#PVC Wire Rope

Explore tagged Tumblr posts

Text

PVC Coated Rope । PVC Wire Rope

Wire ropes are integral components in various industries, providing essential support and strength in applications ranging from construction and transportation to marine and mining. To enhance their durability and performance, PVC coated wire ropes have emerged as a reliable solution.

PVC Coated Wire Ropes:

PVC coated wire ropes are standard wire ropes that have been coated with a protective layer of polyvinyl chloride (PVC) material. This coating offers several advantages over uncoated wire ropes, including enhanced resistance to corrosion, abrasion, and environmental elements. PVC coatings also provide improved grip, making them suitable for applications that require secure handling and grip strength.

Applications of PVC Coated Wire Ropes:

Construction Industry: PVC coated wire ropes find extensive use in construction for applications like hoisting, cranes, winches, and suspension bridges. The corrosion resistance and improved grip make them reliable and safe for lifting heavy loads

Marine Industry: In marine environments, PVC coated wire ropes are used in applications such as ship rigging, dockside cranes, fishing nets, and offshore installations. The PVC coating protects against saltwater corrosion and extends the longevity of the wire ropes.

Transportation and Automotive Industry: PVC coated wire ropes are employed in various transportation applications, including cable cars, ski lifts, and suspension systems for bridges. The weather resistance and abrasion resistance properties make them suitable for withstanding extreme conditions.

PVC Coated wire ropes provide an excellent solution for industries that require enhanced durability, corrosion resistance, and improved grip. Asahi Ropes, a renowned manufacturer, offers a range of PVC coated wire ropes that meet the highest standards of quality and reliability. Whether in construction, marine, transportation, or recreational applications, PVC coated wire ropes have proven to be a versatile choice. Embracing this innovative solution can significantly enhance operational efficiency, reduce maintenance costs, and improve overall safety.

Tag:- PVC Coated Rope, PVC Wire Rope

0 notes

Text

Trusted Lashing and Securing Services for Oversized Break Bulk Cargo in Dubai

In today’s global logistics and shipping industry, safe cargo handling is a top priority—especially when dealing with heavy, oversized, or irregular-shaped goods. For companies operating in the Middle East, ensuring reliable lashing and securing of oversized break bulk cargo in Dubai is critical to protect cargo during transport and maintain compliance with international standards.

At Innovation Marine International, we specialize in high-quality cargo packing and lashing services in Dubai, offering tailored solutions for industries such as oil & gas, construction, marine, and manufacturing. From heavy machinery and equipment to pipeline systems and containers, we handle each item with care, precision, and expertise.

✅ What is Oversized Break Bulk Cargo?

Oversized break bulk cargo refers to cargo that is too large or heavy to fit into standard shipping containers. These shipments are typically transported as individual pieces and require special loading, securing, and unloading procedures.

Common examples include:

Industrial machinery

Construction equipment

Steel structures

Pipes and tubes

Wind turbine parts

Due to their size and weight, these items are vulnerable to shifting, tipping, or damage if not properly secured during transit. That’s why professional lashing is so important.

🧰 Expert Lashing and Securing Solutions

Innovation Marine International brings years of experience and industry knowledge to deliver top-tier lashing services. We use high-strength materials such as steel chains, polyester belts, ratchet straps, wooden blocks, dunnage bags, and anti-slip mats to secure cargo based on its size, shape, and fragility.

Our team strictly follows IMO and port authority safety guidelines, ensuring full compliance at all times.

🔩 Pipe Lashing Team in UAE

We are proud to have a specialized pipe lashing team in the UAE trained to handle industrial pipes of various lengths, diameters, and weights. Whether transporting steel pipelines for oil & gas projects or large diameter PVC pipes for infrastructure development, our team secures them using proven techniques that prevent sliding, friction damage, and structural stress during movement.

Our lashing methods also minimize the risk of corrosion or contamination, thanks to protective packaging and anti-moisture wraps.

🚛 Container Lashing in UAE

If your cargo is containerized, you still need the assurance of proper internal securing. Our container lashing services in the UAE include both on-site and port-based support for securing goods inside 20ft, 40ft, and open-top containers. We manage:

Lashing of heavy and unbalanced items

Block and brace techniques

Steel wire rope securing

Cargo inspection and documentation

We offer fast and reliable support at major ports including Jebel Ali, Port Rashid, Hamriyah Port, and Khalifa Port.

📦 Industrial Packaging Company UAE – Beyond Just Lashing

Innovation Marine isn’t just a lashing provider—we are a full-service industrial packaging company in the UAE. Our packaging solutions are engineered to protect your cargo from environmental elements, impact damage, and moisture during international transport.

We provide:

Heat shrink wrapping

Wooden crating

VCI (Vapor Corrosion Inhibitor) packaging

Vacuum sealing

Heavy-duty palletization

Each packaging solution is customized based on the nature and value of your cargo.

🌐 Why Clients Choose Innovation Marine International

✅ Experienced, certified lashing crew ✅ On-site cargo handling across UAE ports ✅ Fast turnaround times ✅ High-quality materials & tools ✅ End-to-end cargo safety assurance ✅ Real-time reporting and photographic proof of lashing

We are committed to minimizing risk and maximizing efficiency for your logistics operations.

🏗 Serving Key Industries

Our lashing and packaging solutions are trusted by clients in:

Oil & Gas

Renewable Energy

Heavy Equipment

Automotive

Marine & Offshore

Defense & Aerospace

Whether it’s project cargo or regular shipment cycles, we handle every job with the same level of dedication and professionalism.

📍 Our Service Locations

We serve all major shipping hubs across the UAE, including:

Dubai

Abu Dhabi

Sharjah

Ajman

Ras Al Khaimah

Fujairah

Khor Fakkan

Our team is equipped for both port-side and remote industrial site lashing requirements.

📞 Contact Us

Ready to ensure your cargo reaches its destination safely and securely? Partner with Innovation Marine International, your trusted expert for cargo packing and lashing services in Dubai.

🔗 https://innovationmarineintl.com

We’re here to support your next shipment—any size, any destination.

#CargoServices#FreightForwarding#LogisticsSolutions#ShippingServices#SupplyChainManagement#DubaiLogistics#UAEShipping#DubaiFreight

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] HUMBLE Ultimate Cable Protector | Spiral Triple Colour 1.5 Meter / 150 cm | Plastic Cord Wire Charger Winder for iPhone and Android Charging CablesThese cord protectors are lightweight, durable and will easily fit a variety of cord types. Colour: multicolor Spiral Triple Colors Cable Cord Protectors Winders for Mobile Phone Charging Cable Earphones (1.5 m) They can protect charging cables as well as earphone cords from dirt, frays, tangles, and knots. Stand out from the crowd by combining different colors, you just need to take little time to finish this simple DIY work, then you'll get a cord of your own that you never expected. All things are difficult before they are easy, wrap with 1 rope, at the beginning may take you much of time, just relax & concentrate, 100% sure you can finish it within 10minutes. These cord protectors are lightweight, durable and will easily fit a variety of cord types. earphone cords from dirt, frays, tangles, and knots. Stand out from the crowd by combining different colors, you just need to take little time to finish this simple DIY work, then you'll get a brand new cord of your own that you never expected. All things are difficult before they are easy, wrap with 1 rope, at the beginning may take you much of time, just relax & concentrate, 100% sure you can finish it within 10minutesFunctions;→ These cord protectors are lightweight, durable, and will easily fit a variety of cords,→ Protect your wire and cords from dirt, frays, tangles, and knots.→ Durable, colored, flexible spiral core made of high-quality PVC→ Prolong the life of your cable and avoid your cable getting mixed up again.→ Protect wire and cords from dirt, frays, tangles, and knots, the risk of fraying and breaking reduces by 80%→Material PVC layer absorbs impacts preventing harmful twists & bends protects your cable against daily wear & tear. ✅ INCREASES CABLE LIFE: Stop replacing expensive iPhone and Android charger cables. Spiral Cable Protector covers the entire charging cable, reducing the risk of fraying and breaking by well over 80% ✅ COST SAVING: Spiral Cable Saver saves time and money at just a fraction of the cost of original iPhone and Android charging cables. ✅ COMPATABILITY: Suitable for all types of cables and cords like charger, headphone etc. ✅ Durable, colored and flexible spiral cord made of high quality PVC and can be applied as phone charger saver. ✅ BEST GIFT YOUR LOVED ONE : Charger wire protectors, wire protector spiral, data cable protector, cable protection flexible spiral wrap, can be a perfect gift for your Mother, Father, Brother, Sister, Best Friend, Girlfriend, Boyfriend and everyone. [ad_2]

0 notes

Text

Applications of Wire Ropes Across Industries and Sectors

Wire ropes are an integral part of modern engineering and industrial operations. Built from strands of metal wire twisted into a strong, flexible structure, they are trusted for their durability, load-bearing capacity, and resistance to wear. From lifting and hoisting to securing and towing, wire ropes are used in a variety of industries, each demanding specific performance characteristics.

In this post, we explore the wide-ranging applications of wire ropes across industries and sectors, while also understanding how a reputable wire rope company in India plays a crucial role in supplying top-tier solutions.

What Is a Wire Rope?

A wire rope consists of multiple strands of metal wires, twisted in a helical pattern around a core. This structure enhances flexibility while maintaining high tensile strength, making it ideal for mechanical operations.

The wire rope making process involves careful selection of materials (often high-carbon steel), precise engineering, and rigorous testing to meet industry-specific standards.

1. Construction and Infrastructure

Wire ropes are heavily used in the construction sector for:

Tower Cranes and Lifting Equipment

Suspension Bridges

Concrete Formwork and Structural Support

Construction requires wire ropes with high tensile strength and fatigue resistance. Reliable wire rope manufacturers in India produce ropes tailored to perform in these heavy-duty applications.

2. Mining Industry

Wire ropes are essential in mining operations for:

Hoisting and Dragging Ore

Underground Mining Lifts

Slope and Shaft Transportation

Given the abrasive environment, mining demands ropes with exceptional abrasion resistance and tensile capacity. A specialized wire rope company in India will often design ropes specifically for these challenging settings.

3. Oil and Gas Sector

In offshore drilling and rig operations, wire ropes are employed for:

Drilling Line Operations

Mooring and Anchoring

Winching and Hoisting

Ropes here must resist corrosion, extreme temperatures, and constant pressure. The wire rope making process for oil rigs includes galvanizing and using plastic-impregnated cores for added durability.

4. Marine and Shipping

In this sector, wire ropes support:

Anchor Handling

Fishing Nets and Trawling

Mooring and Towing Vessels

Marine-grade ropes must resist saltwater corrosion. Most wire rope manufacturers in India offer customized options specifically for marine applications, often using stainless steel or galvanized coatings.

5. Elevators and Lifts

Elevators rely on wire ropes for:

Suspension Systems

Counterweight Support

Safety and Braking Mechanisms

The ropes must provide smooth operation with minimal elongation. Advanced wire rope making techniques ensure elevator ropes meet safety and durability standards.

6. Cranes and Hoists

Whether it’s a mobile crane, gantry crane, or industrial hoist, wire ropes are used for:

Load Lifting

Boom Extensions

Winch Systems

For this, high fatigue resistance and flexibility are essential. A certified wire rope company in India will ensure the ropes are pre-stretched and tested for performance.

7. Agriculture and Forestry

Wire ropes in these fields are used for:

Winching Logs

Suspending Tools or Machinery

Fencing and Structural Supports

These ropes need to be lightweight yet strong, corrosion-resistant, and easy to install, making galvanized and PVC-coated options popular.

8. Adventure Sports and Safety Systems

Wire ropes are used in:

Ziplining and Rappelling

Bridge Walks and Canopy Tours

Safety Harness Anchors

Safety is critical, so wire rope manufacturers India adhere to international safety norms. These ropes often undergo magnetic flaw detection and ultrasonic testing.

9. Railways and Transport

Wire ropes find their place in:

Cable Cars and Trams

Signal and Suspension Systems

Wagon Pulling and Braking Systems

Their resistance to dynamic loads and harsh environmental conditions makes them ideal in this context.

10. Entertainment and Stage Rigging

In theaters, events, and stadiums, wire ropes are used for:

Lifting and Moving Scenery

Suspending Lights and Sound Equipment

Securing Large Structures

These applications require quiet, smooth-running wire ropes with high fatigue resistance.

11. Aerospace and Defense

Wire ropes are used in:

Aircraft Control Systems

Satellite Launch Pads

Missile and Weapon Lifts

Lightweight, non-magnetic ropes made through specialized wire rope-making processes are essential in this industry.

12. Renewable Energy (Wind & Solar)

In the green energy sectors, wire ropes are utilized for:

Wind Turbine Installation

Solar Panel Mounting

Maintenance Equipment Lifts

With high exposure to environmental conditions, these ropes are made to withstand UV radiation and corrosion.

Why Choosing the Right Wire Rope Company Matters

Not all wire ropes are made the same. Choosing a professional and certified wire rope company in India ensures you receive:

High-quality, tested products

Industry-specific engineering

On-time delivery and support

Compliance with global safety standards

With years of expertise in wire rope making, the top wire rope manufacturers in India provide custom solutions across sectors, optimizing performance and safety.

Conclusion

Wire ropes are far more than simple lifting tools—they’re the backbone of countless industries. From mining to marine, from construction to aerospace, they support and secure vital operations around the world. As industries evolve, so does the technology behind wire rope manufacturing, with a clear focus on durability, flexibility, and safety.

When looking for reliable solutions, partnering with a reputed wire rope company in India makes all the difference. Whether you need heavy-duty ropes for cranes or corrosion-resistant solutions for offshore rigs, trusted wire rope manufacturers India will deliver the quality and performance you can count on.

0 notes

Text

DIY Alternatives to Traditional Temporary Enclosures

You know that feeling when you step onto your porch or patio, only to be greeted by a swarm of mosquitoes or an unexpected gust of wind that sends your coffee flying? Yeah, not exactly the peaceful retreat you had in mind. Traditional temporary enclosures, like screened-in patios or roll-down vinyl panels, are great, but they can be pricey and permanent. If you're looking for creative, cost-effective solutions, DIY alternatives might be your best bet.

Let’s walk through some practical, stylish, and budget-friendly ways to create an enclosed outdoor space that fits your needs—whether you're a homeowner looking for an extra sunroom, a retiree seeking a bug-free relaxation spot, or a café owner needing a seasonal patio setup.

1. Retractable Outdoor Curtains: The Budget-Friendly MVP

If you want a quick, stylish, and flexible way to enclose a space, retractable outdoor curtains are your new best friend. They're easy to install, relatively cheap, and can be adjusted depending on the weather or your mood.

Why They Work:

Instant privacy: Want to block nosy neighbors or street views? Done.

Weather control: They help reduce wind, light rain, and harsh sunlight.

Style options: From sheer flowy fabrics to heavy-duty weatherproof panels, the choices are endless.

Easy installation: A basic curtain rod or tension wire system is all you need.

Pro tip: Go for moisture-resistant, UV-blocking fabric to avoid mold and fading. Bonus points if you add tiebacks for a polished look when they’re open!

2. DIY Sliding Panels: A Modern Take on Temporary Enclosures

If you like the idea of flexibility but want something sturdier than fabric, consider making your own sliding panel system. Using materials like polycarbonate sheets, wood slats, or repurposed old windows, you can create panels that slide along a track, allowing you to adjust your enclosure as needed.

How It Works:

Mount a track (like a closet door system or barn door rail) to the ceiling of your patio or deck.

Attach lightweight panels that can be pushed to the side when not in use.

Choose clear panels for a greenhouse effect or frosted or wood slat panels for added privacy.

This setup works great for patios, balconies, or even restaurant seating areas that need seasonal adjustments.

3. Repurposed Storm Windows: The Green DIY Approach

If you’re all about sustainable solutions, repurposed storm windows can make an excellent semi-permanent enclosure. You can often find them cheap (or even free) on local resale sites.

The Benefits:

They provide solid wind and rain protection while still letting in light.

They can be easily removed and reinstalled each season.

The vintage look can add charm to your space.

Installation Tip: Secure them using simple brackets or hinges so they can be lifted off when you want an open space.

4. PVC Pipe & Clear Vinyl Panels: The DIY Greenhouse-Style Setup

For those who want a lightweight but durable enclosure—maybe for a sunroom effect or a covered greenhouse—PVC pipe frames with clear vinyl sheets offer a solid option.

How to Do It:

Build a frame using PVC pipes and corner connectors.

Attach clear vinyl panels (or shower curtains if you're on a budget) using Velcro or zip ties.

Add roll-up sides with eyelets and ropes for adjustable ventilation.

This setup is fantastic for plant lovers, small business patios, or homeowners wanting a cozy sunlit reading nook.

5. Bamboo or Reed Roll-Up Shades: Natural & Rustic

If you love that resort-style aesthetic, bamboo or reed shades might be exactly what you need. These roll-up shades attach to your pergola, porch, or balcony and can be pulled down when you need shade or privacy.

Why You'll Love Them:

They filter sunlight without completely blocking your view.

They’re affordable and super easy to install.

They give off that relaxed, tropical vibe.

Pro Tip: If you live in a windy area, secure the bottom with hooks or small weights to prevent them from flapping around.

6. Shipping Pallet Wall: A DIY Lover’s Dream

Got access to free or cheap shipping pallets? A pallet wall can be an awesome way to enclose part of your space while adding character. You can either leave gaps for airflow or weave in outdoor fabric for more privacy.

Why It Works:

It’s sturdy, customizable, and dirt cheap.

You can paint or stain it to match your outdoor decor.

It doubles as a vertical garden if you add planter boxes!

This is a great solution for backyards, side patios, or even small business spaces that need some separation.

7. Magnetic or Zip-On Bug Screens: The No-Fuss Option

If your biggest issue is bugs (hello, summer in South Bend), a magnetic or zip-on bug screen might be the best alternative to a screened-in porch. These are designed to attach to existing openings and provide a flexible barrier against mosquitoes, flies, and other unwanted guests.

Best Options:

Magnetic door screens – Great for back doors or patio entrances. They snap shut behind you!

Zip-on mesh panels – Attach to pergolas, balconies, or even garage door openings for an instant bug-free zone.

Easy to install, cheap, and highly effective—sometimes the simplest solutions are the best!

8. Repurposed French Doors for a High-End Look

If you’re leaning towards something a little more polished but still want a DIY project, repurposing old French doors can be an amazing solution. They can be mounted on hinges or installed as sliding doors for a semi-permanent enclosure.

Why They're Awesome:

They provide an upscale look without a hefty price tag.

They let in tons of natural light.

They can be found secondhand, making them an eco-friendly option.

Perfect for sunrooms, home offices, or even enclosed patios, this idea blends practicality with elegance.

Final Thoughts

So, whether you’re looking for something quick and cheap, like outdoor curtains, or you’re ready to tackle a full sliding panel project, there are plenty of ways to create a temporary enclosure that fits your needs.

If you're in the South Bend area and need guidance, hardware, or even custom screen solutions, Screenmobile of Michiana Shores, MI, has got you covered. Sometimes, mixing a little DIY ingenuity with professional expertise gives you the best of both worlds.

What’s your go-to enclosure trick? Let us know in the comments!

1 note

·

View note

Text

How Wire Rope is Manufactured? A Step-by-Step Process Breakdown

Wire ropes are essential in industries like construction, mining, marine, and material handling due to their strength, flexibility, and durability. But have you ever wondered how these high-performance ropes are made? In this article, we’ll break down the step-by-step manufacturing process of wire ropes, helping you understand the precision and quality control involved.

Step 1: Wire Drawing – Creating the Base Material

The process begins with high-quality steel rods, which are drawn through a series of dies to reduce their diameter. This cold-working process increases tensile strength while maintaining flexibility. The wire is then coated (galvanized or stainless) for corrosion resistance, depending on its application.

Step 2: Strand Formation – Twisting Wires for Strength

Multiple wires are twisted together to form strands. The arrangement (6x19, 6x36, 7x7, etc.) determines the rope’s flexibility and load-bearing capacity. A central core wire is often used for structural stability.

Step 3: Rope Closing – The Final Twist

Strands are helically wound around a core (fiber or steel) to form the complete wire rope. The direction of twisting (regular lay vs. lang lay) affects performance in different applications.

Step 4: Pre-Stretching & Stabilizing

To minimize elongation under load, the rope undergoes pre-stretching, ensuring dimensional stability. This step is crucial for heavy-duty applications like cranes and elevators.

Step 5: Quality Testing & Certification

Reputed wire rope manufacturers and suppliers in India conduct rigorous tests, including: ✔ Tensile strength testing ✔ Fatigue resistance checks ✔ Corrosion & abrasion testing Only after passing these tests does the wire rope receive ISO/CE certifications for industrial use.

Step 6: Lubrication & Coating (Optional)

For enhanced durability, wire ropes are lubricated internally and externally. Special coatings (PVC, zinc, or polymer) are applied for harsh environments like marine or chemical industries.

Step 7: Cutting, Coiling & Packaging

The final wire rope is cut to required lengths, coiled, and packed for shipment. Proper packaging ensures no damage during transit.

Why Choose Trusted Wire Rope Manufacturers and Suppliers in India?

India is home to several leading wire rope manufacturers and suppliers, ensuring high-quality, cost-effective solutions for global industries. When selecting a supplier, consider: ✅ ISO/CE certifications ✅ Customization options ✅ Testing & quality assurance ✅ On-time delivery & after-sales support

About SVIBO Industries – Your Reliable Wire Rope Supplier

SVIBO Industries is a trusted name among wire rope manufacturers and suppliers in India, offering high-performance, durable wire ropes for construction, mining, and industrial applications. With a commitment to quality and customer satisfaction, SVIBO ensures: ✔ Premium-grade materials ✔ Rigorous quality testing ✔ Custom solutions for diverse industries

Contact SVIBO Industries Today! 📍 Address: 111,112,113 Mahatma Phule Peth, Block No 101, Sevadham Building, 1st Floor, Pune, Maharashtra 411042 📞 Phone: 8208803755 📧 Email: [email protected] 🗺️ Get Directions

0 notes

Text

Why Prisons & Military Sites Choose V Mesh Wire Fencing

Introduction

When it comes to high-security perimeters, not all fencing is created equal. Prisons, military bases, and other sensitive facilities require maximum deterrence, strength, and longevity—which is why V Mesh wire fencing has become the gold standard.

But what makes V Mesh the top choice for critical security applications? This article explores its unique design advantages, real-world performance, and key reasons why it outperforms traditional fencing like chain link or razor wire.

V Mesh Wire Fencing

1. What Is V Mesh Wire Fencing?

V Mesh (also called "Vertical Mesh" or "Anti-Climb Mesh") is a high-security steel fencing system characterized by: ✔ Vertical & horizontal wires welded in a tight "V" pattern ✔ Small apertures (typically 50mm x 100mm) to prevent grip points ✔ Heavy-duty construction (4mm–6mm wire thickness) ✔ Hot-dip galvanized or PVC-coated for extreme weather resistance

Unlike chain link, V Mesh is virtually impossible to climb or cut through, making it ideal for prisons, military zones, and high-risk facilities.

V Mesh Wire Fencing Manufacturer

2. Why Prisons Rely on V Mesh Fencing

A) Anti-Climb Design

The V-shaped pattern and small gaps eliminate footholds, making scaling extremely difficult.

Smooth, angled surfaces prevent grappling hooks or rope attachments.

B) Tamper-Proof Security

Welded joints resist cutting tools (bolt cutters, saws).

No weak points—unlike chain link, which can be pried apart.

C) Visibility for Surveillance

Open mesh design allows clear sightlines for guards and cameras.

No blind spots, unlike solid walls or dense fencing.

D) Long-Term Durability

Galvanized steel resists rust, even in coastal or humid environments.

20–30 year lifespan with minimal maintenance.

Case Study: A maximum-security prison in Texas reported zero successful breaches after replacing chain link with V Mesh.

V Mesh Security Fence

3. Military & Government Applications

A) Perimeter Protection for Bases

Stops intruders (spies, terrorists, or protesters).

Blast-resistant in some reinforced configurations.

B) Border & Critical Infrastructure Security

Used in airports, nuclear plants, and embassies.

Deters smuggling & illegal crossings more effectively than traditional fences.

C) Quick Installation for Temporary Zones

Prefabricated panels allow rapid deployment in conflict zones.

Modular design adapts to uneven terrain.

V Mesh Wire Fencing Manufacturer

4. V Mesh vs. Other Security Fences

Feature

V Mesh

Chain Link

Razor Wire

Anti-Climb

✅ Best

❌ Poor

⚠️ Moderate

Cut Resistance

✅ High

❌ Low

⚠️ Medium

Visibility

✅ Clear

✅ Clear

❌ Obstructed

Lifespan

25+ yrs

10–15 yrs

5–10 yrs

Maintenance

Low

Moderate

High

Winner: V Mesh provides the best balance of security, durability, and cost-effectiveness.

5. Key Considerations When Choosing V Mesh

Material: Galvanized steel (rust-proof) vs. PVC-coated (extra corrosion resistance).

Height: Standard 2.4m–6m options; taller for maximum security.

Add-ons: Barbed wire toppers, electric fencing integration, or motion sensors.

Certifications: Look for ISO 1461 (galvanizing standards) and PAS 68 (impact resistance).

V Mesh Wire Fencing

Conclusion

V Mesh wire fencing isn’t just stronger than alternatives—it’s smarter. By combining anti-climb engineering, extreme durability, and surveillance-friendly visibility, it’s the top choice for prisons, military sites, and any facility where security can’t be compromised

0 notes

Text

PVC Coated Wire Ropes

Wire ropes are integral components in various industries, providing essential support and strength in applications ranging from construction and transportation to marine and mining. To enhance their durability and performance, PVC coated wire ropes have emerged as a reliable solution.

PVC Coated Wire Ropes:

PVC coated wire ropes are standard wire ropes that have been coated with a protective layer of polyvinyl chloride (PVC) material. This coating offers several advantages over uncoated wire ropes, including enhanced resistance to corrosion, abrasion, and environmental elements. PVC coatings also provide improved grip, making them suitable for applications that require secure handling and grip strength.

Applications of PVC Coated Wire Ropes:

Construction Industry: PVC coated wire ropes find extensive use in construction for applications like hoisting, cranes, winches, and suspension bridges. The corrosion resistance and improved grip make them reliable and safe for lifting heavy loads.

Marine Industry: In marine environments, PVC coated wire ropes are used in applications such as ship rigging, dockside cranes, fishing nets, and offshore installations. The PVC coating protects against saltwater corrosion and extends the longevity of the wire ropes.

Transportation and Automotive Industry: PVC coated wire ropes are employed in various transportation applications, including cable cars, ski lifts, and suspension systems for bridges. The weather resistance and abrasion resistance properties make them suitable for withstanding extreme conditions.

PVC Coated wire ropes provide an excellent solution for industries that require enhanced durability, corrosion resistance, and improved grip. Asahi Ropes, a renowned manufacturer, offers a range of PVC coated wire ropes that meet the highest standards of quality and reliability. Whether in construction, marine, transportation, or recreational applications, PVC coated wire ropes have proven to be a versatile choice. Embracing this innovative solution can significantly enhance operational efficiency, reduce maintenance costs, and improve overall safety.

0 notes

Text

Top Wire and Cable manufacturer in India

India's wire and cable industry is a cornerstone of the nation's infrastructure development, driving progress across telecommunications, automotive, railways, and power sectors. This industry is characterized by a blend of established giants and innovative newcomers, all contributing to India's growth story.

ASIO Electrical: Pioneering Excellence in Wire and Cable Manufacturing

ASIO Electrical is at the forefront of this dynamic industry and is renowned for its commitment to quality and innovation. ASIO Electrical has established itself as a leader in the Indian wire and cable manufacturing sector, offering a diverse range of products that cater to various industries. Their dedication to adopting cutting-edge technology and adhering to stringent quality standards has earned them a reputation for reliability and excellence.

Polycab India: A Dominant Force in the Market

Polycab India Limited, headquartered in Mumbai, is another major player in the wire and cable manufacturing industry. Founded in 1964, Polycab has grown to become the largest wire and cable manufacturer in India, holding a significant market share. The company's extensive product portfolio includes wires and cables, electric fans, LED lighting, switches, and switchgear. With a strong emphasis on research and development, Polycab continues to innovate, meeting the evolving needs of its diverse clientele.

Finolex Cables: A Legacy of Quality and Trust

Established in 1958, Finolex Cables Limited is the flagship company of the Finolex Group. Based in Pune, Maharashtra, Finolex is a leading manufacturer of electrical and telecommunication cables in India. The company's product range extends to PVC sheets, electrical switches, and CFLs, serving sectors like construction, automotive, and telecommunications. Finolex's commitment to quality and customer satisfaction has solidified its position as a trusted brand in the market.

Usha Martin: A Global Leader in Wire Rope Manufacturing

Usha Martin Limited, founded in 1961 and headquartered in Kolkata, is a prominent name in the wire and cable industry, particularly known for its wire rope manufacturing. With a global presence, Usha Martin caters to various sectors, including construction, oil and gas, and energy. The company's focus on sustainable practices and technological advancement has enabled it to maintain a competitive edge in both domestic and international markets.

Svarn Group: Driving Innovation Across Multiple Sectors

Founded in 2005, Svarn Group has rapidly emerged as a diversified manufacturing company with a strong presence in the wire and cable industry. Initially focusing on telecom cables to support India's digital transformation, Svarn has expanded its operations to sectors such as automotive, defence, railways, and power. Their commitment to the 'Make in India' initiative underscores their dedication to contributing to the nation's industrial growth.

Industry Challenges and the Path Forward

Despite the robust growth, the wire and cable industry in India faces challenges, including fluctuating raw material costs and evolving regulatory standards. For instance, companies like RR Kabel have reported profit declines due to increased copper prices and reduced demand for electrical products. To navigate these challenges, manufacturers are investing in technology, enhancing operational efficiencies, and diversifying product portfolios to meet the changing demands of the market.

ConclusionThe wire and cable manufacturing industry in India is integral to the nation's infrastructure and economic development. Companies like ASIO Electricals, Polycab India, Finolex Cables, Usha Martin, and Svarn Group exemplify the industry's strength and resilience. Through continuous innovation, adherence to quality, and a commitment to meeting the diverse needs of their customers, these manufacturers are not only powering India's progress but also setting benchmarks in the global arena.

Also Read:

The Best LED Ceiling Panel Lights for Home

Top Electrical Wires & Cables Manufacturer Supplier

Originally published at https://asioworld.blogspot.com

0 notes

Text

Cable Manufacturers in India [5 Best Manufacturers]

A cable is a thick wire or collection of wires, used to transmit electricity or electronic signals and is wrapped in a rubber or plastic sheath. The cable is a thick, strong rope consisting of twisted wires. Providing and producing custom-made cables and wires is a difficult task that requires a company with extensive experience, superior manufacturing capabilities, and industry-recognized certifications. Customers need to find out which manufacturer will provide them with the best and standardized products that are long-lasting.

Here are the top 5 list of cable manufacturers in India, they are:

Polycab India Ltd.

With their factories in Daman and Halol, they made their mark by manufacturing and marketing high-quality wires, which was soon followed by the manufacture of cables. Today, their wires and cables can be used in practically any situation, including homes, offices, and industrial and infrastructure projects. Apart from India, they have a presence in over 43 countries across the globe, making them one of the leading cable manufacturers in India.

Under the Polycab banner, they have recently expanded their electrical engineering prowess to include a wide variety of consumer electricals such as switches and switchgears, lightings and luminaires, fans, geysers and home appliances. Our factories in Halol, Baroda, Nashik, Bhilwadi and Roorkee manufacture all their products as per stringent standards. The overwhelming response they have received from all their large and small customers has inspired them to set new benchmarks in quality, aesthetics and safety.

Sterlite Technologies Ltd.

STL is a market-leading digital network integrator. Their 5G-ready digital network solutions help telecom companies, cloud firms, citizen networks and large organizations deliver superior client experience and is one of the top cable manufacturers in India. Through core strengths in optical interconnects, virtualized access solutions, network software and systems integration, STL provides comprehensive 5G ready end-to-end solutions from wired to wireless, design to deployment, connection to computing. They believe in using technology to create a world full of next-generation connected experiences that improve people's lives. They conduct basic research in next-generation network applications at their Centre of Excellence

Finolex Cables Ltd

Finolex Cables Ltd is the largest and most renowned cable manufacturer in India. The organization started its tasks by creating PVC-protected electrical links for the car business. From that point forward, the organization has endeavored to grow its product offering.

The company also manufactures lighting goods, electrical accessories, switchgear, fans and water heaters in addition to a large range of wires and cables. The company has production plants in Pimpri and Urs neighbourhoods of Pune as well as in Goa and Uttarakhand. By constantly upgrading technology, modernizing manufacturing facilities and maintaining the highest standards of quality and services, the company has developed a reputation as an inventive leader and quality manufacturer over the years. Investors have flocked to its shares owing to its meteoric growth, resulting in huge returns on investment over the years.

Havells India Ltd.

Havells India Ltd. is one of the leading cable manufacturers in India and also a leading Fast Moving Electrical Goods (FMEG) company with a strong global presence. Havells has an enviable market share in a wide range of products including industrial and domestic circuit protection devices, cables and wires, motors, fans, etc. It has a low number of client complaints and high customer satisfaction due to the high quality of its items and fast service. It has earned the reputation of being the chosen electrical goods provider for discerning individuals and businesses nationally and internationally. It is dedicated to continue to power the world with its cutting-edge inventions and energy-saving solutions.

RR Cable

RR Cable is a subsidiary of RR Global that has operations in over 85 countries. They continue to strive to provide the best quality products employing the latest advancements in wire design and engineering across multiple business areas including wire and cable. They have the widest selection of premium wires and cables for residential, commercial, industrial and infrastructure applications.

Their products also comply with REACH (Registration, Evaluation, Authorization and Restriction of Hazardous Substances) and RoHS (Restriction of Hazardous Substances) directives.

Note: Are you looking for top manufacturing companies database with all major details? 77Data provides all types of companies data such as machinery, wires, tools, automobile, manufacturing and many more.

Manufacturing companies in Madurai Top manufacturing companies in Bangalore Manufacturing companies in Delhi NCR Manufacturing companies in Nagpur

Conclusion

If you find a wire and cable manufacturer with the required experience, capabilities and certifications of the firm then you will get exactly what you need. The certifications of a factory prove that they meet all the necessary safety and quality requirements. A manufacturer must have great sourcing capabilities to make the type of cable you require. This means that they will need access to a wide range of materials including jacketing and insulating compounds, different types of shielding materials and different types of armor. They will need to be able to obtain these materials quickly, saving you money and time. The top cable manufacturers in India mentioned above are reliable, durable and trustworthy and can be chosen according to your preferences and applications.

Original Source: https://knowledgekablog.wixsite.com/knowledgekablog/post/cable-manufacturers-in-india-5-best-manufacturers

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] HUMBLE Ultimate Cable Protector | Spiral Triple Colour 1.5 Meter / 150 cm | Plastic Cord Wire Charger Winder for iPhone and Android Charging Cables These cord protectors are lightweight, durable and will easily fit a variety of cord types. Colour: multicolor Spiral Triple Colors Cable Cord Protectors Winders for Mobile Phone Charging Cable Earphones (1.5 m) They can protect charging cables as well as earphone cords from dirt, frays, tangles, and knots. Stand out from the crowd by combining different colors, you just need to take little time to finish this simple DIY work, then you'll get a cord of your own that you never expected. All things are difficult before they are easy, wrap with 1 rope, at the beginning may take you much of time, just relax & concentrate, 100% sure you can finish it within 10minutes. These cord protectors are lightweight, durable and will easily fit a variety of cord types. earphone cords from dirt, frays, tangles, and knots. Stand out from the crowd by combining different colors, you just need to take little time to finish this simple DIY work, then you'll get a brand new cord of your own that you never expected. All things are difficult before they are easy, wrap with 1 rope, at the beginning may take you much of time, just relax & concentrate, 100% sure you can finish it within 10minutes Functions; → These cord protectors are lightweight, durable, and will easily fit a variety of cords, → Protect your wire and cords from dirt, frays, tangles, and knots. → Durable, colored, flexible spiral core made of high-quality PVC → Prolong the life of your cable and avoid your cable getting mixed up again. → Protect wire and cords from dirt, frays, tangles, and knots, the risk of fraying and breaking reduces by 80% →Material PVC layer absorbs impacts preventing harmful twists & bends protects your cable against daily wear & tear. ✅ INCREASES CABLE LIFE: Stop replacing expensive iPhone and Android charger cables. Spiral Cable Protector covers the entire charging cable, reducing the risk of fraying and breaking by well over 80% ✅ COST SAVING: Spiral Cable Saver saves time and money at just a fraction of the cost of original iPhone and Android charging cables. ✅ COMPATABILITY: Suitable for all types of cables and cords like charger, headphone etc. ✅ Durable, colored and flexible spiral cord made of high quality PVC and can be applied as phone charger saver. ✅ BEST GIFT YOUR LOVED ONE : Charger wire protectors, wire protector spiral, data cable protector, cable protection flexible spiral wrap, can be a perfect gift for your Mother, Father, Brother, Sister, Best Friend, Girlfriend, Boyfriend and everyone. [ad_2]

0 notes

Text

Jump Rope, Tangle-Free Rapid Speed Jumping Rope Cable with Ball Bearings for Women, Men, and Kids, Adjustable Steel Jump Rope Workout with Foam Handles for Fitness, Home Exercise & Slim Body

See on Amazon I’ve recently acquired this tangle-free jump rope from the brand, and I must say it has revolutionized my fitness journey. The product’s title, ‘Jump Rope for Women, Men, and Kids – Adjustable Steel Jump Rope Workout with Foam Handles,’ truly encapsulates its versatility. , I appreciate the durability of this product. The steel wires, coated with strong PVC material, ensure that it…

0 notes

Text

Want to purchase Metal Wire Rope in Lucknow? Visit Adarsh Steels!

Binding wires come in several types, including PVC-coated binding wire, stainless steel binding wire, and black annealed baling wires. Binding stainless steel reinforcement is done with stainless steel binding wires. Want to know about Metal Wire Rope in Lucknow? Visit Adarsh Steels and buy a high-quality, durable metal wire rope product at a low price.

0 notes

Text

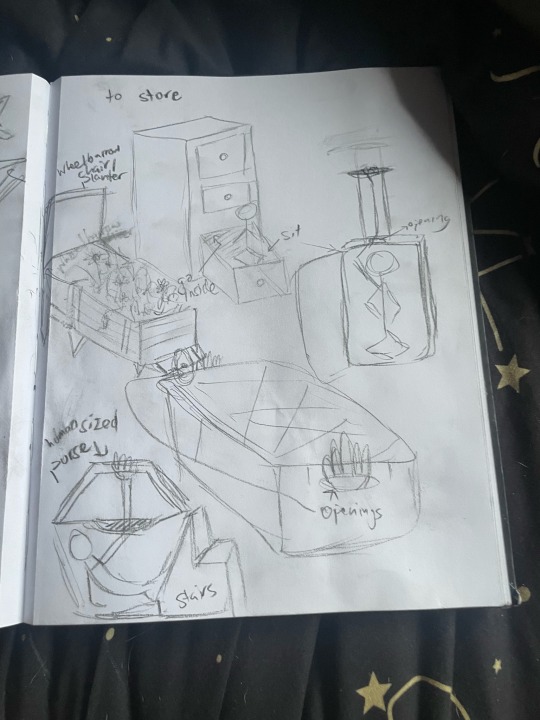

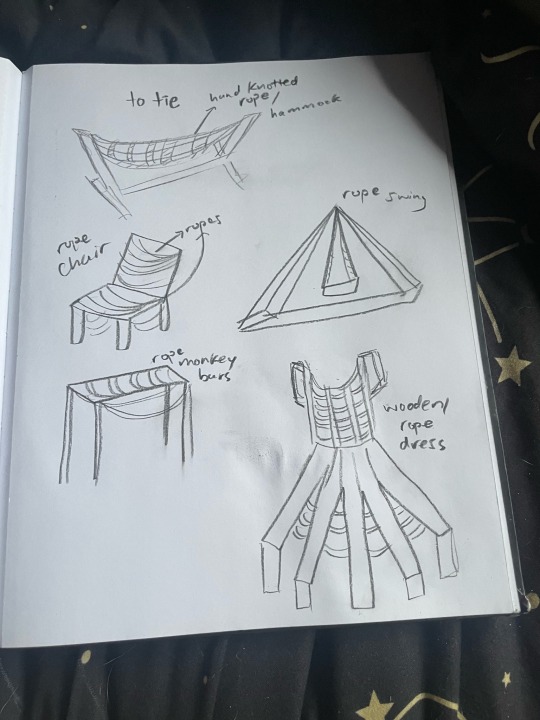

Materials I can use in the Framework of a Body Sculpture:

1. rope

2. spikes

3. cardboard

4. old wires

5. plants

6. wire

7. recycled bedsheets

8. mirrors

9. tires

10. cushions

11. bricks

12. bottlecaps

13. soda tabs

14. plywood

15. glass

16. plastic

17. clay

18. hot glue

19. fake moss

20. lace

21. barbed wire

22. foam

23. pvc pipe

24. pipe cleaners

25. adhesive

26. shells

27. sheet metal

28. stones

29. fake vines

30. leather

sketches i have made:

@3ddimensionsstudiofall2024am

1 note

·

View note

Text

How to Choose the Right Wire Rope for Your Industry Needs

Wire ropes play a critical role in numerous industrial applications—from construction and mining to marine and manufacturing. Choosing the right type of wire rope is essential for safety, performance, and longevity. With so many options available from wire rope manufacturers and suppliers in India, making the right choice can be overwhelming. This guide will help you understand the key factors to consider when selecting wire ropes tailored to your specific industry requirements.

1. Understand the Application

Before selecting a wire rope, clearly define its purpose. Will it be used for lifting, towing, hoisting, or structural support? Each application requires a different strength, flexibility, and construction. For example:

Cranes and Hoists: Need high-tensile ropes with anti-rotation features.

Elevators: Require smooth, fatigue-resistant ropes for constant motion.

Marine Industry: Demands corrosion-resistant materials like galvanized or stainless steel.

2. Choose the Right Material

Wire ropes are typically made from carbon steel or stainless steel. The environment and application will help determine the best material:

Stainless Steel: Ideal for corrosive environments like offshore or chemical plants.

Galvanized Steel: Provides good corrosion resistance at a more affordable price.

Carbon Steel: Offers high strength and is widely used in heavy industries.

3. Select the Proper Construction

Wire ropes are made of multiple strands, and their configuration affects strength and flexibility. Common constructions include:

6x19: Good balance between flexibility and abrasion resistance.

6x36: More flexible, suitable for applications with frequent bending.

8x19 or 19x7 Rotation-Resistant Ropes: Ideal for lifting or crane operations.

4. Check Load Capacity and Safety Factor

Always match the wire rope's breaking strength with the load requirements of your application. Consider the safety factor, which is typically 5:1 or 6:1, depending on the industry. This ensures the rope can handle more than the maximum working load safely.

5. Consider Coating and Lubrication

Coatings like PVC or galvanized finishes help protect against rust and wear. Pre-lubricated ropes reduce friction and extend the lifespan in high-motion systems. Ask your supplier if the ropes are internally and externally lubricated during manufacturing.

6. Choose Reputable Suppliers

Working with reliable wire rope manufacturers and suppliers in India ensures product quality, timely delivery, and support. Look for companies that follow international manufacturing standards, offer product testing certifications, and have a strong track record in your industry.

SVIBO Industries: A Trusted Name in Wire Rope Manufacturing

SVIBO Industries is a leading name among wire rope manufacturers and suppliers in India, offering premium-quality wire ropes for a wide range of industries. With a commitment to safety, durability, and innovation, SVIBO Industries provides tailor-made solutions backed by modern manufacturing processes and strict quality control. Whether you need ropes for lifting, construction, or marine applications, SVIBO ensures you receive products that meet global standards and exceed expectations.

Contact Details-

Address- 111,112,113 Mahatma Phule Peth, Block No 101, Sevadham Building, 1st Floor, Pune, Maharashtra 411042

Phone no- 8208803755

Email- [email protected]

Get Directions

0 notes

Text

Adipic Acid: An Essential Raw Material in Several Industrial Applications

Hexanedioic acid is produced on an industrial scale via a two-step process. In the first step, a mixture of cyclohexanol and cyclohexanone undergoes oxidation in the presence of a nitric acid/acetic acid catalyst system to form a mixture of cyclohexanone oxime and cyclohexanol oxime. This mixture is then hydrolyzed using sulfuric acid to yield hexanedioic acid.

Hexanedioic acid is an organic compound with the formula (CH2)4(COOH)2. It is a white, crystalline, water-soluble solid. Some of its key properties that make it useful commercially include its six-carbon backbone that allows it to acted as a synthetic substitute for hexamethylenediamine, its acidity due to the two carboxyl groups, and its solid state at room temperature which enables ease of handling and transport. Its melting point is 151°C and boiling point is 320°C.

Uses in Nylon Production

By far the largest application and consumer of Adipic Acid is in the production of nylon 66. In this process, hexanedioic acid reacts with hexamethylenediamine to form the polyamide polymer known as nylon 66. Nylon 66 is used extensively to produce fibers, films and engineering resins. Its properties such as high strength, flexibility and toughness have made nylon 66 an essential material in everything from fabrics and clothing to carpets, ropes and wires. The fiber has good resistance to abrasion, sunlight and detergents, making it ideal for carpets and upholstery. Films produced from nylon 66 have applications as food packaging and garbage container lining.

Other Synthetic Polymer Production

Besides nylon 66, Adipic Acid also finds use as a monomer in making other synthetic polyamides and polyesters that have wide-ranging applications. It can react with diamines like dodecamethylenediamine and dimer acid to produce nylon 610 and nylon 612. These polymers demonstrate good dimensional stability, weatherability and chemical resistance and are used in engineering plastics and automotive parts. Hexanedioic acid is also used to synthesize poly(butylene adipate-co-terephthalate) or PBAT, which is a biodegradable polyester alternative to conventional PET in applications like compostable shopping bags and food packaging.

Production of Plasticizers

Adipic Acid derivatives like dioctyl adipate, diisononyl adipate and bis(2-ethylhexyl) adipate are commonly used as high-quality plasticizers. Almost 30% of the hexanedioic acid manufactured globally is consumed in making these plasticizers. They are added to PVC to make it soft and flexible for applications like wires and cables, automobile interior parts, flooring and waterproof sheeting. Plasticized PVC demonstrates better longevity, lower temperature sensitivity and stronger resistance to chemicals compared to other plasticizers.

Niche Applications

Smaller quantities of hexanedioic acid find niche applications as well. It is used as a starting material in pharmaceutical processes and to produce compounds like nylon 66 fiber for specialty brushes. Hexanedioic acid serves as an intermediate in manufacturing dyestuffs, perfumes and plastics. It also acts as an acidulant in certain foods to impart a pleasant tart taste without being too strong. Some manufacturers use it to produce Feed supplementary acidifiers and anticaking agents for fertilizer. Hexanedioic acid has even found application as an essential ingredient in e-liquids for vaping devices.

Considering its versatility and extensive usage, Adipic Acid is projected to experience steady demand growth worldwide in the coming years. Factors such as rising consumption of nylon fibers, films and plasticizers along with increasing industrialization and per-capita plastic consumption willcontinue to drive market expansion. While nylon and plasticiser production remains the core revenue generator, newer applications in specialty polymers and biodegradable plastics are likely to gain importance. However, availability of substitutes remains a challenge, necessitating optimization of manufacturing processes to ensure competitiveness. Ongoing R&D could see hexanedioic acid being utilized in more fields, consolidating its status as a workhorse industrial chemical.

Overall, this comprehensive article provides technical insights about the industrial production, key properties and diverse applications of hexanedioic acid which establish its importance as a raw material in several sectors.

Get more insights on Adipic Acid

About Author:

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#AdipicAcid#NylonProduction#PolymerIndustry#Plasticizers#PolyurethaneFoams#ResinProduction#SyntheticFibers#Coatings

0 notes