#PPE monitoring software

Explore tagged Tumblr posts

Text

Personal Protective Equipment (PPE) Detection Software

Enhance workplace safety with ThirdEye AI's PPE monitoring software for manufacturing. Our personal protective equipment (PPE) detection technology ensures compliance, alerting on violations and promoting a safer environment. With advanced PPE monitoring solutions, track and manage the usage of safety gear seamlessly, safeguarding your workforce and operations. Experience efficient PPE monitoring for heightened workplace safety.

#PPE monitoring software for manufacturing#PPE detection technology#PPE monitoring software#PPE monitoring solutions#personal protective equipment

0 notes

Text

Harnessing the Power of Artificial Intelligence for Workplace Safety

🚀 Ready to see how Artificial Intelligence is transforming workplaces? Visionify is at the forefront of innovation with solutions that leverage AI to enhance safety, productivity, and compliance. Our new blog, “AI for Workplace Safety: The Economic Impact,” dives into the role of AI in creating safer industrial environments.

With Camera AI Technology, companies gain real-time monitoring for Workplace Safety, enabling proactive hazard detection and PPE Compliance assessment. These AI for Workplace Safety solutions make managing risks easier and create safer environments for everyone.

See how PPE Detection and other tools from Visionify are supporting compliance while minimizing incidents. Dive into the future of workplace safety with AI-powered tools designed to make workplaces smarter, safer, and more productive!

Know more.: Vision AI, Workplace Compliance Monitoring, safety tips, PPE Compliance, Easy to use EHs software, Workplace Safety AI solution, Machine Learning for Manufacturing, what is compliance in the workplace, Computer Vision Workplace Safety, Workplace safety Software, AI employee monitoring, safety KPI’s, industrial safety, Industrial safety companies, smoke and fire detector, construction monitoring, hazard analysis, accident prevention, health and safety app, Workplace Safety

#Vision AI#Workplace Compliance Monitoring#safety tips#PPE Compliance#Easy to use EHs software#Workplace Safety AI solution#Machine Learning for Manufacturing#what is compliance in the workplace#Computer Vision Workplace Safety#Workplace safety Software#AI employee monitoring#safety KPI’s#industrial safety#Industrial safety companies#smoke and fire detector#construction monitoring#hazard analysis#accident prevention#health and safety app#Workplace Safety

0 notes

Text

Best Practices for Disinfecting Your CO2 Incubator Safely

Summary

CO2 incubators are essential for cell culture and biomedical research but are prone to contamination due to their warm and humid environment.

To prevent microbial growth and protect research integrity, regular disinfection is crucial. Use non-corrosive, broad-spectrum disinfectants such as 70% ethanol or hydrogen peroxide, and avoid harsh chemicals like bleach.

Follow a clear cleaning schedule that includes daily inspections, weekly pan cleanings, monthly deep cleans, and periodic sterilization using built-in UV or heat cycles.

Always wear your PPE, follow manufacturer guidelines, and disinfect associated lab tools to maintain a contamination-free environment.

Introduction

CO2 incubators are essential tools in laboratories that focus on cell culture, microbiology, and biomedical research. These devices create a controlled environment that mimics physiological conditions, maintaining stable temperature, humidity, and carbon dioxide levels to support cell growth.

However, without sufficient laboratory equipment disinfection, their warm and humid interior makes them a perfect breeding ground for contaminants like bacteria, fungi, and mycoplasma. Apart from contaminating experiments, destroying sample integrity, and increasing downtime in the lab, contaminated equipment poses a potential safety hazard and can lead to compliance violations.

In this guide, we will walk you through the best practices for safely disinfecting your CO2 incubator, choosing the proper disinfectant, and helping you avoid costly mistakes.

Understanding Your CO₂ Incubator

A CO2 incubator is a specialized piece of laboratory equipment designed to cultivate and maintain cell cultures under controlled environmental conditions. Key functions of a CO2 incubator include:

Temperature Control: CO2 incubators maintain a temperature of 37 degrees Celsius, which is optimal for many cell types, including the temperature of the human body.

CO2 Regulation: Your incubator helps maintain the pH of culture media, typically at around 5%, which is optimal for cell viability and function. This process is achieved through a sodium bicarbonate buffering system.

Humidity Control: The incubator maintains 90-95% humidity to prevent the culture media from drying out and to minimize evaporation.

Sterilization: Many CO2 incubators incorporate hot air sterilization routines to prevent contamination, which is a common issue in cell culture labs.

Monitoring and Control: Some CO2 incubators have sensors and software to monitor and adjust parameters such as temperature, humidity, and CO2, ensuring a stable environment for scientific success.

When and How Often Should You Disinfect a CO₂ Incubator?

Routine laboratory equipment disinfection is crucial for preventing contamination of your CO2 incubator. The frequency of disinfection should depend on the incubator's usage frequency, the type of experiment it is used for, and its history of contamination.

Here is a detailed disinfection schedule for you:

Daily

Inspect the interior for signs of spills and contaminants.

Wipe down the exterior of the incubator, especially frequently touched areas like handles.

Check the water pan and ensure it is filled with fresh, sterile, distilled water.

Weekly

Empty, clean, and disinfect the water pan.

Refill with fresh, sterile distilled water.

Monthly

Perform a thorough interior cleaning.

Remove and clean all internal components, such as shelves and racks.

Wipe down the interior chamber with a disinfectant solution (70% ethanol).

Clean and disinfect the CO2 sensor, if it is accessible.

Clean and disinfect the exterior surfaces.

Consider replacing the HEPA filter according to the manufacturer’s specifications.

Every 6 months

If your incubator has an automatic disinfection routine, run it according to the manufacturer’s specifications.

Annually

Schedule professional preventive maintenance, including calibration checks and replacement of worn parts.

When to Disinfect Immediately

If there is visible contamination (mold, strange odor, cloudy water in the pan).

After spills of media or biological material.

After culturing high-risk organisms, such as primary cells, fungi, or pathogens.

Before starting a sensitive or long-term experiment.

After detecting mycoplasma or other microbial contamination during testing.

Choosing the Right CO₂ Incubator Disinfectant

Not all disinfectants are suitable for sensitive equipment, such as a CO2 incubator. Choosing the wrong solution can damage your equipment, leave toxic residues behind, or fail to eliminate stubborn contaminants like mycoplasma. When selecting a disinfectant, prioritize compatibility with your equipment’s materials and efficacy.

Key factors to consider include:

Material Compatibility

Most CO2 incubators are constructed from stainless steel, featuring sensitive sensors and seals. Therefore, when choosing disinfectants, prioritize non-corrosive solutions, such as 70% ethanol or isopropanol. Additionally, ensure that no residues are left that can affect cell culture.

Broad-Spectrum Efficacy

Disinfecting your CO2 is not just about surface cleanliness; it is about biological control. Cell culture incubators are vulnerable to a wide range of contaminants, including bacteria, fungi, mold, viruses, and mycoplasma. A broad-spectrum or general lab disinfectant ensures that you are targeting all relevant threats, not just the usual ones.

Some broad-spectrum solutions include peracetic acid, hydrogen peroxide (3-6%), and quaternary ammonium compounds (Quats).

Ease of Use

In a fast-paced laboratory environment, the best disinfectant is one that is easy to prepare, apply, and remove without requiring extra steps or excessive downtime. Examples of easy-to-use disinfectant solutions include pre-mixed 70% ethanol and hydrogen peroxide.

Step-by-Step Guide to Disinfecting Your CO₂ Incubator

CO2 laboratory equipment disinfection is more than just wiping down the equipment with a chemical solution. The following steps help you achieve a thorough disinfection while also protecting key components:

Pre-Cleaning Precautions

Before starting, turn off your equipment and disconnect the CO2 supply. Follow personal safety procedures, including putting on your personal protective equipment (PPE). Remove all items and components, placing them in a separate area for cleaning and disinfection.

Cleaning the Interior Components

Using a mild detergent and a soft cloth, gently clean the chamber walls, shelves, and supports, the door, and rubber gaskets, as well as other interior components. Rinse the components with sterile water to remove any soap or debris that can interfere with disinfection.

Disinfecting the Water Pan

Empty the water pan and scrub it with detergent and distilled water. Disinfect the pan with 70% ethanol, hydrogen peroxide, or any solution recommended by the equipment’s manufacturer. Wait 5-10 minutes, then rinse the pan with sterile water.

UV or Heat Sterilization Options

If your incubator has an in-built sterilization procedure, run the program after manual sterilization for maximum effect.

High-heat sterilization is the most effective method for complete sterilization, as temperatures can reach 160-180 degrees Celsius, and the disinfection program can run for up to 12 hours. Do not open the door until the full heating and cooling process is complete. Additionally, avoid running this cycle with live cultures, media, or heat-sensitive parts in the equipment.

UV sterilization uses UV-C light (254 nm) to damage microbial DNA. This type of disinfection is only effective for microorganisms on exposed surfaces. It does not effectively clean spores or mycoplasma.

Reassembling and Restarting the Unit

After sterilization, wipe all parts and components of the incubator before returning them inside. Also, reassemble the shelves, racks, and water pans. Reconnect the CO2 and power supply, and wait for the equipment to stabilize in terms of temperature, humidity, and CO2 levels before reintroducing cultures.

Disinfecting Associated Laboratory Equipment

To maintain a contamination-free environment, disinfecting your incubator is not enough. You must ensure that all associated laboratory equipment, especially that which has come into contact with your incubator, is disinfected. Neglecting associated laboratory equipment disinfection can reintroduce bacteria, fungi, or mycoplasma to a freshly cleaned chamber.

For example, you should consider a biosafety cabinet disinfection. Other equipment includes:

Pipettes and Holders

Media Bottles and Reagent Containers

CO2 Supply Lines and Ports

Water Pan

Shelving and Racks

Safety Tips and Common Mistakes to Avoid

Here is how you can stay safe and avoid mistakes that can lead to equipment damage or contamination:

Safety Tips

Always Wear Your PPE

Ensure you always wear your PPE (gloves, eye protection, and lab coat) to prevent skin or eye contact with disinfectants. Also, change your gloves before cleaning and reassembly to avoid cross-contamination.

Work in a Well-Ventilated Area

CO2 incubator disinfectants, such as ethanol and hydrogen peroxide, release vapors. Ensure you are in a well-ventilated area to avoid inhaling these vapors. For maximum protection, work in a fume hood.

Follow Manufacturer Guidelines

Check your equipment’s manuals for a list of approved disinfectants, safe temperature ranges, and appropriate cleaning procedures. Ignoring these guidelines may void your warranties or damage sensitive parts.

Mistakes to Avoid

Using Bleach or Strong Acids

Avoid using bleach because it is corrosive and can damage stainless steel. It can also permanently damage interior surfaces.

Spraying Disinfectant Directly on Sensors or Fans

Never spray disinfectants directly on components. The liquids can damage CO2 sensors, humidity probes, and air circulation fans.

Conclusion

Proper laboratory equipment disinfection is essentially about maintaining cleanliness. It is a crucial process that can significantly impact scientific success, personnel safety, and compliance.

While disinfection is essential, it is more important that you follow proper cleaning procedures, use the right cleaning solution, and follow the manufacturer’s guidelines to ensure adequate disinfection and protect your equipment from damage.

Are you about to disinfect your equipment and unsure about the correct process? Contact R&D Laboratory Equipment for more information.

FAQs

1. What is the best CO₂ incubator disinfectant?

The best disinfectant for your CO2 incubator is a non-corrosive, residue-free solution. Some popular disinfectants include 70% ethanol, hydrogen peroxide, and peracetic acid.

2. How often should the incubator water bath be cleaned?

Your incubator water bath disinfectant should be cleaned and changed every week.

3. Can I use a general lab disinfectant inside my CO₂ incubator?

No, it is generally not recommended to use a general disinfectant inside a CO2 incubator. Many of these disinfectants contain volatile organic compounds (VOCs) that can be harmful to cell cultures and interfere with the incubator's performance.

4. How do I safely disinfect a biosafety cabinet used with incubator samples?

To safely disinfect a biosafety cabinet with used incubator samples, thoroughly clean the interior surfaces with a 70% ethanol disinfectant.

5. What risks are involved with poor laboratory equipment disinfection?

The risks of poor lab equipment disinfection include the spread of laboratory-acquired infections (LAIs), contamination of samples, false results, cross-contamination, compliance violations, etc.

6. What are the hazards of CO2 incubators?

The potential hazards of CO2 incubators include biological contamination, exposure leading to suffocation, operational hazards (temperature fluctuations, power issues), and damage from mishandling. b

7. What are the safety precautions for incubators?

Incubators should be placed away from high-traffic areas, avoid damp, humid, or sheltered areas, and be placed away from direct sunlight, draft, or unbalanced surfaces.

8. How do you disinfect an incubator?

Apply the appropriate disinfectant to a soft cloth. Gently wipe down the interior of the incubator, focusing on areas with visible residue, stains, or debris. Ensure that all surfaces, corners, and doors are cleaned thoroughly. Leave the disinfectant active for 10 minutes before rinsing.

9. How do you prepare an incubator for safe use?

To prepare an incubator for safe use, thoroughly clean and disinfect it, ensure proper temperature and humidity settings, place it in a stable environment and away from drafts or sunlight, and monitor its performance regularly.

10. Can I clean my incubator with bleach?

Bleach is not recommended for cleaning CO2 incubators, especially those with stainless steel chambers.

Original Source: https://rdlaboratoryequipment.com/blogs/all/best-practices-to-disinfect-co2-incubator

0 notes

Text

AI PPE Detection Software

Enhance workplace safety with AI PPE Detection Software. Our advanced PPE tracking system ensures real-time compliance monitoring and reduces risks with automated safety checks.

0 notes

Text

How Safety Platforms Help Prevent Accidents Before They Happen

In today’s fast-paced work environments, preventing accidents before they occur is not just a goal—it’s a necessity. Safety platforms have emerged as pivotal tools in achieving this proactive approach. By leveraging advanced technologies and fostering a culture of safety, these platforms are transforming workplaces across industries.

What Are Safety Platforms?

Safety platforms are integrated systems designed to monitor, analyze, and enhance workplace safety. They combine hardware (like sensors and wearables) with software (such as analytics dashboards and reporting tools) to provide real-time insights and predictive analytics. These platforms aim to identify potential hazards, ensure compliance, and promote a culture of continuous safety improvement.

How Do Safety Platforms Prevent Accidents?

1. Real-Time Monitoring and Alerts

Modern safety platforms utilize sensors and IoT devices to continuously monitor workplace conditions. For instance, AI-powered systems can detect if a worker is not wearing the required PPE or if machinery is operating outside safe parameters. Immediate alerts allow for swift corrective actions, reducing the likelihood of accidents.

2. Predictive Analytics

By analyzing historical data, safety platforms can predict potential hazards. For example, if data shows a pattern of near-misses in a particular area, the system can flag it for further investigation and preventive measures.

3. Enhanced Training and Simulation

Safety platforms often include training modules that use virtual reality (VR) and augmented reality (AR) to simulate hazardous scenarios. This immersive training helps workers recognize and respond to potential dangers effectively.

4. Behavioral Safety Tracking

These platforms can monitor worker behaviors, identifying patterns that may lead to accidents. For instance, frequent short breaks might indicate fatigue, prompting interventions to prevent errors or mishaps.

What Are the Key Features of Effective Safety Platforms?

Integration with Existing Systems: Seamless compatibility with current workplace tools ensures efficient implementation.

User-Friendly Interface: Intuitive dashboards and controls make it easier for staff to engage with the platform.

Scalability: The ability to adapt to various sizes and types of operations is crucial for widespread adoption.

Compliance Management: Automated tracking of regulatory requirements helps maintain adherence to safety standards.

Why Is Proactive Safety Management Important?

Proactive safety management shifts the focus from reacting to incidents to preventing them. This approach not only safeguards employees but also reduces downtime, lowers insurance costs, and enhances overall productivity. By identifying and addressing risks before they result in accidents, organizations can create a safer and more efficient work environment.

How Do Safety Platforms Foster a Culture of Safety?

Safety platforms encourage continuous engagement with safety protocols. Features like gamified training, regular feedback, and easy reporting mechanisms empower employees to take an active role in maintaining a safe workplace. This collective responsibility reinforces a culture where safety is a shared priority.

What Are the Challenges in Implementing Safety Platforms?

Cost: Initial investment in technology and training can be substantial.

Resistance to Change: Employees may be hesitant to adopt new systems, requiring effective change management strategies.

Data Privacy Concerns: Monitoring systems must balance safety with respect for personal privacy.

Technical Issues: Integration with existing systems and ensuring uptime can pose technical challenges.

What Industries Benefit Most from Safety Platforms?

While all industries can benefit, sectors with higher risk profiles see the most significant impact:

Construction: Monitoring equipment usage and worker movements to prevent falls and equipment-related injuries.

Manufacturing: Ensuring machinery operates within safe parameters and workers follow safety protocols.

Healthcare: Protecting staff from exposure to hazardous materials and ensuring patient safety.

Transportation: Monitoring driver fatigue and vehicle conditions to prevent accidents.

How Do Safety Platforms Integrate with Wearable Technology?

Wearable devices, such as smart helmets and vests, can collect data on worker movements, environmental conditions, and physiological indicators. This data feeds into safety platforms, providing real-time insights and enabling immediate responses to potential hazards.

What Is the Future of Safety Platforms?

The evolution of safety platforms will likely include:

Advanced AI Capabilities: Improved predictive analytics for even more accurate hazard identification.

Greater Integration: Seamless connectivity with a broader range of devices and systems.

Enhanced User Experience: More intuitive interfaces and personalized safety recommendations.

Focus on Mental Health: Incorporating tools to monitor and support employee mental well-being.

FAQ

Q1: Are safety platforms suitable for small businesses?

Yes, many safety platforms offer scalable solutions tailored to the needs and budgets of small businesses.

Q2: How do safety platforms handle data privacy?

Reputable platforms comply with data protection regulations and implement robust security measures to safeguard personal information.

Q3: Can safety platforms be customized for specific industries?

Absolutely. Many platforms offer industry-specific modules and features to address unique safety challenges.

Q4: What training is required to use a safety platform?

Training requirements vary, but most platforms are designed with user-friendly interfaces and provide comprehensive onboarding resources.

Q5: How quickly can a safety platform be implemented?

Implementation timelines depend on the complexity of the system and the size of the organization but can range from a few weeks to several months.

0 notes

Text

AI and IoT Integration Transform the Track and Trace Solutions Market

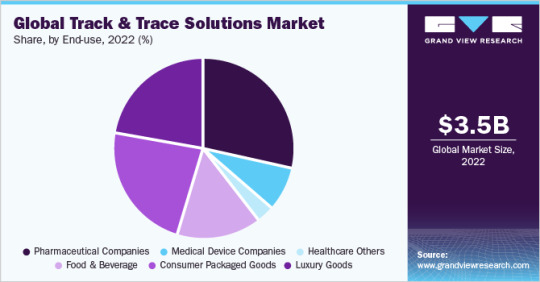

Track and Trace Solutions Market Growth & Trends

The global Track and Trace Solutions Market is experiencing significant growth, driven by various factors, with a projected size of USD 14.3 billion by 2030, expanding at a CAGR of 19.3% from 2023.

Key Drivers:

Brand Protection from Counterfeit Products and Theft: This is a major factor, especially for pharmaceutical and biopharmaceutical companies, as track and trace solutions help enhance distribution channel efficiency and reduce the prevalence of fake products.

Regulatory Compliance: Governments and regulatory authorities worldwide are increasingly implementing stringent regulations (e.g., US Drug Supply Chain Security Act (DSCSA), EU Falsified Medicines Directive (FMD)) that mandate serialization and traceability to ensure product authenticity, safety, and combat illegal supply chains.

Enhanced Supply Chain Transparency and Efficiency: These solutions provide real-time visibility into product movement, aiding in inventory management, managing recalls, and improving overall supply chain operations.

Technological Advancements: The introduction and integration of advanced technologies like RFID, 2D barcodes, IoT, AI, and blockchain are significantly boosting the capabilities and adoption of track and trace systems.

Rising Adoption by Healthcare Manufacturers: The growing medical device and pharmaceutical industries are increasingly deploying these solutions to safeguard their products and reputation.

COVID-19 Outbreak: The pandemic highlighted the critical need for efficient monitoring and tracing technologies, especially for medical supplies and vaccines, leading to increased adoption and innovation in the market. Seizures of false COVID-19 tests and PPE, and initiatives like Smartrac's partnership with SUKU and OPTEL's collaboration with Bureau Veritas for vaccine supply chain logistics, demonstrate this impact.

Challenges:

High Deployment Cost: The initial cost of implementing serialization and aggregation solutions, including hardware, software, and integration with existing systems, can be a significant barrier, particularly for small and medium-sized enterprises (SMEs).

Lack of Common Regulations and Standards: Inconsistent regulations across different geographies can complicate implementation and hinder market growth in some developing regions.

Data Security and Privacy Issues: Handling large volumes of sensitive product and supply chain data requires robust cybersecurity measures to prevent breaches and unauthorized access.

Key Trends:

Serialization as a Prime Method: Serialization, which involves assigning a unique identifier to each product, is a crucial method facilitating easy track and trace globally.

Growth in Software Solutions: Software solutions hold a significant market share due to their ability to provide end-to-end traceability, data management, and compliance with global standards.

Increasing Use of 2D Barcodes and RFID: These technologies are gaining traction due to their ability to store more data and provide fast, secure reading.

Strategic Collaborations and Partnerships: Companies are actively forming alliances to enhance their offerings and expand their market presence.

Overall, the global track and trace solutions market is on a strong growth trajectory, driven by the increasing need for product authenticity, supply chain transparency, and stringent regulatory mandates across various industries, particularly pharmaceuticals and healthcare.

Curious about the Track and Trace Solutions Market? Download your FREE sample copy now and get a sneak peek into the latest insights and trends.

Track and Trace Solutions Market Report Highlights

The software solutions product segment was the largest revenue-generating segment in 2022. This is mainly because of the regulatory mandates for the execution of serialization and aggregation in the healthcare sector

The serialization solutions application segment was the largest grossing segment in 2022. Increasing application of serialization in pharmaceutical and medical device packaging will be a vital factor contributing to the segment growth

The RFID technology segment is expected to exhibit the fastest growth rate during the forecast period. The key factors contributing to the growth of the segment are technological advantages, such as high durability and reusability, more data storage capacity, and no requirement of the line of sight

North America led the global market in 2022. The rising implementation of regulatory standards and regulations, along with the high adoption rate of track and trace solutions by consumers, is anticipated to contribute to the market growth

Track and Trace Solutions Market Segmentation

Grand View Research has segmented the global track and trace solutions market on the basis of product, technology, application, end-use, and region:

Track And Trace Solutions Product Outlook (Revenue, USD Million, 2017 - 2030)

Hardware Systems

Printing & Marking Solutions

Monitoring & Verification Solutions

Labeling Solutions

Others

Software Solutions

Plant Manager Software

Line Controller Software

Bundle Tracking Software

Others

Track And Trace Solutions Technology Outlook (Revenue, USD Million, 2017 - 2030)

Barcode

RFID

Track And Trace Solutions Application Outlook (Revenue, USD Million, 2017 - 2030)

Serialization Solutions

Bottle Serialization

Label Serialization

Carton Serialization

Data Matrix Serialization

Aggregation Solutions

Bundle Aggregation

Case Aggregation

Pallet Aggregation

Track And Trace Solutions End-use Outlook (Revenue, USD Million, 2017 - 2030)

Pharmaceutical Companies

Medical Device Companies

Healthcare Others

Food and Beverage

Consumer Packaged Goods

Luxury Goods

Download your FREE sample PDF copy of the Track and Trace Solutions Market today and explore key data and trends.

0 notes

Text

Top 5 Challenges in Steel Structure Fabrication & How Experts Overcome Them

The field of structural fabrication is one of the most essential pillars in the construction and manufacturing sectors. From bridges to skyscrapers, steel structures form the backbone of modern infrastructure. Yet, behind the scenes of every robust and resilient steel structure lies a complex and multifaceted fabrication process fraught with challenges. Despite its many benefits, steel structure fabrication is not without hurdles. Let's dive into the top five challenges professionals face and explore how seasoned experts overcome them—using innovation, precision, and technology like the plate bending machine.

1. Precision in Design and Execution

One of the most critical challenges in structural fabrication is achieving precision in both design and execution. Unlike other construction materials, steel requires extremely accurate cuts, bends, and joins. A minor error in measurements can lead to structural misalignments, safety risks, and costly rework.

How Experts Overcome It:

Advanced CAD/CAM Software: Modern engineers use cutting-edge Computer-Aided Design (CAD) and Manufacturing (CAM) tools to produce highly accurate blueprints and machining paths.

Laser Cutting & CNC Machines: These technologies help in precise cutting and shaping of steel parts.

Quality Assurance Protocols: Regular inspections and standardized procedures ensure that each piece meets the required specifications.

A pivotal piece of equipment in achieving this precision is the plate bending machine, which ensures uniform curves and bends, reducing the risk of manual errors.

2. Material Handling and Safety

Handling heavy steel components poses safety risks and logistical challenges. Accidents during lifting, welding, or cutting not only endanger workers but also delay project timelines.

How Experts Overcome It:

Training & Safety Protocols: Workers undergo rigorous safety training and are equipped with personal protective equipment (PPE).

Automated Material Handling Systems: Cranes, conveyors, and robotic arms are now widely used to move heavy steel plates safely.

Smart Sensors & IoT Devices: These devices help monitor load balance, temperature, and movement to prevent mishaps.

Using well-calibrated machines like the plate bending machine also reduces the physical labor involved, thereby minimizing the chances of injury.

3. Welding and Joining Techniques

Welding is a vital step in structural fabrication, but it can be difficult due to the varying thickness and composition of steel. Poor welding can result in weak joints, which can compromise the integrity of the entire structure.

How Experts Overcome It:

Skilled Workforce: Certified welders trained in MIG, TIG, and arc welding techniques are indispensable.

Pre-heating and Post-heating Processes: These help in reducing residual stress and avoiding cracks.

Ultrasonic and Radiographic Testing: These non-destructive methods are employed to ensure weld quality.

High-performance plate bending machines are used to shape steel components perfectly before they are welded, ensuring a better fit and stronger joints.

4. Cost Management and Budget Constraints

Steel structure fabrication is often subject to budget constraints and cost overruns due to fluctuating raw material prices, unexpected delays, or inefficient planning.

How Experts Overcome It:

Lean Manufacturing Principles: These practices help minimize waste and optimize resource usage.

Real-Time Project Management Tools: These enable better tracking of material usage, labor hours, and machine downtime.

Bulk Purchasing & Long-Term Contracts: Experts mitigate raw material cost fluctuations by negotiating better deals with suppliers, including plate bending machine manufacturers.

Investing in high-efficiency machines like the plate bending machine reduces labor costs and increases production speed, leading to overall cost savings.

5. Technological Integration and Equipment Maintenance

With rapid technological advancements, integrating new technologies into existing systems poses a challenge. Additionally, maintaining equipment such as plate bending machines requires specialized knowledge.

How Experts Overcome It:

Continuous Training Programs: These keep the workforce updated with the latest tools and technologies.

Scheduled Maintenance Plans: Preventive maintenance of machines ensures longevity and reduces downtime.

Partnering with Reputed Vendors: Collaborating with established plate bending machine manufacturers ensures access to quality products and reliable after-sales service.

Technological integration is not just about staying current; it's about ensuring that every part of the structural fabrication process is optimized for performance and reliability.

Conclusion

The process of steel structure fabrication is intricate and fraught with potential setbacks. However, by understanding the challenges and applying proven solutions, experts are able to maintain high standards of quality, efficiency, and safety. Precision equipment like the plate bending machine, strong relationships with trustworthy plate bending machine manufacturers, and an unwavering commitment to excellence form the backbone of modern structural fabrication success.

For companies looking to delve into the world of steel structure fabrication, aligning with experienced partners and investing in quality tools will make all the difference.

#3 roll bending machine#plate rolling machine#plate bending machine#3 roll plate bending machine#4roll bending machine

0 notes

Text

5 Ways to Reduce Costs in Your Construction Supply Chain Without Sacrificing Quality

5 Ways to Reduce Costs in Your Construction Supply Chain Without Sacrificing Quality

In the construction industry, managing costs is a constant balancing act. Every dollar saved can boost your bottom line, but cutting corners on quality risks delays, rework, and unhappy clients. For contractors and builders, the supply chain—encompassing tools, materials, and equipment—is a prime area for cost optimization. At Supply On Time, we empower construction professionals with high-quality industrial supplies and strategic solutions to keep projects on budget and on schedule.

This post explores five proven strategies to reduce costs in your construction supply chain without compromising the quality your projects demand. From smarter procurement to leveraging technology, these approaches will help you work more efficiently while maintaining the standards that define your reputation.

Streamline Procurement with Strategic Supplier Partnerships

The foundation of a cost-effective supply chain lies in who you choose to supply your materials. Partnering with a reliable supplier like Supply On Time ensures access to durable tools, safety gear, and equipment at competitive prices. Rather than juggling multiple vendors, consolidating your procurement with a single trusted provider reduces administrative overhead and unlocks bulk discounts. A streamlined supplier relationship also means faster communication and fewer errors, saving you time and money.

To implement this, evaluate your current suppliers based on pricing, delivery reliability, and product quality. Transition to a primary supplier that offers a comprehensive catalog, like Supply On Time’s extensive inventory, to simplify ordering and negotiate better terms. For example, a contractor sourcing power tools and PPE from one vendor can reduce shipping costs and secure loyalty discounts, all while ensuring every item meets industry standards.

Adopt Just-In-Time Inventory Practices

Holding excess inventory ties up capital and increases storage costs, but stockouts can halt your job site. Just-In-Time (JIT) inventory strikes a balance by ordering supplies only as needed, minimizing waste while ensuring timely availability. This approach relies on precise coordination with suppliers to deliver materials like fasteners or concrete anchors exactly when your crew needs them.

Start by analyzing your project timelines and identifying high-turnover items. Work with a supplier offering fast delivery options from Supply On Time to support JIT practices. For instance, a builder renovating a commercial space might order safety vests and cutting tools in small batches aligned with project phases, reducing on-site clutter and freeing up funds for other priorities. The key is a supplier you can trust to deliver on time, every time, without compromising quality.

Leverage Technology for Inventory Management

Manual inventory tracking is a recipe for errors, overstocking, and missed opportunities to save. Modern inventory management systems, such as cloud-based software or Enterprise Resource Planning (ERP) tools, provide real-time visibility into your stock levels, helping you order smarter. These platforms can forecast demand based on past projects, preventing costly shortages or surplus.

To get started, invest in a user-friendly tool that integrates with your supplier’s ordering system. Supply On Time’s online platform makes it easy to track orders and reorder essentials like drill bits or gloves. A contractor managing multiple job sites, for example, can use software to monitor tool usage across projects, ensuring they only purchase what’s necessary. This data-driven approach maintains quality by prioritizing reliable, high-performance supplies while cutting unnecessary expenses.

Invest in Durable, High-Quality Tools

It’s tempting to opt for cheaper tools to save upfront, but low-quality equipment often fails faster, leading to replacements and downtime. Investing in durable, high-quality tools from a reputable supplier ensures longevity and performance, reducing long-term costs. For instance, a premium cordless drill from Supply On Time might cost more initially but will outlast a budget model, saving you money over the life of your projects.

Focus on tools and equipment with proven reliability for construction demands, such as those in Supply On Time’s tool catalog. A builder working on heavy-duty framing can prioritize robust hammers and saws that withstand daily use, avoiding frequent replacements. Pair this with regular maintenance to extend tool life, ensuring quality remains high while expenses stay low.

Optimize Delivery Logistics

Delivery costs can quietly erode your budget, especially if you’re paying for rushed shipments or inefficient routes. Optimizing logistics involves consolidating orders, choosing suppliers with local warehouses, and leveraging delivery options that align with your schedule. A supplier with a strong logistics network, like Supply On Time, can minimize shipping fees and ensure supplies arrive when needed.

To reduce costs, plan orders to combine multiple items into a single shipment, cutting down on per-order fees. Take advantage of Supply On Time’s same-day delivery for urgent needs, which is often more cost-effective than expedited shipping from distant vendors. For example, a contractor on a tight deadline can order safety harnesses and anchors in one delivery, avoiding multiple trips or premium shipping charges. Local warehousing also ensures faster, cheaper deliveries without sacrificing the quality of your supplies.

Real-World Impact: A Contractor’s Success

Consider Mike, a contractor overseeing a multi-family housing project. Facing budget pressure, he consolidated his tool and PPE purchases with Supply On Time, negotiated a bulk discount, and adopted JIT inventory for high-use items like nails and gloves. By using inventory software to track usage and scheduling consolidated deliveries, Mike cut his supply chain costs by 15% without compromising the quality of his materials. His crew stayed productive, and the project finished under budget, earning praise from his client.

This kind of efficiency is within reach for any contractor willing to rethink their supply chain.

Getting Started with Cost Savings

Ready to trim your supply chain costs while keeping quality first? Begin with these steps:

Assess your current suppliers and consolidate with a trusted partner like Supply On Time.

Pilot JIT inventory for one project phase to test its impact.

Explore affordable inventory management tools that sync with your ordering process.

Prioritize durable tools and equipment for long-term savings.

Plan deliveries to minimize shipping costs and leverage local suppliers.

Final Thoughts

Reducing costs in your construction supply chain doesn’t mean cutting corners. By partnering with a reliable supplier, embracing smart inventory practices, leveraging technology, investing in quality, and optimizing logistics, you can save money while delivering projects that meet the highest standards. Supply On Time is here to support you with a vast selection of industrial supplies and delivery options designed for construction success.

0 notes

Text

viAct - Scaffolding Safety Management Software

viAct’s Scaffolding Safety Software is built for construction sites to automate scaffold risk monitoring with AI-powered precision. Using real-time Computer Vision via viMAC (Edge Device), it detects unsafe practices and enforces safety 24/7 without manual oversight.

The system alerts site teams for:

• Unsafe scaffold erection/dismantling • Incomplete/unstable platforms • Missing guardrails & mid-rails • Workers without PPE or harnesses • Unauthorized scaffold access • Fall risks and safety violations

With automated incident detection, visual proof, and digital reporting, it streamlines audits and enforces safety compliance.

Fast to deploy and integrate, viAct’s plug-and-play solution helps contractors cut scaffold-related risks, reduce delays, and maintain safer construction zones without disrupting operations.

Intended for these roles:

• Site Safety Managers • Construction Project Managers • Scaffolding Supervisors • EHS Officers • Site Engineers • General Contractors

0 notes

Text

Complete Procurement Guide for PPE Wholesale Suppliers and Wholesale Plumbing Equipment

In today's dynamic construction and maintenance sectors, efficient procurement of essential supplies like personal protective equipment (PPE) and plumbing tools is crucial. This guide offers insights into sourcing from reliable PPE wholesale suppliers and wholesale plumbing equipment providers, ensuring safety, compliance, and operational efficiency.

Why Smart Procurement Matters in Construction and Maintenance

In the construction and maintenance industries, safety and performance depend heavily on the quality of tools and protective gear. Procuring supplies from the right PPE wholesale suppliers and wholesale plumbing equipment distributors is not just a purchasing decision—it’s a strategy that impacts compliance, efficiency, and cost control.

Both categories—PPE and plumbing gear—require high standards. Poor-quality products can jeopardize worker safety or project deadlines. This guide covers the steps to build a resilient procurement strategy across these essential product categories.

Selecting the Right PPE Wholesale Suppliers

Choosing the right PPE wholesale suppliers can make or break your operational readiness. Here’s how to ensure your supplier delivers on quality and reliability:

Key Considerations:

Certification & Compliance: Ensure the PPE meets OSHA, ANSI, or ISO standards.

Range of Products: Look for suppliers offering gloves, helmets, goggles, respirators, and high-visibility apparel.

Stock Availability: Choose suppliers with consistent inventory to handle urgent or bulk orders.

Logistics & Delivery: Fast, dependable shipping is critical for on-site safety.

Bulk Pricing Options: Negotiate rates for large-volume orders without sacrificing quality.

Top PPE wholesale suppliers also offer real-time inventory tracking and automated reordering—an essential for large operations.

How to Source High-Quality Wholesale Plumbing Equipment

Whether you’re outfitting a small team or managing a national network, the right wholesale plumbing equipment makes all the difference in durability and performance.

Tips for Plumbing Equipment Procurement:

Source from Authorized Distributors: Avoid knockoffs by working with certified brands and dealers.

Verify Product Specifications: Check size compatibility, materials, and warranty terms.

Ask About After-Sales Support: Good suppliers provide installation guides, service manuals, and phone support.

Explore Vendor Ratings: Online reviews and trade forums are valuable tools in vetting suppliers.

Common Items to Procure:

Pipe cutters & threaders

Drain inspection cameras

Water pressure gauges

Pipe insulation and sealing tools

Sump pumps & hose kits

Having a go-to source for wholesale plumbing equipment ensures you're always stocked with the right tools for any job.

Streamlining Multi-Category Procurement

Consolidating your vendor list can simplify logistics and improve your bargaining power. Here’s how to optimize your process:

Integration Tactics:

Bundle PPE and Plumbing Orders: Some suppliers handle both categories—ask for cross-category discounts.

Use Procurement Software: Track deliveries, manage invoices, and reorder supplies seamlessly.

Set Up Standing Orders: Reduce manual work by automating monthly restocks.

Monitor KPIs: Track supplier performance on cost, delivery time, and product quality.

By aligning with dependable PPE wholesale suppliers and wholesale plumbing equipment dealers, you gain stability and scalability in your operations.

Procurement Best Practices: Expert Insights

To avoid common procurement pitfalls, consider these expert tips:

Audit Your Suppliers Quarterly: Review pricing, performance, and responsiveness.

Train Staff on Safety Protocols: Ensure they know how to use all PPE and plumbing tools correctly.

Prepare for Emergencies: Keep an emergency stock of high-use PPE and core plumbing tools.

Stay Current: Regulatory changes affect what PPE is approved or what plumbing systems are compliant.

Expert-backed wholesale plumbing equipment and PPE solutions lead to better projects, safer environments, and stronger profit margins.

Conclusion: Build Long-Term Supplier Partnerships

Procurement is not just about price—it’s about building relationships with suppliers who understand your needs. Choosing the right PPE wholesale suppliers and wholesale plumbing equipment partners ensures you meet safety standards, reduce downtime, and enhance your bottom line.

0 notes

Text

The Smart Way Forward: Why AI Vending Machines in Australia Are Revolutionizing Retail

Gone are the days when vending machines were just metal boxes filled with chips and soda. Today, we live in a world where convenience and technology merge, giving rise to the intelligent vending revolution. Welcome to the age of the AI vending machine Australia. These smart systems are changing the way we buy, sell, and manage everyday products across the country.

Whether you are a business owner, a tech enthusiast, or someone looking to launch a passive income stream, AI vending machines are becoming one of the most exciting ventures in retail automation.

In this blog, we’ll explore everything you need to know about the AI vending machine Australia phenomenon — from benefits to challenges, setup steps, real-world success stories, and more.

Section 1: What is an AI Vending Machine?

AI vending machines are self-service retail kiosks powered by artificial intelligence. They offer real-time analytics, contactless transactions, automatic stock monitoring, personalized product suggestions, and more. Think of it as a mini smart shop that never sleeps.

Key Features Include:

Real-time inventory tracking

Predictive stock alerts

Data-driven product recommendations

Touchless and cashless transactions

Remote monitoring and analytics

These machines are popping up across major cities and suburban centers in Australia, revolutionizing vending for good.

Section 2: Why AI Vending Machine Australia is Trending

Australia has always been at the forefront of tech innovation, and the vending sector is no different. The country is embracing smart retail at a rapid pace for a few key reasons:

Rising demand for contactless shopping

Growth in on-the-go consumption

Increased use of data for decision-making

Space-saving retail solutions for small business owners

From airports to universities and gyms to shopping malls, AI vending machine Australia setups are becoming a common sight.

Section 3: Common Uses of AI Vending Machines

AI vending machines aren’t just for snacks. Here are a few ways they’re being used:

Healthy food vending at gyms and offices

Tech accessories at airports and train stations

Beauty and skincare products in malls

Pharmacy and PPE products in hospitals

School supplies in education centers

The possibilities are endless.

Section 4: Challenges of Setting Up an AI Vending Machine in Australia

While the benefits are immense, starting out isn’t without challenges:

High Upfront Costs

AI vending machines are pricier than traditional units.

Solutions: Lease options and shared revenue models are available.

Tech Support and Maintenance

Requires software updates, connectivity troubleshooting, etc.

Solution: Partner with providers who offer full service and remote support.

Location Licensing and Council Approvals

Not all spaces allow vending machines without permits.

Solution: Work with experienced local vending companies familiar with regulations.

Consumer Education

Some users may not be familiar with smart vending interfaces.

Solution: Add instructional screens or QR codes to guide new users.

Section 5: Step-by-Step Guide to Starting Your AI Vending Machine Business in Australia

Step 1: Market Research

Study your target audience.

Understand what products they need and where they need them.

Step 2: Choose the Right Machine

Look for models with strong AI capabilities: predictive analytics, remote access, real-time data, etc.

Ensure it's compliant with Australian standards.

Step 3: Select a Strategic Location

High foot traffic spots: schools, gyms, train stations, coworking spaces

Get permission from property owners or councils

Step 4: Source Your Products

Choose items based on your audience (healthy snacks, electronics, beauty, etc.)

Work with wholesale suppliers or local brands

Step 5: Set Up and Test

Ensure seamless integration of payment systems

Check inventory software and camera systems (if applicable)

Step 6: Launch and Market

Use social media, signage, and local events to promote

Offer initial discounts or loyalty rewards

Step 7: Monitor and Optimize

Use AI insights to change products, pricing, or promotions

Consider expanding once profitable

Section 6: Real-Life Case Study: The Rise of SmartSnacks Co.

Background: SmartSnacks Co. launched their first AI vending machine Australia model in a Brisbane co-working hub. Their idea was to offer healthy, quick meals to busy professionals.

Strategy:

AI-driven product recommendations based on time of day

Contactless payment through card and mobile app

Rotating seasonal items to maintain novelty

Results:

85% product sell-through rate in the first 3 months

Increased daily sales by 40% with AI-assisted restocking

Expanded to three new locations within a year

Quote from Founder:

“The AI really changed the game for us. We weren’t guessing what people wanted. We knew. That insight helped us grow fast and serve better.”

Section 7: Tips for Long-Term Success with AI Vending Machines

Use the Data: The true value of AI vending machines is in the insights. Regularly review which items sell best and when.

Keep It Fresh: Change up your offerings often to keep customers interested.

Stay Serviced: Regularly clean and restock machines to ensure smooth user experience.

Go Green: Promote eco-conscious packaging or carbon-neutral deliveries.

Add a Human Touch: Even in automation, customer service matters. Have a contact method on the machine.

Conclusion: AI Vending Machine Australia - A Smart Business for a Smart Future

AI vending machines are redefining what it means to be convenient, efficient, and smart in retail. Whether you're looking for a side hustle or aiming to build a scalable vending empire, the tools are now smarter than ever before.

With the rise of AI vending machine Australia providers and services, getting started is easier than you might think. The key lies in research, location, and letting AI guide your business decisions.

Now is the perfect time to enter the world of smart vending. If you're in Australia, the opportunity is right outside your door — just one machine away.

0 notes

Text

Technological Advancements in Services For Commercial Strip Out in Sydney!

Technological advancements have drastically altered the landscape of commercial strip-out services in Sydney, increasing efficiency, accuracy, and safety. The technologies have improved processes, cut costs, and made them more environmentally sustainable. You can examine how technology is changing commercial strip outs in Sydney:

How Are Technological Advancements Affecting Commercial Strip Out Services in Sydney?

The growth of technology is changing the means of carrying out commercial strip-outs in Sydney. Some of the developments include:

Sophisticated Machinery and Tools

The adoption of sophisticated machinery and tools has increased the speed and accuracy of strip out work.

Perfect Strip Out & Demolition, among other firms, uses specialist equipment to securely strip out material like vinyl, carpet, and tiles, and decrease the physical labor involved and increase safety measures.

Digital Planning and Project Management

Digital solutions are now an integral part of planning and managing strip-out projects.

Software applications make site-detailed assessments possible, help in scheduling with optimum efficiency, and monitor progress in real time.

This facilitates projects being finished on schedule and under budget, with minimal disruption to businesses.

Sustainable Waste Management

Technological advancements have also enhanced waste management procedures.

Sophisticated sorting technology and recycling systems maximise the reuse and recycling of materials in line with the circular economy principles.

This reduces waste sent to landfills and encourages more sustainable construction.

Improved Safety Measures

Commercial strip outs prioritise safety above all else.

Technology has made it possible to create better safety procedures, such as enhanced personal protective equipment (PPE) and real-time hazard monitoring systems.

These safeguard workers and prevent breaches of safety requirements.

Environmental Monitoring

Environmental monitoring technology assists in monitoring and reducing the environmental footprint of strip-out jobs.

This involves dust monitoring, noise pollution monitoring, and ensuring the safe handling and disposal of hazardous materials.

Collaboration and Communication

Online platforms enhance collaboration and communication among stakeholders, such as clients, contractors, and regulatory authorities.

This provides all the stakeholders with information and coordination throughout the project, minimising miscommunications and delays.

Cost Efficiency

Technological innovation has also brought about cost reduction.

Through process optimisation and waste reduction, companies can reduce their operational expenses without compromising on quality.

This makes commercial strip-out services more affordable and within reach for more clients.

Case Studies and Best Practices

Sydney businesses are exchanging case studies and best practices to encourage innovation and excellence in commercial strip-outs. This involves writing up successful projects and sharing strategies that have enhanced efficiency and sustainability.

Are there any specific tools or machinery that have revolutionised the strip out process?

A number of technological developments have evolved the strip-out process, making it more efficient and safer. The following are some of the principal tools and machinery:

Advanced Demolition Equipment

High-Reach Excavators: Such machines come equipped with advanced demolition equipment such as shears, hammers, or crushers to enable precise disassembly of material without causing further damage to neighboring structures.

Robot Systems: Robotic demolition systems provide greater safety and accuracy by mechanizing dangerous activities like demolishing intricate structures.

Controlled Implosion Techniques: These techniques enable controlled demolition of heavy structures with minimal environmental damage and maximum safety.

Technological Advances

Building Information Modeling (BIM): BIM technology improves project planning and implementation through digital models of buildings, enabling better identification of structural components and strip out planning.

Drones and Sensors: Site monitoring and surveying are done through drones, and structural integrity and environmental conditions are monitored in real-time by sensors, enhancing efficiency and safety.

Sustainable Waste Management Technologies

Advanced Sorting Systems: These systems allow effective separation and recycling of materials, minimizing waste that goes to landfill and fostering sustainability.

Precision Cutting Tools

Thermic Lances: These are devices that employ high-temperature heat to cut through hard materials such as steel, offering precision and control in demolition work.

All these have served to greatly enhance the strip out process by increasing precision, safety, and environmental sustainability.

Conclusion

Technological innovations are revolutionising commercial strip out in Sydney by boosting efficiency, safety, and sustainability. By adopting these technologies, companies can ensure their projects are delivered effectively while helping to create an eco-friendly construction sector.

0 notes

Text

Warehouse Material Handling: Optimal Techniques for Effectiveness

Increasing productivity, reducing expenses, and maintaining a safe working environment all depend on effective warehouse material handling. Businesses can improve supply chain performance, minimize product damage, and streamline operations by implementing smart practices.

1. Improve the layout of the warehouse

Workflow and space utilization are improved by a thoughtful layout:

Zoning: Establish zones for shipping, packing, receiving, and storing.

Clear Pathways: To facilitate the movement of equipment, keep aisles open and free of obstructions.

High-Demand Items: Keep regularly used goods close to areas for dispatch.

Vertical Storage: To make the most of available space, use racks and shelves.

2. Make Use of the Proper Tools

Purchasing the right tools improves safety and productivity:

Pallet jacks and forklifts are perfect for moving large objects.

Conveyor Systems: Automate the movement of materials.

AS/RS: Reduce manual labor and improve inventory accuracy.

Handle large objects safely with cranes and hoists.

3. Put Safety First

Keeping the workplace safe safeguards both employees and inventory:

Instruction: Provide instruction on safe lifting and equipment use.

PPE: Offer safety shoes, gloves, and helmets.

Signage: Indicate walkways and potential hazards clearly.

Emergency Plans: Get ready for spills, fires, and medical emergencies.

4. Enhance Inventory Control

Errors and waste are decreased by efficient inventory control:

Use RFID or barcodes for real-time tracking.

FIFO/LIFO: Use the appropriate rotation techniques.

Verify physical stock counts through routine audits.

Inventory processes can be automated with WMS software.

5. Simplify the Picking and Packing Process

Delivery times are accelerated by faster processing:

Cut down on travel time with batch and zone picking.

Automation: Make packing and sorting faster.

Verify accuracy prior to shipping with quality checks.

6. Make Ergonomics Better

Encourage employee productivity and well-being:

Ergonomic Stations: Adjustable configurations lessen strain.

Lift Assists: Reduce the amount of manual lifting.

Training & Breaks: Keep employees informed and attentive.

7. Make Use of Technology

Smarter operations are driven by modern tools:

IoT & AI: Track conditions and forecast demand.

Reduce manual handling and increase inventory visibility with drones and AGVs.

8. Promote Ongoing Enhancement

Monitor KPIs, get input from staff, and keep up with developments in the field.

Concluding remarks

Material handling optimization improves customer satisfaction, safety, and warehouse performance. A tech-enabled, efficient strategy lays the groundwork for sustained operational success.

To get more information, please check out the link given below.

0 notes

Text

The Importance of Safety in EPC Projects: Ensuring Worker’s Well-being

In the dynamic and often hazardous world of Engineering, Procurement, and Construction (EPC), ensuring the safety and well-being of workers is not just a regulatory requirement but a fundamental aspect of ethical business practice. Safety is the cornerstone of successful project management in the EPC sector, where the risks are high and the impact of negligence can be catastrophic. This blog explores the critical importance of safety in EPC projects, outlining the strategies that can be employed to protect workers and ensure project success.

Why Safety is Paramount in EPC Projects

EPC projects typically involve complex operations and heavy machinery, which are inherent with risks ranging from minor injuries to fatal accidents. The multifaceted nature of these projects, combining engineering, procurement, and construction phases, requires stringent safety protocols to manage and mitigate risks effectively. Ensuring safety is crucial for several reasons:

Protection of Human Life

The primary goal of any safety program is to protect workers from harm. This is not only a moral and ethical responsibility but also a critical component of project management that directly impacts the project’s overall success.

2. Legal and Compliance Obligations

Adhering to national and international safety standards and regulations is mandatory. Compliance helps avoid legal repercussions and potential fines, which can arise from safety violations.

3. Operational Continuity

Accidents and injuries can cause significant project delays, increase costs, and disrupt the construction schedule. A safe working environment is essential for maintaining the continuity and efficiency of operations.

4. Reputation Management

Safety records are a key indicator of a company’s operational integrity and professionalism. High standards of safety enhance a company’s reputation among clients, investors, and within the industry.

Best Practices for Ensuring Safety in EPC Projects

Implementing robust safety measures requires a comprehensive approach, tailored to the unique challenges of each project. Here are some best practices:

Comprehensive Safety Training

All employees, from field workers to management, should undergo regular safety training. This training should cover hazard recognition, equipment handling, emergency procedures, and personal protective equipment (PPE) usage.

2. Risk Assessment and Management

Conduct thorough risk assessments during all phases of the project. Identify potential hazards and implement measures to mitigate them. Continuously monitor and adjust these measures as the project progresses and as new risks emerge.

3. Safety-First Culture

Foster a workplace culture where safety is prioritized above all else. Encourage open communication about safety concerns and ensure that all employees feel empowered to report unsafe conditions without fear of repercussions.

4. Regular Safety Audits and Inspections

Regular audits and inspections ensure that safety protocols are being followed and are effective. These checks help identify lapses in safety measures before they lead to accidents or injuries.

5. Use of Technology

Leverage technology to enhance safety. Tools like drones for site surveys, wearable tech to monitor health indicators, and software for safety data management can significantly reduce risks.

The importance of safety in EPC projects cannot be overstated. It is a critical investment that pays dividends not only in protecting workers but also in ensuring the smooth execution and completion of projects. By prioritizing safety, EPC firms can demonstrate their commitment to excellence and their respect for human life, while fostering a positive and productive work environment. The goal is clear: to achieve a zero-incident workplace where all employees return home safely at the end of each day.

#Top 10 Construction Companies in Pune#Top Construction Companies in Pune#Building Infrastructure Companies in Pune

0 notes

Text

What is Safety AI Software, and Why Should EHS Professionals Adopt It for Behavioral Safety?

Workplace safety remains a top priority across industries, yet human error continues to be a leading cause of accidents and injuries. Whether it’s improper use of personal protective equipment (PPE), mobile phone usage, or unsafe practices on stairs, these behaviors pose significant risks in industrial settings. Addressing these challenges requires more than traditional safety protocols—it calls for intelligent, proactive solutions that not only detect unsafe actions but also offer comprehensive management of safety operations. This is where Safety AI software steps in as a transformative management platform for EHS professionals. By combining real-time monitoring, advanced pattern recognition, and automated feedback, Safety AI platforms provide businesses with powerful tools to enhance workplace safety. These platforms offer a range of AI safety scenarios to detect and monitor unsafe behaviors while also equipping safety managers with robust dashboards and functionalities to oversee and manage safety protocols across entire operations. By offering both detection and management capabilities, Safety AI software not only enhances compliance but also significantly reduces the likelihood of accidents. To truly understand the impact of these platforms, it's essential to compare traditional safety methods with AI-driven approaches, particularly in the context of behavioral safety.

Let's take a closer look at how manual monitoring stacks up against AI-powered solutions and why adopting a technology-first approach is crucial for modern workplace safety strategies.

Traditional Methods vs. AI-Powered Monitoring

Manual Monitoring:

Subjectivity and Inconsistency: Manual safety supervision relies heavily on safety personnel's vigilance, which can vary due to fatigue, distractions, or biases. This often leads to inconsistent reporting of safety violations.

Limited Coverage: Safety personnel can only monitor specific zones at a time, leaving gaps in coverage, especially in large industrial settings.

Reactive Approach: Manual methods primarily focus on incident response rather than prevention, leading to delayed interventions.

Data Management Challenges: Tracking safety incidents manually involves paperwork or fragmented digital records, making trend analysis and reporting time-consuming and error-prone.

AI-Powered Monitoring:

Computer Vision Technology: Utilizes advanced algorithms to analyze live camera feeds, identifying unsafe behaviors such as improper PPE usage, phone distractions, and unsafe stair practices.

Real-Time Behavior Analysis: Instantly detects risky actions like running, skipping steps, or operating equipment unsafely, enabling immediate corrective measures.

Automated Alerts & Notifications: Sends instant alerts to supervisors via SMS, email, or integrated platforms (e.g., Microsoft Teams) when safety violations occur.

Predictive Insights: By analyzing patterns in worker behavior, AI can predict potential safety risks and suggest preventive measures.

Centralized Data Management: Provides a unified dashboard where safety managers can view violations, generate reports, and track compliance trends over time.

Scalability: AI systems can monitor multiple zones simultaneously, ensuring comprehensive coverage even in complex environments.

Key Risk Factors Related to Human Behavior

Improper PPE Usage:

Non-Compliance Detection: AI models can identify if workers are not wearing mandatory safety gear (e.g., helmets, gloves, safety goggles) and generate immediate alerts.

Specific PPE Monitoring: Tracks compliance with job-specific PPE requirements, such as respiratory masks in hazardous zones or high-visibility vests in high-traffic areas.

Fatigue and Distraction:

Mobile Phone Usage: Detects unauthorized phone use in restricted zones, which often leads to reduced situational awareness.

Fatigue Indicators: Monitors behavioral cues such as prolonged inactivity or irregular movements, which may suggest worker fatigue.

Unsafe Manual Handling:

Posture and Movement Analysis: AI evaluates body mechanics during lifting or equipment operation, identifying unsafe practices like overreaching, bending incorrectly, or improper load handling.

Equipment Operation Monitoring: Detects deviations from safe operating procedures, such as bypassing safety guards or using equipment without proper training.

Risky Movements:

Zone Violation Detection: Identifies when workers enter hazardous or restricted areas without proper authorization, mitigating the risk of accidents.

Behavioral Trends Analysis: Tracks how often unsafe behaviors occur, allowing safety managers to address recurring risks through targeted training or procedural adjustments.

Unsafe Practices on Stairs: Monitors behaviors like running, skipping steps, or failing to use handrails, which are common causes of slips and falls.

Non-Compliance with Safety Protocols:

Automated Compliance Checks: AI continuously compares worker behavior against predefined safety protocols, ensuring adherence without manual oversight.

Data-Driven Training Opportunities: Uses violation data to highlight training needs, helping organizations focus on specific safety behaviors that require improvement.

The Power of Safety AI Software: Enhancing Workplace Safety

Traditional safety measures often struggle to address unpredictable human behaviors like improper PPE usage, mobile phone distractions, and unsafe stair practices. Safety AI software offers a smarter solution with real-time monitoring, predictive insights, and automated management tools that help EHS professionals create safer workplaces.

These platforms go beyond detection, providing instant alerts, actionable feedback, advanced analytics, EHS functionalities and adaptive learning features. They transform safety management from reactive to proactive, ensuring compliance and reducing risks effectively.

Let's explore the key features that make Safety AI software a game-changer for workplace safety. 1. Automated Detection: Proactive Safety Management

A key feature of Safety AI software is its automated feedback system, which plays a vital role in enhancing both immediate responses and long-term safety strategies:

Instant Alerts: When unsafe behaviors are detected, the software generates immediate notifications. These can be presented as visual cues on-site, mobile alerts, or directly through the application’s dashboard.

Customizable Notifications: Supervisors receive detailed violation reports, including specifics about the incident, location, and recommended corrective actions. Reports can be configured for real-time alerts or scheduled summaries.

Proactive Behavior Management: Provides actionable insights that help workers adjust their behavior in real time and enable safety managers to develop targeted safety training programs.

Diverse Communication Channels: The alerting system integrates with multiple communication tools, such as SMS, email, Microsoft Teams, and even on-site audio alerts through connected speaker systems.

2. Advanced Dashboard and Analytics: The Command Center for Safety

The dashboard within Safety AI software serves as the operational command center, offering a detailed and organized view of workplace safety operations:

Comprehensive Interface: Displays live camera feeds, tracks safety events, and highlights compliance metrics, providing safety managers with a clear view of safety conditions across all monitored areas.

Data-Driven Insights: The platform generates detailed safety reports, facilitates trend analysis, and offers access to historical data to identify recurring risks and enhance safety protocols.

Scenario Management: Supports a wide range of predefined safety scenarios while allowing for customization to meet specific workplace requirements.

Event Management Tools: Includes advanced event filters, real-time alerts, and well-organized incident logs, enabling EHS professionals to manage safety events more effectively.

Visual Sitemap & Monitoring: Offers a visual representation of the workplace, aiding in identifying high-risk zones and optimizing safety camera placements.

On-Site Alert Systems: Integrates with external hardware such as buzzers and alarm systems to provide immediate audio alerts when safety violations occur.

3. Continuous Learning: AI That Evolves with Workplace Needs

One of the standout advantages of Safety AI software is its ability to continuously learn and adapt to changing workplace dynamics:

Adaptive Algorithms: The software continuously analyzes new safety data, refining its ability to detect potential risks with high accuracy.

Predictive Risk Management: By examining historical safety data, AI models can anticipate potential hazards and offer proactive solutions to mitigate them.

Compliance with Evolving Standards: The AI system updates automatically to align with changes in workplace safety regulations and standards, ensuring organizations maintain compliance.

Data-Driven Improvements: Uses machine learning to evaluate the effectiveness of past safety interventions and provide insights to refine and optimize safety strategies.

4. Integration and Flexibility: Adapting to Any Workplace Environment

Safety AI software offers robust integration capabilities and deployment flexibility to meet the diverse needs of different industries:

Seamless Integration: Works with existing CCTV and IT infrastructure, providing easy integration through APIs and custom solutions to fit specific operational requirements.

Flexible Deployment Options: Supports both SaaS (Software as a Service) and on-premise models, catering to organizations with particular data security and compliance needs.

Customizable Safety Scenarios: Allows safety managers to configure scenarios tailored to their specific workplace challenges, ensuring a personalized and precise safety management approach.

Conclusion

AI-powered behavioral safety observations are transforming workplace safety by reducing human error, enhancing compliance, and preventing accidents before they happen. AI-powered behavioral safety observations, driven by advanced Safety AI software, are transforming workplace safety by reducing human error, enhancing compliance, and preventing accidents before they happen.

With Visionify leading the charge, industries can leverage advanced AI-driven safety solutions to create safer, more efficient, and more compliant workplaces. By integrating AI into their safety programs, businesses can significantly reduce workplace incidents, improve training, and optimize overall operational efficiency.

The future of workplace safety is AI-driven, and companies that adopt AI-powered safety solutions today will be better equipped to protect their workforce and achieve long-term success.

1 note

·

View note

Text

construction project management tips for beginners

Here are some construction project management tips for beginners to help you successfully manage your first projects:

1. Understand the Scope of the Project

Start with clear plans and documents. Review blueprints, contracts, and specs thoroughly. Understand the full scope of work before anything begins.

Set expectations. Clarify goals, timelines, budgets, and deliverables with the client and stakeholders upfront.

2. Build a Solid Schedule

Use tools like Microsoft Project, Primavera P6, or even Excel to create a timeline.

Include milestones, deadlines, and a buffer for delays. Realistically assess how long each task will take.

Plan for contingencies. Something unexpected will happen—always have a backup plan.

3. Communicate Effectively