#Paper Plate Making Machine Paper Plate Making Machine Manufacturer

Explore tagged Tumblr posts

Text

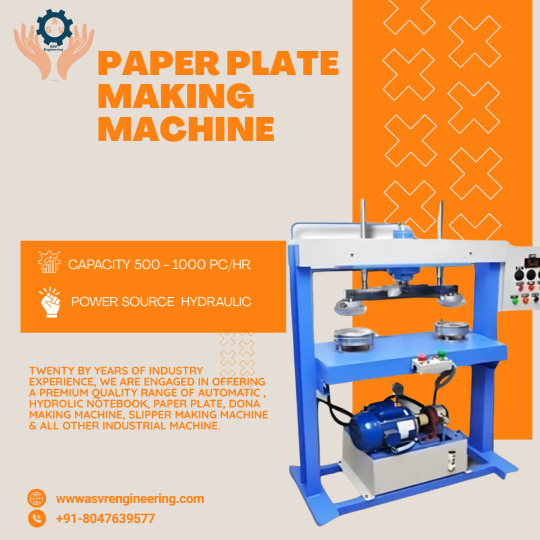

If you are searching for paper plate making machine in India. Then you are at the right place. We, ASVR Engineering Pvt. Ltd are the manufacturer and supplier in the field of best quality paper plate making machine in India. The machines generate the products using the supplied paper material because of their great performance and flawless working life. These machines are available at reasonable price for our clients.

0 notes

Text

Project Report: Paper Cups and Plates Manufacturing Unit

Project Report: Paper Cups and Plates Manufacturing Unit Paper Cups and Plates Manufacturing 1. Introduction- Paper Cups and Plates Manufacturing The plastic cup and Plate Manufacturing industry is facing increasing environmental concerns, and the ban on single-use plastics has led to a surge in demand for eco-friendly alternatives like paper cups and plates. These products are not only…

#disposable glass and plate making machine price in india#manual paper cup making machine price#paper cup making machine low price#paper cup making machine price#paper cup making machine under 1 lakh#paper cups and plates manufacturing unit cost#paper cups and plates manufacturing unit in india#paper cups and plates manufacturing unit near me#paper cups and plates manufacturing unit price#paper plate manufacturers in india#second hand paper cup machine price#top 10 paper cup making machine

0 notes

Text

The Role of Biodegradable Plastics in a Sustainable Future

Plastic air contamination has in fact wound up being an around the world eco-friendly problem, with an estimated 8 million tons of plastic waste acquiring associated with the seas every year. To combat this problem, there has really been an expanding rate of interest in the development and manufacturing of biodegradable plastics.

Biodegradable plastics supply an enduring option to typical plastics by breaking down in the ambience, reducing their effect on the setup.

What is Biodegradable Plastic?

Biodegradable plastic is can be cracked down in normal by microbes like fungi and bacteria. This biodegradable plastics can be composted and returned to the system, unlike routine plastics which can take times to break down.

Types of Biodegradable Plastic

We provides the best eco friendly disposable plate making machine. There are numerous type of biodegradable plastics, each with its really own unique house or commercial residential properties. There are many common types of biodegradable plastics like:

Polylactic Acid: PLA is a polycarbonate complete from renewable vivacities such as sugarcane or cornstarch. It is usually made the most of to make food packaging, disposable tools and various other products that are developed to be composted.

Polyhydroxyalkanoates: They are normally used to make clinical devices, food packaging and various other goods that need a high level of durability.

Starch Mixes: Starch blends are made from a mix of starch and other items such as cellulose or plastic. They are constantly taken advantage of to make disposable mugs, plates, and different various other items that are produced to be composted.

Manufacturing Renovation of Biodegradable Plastic

The manufacturing therapy for biodegradable plastics differs relying on the type of plastic being developed. Pneumatically driven collaborating systems and various other product handling systems are used as a starting factor in the manufacturing of biodegradable plastics.

Resource Handling: The first step is to dump and save the raw materials that will certainly be used to make the plastic. Pneumatic communicating systems are also utilized to carry basic materials from storage to handling equipment. This can consist of products such as starch, polymer pellets and ingredients.

Mixing: Certain machinery of blenders can be applied to blend different vigorous elements in the plastic resolution. This can make certain that the active ingredients are equally distributed prior to the next action and that the final product actually has the desired properties evenly dispersed in the complete set.

Extrusion & Molding: The consistently blended basic material is then extruded and cooled down to a desired shape via a pelletizer. There are numerous options that Agarwal Machineries can supply to boost the top quality of this product like paper pulp moulding machine, bagasse plate making machine, sugarcane bagasse tableware making machine and etc.

Packaging & Storage Space: The end product can be kept in storage silos wholesale before final packing. Final packaging can be done using automated or semi-automatic equipment to load it right into small bags or big bags and then dispatch it.

Mass product handling systems can offer many profits in the manufacturing of biodegradable disposable machine like:

Increased Efficiency: These systems can help to increase performance by lowering the necessity for hand operated handling and transport.

Reduced Risk of Pollution: These methods help in falling the risk of contamination by avoiding cross pollution between the raw materials in addition to the ended products.

Improved Security: Risk of crashes related to manual handling and transportation is reduced considering that guy activity is not required to produce the items.

Healthy Work Environment: Well-designed products dealing with systems aid in improving the total office by reducing dirt which otherwise causes air contamination issues.

Benefits of Biodegradable Plastic

Biodegradable plastics offers diverse benefits over standard plastics like:

Environmental: Biodegradable plastics can be composted and return to the environment, unlike typical plastics which can take times. Its increases to supply maintenance and declines air pollution.

Cost Effective: Biodegradable plastics made from renewable, which can help decrease the level of plastic manufacturing. Moreover, biodegradable plastics can be used to select items that are recognized to be composted, which can develop new markets.

Productivity: Biodegradable plastics can procedure related performance structures to conventional plastics. For example, PLA can be utilized to explain food packaging that is just as solid and durable as standard plastic food product packaging.

Disadvantages of Biodegradable Plastic

Study Required: Biodegradable plastics are still at an incentive phase and even more R&D is required for developing several secure substances that can be utilized to replace the plastics used today.

Availability: These are not as readily available as traditional. This is since they are a practically advance and the manufacturing process is still being adjusted.

Composting Structure: To compost biodegradable plastics, they need to be willing of in a composting center. This is not always an alternative, as not all communities may have such composting centers. Maintaining the benefits and negative aspects of biodegradable plastics, they have the potential to be an extra lasting choice to conventional plastics and we are thrilled to see more applications adopt this eco-friendly innovation in advance to make the earth a much more sustainable area to live.

#Biodegradable Disposable Machine Manufacturer#Eco Friendly Disposable Plate Making Machine#Edge Trimming Machine#Bagasse Plate Making Machine#Pulp Moulding Machine#Pulp Molding Machine#Paper Pulp Molding Machine#Pulp Moulding Machinery

0 notes

Text

A good paper plate-making machine boosts productivity through increased efficiency. Contact reliable paper plate making machine manufacturers for the best equipment.

1 note

·

View note

Text

Top 10 Profitable Paper Products Manufacturing Business Ideas

Unlock the potential of the paper industry with these 10 profitable paper products manufacturing business ideas. Learn how to start and succeed in this sustainable sector.#BusinessIdeas #PaperBusiness #Entrepreneurship #SmallBusiness #Startup #EcoFriendly

The paper business is the most rapidly expanding sector of all time. Paper may be used to make a variety of products, as well as to start small businesses. These ideas not only meet the growing demand for environmentally friendly products but also provide tremendous chances for creativity and success. Today, every business is seeking greenways to be environmentally conscious and socially…

#business tips#Eco-Friendly Business#entrepreneurship#Lucrative Business Ideas#paper and pulp business ideas#paper box business ideas#Paper Business Ideas#paper crafts business ideas#paper plate making machine#Paper Products#Paper Products Manufacturing#Paper Products Manufacturing Business#Paper-Based Business#small business ideas#startup ideas

0 notes

Text

Paper Plate Making Machine in Varanasi: Streamline your Business with Dona Plate Making Machine

Are you looking to enhance efficiency in your business by investing in a paper plate making machine in Varanasi? Contact Laghu Udyog, as we dive into the world of Dona plate making machines and how we can revolutionize your production process.

Why Choose a Dona Plate Making Machine?

If you are in the food service industry or catering business, the need for disposable plates is inevitable. With a Dona plate making machine, you can easily produce high-quality plates in various shapes and sizes to meet the demands of your customers. This machine is designed to be user-friendly, efficient, and environmentally friendly, making it the ideal choice for businesses looking to reduce their carbon footprint.

Benefits of Investing in a Dona Plate Making Machine

Cost-effective production: By investing in a Dona plate making machine, you can significantly reduce the cost of production compared to purchasing pre-made disposable plates.

Customization options: With a Dona plate making machine, you have the flexibility to customize the plates with your logo or design, adding a personal touch to your products.

Eco-friendly solution: The use of paper plates is an environmentally friendly alternative to plastic plates, helping to reduce waste and protect the environment.

Increased production capacity: Dona plate making machines are capable of producing a large number of plates in a short amount of time, allowing you to meet high demands and maximize efficiency.

How to Choose the Right Dona Plate Making Machine in Varanasi

When looking to purchase a Dona plate making machine in Varanasi, there are a few factors to consider ensuring you make the right choice for your business:

Production capacity: Determine the volume of plates you need to produce on a daily basis to choose a machine that can meet your production requirements.

Quality of output: Inspect samples of plates produced by the machine to ensure they meet your standards in terms of quality and durability.

User-friendly features: Select a machine that is easy to operate and maintain, to streamline your production process and minimize downtime.

After-sales support: Choose a supplier that offers reliable after-sales support and maintenance services to keep your machine running smoothly.

Setting Up Your Dona Plate Making Machine in Varanasi

Once you have chosen the right Dona plate making machine for your business, it's time to set it up for optimal performance. Follow these steps to get started:

Read the instruction manual carefully to understand the operation and maintenance requirements of the machine.

Place the machine in a clean and well-ventilated area with access to power sources and water supply if required.

Ensure all safety precautions are in place, such as wearing protective gear and following proper operating procedures.

Test the machine with a small batch of raw materials to check for any issues and make adjustments as needed.

Conclusion In conclusion, investing in a Dona plate making machine in Varanasi can be a game-changer for your business, allowing you to produce high-quality disposable plates efficiently and cost-effectively. With the right machine and proper setup, you can streamline your production process and meet the demands of your customers with ease. So why wait? Take your business to the next level with a Dona plate making machine today with Laghu Udyog in Varanasi.

#Paper plate making machine#business#manufacturer#Dona plate making machine#paper plate machine in Varanasi

0 notes

Text

Paper Plate Making Machine Manufacturers in Siliguri

Creative Industries stands as the foremost destination as top-quality Paper Plate Making Machine Manufacturers in Siliguri. Our extensive range of machines is meticulously designed to meet the diverse manufacturing needs of businesses in the region. With a commitment to excellence and innovation, we ensure that our machines deliver unmatched performance and reliability.

As leading paper plate making machine manufacturers in Siliguri, we prioritise customer satisfaction and strive to exceed expectations at every turn. Our dedication to quality craftsmanship and advanced technology sets us apart in the industry, making us the preferred choice for businesses seeking reliable and efficient paper plate manufacturing solutions.

1 note

·

View note

Text

PAPER PLATE MAKING MACHINE SUPPLIERS IN ODISHA

Product Price: 65000 Minimum order quantity:1 Business Type:Manufacturer Voltage:220V Power:2 HP MOTOR SINGLE PHASE Product Usage:PAPER PLATE MAKING Product Material:IRON Machine Capacity:1200 PCS SITTING THALI PER HOUR Machine Automation:Automatic Website : https://swostikdisposable.com/ call or whatsapp-…

View On WordPress

#paper plate machine dealers in odisha#paper plate machine manufacturers in odisha#paper plate machine suppliers in odisha#paper plate making machine suppliers in odisha

0 notes

Text

What is the maintenance process for an automatic paper bag machine?

Investing in an automatic paper bag machine is a smart move for businesses looking to scale their packaging operations and deliver eco-friendly solutions. However, like any high-performance industrial equipment, it’s essential to maintain the machine properly to ensure consistent output, reduce downtime, and maximize its operational lifespan.

At Prakash Machineries Pvt Ltd, we not only manufacture high-quality automatic paper bag machines but also guide our clients on the best practices for maintaining them. In this article, we’ll walk you through the maintenance process—from daily upkeep to long-term care—so your machine stays efficient and productive for years to come.

Why Maintenance Matters

Regular maintenance isn’t just about avoiding breakdowns—it’s about:

Extending the life of your machine

Reducing unexpected production halts

Maintaining bag quality and consistency

Minimizing repair costs

Ensuring safety for your operators

A well-maintained machine operates smoothly, uses less energy, and supports faster return on investment.

Daily Maintenance Checklist

The foundation of a good maintenance routine starts with daily attention. These are simple yet effective steps your operator should follow every day:

✅ 1. Clean the Machine Surfaces

Wipe down the external surfaces to remove dust, paper scraps, and glue residue.

Make sure the rollers and cutters are clean to avoid smudges or improper cuts.

✅ 2. Inspect Glue Nozzles and Tanks

Check if glue tanks are full.

Clean any dried glue from nozzles to prevent clogging and uneven application.

✅ 3. Check Paper Roll Alignment

Ensure the paper is feeding smoothly without shifting or wrinkling.

Misalignment can affect bag folding, printing, and sealing.

✅ 4. Observe for Unusual Noises or Vibrations

Any unfamiliar sound might indicate a loose component or potential fault. Report and log such issues.

Weekly Maintenance Tasks

Once a week, your machine operators or technical team should perform a more detailed inspection:

🛠️ 1. Lubricate Moving Parts

Apply grease or oil to the bearings, gearboxes, and other moving components as per manufacturer recommendations.

Use high-quality lubricants to avoid buildup or corrosion.

🛠️ 2. Inspect Belts and Chains

Check for signs of wear or tension issues.

Replace any frayed belts or loose chains promptly.

🛠️ 3. Clean Sensors and Electrical Panels

Debris and dust near sensors can cause automation issues.

Use dry air to clean the control panel and PLC components safely.

🛠️ 4. Check Cutters and Blades

Inspect the sharpness and alignment of rotary or flat cutters.

Dull blades should be replaced or sharpened to ensure clean, accurate cuts.

Monthly Maintenance and Calibration

Once a month, it’s good practice to schedule deeper preventive checks:

🔧 1. Check Motor and Drive Units

Examine the servo motors, drive belts, and coupling systems.

Look for overheating signs, oil leaks, or abnormal wear.

🔧 2. Calibrate Sensors and PLC Systems

Recalibrate bag length sensors, glue sensors, and print registration systems.

Ensure your touchscreen panel (HMI) settings match production specifications.

🔧 3. Examine the Handle Unit and Printing Section (if equipped)

Inspect the handle-pasting mechanism for adhesive buildup or wear.

If using inline printing, clean the anilox rollers, plates, and ink tanks.

Spare Parts and Inventory Management

To minimize downtime, always keep critical spare parts in stock, such as

Cutting blades

Glue nozzles

Sensors

Belts

Bearings

Control relays

At Prakash Machineries Pvt. Ltd., we offer full support with spare part kits and supply you with a recommended inventory list during machine installation.

Operator Training and Documentation

A well-trained operator is your first line of defense against machine issues. Ensure your team:

Understands the machine’s interface and alert systems

Follows safety protocols during cleaning or part replacements

Keeps a maintenance logbook for tracking issues and routine service

We provide comprehensive training sessions during installation and offer ongoing support to help your operators become proficient in both operation and maintenance.

When to Call for Professional Service

While most maintenance tasks can be handled in-house, you should schedule a professional service visit in the following cases:

Sudden drop in production speed

Irregular bag sizes or gluing errors

Motor or PLC malfunctions

Electrical safety alerts

After 6–12 months of continuous use for full inspection

Our team at Prakash Machineries Pvt. Ltd. offers annual maintenance contracts (AMCs), remote troubleshooting, and on-site technician visits across India for complete peace of mind.

Conclusion: Maintenance = Maximum Uptime

An automatic paper bag machine is a powerful asset for any packaging business—but like any industrial machine, it performs best when well cared for. A simple, consistent maintenance routine can dramatically improve your machine’s efficiency, reduce breakdowns, and extend its lifespan.

At Prakash Machineries Pvt Ltd, we believe in building machines that last—and supporting them with expert guidance, spare parts, and proactive service.

Need help setting up a maintenance plan for your paper bag machine? Get in touch with Prakash Machineries Pvt Ltd today for personalized service support, spare part kits, and AMC options tailored to your machine and production goals.

#paper bag manufacturer#manufacturer#machines#paper bag#bags#v bottom#square bottom#flexo#breakfast#delicious#chocolate#cake#critical role#chris sturniolo#baking#alien stage#cooking#dan and phil

1 note

·

View note

Text

Creature yet again brings you a thing it found

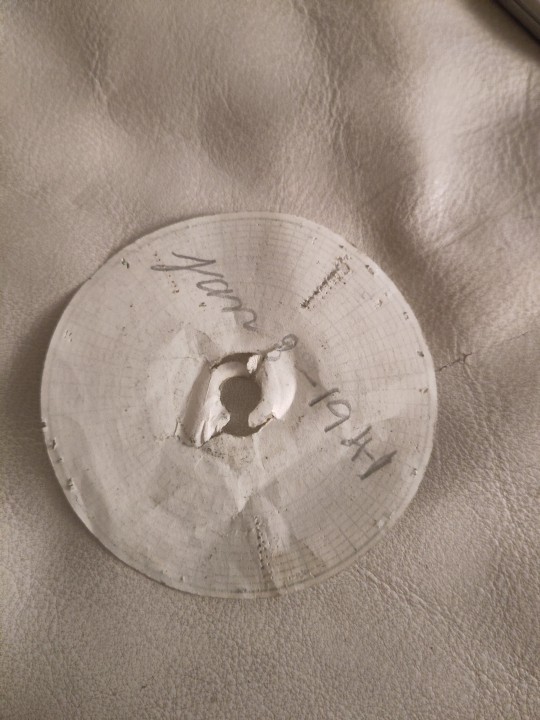

A friend and I found this absolute tank of a timepiece at an antique store and had no clue what we were looking at. It's called a watch-clock or watchman's clock. It's like a punch clock, but you carry it. This one is an Eco Portable.

So we brought it home, watched a youtube video, and managed to pick open the small lever tumbler lock that secured the back.

And inside we found this paper disk which gave us the name of this machine, and the last day it was used, Jan 3 1941. Also that metal plate says "TIME DETECTOR" which is a fucking awesome name.

There are several subassemblies. The lever tumbler lock, the pin and tumbler lock, the punching needles, and the clock itself (which I didn't open, since it is working, and I don't know how to service clocks)

The paper disc turns in sync with the hour hand. Station keys have a projection on the shaft, opposite the teeth, which pushes one of the 10 needle levers to make a hole in the paper disk, corresponding to the number of the station.

A guard carries the watchclock to each station, picks up the tethered key and turns it in the clock. Later, the clock can be opened (making one more hole at the edge of the paper, for tamper detection) with the master key (lever tumbler one) and read to see how the user moved throughout the day.

Later I found another watchclock at a different store. Previous owner evidently didn't manage to pick the lid lock, and resorted to violence with a screwdriver.

This one seemed much newer, and would stamp a paper tape with ink. The metal plate said it should be serviced in August 1965.

Now here's the crazy bit. An article on Detex's website backs up the Wikipedia article on this. Detex was manufacturing these fully mechanical watchclocks up until the end of 2011. Some of these clock designs go back into the 19th century. In 2011 you could call Detex on an iPhone 4s and ask to buy brand new devices whose design has barely changed since the day War of the Worlds was published. And receive paper and spare parts for it until 2016, too. Talk about long-term support.

2 notes

·

View notes

Text

Techpulp, founded in 2019, has quickly established itself as a main leading within the Moulded Fibre machinery industry, known for its dedication to sustainability and advanced technology. We're proud of our careful planning and commitment to delivering excellent machinery.

At Techpulp, we mixture innovation with practicality. Our equipment is regionally designed and manufactured, making sure advanced functionality and high productiveness. We work closely with international companions to ensure smooth get admission to spare parts and extremely good assist, ensuring the seamless operation of our clients' businesses. Sustainability is essential to us—it is woven into each a part of our organisation. We’re putting new requirements in our industry with eco-friendly system that demonstrates our commitment to the surroundings. Whether or not through product format or how we operate, we purpose to lead with the aid of instance. We at Techpulp consider ourselves to be leaders in our area. We are really concerned approximately using environmentally friendly era. We constantly improve our device to satisfy the wishes of our customers. Every pulp moulding machine demonstrates our dedication to growing excessive-acting, energy-green, environmentally friendly machinery inside the effort to create a better future. Innovation drives us ahead. We’re not simply promoting machines; we are fostering a tradition of excellence. Our intention is to empower corporations to gain their production aspirations even as minimizing their environmental footprint. Whether or not you're looking for an edge trimming machine or other contemporary solutions, be part of us at Techpulp as we forge ahead in the direction of a sustainable destiny with our today's system. Allows collaborate to construct an international in which era complements productiveness and champions environmental obligation. Find out how Techpulp can remodel your commercial enterprise and lead your enterprise toward a greater sustainable and prosperous day after today.

#Pulp Moulding Machine#Pulp Molding Machine#Paper Pulp Molding Machine#Paper Pulp Molding Machine price#Pulp Moulding Machinery#Bagasse Tableware Making Machine#Bagasse tableware machine Manufacturer#Bagasse Plate Making Machine

0 notes

Text

From canvas to t-shirt

Transferring an image from a canvas to a t-shirt can be done through a process called heat transfer or heat pressing. Here's a general overview of the steps involved:

Materials Needed:

T-shirt Image printed on transfer paper (designed for heat transfer) Heat press machine Parchment paper or silicone sheet Heat-resistant tape (optional) Steps:

Prepare the Image: Start by designing or selecting the image you want to transfer onto the t-shirt. Make sure it's the desired size and orientation for the t-shirt.

Print on Transfer Paper: Use a printer to print the image onto special transfer paper designed for heat transfer. Make sure to follow the instructions provided by the transfer paper manufacturer.

Preheat the Heat Press: Turn on the heat press machine and set it to the appropriate temperature according to the transfer paper's instructions. Preheat the heat press to the specified temperature.

Prepare the T-shirt: Place the t-shirt on the heat press surface. Smooth out any wrinkles or creases to ensure an even transfer.

Position the Transfer: Place the printed transfer paper with the image facing down onto the t-shirt in the desired position.

Cover with Parchment Paper: Place a piece of parchment paper or a silicone sheet over the transfer paper and t-shirt. This helps protect the transfer paper and t-shirt from direct contact with the heat press.

Press the Image: Carefully lower the heated upper plate of the heat press onto the parchment paper-covered transfer paper and t-shirt. Apply even pressure and maintain the temperature for the duration specified by the transfer paper's instructions (usually around 20-30 seconds).

Remove Heat Press Plate: After the designated time has passed, lift the upper plate of the heat press to remove the pressure from the t-shirt.

Peel Transfer Paper: While the transfer paper is still hot, gently peel it off the t-shirt. Be careful not to smudge or disturb the transferred image. If you encounter any resistance while peeling, wait a few more seconds before trying again.

Cooling Process: Allow the t-shirt to cool down completely. The transferred image will set as it cools.

Final Check: Once the t-shirt is cool, inspect the transferred image to ensure it adhered properly and looks as desired.

Care Instructions: Follow the care instructions provided by the transfer paper manufacturer. Generally, wash the t-shirt inside out in cold water and avoid using harsh detergents or bleach to prolong the life of the transferred image.

Remember, the specifics of each step may vary depending on the heat press machine and transfer paper you're using. Always refer to the manufacturer's instructions for best results.

4 notes

·

View notes

Text

What’s Trending in Manufacturing Equipment for 2025? 9 Machines to Watch

The year 2025 is anticipated to be a time of transformational change for the global manufacturing sector. Specifically, growing consumer demand, intensive sustainable standards, and rapid digitalization are forcing manufacturers across the globe to modernize. In a rapidly changing world, one thing is certain—the factories of the future will be smarter, faster, and cleaner than ever before.

As a leading Paper Cup Making Machines Manufacturer in India, SBS Machinery has seen changes in manufacturing and all these opportunities with the public. Since 1998, SBS Machinery has been a vital contributor to upgrading India’s paper product manufacturing competency through precision engineering, innovation, and world-class support. But today’s market asks for more than legacy; it asks for recreation.

So, which manufacturing equipment should to keep your eye out for in 2025?

In this blog, SBS Machinery presents 9 must-watch manufacturing machines and technologies that are going to be on top in 2025. It doesn’t matter if you are a pilot plant in the food packaging industry or a major beverage brand, or maybe a private label export of paperware. These developments are likely to affect your equipment purchasing process.

And yes, you may be thinking the blog is going to be too broad, but we will also share how SBS Machinery, the Paper Cup Making Machine Manufacturer in India, integrates these very trends into their product ecosystem.

1. AI Paper Cup Making Machines

Artificial intelligence is more than a buzzword; it is an essential part of manufacturing. In 2025, an AI-enabled paper cup-making machine will let you gauge.

On-the-spot quality assessments

Autonomous calibration for paper thickness and heat

Predictive errors and maintenance notifications

At SBS Machinery, we are already using AI modules to optimize the automation paper cup maker. Our AI operating system minimizes material waste and generates responsiveness, where there is no need for repetitive human inspections, while also being suitable for high-volume runs.

If you want to improve consistency and style of operations, upgrade your traditional paper cup maker to an AI-enabled paper cup maker from an established manufacturer like SBS Machinery.

2. Modular manufacturing systems

Customisation is king in 2025. Modular production lines allow businesses to scale according to demand without committing excess machinery and resource allocations. This is especially valuable for first-time entrepreneurs in the biodegradable paperware market, who will be the first to benefit from these scalable options.

At SBS Machinery, we are a leading Paper Cup Making Machine Manufacturer in Delhi. We offer modular units where we can expand later, starting with single-wall cups, to double-wall cups, and ripple cups on the same base frame.

Not only does this increase capital spend efficiency, but it also maximizes floor space utilization, which is vital for MSMEs in Urban India.

3. Intelligent CNC Machines with IoT Features

Computer Numerical Control (CNC) machines are becoming smarter with the Internet of Things (IoT). Manufacturers can identify:

Output effectiveness

Real-time error logs

SBS Machinery collaborates with CNC machine manufacturers to develop high-fidelity components for our machines. Every gear, bearing slot, and mold plate on our paper cup machines is made using CNC specifications, which provides long machine use and consistent final production.

As a Paper Cup Making Machine Manufacturer in India, especially for global clientele, each component must pass international standards, and smart CNC technology is why we can do this.

4. Robotic Automation in Packing & Stacking

Labor shortages and higher wages are pushing producers toward robotics. In paper products, there are now robotic pick-and-place units which are:

Sorting paper cups into their respective sizes,

Aligning them to pack them,

Pacing them into cartons, all with zero human touch.

At SBS Machinery, our high-speed lines can integrate with robotic arms that increase post-production speeds upwards of 40%. For those manufacturers who are shipping thousands of cups each day, it is essential that you upgrade to this technology.

In summary, choosing a Paper Cup Making Machine Manufacturer that includes robotic integration is a major productivity advantage for your enterprise.

5. Green Laser Cutting Equipment

Traditional die-cutting creates noise, uses a ton of power, and creates dust. In entered green laser cutting: an environmentally-friendly, clean, and efficient option.

These lasers provide:

Cleaner cup rim edges

No tool wear

Less noise

Reduced carbon emissions

SBS Machinery is trialing laser-cut edge machines for our high-end customers. This will result in a better appearance and more robust rims for hot beverage cups, imparting a better customer experience and better brand confidence.

6. Solar-powered, so our machines can be made to maximize sustainability

The 2025 manufacturer intends to reduce reliance on the grid. More and more customers are asking for paper cup making machines that can be fully or partially operated on solar power.

SBS Machinery is also providing machines using lower-watt motors and efficient thermal controllers. These improvements will allow for solar-powered operation, especially in hot and sunny states like Rajasthan and states in South India.

As a responsible Paper Cup Making Machine Manufacturer in India and a sustainable Paper Cup Making Machine Manufacturer in India, we feel like sustainability is not an elective; it is our future.

7. Hydraulically-Efficient Energy Systems

Older hydraulic press systems consumed tremendous power. New energy-efficient presses reduce consumption by 30-50% and perform comparably.

SBS Machinery uses these in its deep-draw cup and bowl machines, protecting clients from unmanageable power bills, without sacrificing production.

This is particularly meaningful in cities such as Delhi, which have higher industrial costs.

8. Waste-Free Production Lines

In 2025, your production line won’t have a waste stream if you are rejecting paper cups or reusing paper edge trims; every gram counts.

With the newer machines by SBS Machinery, you have:

Edge trimmer collection boxes,

Recyclable channels,

Compression for resale.

This can amount to 30% recovery as costs over time—this is unavoidably meaningful to any serious manufacturer.

9. Predictive Maintenance Dashboards

Why wait for a machine to fail? Predictive dashboards track:

Motor vibrations

Heat buildup

Lubrication cycles

SBS Machinery accompanies its premium models with predictive software to give customers a warning about issues before they fail.

As a trusted Paper Cup Making Machine Manufacturer, we want customers to have minimum downtime and reduced emergency repair costs

Conclusion

2025 is not just the era of new machines, but rather a smart investment. AI-driven production and solar-sustained machines demonstrate how the manufacturing landscape has changed from technical changes to strategic changes.

For Indian businesses, and particularly for businesses in Delhi, it opens the doors to insurmountable possibilities, but when you do so, let’s choose wisely for a partner.

For SBS Machinery, as a longstanding Paper Cup Making Machine Manufacturer in India, we have never just wanted to be a seller of machines. We treat all of our customers alike, providing value, innovation, and long-term reliability for every customer.

We welcome every customer’s experience with us, whether to put a brand-new unit into commission for the first time, or expand or increase your new capacity in multiple States, embrace what “smart manufacturing” feels like – together with SBS Machinery. Paper Cup Making Machine Manufacturer

1 note

·

View note

Text

Paper Plate Making Machine in Varanasi

Introduction:

Looking to streamline your paper plate production process? Investing in a paper plate making machine for your business. In this blog post, we will introduce the benefits and features of paper plate making machine that is help you boost efficiency and output.

Paper Plate Making Machine in Varanasi: A Lucrative Business Opportunity

Starting a paper plate making business in Varanasi can be a lucrative opportunity. Laghu Udyog offer paper plate making machine in Varanasi. Especially considering the increasing demand for eco-friendly disposable products. With the ban on single-use plastic items, paper plates have become a popular choice for parties, events, and food stalls. Investing in a paper plate making machine can help you tap into this growing market and establish a profitable business.

Types of Paper Plate Making Machines

When it comes to paper plate making machines, there are various types available in the market to suit different production needs. Some of the popular types include manual, semi-automatic, and fully automatic machines. Manual machines are suitable for small-scale production, while semi-automatic and fully automatic machines are ideal for large-scale manufacturing.

Benefits of Using a Paper Plate Making Machine

Investing in a paper plate making machine offers several benefits, including cost-effectiveness, efficiency, and flexibility. With a paper plate making machine, you can produce a large number of plates in a short period, reducing labor costs and increasing productivity. Additionally, these machines are easy to operate and require minimal maintenance, making them an ideal choice for entrepreneurs.

Can You Customize Paper Plates with a Paper Plate Making Machine in Varanasi?

Yes, most paper plate making machines come with customization options that allow you to create plates of different shapes, sizes, and designs. This flexibility enables you to cater to the specific needs of your customers and stand out in the market. Whether you want to produce round, square, or heart-shaped plates, a paper plate making machine can help you achieve your desired results.

Setting Up a Paper Plate Making Business in Varanasi

If you are ready to start a paper plate making business in Varanasi, here are some steps to help you get started:

Research the market demand for paper plates in Varanasi.

Choose the right type of paper plate making machine based on your production capacity.

Purchase raw materials such as paper reels, dies, and chemicals.

Set up the machine in a suitable location with access to electricity and water.

Test the machine and start production.

Market your paper plates to local businesses, events, and retailers.

Conclusion

Starting a paper plate making business in Varanasi can be a profitable venture with the right knowledge and equipment. By investing in a paper plate making machine, you can join the growing market for eco-friendly disposable products and establish a successful business. Follow the tips and guidelines provided in this article to kick start your paper plate making business in Varanasi today.

#paper plate making machine#Dona plate making machine#paper plate machine in Varanasi#business#manufacturer

0 notes

Text

Reject Separator Optimization Of Pulp Making Process

By using the reject separator from Leizhan Company, it is easy to recycle waste paper pulp. The reject separator mainly uses an internal rotor to achieve high-precision separation of impurities and fibers in the pulp.

The application advantages of the reject separator machine include: reducing energy consumption: optimizing the design of the streamlined pulp inlet and the length to diameter ratio of the cylinder, reducing energy consumption, and improving separation efficiency. Wear resistant material: Made of 304 stainless steel or ceramic vertebrae to extend equipment life. Modular maintenance: The front cover design is openable, making it easy to inspect the sieve plate and impeller. Leizhan is a manufacturer specializing in the production of various paper making machinery and pulping equipment.The products are of good quality and affordable.If interested in the product, please feel free to contact us for more details. Email: [email protected]

0 notes

Text

Start Your Home Business with All in One Paper Plate Making Machine: Contact Laghu Udyog Today!

If you want to start your own business then you can earn money sitting at home by installing all in one paper plate machine. Let us tell you that you can earn money by installing Dona Plate Machine or Paper Plate Machine or Disposable Machine. You can easily earn money by selling the same paper plate in the market. If you are interested you can contact Small Industries India. We are the best Paper Plate Making Machine manufacturer and supplier in Bhopal. Contact Small Scale Industries on 8871401838.

0 notes