#Plasma Refinery Complex

Explore tagged Tumblr posts

Text

Theed Spaceport

STAR WARS EPISODE II: Attack of the Clones 00:38:26 - 00:38:35

I probably missed a few ships at the spaceport, but rest assured they’re unidentified vessels. Kinto points out that some of the objects in the spaceport just cargo containers, and also corrected me on the name of the Action VI bulk freighter. Thanks Kinto!

Thanks to Spookywilloww on Wookieepedia for clueing me into the Spaceports spread in the Complete Locations book for further identification of objects in this scene. Previously I was only using the diagram of the spaceport from the DeAgostini Star Wars Encyclopedia #60: Naboo.

I also removed the identifications of the DSS-02 shield generators (the model seen in The Empire Strikes Back) as they're never actually clarified as the same, only labeled as "auxiliary power generators" in Complete Locations.

They're possibly similar generators also produced by Kuat Drive Yards.

#Star Wars#Episode II#Attack of the Clones#Naboo#Theed#unidentified Action VI bulk freighter#unidentified symbol#unidentified starship#unidentified YT-1300 light freighter#unidentified vessel#unidentified Taylander shuttle#unidentified N-1 starfighter#unidentified droid#Theed Spaceport#Jendirian Valley#Theed Royal Hangar#Plasma Refinery Complex#Cliffs of Theed#power generator#docking pier#Gallo Mountains#Solleu River#Dyne 2577 radial sublight engines#cargo module#auxiliary power generator#maintenance hangar#space traffic control#terminal

2 notes

·

View notes

Text

Loud.

part one two three four five

“Why are you buttering me up, Master?” Obi-Wan signs, taking another careful sip of the cookie shake.

Master Tholme unfolds his hands on the table, cane resting against his leg. “Because I understand that you might not want to participate in this mission,” he signs back. It must be one of those days where he doesn’t want to talk. Obi-Wan understands and lets the silence engulf them. “But the Council and I feel that this is where you need to be.”

.

“Master,” Obi-Wan signs and bows.

“Hello, Obi-Wan.”

It’s not the first time he’s seen Qui-Gon again after Melidaan’s parting gift almost killed him. Of course they’ve seen each other. Qui-Gon had been there for him while he recovered, had hovered over Master Tholme’s shoulder like a shadow.

“A particularly annoying shadow,” Master Tholme had commented drily back then. “Which is funny, considering.“

Obi-Wan opens his arms and Qui-Gon’s tall frame closes around him. Maybe a queezing too tight but… but that doesn’t matter. “How are you,” he taps on a broad shoulder.

He’s abruptly let go. Not pushed back, thankfully.

“I am well, thank you.” Qui-Gon falls silent.

Obi-Wan has forced himself to stop trying to make the awkwardness between them less uncomfortable by the time he turned sixteen and Master Tholme sat him down to explain why he should let Qui-Gon come to grips with everything that has happened between them on his own until Qui-Gon reaches out to him.

“How are you?” And the caring and heartbreak lingering in Qui-Gon’s eyes is too much.

“I feel prepared to accompany you on this mission.”

It had been Qui-Gon who had taught him sign language in different iterations useful across the galaxy, before and later. Tholme has taught him tap code, after.

“Then let’s not waste any time,” Qui-Gon says, eyes on his long padawan braid.

.

Meeting Anakin feels… weird in the Force.

“So you don’t talk? Ever?”

Obi-Wan shakes his head, amusement crinkling his eyes.

“You don’t want to or you can’t?” the boy asks before his eyes widen. “Both are fine!”

“Cannot,” he signs carefully, settling on an Outer Rim dialect.

“Oh, ok!”

It’s the beginning of a never ending nightmare. Tatooine. Naboo. The desperate attempts to stop a war from happening.

He keeps to the background, inconspicuous and invisible.

Which is the only reason he ends up in the plasma refinery complex.

.

“It’ll be alright, little one,” Qui-Gon murmurs, gentle fingers wiping tears away before they reach the mask. “Just squeeze my hand.”

“Master,” he taps, hiccups threatening to disrupt something in his throat.

“Take care of the boy.”

.

So he does.

He brings Anakin back to the Temple, watches over his nightmares in silence.

He kneels as Master Tholme cuts his braid.

He explains to the Council what he thinks.

Anakin is bright. Smart and a beacon in the Force. He’s older than usual, granted. But his connection to the Force is palpably vast and potentially dangerous if he isn’t trained to handle that connection. He’s safer in the Temple where they can watch over him and teach him.

The Council agrees.

.

He introduces Anakin to Depa.

Her dry wit has the boy relaxing. Her no-nonsense attitude is a guiding light, a steady framework he can lean on and count on.

Depa delights in showing him the Temple, the opportunities to learn and try out new experiences.

.

Shadow work piles up and suddenly Obi-Wan is running around the galaxy trying to put out fires.

When he’s slumped in the back door of an abandoned factory in the shady part of an Outer Rim planet, struggling to breathe and feeling like he’s dying, lightsaber in a death grip, he makes the decision to return to the Temple. The mask has to change or he will die because he is out of breath. Unacceptable.

The technicians look at him chagrined and apologetic, explain that this is all they can do at the moment, maybe he can take it a bit easier?

“No, you need to adjust the valves on—“ a small voice peeps up from behind his shoulder.

Obi-Wan has been aware Anakin is clinging to his back like a monkey bear. He’s ignored the looks he’s gotten on the way to the tech complex.

“Have at it, then,” he signs.

Anakin looks at him like he’s personally chosen every star in the galaxy as he hands over the mask.

.

“An order.”

“A strong suggestion,” Mace corrects.

“Call it what it is,” Obi-Wan signs, cutting through the air with his hands he’s so furious. “Chancellor Palpatine has no business wanting to spend time with Anakin.”

Mace sighs, leans back in the chair. “I’m aware, Obi-Wan.” He taps his fingers against the armrest but he’s releasing energy, focusing his thoughts, not code. “How are you feeling?”

The renewed esophagus has him out of the mission count for a bit yet, he’s slowly weaned off the artificial nutrition. Overall, he’s starting to feel a bit restless.

“Perhaps you want to enjoy Coruscant’s scenery while you’re here?” Mace asks, a twinkle in his eye. “Though I beg you to not get into trouble,” he adds with a frown. “Too much trouble, I mean. I forgot for a second who I was talking to.”

Spying on the Chancellor is not on Bant’s list of approved activities but what she doesn’t know…

Obi-Wan touches his chin and brings his hand forward.

.

“So you can either sign in the dark or write tap code with these gloves. You can adjust the brightness and still sneak around.”

“Thank you, Ani.” It’s one of the best gifts he’s ever had the honor of receiving. It solves a lot of problems on missions. He hugs the boy close and feels swept up in the thoughtfulness. “I don’t sneak.”

“You totally do and it’s so wizard!”

.

“You were supposed to be my Master!”

439 notes

·

View notes

Text

So, for my own fanfic purposes, I worked on a list of canonical locations on Cybertron. I don't know if any site has a nicely formatted list of cities/city-states, so I thought I might share this list with others. This is mostly comprehensive as I left off locations that were too specific to one continuity or too confusing and it's quite possible I missed a few places. There are some continuity specific places included I think are more flexible. Many items on this list are not expanded upon, so you can have as much fun as you want.

Either way, here's what I got in one handy (very long) list:

Regions

Tri-Torus

- Petrohex

- Polyhex

- Dodecahex

Polar States

- Iacon

- Kaon

Tri-Penninsular Torus

- Uraya

- Praxus

- Protihex

Iacon (capital)

Iacon Central

- Great Dome

- Celestial Spires

-- Celestial Temple

Academy of Science and Technology

Jan-ja

Imperial Amphitheater

Maccadam's Old Oil House

Iaconian Aerial Academy

Metroplex

Trion Square

the Undergrid

Translucentia Heights

the Senate

Xeno Quarter

Hall of Records

Observatory of Iacon

High Council Pavilions

Chamber of the Autobots

Polyhex

Darkmount

Deadend

the original Space Bridge

Polyhex Toll Plaza

a canyon

Grease pits

Nova Cronum

Praetorus Wharf

Chamber of the Ancients

center of philosophy

Protihex

Protihex Medical Mechanics University

Uraya

bigger than Praxus and Protihex

Tyger Pax

idyllic and tranquil

Rust Sea

unstable planetary matter

emits a mostly harmless corrosive gas

Hydrax Plateau

- Damaxus

Toxic Sludge Swamps

Tagan Heights

Durax

Ultirex

- technoversity

Tetrahex

responsible for 40% of industrial output

Tyrest

Jekka Amphitheater

Tyrest University

Altihex

deep space research facilities

underground energon refinery

Altihex casino

Kalis

Pax Cybertronia Decommissioning Depot

Kalis Primary Energon Reserves Control

Kaon

Kolkular

- the Cradle

space bridge

gladitorial rings

Jump Joint

Wreckage Row

mines

Kaon Prison

Kaon Plaza

Ibex

Central Spaceport

Ibex School of Epistemology

Ibex Cup racing circuit

Crystal City

Drouhard University

Refracting Gardens

Geosynchronus Energon Bridge

known for elegant construction and scientific minds

Undercity

mostly deserted

near the Red Sea

Peptex

near Rust Sea

Dodecahex

Shuttle Complex Ohm

Petrohex

Upper Petrohex

Lower Perrohex

Rust Sea tributary

Harmonex

"Singing City"

center for art and learning

Lithic singing crystals

Alyon

uninhabited

Vos

rich in energy resources

close to Tarn

Air Command Center

Stanix

Yuss

- Amprodome

- Justice Building

Fort Scyk

Acid Wastes

Proximax

Transhyperwave Caster Tower

Hyperious

defensive walls

Burthov

docks

launch site

labs and factories

"belongs" to Science Division

Petrex

"twin-mode" city

Simfur

Simfur Temple

Chamber of the Dynasty of Primes

Tarn

power plant

border fortresses

gladitorial rings

original Senate Building

The Decagon

main control center of planetary defenses

Blaster City

low class industrial region

munitions source

weapons manufacturing facility

Rad Zone

dangerous

Plasma Energy Chamber

plasma energy reservoir

Tesarus

artisans and philosophers

Helex

Power Base

gladitorial arena

Axiom Nexus

The Blue Deployer

Widow's Cafe Cybertronian

The Heap

Rodion

waterways

Maccadam's New Oil House

Deltaran Medical Facility

Nyon

Rust Narrows

Acroplex

Gygax

tunnel to Ankmor Park

Ankmor Park

as old as Quintesson supremacy

chemical processing center turned biochemical garden

Galaxxon

industrial

slagwerks

K'th Kinsere

Vaulted Heights

home to High Priests

Triax

the Nexis

Ky-Alexia

stronghold

Plurex

Plurex Flats

Emirate Xaaron Spacebridge Nexus

just outside of Iacon

Well of Allsparks

afterlife

inside the Core

Sistex

Sistex University

Staniz

ship building

Centurion

bright

Praxus

the Assembly

Helix Gardens

Slaughter City

low class industrial center

illegal gladotorial games

Border Regions

borders Iacon

Promontory

Forum of Enlightenment

Predigeon Arch

Cities with no information

Nuon

Pescus Hex

Esserlon

Monoplex

Median

Hexima State

Perihex

Praxium

Bitrex

Ultrix

Valvolux

Carpessa

Glibax

Vaporex

Ambustus Minor

Tribat

Unitrex

Tesk

Teledonia

Detrona

Landmarks

Redox River

Timonium River

Straits of Yuss

Trannis Fork River

Mithril Sea

Argon Sea

- gaseous

Sonic Canyon

The Badlands

Manganese Mountains

Cataclysm Tundra

- Athenaeum Sanctorum

Tri-Torus Loop

Tygun Span

-road between Iacon and Nova Cronum

33 notes

·

View notes

Text

Reliance Industries Company List: A Deep Dive into India’s Corporate Powerhouse

The Reliance Industries Company List includes some of the most impactful and revenue-generating businesses in India’s industrial and digital economy. From oil refining to telecom, fashion retail to media networks, Reliance Industries Limited (RIL) has built an empire that touches nearly every aspect of Indian life. Spearheaded by Mukesh Ambani, RIL has transformed from a textile company into a diversified conglomerate with global influence.

Understanding the Reliance Industries Company List is essential for anyone looking to grasp the magnitude of this corporate powerhouse and how it continues to evolve with time.

Reliance Jio: Digital Revolution Leader

One of the most important names in the Reliance ecosystem is Reliance Jio. This telecom company changed the face of Indian mobile networks by offering free voice services and low-cost data. It led to a digital boom across the country and now provides broadband, enterprise solutions, and 5G services. Jio also supports apps like JioTV and JioCinema.

Reliance Retail: Serving Every Household

Another major company in the Reliance Industries Company List is Reliance Retail. With physical stores like Reliance Fresh, Smart Bazaar, Trends, and the e-commerce platform JioMart, it is India’s largest retailer. It caters to daily needs, fashion, electronics, and more, with unmatched reach from metro cities to rural areas.

Reliance Petroleum: Energy at the Core

The energy vertical is led by Reliance Petroleum, which operates the Jamnagar refinery—one of the largest refining complexes in the world. This refinery processes millions of barrels of crude oil daily and is a major contributor to India’s fuel supply and exports.

Network18 and Viacom18: Media Influence

Network18 is the news and media arm of RIL, running popular news channels such as CNBC-TV18, News18 India, and CNN-News18. In entertainment, Viacom18 manages channels like Colors and digital platforms like JioCinema, which is rapidly growing its audience base through IPL streaming and exclusive shows.

Reliance Life Sciences: Innovating Healthcare

Reliance Life Sciences is a key company in the healthcare sector. It is involved in the development of biosimilars, plasma therapies, and regenerative medicine. This arm reflects Reliance’s long-term vision for contributing to public health and innovation.

Reliance New Energy: Future-Focused Green Vision

One of the most recent additions to the Reliance Industries Company List is Reliance New Energy, focusing on sustainability and green power. The company is investing heavily in solar energy, hydrogen fuel, and battery storage to support India’s clean energy mission.

Reliance Brands: Global Fashion in India

Reliance Brands brings luxury and premium international labels to Indian consumers. Through partnerships with brands like Armani, Diesel, and Steve Madden, this subsidiary is creating a high-end fashion experience in major Indian cities.

Conclusion

The Reliance Industries Company List represents the diversity, resilience, and forward-thinking vision of India’s most prominent conglomerate. From traditional industries to modern technology, Reliance continues to innovate, expand, and lead the way into the future.

0 notes

Text

Beyond the Surface: The Real Impact of the Ceramic Coating Sleeve

There’s a quiet hero in many industrial settings that doesn’t get the spotlight it deserves. It doesn’t spin, it doesn’t flash, and it doesn’t make a sound. Yet, without it, millions of dollars in machinery would wear out faster, production would stall, and safety could be compromised.

That unassuming component? The Ceramic Coating Sleeve.

Often overlooked in broader conversations about maintenance or engineering upgrades, this humble sleeve plays a critical role in extending the lifespan of high-performance components across power plants, chemical refineries, and even aerospace systems. But what exactly makes it so vital?

This blog takes a different approach. Rather than rattling off specs, we’ll look deeper: how this component works, why it matters, and what it reveals about our evolving priorities in industrial reliability.

From Wear to Wow: The Birth of a Solution

In high-friction or high-corrosion environments, even the toughest metals can deteriorate rapidly. Engineers once tried battling this problem with thicker alloys or complex lubrication systems. But these methods came with trade-offs — weight, cost, and operational downtime.

Enter the Ceramic Coating Sleeve.

By applying a ceramic coating — often through plasma spraying, chemical vapor deposition, or sol-gel techniques — manufacturers found they could create a protective barrier that’s:

Incredibly hard (often exceeding 9 on the Mohs scale),

Resistant to heat (some withstand temps over 1000°C),

Chemically inert, meaning it doesn’t degrade in harsh acids or alkalis.

And here's the kicker — it does all of this without significantly adding to the component’s mass or altering its base structure.

The Human Side of Engineering: Why It Matters in the Field

Let’s step away from the lab for a moment. Picture a technician working on-site at a petrochemical plant in the sweltering summer heat. The production line is down — again — because a rotating shaft has worn out faster than expected. They’re under pressure. Every hour of downtime costs thousands.

They install a new Ceramic Coating Sleeve — one that’s been designed not just for the shaft, but also optimized for the specific wear profile of the machinery. This time, they’re not coming back in two months. They’re coming back in two years.

In moments like this, the sleeve isn’t just a product. It’s peace of mind. It’s fewer emergencies, less stress, and higher trust in the system.

That’s what engineering should always strive for: blending material science with meaningful human impact.

A Deep Dive into the Tech: How Does It Work?

Here’s the part that nerds (like us) love.

A Ceramic Coating Sleeve starts with a substrate — typically a metallic or alloy sleeve that fits over a shaft or within a bearing system. It is then coated with ceramics such as:

Aluminum oxide (Al₂O₃) for general wear resistance,

Zirconia (ZrO₂) for thermal shock applications,

Silicon carbide (SiC) or titanium nitride (TiN) for extreme hardness and chemical stability.

These coatings are applied in layers microns thick, but don’t let their size fool you. Even thin coatings can dramatically shift a component’s behavior — reducing friction coefficients, increasing resistance to pitting, and slowing oxidation to a crawl.

Different from the Rest: Why Not Just Go Full Ceramic?

A common question arises: if ceramics are so great, why not make the entire sleeve out of ceramic?

It’s all about balance.

Full ceramic parts are brittle. They don’t like impact or vibration — two things that are unfortunately common in industrial settings. By combining the flexibility of metal with the resilience of ceramic on the surface, Ceramic Coating Sleeves offer the best of both worlds.

This hybrid approach mirrors what we often see in nature — bones that are hard on the outside but spongy inside, or tree trunks that are dense yet flexible. It’s a reminder that sometimes, compromise is the smartest form of innovation.

Applications Across Industries: Not Just for the Big Players

You might think these sleeves are reserved for billion-dollar facilities. But that’s changing fast.

Today, Ceramic Coating Sleeves are showing up in:

Pulp and paper plants, where they protect rollers from slurry and heat,

Automotive manufacturing, especially in EVs where wear resistance is critical,

Pharmaceutical production, where chemical exposure can quickly degrade stainless steel,

Even in food processing lines, where hygiene and abrasion resistance must coexist.

The beauty of this technology is that it scales. A small workshop with a single CNC lathe can benefit from the same principles as a nuclear plant turbine.

Challenges and Considerations: It's Not All Smooth

No solution is without its quirks.

Some challenges include:

Adhesion issues if the substrate isn't prepared correctly,

Cracking or delamination if thermal cycling isn’t considered in design,

Initial cost, which can be higher than untreated sleeves (though cheaper in the long run).

Also, quality control in coating thickness and uniformity is crucial. A poorly applied ceramic layer can do more harm than good. That’s why sourcing from experienced manufacturers and working closely with material scientists can’t be overstated.

Looking Ahead: Smart Coatings and Future Materials

The future of the Ceramic Coating Sleeve isn’t static. Researchers are developing:

Self-healing ceramic coatings that can repair micro-cracks over time,

Smart sleeves with embedded sensors that monitor wear and temperature in real-time,

Eco-friendly ceramic composites using less energy-intensive processing methods.

In other words, the sleeve you install today might soon become a data node in your plant’s predictive maintenance system. That’s an exciting leap from what was once a passive wear component.

Wrapping Up: The Invisible Asset with Massive Impact

In the world of engineering, the loudest innovations often steal the show — think AI, robotics, or giant offshore wind turbines. But there’s a quiet revolution happening beneath the surface, where humble components like the Ceramic Coating Sleeve are redefining what it means to be durable, efficient, and sustainable.

They don’t ask for attention. But they earn respect — quietly, steadily, and reliably.

And maybe that’s what real innovation looks like.

0 notes

Text

Leading Steel Fabrication Services in India – Precision You Can Trust

When it comes to strength, precision, and durability, steel fabrication in India has evolved into a highly specialized sector. Businesses across construction, manufacturing, oil & gas, and infrastructure rely on expert fabricators to produce everything from support beams and frames to custom industrial components. If you're looking for reliable, efficient, and cost-effective steel fabrication services, Eshaji is your go-to partner.

Top Steel Fabrication Company in India

Eshaji is a trusted steel fabrication company in India, offering custom-designed steel structures and components that meet exacting industry standards. Our modern facilities are equipped with CNC machines, plasma cutters, heavy-duty welders, and laser cutting technology to handle both light and heavy structural steel fabrication needs.

We serve a wide range of industries including:

Construction and infrastructure

Automotive and transport

Power plants and refineries

Warehousing and logistics

Custom industrial applications

Our fabrication team works with materials like mild steel, stainless steel, and alloy steel to build products that are not only robust but also tailored to client specifications.

Professional Steel Fabrication Services

At Eshaji, our steel fabrication services include:

Structural steel fabrication

Custom metal frameworks

Welding and assembly

Surface treatment and finishing

On-site installation and support

Whether you require high-precision brackets, mezzanine floors, staircases, or large industrial enclosures, we handle projects of every scale and complexity.

Each project goes through a rigorous quality assurance process to ensure strength, accuracy, and safety compliance. With in-house design and engineering support, we can turn basic sketches or CAD files into perfectly fabricated results.

Why Choose Eshaji?

✔️ Advanced fabrication equipment ✔️ Highly trained engineers and welders ✔️ Competitive pricing and fast turnaround ✔️ Custom design capabilities ✔️ Nationwide delivery and support

With a commitment to quality and on-time delivery, Eshaji has earned a reputation as one of the best steel fabrication companies in India. Our expert team is always ready to assist you with technical input and execution strategy for your fabrication needs.

Call Now

#SteelFabricationIndia#SteelFabricationCompany#FabricationServicesIndia#StructuralSteelIndia#CustomSteelFabrication#EshajiSteelServices

0 notes

Text

How Do Oil and Petroleum Testing Labs Detect Toxicity in Petroleum Products?

Petroleum products power the world, but they also come with potential risks—especially in terms of toxicity. From gasoline and diesel to lubricants and solvents, petroleum derivatives can contain harmful substances that impact human health, ecosystems, and air and water quality. To manage these risks, Oil and Petroleum Testing Lab play a critical role in detecting and analyzing toxicity levels in petroleum products.

Understanding how these labs operate can shed light on their importance in ensuring product safety, protecting the environment, and maintaining compliance with national and international regulations. This blog explores how oil and petroleum testing labs detect toxicity, what techniques they use, and why this process is essential for industries and communities alike.

Why Toxicity Detection in Petroleum Products Matters

Petroleum products contain a complex mixture of hydrocarbons and other compounds, some of which can be toxic, carcinogenic, or environmentally hazardous. If left unchecked, these substances can:

Harm human health through skin contact, inhalation, or ingestion

Pollute air, soil, and water bodies

Damage aquatic life and wildlife

Lead to regulatory violations and legal consequences

That’s why industries from oil refineries to transportation companies rely on accredited Oil and Petroleum Testing Labs to perform detailed toxicity analysis before these products are released into the market or the environment.

What Are Toxic Compounds Found in Petroleum?

Before diving into testing methods, it’s essential to understand the types of toxic substances that labs typically look for in petroleum products:

Polycyclic Aromatic Hydrocarbons (PAHs) Known for their carcinogenic properties and persistence in the environment.

Volatile Organic Compounds (VOCs) Includes benzene, toluene, ethylbenzene, and xylene (BTEX); toxic to humans and can lead to air pollution.

Heavy Metals Such as lead, mercury, cadmium, and arsenic, which pose long-term health risks and bioaccumulate in ecosystems.

Hydrogen Sulfide (H₂S) A toxic gas that can be deadly even at low concentrations.

Phenols and Organic Acids Harmful to aquatic life and corrosive to human tissues.

Key Testing Methods Used in Oil and Petroleum Testing Labs

1. Gas Chromatography-Mass Spectrometry (GC-MS)

One of the most powerful tools in toxicity detection, GC-MS is used to separate, identify, and quantify volatile and semi-volatile organic compounds in petroleum products.

Detects VOCs like benzene and toluene.

Highly accurate, capable of identifying compounds at parts-per-billion (ppb) levels.

Essential for identifying components with carcinogenic or mutagenic potential.

2. Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

Used to analyze metal toxicity in petroleum products.

Detects trace amounts of heavy metals like lead, mercury, and cadmium.

Helps industries prevent equipment corrosion and meet environmental discharge limits.

3. High-Performance Liquid Chromatography (HPLC)

Used to detect non-volatile organic compounds, such as polycyclic aromatic hydrocarbons (PAHs).

Offers high precision in separating complex hydrocarbon mixtures.

Commonly used to assess the long-term environmental impact of spills and leaks.

4. Toxicity Characteristic Leaching Procedure (TCLP)

Developed by the U.S. EPA, TCLP simulates how petroleum waste might leach into groundwater from landfills.

Determines if petroleum waste is classified as hazardous.

Crucial for compliance with waste disposal regulations.

5. Microtox Testing (Biological Toxicity Test)

This bioassay uses bioluminescent bacteria to detect the toxicity of petroleum samples.

Measures how much a sample inhibits the natural light emission of bacteria.

Fast and cost-effective screening method for initial toxicity analysis.

6. Fourier-Transform Infrared Spectroscopy (FTIR)

Identifies the molecular structure of compounds in petroleum products.

Useful for detecting the presence of alcohols, acids, and esters.

Can screen for oxygenated compounds in fuel blends.

Step-by-Step Process of Toxicity Testing in Petroleum Labs

Here’s how a typical Oil and Petroleum Testing Lab approaches toxicity testing:

Step 1: Sample Collection and Preparation

Samples of the petroleum product are collected following strict protocols to avoid contamination. These are often preserved with refrigeration or chemical stabilizers.

Step 2: Physical Property Testing

Before diving into chemical analysis, labs often conduct initial assessments of viscosity, flash point, and density to understand the physical characteristics of the product.

Step 3: Chemical Analysis

Techniques like GC-MS, HPLC, and ICP-MS are used to break down and identify specific toxic compounds.

Step 4: Data Interpretation and Comparison

Results are compared with regulatory thresholds such as:

ASTM standards

EPA limits

REACH and CLP regulations (EU)

ISO testing criteria

Step 5: Reporting and Certification

A final report is issued, often including safety classifications, risk levels, and compliance status. This documentation is crucial for audits, product release, and international trade.

Regulatory Frameworks Guiding Toxicity Testing

Oil and petroleum testing labs must comply with a wide array of global standards, such as:

ASTM D5769: For detecting benzene and toluene in gasoline.

ASTM D323: Vapor pressure test relevant for VOC emissions.

EPA Method 8260/8270: For VOC and SVOC detection in environmental samples.

ISO 11885: Guidelines for heavy metal detection.

REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals.

These frameworks guide labs in determining what tests to perform, how to conduct them, and how to interpret results for regulatory compliance.

The Role of Accredited Testing Labs

Accreditation matters. Reputable labs are typically certified to ISO/IEC 17025, which ensures:

Competence in testing and calibration

Accurate, repeatable results

Compliance with industry best practices

Credibility in global markets

Partnering with an accredited Oil and Petroleum Testing Lab ensures reliable toxicity results that stand up to scrutiny from regulators, buyers, and environmental agencies.

Real-World Applications of Toxicity Testing

Pre-market product approvals – Ensuring fuels and lubricants meet toxicity thresholds before distribution.

Environmental monitoring – Checking for petroleum contaminants in soil and groundwater after leaks or spills.

Worker safety – Identifying hazardous components that may affect employees handling fuels or oils.

Export compliance – Meeting destination country safety regulations for international shipments.

Final Thoughts

Toxicity in petroleum products is not just a chemical concern—it’s a public health, environmental, and regulatory issue. From detecting trace levels of carcinogens to analyzing heavy metals and volatile gases, Oil and Petroleum Testing Labs serve as the gatekeepers of safety.

Whether you're a refiner, distributor, or environmental consultant, investing in certified toxicity testing services ensures that your operations are not only efficient but also safe and compliant with global standards. In a world increasingly focused on health, safety, and sustainability, accurate toxicity detection isn't optional—it's essential.

#oil and petroleum testing lab#oil and petroleum testing#oil testing lab#petroleum testing#testing lab delhi#testing lab near me

0 notes

Text

Mastering Heavy Hydrocarbon Removal: Techniques, Challenges & Innovations

Introduction: What Is Heavy Hydrocarbon Removal?

Heavy hydrocarbon removal refers to the process of extracting or breaking down complex, long-chain hydrocarbons found in crude oil, bitumen, and natural gas.

These heavy molecules are more difficult to refine and can cause operational inefficiencies if not treated properly.

Efficient removal is essential for producing clean fuels, protecting equipment, and ensuring regulatory compliance.

Why Heavy Hydrocarbon Removal Is Essential

Boosts Product Quality

Removing heavy hydrocarbons enhances the quality and consistency of refined products like gasoline, diesel, and jet fuel.

Improves Process Efficiency

Cleaner feedstock means faster, more efficient refining with fewer interruptions.

Reduces Equipment Damage

Prevents clogging and fouling in heat exchangers, reactors, and pipelines.

Meets Environmental Standards

Helps in reducing harmful emissions and complying with environmental regulations.

Increases Economic Value

Adds profitability by converting waste into useful byproducts and improving overall yield.

Key Techniques for Heavy Hydrocarbon Removal

Thermal Cracking

Applies high temperatures to break down large hydrocarbon molecules.

Often used in vacuum distillation and coking processes.

Catalytic Cracking (FCC - Fluid Catalytic Cracking)

Uses catalysts to promote chemical reactions at lower temperatures.

Increases efficiency while reducing energy consumption.

Hydrotreating and Hydrocracking

Adds hydrogen to heavy hydrocarbons in the presence of catalysts.

Produces cleaner, more stable fuel products.

Solvent Extraction

Employs selective solvents to dissolve and separate heavy fractions.

Ideal for removing asphaltenes and other impurities.

Adsorption Processes

Uses adsorbents like activated carbon or silica gel to capture heavy components.

Effective in polishing stages or for low-concentration streams.

Membrane Separation

Filters out heavy hydrocarbons using semi-permeable membranes.

Offers a low-energy, compact alternative to traditional methods.

Innovations Transforming Heavy Hydrocarbon Removal

Advanced Catalysts

Next-generation catalysts offer higher selectivity, greater activity, and longer life.

Reduces operational costs and enhances sustainability.

AI and Machine Learning

Predictive analytics optimize process parameters in real time.

Improves efficiency and reduces human error.

Modular Treatment Units

Skid-mounted systems for on-site hydrocarbon removal at oil fields or remote locations.

Reduces the need for transport and central processing.

Green Solvents

Development of bio-based, non-toxic solvents to minimize environmental impact.

Aligns with ESG (Environmental, Social, Governance) goals.

Plasma-Based Technology

Uses plasma reactors to break down heavy hydrocarbons at the molecular level.

Still emerging but shows great promise for clean energy applications.

Common Challenges in Heavy Hydrocarbon Removal

High Operating Costs

Many processes are energy-intensive and require expensive equipment.

Fouling and Corrosion

Heavy hydrocarbons often contain sulfur and nitrogen compounds that damage equipment.

Process Complexity

Requires precise control and monitoring to maintain consistent performance.

Waste Management

Removal processes generate sludge and other residues that require proper disposal.

Skilled Workforce Requirements

Operating advanced systems demands specialized training and knowledge.

Environmental Impact and Sustainability Considerations

Carbon Emissions Reduction

Cleaner processing leads to fewer CO₂ and methane emissions.

Waste Minimization

Effective heavy hydrocarbon removal turns potential waste into usable fuel fractions.

Water Usage Optimization

New systems aim to reduce water dependency in extraction and separation processes.

Cleaner Fuels Production

Contributes to low-sulfur, low-aromatic fuel standards for marine, road, and aviation sectors.

Applications Across Industries

Refineries

Core application in converting crude oil into transport fuels and petrochemicals.

Petrochemicals

Produces cleaner feedstock for polymers, plastics, and synthetic fibers.

Natural Gas Processing

Removes condensates and heavy components from natural gas streams.

Environmental Remediation

Useful in cleaning up hydrocarbon-contaminated soil and groundwater.

The Future of Heavy Hydrocarbon Removal

Hybrid Systems

Combining techniques like membrane separation with catalytic processes for better efficiency.

Digital Twins

Virtual models simulate operations to predict outcomes and reduce trial-and-error.

Low-Carbon Refining

Integration with carbon capture technologies to make refining more eco-friendly.

Government Incentives & ESG Pressures

Increased investment due to global push toward cleaner energy and sustainable practices.

Conclusion: Mastering the Art of Cleaner Processing

Heavy hydrocarbon removal is no longer just a technical necessity—it’s a strategic advantage.

Companies that invest in modern techniques and sustainable innovations will lead the future of clean energy and efficient refining.

With proper planning, technology, and training, industries can master heavy hydrocarbon removal and drive the shift toward a more sustainable, cost-effective, and environmentally responsible operation.

0 notes

Text

Steel Fabrication Machinery Suppliers in the UAE: Powering the Nation’s Infrastructure

The steel fabrication industry plays a crucial role in the development and growth of infrastructure across the UAE. From the towering skyscrapers that define the skyline of Dubai to the vast industrial plants and oil refineries, steel fabrication is at the heart of construction and manufacturing in the region. The demand for high-quality, precise, and efficient steel fabrication machinery is paramount to meet the rigorous standards of the industry. This article delves into the world of steel fabrication machinery suppliers in UAE, highlighting the significance of their offerings and the impact they have on the country's infrastructure.

The Role of Steel Fabrication in the UAE

Steel fabrication is the process of cutting, bending, and assembling steel to create various structures and components. It is a critical component of construction, manufacturing, and industrial projects. The UAE, with its rapidly growing economy and ambitious construction projects, relies heavily on steel fabrication for everything from residential buildings to complex industrial facilities.

In the UAE, the construction sector alone is a significant contributor to the nation's GDP. The demand for steel products, such as beams, columns, trusses, and custom-fabricated components, is ever-growing. This demand is met by a network of steel fabrication companies that rely on advanced machinery to deliver precision-engineered products.

The Importance of High-Quality Machinery

Steel fabrication is a precise and intricate process that requires the use of advanced machinery. The quality of the machinery directly affects the quality of the final product. In the UAE, where construction standards are among the highest in the world, the need for top-notch machinery cannot be overstated.

The machinery used in steel fabrication includes cutting machines, bending machines, welding machines, and various other tools designed to manipulate steel into the desired shapes and sizes. Each piece of equipment must be capable of handling the specific demands of the project, whether it's creating intricate designs or ensuring the structural integrity of large steel components.

Types of Steel Fabrication Machinery

Steel fabrication machinery encompasses a wide range of equipment, each designed for specific tasks within the fabrication process. Some of the most commonly used machines include:

Cutting Machines: These machines are used to cut steel plates, beams, and other components to the required dimensions. Types of cutting machines include plasma cutters, laser cutters, and oxy-fuel cutters. Precision and efficiency are key in this stage, as accurate cuts are essential for the integrity of the final product.

Bending Machines: Bending machines are used to shape steel into various forms, such as angles, curves, and tubes. These machines are vital for creating components like beams, pipes, and structural elements. CNC (Computer Numerical Control) bending machines are particularly popular due to their precision and ability to handle complex bending tasks.

Welding Machines: Welding is a critical process in steel fabrication, as it joins steel components together to form the final structure. Welding machines come in various types, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and arc welding machines. Each type of welding machine is suited for different applications, depending on the material thickness and the required strength of the weld.

Drilling and Punching Machines: These machines are used to create holes and notches in steel components, allowing for the assembly of structures. Precision drilling and punching are essential for ensuring that components fit together correctly and that the final structure is secure.

Shearing Machines: Shearing machines are used to cut large sheets of steel into smaller, more manageable sizes. These machines are particularly useful for preparing materials for further processing, such as bending or welding.

Roll Forming Machines: Roll forming machines are used to create long, continuous shapes, such as beams and channels, by passing steel through a series of rollers. This process is ideal for producing large quantities of uniform components quickly and efficiently.

The Significance of Local Suppliers

In the UAE, sourcing steel fabrication machinery from local suppliers offers several advantages. Local suppliers are more attuned to the specific needs of the region’s industries, and they can provide machinery that is tailored to the unique requirements of projects in the UAE. Additionally, local suppliers often offer better after-sales support, including maintenance services and the availability of spare parts, which is crucial for minimizing downtime and ensuring the longevity of the machinery.

Another advantage of local suppliers is their ability to offer training and support to operators. Operating complex steel fabrication machinery requires specialized skills, and local suppliers can provide training to ensure that operators are proficient in using the equipment. This not only improves the efficiency of the fabrication process but also enhances the safety of the workplace.

Challenges Faced by Steel Fabrication Machinery Suppliers

While the demand for steel fabrication machinery in the UAE is strong, suppliers face several challenges in meeting the needs of their customers. One of the primary challenges is keeping up with technological advancements. The steel fabrication industry is constantly evolving, with new technologies and techniques being developed to improve efficiency and precision. Suppliers must stay ahead of these trends to provide their customers with the latest and most advanced machinery.

Another challenge is the need to balance cost and quality. While customers in the UAE demand high-quality machinery, there is also pressure to keep costs down. Suppliers must carefully select the machinery they offer to ensure that it meets the required standards while remaining cost-effective.

Future Trends in Steel Fabrication Machinery

The steel fabrication industry in the UAE is poised for further growth, driven by ongoing infrastructure projects and the development of new industrial sectors. As the industry grows, so too will the demand for advanced steel fabrication machinery. Several trends are expected to shape the future of the industry:

Automation: The adoption of automation in steel fabrication is expected to increase, with more companies investing in CNC machines and robotic systems. Automation can significantly improve the efficiency and precision of the fabrication process, reducing the need for manual labor and minimizing errors.

Sustainability: As sustainability becomes a greater focus in the construction industry, there will be a growing demand for machinery that is energy-efficient and capable of working with sustainable materials. Suppliers will need to offer machinery that meets these requirements to stay competitive.

Customization: The ability to customize machinery to meet the specific needs of a project will become increasingly important. Suppliers who can offer flexible solutions and tailor their machinery to the unique requirements of their customers will have a competitive edge.

Integration with Digital Tools: The integration of digital tools, such as Building Information Modeling (BIM) and advanced software for design and planning, will become more prevalent. Suppliers will need to offer machinery that can seamlessly integrate with these tools to enhance the overall fabrication process.

Conclusion

Steel fabrication machinery suppliers in UAE play a vital role in supporting the nation's construction and industrial sectors. Their ability to provide high-quality, advanced machinery is essential for ensuring that projects are completed to the highest standards. As the industry continues to evolve, suppliers will need to stay ahead of trends and challenges to meet the growing demands of their customers. By focusing on innovation, quality, and customer support, steel fabrication machinery suppliers in the UAE will continue to power the nation’s infrastructure and contribute to its ongoing development.

0 notes

Text

The Role of Assaying in Gold Refining: Ensuring Quality Standards

When it comes to the glittering world of gold refining, the crucial process of assaying takes center stage. Assaying serves as the bedrock for ensuring impeccable quality standards in the gold refining industry. In this article, we delve into the significance of assaying, how it guarantees the purity of refined gold, and why it's a non-negotiable step in the refining process.

What is Assaying?

Assaying is a meticulous analytical procedure employed in the gold refining process to ascertain the precise composition and purity of gold alloys. This technique involves subjecting a sample of the gold alloy to various chemical and physical tests to determine its exact properties. By doing so, refineries can accurately determine the gold content, identify any impurities, and make necessary adjustments to ensure the final product meets the desired quality standards.

The Process of Assaying

Sample Collection: A small representative sample is extracted from the gold alloy, ensuring it accurately reflects the entire batch.

Fire Assay: This traditional method involves melting the sample at high temperatures to separate impurities from the gold.

Cupellation: The molten sample is placed in a cupel made of bone ash, which absorbs impurities like lead and leaves behind a button of pure gold.

Gravimetric Analysis: The button of pure gold is weighed to determine its mass and calculate the gold content.

Chemical Analysis: Advanced techniques such as atomic absorption spectroscopy and inductively coupled plasma mass spectrometry are used to identify trace elements and confirm purity levels.

Importance of Assaying

Assaying plays a pivotal role in maintaining the integrity of the gold supply chain. Its significance lies in:

Quality Assurance: Assaying guarantees that the refined gold meets industry standards, ensuring customers receive genuine, high-quality products.

Value Determination: Accurate gold content assessment directly influences the value of the gold, preventing undervaluation or overvaluation.

Compliance: Many countries have strict regulations regarding the purity of gold products. Assaying ensures compliance with these regulations, averting legal issues.

Credibility: Refineries and manufacturers can establish credibility by providing assayed gold with documented purity levels.

FAQs

Q1: Is assaying only used in gold refining?

Assaying is widely employed in various fields, including metallurgy, mining, and jewelry making, to determine the composition of precious metals and other elements.

Q2: How long does the assaying process usually take?

The duration varies depending on the complexity of the sample and the chosen assaying techniques. It can range from a few hours to a couple of days.

Q3: Can impurities be completely eliminated through assaying?

While assaying helps in significantly reducing impurities, achieving absolute purity is practically challenging. The goal is to achieve purity levels that adhere to industry standards.

In the realm of gold refining, assaying emerges as the guardian of quality, purity, and credibility. Through meticulous analysis and advanced techniques, assaying ensures that every ounce of refined gold lives up to its prestigious reputation. This process stands as a testament to the dedication of the industry in providing customers with gold products that truly glitter with authenticity and value.

So, the next time you admire a stunning piece of gold jewelry or a gleaming gold bar, remember that behind that brilliance lies the precise science of assaying, assuring us that the allure of gold is backed by the assurance of quality.

0 notes

Text

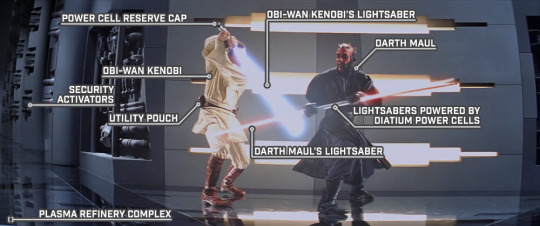

Behind the Back

STAR WARS EPISODE I: The Phantom Menace 02:01:35

The interesting thing in this shot is you can actually see the prop lightsaber used by Ray Park as Darth Maul here, when the "glow" effect is slightly off from the angle of the prop weapon.

#Star Wars#Episode I#The Phantom Menace#Naboo#Theed#Battle of Theed#Battle of Naboo#Plasma Refinery Complex#Duel of the Fates#Obi-Wan Kenobi#Obi-Wan Kenobi's lightsaber#Darth Maul#Darth Maul's lightsaber#power cell reserve cap#security activator#utility pouch#diatium power cell

9 notes

·

View notes

Text

Wow I was? Lucky shot! This is fascinating lore. Considering what happens to Qui-Gon though this can also be rather funny. *Qui-Gon teaching Obi-Wan how to become a force ghost* ok so you need to find seven doors,,,

Also does this imply that the Naboo thought that their plasma refinery complex was hell?

Everyone from Naboo goes to hell when they die.

39 notes

·

View notes

Text

Horizon WIP Post 13

The Story of Enceladus

Enceladus is known as the Second World, the second system liberated from PSSA control in 2223. As the nascent ICM would wrap Titan in their grasp, their attention would soon turn to the icy moon, eager to exploit the strategic position that the subsurface ocean provided. The PSSA, sensing that the Saturn system had begun to slip from their grasp, would dispatch well over 30 ships to help secure it, landing thousands of troops to ensure a strong presence at spaceports and industrial facilities. The ICM, acting as a unified Navy for the first time, would see this not as a deterrent, but a call to arms. For the very first time, they would make themselves known, launching long range volleys at the assets in orbit, using 21 extensively modified Behemoth class cruisers. The PSSA, initially, was skeptical of their ability to engage, but soon found that ICM tactics were unlike anything they had ever seen. Shot after shot was fired from the ICM position, staged just inside the terminator. The line held, for now, but all would change when a bold crew, the crew of the ICM Destroyer Gargantua, would make a break for it, charging headfirst at the central grouping of vessels, taking shell after shell. Their crew were most likely dead before they made it to the line, but they were, in the eyes of the ICM, a necessary sacrifice. Their fusion reactor, primed to explode in proximity to the PSSA forces, would rupture in a cloud of plasma, disabling at least 7 PSSA ships, enabling ICM forces to charge towards a now confused and weakened enemy. It was the shot that the ICM needed, and the remaining 20 ICM ships would scatter the PSSA Navy, destroying 19 of the 30 ships in orbit - sparing no one. Transports, clearly trying to make a run from the fighting, were captured by slower boarding craft rising from Titan’s surface, and all of those in uniform would be taken back to the ICM capital for incarceration. The moon would fall quickly, and landing teams would soon secure the capital city, capturing and executing those who occupied her. With PSSA forces in retreat to Mimas, the ICM flag flew over Diyar Planitia for the first time.

Growth on Enceladus would be rapid, and almost chaotic. New shipyards, water refineries, and soil production facilities would spring to life, and geothermal vents would be tapped for power. Construction crews would face a harsh radiation and cryogeological environment, with losses mounting in the first years after the invasion. The Great Dying was most felt here, in the harsh outer fringes of ICM territory, but the message from the State was clear - the work must go on, the factories must churn out machine after machine. It was a matter of survival. The great grooves of Enceladus would be carved into channels for cargo, and a robotic spiderweb of industry would begin to occupy the surface. Anyone with a powerful enough telescope could see the surface of the world changing before their very eyes. Tycho Drive Yards became the centerpiece of ICM construction on Enceladus, a monument to industry and military might. It would be here that the first indigenous ICM ships would be built, great behemoths that would hope to one day rival the might of the PSSA’s ever growing military complex. Soldiers would report to this icy world to train, and its ferocity and might would become something of legend throughout ICM culture. It was a harsh and cruel world, but it was a necessary world. An ever vigilant reminder of their power.

#horizon#space#alt future#alt history#science fiction#hard science fiction#story#worldbuilding#ICM#PSSA#sci fi#wip#science#combat

10 notes

·

View notes

Text

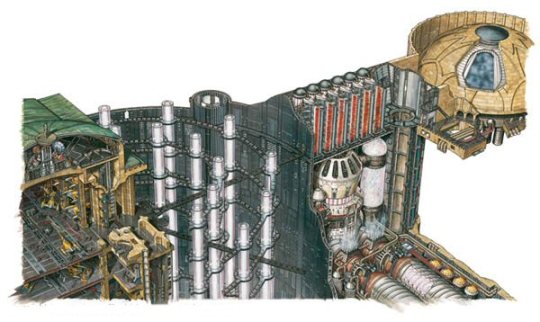

TPM Week 2018, day 5: Favorite location ⇥ Theed’s Plasma Refinery Complex

It’s not the most beautiful location of the movie (I would put the palace before, or Gunga City, Theed’s streets, or the coziness of Anakin and Shmi’s home), it even has an oppressive atmosphere because of Maul’s visit and Qui-Gon’s death, but I think the set was really well conceived.

First, there is the fact that it includes the city’s main power generator. It’s Theed’s heart. But also a place that feels like we’re not supposed to be here. The colors change when we follow the Jedi in there: from golds and coppers we go to blue, grey, black. The place is a little scary, or at least intimidating, and it must be quite impressive to actually be there, what with the heights (and no guardrails, we die like clumsy idiots) and the energy that is held here. Of course, the Jedi don’t care and just fight around, but it’s Jedi Business. Heart of the city, but also core of the story. The plasma that is drawn and exported from the planet was a cause of the tensions with the Trade Federation that lead to the blockade and invasion.

It also goes well with the idea that Obi-Wan is passing a trial (even if we only see it that way afterwards, when he is knighted after his Master’s death and not during the fight itself): the place looks a lot like a location from a video game… Here’s the map:

On the left, the hangar. The room where you can come and leave, as opposed to the following corridors and sections and the final dead-end on the right, that are similar to the several steps to take before really fighting the boss of the dungeon.

It’s not a welcoming place. It’s not habitable or livable. It’s only what keeps the city alive. It’s the backstage. It’s powerful, necessary, but dangerous.

I also like to read it as a kind of representation of the Jedi mind… In ROTS, Mustafar is Anakin, in AOTC, Geonosis’ Arena is Padmé, and in TPM, Theed’s plasma refinery complex is Obi-Wan. Qui-Gon and him were separated during their fight against Maul by those laser gates that are meant to protect, but didn’t turn in the Jedi’s favor in this occasion. Obi-Wan was stuck behind them and couldn’t do anything. The Jedi teach to let go, to release one’s feelings to the Force, to meditate to put order into one’s mind, to separate to avoid confusion. It’s like the red doors: duty and feelings, for example, are not meant to be together. If you’re in one, the other will be closed. In this scene, we see Obi-Wan struggling to be a Jedi. He acts like Maul, he lets his feelings get in the way, he loves, he hates, and he’s young. He is trying to be a good Jedi and to put his doors in place — but loosing Qui-Gon is what entails, because attachment is forbidden. It’s as if he wasn’t able to get beyond the last door in time because he was struggling with the detachments he had to make. The door bothered him, and that’s what had him fail. (It will be the same years later with Anakin. Kriffing Jedi doors.)

#Star Wars#I am trying.#tpmweek2018#day 5#Naboo#Obi Wan#Qui Gon#Jedi Business#not the Jedi way#Theed#plasma#Am I only saying idiocies?#I hope not...#sorry!#meta#SW meta#worldbuilding#scratch that (as in write it down please)

21 notes

·

View notes

Text

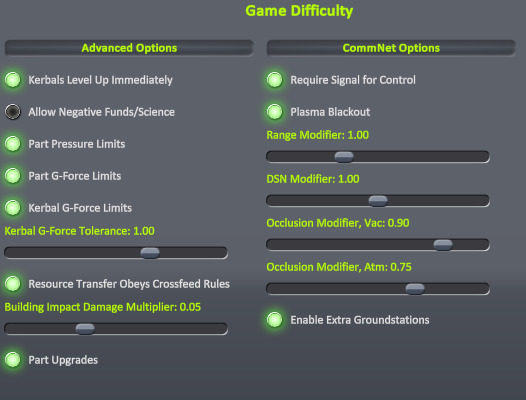

In Space Nobody Can Hear Your Dyson

Well.

I did say we'd fail again, didn't I? Just... not yet.

With a resolve to get back to structured writing, my initial plan here is to do the thing and run the Joolian mission that I have failed to complete so many times before. Why is it going to work this time, you ask? I think I have probably learned just barely enough corporate discipline over the last five years to sit down and "enjoy work" doing something like this.

"I'm gonna be the guy" as the quote goes.

The Vision

I will prepare a new save game to enable me to run a "grand tour" of the Jool system; the tour will land on the surface of all Joolian moons, collect a large amount of science, and otherwise "prepare Jool" to be further exploited for science.

After several rounds of running through a simple bullet-point plan, here is the rough layout of the progress plan for this save:

1. Orbit and standard early game

This category contains nothing exciting, this is the usual sounding rockets leading to ballistic flight to orbit.

Key details:

Stay $ positive

Every mission must earn science

Try to get every initial crew member 1 star

Ships under 25k in price, 30 parts, 16t

2. Local communication: Mun/Minmus communications

Here I anticipate needing to set up communications networks for probes, as for this stage I have shut off partial control without signal.

Key details:

Upgrade to DSN-1

Deliver probes to Minmas and the Mun that maintain 100% contact to the surface at all times.

Do not die of boredom

Experiment with satellite contracts again

3. Local science: Mun/Minmus flybys, single-use probes

This stage will be the first notable attempt to reach the surfaces of Minmas and the Mun, ideally combined with lucrative contracts.

Key details:

Cheap probes

Do as many missions as humanly possible

Don't take the materials bay with probes? Experiment with the science canister.

Experiment with rescue contracts

4. Science station at Minmus

The last two or three times I have played Kerbal Space Program, I only just began to wrap my head around the slow drip-feed of science offered by science stations. I love it. This time we go whole hog.

Key details:

Cost is no object

Docking ports critical

Have PPD-10 to circulate crew

Upgrade R&D (450k)

Generate a ton of electricity

Some in-orbit construction may be required (wee!)

Experiment with Station contracts

5. Refuelling at Minmus (Miner, Tanks, Refinery)

Key to ferrying scientists back and forth and collecting great piles of data from Minmas is a lander than we can refuel. At this stage I'll be anticipating delivering a large fuel tank, a refinery component, and a land-and-return mining vessel to bring ore up for processing.

Key details:

I have savaged myself with debate over this step.

Tanks are self explanatory, likely two missions delivering empty or partially empty tanks to the science station to connect up.

A "primary hub" connector - some kind of jury-rigged HubMax with crossfeed enabled.

1 Tiny space tug that's cute as a button

Refinery. Urgh. This debate grew so troublesome I reframed the question as a thought experiment and framed it to some of my developers at work (what!? some people waste company paper printing stuff out, I waste 15 minutes of time making our chief security officer and lead application architect help me solve KSP problems) on whether or not... well, I'll get into this later. For now, the Refinery will be attached to the station.

Mining ship. I really miss the old BEAST model ships from right after resourcing was released in KSP, I'll see if I can find a screenshot because it is a real monstrosity.

I may explore a surface base idea but... man there's too many options here. I'm not a creative person, I'm an optimiser of other people's ideas (proof more than ever that I am a manager).

6. Tanker to Kerbin / Kerbin fuelling point

Once we have the Minmus station running at an acceptable capacity (more on this) we'll be setting up a reusable tanker that will likely double as a refuelling point in low Kerbin orbit.

Key details:

A simple ship with no pilot for moving fuel around.

A low-cost station around Kerbin (maybe I'll put a science segment there?) capable of housing more fuel than is ever neccessary. (2 orange cans)

1 Tiny space tug that's as cute as a fuzzy baby kitten.

7. Upgrade local communications: Eve and Moho coverage

I hope by this point I will have found whatver I guide I once did on evenly distributing satellites, otherwise I'll be taking C4 up to existing satellites and replacing them with superior ones.

Key details:

Cost is no object, but unlikely to be notable anyway.

I think I will be replacing the existing satellites, so I'm glad I'm launching my current "DSN" (LSN really, local space network) with extra fuel in the tanks for deorbiting.

Minimum DSN-2

Minimum 1x RA-15 relays (this + DSN-2 will get me 27.39 gm range, 18% str at moho max range and 5% at eve)

Signal Strength Calculator and Antenna Selector

KSP RemoteTech Planner

8. Inner Planet exploration: Eve and Moho

This isn't really exploration, there will be no kerbinned (as opposed to manned) landings at this point, I am hoping to send several probes to each world for the purpose of science, leaving DSN relays in orbit, and lastly to deliver scansat probes.

Key details:

This will be a fairly critical test run of the sort of mission that will be going to Jool.

I'm not really familiar with the impact of DSN on probe operations, so I will need to accept some huge risks regarding the quality of science that I can get returned from these missions. I'm likely to be caught off guard when Kerbin moves behind the sun.

These will be expensive missions including maximum number of science parts.

9. Fuel and Science stockpiling

At this point there's going to be a lot of fast-forwarding while I do the least fun part of a long Kerbal Space Program playthrough like this - smashing the "transmit science" button and then mining ore over and over until all the tankers are full and I have all the research I need.

Key details:

Busywork.

10. Expand the DSN, Jool coverage

Same deal as step 7, but even bigger dishes.

Key details:

Not much to say here, the network is being upgraded to host at least 1 RA-100 on each commsat (6% min strength at Dres, 50% at Duna)

Ideally I'll hit DSN-3 as well

11.Outer Planet Exploration: Dres, Jool, Duna

A similar idea to step 8 for Dres, but for Jool a bit different: For Jool I'm very much going to prioritise communication and refuelling as my first mission out there, the full tour comes later. Then I'll send a brace of Joolian probes out to get things started. For Duna, well, in all my years of playing KSP I think the last time I sent a kerbinned mission to Duna and returned it would have to be quite far back before 1.0. Time to do it again.

Key details:

I'll get you yet, Tylo.

Nervous about the prospect of the Duna mission as basically all the difficulty settings are on and if I mess up this is not a flight that can be easily reverted.

The rest is fairly standard at this point, I'll be retrofitting/upgrading the probes sent to Eve and Moho to reach the outer planets, further pushing me into the comfort zone of Jool.

12. Refuelling at Pol or Bop: (Miner, Tanks, Refinery)

Once the "exploratory" phase ends for Jool I'll be sending the heavy equipment out to set up shop to wait for the inevitable Joolian explorers.

Key details:

A revised version of the likely very dated miner still running on Minmas at this point. Except 50+ gm away.

13. We do the thing.

Key details:

Am I person enough to handle this?

We'll talk about this stage when we get to it.

Other thoughts, apprenhensions, general notes

I think hate Tylo. I think I will take a disposable lander to Tylo. This violates the very notion of the grand tour in a single reusable ship.

Do I need to stop at Dres and set up a DSN at cardinal points around it's orbit? Dres wobbles between 35gm and 46~gm from Kerbol, and sets us up in the "middle" of the Kerbol system. Would be a big time sink to set up.

Will massively upgraded satellites around Kerbin do the job of getting me to 90%+ signal strength at Jool? Hence why I am thinking about the problem above.

Should I do a Jool sample return mission with an automated probe first, just to get a sense of the timeline?

I should really output a Gantt Chart for this

Mods in use

AmpYear - power management Chatterer - I like it DockingPortAlignmentIndicator - it's good ForScience - Debating this one, I definitely want something that makes science more obvious

KAS (Kerbal Attachment System) - I have primarily played stock since I started with KSP, this is one of the most popular non-stock mods of all time, I should fiddle with it.

KIS (Kerbal Inventory System) - exact same reason as KAS, but it's a bit newer

MechJeb 2 - I have flown a mission from the surface of Kerbin to the surface of the Mun, locked in cockpit only, in real time, I have earned this. Pardon my language but Fuck you I have 700 hours in KSP and anyone who says "Mechjeb is cheating" is a chode who is clearly a terrible person.

PlanetShine - I like the way it looks. It brings to life Kerbol's planet's albedo.

RealisticAtmosphere - I like the way this looks as well. Makes atmospheres around planets look nicer on approach.

RealPlume - More visual mods! Makes rocket engines nice.

ReentryParticleEffect - Makes reentry look better, sparks, plasma stream, etc.

ScanSat - Just curious more than anything. SXT (parts) - Just the RTG, solarHex, and Minigoo parts. The minigoo part is the greatest part ever invented by anyone ever.

KerbalAlarmClock - Needed.

Kerbal Kolonization - Giving it a try, I like some of the parts but don't plan to build colonies.

Kronal Viewer - only works in 32-bit, apparently, but I may use it to take some screenshots of more complex ships build in the mid and late-game.

Difficulty Settings

2 notes

·

View notes

Text

Durable and corrosion resistant filtration screens for high temperature applications

Precision woven meshes are produced in different types of weaves. Plain square weave is available for simple sieving applications through different weave techniques. Dutch twill weave is used for the wide variety of surface filtration applications.

High tensile strength Inconel mesh screens offer good permeability and are available in single wrap to complex multi layered structures. They can be produced in diffusion bonded types to increase performance security of pore shape and size and have the wide range of pore sizes of any filter media type. These filter screens are also provided in different configuration such as sintered metal fiber, woven wire mesh and other types.

Features and advantages

Cartridges: Mesh is a robust, non-shedding media which offers resistance to mechanical abrasion.

Different types of weaves: Available in plain square mesh, reverse plain dutch, broad mesh twill, single plain weave and dutch twill weave to provide the absolute rating.

Precise aperture: The meshes are made to precise aperture demands of both size and shape

Single layered designs to multi-layered structures” These can be produces in a wide range of layer combinations based on the specific grade and micron requirement

Higher filtration area : The mesh structure allows the reduction of the count of cartridges and overall footprint of the configuration

Smooth surface: The production process of these mesh screens enables us to achieve a smooth surface. It is commonly demanded in backwash applications.

Applications of woven wire mesh screens

Catalyst recovery and retention: For application of removing catalyst dust on different catalyst hoppers or FCC reproducer stream on refineries

Chemicals and Gas production: To clean syngas from pet coke, IGCC trains and others, for the formation of hydrogen and other chemicals.

Vent filters: To control dust emission in different industrial applications.

Agrochemical: Usually for ammonia systems used on nitric acid and urea plants

Steam: Applications in chemical, food, beverage and pharmaceutical plants

Pharmaceutical recovery: For medium pressure applications in blenders and dryers

Polymer melt: To filter hot polymers for use in the production of artificial polymer films, fibers and bottles.

The filter cartridges and elements are made in different materials varying from stainless steels to high temperature corrosion resistant grades such as Monel, Inconel and Incoloy grades. The cartridge designs involve a precision pack to provide protection and act as support mesh on either side of the fitler medium, around a support core to provide effective filtration area of the cylindrical element. The filter media and support meshes are plasma or TIG sema welded and media support core and fittings ensure integral cartridge preventing the risk of bypassing and the presence of extractables derived from bonding agents. The production method of mesh screens enables their use at diverse temperature ranges varying from -269oC to 1000oC and up to 25 bar. Higher service temperatures and differential pressures can be accommodated by design.

These screens are usually made of different grades such as SS 316, Inconel, Hastelloy, FeCrAlloy depending on their applications.

0 notes