#Packaging Machine

Explore tagged Tumblr posts

Text

The flexible packaging industry is undergoing a revolution, driven by innovative technologies that prioritize precision, efficiency, and versatility. Among these advancements, the Slitter Rewinder Machine stands as a cornerstone of modern converting solutions.

#krishnaengineeringworks#flexible packaging#packaging#packagingindustry#machines#machine#manufacturer#slitterrewindermachine#machinery#export#supplier#industrial#packaging machine

2 notes

·

View notes

Text

Automatic Liquid Packaging Machine

AS1000, for water, milk and beverage.

PE Film Width: 320mm

Filling Capacity: 200~500ml

Packaging Speed: 2000bags/h

3 notes

·

View notes

Text

#ketchup packaging machine#tomato paste packaging machine#packaging machine supplier in kenya#packaging machine supplier in south africa#hffs packaging machine#bottling lines#nichrome africa#packaging machine

0 notes

Text

Sugar Packaging Machine

Nichrome manufactures cost-effective, technology-driven automatic sugar packaging and filling machines, capable of handling various quantities up to 10kg in versatile pouch formats.

#sugar packaging machine#sugar packaging#sugar packaging machine manufacture#retail sugar packaging machine#retail sugar#packaging machine#automatic sugar packaging machine

0 notes

Text

Streamline Your Bottled Water Production with Advanced 5-Gallon Filling & Packaging Solutions

At Aqua Experts UAE, we empower water bottling plants with automated, hygienic, and high-efficiency 5 Gallon Filling & Packaging Machineries, making us one of the most trusted suppliers in the UAE.

🔧 Why Choose Our 5-Gallon Systems? ✅ Fully Automated Operation – From decapping to rinsing, filling, capping, labeling, and packing – all in one streamlined line. ✅ High Output, Low Labor – Engineered to deliver high-capacity performance with minimal manpower. ✅ Hygienic Design – Built with food-grade materials to meet international health & safety standards. ✅ Modular & Scalable – Designed for small, medium, and large-scale bottled water operations.

🏭 Ideal for: ✔️ Bottled Water Plants ✔️ Beverage Manufacturers ✔️ Contract Packaging Facilities

When efficiency, hygiene, and consistency matter—our systems deliver.

🔗 Explore the Range: 5 Gallon Filling & Packaging Machineries Suppliers in UAE

0 notes

Text

0 notes

Video

youtube

Cereal oatmeal packaging machine with automatic weigher and double sides...

Bestar high configuration automatic weighing packaging machine for cereal oatmeal. With 14-head 2.5L anit-leakage weigher for fast & accurate work. Weigher surface with Teflon coating for non-sticking. With a 10-inch Siemens touchscreen, large and convenient for operation. Customized two labeling machine for stickers at the front & back of the pouch. Matching a powerful vacuum cleaner to keep the machine and the working environment clean and pollution-free. Everything is built to work smoothly together for simple operation and reliable results.

#youtube#packing machine#packaging machine#weighing packaging#automatic weighing machine#cereal oatmeal#oatmeal packaging machine#automatic oatmeal packing machine#labeling packaging#automatic labeling#bestar packaging#bestar rachel

0 notes

Text

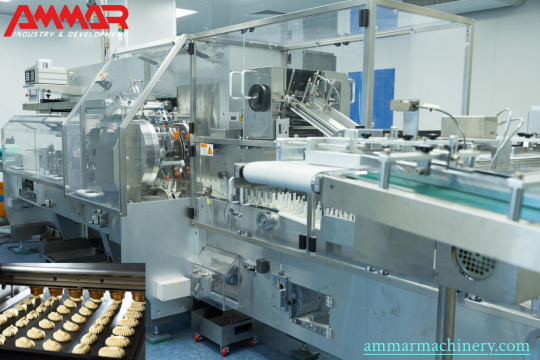

When it comes to selling chocolate, how you package it can be just as important as how it tastes. While wrapping ensures the safety and appeal of your product, Chocolate Labeling Machines take that final step to communicate your identity to the consumer. At Ammar Machinery, we specialize in high-performance Labeling Machines designed specifically for chocolate products, combining accuracy, efficiency, and a sleek finish.

#chocolate wrapping machine#chocolate packaging machine#chocolate making machine#machinery manufacturer#machinery manufacturing company#chocolate industry#packaging machine

1 note

·

View note

Text

#Robotic Case Packing Machine#Packaging Robots#Robotic Packaging Automation#Robotic Case Packers#Robotic Palletizers#packaging machine#packaging automation#lube oil blending plant#lube oil blending machinery

0 notes

Text

Precision Filling Machines for Powders & Granules | Munky Packaging Machine

Munky’s Filling Machine Offers High-Accuracy Filling Solutions for Powders, Granules, Seeds, and Spices. Equipped with Advanced Controls and Sensor-Based Automation, These Machines Reduce Wastage, Maintain Hygiene, and Deliver Consistent Output. Whether You're in Food Production, Agriculture, or Industrial Manufacturing, Our Filling Machines Meet the Demands of Small and Large Batch Operations. the System Supports a Variety of Pouch Sizes and Integrates Seamlessly into Your Existing Packaging Line. Built with Stainless Steel for Durability and Easy Maintenance, Munky’s Machines Are Trusted Across India. Make Your Packaging Smart, Fast, and Precise with Our Industry-Leading Filling Technology. Request a Quote Now.

Call Now:- 9599919442

#Packaging Machine#Packing Machinery#Automatic Packing Machine#Chips Packing Machine#Filling Machine

0 notes

Text

1 note

·

View note

Text

Filpack Servo 12K

This machine is the fastest milk pouch packaging machine, with a speed of 12,000 packs/hour. It can pack CSPP pouches of 200 ml, 500 ml and 1000 ml with equal ease and accuracy.

FILPACK SERVO 12K is a heavy duty machine with simple maintenance-friendly construction. It is built for hygiene with product contact parts of stainless steel and a UV film sterilisation system for the packaging material.

Independent balance tanks offer flexibility to handle single or different products simultaneously.

#packaging machine#milk pouch packaging machine#milk packaging#milk packaging machine supplier in bangladesh#milk filling machine#milk packaging machine#milk pouch packaging machine bangladesh#filpack servo 12k#filling system

0 notes

Text

#packaging machine#spice packaging machine#rice packaging machine#seed packging machine#milk packaging machine

0 notes

Text

Wing 200 E-line Snack Pack

Exclusive packaging solution for startups and small-medium enterprises.

Discover all the superior expertise and reliability of Nichrome, in a compact, affordable format - designed to fit your space, budget and performance expectations. After all, as India’s leading packaging solutions provider, Nichrome understands your products and your needs. For more information about Wing 200 E-line Snack pack visit https://www.nichrome.com/

#packaging machine#snack packaging machine#automatic packaging machine#automatic packaging machines#packaging machine manufacture in india#packaging solution

0 notes

Text

Selecting equipment for a granular organic fertilizer production line is a complex process that requires comprehensive consideration of multiple factors to ensure the smooth operation of the production line and the quality and stability of the product. The following are the main factors to consider: 1. Production capacity Annual or daily output: First of all, it is necessary to clarify the production capacity of the production line, such as how many tons of granular organic fertilizer can be produced annually or how many tons of granular organic fertilizer can be produced per day. This directly determines the scale and quantity of equipment required. Production efficiency: The production efficiency of the equipment is also an important consideration. It determines how much fertilizer can be produced per unit time, thus affecting the overall production capacity of the production line.

2. Product type Granular shape: Determine what shape of granular organic fertilizer is produced, such as standard spherical, cylindrical, oblate, etc. Different shapes may require different types of granulators. Fertilizer type: Is it pure organic fertilizer, organic-inorganic compound fertilizer, biological organic fertilizer or compound microbial fertilizer? Different types of fertilizers also have different requirements for equipment. 3. Equipment selection Granulator: Select a suitable granulator according to the shape of the particles and production requirements, such as disc granulator, drum granulator, wet granulator, flat die granulator, ring film granulator, etc. Fermentation equipment: Select suitable fermentation equipment, such as trough compost turner, chain plate compost turner or self-propelled compost turner, etc., to ensure that the raw materials are fully fermented and mature. Pulverizer: Select a pulverizer suitable for processing fermented materials to crush them into fine powder for subsequent granulation. Drying and cooling equipment: Configure dryers and coolers to remove excess moisture from the particles and reduce the temperature. Screening equipment: Use a sieving machine to grade and screen the particles to ensure the uniformity and quality of the product. Packaging equipment: Select a fully automatic packaging machine to quantitatively weigh and package the finished products.

0 notes

Text

How Electromec Ensures Precision Engineering in Every Machine

Electromec India Pvt. Ltd. is at the forefront of innovation in post-printing and packaging machinery. This article explores the unique features, industry relevance, and business impact of this machine or topic. It highlights how Electromec's technology boosts productivity, enhances precision, and contributes to streamlined operations. Whether you're in publishing, commercial printing, or packaging, understanding this solution can help you make better investments. Read on to know how Electromec machines meet evolving market demands and set benchmarks in performance and quality

0 notes