#PVDF Bottom Valve

Explore tagged Tumblr posts

Text

PVDF Bottom Valve DN15-300

Superior quality White PVDF Bottom Valve completely sealed DN50-DN300 plastic pvdf industrial Foot Valve Type:Foot Valves Model Number:H11F-10F Application:General Temperature of Media:Medium Temperature, Normal Temperature Power:Manual Media:Acid

0 notes

Text

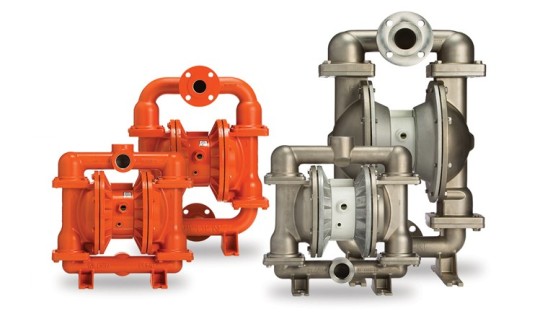

TEN REASONS YOU MUST USE ENGINEERED AODD PUMPS

Oil rigs, midstream production and refineries are dangerous places where one spark during a highly combustible environment can mean disaster.

When you’re working within the oil and gas industry, you don’t have time to fiddle with unreliable equipment. Whether onshore or offshore, you would like machinery you'll trust to try to do the work the primary time.

Air-operated double-diaphragm (AODD) pumps are one among the foremost critical pieces of kit to the industry. Oil and gas workers calculate AODD pump to not only keep their production moving smoothly, but also to stay them safe.

In fact, there are many reasons you ought to use engineered AODD pumps in critical applications, like those within the oil and gas industry.

1. AODD pumps are safe in potentially explosive environments.

AODD pumps by their nature don't use electricity and are fully groundable. This is often important because groundable equipment prevents static discharge from igniting a combustible environment.

2. Gas powered pumps are available.

Traditional AODD pumps are designed to be used with air only. Over the years, oil and gas operators have opted to power their diaphragm pumps with easily accessible gas .This g-series pump line is csa certified to be operated with either sweet/sour gas or instrument air. AODD Pump Suppliers provide safety features and help standardize inventory for multiple locations.

3. GODD pumps are versatile.

Gas or air operated heavy-duty flap valve pumps can safely carry the abrasive slurries, suspended and non-suspended solids and enormous line-size solids found within the oil and gas market. Gas/oil field pumps are often utilized in a good range of applications, including:

• lube oil transfer

• Glycol recirculation/heat trace

• flare knockout

• Glycol transfer/water make-up

• Sump/general transfer

• Tank bottom recirculation/transfer

• Utility/general transfer

• Separators and knockout drums

• General-duty spill cleanup

• Diesel fuel transfer

• Seawater pump for drilling fluid make-up

• produced water/condensate transfer

• cellar pump-out and dirt transfer

4. AODD pumps are often utilized in flare knockout applications.

AODD pumps can pump liquids with entrained gasses while many other pump designs will air bind thanks to excessive amounts of gasses present. The liquid and gas mixture can then be disposed of or reprocessed.

5. Different porting options are available.

Look for AODD Pump manufacturers who offer bottom discharge porting, which prevents settling, solids from shortening pump life and provides superior suction lift.

6. Flap valve pumps offer superior solids handling.

Flap valve pumps with top suction configurations are designed to pump solids without causing damage to pump internals caused by solids build up.

7. AODD pumps are portable.

Safely and simply transported, double diaphragm pumps are made for tough environments. Some are made with roll cages or skid bases, in order that they are often thrown within the back of a truck and brought from one site to a different.

8. AODD pumps work consistently despite the temperature.

AODD pumps can operate within the freezing and very high temperatures encountered on oil rigs or in gas fields.

9. Containment-duty AODD pumps help prevent leaks.

Metallic and non-metallic containment-duty pumps are ideal for pumping highly corrosive and unsafe chemical fluids. These are often constructed of aluminum, cast iron, chrome steel, alloy c, polypropylene and pvdf bodies with elastomeric and ptfe options for diaphragms and check valves. Unlike a standard AODD, the planning of the pump will prevent fluid from leaking within the event of a diaphragm failure. It'll also prevent instrument air powering the pump, from entering the method fluid when the diaphragm fails.

10. Accessories can improve pump efficiency/lifespan.

Accessories, like filter regulators and liquid level control, are often purchased and installed to extend the method control of the method and lengthen the lifespan of the pump.

0 notes

Text

Chemical Storage Tanks Manufacturer and Supplier

The Industrial Revolution now extraordinary jumps forward in the story of Chemical Storage

STEP Techno Solutions LLP offers a wide range of solutions for storing Chemical which is critical to handle. From experience, we know that every application has its own specific requirements therefore STEP provide the storage solutions include detail engineering, manufacturing, design and select the raw material as per application and user requirement. Our storage tanks can be equipped with accessories and attachments such as Nozzles, Valves, Level Indicator, Ladder, Platform and Pumps.MOC : PP / HDPE / PVDF / ECTFE / PVC / PP + FRP / HDPE + FRP / PVDF + FRP / ECTFE + FRP

Main Advantage of Storage Tank

1. Ready to install 2. Anywhere can install 3. Spillage Proof 4. Upto20 years of Life 5. Modification and Repairing promising

Available accessories

1. Level Indicator 2. Stirrer Fixing Arrangements 3. Saddles 4. Air Vent 5. Drain Connection 6. Main Hole 7. Inlet 8. Outlet 9. Ball Valve

Available Shape

1. Round 2. Rectangular 3. Square 4. Vertical 5. Horizontal 6. Conical Bottom 7. Conical Top 8. Oval 9. Dish end 10.“L” Shape Custom

#Chemical Storage Tank Manufacturers Ahmedabad#Chemical Storage Tank Manufacturers Gujarat#Chemical Storage Tank Manufacturers India

0 notes

Text

FV Direct Type Centrifugal Pump

The pump body is all PVDF and FRPP resin injection molding,so the inlet and outlet pipe lines should have support or suspension structure, should not be supported only by the joint flanges. The inlet pipeline should not have more than 2pcs 90° elbow. The FP, FV type centrifugal pump shall be installed at the front end of the suction tube to ensure that the pump is filled with liquid before starting the pump.The suction nozzle or the bottom valve shall be installed with a strainer, or a strainer shall be installed at the inlet to prevent the sundries from being sucked into the pump and ensure that the pump can function properly.

0 notes