#Predictive Maintenance Rotary Devices

Explore tagged Tumblr posts

Text

Explore the power of predictive maintenance with AI/ML for vacuum pumps, motors, and more. Enhance reliability and reduce downtime. Learn more!

#Predictive Maintenance Vacuum Pumps#Vacuum Pump Reliability#Vacuum Pump Failure Prevention#Predictive Maintenance Motors#Predictive Maintenance Furnaces#Predictive Maintenance Rotary Devices#Predictive Maintenance AI/ML Bases#AI/ML for Equipment Maintenance#Machine Learning in Maintenance#Predictive Analytics for Maintenance#ML Algorithms for Maintenance

0 notes

Text

Torque Sensor Market Size Powering Precision Measurement and Control Across Industries

The Torque Sensor Market Size is witnessing substantial expansion, driven by growing demand across automotive, industrial automation, and robotics sectors. As precision, safety, and efficiency become paramount, torque sensors are proving indispensable in applications where force and rotational performance must be closely monitored and controlled. According to Market Size Research Future, the global torque sensor Market Size is projected to reach USD 15.37 billion by 2032, growing at a CAGR of 7.50% during the forecast period (2024–2032).

Market Size Overview

Torque sensors, also known as torque transducers, measure the torque (rotational force) on a rotating system such as an engine, crankshaft, gearbox, or rotor. With their increasing adoption in electric vehicles (EVs), aerospace engineering, and automated manufacturing systems, these sensors are becoming critical components in modern engineering.

Industries are investing in real-time monitoring solutions, and torque sensors offer precise measurements that help prevent failures, improve performance, and ensure compliance with safety and quality standards. Moreover, the shift toward Industry 4.0 and smart manufacturing is opening new opportunities for sensor-based monitoring and automation.

Market Size Segmentation

To better understand the dynamics, the torque sensor Market Size is segmented based on type, technology, application, and region:

By Type:

Rotary Torque Sensors (widely used in automotive and industrial machinery)

Reaction Torque Sensors (ideal for static torque measurements)

By Technology:

Strain Gauge

Surface Acoustic Wave (SAW)

Optical

Magnetoelastic

MEMS

By Application:

Automotive

Aerospace

Industrial

Medical

Test & Measurement

Robotics

By Region:

North America

Europe

Asia-Pacific

Rest of the World

Key Market Size Trends

1. Rising Demand from Electric Vehicles (EVs):

Torque sensors are integral in monitoring motor output and optimizing energy consumption in EVs. Their role in battery efficiency and safety systems is increasing as EV adoption accelerates globally.

2. Integration with Industrial IoT (IIoT):

As factories embrace digital transformation, torque sensors are increasingly being linked with cloud and edge computing platforms for predictive maintenance and real-time performance analytics.

3. Miniaturization of Sensors:

Advancements in MEMS technology are driving the development of compact, lightweight, and high-performance torque sensors for wearable medical devices, portable tools, and small-scale robotics.

4. Robotics and Automation Boom:

Torque sensors are critical in collaborative robots (cobots) to enhance tactile sensing and force feedback. As automation spreads across small and mid-sized enterprises, the Market Size for embedded torque sensing is expanding rapidly.

Segment Insights

Rotary Torque Sensors Dominate

Rotary torque sensors hold the largest Market Size share due to their versatility in rotating machinery, including transmission testing, dynamometers, and electric motor applications. Their wide adoption in automotive R&D and factory automation is a major driver of growth.

Strain Gauge Technology Leads

Among all technologies, strain gauge-based sensors are most commonly used due to their accuracy and reliability. However, SAW and optical torque sensors are gaining momentum, especially in high-speed and wireless applications.

Automotive Sector Remains Key End-User

Torque sensors are vital for powertrain testing, steering systems, brake-by-wire, and transmission efficiency in automobiles. With EVs and autonomous driving technologies evolving, the demand for advanced torque sensing continues to rise.

End-User Insights

Automotive Industry:

From combustion engine diagnostics to EV motor efficiency, torque sensors are used in drivetrain testing, power steering systems, and hybrid motor control.

Aerospace:

In aircraft engine performance monitoring, torque sensors ensure safe and efficient operation of critical propulsion systems and flight components.

Medical:

Torque sensors are used in surgical robotics, prosthetics, and medical device testing, helping ensure precision and safety in sensitive applications.

Industrial Machinery:

Predictive maintenance and process optimization rely on torque data in motors, pumps, compressors, and robotic arms, boosting productivity and reducing downtime.

Key Players in the Market Size

Leading companies are investing in innovation, strategic partnerships, and expanding global footprints to remain competitive:

Honeywell International Inc.

ABB Ltd.

Crane Electronics Ltd.

Futek Advanced Sensor Technology Inc.

Interface Inc.

Kistler Group

TE Connectivity Ltd.

HBM (Hottinger Baldwin Messtechnik GmbH)

Datum Electronics Ltd.

Magtrol Inc.

These players focus on enhancing sensor precision, reducing size, and enabling wireless connectivity, which align with growing demand for real-time data in various industries.

Conclusion

The torque sensor Market Size is primed for strong growth, fueled by its pivotal role in optimizing industrial performance, advancing automotive innovation, and enabling precision in robotics and healthcare. As industries push toward greater automation, safety, and energy efficiency, torque sensing technology will remain at the forefront of this transformation.

Trending Report Highlights

Explore more insightful reports from emerging and adjacent Market Sizes:

Proximity Sensor Market Size

Wi-Fi Adapter Card Market Size

5G Processor Market Size

Kids Tablet Market Size

Laser Projector Market Size

Underwater Lighting Market Size

Static Random-Access Memory (SRAM) Market Size

Wafer Fabrication Market Size

Plasma Lighting Market Size

Fluorescent Lighting Market Size

Body Area Network Market Size

Gyroscope Market Size

0 notes

Text

Advanced RPD Gas Meter Solutions for Precise Flow Control

Gas flow isn't always easy to predict. In high-stakes industries, even the slightest measurement error can lead to wasted resources or compliance issues. That’s where the RPD gas meter proves its value offering accurate, dependable readings that stay consistent even under changing pressure and flow conditions.

How RPD Gas Meters Work

The rotary positive displacement (RPD) design uses interlocking rotors to capture and measure exact gas volumes. This method ensures smooth, turbulence-free operation across a wide range of flow rates. Whether for industrial or commercial use, an RPD gas meter delivers performance that’s both stable and efficient.

Contact Flow Meter Suppliers today and step into the future of gas flow measurement.

Built for Demanding Applications

An RPD gas meter is more than just a measuring device it’s a long-term solution. With durable construction, low pressure drop, and minimal maintenance needs, these meters are ideal for energy utilities, chemical plants, and large-scale gas distribution systems.

Where to Find Reliable RPD Gas Meters

As a trusted RPD gas meter manufacturer and supplier, Flow Meter Suppliers offers advanced models tailored to your specific requirements. From technical consultation to post-installation support, we ensure your system runs with total accuracy and minimal downtime.

Long-Term Value You Can Count On

Our RPD meters aren’t just accurate, they last. With extended service life and consistent output, they reduce the need for frequent checks or costly replacements. In industries where every cubic meter counts, that’s an advantage worth investing in.

Need expert guidance or a quote that fits your project? Reach out to Flow Meter Suppliers for reliable RPD gas meter solutions.

0 notes

Text

Bridging Two Worlds of Power: A Human‑Centered Deep Dive into the AC-DC Rectifier

Walk into any modern factory, data center, or hospital and you’ll find a silent choreography taking place behind the walls. Alternating current (AC) from the grid pulses at 50 or 60 hertz, while sensitive electronics, motor drives, battery banks, and medical devices sip direct current (DC) with laser‑like precision. Linking these two electrical universes is the unassuming yet indispensable AC-DC Rectifier.

Most people never see it. Fewer still give it a second thought. But every smartphone charge, every MRI scan, and every impeccably timed robot arm owes its reliability to this device. Let’s shine a light on the rectifier’s story—equal parts physics, engineering craft, and human impact—and discover why perfecting it matters more than ever.

1 | The Rectifier’s Reason for Being

The utility grid delivers AC because it travels long distances efficiently and is easily transformed to higher or lower voltages. Electronics, however, crave DC: a one‑way stream of electrons that won’t flip polarity dozens of times per second. Converting AC into DC used to be a messy affair of rotary converters and mercury‑arc tubes. Modern solutions rely on power semiconductors—diodes, thyristors, and insulated‑gate bipolar transistors (IGBTs)—arranged in clever topologies that “rectify” AC waves into smooth DC rails.

At first glance, that seems straightforward: block current in one direction, allow it in the other. Yet achieving low ripple, high power factor, minimal electromagnetic interference, and bulletproof reliability under harsh conditions is anything but simple. It’s equal parts art and advanced materials science.

2 | A Day in the Life: Raj’s Unexpected Victory

Picture Raj, a 38‑year‑old maintenance engineer at a bustling metro‑rail depot in Mumbai. Every night, 50 train cars roll in for inspection, and each must fully recharge its traction batteries before dawn. Years ago, Raj’s team relied on bulky silicon‑controlled‑rectifier (SCR) chargers. They ran hot, wasted energy, and thumped the grid with harmonics. When heat waves hit, the chargers’ fans worked overtime—sometimes failing, sometimes igniting dust bunnies.

Last year, the depot upgraded to a bank of high‑frequency switch‑mode units featuring an advanced AC-DC Rectifier. Overnight, efficiency jumped from 88 % to 96 %, charger cabinets shrank by half, and the harmonic filter room was repurposed as a parts warehouse. Raj’s life changed too: no more 3 a.m. emergency calls about blown fuses or scorched busbars. He even has time to mentor apprentices in predictive maintenance.

Human stories like Raj’s are why rectifier design matters. Lower power loss reduces energy bills and CO₂ emissions; greater reliability fosters safer workplaces and better work–life balance.

3 | Breaking Down the Technology

a. Topologies That Tame the Wave

Six‑Pulse Diode Bridge Simple, rugged, cheap. Generates high ripple and poor power factor—acceptable for motors, less so for precision electronics.

SCR/Thyristor‑Controlled Bridge Phase‑controlled. Allows adjustable DC voltage but injects significant harmonics and flicker.

Active Front‑End (IGBT‑based PWM) The modern workhorse. Uses pulse‑width modulation at tens of kHz, yielding near‑unity power factor, sinusoidal input current, and programmable output.

b. Key Performance Metrics

Efficiency (η): Fraction of AC input power that emerges as usable DC. Every 1 % lost becomes heat to manage.

Total Harmonic Distortion (THDi): Lower is kinder to the grid and upstream transformers.

Power Factor (PF): Closer to 1 means less reactive power and smaller conductor sizes.

Mean Time Between Failures (MTBF): Drives lifecycle economics—especially critical in telecom and healthcare.

Modern digital controllers co‑opt fast microprocessors, using space‑vector modulation and soft‑switching to squeeze out extra efficiency while shrinking magnetics and capacitors. The result: kilowatts of perfectly regulated DC in a chassis the size of a briefcase.

4 | Sustainability—The Hidden Bonus

The energy world is racing toward decarbonization. A high‑performance AC-DC Rectifier quietly accelerates that shift in three ways:

Cutting Losses at Scale A single 1 MW rectifier improving from 90 % to 96 % efficiency saves roughly 52 MWh per year—enough to power 150 Indian homes. Multiply by thousands of installations, and gigawatt‑hours appear.

Enabling Renewables Solar microgrids and wind farms use bidirectional rectifiers (a.k.a. converters) to tie storage batteries into the AC network. Precise control keeps frequency stable even when clouds or gusts play havoc.

Electrifying Heavy Industry Aluminum smelters, electro‑chlorination, and hydrogen electrolysers depend on massive DC currents. Cleaner, smoother DC means longer electrode life and fewer chemical by‑products.

5 | Challenges & Frontiers

Wide‑Bandgap Semiconductors Silicon carbide (SiC) and gallium nitride (GaN) devices switch faster with lower losses, but they’re costly and require novel gate drivers and packaging.

Thermal Management As power density climbs, getting heat out is paramount. Designers experiment with vapor‑chamber heat sinks, cold plates, and even two‑phase immersion cooling.

Cybersecurity Smart rectifiers connect to SCADA and cloud dashboards. Protecting that digital doorway from malware is now as critical as guarding against voltage spikes.

6 | Future Vision: DC Microgrids and Beyond

Some visionaries propose returning to an Edison‑style DC distribution—at least within factories, campuses, or ships. LEDs, data servers, EV chargers, and variable‑speed drives already run on DC internally; avoiding double conversion could save 5–10 % system energy. Centralized solid‑state AC-DC Rectifier stations would feed 380 V DC buses, with point‑of‑use converters providing final voltage regulation. Pilot projects in Japan and Europe show promising reductions in both copper usage and downtime.

Add renewables, storage, and vehicle‑to‑grid interfaces, and you get a resilient, modular, low‑carbon energy ecosystem—all orchestrated by that seemingly humble bridge between waveforms.

Closing Reflection

The next time your phone charges silently, a PET scanner whirs to life, or an e‑bus glides away from its depot, remember the invisible bridge making it possible. The AC-DC Rectifier may never star in glossy ads, but its quiet efficiency and rock‑solid dependability anchor the electrified world we inhabit—and the greener one we aspire to build.

0 notes

Text

Shafted Hall Effect Sensors Market 2025-2032

MARKET INSIGHTS

The global Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Shafted Hall effect sensors are compact magnetic field sensing devices with injection-molded housings designed for precision measurement in rotary and linear motion applications. These sensors operate on the Hall effect principle, where they detect changes in magnetic fields to measure position, speed, or directional movement. Their rugged construction allows operation across wide temperature ranges (-40°C to 150°C) while maintaining resistance to moisture and environmental contaminants.

The market growth is driven by increasing automation in industrial sectors and rising demand for contactless sensing solutions in automotive applications. While the industrial equipment segment currently dominates with over 45% market share, the automotive sector is witnessing accelerated adoption due to electrification trends. Recent advancements include miniaturized form factors with improved signal-to-noise ratios, enabling higher precision in tight spaces. Key players like Sensata Technologies and TE Connectivity are expanding their portfolios with IoT-enabled sensors featuring integrated diagnostics.

Download Your Free Copy of the Sample Report-https://semiconductorinsight.com/download-sample-report/?product_id=97643

Key Industry Players

Innovation and Global Expansion Drive Market Competition

The global Shafted Hall Effect Sensors market is moderately fragmented, with established multinational corporations competing alongside specialized regional players. Sensata Technologies leads the market with its comprehensive portfolio of rugged, high-performance sensors designed for automotive and industrial applications. The company’s strong engineering capabilities and vertically integrated manufacturing give it a competitive edge in pricing and quality control.

TE Connectivity and Amphenol Corporation maintain significant market positions due to their extensive distribution networks and ability to provide customized sensor solutions. These companies have strategically expanded their production facilities in Asia to capitalize on growing demand from China’s automotive sector.

Several European manufacturers like Gefran and Elen srl have carved out strong niches in precision industrial applications. Their expertise in developing sensors that operate reliably in harsh environments has made them preferred suppliers for heavy machinery and automation systems.

Meanwhile, DiscoverIE Plc and Novotechnik are investing heavily in next-generation Hall Effect technologies that integrate digital interfaces and IoT capabilities. These enhancements allow for predictive maintenance features – a key value proposition for industrial customers looking to minimize downtime.

List of Key Shafted Hall Effect Sensor Manufacturers

Sensata Technologies (U.S.)

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Gefran (Italy)

Elen srl (Italy)

Servotech Instrumentation (India)

P3 America (U.S.)

Novotechnik (Germany)

Vishay (U.S.)

DiscoverIE Plc (U.K.)

Segment Analysis:

By Type

Rotary Hall Effect Sensor Segment Leads Due to Wide Industrial and Automotive Applications

The market is segmented based on type into:

Rotary Hall Effect Sensor

Linear Hall Effect Sensor

By Application

Industrial Equipment Segment Dominates Market Owing to Automation and Process Control Requirements

The market is segmented based on application into:

Industrial Equipment

Automotive

Telecommunications Equipment

Others

By End-User

Manufacturing Sector Holds Major Share Due to Precision Measurement Needs

The market is segmented based on end-user into:

Manufacturing Industries

Automotive OEMs

Telecom Providers

Consumer Electronics

Others

Request Your Free Sample Report-https://semiconductorinsight.com/download-sample-report/?product_id=97643

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Shafted Hall Effect Sensors Market?

-> Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Which key companies operate in this market?

-> Key players include Sensata Technologies, TE Connectivity, Amphenol Corporation, Vishay, and Gefran, with the top five companies holding approximately 38% market share.

What are the key growth drivers?

-> Major growth drivers include increasing industrial automation, growing electric vehicle production, and demand for precision sensing in manufacturing equipment.

Which region dominates the market?

-> Asia-Pacific accounts for 42% of global demand (2024) and shows the highest growth potential, while North America leads in technological innovation.

What are the emerging trends?

-> Emerging trends include development of smart sensors with integrated diagnostics, miniaturization for compact applications, and adoption in renewable energy systems.

About Semiconductor Insight:

Established in 2016, Semiconductor Insight specializes in providing comprehensive semiconductor industry research and analysis to support businesses in making well-informed decisions within this dynamic and fast-paced sector. From the beginning, we have been committed to delivering in-depth semiconductor market research, identifying key trends, opportunities, and challenges shaping the global semiconductor industry.

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014

[+91 8087992013]

0 notes

Text

Torque Sensors: Enabling Smart Mechanical Systems – Engineered by Star EMBSYS

Torque Sensors: Enabling Smart Mechanical Systems – Engineered by Star EMBSYS

In today’s era of automation, robotics, and precision engineering, measuring torque—the rotational force applied to an object—is fundamental. From electric vehicles to industrial machinery, the ability to accurately monitor torque enables smarter control, better performance, and enhanced safety.

At Star EMBSYS, we specialize in developing and integrating torque sensor systems into embedded platforms for a wide range of industrial and research applications. Whether it's for real-time monitoring, automated testing, or predictive maintenance, torque sensing is at the heart of many high-performance systems.

What is a Torque Sensor?

A torque sensor, also known as a torque transducer or torque meter, is a device that measures the twisting force applied on a rotating or stationary shaft. The sensor converts this mechanical input into an electrical signal, which can then be read and processed by a controller, data logger, or embedded system.

Torque sensors come in two main types:

Rotary Torque Sensors – Measure torque in rotating systems.

Static (Reaction) Torque Sensors – Measure torque without shaft rotation.

How Torque Sensors Work

Most modern torque sensors operate based on:

Strain Gauge Technology: Detects minute changes in resistance as torque deforms a sensor element.

Magnetoelastic Sensing: Uses changes in magnetic properties under stress.

Optical or Capacitive Techniques: Employed in specialized high-precision applications.

At Star EMBSYS, we primarily use strain gauge-based sensors due to their balance of sensitivity, reliability, and cost-effectiveness.

Applications of Torque Sensors

Torque sensors are used in:

Industrial Automation – Monitoring load on motors, pumps, and gearboxes.

Automotive Systems – Engine and drivetrain testing, EV torque analysis.

Robotics – Force feedback in joints and actuators.

Test Benches – Real-time torque measurement in R&D labs.

Aerospace & Defense – Component testing under dynamic loads.

Medical Devices – Precision torque control in surgical tools.

Star EMBSYS provides embedded solutions that make torque data actionable—by offering precise real-time feedback, wireless transmission, and cloud-based analytics.

What Sets Star EMBSYS Apart

Custom-Tailored Sensor Integration: Torque range, accuracy, and interface customized to your needs.

Advanced Embedded System Design: Microcontroller- and FPGA-based systems with high-resolution ADCs.

Real-Time Data Processing: Filtering, calibration, and display via PC, mobile, or industrial HMIs.

IoT-Ready Solutions: For remote torque monitoring and predictive maintenance.

Whether you need a compact board-level integration or a complete torque testing setup, Star EMBSYS delivers reliable, scalable, and efficient solutions.

Case Example: Torque Monitoring in Electric Motor Assembly

In one recent project, Star EMBSYS engineered a torque sensing solution for an electric motor assembly line. Using high-precision strain gauge sensors connected to an embedded control unit, operators could monitor torque during bolt tightening in real time. The result? Improved assembly quality, reduced component failure, and full traceability of torque data—accessible from both local terminals and the cloud.

Conclusion

Torque sensors are critical components in today’s intelligent mechanical systems. With the right sensor and embedded integration, companies can gain deeper insights, improve control, and ensure operational safety.

At Star EMBSYS, we combine sensor expertise with embedded design to deliver robust, accurate, and application-specific torque measurement solutions.

Need torque sensing in your system? Get in touch with Star EMBSYS—your partner in smart mechanical measurement.

Visit:- https://www.starembsys.com/torque-sensor.html

0 notes

Text

Steady Growth Ahead: Vertical Injection Molding Market at 4.3% CAGR

The global Vertical Injection Molding Machine market, valued at USD 806.8 million in 2022, is set to expand at a robust CAGR of 4.3% between 2023 and 2031, reaching an estimated USD 1.2 billion by the end of 2031. This growth is propelled by technological advancements, rising demand for lightweight components across industries, and increasing integration of robotics and computerized molding processes.

Market Overview

Vertical injection molding machines feature a vertically oriented clamping and injection unit, leveraging gravity to enhance precision and energy efficiency. Their compact footprint makes them ideal for space-constrained production lines. Predominantly used in insert molding where pre-placed metal or other components are overmolded with plastic these machines serve diverse sectors including automotive, electronics, medical, packaging, and consumer goods.

Market Drivers & Trends

Energy Efficiency: Vertical machines consume less energy than their horizontal counterparts by minimizing continuous movement of clamping units.

Robotic Integration: Automation from component loading to part removal is driving productivity and quality. Manufacturers like Newbury offer C-Frame rotary table designs with turnkey robotic integration.

Lightweight Components Demand: The shift toward lighter plastic parts in automotive and electronics for fuel efficiency and portability is boosting demand.

Compact Footprint: Limited factory space in urbanized regions favors vertical designs, optimizing floor layouts.

Latest Market Trends

Hybrid Technologies: Blending hydraulic and electric drives to balance high clamping force with precision and lower maintenance costs.

All-Electric Vertical Machines: Gaining traction in cleanroom and medical device manufacturing for zero-emission operation.

IoT-Enabled Monitoring: Real-time data analytics to predict maintenance needs and minimize downtime.

Sustainable Materials: Compatibility with bio-based resins and recycled plastics to meet environmental regulations.

Key Players and Industry Leaders

ARBURG GmbH + Co KG

The Japan Steel Works, LTD.

Nissei Plastic Industrial Co., Ltd

Sumitomo Heavy Industries

Engel Austria

Milacron Holdings Corp

Tayu Machinery Co., Ltd

Wittmann Battenfeld GmbH

Shibaura Machine (Toshiba Machine Co., Ltd)

Pratishna Engineers Ltd

Toyo Machinery & Metal Co., Ltd.

Husky Injection Molding Systems Ltd.

Niigata Machine Techno Co., Ltd.

Preview essential insights and takeaways from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82265

Recent Developments

February 15, 2023: ARBURG’s Allrounder 470 H hybrid machine debuts, offering up to 30% energy savings and reduced carbon footprint compared to conventional models.

December 2022: JSW’s JLM3000-MGIIeL sets a new benchmark with its record 3,000-ton mold clamping force, addressing the needs of large-scale automotive and aerospace component production.

Q1 2024: Engel Austria unveiled its tie-barless vertical machine, enabling faster mold changeovers and expanded mold accessibility.

Q2 2024: Sumitomo introduced an integrated IoT platform across its vertical machine line, allowing remote diagnostics and process optimization.

Market Opportunities

Automotive Lightweighting: Rising adoption of plastic parts for interior panels, under-hood components, and structural elements.

Medical Device Manufacturing: Growth in single-use and precision-critical components, such as syringes, diagnostic cartridges, and implantable devices.

Consumer Electronics: Miniaturization trends demand complex, high-precision plastic housings and connectors.

Packaging Innovation: Demand for customized closures, caps, and tamper-evident designs in food, beverage, and personal care segments.

Emerging Economies: Rapid industrialization in Asia Pacific and Latin America offers new OEM and contract manufacturer partnerships.

Future Outlook

Analysts anticipate that continued R&D investment will yield machines with smarter controls, lower energy footprints, and greater flexibility for multi-material molding. The push toward Industry 4.0 will further accelerate adoption of vertical presses with embedded sensors, predictive maintenance algorithms, and seamless integration into fully automated production lines. By 2031, the market is expected to witness:

Wider Hybrid Adoption: Hybrid machines capturing significant market share by combining the strengths of hydraulic and electric systems.

Expanded All-Electric Use Cases: Particularly in sectors requiring ultra-clean operation and minimal noise.

Enhanced Circularity: Greater compatibility with recycled and bio-based polymers to meet sustainability targets.

Market Segmentation

Segment

Sub-Segment

Input Material

Plastic; Rubber; Others

Clamping Force

Up to 20 T; 21–40 T; 41–50 T; 51–70 T; 71–80 T; 81–100 T; > 100 T

Type

Hydraulic; Electric; Hybrid

Automation Grade

Automatic; Semi-automatic

End-Use

Consumer Goods; Automotive & Aerospace; Agriculture & Waste Management; Medical & Science; Electrical & Electronics; Construction; Packaging; Others

Regional Insights

Asia Pacific: Held the largest share in 2022 due to rapid automotive and consumer goods production, and ongoing urbanization driving factory expansions.

Europe: Accounted for 32.4% of the market in 2022, with strong demand for high-precision medical and automotive components; expected to remain stable through 2031 (~31.8%).

North America: Growing emphasis on reshoring and automation in plastics manufacturing; rising investment in electric vehicle components.

Latin America & MEA: Emerging markets for packaging and agricultural equipment parts, offering untapped growth potential.

Why Buy This Report?

Comprehensive Analysis: Detailed cross-segment and regional breakdowns, with quantitative and qualitative insights.

Competitive Intelligence: Company profiles of 15+ key players, including market share, financials, and strategic initiatives.

Future-Ready Insights: Forecasts to 2031, highlighting emerging opportunities and potential challenges.

Actionable Recommendations: Tailored strategies for OEMs, molders, and equipment suppliers to capitalize on market trends.

Format: Electronic (PDF) + Excel for easy data manipulation.

Explore Latest Research Reports by Transparency Market Research:

Fabric Reinforcements Market for Liquid-applied Roofing: https://www.transparencymarketresearch.com/fabric-reinforcements-market-for-liquid-applied-roofing.html

Monochloroacetic Acid Market: https://www.transparencymarketresearch.com/monochloroacetic-acid-market.html

Boranophosphates Market: https://www.transparencymarketresearch.com/boranophosphates-market.html

Caproic Acid Market: https://www.transparencymarketresearch.com/caproic-acid-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Electronic Sensors – Techknow Engineering Enterprise

Electronic sensors are the core components of modern automation, control, and monitoring systems. At Techknow Engineering Enterprise, we offer a wide range of high-precision electronic sensors that deliver accurate data and ensure optimal performance for industrial and commercial applications. Whether you're working with hydraulic systems, automation equipment, or process control setups, our sensors provide reliable inputs to keep your operations running smoothly.

What Are Electronic Sensors?

Electronic sensors are devices that detect and respond to physical or environmental changes by converting them into electrical signals. These signals are then processed and used to monitor or control machines, systems, or processes.

Sensors play a key role in automation, predictive maintenance, safety systems, and efficiency improvements. From temperature and pressure sensing to position and level detection, these devices offer a gateway to intelligent operation.

Types of Electronic Sensors Offered by Techknow

At Techknow Engineering Enterprise, we supply a wide variety of electronic sensors suited for different environments and needs:

1. Pressure Sensors

Measure fluid or gas pressure in hydraulic and pneumatic systems

Ideal for monitoring system health and detecting leaks

Available in analog and digital outputs

2. Temperature Sensors

Detect temperature variations and relay accurate readings for process control

Used in HVAC systems, engines, manufacturing plants, and more

Options include thermocouples, RTDs, and thermistors

3. Level Sensors

Measure fluid levels in tanks, vessels, and pipelines

Available in ultrasonic, capacitive, and float-based versions

Suitable for water, oil, chemicals, and other media

4. Proximity Sensors

Detect the presence of nearby objects without physical contact

Common in automation, safety interlocks, and conveyor systems

Available in inductive, capacitive, and optical types

5. Position and Displacement Sensors

Track linear or rotary movement with high accuracy

Essential for automation, robotics, and industrial control systems

6. Flow Sensors

Monitor fluid flow rate in hydraulic, pneumatic, or water-based systems

Used in process industries, cooling systems, and more

Key Features of Our Electronic Sensors

✅ High accuracy and fast response times

✅ Wide range of sensing technologies and output types

✅ Durable design with IP-rated protection for harsh environments

✅ Compact and easy-to-install form factors

✅ Customizable configurations to meet unique application needs

Applications of Electronic Sensors

Our electronic sensors are widely used across industries, including:

🏭 Industrial Automation – Machine control, feedback systems, and predictive maintenance

🚜 Hydraulic Systems – Pressure, temperature, and fluid monitoring

🏗️ Construction Equipment – Positioning and load monitoring

🚛 Automotive Systems – Engine control, fluid levels, safety monitoring

🧪 Chemical & Pharmaceutical Plants – Accurate flow and temperature regulation

🌡️ HVAC Systems – Environmental control and temperature feedback

Why Choose Techknow Engineering Enterprise?

Techknow Engineering Enterprise is a trusted supplier of advanced electronic sensor technologies designed for precision, reliability, and long-term performance. Here’s why we’re the preferred choice:

🔍 Expert product knowledge and technical support

💡 Customized sensor solutions for OEMs and industry professionals

🏭 Partnership with top-tier sensor manufacturers

🚚 Fast delivery with ready stock for common sensor types

🧰 Wide selection of sensors for every sensing requirement

Get in Touch

If you’re looking for dependable electronic sensors for your industrial or commercial application, reach out to Techknow Engineering Enterprise. Our team is ready to help you select the best sensor solutions to enhance your system's performance and reliability.

0 notes

Text

The Complete Guide to Industrial Flow Measurement Technology

In today's precision-driven industrial landscape, accurate flow measurement isn't just a technical requirement—it's the backbone of efficient operations, quality control, and regulatory compliance. Whether you're managing water treatment facilities, chemical processing plants, or food and beverage production lines, understanding the intricacies of industrial flow measurement technology can significantly impact your bottom line.

Understanding the Fundamentals of Industrial Flow Measurement

At its core, industrial flow measurement involves quantifying the rate at which liquids or gases move through pipes, channels, or vessels. This seemingly simple concept becomes increasingly complex as we consider variables like fluid properties, environmental conditions, and specific application requirements.

The evolution of flow measurement technology has transformed from basic mechanical devices to sophisticated electronic systems capable of providing unprecedented accuracy. Modern solutions offer not just flow data, but intelligent analytics that drive process optimization and predictive maintenance.

Selecting the Right Flow Measurement Principle

Different industrial applications demand different measurement approaches. Let's explore the major technologies driving today's flow measurement landscape:

Velocity-Based Measurement

These technologies measure flow by detecting the speed at which fluid moves through a defined area:

Magnetic principles in flow measurement have revolutionized how we monitor conductive liquids. By generating a magnetic field across a pipe and measuring the voltage produced as the liquid flows through it, these devices offer exceptional accuracy with minimal pressure drop. This technology excels in applications involving water, chemicals, and slurries.

Ultrasonic technology utilizes sound waves to determine flow rates either through transit-time or Doppler methods. Transit-time systems measure how long it takes ultrasonic signals to travel upstream versus downstream, while Doppler systems analyze frequency shifts as sound waves bounce off particles in the fluid. These non-invasive solutions work well for clean liquids and natural gas applications.

Positive Displacement Measurement

These mechanical systems physically capture and count discrete volumes of fluid:

Rotary meters use rotating components that trap and release measured quantities of fluid. Their high accuracy makes them ideal for custody transfer applications, though they typically require more maintenance than electronic alternatives.

Mass Flow Measurement

Instead of volumetric calculations, these technologies directly measure the mass flow rate:

Coriolis technology represents the pinnacle of mass flow measurement precision. By vibrating tubes and measuring how fluid flow affects these vibrations through the Coriolis effect, these instruments deliver exceptional accuracy regardless of fluid properties. While initially expensive, their low maintenance requirements and multi-parameter measurement capabilities often justify the investment.

Differential Pressure Measurement

This classic approach relies on measuring pressure differences across a restriction:

Orifice plates and venturi tubes create predictable pressure drops that correlate with flow rates. Though simple in principle, these systems require careful engineering to account for various flow conditions.

Variable Area Measurement

Rotameter technology uses a tapered tube with a float that rises in proportion to flow rate. These visual indicators offer simplicity and reliability for less demanding applications.

Critical Factors Affecting Flow Measurement Accuracy

Several variables can impact measurement performance:

Installation considerations: Proper straight pipe runs before and after meters prevent turbulence that can compromise accuracy.

Fluid properties: Viscosity, density, temperature, and conductivity all influence measurement performance.

Environmental factors: Vibration, electromagnetic interference, and ambient temperature fluctuations can affect sensitive instruments.

Calibration requirements: Regular verification against known standards ensures continued accuracy throughout a meter's operational life.

Advanced Features in Modern Flow Measurement Systems

Today's flow measurement technology extends far beyond basic rate detection:

Digital communication protocols like HART, Profibus, and Foundation Fieldbus enable seamless integration with control systems.

Self-diagnostic capabilities alert operators to potential issues before they affect production.

Multi-parameter measurement combines flow data with temperature, pressure, and density readings for comprehensive process insight.

Battery-powered options enable remote installation where power infrastructure is limited.

Selecting the Optimal Flow Measurement Solution

When evaluating flow measurement technologies for your application, consider these factors:

Process fluid characteristics: Conductivity, viscosity, and cleanliness will eliminate certain technologies from consideration.

Required accuracy: Higher precision typically demands more sophisticated technology and proper installation.

Installation constraints: Available straight pipe runs, power availability, and environmental conditions matter.

Budget considerations: While initial purchase price matters, total cost of ownership—including maintenance, calibration, and operational impact—should guide decision-making.

Regulatory requirements: Certain industries face strict metrological standards that influence technology selection.

Industry-Specific Applications

Different sectors leverage flow measurement technology in unique ways:

Water/wastewater: Magnetic flow meters excel in treatment processes and distribution networks.

Oil and gas: Coriolis meters provide the high accuracy needed for custody transfer and process control.

Chemical processing: Corrosion-resistant flow meters with appropriate safety certifications ensure reliable measurement of aggressive media.

Food and beverage: Hygienic design flow meters meet stringent sanitation requirements while providing the accuracy needed for recipe control.

Future Trends in Flow Measurement

As we look ahead, several developments promise to reshape industrial flow measurement:

IoT integration enables real-time monitoring and analytics across distributed facilities.

Artificial intelligence applications will enhance predictive maintenance and flow pattern recognition.

Miniaturization continues to reduce the physical footprint of sophisticated measurement technologies.

Enhanced battery life expands the feasibility of wireless flow measurement in remote locations.

Conclusion

Choosing the right industrial flow measurement technology involves balancing technical requirements, operational constraints, and economic considerations. By understanding the principles, limitations, and advantages of different measurement approaches, you can make informed decisions that optimize process efficiency, product quality, and regulatory compliance.

The ideal flow measurement solution isn't necessarily the most expensive or technically advanced—it's the one that delivers reliable, accurate data for your specific application while minimizing total cost of ownership. As technology continues to evolve, staying informed about emerging capabilities will ensure your measurement infrastructure remains both effective and competitive.

For more information about specific flow measurement solutions for your application, consult with experienced measurement professionals who can evaluate your unique requirements and recommend appropriate technologies.

0 notes

Text

Efficiency Meets Reliability from Gajjar Compressor

In today’s fast-paced industries, where production uptime and energy savings are critical, having reliable and efficient compressed air solutions is essential. Gajjar Compressor, a recognized leader in the field, has set new benchmarks for quality, efficiency, and dependability. Let’s explore how Gajjar Compressor brings unmatched efficiency and reliability to its clients around the globe.

1. Introduction: The Dual Demands of Modern Industry

Industries today need compressed air systems that deliver both high performance and consistent reliability. Compressed air, often referred to as the "fourth utility" after electricity, gas, and water, plays a fundamental role in powering numerous applications, from assembly lines and manufacturing processes to food packaging and medical devices. Gajjar Compressor meets these demands head-on with products designed to optimize productivity and minimize operational costs.

2. A Legacy of Excellence in Compressed Air Solutions

Founded on the principles of innovation and customer satisfaction, Gajjar Compressor has built a reputation as a trusted partner for industries across sectors. With a wide range of products that include rotary screw compressors, oil-free compressors, and high-pressure compressors, Gajjar Compressor provides versatile solutions that cater to unique industry requirements. This legacy of excellence extends from manufacturing high-quality equipment to offering responsive after-sales support, ensuring a seamless experience for all customers.

3. Why Efficiency is Critical in Compressed Air Systems

Efficiency in compressed air systems translates directly to savings on energy costs, reduced maintenance, and lower environmental impact. Compressed air accounts for a significant portion of energy consumption in industrial settings, so maximizing the efficiency of these systems is crucial. Gajjar Compressor’s product range is designed with cutting-edge technologies that reduce energy usage and optimize performance, making them ideal for businesses looking to reduce operational costs without compromising on quality or reliability.

4. Reliability Redefined: Quality That Stands the Test of Time

Reliability in compressed air systems is non-negotiable, especially in industries where downtime can be costly. Gajjar Compressor ensures that every component in its systems is engineered for durability. From robust motors and wear-resistant parts to advanced monitoring systems, each compressor undergoes rigorous testing to meet stringent quality standards. The result is a product range that clients can depend on for uninterrupted operation, even in the most demanding conditions.

5. Advanced Technology for Enhanced Performance

Gajjar Compressor stays ahead of industry trends by integrating advanced technology into its products. Innovations such as variable speed drives (VSDs), smart controllers, and energy-efficient motors set Gajjar’s products apart. These technological advancements allow users to adjust the compressor output to match the demand, resulting in energy savings and extended equipment life. Additionally, remote monitoring capabilities offer real-time insights, enabling predictive maintenance and reducing the risk of unexpected breakdowns.

6. Eco-Friendly Solutions: Committed to a Greener Future

As industries strive to meet environmental standards, Gajjar Compressor is committed to helping its clients reduce their carbon footprint. By designing products that are energy-efficient and have minimal environmental impact, Gajjar Compressor supports businesses in their journey toward sustainability. Their oil-free compressors, for instance, not only reduce the risk of contamination but also consume less energy, making them a preferred choice for industries focused on green practices.

7. Tailored Solutions for Every Industry

One of the key strengths of Gajjar Compressor is its ability to provide customized solutions to meet specific industry needs. From automotive and pharmaceuticals to food processing and electronics, each industry has unique requirements for compressed air systems. Gajjar’s engineering team works closely with clients to understand their application needs, recommending the best-fit solution that delivers optimal performance while staying within budget.

8. Top Benefits of Choosing Gajjar Compressor

Energy Efficiency: Reduced energy costs due to advanced technology and design.

Durability: High-quality materials and engineering ensure long-lasting performance.

Reliability: Trusted, uninterrupted operation even in demanding environments.

Low Maintenance: Designed to minimize maintenance needs and costs.

Custom Solutions: Adaptable products to meet unique industry specifications.

9. Exceptional After-Sales Service: More than Just a Manufacturer

Gajjar Compressor believes in fostering long-term relationships with its clients, which is why the company places great emphasis on after-sales service. The service team is available to assist with installation, regular maintenance, and emergency repairs. Comprehensive service packages are also offered to ensure that clients’ compressors remain in top condition throughout their operational life. By providing expert technical support, Gajjar Compressor minimizes downtime, helping clients keep their operations running smoothly.

10. Case Study: Gajjar Compressor in the Food Processing Industry

In the food processing industry, hygiene, and air purity are critical. A leading food processing company recently turned to Gajjar Compressor for an oil-free air compressor solution. With Gajjar’s reliable oil-free compressors, the company was able to meet strict air quality standards and achieve significant energy savings. The custom solution provided by Gajjar also reduced maintenance costs and improved production uptime, demonstrating how efficiency and reliability can go hand in hand to deliver real value.

11. Cost Efficiency: Saving More in the Long Run

While investing in a high-quality compressor may require a higher upfront cost, Gajjar Compressor’s products deliver substantial savings over time. With their energy-efficient design, lower maintenance requirements, and longer lifespan, these compressors offer a low total cost of ownership (TCO). For businesses that need continuous operation, the reliability of Gajjar’s compressors means fewer interruptions and lower operational costs, making it a wise investment for the long haul.

12. Global Reach with Local Support

With a growing international presence, Gajjar Compressor serves clients worldwide, bringing global standards of quality and service to every region. Despite its global reach, Gajjar maintains a strong focus on providing localized support, ensuring that clients receive personalized service regardless of their location. This combination of global expertise and local support enhances customer satisfaction and ensures the highest level of service.

13. Conclusion: The Future of Efficiency and Reliability with Gajjar Compressor

As industries continue to evolve, the demand for efficient and reliable compressed air solutions will only grow. Gajjar Compressor is well-positioned to lead the way, offering products that are not only technologically advanced but also designed to meet the specific needs of diverse industries. By choosing Gajjar Compressor, businesses can be assured of a partner that values efficiency, durability, and customer satisfaction.

14. Why Choose Gajjar Compressor?

For businesses aiming to maximize uptime, reduce operational costs, and meet environmental standards, Gajjar Compressor offers a solution that balances efficiency and reliability perfectly. The company’s dedication to innovation, quality, and client satisfaction is evident in every product and service it offers, making Gajjar Compressor a top choice for companies worldwide.

By focusing on efficiency and reliability, Gajjar Compressor has earned a reputation as a trusted provider of high-quality compressed air systems. As more companies recognize the importance of reliable compressed air solutions, Gajjar Compressor stands out as a leader, providing value and performance that goes beyond expectations.

0 notes

Text

🛠️🔮 Discover the power of predictive maintenance in factory settings! In today's competitive manufacturing landscape, minimizing downtime and maximizing efficiency are crucial. Learn how predictive maintenance can revolutionize your operations, saving costs and improving efficiency.

#Implementing Predictive Maintenance#predictive maintenance#Predictive Maintenance Action#predictive maintenance for rotary devices#predictive maintenance for vacuum pumps#Predictive Maintenance in Factory#predictive maintenance semiconductor industry

0 notes

Text

Magneto Elastic Torque Sensor Industry Insights Opportunities, Key Applications & Market Dynamics

The Magneto Elastic Torque Sensor Market is gaining significant momentum as industries seek compact, contactless, and reliable torque measurement technologies for high-efficiency mechanical systems. Magneto elastic torque sensors are increasingly used in electric vehicles (EVs), robotics, industrial automation, and aerospace due to their durability, real-time output, and resistance to harsh environments. The global market was valued at around USD 1.2 billion in 2023 and is projected to reach USD 2.9 billion by 2032, expanding at a CAGR of 8.5% during the forecast period.

These sensors leverage the magnetoelastic effect to measure torque in rotating shafts without requiring direct physical contact, making them ideal for dynamic systems. Their integration with smart control systems and real-time analytics platforms enhances predictive maintenance and improves performance reliability.

Market Segmentation

By Type

Rotary Torque Sensors

Static Torque Sensors

Contactless Torque Sensors

Digital Torque Sensors

By Output Signal

Analog Output

Digital Output

Frequency Output

Voltage Output

By Application

Automotive

Aerospace & Defense

Industrial Automation

Robotics

Energy and Power

Medical Devices

Marine Systems

By Region

North America: Strong demand from EV and aerospace sectors

Europe: Driven by automotive OEMs and energy innovation

Asia Pacific: Fastest-growing region with a surge in EV manufacturing and smart factories

Middle East & Africa: Niche applications in oil & gas and energy

Latin America: Gradual growth in automotive and industrial upgrades

Trends

1. Surge in Electric Vehicle Integration

EV drivetrains rely heavily on torque sensors for energy efficiency, acceleration control, and drivetrain monitoring. Magneto elastic sensors meet these demands with their real-time response and non-intrusive design.

2. Growing Role in Robotics and Cobots

High-precision torque measurement in robotic joints and collaborative robots (cobots) is essential for safety and task accuracy. These sensors provide quick feedback that allows smooth human-machine interaction.

3. Industrial Automation and Predictive Maintenance

Smart factories are adopting torque sensors for machine diagnostics and preventive maintenance. Integration with IoT platforms enables real-time alerts for component wear or overload conditions.

4. Miniaturization and Modular Sensor Designs

Smaller, more adaptable sensor packages are being developed for compact machinery, medical equipment, and drone propulsion systems, increasing the range of industrial deployment.

5. Aerospace Focus on Weight and Efficiency

Torque sensors are used in flight control systems, landing gears, and actuators. Lightweight, durable, and EMI-resistant designs are particularly valuable in high-stakes aviation environments.

Segment Insights

Rotary Torque Sensors Lead Demand

Rotary sensors dominate the market due to their widespread application in rotating machinery such as motors, generators, engines, and pumps. These sensors provide continuous data without contact-based wear.

Digital Output Gaining Popularity

Digital output sensors are replacing analog types, offering greater integration with data analytics systems and compatibility with smart devices used in Industry 4.0 environments.

Automotive Sector Is the Largest Application

The automotive industry is the largest consumer, particularly for applications in transmission testing, chassis dynamics, and hybrid vehicle optimization. Lightweight, robust, and cost-effective solutions are in high demand.

Asia Pacific Emerges as Key Growth Driver

China, Japan, and South Korea are leading regional adoption due to government incentives for electric mobility and rapid automation in the manufacturing sector. India is catching up with localized production and exports.

End-User Insights

Automotive and Electric Vehicles

Torque sensors are critical for powertrain testing, torque vectoring, regenerative braking, and vehicle dynamics. As EV adoption increases globally, so does the need for advanced torque monitoring systems to ensure optimal battery and drivetrain performance.

Industrial Automation and Manufacturing

Factories are adopting real-time torque measurement to control motor-driven processes. These sensors improve machine longevity and help monitor load variations, preventing unexpected breakdowns.

Aerospace and Defense

In aviation, torque sensors support actuation systems, flaps, and rudder controls. Their reliability in extreme conditions and compact form factor make them suitable for both manned and unmanned systems.

Robotics

As precision and responsiveness define robotic efficiency, torque sensors embedded in joints allow controlled force application, helping in surgical robots, warehouse automation, and cobots.

Energy and Power Generation

Turbine systems, generators, and other rotating equipment require accurate torque data to maintain output stability. Sensors enable condition monitoring and fault detection in real-time.

Medical Devices

Medical robotics and prosthetic limbs use compact torque sensors to measure applied forces. This helps design intuitive control algorithms that adapt to human motion naturally.

Key Players

Leading companies in the Magneto Elastic Torque Sensor Market include:

Honeywell International Inc. – Offers a wide portfolio of torque sensors for aerospace and industrial sectors.

Kistler Group – Specializes in sensor technology for automotive and dynamic applications.

ABB Group – Known for its torque sensing solutions in automation and process control.

FUTEK Advanced Sensor Technology Inc. – Designs high-precision sensors for medical, aerospace, and robotics markets.

HBM (Hottinger Brüel & Kjær) – Offers torque transducers widely used in EV and motor testing.

TE Connectivity – Provides custom torque sensors for automotive and industrial use cases.

Sensor Technology Ltd. – UK-based firm known for its wireless torque measurement technology.

Datum Electronics Ltd. – Supplies torque sensors tailored to marine and energy industries.

MagCanica Inc. – Focuses on high-performance magnetoelastic torque sensors for motorsport and aerospace.

Magtrol Inc. – Delivers torque sensors and test benches for industrial automation.

Trending Report Highlights

Wet Chemicals Market

Taiwan Robotics Market

Automatic Elevator Inverter Market

Autonomous Mobile Robot Market

Washdown Sensor Market

0 notes

Text

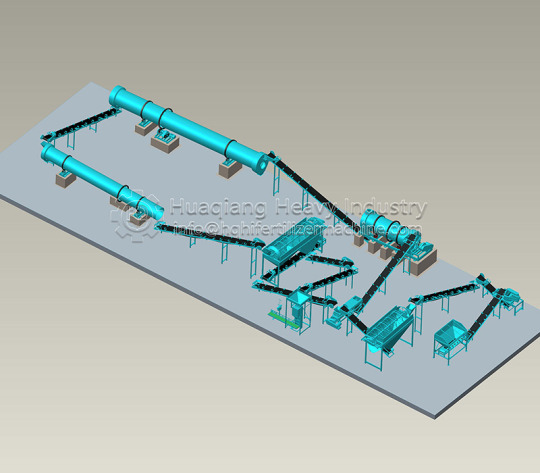

In the process of organic fertilizer production, the stable operation of large organic fertilizer equipment is the key to ensure production efficiency and product quality. Therefore, it is very important to develop a reasonable and effective equipment maintenance plan. So, how do you do this?

First, understanding device characteristics is fundamental. Organic Fertilizer Production Line, including Rotary Drum Granulator, Disc Granulator and other core equipment, each equipment has its specific working principle and performance characteristics.

When developing a maintenance plan, these characteristics must be fully considered to ensure that the plan is scientific and targeted. Rotary Drum Granulator, for example, requires regular internal cleaning of accumulated material and inspection and replacement of worn parts to extend equipment life.

Second, preventive maintenance is key. Through regular inspection and maintenance of organic fertilizer production equipment, potential faults can be discovered and dealt with in time to avoid production losses caused by sudden equipment shutdown. This includes checking whether the wiring of the electrical system is firm, whether the lubrication system is smooth, and whether the transmission components are worn. At the same time, the use of modern technical means, such as vibration monitoring, temperature monitoring, real-time monitoring of equipment, to achieve fault warning and prediction.

In addition, reasonable arrangement of maintenance cycle is guaranteed. Develop a scientific maintenance cycle according to the frequency of use, working environment and historical maintenance records of the equipment. For key equipment, such as Windrow Compost Turning Machine, Cage Crusher, etc., the maintenance cycle should be shortened to ensure that it is always in good condition. At the same time, a maintenance file is established to record the time, content, and result of each maintenance, which provides reference for subsequent device management.

Finally, training a professional maintenance team is the support. Having a maintenance team with professional knowledge and skills is an important guarantee for the implementation of maintenance plans. Improve the maintenance skills and troubleshooting ability of team members through training and learning to ensure the smooth maintenance of equipment.

In summary, to develop a reasonable maintenance plan for large-scale organic fertilizer equipment, it is necessary to fully understand the characteristics of the equipment, implement preventive maintenance, rationally arrange maintenance cycles and train professional maintenance teams. The implementation of these measures will help improve the stability and reliability of organic fertilizer production equipment, and provide a strong guarantee for the sustainable development of enterprises and product quality.

0 notes

Text

Revolutionizing Machining: The Precision and Reliability of CNC Rotary Tables

CNC rotary tables have become essential tools in modern manufacturing. Leveraging on the additional axis of rotation – typically referred to as the 4th or 5th axis, depending on the setup – CNC rotary tables enhance the capabilities of CNC machines. By integrating a CNC rotary table into a three-axis CNC machine, manufacturers can achieve greater flexibility, efficiency, and precision, elevating their production capabilities.

Importance of Selecting the Right CNC Rotary Table

It’s a well-known fact that CNC rotary tables are versatile devices that allow for the creation of intricate and precise components, significantly improving the overall machining process. However, choosing the right CNC rotary table manufacturer is crucial to optimise your machining operations. Factors such as the manufacturer’s reputation, experience, and ability to deliver customised solutions directly impact production efficiency, accuracy, and overall performance. And so, a thorough evaluation of these aspects is essential for achieving the best results.

Key Functions of CNC Rotary Tables

CNC rotary tables offer enhanced workpiece manipulation and positioning. Their ability to introduce a rotational axis to CNC machines allows for complex machining operations that would be inconceivable with traditional three-axis machines. This capability is vital for producing parts with intricate geometries and multiple features. Its key functions include:

Precision Machining Perfected: CNC rotary tables significantly enhance the accuracy and precision of machining operations. By providing unparalleled control over workpiece orientation, they enable the creation of intricate geometries and precise features with unmatched accuracy. This control reduces the risk of human error, leading to consistent and reliable part quality. Moreover, its precise control over cutting angles and feed rates contributes to exceptional surface finishes, meeting the most demanding industry standards.

Efficiency Boost and Material Optimisation: The integration of a CNC rotary table streamlines machining processes by consolidating multiple operations into a single setup, reducing cycle times and increasing throughput. Automated workpiece rotation minimises manual intervention, leading to cost savings and improved resource allocation. Additionally, precise part positioning and orientation enable maximum material utilisation, reducing waste and enhancing profitability.

Versatility: CNC rotary tables offer significant versatility, allowing for a wide range of applications across different industries. These tables can be seamlessly integrated into existing machining setups, expanding capabilities without requiring extensive modifications. Their adaptability makes them suitable for various machining tasks, from simple indexing to complex contouring.

Technologically Compatible: Modern CNC rotary tables are compatible with advanced CNC controls and automation systems, ensuring long-term investment value. Its ability to integrate with IoT and predictive maintenance systems further optimises performance, reduces downtime, and provides valuable data for process improvement.

Technological Advancements in CNC Rotary Tables

Modern CNC rotary tables have undergone significant technological evolution, making them highly precise, versatile, and efficient components in manufacturing. Its key advancements are:

Enhanced Precision: The high-resolution encoders, digital servo drives, and closed-loop control systems deliver unparalleled accuracy and repeatability, enabling the creation of complex parts with tight tolerances.

Seamless Integration: CNC rotary tables’ advanced software and compatibility with various CNC machines streamline operations, reducing setup times and errors. Besides, its user-friendly interfaces simplify programming and operation.

Improved Performance: The direct drive technology, high-torque motors, and advanced materials enhance rotary table performance, allowing for heavier loads, higher speeds, and longer lifespan.

These technological strides have elevated CNC rotary tables from essential tools to indispensable components in modern manufacturing, driving increased productivity, efficiency, and part quality.

Applications of CNC Rotary Tables in CNC Machining

CNC rotary tables are used in CNC machining for precise part positioning, multi-axis contouring, complex angle machining, and efficient indexing to enhance the versatility and accuracy of the manufacturing process. Its key applications include:

Multi-Axis Machining: CNC rotary tables facilitate the creation of intricate shapes and contours by integrating linear and rotary axes. This capability allows for the machining of complex parts in a single setup, eliminating the need for multiple fixtures and setups.

Precision Machining: CNC rotary tables support precise drilling, tapping, milling, and engraving, making it possible to achieve high-quality finishes and detailed geometries.

Indexing and Positioning: Accurate workpiece positioning allows for consistent machining of identical features. This is ideal for high-volume production runs where uniformity is critical. Besides, CNC rotary tables enable precise angular positioning for assembling components with exact relationships, which is essential for creating complex assemblies and ensuring proper fit and function.

By incorporating a CNC rotary table into your machining operations, you can significantly enhance your ability to produce complex and high-precision parts, improve overall part quality, and increase productivity.

Industry-Specific Applications of CNC Rotary Tables

Mould and Die Making: CNC rotary tables are ideal for creating complex moulds and dies with intricate undercuts and cavities, essential for producing detailed and precise manufacturing tools.

Automotive: They are used for machining complex parts such as engine blocks, transmission components, and gears, meeting the demanding specifications of the automotive sector.

Aerospace: CNC rotary tables facilitate the production of critical aerospace components, including turbine blades and engine parts, which require high precision and complex geometries.

Medical Devices: The ability to machine intricate implants and surgical instruments with high accuracy is crucial in medical devices manufacturing, where precision and reliability are paramount.

Beyond these specific industries, CNC rotary tables have a wide range of applications across various sectors, including electronics, construction equipment, consumer goods, among others. The versatility of CNC rotary tables makes it essential tools for a variety of industries, enabling efficient and precise machining of complex parts. Key Takeaways The high precision, durability, seamless integration, and efficiency of CNC rotary tables make them essential tools in modern manufacturing. As industries push for greater complexity and quality, CNC rotary tables play an even more crucial role in achieving manufacturing excellence.

By recognizing the key applications and advantages of CNC rotary tables and effectively utilizing their rotational capabilities, businesses will not only enhance their machining processes but also produce superior products that meet the demands of today’s competitive market. UCAM is at the forefront of manufacturing CNC rotary tables, offering an extensive range of high-precision and reliable products. Our rotary tables are renowned for robust construction, advanced technology, and seamless integration with various CNC machines.

0 notes

Text

Electric Actuators: The Silent Powerhouses of Modern Automation

Introduction: The Electrifying Revolution in Control Systems

In the ever-evolving landscape of industrial automation, electric actuators have emerged as game-changers. These powerful devices are transforming how businesses across the USA manage their automated control systems, offering unprecedented precision, efficiency, and reliability. As industries push towards smarter, more sustainable operations, electric actuators are leading the charge, proving that the future of automation is electric.

What Are Electric Actuators?

Before we dive into their revolutionary impact, let's define electric actuators:

Electric actuators are devices that convert electrical energy into mechanical motion to control various mechanisms, such as valves, dampers, or louvers. They use electric motors to provide linear or rotary motion, allowing for precise control in automated systems.

The Advantages Driving the Electric Actuator Revolution

1. Unparalleled Precision and Control

Electric actuators offer a level of precision that's hard to match:

- Fine-tuned positioning: Can achieve exact positions with accuracies down to fractions of a millimeter.

- Programmable movement: Easily integrated with digital control systems for complex motion profiles.

- Consistent performance: Maintain accuracy over time, even under varying load conditions.

A study by the Automation Federation found that electric actuators can improve positioning accuracy by up to 30% compared to traditional pneumatic systems.

2. Energy Efficiency and Cost Savings

The switch to electric actuators often leads to significant energy savings:

- Lower power consumption: Only use energy when actively moving or holding position.

- Reduced maintenance costs: Fewer moving parts mean less wear and tear.

- Elimination of compressed air systems: No need for costly air compressors and associated infrastructure.

According to the U.S. Department of Energy, replacing pneumatic actuators with electric alternatives can result in energy savings of up to 40% in many industrial applications.

3. Enhanced Reliability and Longevity

Electric actuators are built to last:

- Robust design: Can withstand harsh industrial environments.

- Self-locking capability: Many models can hold position without continuous power, enhancing safety.

- Long service life: With proper maintenance, can operate reliably for decades.

4. Smart Integration and Industry 4.0 Compatibility

In the age of smart factories, electric actuators shine:

- Easy integration with IoT systems: Can be monitored and controlled remotely.

- Data collection and analysis: Provide valuable operational data for predictive maintenance.

- Adaptive control: Can adjust their operation based on real-time feedback and changing conditions.

Applications Across Industries

Electric actuators find use in a wide range of sectors:

- Oil and gas

- Water treatment

- Power generation

- Aerospace

- Food and beverage production

- Pharmaceutical manufacturing

The Efficiency Factor

Efficiency is where electric actuators truly excel:

1. Rapid response times: Can start, stop, and change direction quickly.

2. Variable speed control: Allows for optimized movement and energy use.

3. High duty cycle capability: Can operate continuously in many applications.

A report from the Industrial Internet Consortium suggests that the implementation of smart electric actuators can improve overall system efficiency by up to 25% in complex industrial processes.

Environmental Considerations

As sustainability becomes increasingly important, electric actuators offer significant environmental advantages:

- Reduced carbon footprint: More energy-efficient operation leads to lower emissions.

- Elimination of hydraulic fluid leaks: No risk of contamination from oil leaks.

- Quieter operation: Contribute to a better working environment with lower noise levels.

Overcoming Challenges

While electric actuators offer numerous benefits, it's important to address potential challenges:

- Initial cost: Can be higher than traditional pneumatic or hydraulic options.

- Power requirements: May need upgrades to electrical systems in some facilities.

- Training needs: Operators may require additional training for maintenance and troubleshooting.

However, the long-term benefits often outweigh these initial hurdles, making electric actuators a smart investment for many businesses.

Conclusion: Powering the Future of Automation

As we've seen, electric actuators are revolutionizing automated control systems across industries. Their combination of precision, efficiency, and smart capabilities makes them indispensable tools in the modern industrial landscape. From ensuring exact positioning in critical processes to providing valuable data for system optimization, electric actuators are paving the way for smarter, more sustainable automation.

Ready to electrify your control systems? Consider DynaQuip Controls for your electric actuator needs. With a reputation for quality and innovation, DynaQuip Controls can help you find the perfect electric actuator solution to enhance your automation systems and boost overall efficiency.

Don't let outdated or inefficient control systems hold your business back. Embrace the power of electric actuators and watch as your operations become more precise, efficient, and future-ready. With electric actuators, you're not just controlling motion – you're unleashing the potential for greater productivity, sustainability, and competitive advantage in today's fast-paced industrial world.

0 notes

Text

High Temperature Furnaces: Innovation and Applications

High temperature furnaces are a critical component in various industrial processes, enabling the achievement of extreme temperatures necessary for specific material treatments. These furnaces are instrumental in metallurgy, ceramics, and many other fields that require the manipulation and transformation of materials at high temperatures. This article explores the functionalities, types, innovations, and applications of high temperature furnaces, offering insights into their vital role in modern industry.

Understanding High Temperature Furnaces