#Pathway tensile Structure

Explore tagged Tumblr posts

Text

🌞 Upgrade your outdoor space with a Motorized Roof from RetractableRoofManufacturer.com! 🏡 Whether it's for your patio, pool, or garden, our innovative designs bring convenience and style to your home. 👉 Explore our range today and transform your space!

#MotorizedRoof #OutdoorLiving #RetractableRoof #HomeImprovement

#MotorizedRoof#OutdoorLiving#RetractableRoof#HomeImprovement#Retractable Roof#Retractable Tensile Roof#Motorized Roof#Tensile Car Parking#Tensile Gazebo#Tensile Structure Manufacturer#Swimming Pool Tensile Structure#Triangle Tensile#Tensile Fabric#Pathway tensile Structure#Car parking tensile structure

1 note

·

View note

Text

we can never be gods, after all - but we can become something less than human with frightening ease [...] the knives that will slaughter heaven, our heads bloody but unbowed [...] for ours is a fate worse than death...

━━━ 𝐎𝐫𝐨𝐜𝐡𝐢𝐦𝐚𝐫𝐮'𝐬 𝐁𝐢𝐨𝐥𝐨𝐠𝐢𝐜𝐚𝐥 𝐒𝐲𝐬𝐭𝐞𝐦𝐬: 𝐀 𝐂𝐨𝐦𝐩𝐚𝐫𝐚𝐭𝐢𝐯𝐞 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬

Orochimaru's physiology presents a unique integration of human and ophidian characteristics resulting from both hereditary traits and deliberate modifications. The foundational serpentine attributes originate from his clan lineage, which maintains a documented kinship with serpentkind, purportedly tracing back to the mythical Snake King Sheshanaga. Through extensive experimentation, Orochimaru has amplified these ancestral traits, creating a stable but imperfect human-snake hybrid system.

The olfactory processing demonstrates one of the more complex integrations. While lacking a snake's forked tongue and functional vomeronasal organ (VNO), Orochimaru's brain compensates through synesthetic interpretation of chemical stimuli. Ambient odors trigger concurrent color and taste perceptions, often bearing no logical relation to the source scent.

This cross-wiring enables limited chakra signature detection, though with significantly reduced accuracy compared to specialized sensory ninja like Karin. The mechanism appears to repurpose vestigial VNO neural pathways present in all humans but typically dormant.

Visual capabilities show selective enhancement within human parameters. The distinctive slit pupils provide superior night vision comparable to nocturnal serpents, while maintaining full photopic function. A dual ocular protection system has developed - combining standard mobile eyelids with a permanent, transparent brille membrane.

This adaptation provides continuous defense against particulate matter while preserving visual perception. The system includes latent infrared detection capacity through specialized thermoreceptors in the medial canthal region, though with significant limitations compared to true pit vipers. Thermal data processing occurs through secondary neural pathways to the optic tectum, producing only rudimentary spatial awareness when primary vision is compromised.

The skin and its associated structures exhibit several ophidian adaptations. The epidermis remains completely hairless except for standard cranial and eyebrow growth, with increased susceptibility to dry skin in arid conditions requiring regular moisturizing. Full epidermal shedding is possible, though metabolically costly and accompanied by substantial discomfort. Unlike snakes, the dermal layer lacks true scales but demonstrates increased tensile strength and elasticity.

His teeth follows a polyphyodont replacement pattern, allowing continuous regeneration throughout his lifespan. Orochimaru maintains venom production capabilities chemically similar to Bungarus candidus (Malayan krait) neurotoxins, with an estimated 50% mortality rate in treated cases. Notably, he exhibits voluntary control over venom delivery, unlike his serpentine counterparts which employ automatic envenomation.

Metabolic and digestive functions show pronounced reptilian influences. Orochimaru enters extended periods of postprandial lethargy while processing meals, though not to the extreme degree seen in true snakes.

His system operates optimally in warm environments, with cold temperatures significantly impairing metabolic efficiency. His dietary requirements remain strictly carnivorous, with digestive enzymes capable of processing uncooked proteins, though he typically prefers prepared meats. The jaw structure permits extreme expansion through flexible mandibular articulation rather than true dislocation.

Reproductive biology presents the sole system unaffected by serpentine modifications, maintaining standard human functionality. This preservation suggests either biological necessity or deliberate design choice in his transformation process.

These collective adaptations create a physiologically unstable but functionally viable hybrid system requiring specific environmental conditions, that are often not met, and continual maintenance to sustain equilibrium between human and reptilian subsystems. Each modification provides strategic advantages while introducing corresponding vulnerabilities that Orochimaru must actively manage.

#𝐇𝐈𝐃𝐃𝐄𝐍 𝐁𝐘 𝐓𝐇𝐄 𝐒𝐎𝐔𝐍𝐃 . in depth study . orochimaru#𝐒𝐇𝐈𝐍𝐍𝐎𝐆𝐈 . save .#yes i took the silly huge headcanon i wrote when i was 16#and turned it into a scientific paper sort of#i added links to the materials i read and definitions !!#just so you can see that 1) i'm not just making stuff up#tw snake mention#tw emetophobia#i also added the source of where i got all my snake info#it's the first link#i think i ate two dictionaries writing this english is hard bros

2 notes

·

View notes

Text

Behind the Scenes: How JRE Developers Plan and Execute High‑Quality Infrastructure

When you drive past a new residential or commercial project by JRE Developers, what appears on the surface as clean buildings and landscaped roads is actually the result of meticulous planning, strong project management, and uncompromising quality control. In this post, we reveal the behind‑the‑scenes process that ensures each development stands the test of time—highlighting how JRE Developers plan and execute top-tier infrastructure.

1. Master Planning & Strategic Site Selection

High-quality infrastructure begins long before the first brick is laid. At JRE Developers, the journey starts with site selection and master planning:

Location Intelligence: Our team analyzes proximity to highways, transit, schools, hospitals, and commercial centers. We prioritize growth corridors to offer both convenience and promising property appreciation—crucial for those searching for “plots for sale in [city]” or “investment-ready plots near me”.

Zoning & Regulatory Compliance: Each parcel undergoes due-diligence checks that include:

Title and ownership verification

Environmental clearance

Local zoning norms and land-use restrictions

This early groundwork helps prevent legal delays and instills trust—reinforcing keywords like RERA-compliant real estate developer and transparent property investment.

Infrastructure Planning: Based on site characteristics (e.g., terrain, flood zones), we craft a robust layout for internal roads, utility access (water, power, sewage), sustainable landscaping, and networking pathways.

2. Design, Engineering & Cost Optimization

Once the site is secured, we enter the design and engineering phase:

Conceptual & Structural DesignArchitects collaborate with civil and structural engineers to ensure designs are not only visually appealing but also engineered to withstand local climate, geography, and seismic factors. Whether building plots, villas, or complexes, JRE integrates civil engineering best practices into every project.

Feasibility & Cost PlanningA project viability study considers soil testing, ground water evaluation, and projected expenses for roads and utilities. Using this, we issue a detailed buildable plan, supporting fair pricing and “affordable luxury” positioning.

Infrastructure Budget AllocationCapital is strategically assigned to:

Durable internal roads and paving

Underground electrical and telecom networks

Wastewater management (drains, soak-pits, sewage)

Water pipelines and pressure systems

Green spaces, stormwater pits, and street lighting

3. Procurement & Quality Materials

Delivering lasting infrastructure requires the right materials:

Vendor Management We partner only with verified suppliers for cement, steel, aggregates, pipes, cables, and fittings—ensuring durability and consistent quality.

Material Testing & Lab ReportsSamples undergo routine quality checks at accredited labs. From compressive strength of concrete to steel tensile tests, each batch is certified—backing keywords like quality construction practices and third-party testing labs.

Inventory & Supply Chain MonitoringTo prevent construction delays, we deploy logistics for timely delivery and safe storage at site warehouses.

4. Schedule Enforcement & Project Management

Strong project oversight turns plans into reality:

Gantt & Work Breakdown Structures Activities—excavation, leveling, foundations, roadmaking, pipelines—are scheduled into a Gantt chart to manage dependencies and enforce timelines.

Site Supervision & Safety ProtocolsQualified engineers oversee daily execution. Contractor teams follow daily checklists, and safety protocols—PPE, fall protection, fire safety—are strictly enforced.

Time-Lapse Monitoring & ReportingWe install site cameras and publish monthly progress updates showcasing groundwork, road laying, trenching, and external utilities—building client confidence with transparent status tracking.

5. Technology & Sustainability Integration

JRE is committed to modern, eco-conscious infrastructure:

Smart Infrastructure Installation of power lines with future-proof conduits, outdoor lighting that supports LEDs, and provisions for CCTV and broadband.

Stormwater & Green DrainageRoads include shuttering, camber, and slope. Storm drains and soak pits are integrated into landscaping to reduce runoff and flooding.

Eco-Friendly PracticesWe use recycled-water strategies, rainwater harvesting, and energy-efficient street lighting—appealing to buyers seeking sustainable building projects.

6. Quality Audits & Regulatory Approvals

We leave no room for error:

Third‑Party Technical Audits At critical stages—like laying water pipelines or underground cables—we engage external structural and MEP auditors to verify adherence to drawings and specs.

Regulatory Inspections & Certifications Before occupancy or handover, we secure NOC approvals from electrical, local body, and environmental authorities, ensuring full legal compliance.

RERA Registration & Consumer RightsProjects are registered under RERA with all documents available online, offering transparency on approvals, timelines, and legal recourse.

7. Handover Process & After-Sales Support

We finalize a project only when customers are happy:

Client Site Walk & Punch‑ListDuring handover, clients inspect internal roads, landscaped parks, streetlights, drains, and electric supply. Any defects get logged and resolved within a set timeframe.

As‑Built DocumentationBuyers receive project blueprints, internal line maps, infrastructure layouts, and shared-area service manuals to assist in future maintenance.

Maintenance & WarrantyWe activate maintenance services—cleaning, landscaping, light replacements—and stand by infrastructure with warranty guarantees.

8. Showcasing Reliability Through Completed Projects

JRE Developers has built a track record of successful infrastructure delivery:

Example Project: Green Acres VillasCompleted ahead of schedule with award-winning internal roads, LED-lit boulevard, and green zones—enhancing resale value and buyer satisfaction.

Example Project: Sunrise PlotsFeaturing asphalt roads, underground MEP utilities, and eco-friendly street lighting, this project attracted significant investor interest due to its high-spec execution.

Client Testimonials“JRE’s attention to stormwater drains saved us from seasonal flooding,” says Mr. Singh, Green Acres resident.

Keywords like best real estate developer in [city], high-quality infrastructure plots, and trustworthy builder underscore JRE’s brand positioning through these testimonials.

Why This Process Matters to Buyers & Investors

Timely Delivery – No more chasing commitments. We deliver fully functional roads, utilities, and green areas on time.

Asset Value – Good infrastructure appreciation over time compared to shell-only developments.

Living Convenience – Safe, landscaped environments with proper lighting and drainage secure peace of mind.

Peace of Mind – Compliance with RERA, approvals, and documented handovers mean real protection.

Responsible Construction – Green policies help investors align with increasingly eco-conscious homebuyers.

Final Thoughts

You don’t just purchase land or a villa from JRE Developers—you invest in confidence. Our multi-layered process—from choosing a site to winning approvals, sourcing materials, executing with oversight, integrating sustainability, and delivering with care—ensures that each project features high-quality infrastructure, strong resale value, and client satisfaction.

If you’re ready for reliable real estate backed by transparent planning and hybrid project management, get in touch with us today. Discover JRE Developers’ dedication to quality—before we break ground, and long after we open the gates.

0 notes

Text

High Ductile Metals Are Essentials For Electrical Wiring And Conductors

In the field of electrical engineering, the performance and reliability of a system are determined not just by its design or load capacity but also by the quality of materials used. One of the most important yet often overlooked characteristics of these materials is ductility.

A highly ductile metal plays a critical role in the performance and safety of electrical wiring and conductors. From ease of installation to long-term durability and operational efficiency, ductile materials form the foundation of dependable electrical infrastructure.

Understanding Ductility in Electrical Applications

Ductility is defined as a metal’s ability to undergo plastic deformation under tensile stress — in simple terms, its capacity to be drawn into wires or stretched without breaking. This property is indispensable in electrical applications, where wiring systems must be routed through complex structures, endure environmental changes, and remain functional over time.

Unlike brittle materials, which fracture easily, ductile metals can absorb stress and adapt to physical and thermal shifts without compromising structural integrity or electrical performance.

The Demands Placed on Electrical Conductors

Electrical wiring is subject to a range of mechanical, thermal, and environmental stresses:

Mechanical stress during installation, as wires are pulled through conduits and around sharp corners.

Thermal cycling, where current flow causes wires to heat up and cool down repeatedly.

Environmental vibration in locations such as factories, railways, or moving vehicles.

Long-term load stress at junctions, terminals, and bends.

Only a Highly Ductile Metal can perform reliably in such conditions. It ensures that the wire does not crack, weaken, or lose conductivity over time.

Key Advantages of Using Highly Ductile Metals

A. Ease of Installation

Wiring pathways are rarely straight. During installation, wires often need to be pulled, bent, and routed through complex architectural spaces. A ductile metal withstands this mechanical handling without cracking, kinking, or breaking, ensuring both structural and electrical integrity.

B. Resistance to Thermal Stress

As electrical current flows, it generates heat. Over time, this causes expansion and contraction in the conductor material. A ductile metal can absorb these temperature changes without developing fatigue or microfractures, leading to longer system life and fewer failures.

C. Adaptability to Vibration and Motion

In industrial and mobile environments, vibration is constant. Rigid or low-ductility materials may weaken or break under these conditions. Highly ductile metals remain resilient, preserving continuous power flow without physical deterioration.

D. Enhanced Safety and Reliability

Failures in electrical wiring often occur at stress points — bends, connectors, or junctions. These areas experience the highest mechanical load. Ductile metals distribute stress more effectively, reducing the risk of insulation failure, sparking, or electrical fires.

E. Long-Term Cost Efficiency

Though ductile materials such as copper may have a higher upfront cost, they offer significantly lower maintenance, fewer replacements, and a reduced risk of system-wide issues. Over time, the investment results in both performance and financial efficiency.

Metals Commonly Used for Ductile Wiring

The two most widely used ductile metals in electrical conductors are:

Copper: Known for its superior conductivity and high ductility, copper remains the most trusted material for residential, commercial, and industrial wiring.

Aluminium: While slightly less conductive and ductile than copper, aluminium is lighter and more cost-effective, making it suitable for large-scale and overhead power applications.

Both materials meet the demands of modern electrical systems due to their ability to combine flexibility with consistent performance.

The Role of SBF Rapid in Engineering-Grade Materials

At SBF Rapid, we recognize that the durability of any infrastructure — whether structural or electrical — depends on the quality of materials used. Our commitment to strength is balanced with a focus on adaptability. Whether through our TMT bars or any engineered metal, our processes emphasize properties such as ductility, tensile strength, and fatigue resistance.

This understanding of how metals behave under real-world conditions guides our product development and quality control practices. In environments where performance under pressure is non-negotiable, ductility remains a key parameter in our material standards.

What Happens When Ductility Is Ignored?

Using low-ductility metals in electrical conductors can lead to:

Cracking or breakage during installation

Fatigue failures under thermal cycling

Electrical losses due to poor conductor contact

Increased risk of fire and safety hazards

Costly maintenance and early replacement

These risks emphasize that ductility is not merely a physical property — it is a performance guarantee.

Final Thoughts

Electrical systems are no longer simple. From high-efficiency commercial buildings to fast-moving vehicles and high-load industrial operations, wiring systems must be robust, responsive, and long-lasting.

A highly ductile metal ensures that conductors adapt to stress, perform reliably under heat and vibration, and support the safe flow of electricity across years of service. Ductility protects not only the wire but the entire system it powers.

0 notes

Text

Should Dowel Bars Be Used in Rural Road Construction?

Rural roads are more than just pathways—they’re lifelines. They carry not only vehicles but also the hopes of farmers, the daily commute of schoolchildren, and the pulse of local economies. Yet too often, these roads tell a familiar story: endless repairs, unexpected cracks, and surfaces that don't last a season. Harsh weather, poor drainage, and weak construction joints take a silent but steady toll. This is where solutions like dowel bars and HR coils become crucial—not as afterthoughts, but as essentials for building roads that endure.

Why Rural Roads Fail Differently

Unlike urban highways, rural pavements often suffer not due to traffic overload but from improper joint handling. Many fail not because of high volume but because of what lies beneath—unstable subgrades, erratic water tables, and inconsistent slab bonding. This leads to joint deterioration, faulting, and slab displacement, quietly eroding the strength of the pavement over time.

The Role of Dowel Bars in Road Longevity

Dowel bars in road construction address the core of this issue—they offer a stable connection between adjacent slabs, enabling them to share loads evenly. This means when a wheel crosses a joint, the load doesn’t fall entirely on one side. Instead, it’s distributed, reducing stress concentration and minimizing wear. For roads that see tractors one day and water tankers the next, that’s a game-changer.

How HR Coils Complement the Structure

What adds even more resilience is when HR coils are introduced into the slab framework. Known for their tensile strength and flexibility, HR coils help the concrete accommodate temperature fluctuations and minor ground movements without cracking. Together, dowel bars and HR coils form a structural duo—one anchors, the other flexes.

Why It Matters for Rural Settings

The synergy is particularly vital in rural settings where monsoons swell the soil and winters harden it. Roads built without these reinforcements often display early signs of slab shifting and joint misalignment. In contrast, those using dowel bars in road designs maintain their geometry for years, with only minimal maintenance required.

A prime example lies in rural Karnataka, where test sections using dowel bar-jointed slabs showed 40% fewer cracks after three years compared to traditional methods. Engineers on site observed reduced faulting even with consistent agricultural vehicle movement. These are real-world outcomes—not theoretical assumptions.

Dispelling the Cost Myth

Still, there’s hesitation. Some believe dowel bars are suited only for expressways or expensive urban projects. But modern civil engineering proves otherwise. With newer installation methods and modular reinforcement designs, rural contractors can adopt these systems without overshooting budgets. What once seemed "overbuilt" now fits smartly into cost-effective, sustainable planning.

In fact, the upfront investment in dowel bars and HR coils translates to fewer repairs, reduced downtime, and lower life-cycle costs. Instead of spending on patch-ups every monsoon, the funds can go toward road extensions or drainage improvements. For local authorities working with limited resources, that shift is monumental.

More Than Materials—It's a Commitment

Beyond the technical benefits lies an emotional one—reliability. Villagers begin to trust a road that doesn't disintegrate under their daily journeys. Children reach school safely. Farmers deliver produce on time. That’s not just engineering—that’s impact.

So, should dowel bars be used in rural road construction? Without a doubt. Their presence ensures that roads don’t just exist—they endure. When paired with HR coils, the result is a reinforced promise: a path built not just to connect but to last.

Conclusion

Rural roads deserve more than makeshift fixes. They need structural foresight. Dowel bars and HR coils offer that foresight—a solution rooted in strength, experience, and long-term value. These elements transform vulnerable stretches into robust lifelines, empowering rural communities to thrive with confidence. The next time a road is planned in a village, let it be more than just concrete. Let it be commitment, reinforced.

#dowel bars#HR coils#rural roads#road strength#road cracks fix#load transfer#road joints#slab support#road repairs#rural paving#HR steel use#road faults#road lifespan#concrete roads#road stability#pavement life#joint failures#monsoon roads#low-cost roads#road building

0 notes

Text

Tensile Structure - Expert Solutions for Every Space

Discover high-quality Tensile Structure with Ekra Decor – your trusted partner in innovative architectural fabric solutions since 1998. Whether you're looking to enhance a commercial space or add functional elegance to a residential area, our tensile structures deliver unmatched durability, style, and performance.

At Ekra Decor, we offer a wide range of custom-designed tensile structures tailored to suit different applications, including:

Car Parking Tensile Structures – Protect your vehicles with strong, UV-resistant fabric canopies.

Gazebo Tensile Structures – Create beautiful outdoor seating or lounging areas with aesthetic appeal.

Walkway Tensile Structures – Ensure safe, covered pathways for pedestrians in schools, malls, or parks.

Auditorium Tensile Structures – Provide shade and protection with large-span designs for public gatherings.

Swimming Pool Tensile Structures – Add shade and a sleek modern look to pool areas.

Outdoor Tensile Structures – Ideal for gardens, event spaces, cafes, or rooftops.

Our team of experts handles everything from design and sail fabrication to steel structure installation and post-sale maintenance. We combine form and function to ensure each project stands out in both visual appeal and structural integrity.

With a focus on quality, timely delivery, and customer satisfaction, Ekra Decor continues to be one of the top choices for tensile architecture in India.

#TensileStructure#TensileArchitecture#EkraDecor#CarParkingTensile#GazeboTensileStructure#WalkwayTensileStructure#OutdoorTensileStructure#SwimmingPoolTensile#ModernArchitecture#ArchitecturalDesign#ShadeStructures#FabricStructure#MembraneStructure#TensileFabric#SpaceDesign

0 notes

Text

Water Proofing and Bonding Material Manufacturing and Supply in Andhra Pradesh - Duroxz

Introduction to Waterproofing and Bonding Materials in Andhra Pradesh

In the dynamic and rapidly evolving construction sector of Andhra Pradesh, the demand for high-performance waterproofing and bonding materials has reached an all-time high.

As urban infrastructure expands and residential, commercial, and industrial developments accelerate, the need for durable, weather-resistant, and long-lasting building protection solutions is paramount. At Duroxz, we lead the way in manufacturing and supplying advanced waterproofing and bonding materials tailored to meet the specific demands of Andhra Pradesh's diverse climate and construction challenges.

👉 Explore Our Waterproofing Solutions

Why Waterproofing Matters: Protecting Infrastructure in Humid Climates

Andhra Pradesh experiences high humidity levels, coastal salt-laden winds, and substantial monsoon rainfall. Without proper waterproofing solutions, structures face the inevitable consequences of moisture infiltration, including:

Structural deterioration

Cracks and seepage

Algal and fungal growth

Corrosion of reinforcement

Reduced lifespan of buildings

Duroxz waterproofing products are scientifically formulated to prevent such damages, ensuring extended structural integrity and reduced maintenance costs.

Our Range of Waterproofing Products

We offer a comprehensive portfolio of waterproofing materials that cater to both residential and commercial applications:

1. Liquid Waterproofing Membranes

Our polyurethane-based and acrylic-based liquid membranes provide seamless waterproof barriers. These coatings are ideal for:

Terraces and roofs

Balconies and podium decks

Basements and retaining walls

They form a flexible, UV-resistant membrane that adapts to surface movements, offering superior protection.

👉 Learn More About Waterproof Membranes

2. Cementitious Waterproofing Compounds

Used in internal wet areas, water tanks, and swimming pools, our cementitious solutions form a rigid barrier against moisture. They bond well with masonry and concrete, ensuring a watertight seal.

3. Bituminous Coatings and Membranes

Our bitumen-based waterproofing systems are perfect for areas with extreme weather exposure. Ideal for foundation walls, substructures, and roofing systems, these solutions offer excellent resistance to water and aggressive ground salts.

4. Crystalline Waterproofing Solutions

These advanced solutions penetrate concrete capillaries and form insoluble crystals, sealing pathways for moisture ingress. Suitable for below-ground structures, they provide lifetime protection from water infiltration.

High-Performance Bonding Agents by Duroxz

Bonding strength is the foundation of structural durability. Our high-performance bonding materials are engineered for maximum adhesion, enabling effective integration of new construction materials with existing surfaces.

1. Latex-Based Bonding Agents

Designed to bond cementitious mortars, plaster, and concrete, our latex-based agents enhance:

Tensile strength

Flexural properties

Adhesion to old substrates

2. Epoxy-Based Adhesives

Used extensively in industrial construction and repair, these agents are known for:

High chemical resistance

Non-shrink properties

Exceptional bonding to metal, tile, and concrete

3. Acrylic Bonding Compounds

These user-friendly and water-resistant bonding materials are ideal for plaster bonding, floor overlays, and repair mortar enhancements, providing robust adhesion without compromising on workability.

Industry Applications in Andhra Pradesh

Our products are extensively used across multiple sectors in Andhra Pradesh:

Real estate and housing projects

Road and bridge infrastructure

Irrigation canals and reservoirs

Industrial warehouses and plants

Ports and marine structures

Each of our solutions is custom-formulated to match site-specific requirements, ensuring reliability and performance across varied construction environments.

Commitment to Quality and Compliance

At Duroxz, we are committed to international quality standards. Our products undergo rigorous quality control processes, including:

Lab-tested formulations

Field application trials

Third-party certification

ISO-compliant manufacturing

This ensures every batch meets the highest industry standards for durability, strength, and environmental safety.

Sustainability in Construction

We believe in building responsibly. Our products are designed with eco-sustainability in mind:

Low VOC formulations

Non-toxic components

Recyclable packaging

Energy-efficient application processes

Our green approach helps developers and contractors in Andhra Pradesh meet environmental compliance norms and LEED certifications.

Expert Technical Support and On-Site Assistance

We don’t just supply materials—we provide end-to-end technical consultation and application support:

Site inspection and analysis

Product recommendation based on substrate and environment

Guided application procedures

Post-application performance monitoring

Our dedicated team of engineers and applicators ensure the solution fits your exact project requirements.

Partner with Duroxz for Trusted Waterproofing and Bonding Solutions

For decades, Duroxz has earned the trust of engineers, architects, and developers across Andhra Pradesh. With a focus on innovation, reliability, and technical excellence, we continue to pioneer breakthroughs in waterproofing and bonding technology that future-proof your constructions.

Why Choose Duroxz?

Local manufacturing and supply chain

Customized formulations for Andhra Pradesh's climate

Trained applicator network

Timely delivery and competitive pricing

Proven track record of successful projects

👉 Get Expert Waterproofing Advice Today

Get in Touch

If you're seeking dependable waterproofing and bonding material manufacturing and supply in Andhra Pradesh, look no further than Duroxz. Our team is here to assist you with the most advanced, efficient, and cost-effective solutions in the market.

#tilegrout#constructionmaterials#tileinstallation#elegantinteriors#homeimprovement#duroxz#stoneinstallation#duropox99#tilefixing

0 notes

Text

The Crucial Role of Steel Components in Modern Construction

Steel pipe companies play a fundamental position in improving concrete sturdiness, forming an often-left-out partnership with other cloth manufacturers inside the creation industry. This collaboration creates systems that stand up to a long time of use under challenging situations.

The Foundation of Lasting Infrastructure

When designing infrastructure meant to last generations, the first class of substances turns into paramount. The expertise of metallic pipe corporations manifests in components that provide critical structural support within concrete packages. These specialized manufacturers expand pipes that serve more than one function past mere conduits—they end up as critical reinforcement elements.

The relationship among metallic pipe groups and TMT bar manufacturers represents one of creation's most crucial material synergies. Together, these two sectors create the spine of strengthened concrete—the building material that literally supports present-day civilization. TMT bar manufacturers focus on imparting the tensile energy concrete inherently lacks, while steel pipe elements supply complementary structural advantages.

Enhanced Performance Through Material Integration

The technical improvements pioneered by using metallic pipe organizations directly impact concrete performance in numerous key approaches:

Specialized metal pipes provide channels for strain distribution at some point in concrete systems, stopping commonplace failure factors. When integrated with products from the best TMT bar producers, those structures create remarkably resilient homes able to resist seismic events and extreme weather.

The right association of binding twine secures reinforcement additives exactly as engineers specify. This reputedly modest detail plays a vital role in keeping structural integrity for the duration of the concrete pouring process—when displacement of even some centimeters could compromise an entire structure.

Innovative metallic pipe groups have evolved surface textures and connection systems especially designed to bond more efficaciously with concrete. These advancements supplement the ribbed surfaces of products from TMT bar producers, creating composite substances with advanced performance traits.

Practical Applications in Construction

On construction websites across the globe, the partnership among metal pipe groups and urban reinforcement will become, without difficulty, apparent. In high-upward thrust creation, steel pipe additives create particular pathways for utilities while simultaneously contributing to structural support. The calculated placement of materials from TMT bar manufacturers alongside these pipe systems creates homes able to help tremendous masses.

Binding twine secures the entire assembly throughout the vital concrete pouring segment. This unassuming product represents the important hyperlink that holds the whole lot in role until the concrete treatment options. Leading metal pipe groups are painting intently with providers of binding twine to ensure compatibility among these interconnected additives.

In infrastructure tasks like bridges and dams, the understanding of metal pipe companies becomes specifically treasured. These applications call for substances that could face up to constant pressure from visitors, water pressure, and environmental factors. The careful integration of substances from TMT bar producers with specialized pipe additives creates structures with appreciably extended service lives.

Advancing Construction Through Collaboration

The future of construction relies more and more upon state-of-the-art cloth integration. Steel pipe organizations maintain developing revolutionary merchandise that supplements advances made by TMT bar producers. This collaboration drives enhancements in construction performance, safety, and sustainability.

Modern binding twine products now feature corrosion-resistant coatings that, in addition, enhance concrete durability. When paired with advanced steel pipes and reinforcement bars, these structures create structures with unparalleled toughness.

The technical know-how provided via metallic pipe businesses ultimately translates to buildings and infrastructure that better serve groups. By working alongside TMT bar manufacturers and other material professionals, those companies help create the physical basis upon which society's capabilities are built.

For designers and builders in search of remarkable structural overall performance, knowledge of the complementary relationships between one-of-a-kind steel additives turns into vital knowledge. The careful selection of merchandise from legitimate metallic pipe agencies, mixed with exceptional materials from TMT bar producers, results in concrete systems that certainly stand the test of time.

#Steel in building#Modern steel use#Steel strength#Steel design#Steel in homes#Steel role#Steel framing#Steel support#Steel beams#Steel columns#Steel roofing#Steel joints#Steel structure#Steel bridges#Steel walls#Steel base#Strong steel#Durable steel#Steel in infra#Steel trends

0 notes

Text

Oxidized Regenerated Cellulose Gauze: The Haemostatic Solution for Orthopaedic Surgeons

Introduction

Orthopaedic surgeries involve procedures on the musculoskeletal system, including bones, joints, ligaments, tendons, and muscles. These surgeries are often complex and may involve significant blood loss due to the highly vascular nature of bone and soft tissue. Uncontrolled bleeding can lead to complications such as wound issues, infections, delayed rehabilitation, prolonged hospital stays, and increased healthcare cost. Thus, achieving effective haemostasis is a critical component of orthopaedic surgical practice [1].

To address these challenges, various haemostatic agents have been developed to aid surgeons in controlling bleeding efficiently. One of the most commonly used haemostatic agents in orthopaedic and other surgical procedures is oxidized regenerated cellulose gauze (ORCG). ORCG promotes haemostasis by activating the body’s natural coagulation pathways. Upon contact with blood, it forms a gelatinous mass that acts as a matrix for platelet adherence, rapidly facilitating clot formation. Additionally, the low pH environment it creates induces vasoconstriction, further reducing bleeding, while also offering antimicrobial properties [2, 3].

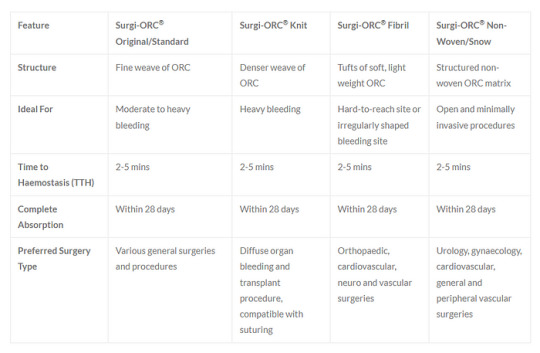

Surgi-ORC® Variants: A Comprehensive Comparative Analysis

FeatureSurgi-ORC® Original/StandardSurgi-ORC® KnitSurgi-ORC® FibrilSurgi-ORC® Non-Woven/SnowStructureFine weave of ORCDenser weave of ORCTufts of soft, light weight ORCStructured non-woven ORC matrixIdeal ForModerate to heavy bleedingHeavy bleedingHard-to-reach site or irregularly shaped bleeding siteOpen and minimally invasive proceduresTime to Haemostasis (TTH)2–5 mins2–5 mins2–5 mins2–5 minsComplete AbsorptionWithin 28 daysWithin 28 daysWithin 28 daysWithin 28 daysPreferred Surgery TypeVarious general surgeries and proceduresDiffuse organ bleeding and transplant procedure, compatible with suturingOrthopaedic, cardiovascular, neuro and vascular surgeriesUrology, gynaecology, cardiovascular, general and peripheral vascular surgeries

Clinical Study: Surgi-ORC® in Orthopaedic Surgeries

A recent multicenter prospective study evaluated the safety and efficacy of Surgi-ORC® in orthopaedic surgeries, providing valuable statistical insights into its performance. The study included 59 patients undergoing upper limb, lower limb, and axial skeleton surgeries, with bleeding classified as mild (35.6%) or moderate (64.4%). The mean blood loss recorded was 60.96 mL, ranging from 15 to 200 mL.

Among the Surgi-ORC® variants used, the average time to haemostasis (TTH) varied:

Surgi-ORC® Fibril followed with a TTH of 1.67 minutes.

Surgi-ORC® Non-Woven/Snow recorded 1.53 minutes.

Surgi-ORC® Original/Standard took 1.95 minutes.

Surgi-ORC® Knit required the longest time, averaging 2.28 minutes.

Fig.2: Post-surgical X-ray examination shows no traces or residue of Surgi-ORC® on day 2

Choosing the Right Variant for the Right Indication

Each variant of Surgi-ORC® is designed to meet specific surgical challenges. Understanding the strengths of each can help surgeons optimize their choice for better clinical outcomes.

Surgi-ORC® Fibril is highly flexible and conforms well to uneven surfaces, making it particularly useful in orthopaedic surgeries where targeted haemostasis is required. It is effective for stopping localized bleeding in intricate anatomical regions.

Surgi-ORC® Non-Woven/Snow is a lightweight and easily removable variant, best suited for procedures where precise placement and quick handling are necessary. Its pliable nature ensures smooth application without disrupting the surgical field.

Surgi-ORC® Knit offers high tensile strength, making it ideal for controlling heavy bleeding, especially in cases requiring structural support. It provides excellent stability upon application, reducing movement or displacement during surgery.

Surgi-ORC® Original/Standard serves as a versatile option for various general surgical procedures. It provides a balance of easy handling and effective bleeding control, making it a go-to choice for a variety of surgical scenarios.

Conclusion

While all Surgi-ORC® variants share the same fundamental chemical composition, their differences in structural design and application make them uniquely suited to specific surgical scenarios. Choosing the right variant depends on the nature of the bleeding, the complexity of the procedure, and the surgeon’s preference. By leveraging the strengths of each Surgi-ORC® variant, surgeons can enhance haemostatic control, reduce surgical complications, and improve overall patient outcomes in orthopaedic procedures.

0 notes

Text

Joining Forces: The Vital Role of Welding in Battery Production

Whether dealing with square or cylindrical batteries, welding stands as a cornerstone of the manufacturing process. In the intricate dance of lithium-ion battery production, welding techniques are primarily employed in the middle and later stages, where precision and reliability are paramount.

Let's explore some key welding processes that contribute to the creation of safe and efficient batteries:

1. Safeguarding with Explosion-Proof Valve Welding (Safety Vent Welding)

The explosion-proof valve, often called a pressure relief valve, is a critical safety feature. It's a thin-walled component located on the battery's top cover. In the event of excessive internal pressure, this valve is designed to rupture, releasing gas and preventing a catastrophic battery burst.

This valve boasts a clever design, typically involving laser welding two precisely shaped aluminium sheets together. The laser welding process must be meticulously controlled to ensure a reliable seal and consistent rupture pressure. If the weld is too weak or too strong, it can significantly compromise battery safety. Therefore, this process demands extremely precise control over the heat applied.

2. Connecting the Power: Terminal Welding

The battery cover features positive and negative terminals, which serve as the pathways for electrical current. Electrons flow from the active materials within the battery, through foils, tabs, and terminal extensions, ultimately reaching the vehicle's electrical components.

Terminal connections are categorized as internal and external. Internal connections involve welding the battery cell tab to the cover's terminal. External connections involve welding the battery terminal to connecting pieces, forming series or parallel circuits within a battery module.

Typically, the positive terminal is made of aluminium, while the negative terminal is made of copper. A common construction involves riveting followed by full welding. To meet the required tensile strength and conductivity, fibre lasers or composite welding lasers, known for their excellent beam quality and uniform energy distribution, are preferred. These lasers help achieve stable welds in both aluminum-aluminum and copper-copper structures, minimizing spatter and maximizing production yield.

3. Bridging the Gap: Tab Extension Welding

Adapters and flexible connectors are essential components that link the battery cover and the battery cell. These components must withstand high currents, maintain structural integrity, and minimize spatter. Therefore, the welding process must create a sufficiently wide weld while preventing any particles from falling onto the battery cell, which could cause a short circuit. Copper, being a highly reflective material, requires a higher energy density for successful welding.

4. Sealing the Shell: Shell Sealing Welding (Can Sealing Welding)

Power battery shells are typically made of aluminium alloy, with some made of pure aluminium. Stainless steel, particularly 304 stainless steels, is also used due to its excellent laser weldability.

Continuous laser welding of thin-shell lithium-ion batteries significantly boosts efficiency while enhancing appearance and sealing. To achieve even faster welding speeds and a more uniform appearance, many manufacturers are adopting composite welding and annular spot welding, moving away from slower single-fiber welding. In mass production, welding speeds have reached impressive levels, while ensuring weld stability.

5. Securing the Seal: Sealing Nail Welding

Sealing nails, or injection hole caps, come in various forms, often round caps. The welding process must ensure a robust seal capable of withstanding high pressure, free from pinholes, cracks, or explosion points.

As the final step in battery core welding, the yield of sealing pin welding is particularly important. Residual electrolyte can lead to defects like explosion points and pinholes. Minimizing heat input is crucial for suppressing these defects. Laser welding significantly enhances stability and consistency, leading to improved yields.

6. Building Modules and Packs: Module and PACK Welding (Busbar Welding)

A battery module is essentially a combination of lithium-ion cells connected in series and parallel, equipped with individual cell monitoring and management devices. The module's structural design dictates its performance and safety. It must support, secure, and protect the cells while meeting overcurrent requirements, ensuring current uniformity, controlling cell temperature, and providing a means to cut off power in case of severe abnormalities.

Because laser welding copper and aluminium together can create brittle compounds, it is generally used for copper to copper and aluminium to aluminium, in addition to ultrasonic welding. Because copper and aluminium have high laser reflectivity and conduct heat quickly, the connecting piece tends to be thick, requiring higher power lasers.

In Conclusion:

Welding is not merely a joining process in battery production; it's a critical determinant of safety, performance, and longevity. Each welding stage, from the delicate safety vent to the robust module assembly, demands precision and control. The adoption of advanced laser technologies and meticulous process management are essential for achieving high-quality, reliable welds. As battery technology continues to evolve, so too will the welding techniques that underpin its advancement, ensuring safer and more efficient energy storage solutions.

#laser welding#laser welding machine#laser welding machine in India#laser welding equipment#fiber laser welding machine

0 notes

Text

The Best Building Materials for Your Next Residential Construction Project

Introduction

Choosing the right building materials is crucial when constructing a durable, energy-efficient, and cost-effective residential property. With various options available, selecting the best materials requires considering factors like strength, insulation, sustainability, and cost-effectiveness.

In this guide, we’ll explore the top building materials for residential construction and provide insights into their benefits, applications, and long-term value. If you’re looking for premium-quality construction materials, check out AHM Building Materials for a wide selection of cement, concrete, fasteners, adhesives, and more.

1. Concrete: The Foundation of Strong Homes

Concrete is one of the most widely used materials in residential construction due to its durability, strength, and low maintenance. It is used in foundations, walls, driveways, and patios.

✔ Benefits of Concrete:

High strength and durability

Fire and water resistance

Energy-efficient due to thermal mass properties

Modern precast concrete panels and lightweight concrete blocks are becoming popular for quick and efficient home construction.

2. Bricks: A Classic and Timeless Choice

Bricks have been used for centuries in home construction, providing structural integrity and aesthetic appeal. They are made from clay or concrete and come in different styles.

✔ Advantages of Brickwork:

Weather-resistant and long-lasting

Excellent insulation for temperature regulation

Fire-resistant and low-maintenance

Bricks are ideal for exterior walls, fireplaces, and garden pathways. Brick veneers are also an option for a modern touch without the weight of traditional bricks.

3. Wood: A Versatile and Natural Material

Wood remains a favorite choice for residential construction due to its versatility, sustainability, and aesthetic appeal. It is commonly used for framing, flooring, roofing, and interior décor.

✔ Why Choose Wood?

Lightweight yet strong and flexible

Natural insulation properties for energy efficiency

Eco-friendly when sourced from sustainable forests

Popular types include oak, pine, cedar, and engineered wood products like plywood and MDF.

4. Steel: A Modern Solution for Strength and Longevity

Steel is increasingly used in residential construction, especially in structural framing and roofing. It is highly durable and resistant to extreme weather conditions.

✔ Steel’s Key Advantages:

High tensile strength and durability

Pest-resistant and fireproof

Recyclable and eco-friendly

Steel-framed homes are gaining popularity due to their modern design flexibility and earthquake resistance.

5. Glass: Enhancing Natural Light and Modern Aesthetics

Glass is a crucial material in modern home designs, providing natural light, insulation, and energy efficiency. It is used in windows, doors, skylights, and partitions.

✔ Benefits of Using Glass in Homes:

Improves indoor lighting and energy efficiency

Adds elegance and modern appeal

Can be reinforced for extra security

Double-glazed and low-emissivity (Low-E) glass are great options for reducing heat loss and improving insulation.

6. Cement: Essential for Stability and Longevity

Cement is a fundamental component in concrete, plaster, and mortar. It binds materials together and enhances the stability of a structure.

✔ Why Cement is a Must-Have?

Essential for foundations, flooring, and walls

Water-resistant and long-lasting

Can be combined with various aggregates for different applications

Buying high-quality cement online ensures better performance and durability. Visit AHM Building Materials for premium-grade cement.

7. Stone: A Durable and Luxurious Option

Natural stone is a high-end material used in flooring, walls, countertops, and landscaping. It offers aesthetic appeal and unmatched durability.

✔ Advantages of Stone in Home Construction:

Highly resistant to weather and wear

Timeless and elegant look

Naturally fire-resistant

Popular choices include granite, marble, limestone, and slate.

8. Insulation Materials: Enhancing Comfort and Efficiency

Proper insulation is essential for energy efficiency and indoor comfort. Various insulation materials are available, including:

✔ Fiberglass insulation – Common and cost-effective ✔ Spray foam insulation – Seals gaps and enhances energy efficiency ✔ Reflective insulation – Ideal for warm climates

Investing in quality insulation helps reduce energy bills and improves indoor air quality.

9. Roofing Materials: Protection Against the Elements

Choosing the right roofing material ensures durability, weather resistance, and energy efficiency.

✔ Common Roofing Materials:

Asphalt shingles – Affordable and widely used

Metal roofing – Durable and fire-resistant

Clay tiles – Long-lasting with excellent insulation

Slate roofing – Elegant and highly durable

A strong roofing system protects the home from rain, snow, wind, and extreme temperatures.

10. Adhesives and Sealants: Ensuring Long-Term Stability

Adhesives and sealants play a crucial role in construction and home repairs. They are used for bonding materials, waterproofing, and sealing gaps.

✔ Types of Adhesives and Sealants:

Silicone sealants – Used for waterproofing windows and bathrooms

Polyurethane adhesives – Strong bonding for various materials

Construction-grade glue – Ideal for drywall, wood, and tiles

For top-quality adhesives and sealants, check out AHM Building Materials to find the best products for your project.

Conclusion

Selecting the best building materials for your residential project is essential for durability, energy efficiency, and aesthetic appeal. Whether you’re constructing a new home or renovating an existing property, investing in quality materials ensures long-term benefits.

For the best building materials, tools, and accessories, visit AHM Building Materials and get premium construction supplies at competitive prices.

0 notes

Text

Strong Cage Traps – Built for Durability and Performance by Comstock Custom Cage

When dealing with wildlife trapping, durability and security are top priorities. Strong cage traps provide a reliable and humane way to capture nuisance animals without risk of escape or harm. Comstock Custom Cage specializes in manufacturing high-quality, heavy-duty traps designed to handle aggressive wildlife while maintaining efficiency in various environments. Whether you're a professional trapper or a homeowner looking for a long-term solution, our traps ensure effective animal control with superior craftsmanship.

Heavy-Duty Construction for Maximum Strength

A strong cage trap must withstand forceful animals that try to break free. Our traps are built from high-gauge galvanized steel, providing excellent resistance against bending, rusting, and harsh weather conditions. Unlike cheap wire traps, which can easily deform, Comstock Custom Cage traps maintain their structure even when dealing with large or powerful animals. The reinforced frame and high-tensile mesh ensure that no animal can chew or claw its way out.

Secure and Escape-Proof Mechanism

Security is a key factor when choosing a cage trap. Comstock Custom Cage designs traps with self-locking doors and high-tension springs, ensuring that once an animal enters, it stays inside. The one-way entry prevents escape, and the secure door-locking mechanism eliminates the risk of accidental openings. Whether you need to trap raccoons, skunks, or beavers, our traps provide peace of mind that the captured animal will remain safely contained.

Humane and Ethical Wildlife Trapping

Effective animal trapping should always be humane. Our strong cage traps are designed to prevent injury while providing enough space for the captured animal to remain comfortable. The smooth interior prevents cuts or abrasions, and the safe-release feature allows for easy relocation. Whether used for pest control, conservation, or wildlife rescue, our traps ensure ethical handling without causing unnecessary stress to the animal.

Versatile for Different Trapping Needs

Comstock Custom Cage traps are built for both land and water trapping, making them highly versatile. Whether dealing with ground-dwelling animals like woodchucks or aquatic species like muskrats and beavers, our traps provide efficient results in any setting. Available in single or double-door models, they offer flexible options for various trapping scenarios.

Effective Use and Placement for Best Results

To maximize success, proper trap placement and baiting are essential. Select the right size trap based on the targeted species and use highly attractive bait such as fruits, vegetables, or protein-based lures. Position the trap near active burrows, feeding areas, or along natural pathways. Regular monitoring ensures that captured animals are handled promptly and ethically.

Get the Best Strong Cage Traps from Comstock Custom Cage

For those seeking strong cage traps that provide durability, security, and humane trapping solutions, Comstock Custom Cage is the trusted choice. Our expertly crafted traps ensure long-lasting performance, making them the ideal solution for wildlife management professionals and homeowners alike. Contact us today for the highest-quality cage traps on the market!

1 note

·

View note

Text

FE550 TMT (Thermo-Mechanic8ally Treated) bars

FE550 TMT (Thermo-Mechanically Treated) bars are a type of high-strength reinforcement steel that have been increasingly used in construction and architecture due to their superior mechanical properties and durability. While traditionally used for structural reinforcement in concrete, innovative uses of FE550 TMT bars are emerging in architectural design, combining both aesthetic and functional advantages. Here are a few innovative applications of FE550 TMT bars in architecture:

1. Architectural Facades and Cladding

Aesthetic Metal Mesh Facades: FE550 TMT bars can be fabricated into intricate designs to form metal mesh or wireframe facades. The high tensile strength of FE550 allows for thinner yet stronger elements, enabling architects to create modern, lightweight facades with complex geometries.

Exposed Structural Elements: Using TMT bars as visible structural components can contribute to the aesthetic value of a building. The raw industrial look of exposed reinforcement can add to the design language, particularly in contemporary or industrial-style buildings.

2. Bridge and Overhead Structures

Bridge Cable Assemblies: FE550 TMT bars can be used for cable systems in suspension bridges or overhead structures, offering higher durability and strength for long spans. The bars can also be used as tension cables in architectural bridge design, providing both aesthetic elegance and structural integrity.

Skywalks and Elevated Pathways: Lightweight, high-strength FE550 bars can be used for creating elevated pedestrian walkways or skywalks. The bars allow for the creation of slender, graceful supports while maintaining safety and stability.

3. Pre-Engineered Modular Systems

Modular Steel Frameworks: FE550 TMT bars can be used in the fabrication of modular, prefabricated construction systems. For example, a modular steel frame made of TMT bars could be used in the construction of pre-engineered buildings, allowing for rapid assembly, disassembly, and transportation of architectural units.

Space Frames: Architects and engineers use TMT bars to create space frames that are lightweight, yet capable of supporting heavy loads. These frames can be used for large-scale roofing systems, exhibition halls, or sports arenas.

4. Sustainable Architecture

Green Building Elements: The long-term durability and recyclability of FE550 TMT bars make them an ideal material for sustainable architecture. As buildings strive for higher energy efficiency and sustainability, FE550 can be incorporated into the structural elements of energy-efficient buildings, minimizing material waste and ensuring the longevity of the structure.

Reinforced Concrete and Low-Cost Housing: FE550 TMT bars can be used to reinforce concrete structures in low-cost housing projects, ensuring that the buildings are strong, resilient, and durable. Their higher tensile strength means that less material is required for the same load-bearing capacity, making them ideal for resource-efficient construction.

5. Innovative Structural Elements

Architectural Sculptures and Installations: FE550 TMT bars can be used as reinforcement in architectural sculptures, creating artistic installations that are both structurally sound and visually striking. The flexibility of the material allows artists to design freeform structures with complex geometries, which are often challenging to achieve with traditional materials.

Non-Rectilinear Design: The flexibility of FE550 TMT bars makes it easier to create curvilinear or organic architectural forms, such as flowing roofs or undulating walls. This provides architects with more freedom in designing buildings that break away from traditional linear forms.

6. Innovative Flooring Systems

Reinforced Floor Slabs with Custom Designs: The flexibility and strength of FE550 TMT bars enable the design of reinforced concrete slabs with more complex and innovative shapes. These can be used in the design of expansive floor systems, cantilevered structures, or large open spaces without the need for numerous supporting columns.

Thin, Strong Concrete Floors: Since FE550 TMT bars allow for thinner but stronger concrete floors, architects can achieve more open spaces with fewer columns or supports, making spaces appear more fluid and connected.

7. High-Rise Buildings and Skyscrapers

Seismic Resistance: FE550 TMT bars are especially useful in regions with high seismic activity. They can be used to create reinforced concrete cores and structural frames in high-rise buildings, ensuring that the buildings are resilient to ground movement while maintaining aesthetic appeal.

Elevated Structural Frames: In skyscraper construction, the use of FE550 TMT bars in structural frames allows for the creation of lighter and more flexible steel-reinforced concrete components. This can help reduce the overall weight of a building while still providing the necessary strength and support for tall structures.

8. Temporary Structures

Event Pavilions: Temporary structures, such as pavilions or exhibition halls, can be made using FE550 TMT bars. The material's high strength allows the construction of these structures with less steel, yet they maintain a high level of durability and stability. This is particularly important for structures that need to endure stress over a short period but still maintain an elegant and temporary design.

9. Artistic Concrete and Steel Combinations

Hybrid Design Projects: Combining the use of FE550 TMT bars with concrete and other materials in architectural projects opens up new avenues for design. The bars can be integrated into artistic concrete designs to create textures, reliefs, and shapes that are not only functional but also visually stimulating.

Patterned Surfaces: FE550 TMT bars can also be used as part of the formwork for concrete casting, allowing for unique patterns and textures to be imprinted on the concrete surfaces.

0 notes

Text

Advantages And Applications Of Post-Tension Slabs

Post-tensioning, a technique that enhances the strength and durability of concrete structures, has gained significant traction in recent years. Among its various applications, post tension slab stand out as a versatile and effective solution for achieving longer spans, reduced thicknesses, and enhanced performance.

Post-tension slabs are concrete slabs reinforced with high-strength steel tendons that are tensioned after the concrete has cured. Unlike traditional reinforced concrete slabs, which rely solely on the compressive strength of the concrete, post-tension slabs utilise the combined strength of concrete and steel to resist bending and cracking. This results in thinner, lighter slabs with increased load-carrying capacity and reduced deflection.

The Post-Tensioning Process

The process of constructing a post-tension slab begins with the placement of ducts or sleeves within the concrete forms before pouring. These ducts serve as pathways for the steel tendons, which are then threaded through after the concrete has hardened. Once in place, the tendons are tensioned using hydraulic jacks, applying a predetermined amount of force to achieve the desired level of pre-stress. This tensioning process places the concrete under compression, enhancing its structural integrity and allowing for longer spans between supports.

Benefits of Post-Tension Slabs

Post-tension slabs offer several key benefits over traditional reinforced concrete slabs:

Increased Strength and Durability: By introducing tension to the concrete, post-tension slabs are able to withstand higher loads and resist bending and cracking more effectively, resulting in longer-lasting, more resilient structures.

Longer Spans: Post-tension slabs allow for longer spans between supports, reducing the need for additional columns or beams and providing greater flexibility in architectural and structural design.

Reduced Thickness: The use of post-tensioning enables thinner slab thicknesses without compromising structural integrity, resulting in material savings and reduced overall construction costs.

Improved Crack Control: Post-tensioning helps control cracking in concrete by applying compressive forces to counteract tensile stresses, minimising the formation and propagation of cracks.

Faster Construction: Post-tension slabs can be constructed more quickly than traditional reinforced concrete slabs, thanks to their lighter weight and reduced thickness. This can lead to shorter construction schedules and lower labour costs.

Applications of Post-Tension Slabs:

Post-tension slabs find widespread use in various construction applications, including:

Residential Buildings: Post-tension slabs are commonly used in residential construction for floors, balconies, and garage slabs, where longer spans and reduced thicknesses are desired to maximise usable space and minimise structural depth.

Commercial Buildings: In commercial construction, post-tension slabs are utilised for office buildings, retail centres, and hotels, where large open floor plans and long spans are often required to accommodate diverse tenant needs and architectural designs.

Industrial Facilities: Post-tension slabs are ideal for industrial facilities such as warehouses, distribution centres, and manufacturing plants, where heavy loads and high traffic demand durable, low-maintenance flooring solutions.

Parking Structures: Post-tension slabs are commonly used in parking garages and decks to create large, column-free parking areas with minimal structural depth, maximising parking capacity and efficiency.

Considerations for Implementation:

While post-tension slabs offer numerous benefits, there are several considerations to keep in mind when implementing them:

Design Expertise: Proper design is essential for the successful implementation of post-tension slabs. Work with experienced structural engineers and post-tensioning specialists to ensure the design meets all safety, performance, and code requirements.

Construction Practices: Post-tension slabs require specialised construction practices to ensure proper installation and tensioning of the tendons. Work with qualified contractors who have experience with post-tensioning techniques and follow industry best practices.

Quality Control: Quality control is crucial during the construction of post-tension slabs to ensure the integrity and performance of the finished structure. Regular inspections, testing, and monitoring are essential to detect any issues or deficiencies and address them promptly.

Maintenance and Repair: While post-tension slabs are durable and long-lasting, they still require regular maintenance and occasional repairs to ensure continued performance and safety. Follow recommended maintenance practices and address any issues promptly to prevent further damage.

1 note

·

View note

Text

Amorphous Metals Market: Pathways to Industry Dominance

The latest report, titled ‘Global Amorphous Metals Market,’ comprises a profound analysis of the fundamental parameters contributing to the global Amorphous Metals market scenario. The research report provides the reader with an in-depth interpretation of the Amorphous Metals market dynamics, including the crucial drivers, opportunities, threats, and challenges. The report also describes the key business strategies, demand and supply ratios, leading regions, and the renowned market players, in a nutshell, offering a futuristic outlook of the overall Amorphous Metals industry. The market intelligence report is a prototype of the 360° overview of the global Amorphous Metals industry, shedding light on the estimated market value, share, growth trends, gross revenue, competitive overview, prominent manufacturers and buyers, available product types, and end-use applications.

The global amorphous metals market size reached USD 985.4 Million in 2020 and is expected to register a revenue CAGR of 8.8% during the forecast period, according to latest analysis by Emergen Research. Increasing need for good thermal conductivity and increasing need for high resistance against corrosion is expected to support market revenue growth between 2021 and 2028. In addition, increasing need for amorphous metals for scratch resistance will boost revenue growth of the market.Corrosion and abrasion of metals used in building construction are major issues in all countries, and better substitutionsare urgently required to address this issue. Corrosion of metals can be problematic because it could result in affecting building structure and strength. Amorphous metals provide a good solution to this problem. Amorphous metals have plenty of useful properties and are harder than crystalline metals as it has high tensile yield strength and lesser ductility than crystalline alloys, allowing the metals to withstand physical damage and scratches more effectively. In addition, amorphous metal films are used in various sports equipment, medical gadgets, and electrical equipment to provide a protective layer as the metals are deposited using a high velocity oxygen fuel technique, resulting in better scratch resistance.

To receive a PDF sample of the report, visit @ https://www.emergenresearch.com/request-sample/918

The latest research report is dubbed as the first document encompassing the latest information about the Amorphous Metals market that has been gravely affected by the COVID-19 pandemic. The global health crisis poses significant threats to the future growth of the Amorphous Metals industry. The report assesses the profound changes in this business setting caused by the outbreak and considers the prominent market aspects that have been severely disrupted by the pandemic. The report thus expounds on the rapidly changing market scenario in this COVID-19 era, which aims to help businesses involved in this sector overcome the pandemic’s gripping effects and formulate new growth strategies to boost the COVID-19 preparedness.

Market Overview:

The report bifurcates the Amorphous Metals market on the basis of different product types, applications, end-user industries, and key regions of the world where the market has already established its presence. The report accurately offers insights into the supply-demand ratio and production and consumption volume of each segment.

Amorphous Metals Market Segmentation:

Type Outlook (Revenue, USD Million, Volume, Tons; 2018–2028)

Iron Based

Cobalt Based

Others

Process Outlook (Revenue, USD Million, Volume, Tons; 2018–2028)

Chemical Process

Physical Process

Others

Application Outlook (Revenue, USD Million, Volume, Tons; 2018–2028)

Distribution Transformer

Electronic Machinery

Electronic Components

Others

It focuses on the recent mergers & acquisitions, joint ventures, collaborations, partnerships, licensing agreements, brand promotions, and product launches, among others. The report also provides details about the company overview, business expansion plans, product portfolio, manufacturing and production capacity, global market position, financial status, and consumer base.

The report also discusses the key players involved in the market such as

Hitachi Metal, Ltd., Materion Corporation, Qingdao Yunlu Advanced Materials Technology Co., Ltd., China Amorphous Technology Co., Ltd., Zhaojing Incorporated, Shijiazhuang Shenke Metal Products Co., Ltd., Federal Steel Supply, Inc., Advanced Metal Technology, Inc. (Amtech), Henan Zhongyue Amorphous New Materials Co., Ltd., and Junhua Technology Co., Ltd

Request customization of the report @ https://www.emergenresearch.com/request-for-customization/918

Global Amorphous Metals Market Highlights:

Regional demand estimation and forecast

Product Mix Matrix

R&D Analysis

Cost-Benefit Analysis

Pre-commodity pricing volatility

Supply chain optimization analysis

Technological updates analysis

Raw Material Sourcing Strategy

Competitive Analysis

Mergers & Acquisitions

Location Quotients Analysis

Carbon Footprint Analysis

Patent Analysis

Vendor Management

Regional Landscape section of the Amorphous Metals report offers deeper insights into the regulatory framework, current and emerging market trends, production and consumption patterns, supply and demand dynamics, import/export, and presence of major players in each region.

The various regions analyzed in the report include:

North America (U.S., Canada)

Europe (U.K., Italy, Germany, France, Rest of EU)

Asia Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

Latin America (Chile, Brazil, Argentina, Rest of Latin America)

Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

Browse Full Report Description + Research Methodology + Table of Content + Infographics @ https://www.emergenresearch.com/industry-report/amorphous-metals-market

Highlights of Table of Contents (TOC):

Overview of Global Amorphous Metals Market

Competitive analysis of the Amorphous Metals market

Regional analysis of Global Amorphous Metals market production and revenue

Regional analysis of Global Amorphous Metals market supply, consumption, and export & import

Type-based market analysis of global Amorphous Metals production, revenue, and price trends

Application-based analysis of the global Amorphous Metals market

Manufacturer profiles, manufacturing cost, and upstream and downstream analysis of global Amorphous Metals market

Global Amorphous Metals market forecast (2020-2027)

Conclusion of the research report

Appendix

Thank you for reading our report. Please get in touch with us if you have any query regarding the report or its customization. Our team will ensure the report is best suited to your needs.

Look Over transcripts provided by Emergen Research

Carbon Capture and Storage Market

Intraoperative Radiation Therapy Market

Epoxy Curing Agents Market

Mass Flow Controller Market

Industrial Valves Market

Facility Management Market

Digital Maintenance, Repair, and Operations Market

Tractors Market

About Us:

Emergen Research is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target, and analyse consumer behavior shifts across demographics, across industries, and help clients make smarter business decisions. We offer market intelligence studies ensuring relevant and fact-based research across multiple industries, including Healthcare, Touch Points, Chemicals, Types, and Energy. We consistently update our research offerings to ensure our clients are aware of the latest trends existent in the market. Emergen Research has a strong base of experienced analysts from varied areas of expertise. Our industry experience and ability to develop a concrete solution to any research problems provides our clients with the ability to secure an edge over their respective competitors.

Contact Us:

Eric Lee

Corporate Sales Specialist

Emergen Research

Direct Line: +1 (604) 757-9756

E-mail: [email protected]

Visit for More Insights: https://www.emergenresearch.com/insight

0 notes

Text

A walkway covering tensile structure is a type of architectural and engineering design that provides a sheltered and aesthetically pleasing pathway or walkway using a tensile membrane system. Tensile structures are known for their ability to span large distances and create unique, lightweight, and visually appealing architectural elements. Here are some key features and considerations for walkway covering tensile structures:

Structural Framework: The membrane is supported by a structural framework, which can be made of steel, aluminum, or other suitable materials. This framework provides stability and shape to the tensile structure.

Design Flexibility: Tensile structures offer great design flexibility, allowing architects and designers to create unique and eye-catching walkway coverings. They can be curved, twisted, or angled to fit the specific requirements and aesthetics of the site.

Weather Protection: One of the primary purposes of a walkway covering is to provide shelter from the elements. Tensile structures are designed to offer protection from rain, sun, and snow, making them suitable for a variety of outdoor environments.

Natural Lighting: Tensile membranes can be designed to allow natural light to pass through, creating a well-lit and comfortable walkway. This can be achieved through translucent or semitransparent membrane materials.

Durability: Tensile structures are engineered to withstand environmental factors such as wind, snow, and seismic loads. Properly maintained tensile structures can have a long service life.