and innovations do not leave the industry. One of the substantial advancements has taken place in the way it deals with the circuit card assembly process. PCB board assembly is how PCBs make the manufacturing of electronic devices simple for a company to optimize its operations, improve product quality, and deliver in response to the ever-increasing demands of the marketplace. To read more click on the link now.

0 notes

Text

Printed Circuit Board (PCB) design is a meticulous art that requires precise attention to detail. Central to this process is PCB routing, the sophisticated method of connecting electrical components, defining the pathways for signal propagation within the circuit. This critical phase not only determines the efficiency of signal transmission but also holds the key to signal integrity, which is essential for optimal circuit performance. In this article, we’ll explore PCB routing in depth, highlighting its significance, best practices, guidelines, rules, recommendations, and strategies to ensure you achieve superior signal integrity in your designs.

0 notes

Text

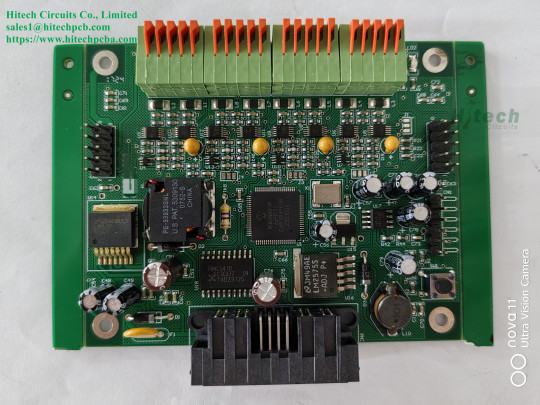

Professional PCBA Manufacturing Service by Hitech Circuits in China

As the demand for electronic devices continues to grow, understanding the complexities of Printed Circuit Board Assembly (PCBA) has become increasingly crucial. This comprehensive guide will provide an in-depth look at the PCBA process, the types of PCB assembly, and the various techniques and tips involved. We will also explore the meaning of PCBA in electronics, ensuring you have a thorough understanding of this vital component.

PCBA stands for Printed Circuit Board Assembly. Up to this meaning, it’s all fine. But the real problem starts right from here. Many, in fact, most people don’t understand the true meaning and purpose of the PCBA. And many would even confuse it with the PCB.

So, we decided to write on what is PCBA. Of course, it has a close connection with the Printed Circuit Board (PCB). A PCB refers to an electronic pad designed to transmit electronic signals while dissipating the heat generated due to the digital transmission.

And the PCBA refers to the complete electronic board after all of its components are assembled completely. It has several incredible benefits that make it a much sought-after element in the communicating and electronics industry.

Printed Circuit Board Assembly Services

Printed Circuit Board Assembly Service ( PCB Files & BOM List, please send to [email protected] ( Fast Quote )

Printed Circuit Board Assembly is a process that requires knowledge not just of Printed Circuit Board components and assembly but also of printed circuit board design, Printed Circuit Board fabrication and a strong understanding of the final product. Circuit board assembly is just one piece of the puzzle to delivering the perfect product the first time.

Printed Circuit Boards (PCBs) are across many industrial and consumer electronics, used in products ranging from remote controls to military weaponry. The versatility of PCBs comes from their lightweight, compact, and flexible construction, which can be adapted to suit circuits of any complexity. Though PCBs are relatively commonplace, their complexity makes it critical to source new circuit boards from reliable suppliers. Printed Circuit Board Assembly services harness these complexities.

Hitech Group offers comprehensive Printed Circuit Board Assembly services that help our customers fully realize their designs. We have extensive experience working with customers in a broad range of highly innovative industries, including Communication, Aerospace & Defence, Automotive, Industrial control, Medical equipments, Oil & Gas, Security, and so on.

What does PCBA Stand for in Electronics?

PCBA stands for Printed Circuit Board Assembly. It refers to the process of soldering electronic components to a printed circuit board (PCB) to create a functional circuit. The PCB is essentially the backbone of electronic devices, providing a solid foundation for components and facilitating connections between them. The assembly process involves soldering components to the board, and this completed assembly is then referred to as PCBA.

We offer the following PCB assembly services:

Quick-turn prototype printed circuit boardassembly Turn-key printed wiring board assembly Partial turn-key PCB assembly Consignment assembly RoHS compliant lead-free PCB assembly Non-RoHS assembly Conformal coating Final box-build and packaging

The process of PCBA manufacturing

Electronic Components sourcing – PCB fabrication- SMT Patch – DIP plug-in – board Assembly testing – Finished product assembly PCB Assembly requires electronic components and consumables Printed Circuit Board, Electronic Components, Solder Wire, Solder Paste, Welding Rod, Solder Preform (depending on welding type), Scaling Powder, Welding Platform, Wave Soldering Machine, SMT Equipment, Testing Equipment PCB manufacturing Hitech Group provides a full set of PCBA manufacturing and part of PCB assembly manufacturing. In the full range of PCB assembly manufacturing, we handle PCB production, material procurement, online order tracking, incoming material certification/quality inspection, and final assembly. In some PCB manufacturing, you can order PCB and some materials by yourself, and we complete other parts.

Please feel free to contact [email protected] if you have any PCB needs.

For more, please visit https://hitechcircuits.com/pcb-assembly/printed-circuit-board-assembly-services/

0 notes

Text

Enhance Your Electronics with Aluminum PCB Boards

Hitech Circuits Co., Ltd. is a top PCB manufacturer in China, dedicated to providing high-quality products. We offer a variety of metal-based printed circuit boards, including Aluminum PCBs, Copper PCBs, Ceramic PCBs, and Metal Core PCBs, all at great prices. Trust us for your PCB needs. Visit our website today!

0 notes

Text

Nice looking silver plated PCB board made of PET on display!

#pcb#pcb china#pcb assembly#pcb manufacturer#pcbdesign#https://www.dqspcba.com/#flexible pcb board#flex pcb

3 notes

·

View notes

Text

PCB layout--MakerPCB

PCB or PCB assembly quickly offer, feel free email to [email protected]

https://www.linkedin.com/in/marcia-liu-0566a11b1/

#electronic#uav#pcb assembly#pcb#pcb manufacturer#flexible pcb board#flex pcb#electrical design#engineering#electrical#electricity

4 notes

·

View notes

Text

hi,I'm zoe,a sales engineer in the Shenzhen STHL Electronics Co.,Ltd.we are a professional PCB & PCBA manufacturing servicer with more than 18 years of experience located in Shenzhen, China. Mainly provide services of electronic components sourcing + PCB fabrication + PCB Assembly + Housing assembly + Function testing services.

Our factory covers 7000+ square meters, has 5 (Panasonic) high-speed SMT production lines, 2 DIP lines, 2 testing lines, and 180+ workers, passed ISO9001, ISO14001, ISO13485 and IATF 16949 certifications, win recognization by Littelfuse, Hisense,Surfilter, etc.

2 notes

·

View notes

Text

PCB schematic/design/fabrication/assembly

MPN TECH Pte Ltd provides One-Stop PCBA Solutions in Singapore, which support from R&D prototype to mass production. We have built long-term collaborations with many local startups, SIMES, MNCS, etc. We also have lots of overseas PCBA projects in Europe and the US. If any questions feel free to let me know.

Our Solutions:

PCB Design;

PCB Fabrication;

Components souring;

PCB Assembly;(SG Local machine Assembly)

3 notes

·

View notes

Text

#circuit board manufacturing#circuit board manufacturing companies#electronics manufacturing company#electronics manufacturing company in delhi#pcb assembly#pcb assembly services#pcb board assembly#pcb board manufacturer#pcb board manufacturers in India#pcb manufacturer in delhi ncr#pcb suppliers in india#printed circuit board manufacturers in India

0 notes

Text

What Defines Quality in Circuit Card Assembly? How is PCB Board Assembly Executed for Reliability?

Circuit Card Assembly (CCA) is a basic prepare in the electronics manufacturing industry, including the exact arrangement and soldering of electronic components onto printed circuit boards (PCBs). Quality in circuit card assembly is characterized by a few key variables counting component exactness, fastening keenness, cleanliness, testing, and adherence to industry benchmarks. These components guarantee that the conclusion item performs dependably in its designing application, whether in customer electronics, aviation, restorative electronics, or mechanical machinery.

One of the first markers of quality in circuit card Assembly is component situation exactness. Misaligned or erroneously arranged components can lead to glitches, shorts, or indeed total gadget disappointment. Computerized machines like pick-and-place frameworks are utilized to accomplish tall accuracy and consistency, altogether lessening the plausibility of human error.

Solder joint integrity is another major quality determinant. Destitute soldering can cause irregular associations or add up to detachment. Methods such as reflow fastening for surface-mount components and wave fastening for through-hole components offer assistance guarantee solid, solid joints. These forms are carefully controlled in terms of temperature and timing to avoid harm to touchy components and to guarantee appropriate wetting of solder.

Cleanliness moreover plays a significant part in circuit card assembly. Leftover flux, tidy, or other contaminants can debase execution or cause erosion over time. Subsequently, post-soldering cleaning forms are utilized, particularly for high-reliability applications, to evacuate ionic and non-ionic build-ups that might affect the board's function.

Rigorous testing procedures are crucial to keep up quality. Visual review, Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and Functional Testing (FCT) are standard hones. These procedures offer assistance distinguish lost components, destitute patch joints, and useful mistakes some time recently the item comes to the client. AOI and X-ray assessment are especially valuable for confirming patch joints beneath components like BGAs (Ball Framework Clusters), which are not obvious to the exposed eye.

Adherence to industry measures, such as IPC-A-610 for worthiness of electronic congregations and ISO 9001 for quality administration frameworks, too characterizes quality in CCA. Compliance guarantees that manufacturing forms meet all inclusive recognized benchmarks for execution and reliability.

To execute PCB Board Assembly for unwavering quality, a orderly and controlled manufacturing approach is significant. This incorporates design for manufacturability (DFM), which guarantees that the PCB format minimizes manufacturing issues and maximizes abdicate. Selecting high-quality components, utilizing vigorous materials for the board substrate, and keeping up strict natural controls (like stickiness and inactive security) encourage contribute to the long-term unwavering quality of the amassed board.

In expansion, thermal management amid both manufacturing and operational utilize is basic. Heat sinks, thermal vias, and suitable PCB design diminish the hazard of heat-related disappointments. Unwavering quality testing such as warm cycling, vibration testing, and natural push screening recreate real-world conditions and offer assistance distinguish shortcomings some time recently the item is released.

In conclusion, quality in circuit card Assembly is a mix of exactness building, thorough testing, and adherence to measures. PCB board assembly, when executed with these standards, comes about in dependable, strong items able of withstanding the requests of their applications. Together, these hones frame the spine of high-performance electronics manufacturing.

0 notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

PCB Assembly Process Explained: A Detailed Handbook Discover the essentials of PCB assembly in this comprehensive guide. Get insights into every step, from design to production. Ready to enhance your electronics project? Visit A2ZEMS for expert PCB solutions.

1 note

·

View note

Text

PCB Fabrication is the foundational process that transforms raw materials into the physical structure of a Printed Circuit Board. It involves several steps that convert a schematic diagram into a tangible board. This process lays down the framework for the electronic components that will be added later.

0 notes