#Production Efficiency

Explore tagged Tumblr posts

Text

Factory Management Software (F-VAPP) for Valves Maintenance & Manufacturing Factories and Workshops. 🖥 ------ Revolutionize your valve production and maintenance with F-VAPP—a comprehensive factory management software designed by industry experts who understand the specific needs of the valves manufacturing world. F-VAPP is not just a tool, it's a fully integrated solution that enhances every aspect of your factory’s operations. 📈 ------ Hosted securely on your internal server, F-VAPP provides role-based access for every department, ensuring seamless workflows. It’s more than just software—it’s a complete management system that knows how to prioritize and automate daily operations for each machine and section. F-VAPP deeply understands the intricate processes of valve manufacturing and maintenance, making sure every task is executed efficiently with priorities clearly in place. ---- Why F-VAPP? ---- 1- Tailor-made for the valves industry, considering every detail in production and maintenance. 2- Automated daily operations for machines and departments, prioritizing workflows for maximum efficiency. 3- Real-time production line monitoring and machine load management to optimize operations. 4- Full control over inventory management and cost automation for smart financial planning. 5- User-friendly yet powerful interface that’s simple to navigate and efficient for everyday use. 6- Comprehensive reporting tools for actionable insights and informed decision-making. 7- Streamlined processes through custom roles and permissions, helping you build a clear organizational chart and strong operational workflows. 8- Enhanced collaboration between departments, improving overall productivity and quality management. ---- With F-VAPP, your factory’s operations aren’t just managed—they’re optimized. From inventory control to production management, every function is fine-tuned for efficiency and performance. ---- Key Benefits: ---- 1- Boost productivity by ensuring smooth, prioritized workflows for machines and workers. 2- Gain real-time insights into machine performance, production schedules, and factory output. 3- Automate complex processes like costing, pricing, and inventory management. 4- Seamlessly integrate departments, improving quality control and production planning. 5- Build the perfect organizational structure with clear roles and responsibilities. 6- Generate detailed reports to guide smarter business decisions. ---- F-VAPP goes beyond software. It’s a full-scale factory management system built to meet the specific needs of the valves manufacturing and maintenance industry. Take your operations to the next level with a system designed by professionals, for professionals. 🛠

2 notes

·

View notes

Text

Unlocking Manufacturing Excellence: A Deep Dive into ERPNext's Powerful Features and Services by Sigzen Technologies

In the dynamic and ever-evolving landscape of modern manufacturing, the quest for operational excellence has become more critical than ever. In this pursuit, businesses are increasingly turning to advanced Enterprise Resource Planning (ERP) solutions, and one that stands out prominently is ERPNext. Spearheading innovation in the manufacturing module of ERPNext is Sigzen Technologies, a…

View On WordPress

#Business Innovation#ERPNext Deep Dive#ERPNext Features#Manufacturing Excellence#Manufacturing Revolution#Manufacturing Technology#Production Efficiency#Tech Solutions

2 notes

·

View notes

Text

Exploring the Future of 3D Printing with QSY

The 3D printing industry is evolving rapidly, and one brand that stands out is QSY, known for its high-precision SLS printing service. This innovative technology allows for the creation of intricate designs with remarkable accuracy, making it a favorite among engineers, designers, and manufacturers alike.

QSY's commitment to quality ensures that every project meets the highest standards, enabling clients to bring their visions to life with ease. The high-precision SLS printing service not only enhances the detail of prototypes but also significantly reduces production times, paving the way for more efficient workflows.

As we look to the future, QSY continues to push the boundaries of what's possible in 3D printing. Their dedication to excellence and innovation is inspiring, and it's exciting to see how they will shape the landscape of manufacturing and design. Whether you're looking to create functional prototypes or artistic pieces, QSY's high-precision SLS printing service is sure to exceed your expectations.

0 notes

Text

Red and Yellow Andon: Boosting Manufacturing Efficiency Through Visual Management

In today’s fast-paced industrial environment, the need for real-time communication on the shop floor is more critical than ever. Manufacturers are constantly seeking smarter ways to minimize downtime, improve safety, and ensure smooth operations. One of the most effective tools for achieving this is the Andon system, particularly using Red and Yellow Andon lights.

What is an Andon System?

An Andon system is a visual alert tool used in lean manufacturing to notify operators and managers about production line issues. It helps enhance process visibility, team coordination, and problem resolution.

At Vidgastech, we specialize in designing smart Andon systems tailored for various industrial needs. Our systems use a combination of red and yellow signals to streamline operations and promote rapid response.

Understanding Red and Yellow Andon Signals

🔴 Red Andon Light: This indicates a critical issue that requires immediate attention, such as a machine malfunction, safety hazard, or production stop.

🟡 Yellow Andon Light: A warning signal to show non-critical issues, such as material shortages, minor defects, or preventive maintenance alerts.

These signals help teams act quickly and effectively, reducing downtime and boosting overall productivity.

Benefits of Red and Yellow Andon in Manufacturing

✅ Faster identification and resolution of issues ✅ Improved communication between teams and supervisors ✅ Reduced downtime and higher throughput ✅ Enhanced worker safety and accountability ✅ Supports lean and Six Sigma practices

Why Choose Vidgastech’s Andon Solutions?

At Vidgastech, we understand the unique challenges of modern manufacturing. Our Red and Yellow Andon systems are designed with reliability, clarity, and scalability in mind. We offer:

High-visibility LED Andon lights

IoT integration for real-time monitoring

Custom alerts and configurations

Easy installation and low maintenance

Whether you operate in automotive, electronics, packaging, or food processing, our solutions can be adapted to your specific requirements.

Final Thoughts

Implementing a Red and Yellow Andon system is more than just installing lights—it's about building a culture of responsiveness and continuous improvement. With Vidgastech’s expertise and technology, your facility can achieve greater control, visibility, and operational efficiency.

About Vidgastech Vidgastech is a leading provider of industrial automation solutions, helping businesses transform their shop floors into smart, responsive production environments.

🔗 Learn more at: https://www.vidgastech.com

#Red Andon Light#Yellow Andon Light#Andon System#Lean Manufacturing#Visual Alerts#Production Efficiency#Vidgastech#Smart Factory Solutions

0 notes

Text

The Role of Automation in Modern Soft Drink Plants

In recent years, the beverage industry has undergone significant transformations, particularly in the realm of production processes. Soft drink plants have embraced automation to enhance efficiency, reduce operational costs, and improve product quality. This article delves into the critical role automation plays in modern soft drink plants, examining its benefits, the technologies involved, and the future of automation in the beverage industry.

Understanding Automation in Soft Drink Plants

Automation refers to the use of technology to perform tasks with minimal human intervention. In soft drink plants, this encompasses a wide range of processes, including ingredient handling, mixing, carbonation, packaging, and quality control. By integrating automated systems, soft drink plants can streamline operations, minimize errors, and maintain consistent product quality.

Benefits of Automation in Soft Drink Plants

Increased Efficiency Automation significantly boosts the efficiency of production lines in soft drink plants. With advanced machinery capable of operating at high speeds, companies can produce larger quantities of beverages in a shorter timeframe. For instance, automated filling and capping machines can handle thousands of bottles per hour, far surpassing the output of manual processes.

Cost Reduction While the initial investment in automation may be substantial, the long-term savings can be significant. Automated systems reduce labor costs by minimizing the need for manual labor in repetitive tasks. Additionally, automated processes can help in reducing material waste and enhancing energy efficiency, further driving down operational costs in soft drink plants.

Improved Quality Control Consistency is crucial in the soft drink plant industry, where consumers expect the same taste and quality with every purchase. Automation facilitates rigorous quality control measures through advanced monitoring systems. These systems can continuously check for product quality, ensuring that every bottle meets industry standards before reaching consumers. This leads to higher customer satisfaction and fewer product recalls.

Enhanced Safety The beverage production environment can pose various safety risks, from handling heavy machinery to managing hazardous substances. Automation in soft drink plants minimizes these risks by reducing human involvement in dangerous processes. Automated systems can handle tasks such as cleaning and maintenance, thereby creating a safer workplace for employees.

Flexibility and Scalability Modern automated systems are designed to be flexible and scalable, allowing soft drink plants to adapt to changing market demands. With the ability to easily switch between different product lines or adjust production volumes, companies can respond swiftly to consumer preferences without significant downtime.

Technologies Driving Automation in Soft Drink Plants

Several technologies are instrumental in the automation of soft drink plants:

1. Robotics

Robotic systems have become integral to the operations of soft drink plants. Robots are employed for various tasks, including packing, palletizing, and material handling. These machines can work continuously without fatigue, increasing productivity while ensuring precise handling of products.

2. Supervisory Control and Data Acquisition (SCADA)

SCADA systems play a vital role in monitoring and controlling production processes in soft drink plants. These systems provide real-time data on equipment performance, allowing operators to make informed decisions and quickly address any issues that arise.

3. Internet of Things (IoT)

The integration of IoT technology in soft drink plants enables the connection of machinery and equipment to the internet. This connectivity allows for remote monitoring and control of production processes, providing insights into operational efficiency and enabling predictive maintenance.

4. Artificial Intelligence (AI) and Machine Learning

AI and machine learning algorithms are increasingly being used in soft drink plants to analyze production data, forecast demand, and optimize processes. These technologies can identify patterns and trends, allowing companies to make data-driven decisions that enhance productivity and reduce costs.

Challenges of Implementing Automation in Soft Drink Plants

While the benefits of automation are substantial, soft drink plants may face several challenges when implementing these technologies:

High Initial Costs The initial investment in automated equipment and systems can be considerable. Many smaller soft drink plants may struggle to afford the upfront costs associated with automation.

Integration with Existing Systems Integrating new automated technologies with existing systems can pose challenges. Compatibility issues may arise, requiring additional time and resources to ensure seamless operations.

Training and Skill Development As automation becomes more prevalent, there is a growing need for skilled workers who can operate and maintain advanced machinery. Soft drink plants may need to invest in training programs to equip their workforce with the necessary skills.

Dependence on Technology Increased automation can lead to a higher dependence on technology, making soft drink plants vulnerable to technical failures or cyber threats. Robust backup systems and cybersecurity measures are essential to mitigate these risks.

The Future of Automation in Soft Drink Plants

The future of automation in soft drink plants looks promising, with ongoing advancements in technology driving further improvements in efficiency and productivity. As artificial intelligence, machine learning, and IoT continue to evolve, soft drink plants will likely become more intelligent and self-sufficient.

Furthermore, the push for sustainability in the beverage industry will drive innovation in automation. Soft drink plants will increasingly adopt technologies that minimize waste, conserve energy, and reduce the carbon footprint of production processes. Automation will play a crucial role in achieving these sustainability goals.

Conclusion

In conclusion, automation is revolutionizing the way soft drink plants operate, offering numerous benefits such as increased efficiency, cost reduction, improved quality control, enhanced safety, and greater flexibility. While challenges remain, the advancements in technology present significant opportunities for growth and innovation in the beverage industry. As soft drink plants continue to embrace automation, they will be better equipped to meet consumer demands and navigate the complexities of the modern marketplace. The future of the soft drink industry is undeniably tied to the role of automation, ensuring that these plants remain competitive and sustainable for years to come.

0 notes

Text

Role of Rapid Mixer Granulator in Pharmaceutical Manufacturing: A Game Changer in Production Excellence

The production of life-saving medication is about precision, consistency, and efficiency in every phase. If the differences come across in the production aspect, it really depends on the machinery used. Among such pivotal changes in the approach of pharmaceutical manufacturers towards the process of granulation of product is the equipment known as the Rapid Mixer Granulator.

Granulation Problem

Picture a pharmaceutical manufacturing site where teams are under way for poor batch quality, increased processing times, and the pressure always to ensure extremely demanding regulatory compliance. These aren't just production metrics of consequence – they have a direct impact on the real patients waiting for their medicines.

The conventional granulation techniques often require transfer from one machine to another and are accompanied by a higher risk of human error. Transfer between machines has possibilities of contamination. Apart from this, long processing times prevent achieving full production capacity.

How Rapid Mixer Granulator is Changing Pharmaceutical Production

The Rapid Mixer Granulator is a multi-functional, integral unit combining mixing, granulation, and drying together in one powerful component. Think of it like a master chef who can prepare, cook, and plate a gourmet meal in one efficient workspace. Because transfer steps are no longer involved, the risk of contamination is decreased, and the overall granulation process can move at a lightning-fast pace.

Critical Features with Robust Performance

Computer Control System: Real-time control over the critical parameters that affect the quality of the batch

High-Speed Chopper Design: Uniform particle distribution facilitates improved flowability and compression properties

Automated Process Sequences: Less operator intervention minimizes errors, while quality is preserved

Clean-in-Place Systems: Easily switch between batches with decreased chances of contamination

Recently, a mid-sized pharmaceutical manufacturer in New Jersey has shown a 40% reduction in batch processing time after installing an RMG system. More importantly, their batch-to-batch consistency improved significantly with much fewer rejected batches and higher production yields.

The Scientific Advantage

The RMG was established based on fundamental particle science. Based on these considerations, its design looks into such aspects as:

Powder flow properties

Particle size distribution

Moisture content regulation

Optimization of the binding mechanism

These scientific principles translate to practical advantages that pharmaceutical manufacturers can measure, such as:

Better product quality

Uniform particle size distribution

Better content uniformity

Improved dissolution properties

Operational efficiency

Less processing time

Lower energy consumption

Less material waste

Regulatory compliance

Better documentation

Reproducible processes

Full batch traceability

Making the Right Investment Decision

In making an investment decision regarding production equipment, pharmaceutical manufacturers should balance between short-term needs and long-term value. The Rapid Mixer Granulator forms a strategic investment with the payoff in the following immediate benefits:

Reduced labor cost due to automation

Less servicing costs

Fewer time-cycles per batch

Higher quality product

Long-term Benefits

Increased capacity

Improved regulatory compliance

Better resource utilization

Fewer problems due to quality

More than the Machine

If an RMG system is in place and it is operating correctly, it is more than the machine. These systems make the manufacturing teams feel positive about maintaining quality consistency. The operators enjoy the reduced physical handling, and quality control teams appreciate a complete record of data.

The Future

Given the evolution of this industry based on the market's growing demand for efficiency, quality, and sustainability, the Rapid Mixer Granulator aligns with all these while providing a solution not just according to current needs but also sets its manufacturers up for the future.

More than mere equipment, the RMG represents an investment in manufacturing excellence for pharmaceutical manufacturers seeking to optimize granulation processes. Combining the science of precision with the practicality of efficiency, the RMG delivers the consistency and quality demanded by modern pharmaceutical production.

Whether you're expanding your production capacity or revamping your existing plant with the latest in facilities, take a closer look at a Rapid Mixer Granulator for your production process. The proof is indeed in the pudding: higher quality, greater efficiency, and greater compliance—all delivered through one well-designed system.

#Rapid Mixer Granulator#Pharmaceutical Manufacturing#Production Efficiency#Quality Assurance#Cost-Effective Solutions

0 notes

Text

By streamlining concrete pipe manufacturing and prioritizing precision and innovation, we ensure top-tier products that surpass industry standards. This holistic approach enhances every step of production, from raw material handling to final product delivery.

0 notes

Text

How to Calculate Production Efficiency?

When discussing manufacturing and production, achieving operational excellence requires a close analysis of key performance metrics, with production efficiency as the pivotal measure.

The concept encapsulates the complexities of resource allocation, process optimization, and output maximization, acting as a barometer for the performance of a manufacturing instrument. Rooted in mathematical precision, the calculation of production efficiency is a compass guiding enterprises through the complicated web of inputs and outputs, presenting a clear cut idea of the efficacy with which resources are transformed into tangible products.

What is Production Efficiency?

Production efficiency is a key performance indicator that assesses how well a manufacturing process converts inputs into outputs. It involves evaluating the utilization of resources, time, and materials to ensure maximum productivity.

Why is Production Efficiency so Important?

Production efficiency is a critical metric for several reasons. Let’s check it out quickly.

Cost Reduction: Efficient production processes lead to lower production costs, ensuring competitiveness in the market.

Resource Optimization: Maximizing efficiency allows businesses to make the most of their resources, minimizing waste and improving sustainability.

Timely Deliveries: Efficient production ensures timely delivery of products, enhancing customer satisfaction and maintaining a positive brand image.

Improved Profitability: Higher production efficiency directly correlates with increased profitability, making it a key focus for businesses aiming to thrive in a competitive environment.

How to Improve Production Efficiency with CMMS?

CMMS helps achieve production efficiency by introducing a systematic and proactive approach to maintenance. CMMS transforms production management into a streamlined, efficient, and future-ready process, ensuring organizations stay ahead in the competitive business world.

Predictive Maintenance

Asset Tracking

Work Order Management

Data Analytics

Inventory Management

Mobile Accessibility

Documentation and Compliance

Ending Note:

Maximizing production efficiency is essential for sustained success. Businesses can achieve optimal performance by understanding the concept, calculating efficiency, and addressing roadblocks. Implementing CMMS solutions further enhances the ability to proactively manage maintenance and improve overall production efficiency, ensuring long-term viability and profitability.

If you’re eager to explore how CMMS can revolutionize your production processes and drive success, contact us at [email protected]. Our experts are ready to guide you on the transformative journey toward enhanced efficiency and sustainable growth.

#Asset Management#CMMS Software#Inventory Management#Predictive Maintenance#Production Efficiency#Work Order Management

0 notes

Text

youtube

A Customer Testimonial for SimpleDay, Your Trusted Monday.com Authorized Partner | Unlocking Success

n this insightful customer testimonial, Tom Nelson from American Tank in Windsor, California, shares his experience with SimpleDay's expert solutions. Discover how we transformed American Tank's management and production systems, providing them with unparalleled efficiency and reducing stress, errors, and production time by over 80%. If you're seeking production efficiencies, management oversight, quality controls, and a comprehensive history archive, join us in exploring the impactful collaboration between American Tank and SimpleDay. Ready to elevate your business with Monday.com? Trust the experts at SimpleDay to be your Chief Engineers on the path to success. Subscribe now for more success stories and valuable insights!

#business efficiency#manufacturing success#american tank#productivity boost#collaboration success#production efficiency#customer acquisition#procurement success#business management#testimonial video#a customer testimonial for simpleday#your trusted monday.com authorized partner | unlocking success#Tom Nelson#Monday.com Authorized Partner#monday.com#custom implemention#tara horn monday.com#monday.com tutorials#monday.com quick tutorial#optimize your workflow#Youtube

1 note

·

View note

Text

Unlocking Efficiency and Purity: Exploring the Range of Shree Vishwakarma Magnetic Separators

Shree Vishwakarma Magnets, a reputable producer, manufactures high-quality, customizable Magnetic Separators including Wet Magnetic Separator, Overband Magnetic Separator, Hump Magnetic Separator, and Roller Type Magnetic Separator. Magnetic separators play a pivotal role in ensuring efficiency, purity, and quality. They're renowned for quality and customer satisfaction, delivering efficiency and purity to industries. This magnetic separator not only enhances the overall efficiency of numerous operations but also extends the life of machinery and equipment. Contact us for bulk orders and optimize your processes.

#Magnetic Separators#Industrial Equipment#Efficiency#Quality Control#Manufacturing#Customization#Bulk Orders#Machinery#Industrial Solutions#Purity#Magnetic Technology#Customer Satisfaction#Production Efficiency#Magnetic Innovation#Machine Maintenance#Process Optimization#Industry Solutions#Magnetic Performance#Reliability#Shree Vishwakarma Magnets#Wet Magnetic Separator#Overband Magnetic Separator#Hump Magnetic Separator#Roller Type Magnetic Separator

1 note

·

View note

Link

9 effective ways to improve aluminum profile yield, here we discuss from aluminum billets to the inspection process to improve aluminum profile yield.

#improve aluminum profile yield#aluminum profile#aluminum extrusion#aluminum production#production efficiency#effective way

0 notes

Text

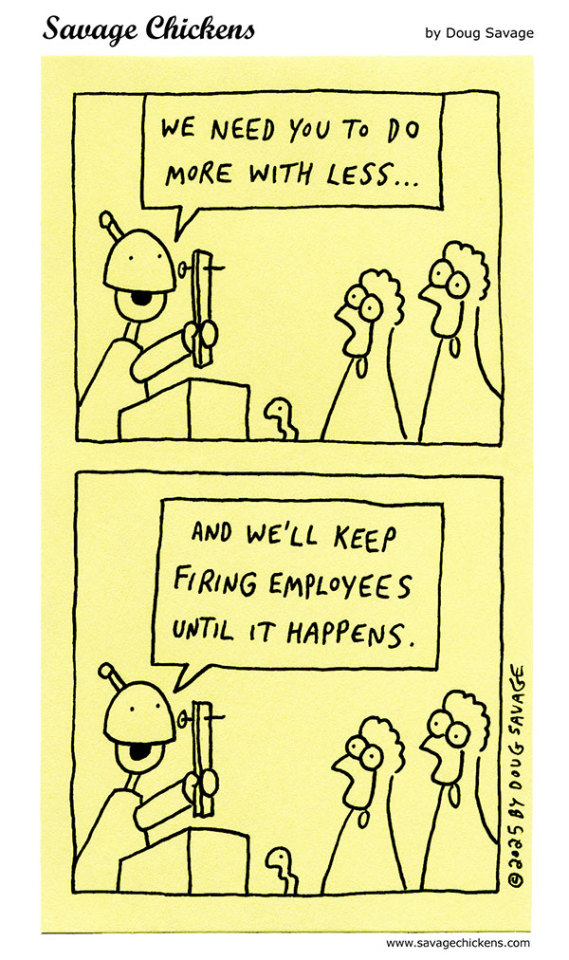

We put enormous emphasis on optimizing quantities. Our attention is shackled to screens where we make certain numbers go up and other numbers go down. We want to measure everything so that we can control and optimize it. The benefit of this is that we are able to fulfill our material needs more efficiently and with less effort.

But by doing so, we begin to think only about quantities. We create incentives to sacrifice quality in order to obtain better quantitative results. We become so focused on measuring and optimizing, on increasing efficiency and productivity, that we stop thinking about what is happening to us in our day-to-day lives.

It is perhaps not surprising that we then feel there is something missing — as though life is not going as well as it ought to be, even though all of the numbers are moving in the right direction.

Read more...

53 notes

·

View notes

Text

Glansa Solutions specializes in smart factory technologies, including advanced Andon devices for real-time production monitoring. Our customizable Andon systems help manufacturers reduce downtime, improve shop floor communication, and support lean manufacturing processes. Trusted by industries like automotive, electronics, and FMCG.

#Andon Device#Glansa Solutions#Lean Manufacturing Tools#Industrial Automation#Smart Factory Systems#Shop Floor Monitoring#Real-Time Alert System#Production Efficiency

0 notes

Note

Hey! I was wondering if it was planned for the MC to have an appearance? In the sense of height, skin tone, hair length/texture, etc. So far, I haven't noticed any references to anything like that or choices that determine it, but I know a lot of visual novels sometimes rely on height to create more tension (Y'know, like some characters towering over others and that famous "let me help you with that!" When a character is too short to reach something) or hair combing/braiding to signify intimacy between characters.

If this has already been answered or I've missed something in the game, feel free to ignore this lol!

Noooope. We try to be mindful about not writing anything regarding MC’s appearance or physical features! For various reasons.

In fact, hair especially is something that we make sure NOT to incorporate or emphasize often considering that not everyone who plays this game has hair that people can run their fingers through/hair that can be ruffled/or even hair that can be seen.

So really, we try to be as ambiguous and unassuming as possible when it comes to the MC.

#keyframes asks#there’s other things like— okay if the MC is short and another character offers to help because of it— then what about a tall MC?#might as well just have the other character help regardless of height so there’s no point in clocking it#an inside look on the things we devs have to consider to make things inclusive#and also efficient for production uwu

79 notes

·

View notes

Text

The Plan for More.

And more productivity.

55 notes

·

View notes