#Precision turned components

Explore tagged Tumblr posts

Text

#stainless steel dowel pins#stainless steel dowels#precision turned components#small turned parts#Stainless Steel Shafts#Stainless Steel Axis#Stainless Steel Pin#Precision Pins#Grooved Pin#Knurled pins#ss shaft#ss pins

2 notes

·

View notes

Text

Exploring the Uses of Precision Turned Components

Looking to understand where and how tiny, super-accurate parts are used in big industries? Check out our blog Exploring the Uses of Precision Turned Components! It’s a simple and interesting read that shows how these small parts power machines, vehicles, gadgets, and more. Don’t miss it give it a quick read!

0 notes

Text

Precision Machined components manufacturers in india

Sanmati Components is one of the leading Precision Machined Components Manufacturers in India. Contact us for Precision Machined Parts Manufacturers and Critical Machined Components in India https://www.sanmaticomponents.com/precision-machined-components-manufacturer-india-machined-components-manufacturer.php

0 notes

Text

Precision Turned Components: Ensuring Quality and Consistency in Mass Production

Precision turned components are integral to numerous industries, including automotive, aerospace, electronics, and medical devices. In mass production, ensuring the quality and consistency of these components is critical, as even minor imperfections can lead to significant performance issues. With growing demand and stringent industry requirements, manufacturers must adopt advanced techniques to maintain high standards in mass production. This blog explores how precision turned components manufacturers ensure quality and consistency throughout the production process.

1. Importance of Quality and Consistency in Mass Production

Mass production of precision turned components requires adherence to tight tolerances and exact specifications. In industries where precision is critical, such as aerospace or medical devices, even the slightest deviations can lead to malfunctioning parts, safety hazards, or costly rework. Ensuring consistency across large production volumes guarantees that every component functions as expected, reducing the risk of product failures and enhancing customer satisfaction.

2. Utilizing Advanced CNC Machining for Precision

Computer Numerical Control (CNC) Machining is the backbone of modern precision turned component manufacturing. CNC machines offer unparalleled precision and repeatability, allowing manufacturers to produce components with exacting specifications repeatedly. These machines can operate continuously, reducing human error and ensuring that each part is identical to the next.

Manufacturers also utilize multi-axis CNC machines, which allow for complex geometries to be produced without needing multiple setups. This increases efficiency while ensuring that quality remains consistent throughout the production process.

3. Implementing In-Process Quality Control Systems

In mass production, quality control cannot be limited to post-production inspections. In-process quality control systems are essential for ensuring that potential issues are detected and corrected in real-time. By integrating sensors and monitoring technologies within CNC machines, manufacturers can identify deviations from tolerances as they occur, allowing for immediate adjustments.

Advanced measurement tools, such as coordinate measuring machines (CMM) and laser scanners, are often employed to verify that components meet precise specifications. This real-time feedback loop minimizes defects and improves overall product consistency.

4. Standardizing Processes and Workflow

Consistency in mass production relies on standardized processes and workflows. Manufacturers establish standard operating procedures (SOPs) for every step of the production process to ensure that each operation is carried out uniformly. These SOPs cover everything from material handling and machine setup to tool maintenance and quality checks.

By implementing lean manufacturing principles, manufacturers can streamline production processes, reduce waste, and ensure efficient use of resources. This results in a more consistent output, where every component produced meets the desired quality standards.

5. Investing in High-Quality Materials and Tooling

Material selection plays a critical role in maintaining the quality of precision turned components. Manufacturers must ensure that they source high-quality materials that offer consistent properties across the production batch. Variability in materials can lead to machining inconsistencies, resulting in defects or performance issues in the final components.

In addition to materials, manufacturers also invest in high-quality tooling and cutting tools. Well-maintained and sharp tools are essential for producing clean cuts and accurate dimensions, especially in mass production. Regular tool maintenance schedules and replacement plans help prevent tool wear from affecting component quality.

6. Statistical Process Control (SPC) for Ongoing Monitoring

Statistical Process Control (SPC) is a data-driven approach to monitoring and controlling manufacturing processes. SPC involves collecting data on key process parameters, such as dimensions, tolerances, and surface finish, and using statistical analysis to detect variations. By analyzing this data, manufacturers can identify trends and make necessary adjustments to prevent defects before they occur.

SPC helps manufacturers maintain consistent quality over long production runs, ensuring that each precision turned component meets the required specifications. The use of statistical methods allows for greater control over the process and helps identify potential problems early in the production cycle.

7. Continuous Training and Skill Development

Even with the most advanced machines and processes in place, skilled operators are essential for ensuring quality and consistency. Manufacturers invest in the continuous training and development of their workforce to keep them up-to-date with the latest technologies and best practices in precision turned component manufacturing.

By empowering their team with the knowledge to troubleshoot issues, operate CNC machines efficiently, and adhere to quality standards, manufacturers can enhance the overall quality of their mass-produced components.

Conclusion

Ensuring quality and consistency in mass production of precision turned components is a complex task that requires a combination of advanced technology, rigorous quality control measures, and standardized processes. Manufacturers who invest in CNC machining, in-process quality control, high-quality materials, SPC, and continuous training can achieve the level of precision and reliability needed to meet the demands of high-performance industries. At Meck Industries, we are committed to delivering precision turned components of the highest quality. With our advanced CNC capabilities, robust quality control systems, and dedication to excellence, we ensure that every component we manufacture meets the stringent requirements of our clients, no matter the production volume.

#precision turned components#precision turned components manufacturer#precision turned components manufacturer in india

0 notes

Text

CNC Machined Parts in Ahmedabad

Scharf Precision Engineering is a leading provider of CNC machined parts and components in Ahmedabad. We specialize in CNC machined parts as per customer requirements with international standards. We have been serving clients from different industries including aerospace, military, energy and electronics.

#CNC Machined Parts#Precision Turned Components#CNC Machined Components#Custom Machined Parts#CNC Machined Parts Production#Ahmedabad

1 note

·

View note

Text

Enhancing Manufacturing Efficiency: 5 Compelling Reasons to Utilize Precision Turned Components in India

Utilizing precision turned components in your power transmission systems offers numerous benefits. While the initial costs may be higher, this extra investment typically yields returns in terms of enhanced efficiency, increased productivity, and reduced maintenance and downtime. Components offered by Turned Components Manufacturers Mumbai, India have the potential to reduce your recurring operational energy expenses by diminishing friction and heat wastage, all while maintaining the capacity to generate equal power output when operating at reduced speeds.

0 notes

Text

How are Precision Turned Components Manufactured?

Precision machined components get their name because they apply precisely and produce the expected results when used in a machine. These components are essential for modern manufacturing because modern precision devices must attain incredibly small tolerances and exact fittings.

The idea of precise machining is not new, but with the development of computers and software, the manufacturing process has added a new degree of accuracy, fit, and tolerance. This category includes all machining operations, including turning, milling, drilling, honing, grinding, and other operations, all of which benefit from CAD and CAM software.

Sketch/drawing

Obtaining the drawings, technical specifications, and parameters for the parts is the first step in making precision turned components. As the design is input into the computer system, all that is required to begin is a sketch with the appropriate markings. Before being submitted for approval, a drawing provided by the customer is revised internally.

CAD

The technical specifications are entered into the computer-aided design software because a sketch or drawing by itself won't enable a precise manufacturing process. As opposed to a 2D depiction, which makes it impossible to see around bends, slits, and difficult-to-reach areas, CAD software enables 3D rendering of the drawing. After the redesigning is finished, the machine parts manufacturer in Texas sends the revised sketch and the 3D design for final approval.

Machining

The customer's consent is required before the machining process may start. Precision machining, sometimes known as CNC machining, is performed differently than on a standard lathe. The machine uses the input data to build precise cuts, drills, holes, bevels, and threads that give the blanks the desired shapes in accordance with customer specifications.

Post-machining

The work is not finished simply by drilling, cutting, or imparting the necessary shapes to blanks. Some of the things that need to be examined during the post-machining process are deburring, inspection, and dimensional integrity. After everything is completed, each part is given a final check to ensure that it complies with the plans before being produced as exact machine parts.

After the process

While the technological requirements for producing precisely machined components are important, it is also important to emphasize the value of a human operator who is familiar with the CNC process and precision machining. Despite the fact that CNC machines can operate independently, it is essential to have a supervisor to make sure that each item conforms to the tolerance parameters specified for that particular part.

Mastering precision

Precision-turned components are vital in modern manufacturing. They are made with meticulous sketches and technical specifications. Transformed into 3D designs via Computer-Aided Design (CAD) software, these blueprints guide the manufacturing process.

Advanced CNC machining techniques, driven by these designs, craft intricate cuts, holes, and threads with utmost accuracy. Post-machining, rigorous inspections using tools like coordinate measuring machines guarantee dimensional integrity and flawless finishes.

Integrating human expertise, technological precision, and stringent quality checks, manufacturers ensure every component meets exact specifications. This synergy between human skill and cutting-edge technology defines the art and science behind precision turned components that shape diverse industries worldwide.

Resource Box

Buy precision machine components from Arek Solutions because they are a reputed precision machining parts manufacturer who meticulously crafts parts to provide you with components with accuracy. You can buy turned parts for any industry from Arek Solutions.

#precision machined components#precision machining parts manufacturer#precision turned components#machine parts manufacturer texas#machining components

0 notes

Text

baking never feels more like science to me than when i'm trying to cobble together an intricate multi step recipe together from several different recipes and tutorials online because the recipe I'm imagining doesn't exist....

#genuinely feels like a science experiment making something fancier than a frosted layer cake#have to do all kinds of volume and weight conversions because one recipe is japanese and the other is indian and the other is english lmfao#none of the recipes are probably the exact volume I need so i might have to make some minis with my extra stuff#i have to find a very precise sheet pan size tomorrow for the patterned cake i'm gonna use as the outer bit#otherwise i'll have to make my own from parchment paper??? or tin foil??? man idk.....#i had to write out all of my instructions and ingredient lists so i don't have to go between 6 different websites tomorrow/sat#i had to do research on fucking. gelatine 😭because it's impossible to find gelatine sheets here and they're used in EVERY mousse recipe#and there's apparently a huge debate on what the ACTUAL conversion of sheet gelatine to powdered gelatine is for baking#I also had to type up like an exact order to make each component because most need a significant amount of cooling time#grayson im gonna try my hardest to make you this fancy ass lemon cake and i pray i succeed this time where i failed on my own birthday#2 yrs ago but also i think this will go better bc i'm not doing a jelly insert or a candied mirror glaze#I'm also making my own candied lemons and lemon curd even though i don't have to#mostly because i wanna try doing it and the sheer power of getting to say i made the whole thing from scratch *#minus the actual cake mix because i don't have a good from scratch cake track record and box mixes are so so reliable#and i have too many moving parts to worry about finding a new cake recipe#every fucking cake recipe now is a fucking genoise sponge for SOME REASON#which is NOTORIOUSLY DIFFICULT AND A HUGE PAIN IN THE ASS BECAUSE IT USES NO RISING AGENTS#i want to throttle whoever it was that made online recipe people turn to only using variations of a genoise sponge for their cake recipes#honestly i need to maybe join the baking subreddit and ask for some good old baking/cookbooks with reliable baking recipes#ones that aren't crazy labor intensive for fucks sake i'm not a french patisserie#my stuff#it would be cool to one day have baked enough and have enough know how of how standard baking recipe components work#so i can just come up with my own recipes on my own#and just use whatever flavors i want#i feel like i would enjoy being a baker except if i had to make wedding cakes

9 notes

·

View notes

Text

#Stainless Steel Pin Manufacturer in Delhi#Stainless Steel Pins Manufacturer#Hinge Pins Manufacturer#Dowel Pins Manufacturer#KNURLED PINS Manufacturer#Precision CNC Turned Component Manufacturer#Precision Turned Component Manufacturer

2 notes

·

View notes

Text

Benefits of Using CNC Turned Components in Modern Manufacturing

Discover the top 5 benefits of using CNC turned components in modern manufacturing, including precision, efficiency, and cost-effectiveness for enhanced production quality.

#CNC Turned Components Exporter in Mumbai#CNC Turned Components Manufacturer in Mumbai#Precision CNC Turned Components#Precision VMC Milling Components

0 notes

Text

CNC Machining Manufacturer in Pune – ANJALI T. PRECISION

In the ever-evolving world of manufacturing, precision, efficiency, and innovation have become the pillars of modern industry. Pune, often referred to as the engineering and manufacturing hub of India, is home to several leading CNC machining companies. Among them, ANJALI T. PRECISION stands out as a trusted name in the field of CNC Machining and precision components manufacturing.

Who We Are – About ANJALI T. PRECISION

Established with a vision to deliver world-class CNC machining services, ANJALI T. PRECISION has earned a solid reputation as a leading CNC Machining Manufacturer in Pune. Our company is known for its commitment to quality, advanced technological infrastructure, and client-centric approach. With years of industry experience, we have been consistently delivering high-precision, complex, and cost-effective components to diverse industries including automotive, aerospace, electronics, defense, and industrial equipment.

What is CNC Machining?

CNC (Computer Numerical Control) Machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It enables the creation of precise and complex parts with tight tolerances and smooth finishes.

At ANJALI T. PRECISION, we specialize in:

CNC Turning

CNC Milling

VMC (Vertical Machining Center) operations

Drilling and Tapping

Custom CNC Machining Solutions

Our Services

1. CNC Turning and Milling

Our state-of-the-art CNC turning and milling machines produce high-accuracy components for critical applications. We work with a wide range of materials including stainless steel, aluminum, brass, copper, and various engineering plastics.

2. Prototype to Production

Whether it's a single prototype or full-scale production, we have the expertise and resources to support both short-run and high-volume requirements.

3. Custom Component Manufacturing

We specialize in customized parts as per client drawings and specifications. Our skilled engineers and machinists ensure top-notch output at every stage.

4. Quality Inspection and Assurance

Our in-house quality control processes include 3D measuring tools, surface roughness testers, height gauges, and other advanced inspection instruments. We strictly follow ISO quality standards to ensure zero-defect products.

Why Choose ANJALI T. PRECISION?

✔ Advanced Infrastructure

Our modern manufacturing facility in Pune is equipped with cutting-edge CNC machines and tools, allowing us to meet the most demanding machining requirements.

✔ Experienced Workforce

We have a team of highly trained engineers, CNC programmers, and operators who are passionate about delivering perfection.

✔ On-Time Delivery

We understand the importance of deadlines. Our streamlined workflow ensures timely deliveries without compromising on quality.

✔ Competitive Pricing

By optimizing our operations and processes, we offer the most competitive rates in the industry.

✔ End-to-End Solutions

From design review and raw material sourcing to machining, finishing, and final inspection – we offer complete CNC machining solutions under one roof.

Industries We Serve

Automotive

Aerospace

Medical Equipment

Defense & Military

Textile Machinery

Robotics & Automation

Electronics & Electrical

Heavy Engineering

Customer-Centric Approach

At ANJALI T. PRECISION, every client is important. We believe in building long-term partnerships based on trust, transparency, and technical excellence. Our support team ensures clear communication, quick response times, and personalized services to meet your project goals.

CNC Machining in Pune – The ANJALI T. PRECISION Advantage

Pune’s strategic location, skilled workforce, and proximity to major OEMs make it an ideal hub for CNC machining. With ANJALI T. PRECISION, you're not just hiring a manufacturer; you're partnering with a team that is committed to engineering excellence and precision craftsmanship.

Contact Us

ANJALI T. PRECISION – CNC Machining Manufacturer in Pune 📍Address: Gate 1652, 3M Industrial Estate, 1652, Dehu - Alandi Rd, Patilnagar, Chikhali, Pimpri-Chinchwad, Maharashtra 412114 📞 Phone: 092256 34833 📧 Email: [email protected] 🌐 Website:https://www.anjalitprecision.com/

Looking for a Reliable CNC Machining Partner in Pune?

Contact ANJALI T. PRECISION today and let us help you turn your designs into high-quality, precision-engineered reality.

#CNC Machining Manufacturer in Pune#CNC Machining Services Pune#Precision CNC Components#CNC Turning and Milling Pune#Custom CNC Parts Manufacturer#VMC Machining Services#CNC Job Work Pune#CNC Precision Engineering#Anjali T. Precision Pune#CNC Components Supplier India.

0 notes

Text

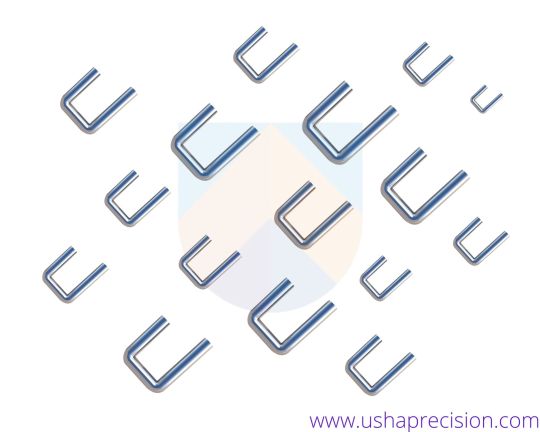

Usha Precision

We possess well-equipped production units with skilled employees, which are backed by latest technology and sophisticated machinery.

#U-Pins#Semi Tubular Rivets#precision turned components#stainless steel suppliers#metal manufacturing#stainless steel fabricators near me#stainless steel manufacturers#stainless steel fabricators

0 notes

Text

Precision Turned Components – Quality You Can Trust!

Start exploring high-quality Precision Turned Components with Usha Precision Products Pvt. Ltd.! We make strong and Switches parts for many industries. Our products help machines work smoothly and last longer. With great care and top materials, we ensure perfect results. Trust us for the best precision parts. Let’s build the future together!

0 notes

Text

GK Metals - Brass Parts Manufacturer in Jamnagar, India

GK Metals is a leading brass parts manufacturer in Jamnagar, India. With our expertise, advanced technology, and commitment to quality, we offer a comprehensive range of brass components to meet diverse industrial needs. Contact us today to discuss your project requirements.

#brass components#brass parts#precision brass components#brass components manufacturers in Jamnagar#brass parts manufacturer in jamnagar#brass parts exporters in jamnagar#brass turned parts jamnagar#precision brass turned components#brass turned components#brass precision turned components

0 notes

Text

Jamnagar: India’s Hub for High-Quality Brass Components

India is renowned for its robust manufacturing sector, and the brass components industry is no exception. Among the top hubs for brass fittings and brass components manufacturing in India, Jamnagar stands out as a key player. Known as the "Brass City of India," Jamnagar is home to numerous manufacturers producing a range of products, from brass fittings to brass precision turned components.

Why Jamnagar Leads in Brass Manufacturing

Jamnagar’s success in the brass components industry is driven by several key factors:

Strategic Location: Located near the coast of Gujarat, Jamnagar benefits from easy access to raw materials and major shipping routes, making it an ideal location for both manufacturing and brass pipe fittings manufacturing.

Skilled Workforce: Jamnagar has developed a highly skilled labor force, specializing in brass turned components and brass fittings. The workforce’s expertise ensures the production of high-quality, precision products.

Raw Material Availability: The proximity to raw materials plays a critical role in Jamnagar’s dominance in the industry, ensuring a steady supply for brass components manufacturers.

Established Ecosystem: The city has created a strong ecosystem for brass plumbing fittings and brass tube fittings, with supporting industries in plating, polishing, and machining, which are essential for producing top-tier brass components.

Brass Precision Turned Components: A Key to Industrial Success

Brass precision turned components are at the heart of industries requiring high durability and accuracy. From automotive to telecommunications, sectors across the globe rely on these components for smooth operations. Manufacturers in Jamnagar, including industry leaders like Atlas Metal Industries, are known for producing components that meet international standards of precision, making them essential in high-precision applications.

Atlas Metal Industries: Your Trusted Brass Components Manufacturer

As a leading brass fitting manufacturer in India, Atlas Metal Industries plays a pivotal role in the industry. With decades of experience, Atlas Metal Industries is recognized for providing superior brass components and brass precision turned components that meet the needs of diverse industries. The key benefits of sourcing products from Atlas Metal Industries include:

Competitive Pricing: Thanks to its strategic location and access to raw materials, Atlas Metal Industries offers cost-effective solutions for brass pipe fittings without compromising on quality.

Quality Assurance: Rigorous quality control processes ensure that every brass component produced meets the highest standards, making it ideal for critical applications.

On-Time Delivery: With a well-established supply chain, Atlas Metal Industries guarantees timely delivery of brass components to clients globally.

The Future of Brass Manufacturing in India

The brass components manufacturing industry in India is on an upward trajectory, with several emerging trends shaping the future:

Technological Innovations: The integration of CNC machining and automation is enhancing the efficiency and accuracy of brass components manufacturing.

Sustainability: Manufacturers are increasingly adopting eco-friendly practices and focusing on the recycling of materials to reduce their environmental impact.

Global Expansion: As demand for high-quality brass components increases, Jamnagar is poised to expand its presence in the global market.

Companies like Atlas Metal Industries are embracing these trends, integrating new technologies to meet evolving market demands.

Conclusion: Why Choose Brass Components from Jamnagar

Jamnagar’s prominence in the brass fittings manufacturing sector is a result of its strategic location, skilled workforce, and robust manufacturing infrastructure. For businesses looking for top-quality brass components and precision turned components, Jamnagar offers the perfect solution. Atlas Metal Industries stands out as a reliable partner for businesses seeking high-performance brass components.

To learn more about the high-quality brass components we offer, visit Atlas Metal Industries or contact us at [email protected] or +91-288 2730 944.

#brass components#brass components manufacturer#brass precision turned components manufacturers#brass turned components#brass manufacturers in india#brass pipe manufacturers in jamnagar#brass precision turned components factory#best brass products in india#brass components manufacturer in jamnagar#brass conduit fittings in india#copper lugs manufacturers in india#cable lugs manufacturers in india#lugs manufacturers in india#brass fitting manufacturers in india#brass fittings manufacturers in jamnagar

1 note

·

View note

Text

Best Manufacturer of Precision Turned Components

Scharf Precision Engineering is a well-known manufacturer of precision turned components in Ahmedabad. We manufacture and supply world-class quality precision turned components for various industries. We deliver quality and precision CNC machined parts and turned components for your engineering needs.

1 note

·

View note