#Prefabricated Noise Control

Explore tagged Tumblr posts

Text

EPACK Prefab provides durable Acoustic Enclosures designed to minimize noise pollution in industrial and commercial spaces. These housings are built for superior soundproofing, durability, and easy installation, ensuring a quieter and safer environment. Choose EPACK Prefab for reliable noise control solutions!

#Acoustic Enclosure#Soundproof Housing#Noise Control Solutions#Modular Acoustic Housing#Industrial Noise Reduction#Portable Acoustic Enclosures#Durable Soundproof Enclosure#Prefabricated Noise Control#Generator Acoustic Enclosure#EPACK Prefab Acoustic Solutions.

0 notes

Text

Introductions Pt. 2

You continue your introductions to the stuck Dark Angel.

Warnings: drug use, Some one being stuck in a pit caused by shoddy construction.

Summary: You try to help the Dark Angel that seems to be stuck in the pit.

You took another drag, it was a big one. The cheery red glow of the joint flared, and then spent an embarrassingly long time, coughing your lungs up. Joints were always a crap shoot. The two red lenses you could see from the pit kept locked on you. Whoever, or whatever, was down there, called out again, id unnerving deep voice sound more like gravel then words. It made you feel a bit floaty. Then you started again.

“ Okay, okay, I’m good. Let's try to get a better look at what going on.” You manage to gasp as you fight to get your coughing under control. Slow clumsy hands searched through your inner pockets for your cell phone and then got the flashlight going. You edged to the side and a little forward to get a better angle and then shone the light down into the pit. There was a light feel-good atmosphere that beckoned you towards the edge, but you very carefully kept back. The last thing you needed was the two of you stuck in the pit.

It was definitely taller than you had expected it to be, the pit was also deeper. Looking down you noticed that the bottom of the pit seemed to be the concrete foundations and mechanical greebily bits, that presumably made something work, you also noticed that the dark green metal boots had broken though the concrete below him, which explained why the dude was so much lower than you expected him to be.

You have a better look at the… Marine? It had to be one, you had never seen one in person before, but this was not one of the blue ones with gold trim that you saw on TV. it had to be a marine though, nothing else that you could think of really had that refrigerator shape. He was a dark forest green, and he looked like the embodiment of the phrase ‘visual noise’. The light of the flashlight shone off of chains, small bits of paper with red seals, and some almost monk-like robes. Watching the armour lean back in an attempt to look up was almost adorable. Your high mind could not help but think of a medieval beetle. Smirking a little you started looking around, it looked like his boots had only cracked through to the calves, and given the way he shuffled a little he had some movement.

“I don’t suppose you can move your feet can you?” You asked it rhetorically, the Marine seemed to whine a bit before grumbling some sort of comment of his own. You resorted to charades, pointing to his feet and then lifting your feet up exaggeratedly before flashing a thumbs up with a smile or a thumbs down with an exaggerated frown.

Obligingly he flashed the world’s most awkward thumbs up, seemingly confused at the motion before lifting up one foot as demonstration. As soon as he placed it on top of the cheap prefabricated concrete, the concrete started to crack under his foot, and then it broke through again, with a nasty sounding crunch.

“Okay, bub. You just hang tight there I guess, not much we can do just the two of us.” You looked down at your cell again, no service, of course. “We’ll have to figure something out.” Which was unfortunate for him because you were definitely more than a little high and a quick gaze around confirmed that no one else was around to be the responsible one.

“Just a second.” You tell the Marine, signing for them to wait, in the forlorn hope that they possibly know ASL, given the grumbling in ever increasing volume you assumed they did not. Your book clad feet crisply walked towards Russ’s house. It was where you were going anyway and where you knew people would be gathering. Kristy would be there, and Kristy was organized and responsible enough to deal with this. You had just made it to the road when you heard what sounded like a chainsaw kick up and the pop and snap of buckling concrete behind you.

Do you turn around to check in on the Marine, or do you continue to Russ’s house to get help?

Part 3

#cw drug use#some one being stuck in a pit#dark angels#reader insert#choose your own adventure via vote#warhammer 40000#creative exercise#oops I actually had to work today so it is poorly edited#I will edit it at the end of the day.

12 notes

·

View notes

Text

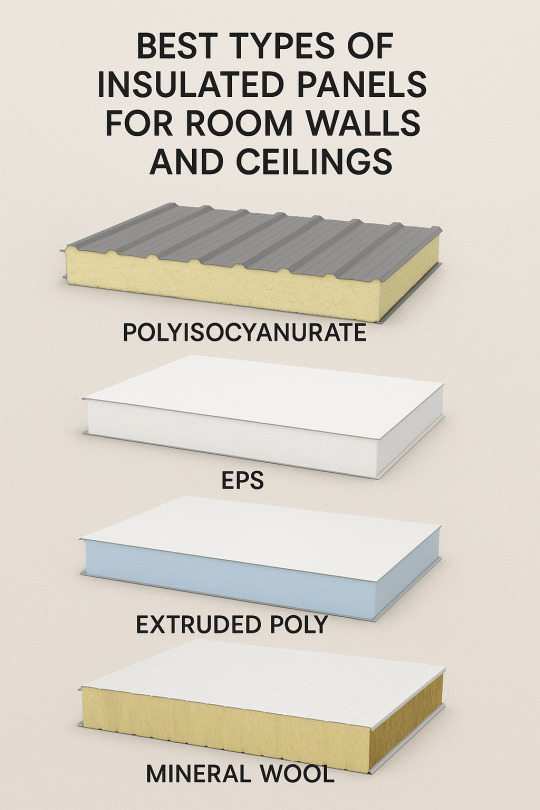

Best Types of Insulated Panels for Room Walls and Ceilings

In modern construction, energy efficiency, durability, and speed are more important than ever. Whether you're building a residential home, commercial office, warehouse, or prefab structure, choosing the right insulation for walls and ceilings is key to maintaining indoor comfort and reducing energy costs.

Insulated panels are prefabricated systems that combine insulation and structural support in a single solution. They’re ideal for temperature control, noise reduction, and structural strength. Here's a look at the best types of insulated panels for room walls and ceilings, each with its own advantages:

1. Polyisocyanurate (PIR) Panels

Polyisocyanurate, or PIR, is one of the highest-performing thermal insulation materials used in construction today. These panels consist of rigid foam sandwiched between two metal or board layers.

Key Benefits:

Superior thermal efficiency – high R-value per inch

Fire resistance – self-extinguishing properties

Lightweight and durable – easy to handle and install

Moisture resistance – ideal for both indoor and outdoor use

PIR panels are ideal for temperature-controlled spaces such as cold storage, server rooms, and industrial buildings.

2. Expanded Polystyrene (EPS) Panels

EPS panels are made from expanded polystyrene foam, known for its excellent insulating properties and cost-effectiveness. These panels are widely used in prefabricated and modular buildings.

Key Benefits:

Affordable insulation solution

Good thermal and acoustic performance

Lightweight and easy to cut or install

Environmentally friendly and recyclable

EPS panels are great for residential rooms, partitions, and standard prefab structures where cost and speed are priorities.

3. Extruded Polystyrene (XPS) Panels

Extruded polystyrene is a denser and stronger form of polystyrene insulation. XPS panels offer excellent thermal performance and resistance to moisture, making them ideal for high-humidity environments.

Key Benefits:

High compressive strength

Excellent moisture and water resistance

Smooth surface finish

Long-term durability

These panels are often used for roofs, ceilings, basements, and cold storage facilities.

4. Mineral Wool Panels

Mineral wool (or rock wool) panels are made from natural stone or slag fibers. Known for their fire resistance and soundproofing qualities, these panels are ideal for buildings where fire safety is a top priority.

Key Benefits:

Non-combustible and fire-resistant

Excellent sound insulation

Resistant to pests, mold, and rot

Eco-friendly and recyclable

They are commonly used in commercial and industrial spaces, especially in applications requiring acoustic control and fire safety.

Conclusion

The choice of insulated panels depends on your building's requirements—whether it’s superior thermal performance, moisture resistance, acoustic insulation, or fire safety.

Polyisocyanurate is best for energy efficiency, EPS offers an economical and lightweight option, XPS excels in moisture-prone areas, and Mineral Wool provides unbeatable fire and sound insulation.

Investing in the right insulation solution helps you reduce energy bills, enhance occupant comfort, and extend the life of your building.

Looking for high-quality insulated panel solutions? Partner with trusted manufacturers like Engko for expert guidance and top-grade materials tailored to your project.

#prefab#pre engineered building manufacturers#prefabricated#peb#prefabricated structure#warehouse#industrial

1 note

·

View note

Text

Elevating Interiors: Global Ceiling Tiles Industry Analysis and Future Prospects

Market Overview

The ceiling tiles market was valued at approximately USD 6.9 billion in 2021 and is expected to grow at a CAGR of around 7% from 2022 to 2030, reaching an estimated USD 12.7 billion by the end of the forecast period, driven by rapid urbanization, rising construction activities, and growing demand for aesthetically appealing and acoustically efficient interiors.

Ceiling tiles, also known as ceiling panels, are lightweight construction materials used in interior ceilings to enhance aesthetics, improve acoustics, and conceal HVAC systems or structural elements. These tiles are popular in commercial, residential, and industrial settings.

Market Dynamics

Drivers

Urbanization and Commercial Construction Boom Increasing global urbanization and the growth of commercial spaces like offices, malls, hospitals, and educational institutions are significantly boosting demand for ceiling tiles.

Rising Focus on Interior Aesthetics and Acoustics Modern consumers and businesses prioritize indoor aesthetics and soundproofing, both of which ceiling tiles help achieve. Acoustic ceiling tiles are particularly in demand in offices and theaters.

Green Building Trends Eco-friendly and recyclable ceiling tile materials are gaining popularity due to sustainability concerns and green certification requirements (like LEED).

Technological Advancements Innovation in product design—such as antimicrobial coatings, moisture resistance, and smart integration—is expanding market potential.

Challenges

High Installation and Maintenance Costs Especially in emerging markets, cost barriers may hinder adoption.

Environmental and Disposal Concerns Some ceiling tile materials pose challenges in terms of disposal and recyclability.

Opportunities

Emerging Markets in Asia-Pacific and Africa Growing middle-class populations and infrastructure spending in countries like India, Indonesia, and Nigeria present significant growth opportunities.

Customization and Modular Construction Demand for modular and prefabricated buildings is increasing, where pre-engineered ceiling tiles play a vital role.

Regional Analysis

North America

North America remains one of the largest markets due to early adoption, strict building codes, and the presence of major manufacturers like Armstrong World Industries. The U.S. accounts for the bulk of the regional share.

Europe

The European market is driven by demand for sustainable and fire-rated building materials. Countries such as Germany, the UK, and France lead with renovation projects in both commercial and residential sectors.

Asia-Pacific

This region is projected to experience the fastest growth. Rapid urban expansion, rising disposable incomes, and government infrastructure initiatives in countries like China, India, and Japan are fueling demand.

Latin America and Middle East & Africa (MEA)

Though smaller in size, these regions are seeing steady growth due to increasing commercial construction and international investments in real estate.

Segmental Analysis

By Material Type

Mineral Fiber (largest share) Widely used due to affordability, acoustic performance, and fire resistance.

Metal Popular in modern commercial buildings; known for durability and sleek aesthetics.

Gypsum Used in moisture-prone areas; offers good insulation.

PVC and Others Includes wood, fiberglass, and composite tiles.

By Application

Commercial (dominant segment) Offices, shopping malls, hospitals, schools—spaces where acoustics and appearance are crucial.

Residential Gaining traction in luxury and high-end housing, especially in urban areas.

Industrial Used in controlled environments like labs and clean rooms for dust and noise control.

Key Trends

Integration with Smart Building Systems New ceiling tiles are designed to support integrated lighting, sound, and HVAC systems.

Focus on Acoustic Performance Acoustic tiles are becoming standard in workplaces and institutions to improve productivity and privacy.

Use of Recycled and Biodegradable Materials Sustainable materials are being used more frequently to comply with global environmental standards.

Design Innovation and Customization Consumers are seeking unique finishes, colors, and patterns to align with interior design themes.

Request PDF Brochure: https://www.thebrainyinsights.com/enquiry/sample-request/13174

List of Key Players

Armstrong World Industries, Inc.

Knauf Ceiling Solutions

USG Corporation

Saint-Gobain S.A.

Rockfon (ROCKWOOL International)

Odenwald Faserplattenwerk GmbH (OWA)

SAS International

Grenzebach BSH GmbH

Techno Ceiling Products

New Ceiling Tiles LLC

These players are investing in R&D to enhance product performance, expand product lines, and develop sustainable solutions.

Conclusion

The ceiling tiles market is set for sustained growth through 2030, powered by construction sector expansion, rising aesthetic and acoustic preferences, and innovations in eco-friendly materials. While North America and Europe remain mature markets, Asia-Pacific is the new growth frontier, where urban development and infrastructure investments are rapidly accelerating adoption. With an increasing shift toward smart, green, and visually appealing interiors, ceiling tiles will play a key role in future building trends.

For Further Information:

Market Introduction

Market Dynamics

Segment Analysis

Some of the Key Market Players

0 notes

Text

Innovative Acoustic Treatment for Carbon-Neutral Buildings

Modern architecture is undergoing a transformation. As the world shifts toward more eco-conscious construction, a new hero is rising to the forefront—Acoustic Treatment. Often underestimated in the early design stages, acoustic treatment is now a defining element in the journey toward creating carbon-neutral buildings that are not only energy-efficient but also acoustically balanced.

While green materials and renewable energy sources steal the spotlight, it’s the unseen (or unheard) factors—like sound control—that truly define a holistic, high-performance building. The right acoustic treatment doesn’t just reduce noise; it enhances well-being, supports productivity, and aligns seamlessly with sustainability goals.

Let’s delve into how innovation in acoustic treatment is echoing through the corridors of sustainable design.

Sound of Sustainability: Why Acoustics Matter in Green Architecture

When thinking of carbon-neutral buildings, the focus is usually on solar panels, rainwater harvesting, or smart HVAC systems. Yet, acoustic treatment plays a crucial role in maintaining comfort and reducing environmental impact.

Poor acoustics in a workspace or home can lead to stress, fatigue, and even long-term health issues. That means any truly sustainable building must consider both physical and mental wellness—which is where acoustic treatment becomes indispensable.

But the challenge lies in balancing performance with purpose: How do you ensure high-quality sound insulation while reducing the building’s carbon footprint?

Nature-Inspired Materials Are Redefining Sound Absorption

Biophilic design isn’t just about indoor plants and sunlight—it’s now influencing acoustic treatment too. New materials inspired by nature are transforming how we approach sound absorption.

Take mycelium panels, made from mushroom roots. These panels are not only biodegradable but also highly effective at controlling echo and reverberation. Then there’s recycled PET felt, derived from discarded plastic bottles, which serves as a flexible and lightweight acoustic treatment option with a minimal carbon footprint.

Wood wool, cork, hemp, and even seaweed are also entering the material palette for acoustic treatment, helping designers meet green certification standards like LEED and WELL.

Smart Systems, Smarter Soundscapes

With IoT and AI shaping our built environments, acoustic treatment is becoming smarter, too. Adaptive acoustic systems can now “listen” and respond to the noise levels in real-time.

For example, in a multi-use space like a co-working hub, the acoustic treatment system can increase absorption during high-traffic hours and lower it when ambient noise levels drop. These dynamic systems not only enhance user comfort but also reduce the need for constant manual adjustment or retrofitting.

Moreover, energy-efficient sound masking solutions—like low-power speakers integrated with acoustic panels—are offering a dual benefit: enhanced sound control and lower electricity consumption.

Modular and Prefabricated Acoustic Systems: Sustainability Meets Flexibility

Today’s carbon-neutral buildings need to be agile. Enter modular and prefabricated acoustic treatment systems, designed to offer flexibility without compromising on environmental goals.

Think demountable acoustic panels that can be reconfigured for different layouts, or ceiling baffles made of recyclable materials that can be reused in future projects. These solutions minimize waste and contribute to a building’s life cycle efficiency.

Such plug-and-play acoustic treatment innovations are perfect for tenant improvement projects, co-working environments, or educational institutions that evolve over time.

Acoustics Beyond Walls: Exterior Sound Control

Acoustic treatment is no longer confined to interiors. Outdoor environments—especially in urban settings—are increasingly adopting acoustic strategies to mitigate noise pollution.

Green walls, water features, and acoustic fencing made from upcycled rubber or composite wood are part of this trend. These solutions help buffer traffic and industrial noise while adding to the aesthetic and ecological value of a site.

In carbon-neutral campuses or sustainable housing projects, these outdoor acoustic treatment features serve as a bridge between nature and nurture—delivering tranquility without increasing carbon load.

Case in Point: Global Innovations That Inspire

The Edge in Amsterdam—known as the greenest building in the world—features high-performance acoustic treatment using recycled and locally sourced materials to support wellness in its open-plan office spaces.

Google’s Bay View Campus—designed with sustainability at its core—employs PET-based ceiling clouds for effective acoustic treatment, reducing both noise and environmental impact.

India’s Infosys campuses, especially in Pune and Hyderabad, have also begun to incorporate acoustic zoning and bio-based materials as part of their green building strategies.

These examples prove that world-class architecture can, and must, embrace acoustic treatment as a sustainability essential—not just a nice-to-have.

Cost Myth: Green Acoustics Are Affordable in the Long Run

One of the biggest myths in building design is that eco-friendly equals expensive. While innovative acoustic treatment materials may have a slightly higher upfront cost, they offer immense long-term benefits.

Reduced energy bills (due to integrated thermal-acoustic panels), lower maintenance, improved occupant satisfaction, and eligibility for green certifications are just some of the tangible returns.

In fact, developers and facility managers are increasingly viewing acoustic treatment as a sound investment—literally and figuratively.

Looking Ahead: The Future is Quiet and Green

The demand for carbon-neutral buildings is no longer a niche—it's becoming the norm. And as we design the spaces of the future, one thing is clear: acoustic treatment will be at the heart of innovation.

From algorithm-driven design tools that optimize room acoustics before construction, to biodegradable panels that align with cradle-to-cradle philosophies, the next wave of acoustic treatment is about harmony—between people, performance, and the planet.

Final Thoughts

When we design spaces that sound as good as they look—and do as much good for the planet as they do for people—we’re building more than architecture. We’re building a legacy.

By integrating acoustic treatment into the core of sustainable architecture, we’re not just reducing noise—we’re amplifying the message of responsible innovation.

0 notes

Text

Reducing Environmental Hazards on Construction Sites: Best Practices

Construction sites are vital to the development of modern infrastructure, but they can also be significant sources of environmental hazards. From air and noise pollution to hazardous waste and contaminated run-off, poorly managed construction sites pose risks not only to the environment but also to public health and safety.

To mitigate these risks, it's crucial to adopt best practices in environmental management. Whether you are managing a small-scale residential build or a large commercial development, reducing your site's environmental impact is both a legal and ethical responsibility — and it starts with proper planning, site practices, and waste management.

Understanding Environmental Hazards on Site

Environmental hazards on construction sites come in many forms:

Air pollution from dust and diesel emissions

Water pollution from chemical run-off or sedimentation

Soil contamination from spills of fuel, oil, or hazardous materials

Noise pollution affecting nearby communities

Waste mismanagement, including improper disposal of materials

These issues can result in costly fines, project delays, and long-term environmental damage if not addressed proactively.

Best Practices to Minimise Environmental Risks

Here are some of the most effective ways to reduce environmental hazards on construction sites:

1. Conduct a Site Environmental Impact Assessment

Before work begins, carry out a comprehensive environmental assessment. This helps identify potential hazards and ensures appropriate control measures are put in place. Consider factors like proximity to water sources, local wildlife, and air quality.

2. Implement Dust and Emissions Control

Dust can cause respiratory issues for workers and nearby residents, while diesel emissions contribute to air pollution. To manage this:

Use water sprays to suppress dust on dry days.

Minimise vehicle idling and use low-emission equipment.

Install barriers to contain dust from demolition or excavation.

3. Control Surface Water and Prevent Contamination

Run-off from construction sites can carry oil, chemicals, and sediments into nearby water bodies. Implement containment systems like:

Silt fences and sediment traps

Proper drainage planning

Secure storage for chemicals and fuels away from drains

4. Proper Waste Management

Waste is one of the most visible environmental issues on any construction site. Best practices include:

Segregating materials (e.g., wood, metal, concrete, hazardous waste)

Using clearly labelled skips and containers

Partnering with licensed waste carriers who prioritise recycling

Maguire Skips & Waste, for example, offers tailored waste management solutions across South London and Greater London, helping builders responsibly dispose of construction waste while meeting environmental and legal standards.

5. Use Sustainable Building Materials

Choose materials that are locally sourced, recyclable, or have low environmental impact. Prefabricated materials and modular construction methods can also reduce on-site waste and resource usage.

6. Train Workers on Environmental Awareness

Your team plays a critical role in hazard reduction. Provide training to ensure workers understand:

How to handle hazardous materials safely

Spill response procedures

Importance of waste segregation

Energy-saving practices on site

Such training should be part of a wider health and safety programme, especially in highly regulated regions like Health and Safety in London, where compliance standards are strict and continuously evolving.

7. Noise and Vibration Control

Noise and vibration can disrupt local communities and ecosystems. Reduce their impact by:

Limiting noisy operations to standard working hours

Using acoustic barriers

Selecting quieter equipment and machinery

Monitoring noise levels regularly also helps ensure compliance with local regulations.

8. Spill Prevention and Response

Even minor spills of oil or chemicals can cause significant environmental damage. Preventative measures include:

Using spill trays and bunds under storage areas

Storing chemicals in designated, secure locations

Keeping spill kits on site and training workers in their use

Effective spill response is especially important on sites governed by strict local legislation, such as projects in Health and Safety in Berkshire, where environmental and safety protocols are rigorously enforced.

9. Keep Accurate Records and Documentation

Maintain thorough documentation of your environmental policies, training records, incident logs, and waste transfer notes. These records not only ensure legal compliance but can also be useful for audits and stakeholder transparency.

The Benefits of Environmental Responsibility

Reducing environmental hazards isn’t just about avoiding penalties — it offers real business benefits:

Reputation Management – Eco-conscious practices enhance your company's image.

Cost Savings – Efficient use of materials and energy lowers operating costs.

Employee Wellbeing – Safer, cleaner sites improve working conditions and morale.

Legal Compliance – Proactive measures reduce the risk of fines and project shutdowns.

Conclusion

Environmental responsibility is a key component of modern construction site management. By following best practices — including waste segregation, emissions control, worker training, and spill prevention — construction companies can reduce their environmental footprint while ensuring compliance with local health and safety regulations.

Whether you're operating in the heart of the capital under Health and Safety in London guidelines or managing projects in stricter local environments like Health and Safety in Berkshire, adopting these measures leads to safer, cleaner, and more sustainable construction sites.

#business#health#health and safety#safety#safety training#real estate#services#construction#public health and safety#Health and Safety in London#Health and Safety in Berkshire

0 notes

Text

The Role of PPVC Construction in Sustainable Building Practices

In today's rapidly urbanizing world, the construction industry faces mounting pressure to adopt more sustainable practices. PPVC construction (Prefabricated Prefinished Volumetric Construction) has emerged as a game-changing approach that addresses many environmental challenges while improving efficiency.

This innovative building method involves manufacturing complete modules off-site before transporting them to the final location for assembly—significantly reducing waste and environmental impact.

Reducing Environmental Footprint Through Prefabrication

Prefabrication dramatically cuts construction waste compared to traditional building methods. By manufacturing components in controlled factory environments, materials can be precisely measured and utilized, minimizing excess. Studies suggest that prefabricated construction can reduce waste by up to 90% compared to conventional on-site building techniques.

The controlled environment also enables better quality control, resulting in fewer defects and rework—further reducing material waste. Additionally, the reduced construction time means less disturbance to surrounding areas, decreased noise pollution, and lower emissions from construction equipment.

Optimizing Resource Efficiency

The precision manufacturing process involved in prefabrication allows for optimal material usage. Many concrete casting molds suppliers have developed specialized systems that enable multiple uses of the same molds, significantly reducing raw material consumption.

Moldtech's innovative 4-wall construction module system exemplifies this efficiency, with hydraulic systems that assist in the initial demolding process, allowing for quick turnaround and reuse of molds. Their system of removable outer sides using Dywidag bar and nut mechanisms ensures that the molds can be easily opened and removed by crane in minimal time.

Energy efficiency is another major benefit. Factory-built modules often incorporate better insulation and tighter building envelopes than traditional construction can achieve on-site. The precast molds used in prefabrication create components with consistent dimensions and precise specifications, resulting in buildings that require less energy for heating and cooling throughout their lifecycle.

Extending Building Lifecycle

PPVC construction contributes to sustainability by creating structures with longer lifespans and greater adaptability. The precise manufacturing processes result in components with consistent quality and durability. Furthermore, the modular nature of these buildings allows for easier renovations, repurposing, and even relocation—extending the useful life of construction materials.

When a building eventually reaches the end of its life, the modular components are easier to disassemble, facilitating more effective recycling and material recovery compared to traditional demolition.

Addressing Urban Challenges

As cities grow denser, the reduced site impact of prefabricated construction becomes increasingly valuable. The shorter construction timeline means less disruption to urban environments, while the higher precision manufacturing results in buildings that better meet increasingly stringent environmental regulations.

The Future of Sustainable Construction

The construction industry's environmental impact is under greater scrutiny than ever before. PPVC construction offers a viable path forward by addressing multiple sustainability concerns simultaneously. As technology advances and manufacturing processes become even more refined, we can expect this approach to play an increasingly central role in creating the sustainable built environment of tomorrow.

Ready to transform your construction projects with sustainable, efficient building solutions? Contact Moldtech today to learn how their advanced modular systems can help you achieve superior quality finishes while reducing environmental impact and construction timelines. Their specialized hydraulic systems and innovative mold designs ensure optimal results for residential and public building projects alike.

0 notes

Text

Customize Your 50 x 50 Metal Building for Maximum Durability.

A 50x50 metal building is a good blank canvas to customize for various needs. Whether you need a garage, workshop, warehouse, or livestock shelter, it should provide enough room for your immediate requirements.

Of course, your needs could change over time, so it’s important to plan and customize your 50x50 building in a way that will simplify expansions down the road. Thankfully, metal buildings are durable and can be built with a modular framing system. This means that your building will last, and when you do need to add on or make changes, it will be a much smoother process.

This article shares tips for customizing your 50 x 50 metal building to ensure that it aligns with your current needs while being prepared for future requirements.

Planning your building

To start, think about how you'll be using your 50x50 metal building. This will help the fabricator recommend the ideal steel gauge for maximum durability. Aside from your intended use, the fabricator will also factor in your location's building codes, potential loads, and environmental conditions in designing your structure to give you a safe and code-compliant structure.

Designing for long-lasting functionality

Choose a reputable fabricator known for their ability to customize pre-engineered or prefabricated metal structures based on different design and layout requirements. The best companies can provide dedicated building consultants who can work with you to plan the placement of windows and doors, plumbing, and light, as well as ensure smooth accessibility and movement for spaces with high foot traffic.

Enhancing your metal building’s function

Flexibility is one of the perks of using a pre-engineered 50 x 50 metal building. It can be designed with few or no interior columns to ensure a more flexible layout. Moreover, it can be made with large openings for windows and doors to maximize airflow and natural light. Building consultants will position these features strategically to reduce energy costs and optimize insulation.

Additionally, metal buildings can support any insulation technology or material for moisture and temperature control and noise reduction. This can mean more energy savings and lower heating and cooling costs.

Future expansions

Versatility is another reason to choose prefabricated 50 x 50 metal buildings. You can expand them lengthwise or crosswise to keep up with growing space requirements.

Build a 50x50 building with steel.

Let Armstrong Steel customize a 50x50 metal building that matches your exact specifications. Get a quote on their website, or speak to one of their building consultants by calling 1-800-345-4610.

0 notes

Text

The Role of Building Envelope Systems in Modern Construction – Precision in Glazing Shop Drawings

Introduction

The building envelope is a critical element in modern construction, serving as the primary barrier between the interior and exterior environments. It plays a crucial role in structural integrity, energy efficiency, weather resistance, and architectural design. With advancements in prefabrication and modular construction, integrated building envelope systems have become the standard for high-performance buildings.

Among the most crucial components of a building envelope is its glazing system, which enhances natural lighting, insulation, and aesthetics. However, to achieve seamless execution, glazing shop drawings are essential to guide the design, fabrication, and installation process.

What is a Building Envelope System?

A building envelope consists of all external building components that separate indoor and outdoor environments, including walls, windows, roofs, and curtain walls. It performs multiple critical functions:

Structural Support: Provides stability and protects against external forces.

Moisture and Thermal Control: Regulates indoor temperature and prevents water infiltration.

Aesthetic Appeal: Enhances the visual design of the building.

Energy Efficiency: Optimizes insulation, reducing heating and cooling costs.

Modern high-performance building envelopes incorporate advanced prefabricated panels, glazing systems, and lightweight materials, requiring meticulous planning and precision detailing to ensure durability and sustainability.

The Importance of Glazing Shop Drawings in Building Envelopes

Glazing systems, including curtain walls, windows, storefronts, and structural glazing, must seamlessly integrate with the building envelope. Glazing shop drawings play a vital role in ensuring accuracy and coordination with other building components.

Key Aspects of Glazing Shop Drawings

Material and Glass Specifications – Defines glass types, thickness, coatings, and performance ratings.

Frame and Mullion Details – Ensures structural compatibility with precast or steel frameworks.

Sealing and Weatherproofing Guidelines – Prevents air and water infiltration.

Thermal and Acoustic Performance Requirements – Supports energy efficiency and noise reduction.

Fastening and Installation Instructions – Guarantees secure alignment and stability.

Without detailed glazing shop drawings, installation errors, misalignments, and material conflicts can lead to costly rework and extended project timelines.

Prefabrication and High-Performance Building Envelopes

Companies like Clark Pacific, Enclos Corporation, and Harmon Inc. are pioneers in prefabricated building envelope solutions. They integrate precast panels, curtain walls, and glazing systems to create efficient, durable, and aesthetically striking facades.

Benefits of Prefabricated Building Envelopes

Faster Installation – Off-site manufacturing accelerates construction schedules.

High-Quality Control – Factory-controlled production ensures precision and durability.

Sustainability – Reduces material waste and improves energy efficiency.

As urban development moves toward sustainable and high-performance construction, accurate glazing shop drawings and prefabricated façade solutions will be key to optimizing project efficiency and long-term durability.

Conclusion

A building envelope system is more than just a protective layer—it defines a structure’s performance, aesthetics, and efficiency. Prefabrication is reshaping modern envelope design, and detailed glazing shop drawings are essential for ensuring flawless integration.

With leading companies like Clark Pacific, Harmon, and Enclos driving innovation in building envelopes, the demand for precise detailing and sustainable prefabricated solutions will continue to rise. Investing in advanced detailing and shop drawing solutions will be crucial for delivering high-quality, durable, and efficient building envelopes in the future.

#Glazing shop drawings#prefabricated panels#curtain walls#Clark Pacific#Metromont Corporation#sustainable prefabricated solutions

0 notes

Text

Enhance Your Construction Speed with Ready Made Concrete in Karachi

The construction industry in Karachi is evolving rapidly, with increasing demand for high-quality materials that ensure durability, cost-effectiveness, and efficiency. One such material revolutionizing the sector is Ready Made Concrete in Karachi. As a pre-mixed, high-strength solution, ready-made concrete simplifies construction, minimizes waste, and enhances structural integrity. This article explores the benefits of using ready-made concrete, its impact on project timelines, and why Allied Materials is a trusted provider in the market.

What is Ready Made Concrete?

Ready-made concrete, also known as ready-mix concrete (RMC), is a precisely manufactured mixture of cement, aggregates, water, and admixtures prepared in a batching plant. This concrete is delivered to the construction site in a fresh, ready-to-use form, eliminating the need for on-site mixing and reducing labor-intensive work.

Benefits of Using Ready Made Concrete in Karachi

1. Faster Construction Process

Traditional concrete preparation requires on-site mixing, which is time-consuming and labor-intensive. Ready-made concrete significantly speeds up the process, ensuring a seamless workflow and enabling builders to meet project deadlines efficiently.

2. Superior Quality and Consistency

Unlike site-mixed concrete, which can have variations in proportioning and quality, ready-made concrete is manufactured under controlled conditions. This results in uniform strength, durability, and workability, ensuring long-lasting structures.

3. Reduced Material Wastage

On-site mixing often leads to excess material wastage due to human errors in measurement and handling. Since ready-made concrete is produced precisely in batching plants, it minimizes waste, making it an environmentally friendly and cost-effective option.

4. Cost Savings in Labor and Equipment

With ready-made concrete, builders save on labor costs associated with mixing and preparation. Additionally, it eliminates the need for purchasing and maintaining mixing equipment, further reducing overall construction expenses.

5. Enhanced Strength and Durability

Ready-made concrete undergoes stringent quality checks, ensuring that the final product meets industry standards. This results in higher strength and durability, making it ideal for both residential and commercial projects in Karachi.

6. Environmental Benefits

Batching plants that produce ready-made concrete follow eco-friendly practices by reducing carbon emissions, conserving raw materials, and minimizing dust and noise pollution at construction sites.

Applications of Ready Made Concrete in Karachi

The versatility of Ready Made Concrete in Karachi makes it suitable for a variety of applications, including:

Residential Buildings: Ideal for foundations, flooring, and columns.

Commercial Complexes: Used in high-rise buildings, shopping malls, and offices.

Infrastructure Projects: Suitable for bridges, roads, tunnels, and dams.

Industrial Facilities: Perfect for warehouses, factories, and storage units.

Precast Structures: Used in prefabricated building components such as walls, beams, and slabs.

Why Choose Allied Materials for Ready Made Concrete in Karachi?

Allied Materials is a leading supplier of Ready Made Concrete in Karachi, known for its superior quality, timely delivery, and customer satisfaction. Here’s why Allied Materials stands out:

State-of-the-Art Batching Plants: Equipped with modern technology for precise mixing and quality control.

Timely Delivery: Ensures fresh concrete reaches the site without delays, preventing project slowdowns.

Customized Mix Designs: Tailors concrete compositions based on specific project needs.

Competitive Pricing: Offers cost-effective solutions without compromising on quality.

Strong Customer Support: Provides expert guidance and after-sales assistance for construction projects.

Factors to Consider When Choosing Ready Made Concrete in Karachi

Before selecting a ready-made concrete supplier, consider the following factors:

Strength and Durability: Ensure the concrete meets the required strength for your project.

Delivery Time: Opt for a supplier with a strong logistics network to avoid delays.

Mix Design Options: Choose a provider that offers various mix designs tailored to different applications.

Reputation and Reliability: Work with a trusted supplier with a track record of successful projects.

Cost Efficiency: Compare prices while ensuring quality standards are met.

The Future of Ready Made Concrete in Karachi

As Karachi’s urban development continues to expand, the demand for Ready Made Concrete in Karachi is expected to rise. With advancements in construction technology and growing awareness about sustainable building materials, ready-made concrete is poised to become the preferred choice for developers and contractors.

Conclusion

Incorporating Ready Made Concrete in Karachi into construction projects is a game-changer, offering unmatched efficiency, quality, and cost-effectiveness. Allied Materials is at the forefront of providing top-grade ready-made concrete, ensuring durable and timely project completions. Whether you are constructing residential buildings, commercial complexes, or large-scale infrastructure, ready-made concrete is the smart choice for modern construction.

0 notes

Text

What are the Plant Room Acoustic Package Solutions for noise mitigation?

Plant rooms are critical spaces within new buildings and industrial facilities where essential mechanical and electrical equipment are located. But these rooms can generate a lot of noise and vibration from HVAC systems, generators, pumps, and other machinery. Acoustic treatment is necessary to prevent this noise from being a nuisance to occupants, hindering productivity, or even reaching a non-compliant level with regulations.

Professional plant room acoustic solutions become necessary to save noise and provide a better working environment. In this blog, we discuss the issues associated with plant room noise, some recognised soundproofing solutions, and the advantages of tailored acoustic treatments.

Plant Room Acoustic Solutions That Actually Work

Airborne noise transmission is an important consideration for plant room acoustics control. Solutions include:

Acoustic Enclosures: Custom-built cabinets for sound-proof monitoring of machine that contain noise at source.

Acoustic Room Doors and Windows: These are special double glazed doors and windows where sound will not escape.

Soundproofing Panels and Insulation: This includes installing high-density panels to walls and ceilings to absorb.

How to Reduce the Noise from HVAC Systems

Plant rooms are an area where a lot of noise can come out of the HVAC systems. Some effective noise control techniques are:

Silencers and Acoustic Louvres: settle noise from air ducts and ventilation openings.

Duct Lagging and Internal Linings: Installing sound-dampening materials within tubes.

Optimize Fans and Motors Speed: Appropriate speeds can limit excessive noise.

Absorption of Sound and Echo Reduction

Better internal acoustics which controls noise within plant rooms. Solutions include:

Ceiling Baffles and Acoustic Panels: Reduce echo by absorbing sound reflections.

Machine Wrap: Covering equipment in sound-absorbent materials.

5 Goodness of Professional Plant Room Acoustic Services

Improved Comfort in the Workplace and at Home

Enhanced Duration and Performance of Equipment

Compliance to the laws & achieving risk reduction

To save costs and improve efficiency in energy

Increased Property Value

Artificial Intelligence Monitoring Systems For Noise

Snow sensors and AI analytics can help detect and control noise as it happens.

Sustainable Acoustic Solutions

Green building initiatives are aided by sustainable and recycled soundproofing materials.

Noise Reduction Solutions That Are Customizable and Modular

For example, prefabricated acoustic enclosures and flexible noise barriers can help reduce noise in a customizable way.

Digital Twin Simulations in the context of Acoustic Design

Noise reduction tools are used prior to establishment to optimize plant room performance.

Plant Room Acoustic Service Company in UAE

At SkyTech LLC, we specialize in plant room acoustic services designed to enhance noise control in industrial, residential or commercial environments. We have 10+ years of experience in plant room acoustics with more than 1000+ satisfied clients, we have earned the name of best plant room acoustic company in Dubai, UAE. With years of experience in plant room echo reduction, our engineers have developed a deep understanding of the unique challenges presented by industrial spaces.

Conclusion

This can improve efficiency and many industries must adhere to regulatory standards, so professional plant room acoustic solutions are a key investment. With soundproofing, vibration isolation, and advanced noise remediation techniques, companies can bring employees of all types the sanctuary they need to focus, interactive, and plush.

Reach out to us today, to hear how we can assist your facility with tailored plant room acoustic solutions.

0 notes

Text

Prefab vs. Custom-Built Three-Season Rooms: What’s Right for You?

Adding a three-season room is one of the best ways to expand your living space while enjoying the beauty of the outdoors—minus the bugs and unpredictable weather. But if you’re thinking about installing one, the big question is: should you go with a prefab model or invest in a custom build?

The answer isn’t as straightforward as you’d think. It depends on your budget, timeline, and how much personalization you want. Let’s break it down in a way that actually makes sense.

What’s the Deal with Prefab three-season rooms?

Prefab (or prefabricated) three-season rooms are manufactured off-site and then delivered to your home in ready-to-assemble pieces. Think of it like a giant, weather-resistant LEGO set. These rooms come in standard sizes and styles, making installation quicker and usually cheaper than a custom build.

The Perks of Prefab

Faster installation – Most prefab kits can be installed in days rather than weeks. Some even take as little as a weekend if you’re handy.

Lower cost – Since these rooms are mass-produced, they tend to cost less per square foot than custom-built options.

Minimal disruption – Because much of the work is done in a factory, there’s less on-site construction mess and noise.

Predictable design – What you see is what you get. You choose from a selection of designs, and it arrives as advertised—no surprises.

The Downsides of Prefab

Limited customization – If you have a specific look or layout in mind, prefab might not be flexible enough for your vision.

Fixed dimensions – These kits come in standard sizes, so if your space is oddly shaped or has unique challenges, fitting a prefab room can be tricky.

Potential quality variation – While many prefab rooms are well-made, some lower-end models use cheaper materials that might not hold up long-term.

Installation might still require a pro – Some kits are DIY-friendly, but larger or more complex models may still need professional assembly.

Custom-built three-season rooms: The Personalized Touch

A custom-built three-season room is designed from scratch to fit your exact space, needs, and aesthetic. This option gives you complete control over everything—from the shape and size to materials, windows, and even built-in features like ceiling fans or skylights.

The Perks of Custom Builds

Tailored to your space – Whether you have an oddly shaped patio or want floor-to-ceiling windows, a custom build can adapt to your home perfectly.

Higher quality materials – You get to choose everything, from insulated glass to more durable framing materials that last longer.

Seamless integration – Custom-built rooms blend in with your existing home, making them feel like a true extension rather than an add-on.

Potential home value boost – Because custom rooms tend to match your home’s architecture better, they often increase resale value more than prefab options.

The Downsides of Custom Builds

Higher costs – Custom builds require skilled labor, more planning, and often pricier materials.

Longer timeline – Since every part of the project is designed and built on-site, it can take weeks—or even months—to complete.

More permits and regulations – You may need local permits or inspections, which can slow things down.

Cost Breakdown: Prefab vs. Custom-Built

If you’re trying to decide between these two options, budget plays a huge role. Here’s a rough breakdown of what you might expect to spend:

So, Which One Should You Choose?

At this point, you might be thinking: “Okay, but which one is actually better?” The answer depends on your priorities.

Go for a Prefab three-season room If:

You want something quick and affordable.

You’re okay with limited customization.

Your home has a standard-sized patio or deck that fits a prefab kit.

You don’t want to deal with permits or complex construction.

Choose a Custom-Built three-season room If:

You have a specific vision for how the space should look.

You’re planning to stay in your home long-term and want higher durability.

Your space has odd dimensions or unique challenges.

You’re willing to invest in quality materials and a seamless design.

Final Thoughts

In South Bend and the surrounding areas, weather is a big factor when deciding on a three-season room. Cold winters and humid summers mean insulation and durability should be top priorities.

If you want a budget-friendly seasonal retreat, a high-quality prefab kit can be a great choice.

If you’re after a year-round usable space with better insulation, a custom build might be worth the investment.

Either way, having a protected, bug-free outdoor space is always a win. If you’re considering adding a three-season room to your home, reach out to a local expert who can guide you through the best options for your space and budget.

1 note

·

View note

Text

Key Features to Consider When Designing a Hospital Sewage Treatment Plant

Introduction

Hospitals generate a significant amount of wastewater daily, which contains a complex mix of biological waste, chemical residues, pharmaceuticals, and pathogens. Effective treatment of this wastewater is crucial not only for environmental protection but also for public health. A well-designed Hospital Sewage Treatment Plant (STP) ensures safe disposal, compliance with environmental regulations, and minimizes health risks. This article explores the key features to consider when designing an efficient and sustainable sewage treatment plant for hospitals.

1. Compliance with Regulatory Standards

Importance: Hospitals must adhere to stringent regulations regarding wastewater treatment and disposal to prevent environmental contamination and health hazards.

Considerations:

Familiarize with local and national wastewater treatment standards.

Ensure the STP meets the parameters for Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Total Suspended Solids (TSS), and pathogen removal.

Plan for periodic audits and regular reporting to environmental authorities.

2. Capacity and Scalability

Importance: Hospitals vary in size and patient capacity, affecting the volume of wastewater generated.

Considerations:

Calculate the daily wastewater volume based on the number of beds, staff, and patient turnover.

Design the STP with future scalability in mind, considering potential hospital expansions.

Include buffer tanks to manage fluctuations in wastewater flow.

3. Effective Pathogen Removal

Importance: Hospital wastewater contains pathogens that can spread infections if not treated properly.

Considerations:

Incorporate disinfection methods such as chlorination, UV treatment, or ozonation.

Ensure proper removal of bacteria, viruses, and other harmful microorganisms.

Implement a multi-stage treatment process for comprehensive pathogen control.

4. Pharmaceutical and Chemical Waste Management

Importance: Hospital effluents often contain residual pharmaceuticals and chemicals that conventional STPs may not fully treat.

Considerations:

Use advanced treatment methods like activated carbon filters, reverse osmosis, or advanced oxidation processes (AOPs) to remove chemical residues.

Implement pre-treatment units for laboratory and pharmacy waste.

Regularly monitor effluent for harmful chemical levels.

5. Energy Efficiency and Sustainability

Importance: Energy-intensive STPs can increase operational costs and environmental impact.

Considerations:

Incorporate energy-efficient equipment such as low-energy blowers and pumps.

Utilize renewable energy sources like solar panels to power certain STP functions.

Explore options for water reuse and resource recovery, such as using treated water for landscaping or cooling systems.

6. Space Optimization

Importance: Hospitals often have space constraints, making compact STP designs essential.

Considerations:

Opt for modular or vertical treatment systems that require less space.

Consider underground or rooftop STP installations if land availability is limited.

Use prefabricated units for quicker installation and reduced space usage.

7. Odor and Noise Control

Importance: Hospitals require a clean and quiet environment; untreated odors and noise from the STP can disrupt this.

Considerations:

Install odor control systems like activated carbon filters or biofilters.

Use noise-reducing equipment and enclosures for pumps and blowers.

Position the STP away from patient care areas when possible.

8. Automation and Monitoring

Importance: Automated systems enhance operational efficiency and reduce manual intervention.

Considerations:

Integrate SCADA (Supervisory Control and Data Acquisition) systems for real-time monitoring.

Use sensors and alarms for key parameters like pH, BOD, COD, and flow rates.

Implement remote access systems for easier control and diagnostics.

9. Sludge Management

Importance: Hospital STPs generate sludge that requires proper handling and disposal to avoid environmental risks.

Considerations:

Include sludge thickening, dewatering, and safe disposal units.

Explore options for converting sludge into compost or using it in biogas plants.

Ensure compliance with local regulations for sludge disposal.

10. Emergency Handling and Backup Systems

Importance: Hospitals cannot afford operational downtime, especially for critical systems like STPs.

Considerations:

Design the STP with backup power sources, such as generators or battery systems.

Include emergency bypass systems to handle unexpected surges or failures.

Develop contingency plans for equipment breakdowns and natural disasters.

Conclusion

Designing an efficient Hospital Sewage Treatment Plant requires careful planning and consideration of various factors, from regulatory compliance to sustainability. An effective STP not only ensures safe wastewater disposal but also supports the hospital's commitment to public health and environmental protection. By focusing on advanced treatment methods, energy efficiency, and future scalability, hospitals can implement sewage treatment solutions that are both practical and eco-friendly.

0 notes

Text

Prefabricated Restroom

Prefabricated Restroom: The Smart Choice for Your Facility

Why Choose a Prefabricated Restroom?

At East Coast Modular Buildings, we understand that restroom facilities are essential for any business, event space, or public setting. Traditional construction can be costly, time-consuming, and disruptive. That’s why we offer high-quality prefabricated restrooms that provide a superior alternative. Whether you need a single-unit restroom or a large-scale facility, our prefabricated restrooms offer a streamlined, efficient, and cost-effective solution.

Prefabricated restrooms are pre-built off-site, transported to your location, and quickly installed with minimal hassle. This means faster turnaround times, lower costs, and reduced environmental impact compared to traditional construction. Our expertise ensures that your prefabricated restroom will be designed to meet your exact needs, blending function, style, and durability seamlessly.

The Advantages of a Prefabricated Restroom

1. Faster Installation and Lower Costs

Traditional restroom construction can take months, causing delays and disrupting your operations. With prefabricated restrooms, installation is significantly faster because the majority of the work is completed off-site. This means you get a fully functional, high-quality restroom in a fraction of the time and at a fraction of the cost.

2. High-Quality, Customizable Designs

Our prefabricated restrooms are not one-size-fits-all. We offer a variety of designs and layouts to match your needs. Whether you need ADA-compliant restrooms, high-end finishes, or simple yet functional designs, we provide options to suit your specific requirements. Each unit is constructed using durable materials that are easy to clean and maintain.

3. Environmentally Friendly Construction

If sustainability is a priority, prefabricated restrooms are the way to go. By constructing the restrooms in a controlled environment, we reduce material waste and energy consumption. Additionally, our restrooms can be outfitted with water-saving fixtures and energy-efficient lighting, further reducing your environmental footprint.

4. Minimal Disruption to Your Property

On-site construction can cause major disruptions, from noise pollution to restricted access. With prefabricated restrooms, installation is quick and efficient, minimizing disturbances to your business, employees, or customers. We deliver the pre-built structure to your location, install it in a matter of hours or days, and leave you with a fully operational facility.

5. Durability and Longevity

Our prefabricated restrooms are built to last. Using high-quality, weather-resistant materials, these structures can withstand heavy use, harsh weather conditions, and the test of time. Unlike temporary restroom solutions like porta-potties, prefabricated restrooms offer a permanent, long-term facility that requires minimal maintenance.

Applications for Prefabricated Restrooms

Construction Sites

Every construction project needs restroom facilities for workers, but traditional options like porta-potties often lack hygiene and comfort. Our prefabricated restrooms provide a clean, comfortable, and long-lasting solution that can be relocated as needed.

Parks and Recreational Facilities

Public parks, hiking trails, and recreational areas require restroom facilities that blend with the natural environment while providing durability and ease of maintenance. Our prefabricated restrooms can be customized to fit aesthetically and functionally into any outdoor setting.

Event Venues and Stadiums

Large gatherings demand restroom facilities that can accommodate high traffic while maintaining cleanliness and efficiency. Prefabricated restrooms are ideal for concert venues, sports arenas, and festival grounds, offering a superior alternative to standard portable restrooms.

Schools and Campuses

Educational institutions often require additional restroom facilities due to expanding student populations or temporary campus expansions. Our prefabricated restrooms provide a quick and cost-effective solution, ensuring students and faculty have access to clean, comfortable facilities.

Commercial and Retail Spaces

Businesses, shopping centers, and office parks can benefit from prefabricated restrooms when additional facilities are needed. Whether as a permanent solution or a temporary fix during renovations, our prefabricated restrooms enhance the customer and employee experience.

Emergency and Disaster Relief

In the wake of natural disasters or emergencies, access to sanitary restroom facilities is crucial. Prefabricated restrooms can be deployed quickly to provide much-needed facilities in disaster relief areas, helping to restore normalcy and hygiene in crisis situations.

Why You Shouldn’t DIY Your Prefabricated Restroom

Many people assume that a DIY approach to restroom construction can save money, but in reality, it often leads to costly mistakes and subpar results. Here’s why hiring professionals like East Coast Modular Buildings is the smarter choice:

1. Compliance with Regulations

Restrooms must adhere to strict building codes, ADA regulations, and health standards. A DIY project risks failing inspections, leading to costly rework and potential fines. Our expertise ensures that every prefabricated restroom we deliver meets all necessary requirements.

2. Plumbing and Electrical Expertise

Properly installing plumbing and electrical systems requires specialized knowledge. Mistakes can lead to leaks, faulty wiring, and safety hazards. Our skilled team ensures that all systems are professionally installed and fully operational upon delivery.

3. Structural Integrity

A prefabricated restroom must be durable, weather-resistant, and built to withstand heavy use. Attempting to construct one without professional experience can result in weak structures that deteriorate quickly. We use high-quality materials and expert craftsmanship to build restrooms that last.

4. Time and Cost Efficiency

What may seem like a cost-saving DIY project can quickly turn into a financial burden due to unexpected challenges, delays, and repair costs. Hiring professionals saves you time and money by delivering a fully built, ready-to-use restroom without the hassle.

5. Customization and Professional Finish

A DIY project often lacks the polished, professional appearance that businesses and public spaces require. Our prefabricated restrooms are designed with aesthetics and functionality in mind, ensuring a sleek, well-finished structure that enhances your property’s appeal.

Why Choose East Coast Modular Buildings?

At East Coast Modular Buildings, we take pride in delivering top-quality prefabricated restrooms tailored to our clients’ needs. When you work with us, you get:

Expert Guidance: From planning to installation, we handle every step with precision and professionalism.

Customization Options: We design restrooms to match your specific requirements, ensuring they meet your needs and aesthetic preferences.

Fast Turnaround: Our prefabricated restrooms are built and installed quickly, minimizing disruptions and allowing you to use them sooner.

Durable and Sustainable Materials: We use high-quality materials to ensure longevity, low maintenance, and environmental responsibility.

Hassle-Free Installation: We take care of everything, from permits to plumbing, so you don’t have to worry about a thing.

If you need a high-quality, efficient, and cost-effective restroom solution, prefabricated restrooms are the perfect choice. Don’t waste time and money on DIY projects that may fall short of expectations. Let East Coast Modular Buildings provide you with a professional, long-lasting restroom facility that meets all your needs. Contact us today to discuss your project and get started!

1 note

·

View note

Text

Cost Benefits of PPVC Methods in Modern Building Projects

The way we build is changing, and Prefabricated Prefinished Volumetric Construction (PPVC) is at the heart of it. With PPVC, entire sections of a building—like rooms or apartments—are made in a factory, complete with walls, floors, and even finishes, then brought to the site to be put together. It’s a practical approach that’s saving money and time.

Let’s look at why PPVC is worth considering for today’s building projects.

Cut Down on Time and Labor Costs

PPVC speeds things up. Since the work happens in a factory, you don’t have to worry about rain or other delays slowing things down. Take a project like the Clement Canopy in Singapore—it used PPVC and finished much faster than traditional methods, sometimes by half the time.

Faster work means fewer days paying workers. Reports show labor costs can drop by 40% for the main structure and even 70% for things like plumbing and electrical work. That’s a big saving without cutting corners.

Work Smarter in a Factory

PPVC Construction makes everything more efficient. Inside a factory, the process is smooth and controlled. For example, figuring out how to make concrete mouldings is simpler with tools like a precast concrete mould.

Moldtech steps in here with smart designs—moulds that use hydraulics to lift the concrete out easily and sides that come off quickly with a crane. These moulds create modules with doors and windows already built in, so there’s less waste and fewer fixes needed later. It’s about getting it right the first time and keeping costs down.

Spend Less On-Site

Building on-site can get expensive—cranes, equipment, and lots of workers add up. With PPVC, most of the hard work is done in the factory, so you need fewer people at the site. This cuts labor costs and makes things safer, which can lower insurance bills too. Plus, there’s less mess and noise, saving on cleanup and keeping the surrounding area happy. In busy cities, where every minute and inch counts, this really pays off.

Invest More Now, Save More Later

PPVC does ask for more money upfront—factory setup and tools like hydraulic moulds aren’t cheap. But the payoff comes fast. Finishing projects quicker means buildings are ready sooner, so rentals or sales can start earlier.

The extra cost over traditional methods is shrinking, often less than 8% now, and you save big on labor and site expenses. With options like energy-saving walls, PPVC keeps delivering value for years. It’s a bigger start for a better finish.

Why PPVC Makes Sense

PPVC isn’t just a new idea—it’s a better way to build. It saves on time, labor, and site costs while delivering solid results. Companies like Moldtech are helping make it happen with their reliable mould systems. Thinking about your next project? Get in touch with us to see how PPVC can work for you—it’s a practical step toward building smarter and saving more.

0 notes

Text

Modular Build

Modular Build: Why You Need It and How It Can Benefit You

Introduction

The construction industry is evolving rapidly, with modular build techniques becoming increasingly popular due to their efficiency, cost savings, and sustainability. If you've been searching for information on “Modular Build,” you likely understand the advantages of prefabricated construction solutions. Modular build refers to the process of constructing sections of a building off-site in a controlled environment and then assembling them on-site. This method streamlines the construction process, minimizes waste, and enhances overall project efficiency. In this article, we will explore why modular build is important, its applications, and the advantages it offers.

Why You Need Modular Build

Modular construction provides numerous benefits that make it a preferred choice for residential, commercial, and industrial projects. Here are some key reasons why you should consider modular build solutions:

Faster Construction – Modular components are fabricated off-site and assembled quickly, significantly reducing project timelines.

Cost-Effective – With lower labor costs and reduced material waste, modular builds provide significant savings compared to traditional construction.

Sustainability – Modular build methods minimize waste and often incorporate eco-friendly materials, making them a more sustainable choice.

Consistent Quality – Factory-controlled manufacturing ensures high precision and quality, reducing the likelihood of construction errors.

Enhanced Safety – Since most construction occurs in a controlled environment, there is a lower risk of on-site accidents and hazards.

Applications of Modular Build

Modular build techniques are widely used across various industries and sectors due to their versatility. Some key applications include:

Residential Homes – Modular homes are becoming increasingly popular for their affordability, customizability, and quick construction timelines.

Commercial Buildings – Offices, retail spaces, and modular workspaces benefit from modular build methods due to their speed and efficiency.

Industrial Facilities – Warehouses, factories, and processing plants utilize modular structures for large-scale and durable building solutions.

Healthcare Facilities – Hospitals, clinics, and medical offices rely on modular build solutions to expand healthcare infrastructure rapidly.

Educational Institutions – Schools and universities use modular classrooms and dormitories to accommodate growing student populations.

Disaster Relief Housing – Modular build structures provide fast and efficient housing solutions in emergency and disaster-stricken areas.

Advantages of Modular Build

Modular construction offers several advantages that make it an attractive choice for builders and property owners alike. Here are some key benefits:

1. Time Efficiency

Modular build significantly reduces construction time, allowing projects to be completed faster than traditional methods.

2. Lower Costs

With streamlined production and assembly, modular build reduces material waste and labor expenses, making it a cost-effective solution.

3. Sustainability

Modular buildings often use eco-friendly materials and generate less waste, making them an environmentally responsible choice.

4. Improved Quality Control

Factory production ensures high standards of quality and consistency in materials and construction techniques.

5. Flexibility and Customization

Modern modular build solutions offer various design options, allowing for customized structures to meet specific needs.

6. Reduced Site Disruptions

Since most work is done off-site, modular build construction minimizes noise, dust, and disruptions at the final location.

7. Scalability

Modular build techniques make it easy to scale projects, whether adding extra rooms, expanding buildings, or creating modular structures.

Conclusion

Modular build is revolutionizing the way buildings are designed and assembled, offering a faster, cost-effective, and sustainable alternative to traditional construction. Whether you're looking for a residential home, commercial building, or industrial facility, modular build solutions provide numerous benefits that make them a smart investment. By embracing modular construction technology, businesses and homeowners can enjoy reduced costs, enhanced quality, and a more efficient building process. Searching for “Modular Build” is the first step toward discovering innovative construction methods that deliver both convenience and long-term value.

1 note

·

View note