#Predictive maintenance software

Explore tagged Tumblr posts

Text

Construction software that integrates with Xero

Explore the construction software that integrates with Xero to streamline your payroll and financial management. Visit Prestartr for tailored solutions that simplify operations and ensure accuracy in payroll processing for construction businesses.

#prestartr#fleet management software#project cost tracking software#civil construction management software#construction software#predictive maintenance software

0 notes

Text

Predictive Maintenance: AI & IoT Revolutionizing Asset Management

For businesses that rely on machinery and equipment, ensuring optimal operations is essential. This is where predictive maintenance becomes a game-changer. Powered by AI and IoT, this proactive maintenance strategy helps monitor equipment conditions in real-time, predicting failures before they occur.

Predictive vs Preventive Maintenance

🔹 Preventive Maintenance follows a time-based servicing schedule, reducing unexpected breakdowns but leading to over-maintenance and higher costs. 🔹 Predictive Maintenance relies on real-time data to determine when servicing is truly needed, reducing downtime, maintenance costs, and extending equipment lifespan.

How IoT Enhances Predictive Maintenance

✔ Real-Time Monitoring – IoT sensors track temperature, vibration, and pressure. ✔ Data Integration – Machines and software communicate seamlessly for better analysis. ✔ Remote Diagnostics – Maintenance teams can monitor assets remotely, reducing manual inspections. ✔ Improved Decision-Making – Accurate data ensures optimized maintenance strategies.

AI’s Role in Predictive Maintenance

✅ Failure Prediction – AI predicts breakdowns in advance. ✅ Anomaly Detection – Identifies irregularities in equipment performance. ✅ Prescriptive Analytics – Provides actionable insights for preventing failures. ✅ Continuous Learning – AI systems improve over time, enhancing prediction accuracy.

0 notes

Text

Factories are transforming their production and quality monitoring processes with advanced automation. As we move toward smart factories and Industry 4.0, vision inspection systems play a crucial role in achieving high standards, minimizing waste, and enhancing production efficiency. Their integration ensures real-time defect detection, improved accuracy, and seamless compliance with industry regulations.

0 notes

Text

XPump is a cutting-edge, AI/ML-based solution designed for real-time monitoring and predictive maintenance of pumps. It continuously tracks critical parameters like vibration, temperature, and voltage, providing early warnings to prevent failures and optimize performance. XPump integrates seamlessly with your existing systems, enhancing operational efficiency and reducing downtime and maintenance costs.

#Real Time Pump Monitoring System#predictive maintenance software#predictive maintenance for pumps#best predictive maintenance software#predictive maintenance systems#predictive maintenance applications#predictive maintenance pumps#predictive maintenance software cost

0 notes

Text

Airline Companies Adopting Best Airline Software Platforms to Boost Efficiency and Profitability

An efficient airline software platform helps most of the stakeholders, such as airline planners and airline companies, in optimizing commercial opportunities with a smart integration of crew, maintenance, fleet scheduling, and others. For more information please visit : https://www.biphouston.com/Adopting-Best-Airline-Software-Platforms-to-Boost-Efficiency-and-Profitability

#airline software platform#airline gating maintenance#airline predictive analytics#airline scheduling system

0 notes

Text

Moving to a Digital Permit-to-Work System | Step-by-Step Guide

Tired of cumbersome paper-based permit systems hindering your operations and compliance efforts? This comprehensive Step-by-Step Guide: Moving to a Digital Permit-to-Work System is your clear pathway to unparalleled safety, compliance, and operational efficiency.

Specifically designed for Maintenance Professionals, Plant Heads, Operations Managers, and Safety Officers in manufacturing and industrial environments, this guide cuts through the complexity. You'll learn how to transform traditional workflows into cloud-based, auditable processes, fostering proactive risk management and ultimate transparency.

Inside this guide, you'll discover: 5 Critical Steps to seamlessly transition to a digital PTW system, from defining requirements to comprehensive phased rollouts. How to integrate essential Lockout/Tagout (LOTO) procedures for enhanced energy isolation during maintenance tasks. Strategies for gaining real-time visibility, leveraging electronic signatures, and achieving workflow automation. Expert insights on stakeholder engagement and training to ensure a smooth adoption.

Beyond outlining best practices, this guide demonstrates their practical application, highlighting how a leading solution like Cryotos Permit-to-Work (PTW) Software embodies these principles. Download this essential digital Permit-to-Work resource now and lead your team into a new era of proactive safety and productivity!

#maintenance management#asset management#maintenance scheduling#cmms software#predictive maintenance#preventive maintenance#facility management software#work order management#ptw#ptw software#loto#digital ptw software#digital ptw#working at heights#hazard analysis#risk assessment#isolation management#job safety analysis#shec certificates

0 notes

Text

"Economy Redefined: Bridgera's Support Makes Predictive Maintenance Implementations Easier"

Suppose that each lost minute in your operations is costing thousands. "Predictive maintenance," fueled by "IoT" and "advanced analytics," is set to revolutionize asset management and operational effectiveness. However, the path ahead is not free of hurdles. With total assistance from Bridgera and the industry's top-of-the-line "IoT solutions," the implementation is as seamless as a drive to the future of "predictive maintenance" with the least trouble or disruption.

#iot#iot solutions#iot platform#iot integration#iot development#iot asset tracking#iot software development services#predictive maintenance#advanced analytics

0 notes

Text

AI-Powered Predictive Maintenance in Pharmaceutical Manufacturing

In pharmaceutical manufacturing, keeping machines running smoothly is essential for producing high-quality medicines. Traditional maintenance methods, like fixing machines after they break or scheduling routine checkups, can lead to unexpected failures or unnecessary repairs. AI-powered predictive maintenance is changing this by helping manufacturers prevent problems before they happen, saving time and money.

#AI development company in Dallas#Artificial Intelligence#AI-powered predictive maintenance#Manufacturing efficiency#Preventive maintenance#AI-based software development

0 notes

Text

How to Improve Overall Equipment Effectiveness (OEE) in Asset Performance Management

Introduction

Overall Equipment Effectiveness (OEE) is a key metric for assessing how efficiently equipment is used within an organization. Improving OEE can significantly impact productivity and profitability. When combined with Asset Performance Management (APM), which includes the use of advanced technologies like predictive maintenance, organizations can achieve optimal equipment utilization. This article provides practical strategies for enhancing OEE using APM principles.

Strategies to Improve OEE with APM

Integrate Predictive Maintenance APM software offers predictive maintenance capabilities that use real-time data to anticipate potential equipment failures. By addressing issues before they result in downtime, equipment availability is maximized, boosting the OEE score.

Leverage Real-Time Monitoring APM software provides continuous monitoring of asset performance, enabling teams to respond swiftly to anomalies. This proactive approach enhances performance and prevents issues that could lower the OEE score.

Optimize Maintenance Schedules Traditional maintenance schedules can result in unnecessary downtime. APM software uses data analytics to suggest maintenance only when needed, ensuring equipment remains operational for as long as possible without compromising performance.

Utilize Data-Driven Insights APM solutions collect extensive data that can be analyzed to find trends, identify inefficiencies, and improve processes. Insights gained from data analytics can help refine operations to achieve better performance and product quality.

Employee Training and Engagement Even with advanced APM systems in place, employee training is essential for effective use. Ensuring staff are well-versed in interpreting data and making informed decisions can significantly contribute to higher overall equipment effectiveness.

Conclusion Improving OEE within an organization requires a combination of strategic approaches and advanced tools like APM software. By leveraging predictive maintenance, real-time monitoring, and data-driven insights, organizations can enhance equipment efficiency, reduce downtime, and achieve sustainable growth. Adopting these strategies ensures that assets operate at peak performance, benefiting overall operations and contributing to long-term success.

#apm#predictive maintenance#asset performance management#overallequipmenteffectiveness#apm software#ombrulla

0 notes

Text

Shoreline AI | Revolutionary APM & Methane Leak Detection

0 notes

Text

Understanding Vision Inspection Technology: Cameras, AI, and Automation

A vision inspection system is crucial in maintaining quality and accuracy. Manufacturers can perform real-time inspections through the combination of cameras and AI. This technology, now enhanced with predictive maintenance software, helps detect defects early and ensures seamless production processes.

What are the uses of Vision Inspection Technology?

Typical uses are:

Quality control in manufacturing

Barcode and label verification in packaging

Automotive and electronics surface defect detection

Pharmaceutical safety inspection to guarantee accurate dosing

Key Components of Vision Inspection Systems

1. Imaging Sensors and Cameras

Industrial cameras take high-quality images for examination. The application determines the type of camera utilised:

2D Cameras – Best suited for barcode scanning and surface defect inspection.

3D Cameras – Employed for accurate measurement and dimensional checking.

Infrared & Thermal Cameras – Ideal for temperature fluctuation detection in electronics and food processing.

2. Machine Learning and AI for Image Processing

Artificial intelligence-based vision inspection is more advanced than rule-based image examination. Machine learning algorithms can improve their defect detection capabilities with increasing accuracy over time as they learn from data. In semiconductor fabrication, for example, AI-based vision systems can detect tiny cracks that human inspectors cannot.

3. Integration of Automation and Robotics

Vision inspection systems are typically integrated with robotic arms and conveyor systems to:

Conduct high-speed, real-time inspections

Automatically reject defective products

Minimise labour-intensive processes

This comes in handy in car assembly plants, where robots assist part placements via vision systems, and the placements are accurately positioned.

4. Product Configurators for Customization and Inspection

Product configurators, combined with vision inspection systems, enable manufacturers to configure products and maintain quality control. Configurators support real-time visualisation to ensure that customer-specific requirements are fulfilled without compromising production efficiency and defect-free output.

Advantages of Vision Inspection Technology

Greater Accuracy – Suppresses human errors and guarantees repetitive quality control.

Increased Speed in Production – Provides real-time high-speed inspection without compromising production pace.

Cost Saving – Saves money on rework, scrap, and labour costs.

Data-Informed Insights – Assists producers in streamlining processes and enhancing quality.

Regulatory Compliance – Proves products adhere to industry standards of quality and safety.

Industries Benefiting from Vision Inspection Technology

Automotive – Identifies components, paint job flaws, and assembly line defects.

Electronics – Exams circuit boards and soldering quality.

Food & Beverage – Examines contaminants, label accuracy, and package integrity.

Pharmaceuticals – Proves accurate labelling, dosage consistency, and tamper-proof packaging.

The Future of Vision Inspection

Technological advancements in AI, edge computing, and IoT have led vision inspection systems to become even smarter. The major trends are:

AI will enable quicker, on-device image analysis.

Cloud integration for data storage and analytics in the cloud.

Augmented reality (AR) overlays to improve defect visualisation.

Collaborative robots work with humans to improve quality control.

Conclusion

Factories are transforming their production and quality monitoring processes with advanced automation. As we move toward smart factories and Industry 4.0, vision inspection systems play a crucial role in achieving high standards, minimizing waste, and enhancing production efficiency. Their integration ensures real-time defect detection, improved accuracy, and seamless compliance with industry regulations.

Investing in new vision inspection technology is a step towards higher precision, efficiency, and market competitiveness for manufacturers who seek to improve their quality control processes.

0 notes

Text

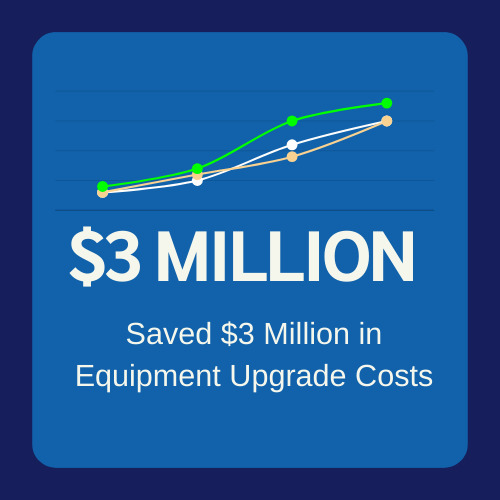

In the fast-paced world of semiconductor manufacturing, staying ahead of technology while managing costs is a constant challenge. Einnosys, a company dedicated to innovative industrial solutions, introduced EIGEMbox—a simple yet powerful device that can transform existing semiconductor equipment by adding modern automation capabilities. This case study explores how EIGEMbox helped semiconductor fabs save a massive $3 million in equipment upgrade costs and enhance their operational efficiency.

#EIGEMBox#SECS/GEM#secs gem software#gem300#secs/gem software#fab automation#predictive maintenance for pumps

0 notes

Text

iDataOps our machine monitoring software fetches the data generated at an equipment level and monitors equipment with predictive maintenance, preventive maintenance and OEE.

#machine monitoring software#predictive machine maintenance#preventive maintenance#asset maintenance management

0 notes

Text

Airline Gating Maintenance

Zulu Airline Systems offers comprehensive airline gating maintenance services designed to ensure the optimal performance and safety of airport gate operations. Our expert team utilizes advanced technology and industry best practices to maintain and enhance gate infrastructure, minimizing downtime and maximizing efficiency. For more information please visit : https://my.visme.co/view/y4rre46x-airline-gating-maintenance

#airline planning system#airline scheduling system#airline software platform#airline gating maintenance#airline predictive analytics

0 notes

Text

How to Calculate Production Efficiency?

When discussing manufacturing and production, achieving operational excellence requires a close analysis of key performance metrics, with production efficiency as the pivotal measure.

The concept encapsulates the complexities of resource allocation, process optimization, and output maximization, acting as a barometer for the performance of a manufacturing instrument. Rooted in mathematical precision, the calculation of production efficiency is a compass guiding enterprises through the complicated web of inputs and outputs, presenting a clear cut idea of the efficacy with which resources are transformed into tangible products.

What is Production Efficiency?

Production efficiency is a key performance indicator that assesses how well a manufacturing process converts inputs into outputs. It involves evaluating the utilization of resources, time, and materials to ensure maximum productivity.

Why is Production Efficiency so Important?

Production efficiency is a critical metric for several reasons. Let’s check it out quickly.

Cost Reduction: Efficient production processes lead to lower production costs, ensuring competitiveness in the market.

Resource Optimization: Maximizing efficiency allows businesses to make the most of their resources, minimizing waste and improving sustainability.

Timely Deliveries: Efficient production ensures timely delivery of products, enhancing customer satisfaction and maintaining a positive brand image.

Improved Profitability: Higher production efficiency directly correlates with increased profitability, making it a key focus for businesses aiming to thrive in a competitive environment.

How to Improve Production Efficiency with CMMS?

CMMS helps achieve production efficiency by introducing a systematic and proactive approach to maintenance. CMMS transforms production management into a streamlined, efficient, and future-ready process, ensuring organizations stay ahead in the competitive business world.

Predictive Maintenance

Asset Tracking

Work Order Management

Data Analytics

Inventory Management

Mobile Accessibility

Documentation and Compliance

Ending Note:

Maximizing production efficiency is essential for sustained success. Businesses can achieve optimal performance by understanding the concept, calculating efficiency, and addressing roadblocks. Implementing CMMS solutions further enhances the ability to proactively manage maintenance and improve overall production efficiency, ensuring long-term viability and profitability.

If you’re eager to explore how CMMS can revolutionize your production processes and drive success, contact us at [email protected]. Our experts are ready to guide you on the transformative journey toward enhanced efficiency and sustainable growth.

#Asset Management#CMMS Software#Inventory Management#Predictive Maintenance#Production Efficiency#Work Order Management

0 notes