#Production Process of Textile Printing

Explore tagged Tumblr posts

Text

Key Elements That Define Quality in Bulk T-Shirt Production

Ordering custom t-shirts in bulk? The cheapest option isn’t always the smartest—especially when your brand’s image is on the line. Bulk orders demand consistent quality at every stage of production.

Here’s what defines a high-quality bulk t-shirt:

1. Fabric Weight & Texture (GSM)The fabric’s weight affects how the shirt looks, feels, and lasts.

120–150 gsm: Budget-friendly or giveaway items

160–180 gsm: Standard everyday use

190+ gsm: Premium and luxury shirts

2. Stitching & Construction QualityClean overlock and coverstitch seams are essential. Loose threads, misaligned hems, or weak stitches lower durability.

3. Color FastnessPoor dyeing leads to fading. Solid coloring ensures your shirts stay vibrant after multiple washes.

4. Print Technique & AccuracyScreen printing, DTG, or transfer—choose the right method for your design. Misalignment or cracking ruins the result.

5. Fit & Pattern PrecisionCorrect sizing and balanced proportions make the shirt flattering and functional. Full size ranges are a plus.

6. Quality Control During ProductionEach stage—from cutting to finishing—should be monitored. Final checks catch any printing errors, stains, or misplaced tags.

7. Packaging & PresentationBulk doesn’t mean messy. Professional folding, tagging, and packaging show you care about quality—down to the last detail.

At Printify360, we take bulk production seriously—ensuring every shirt reflects your brand’s standards.Let’s scale your apparel without sacrificing quality

@printify360

#CustomDesign, #TshirtLovers, #HobbyStyle, #ClubMerch, #PrintOnDemandLife, #HomeDecorWithStyle

bulk t-shirt production, high quality t-shirts, t-shirt weight gsm, print quality control, branded shirts in bulk, promotional t-shirt quality, durable shirt printing, shirt stitching guide, fabric grading, large scale apparel, business apparel printing, shirt packaging standards, accurate sizing, textile QC process, wholesale custom t-shirts

#bulk t-shirt production#high quality t-shirts#t-shirt weight gsm#print quality control#branded shirts in bulk#promotional t-shirt quality#durable shirt printing#shirt stitching guide#fabric grading#large scale apparel#business apparel printing#shirt packaging standards#accurate sizing#textile QC process#wholesale custom t-shirts

0 notes

Text

here's some punk diy tips and ideas

[other than crusty pants and battle jacket, although we still love those greatly.]

why should you diy, when you can just find decorated items everywhere, you can ask. what if you are clumsy at painting or anything?

firstly, good questions. we diy so we don't give credit to the big companies who rule the world. we diy to get more independent from the system we dislike. we diy so to save money. to express uniqueness, recognize eachother and be recognized. and especially to have fun and feel cool. diy is not only about clothing, but anything you can set your mind on. of course, one cannot make EVERYTHING for themselves, there isn't enough time and energy. but making at least small steps are already a statement and more than nothing. also, helping small artists by buying their products is also pretty punk.

that being said, i provide you with some tips of mine, all gained from experience:

anything you drew/painted on, you will WANT TO protect. acrylic paint/markers + acrylic paint varnish/transparent nail polish/textile medium are your best friends. read after anything that's new to you.

i highly recommend working with old clothing or thrift shop finds when it comes to textiles, as it is environmentally friendly and you will stay in budget. Anyways, always make sure that the material you use isn't gonna be problematic. for example, if you want to do some patchwork, the material shouldn't decay easily (if it does, it will come off so quickly.). if you want to paint on it, it shouldn't be rugged.

you can not only draw/paint on your canvas shoes, but can also sew, embroidery (just make sure to use a thimble, plus floss instead of thread could make your work more durable), and add beads and trinkets to your shoelaces. in the case of shoes, never use glue (neither hot nor instant glue) – it will come off quickly. for some inspiration, i'll show you my shoes!

(the fake moss is literally unstoppable from falling off or getting dirty. risky idea.)

it's good to carry around water and food!! you don't even have to pay for decorative water bottles and food boxes, as you can draw on glass and plastic just fine with acrylic markers. just don't forget to paint transparent nail polish all over your drawing. in at least two layers. don't be lazy or laid-back. even posca comes off while washing the dishes. and you WANT TO save your reference pictures/final designs, as the case of emergency is likely. but after all, my water bottle is exactly fine after six months, with no accuring problem.

if your current best option to get stickers from is aliexpress or overpriced decor stores, search for local artists and shops on instagram and tiktok, as it may be their most efficent way of getting you to know them. if it seems like you have no chance, you may can still find a print shop with the option of printing on self-adhesive sheets (at least in hungary, those are pretty cheap). and if you want drawings to print out as stickers, you may use your own or –ONLY IF YOU GET PERMISSION– other artist's work. not only good for decorations for like, headphones, but for vandalism too. WAIT WAIT who said that. who said it. not me. no never

(in case that's also impossible, you can create stickers by printing out/drawing a picture, cover it up in transparent adhesive tape, and then put some two-sided adhesive tape on the white side of the pic. it won't be that durable, but it functions.)

if you want to bleach-paint clothing, get some plastic brushes!! any other brush dissolves. draw your design first with chalk!! never forget to put cardboard inside the clothing, and to wash the finished work in a washing machine before you'd put it on. prepare to be patient with the process. and it's not dangerous to touch 5%-9% household bleach, just wash your hands soon after.

if you want your crusty pants to last veryyy long, wax them. look up on youtube jeans waxing.

some more things i made for myself so to give you some inspiration: totebag with pockets, a small crystal holder cabinet, badges, and i decorated some t-shirts, button-ups, an id card case, phonecase, laptop.

theoretically speaking, there is nothing that an individual would be unable to learn how to make, when it comes to diy. you can't imagine how easy it is to bake bread at home. consuming-focused media makes people believe that it's hard to make anything. of course, everyone has to decide about their own priorities, i don't want to convince or change anyone in here. and if you have any questions, send an ask!! i hope i had been helpful.

#punk diy#tips#tutorial#clothes painting#do it yourself#bleaching#alternative clothing#soren's hoard of words#i hope you'll have fun with this#stay safe and drink water

220 notes

·

View notes

Text

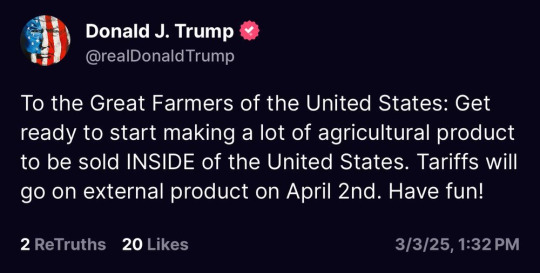

Donald fucked around, we get to find out

Via Narcity: "Starting Tuesday, Canada is slapping new counter-tariffs on U.S. products, targeting $30 billion worth of American goods. And that's just the beginning — Trudeau says an additional $125 billion in tariffs will roll out in the next three weeks if things don't de-escalate."

What follows is the full list of affected American products:

Food & drink

Poultry & eggs — chicken, turkey, goose, duck and their byproducts (fresh, frozen, preserved)

Dairy products — milk, cream, butter, ice cream, yogurt, cheese

Fruits & vegetables — tomatoes, beans, snap peas, citrus fruits, melons, peaches, nectarines, berries

Coffee & tea

Spices & flavourings — pepper, vanilla, dried spices (cinnamon, turmeric, curry, etc.)

Sauces & condiments — soy sauce, ketchup, mustard, mayonnaise, salad dressing, peanut and nut butters

Grains & baking essentials — wheat, rye, rice, barley, oats, flour, mixes and doughs

Oils & fats — canola, sunflower, safflower, palm, peanut and nut oils; margarine and butter substitutes

Sugars & sweeteners — honey, cane sugar, beet sugar, maple sugar and syrup, sugar syrups, molasses

Packaged foods — pasta, pizza, bread, cakes, biscuits, cereal-based foods, soup and broth, pickles, gum, candies, chocolate

Supplements — whey powder, casein, fish oil

Beverages & alcohol — orange juice, soda beer, wine, cider, spirits, liqueurs, coolers, bitters

Tobacco products

Raw & processed tobacco — unmanufactured tobacco, tobacco extracts, chewing tobacco, pipe tobacco

Cigarettes & cigars — cigars, cheroots, cigarillos and cigarettes

Nicotine products — vapes, e-cigarettes, nicotine patches and other smokeless tobacco products

Personal care products

Cosmetics & skincare — makeup, nail polish and manicure tools, hair care, deodorants, soaps and cleansers, razors, shaving products, bath products

Electronic tools — electric razors and clippers, hair dryers, curling irons, flatirons

Fragrances — perfumes, room deodorizers

Oral care — toothpaste, dental floss

Paper products — toilet paper, tissues, napkins

Home & office items

Kitchenware — paper and plastic tableware, storage containers, glassware, cutlery and utensils, kitchen knives, scissors

Furniture & home goods — metal, wooden and plastic furniture; chairs; mattresses and bedding; lighting; storage racks

Home textiles — carpets, rugs, blankets, bed linens, table and kitchen linens, curtains, cleaning cloths

Paper & books — stationery, notebooks, memo pads, binders, file folders, carbon sets, albums, printed materials

Office supplies — letter openers, pencil sharpeners

Artwork — paintings, drawings, pastels

Clothing & accessories

Clothing — shirts, pants, dresses, suits, underwear, hosiery, pyjamas, sweaters, activewear, swimwear, outerwear, baby clothes

Activity-specific attire — diving suits, ski suits, protective gear, life jackets, climbing harnesses, work belts, safety headgear, animal saddlery

Accessories — footwear, hats, gloves, scarves, belts, neckties, jewelry

Bags & luggage — handbags, wallets, suitcases, briefcases, backpacks

Electronics & appliances

Household appliances — refrigerators, freezers, dishwashers, washing machines and dryers, stoves, barbecues, fans, humidifiers, vacuum cleaners, fabric steamers

Countertop appliances & kitchen gadgets — blenders, food mixers, juicers, microwaves, grills, rice cookers, coffee makers, toasters

Gaming & entertainment — video game consoles, board games, card games

Vehicles & machinery

Motorcycles & recreational vehicles — motorbikes, sidecars, recreational boats, drones

Yard equipment — snowblowers, lawnmowers

Tools — saws, pliers, wrenches, spanners, hammers, drills, cutting tools, screwdrivers, staple guns, vices, lighters, pneumatic tools, padlocks

Rubber tires

Building materials

Silica & quartz sands

Plastic wall, floor & ceiling coverings

Window and door fixtures — window and door components and frames, shutters, blinds

Bathroom fixtures — plastic and ceramic baths, showers, sinks and wash basins, toilets, bidets, urinals

Plastic packaging

Wood products — planks, chips, veneer sheets, particle board, MDF, fibreboard, laminated wood, posts, beams, floor panels, wood pulp

Cardboard & paper — cartons, boxes, cases, paper bags

Textiles — tarps, tents, canopies, sails, woven fabric

Precious metals & gemstones — diamonds, silver, palladium

Weapons & ammunition

Firearms — pistols, revolvers, rifles, shotguns, air guns

Ammunition — bullets, cartridges, pellets

"Have fun!"

9 notes

·

View notes

Text

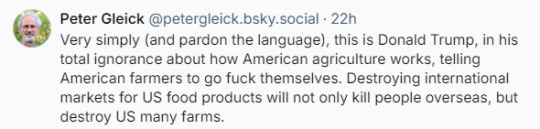

HUgE Jan 2012

BEHIND the DOOR

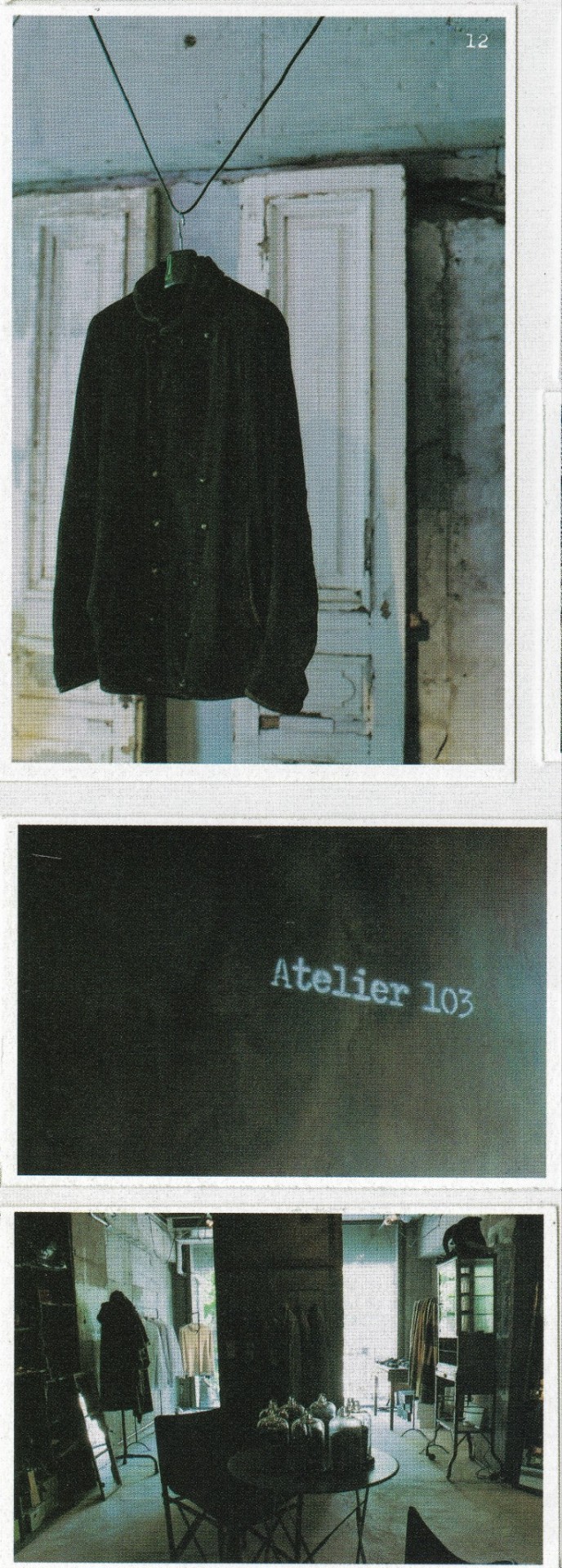

Atelier 103

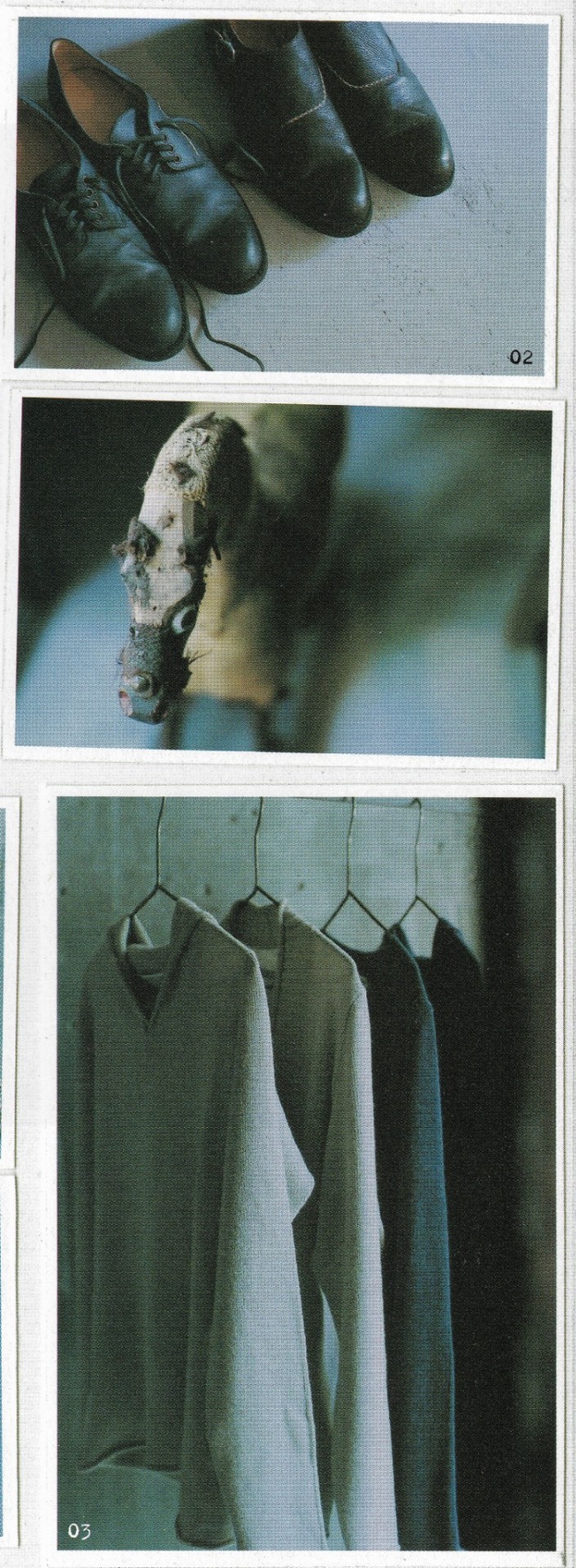

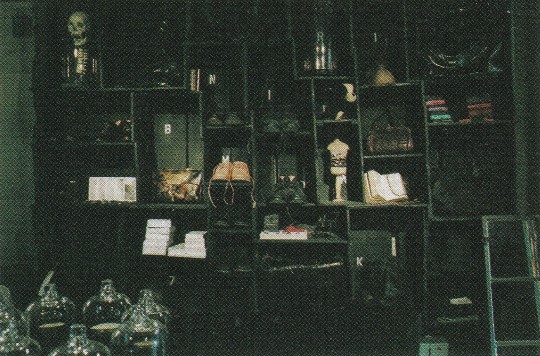

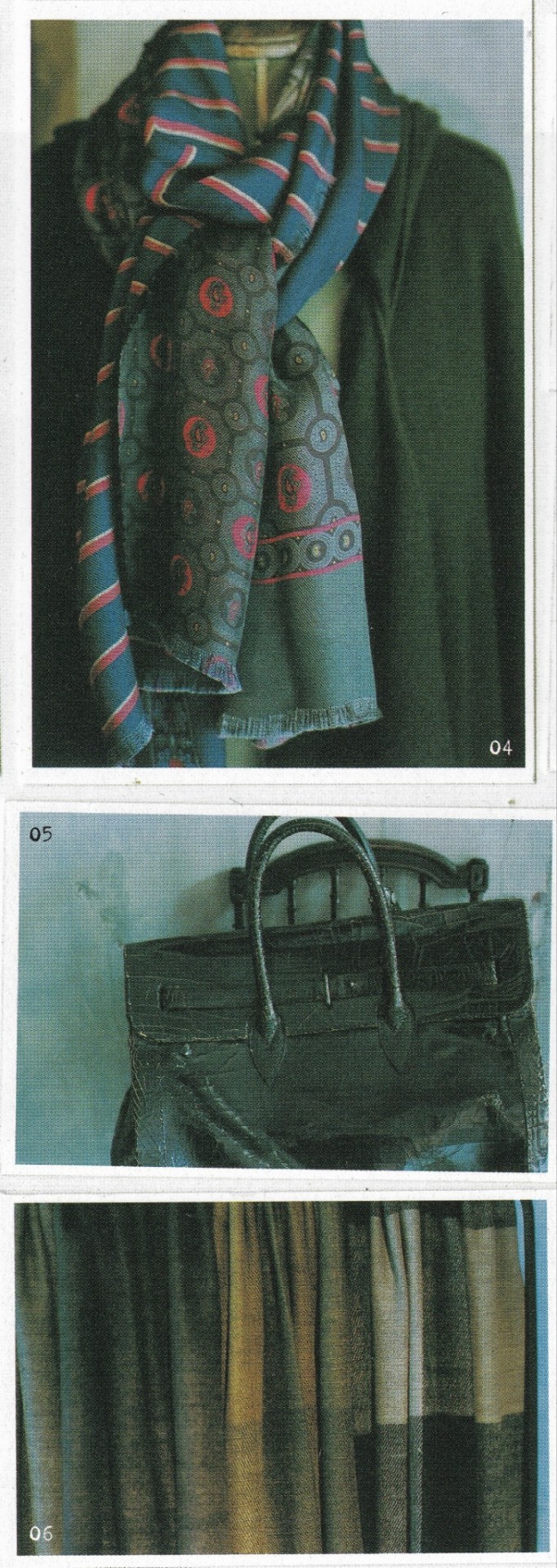

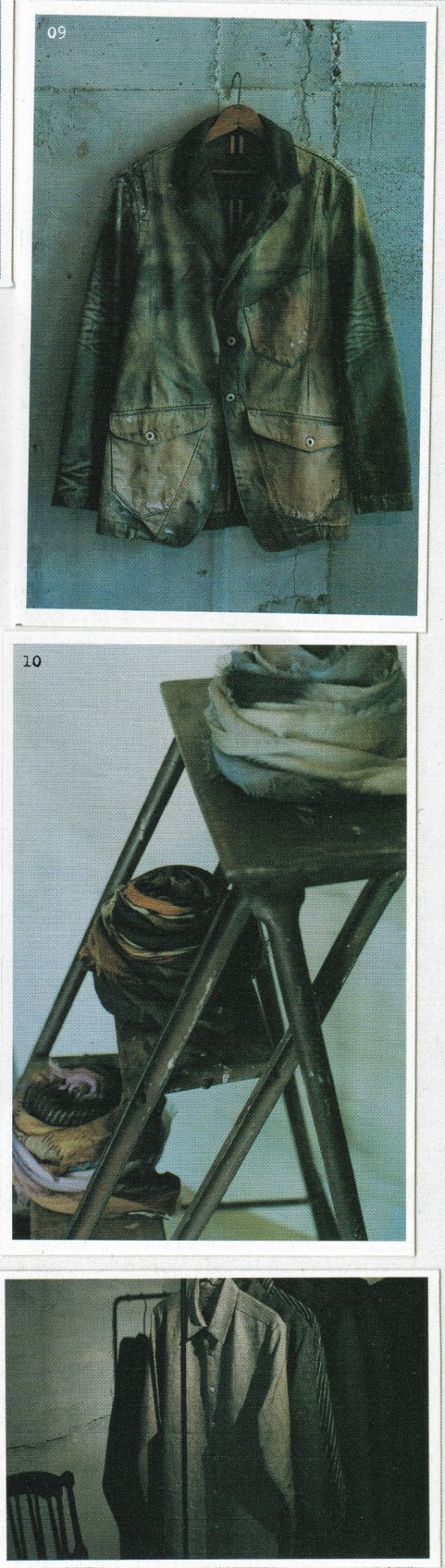

"Clothes that tell the story of their maker." That's what the store opened in August 2010.

This is the buying concept of the select shop "Atelier 103."

The selection is mostly imported goods. If you look at the racks,

From well-known and talented artists to up-and-coming artists with a rebellious spirit,

Unique brands not available in other stores are carefully selected with a thorough discerning eye. Located in a building away from the hustle and bustle of Harajuku.

Behind the heavy door suddenly appears a decadent space.

"Fashion is fun. There are fascinating items waiting to make you feel that way.

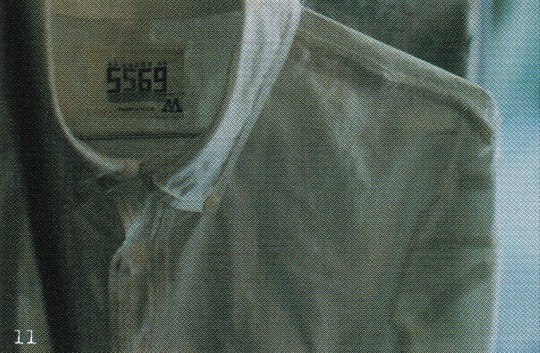

01&11.LA. 5569, a remake brand created by a Japanese artist living in LA, is a brand with a concept of "recycle & fashion". ¥18,900 each

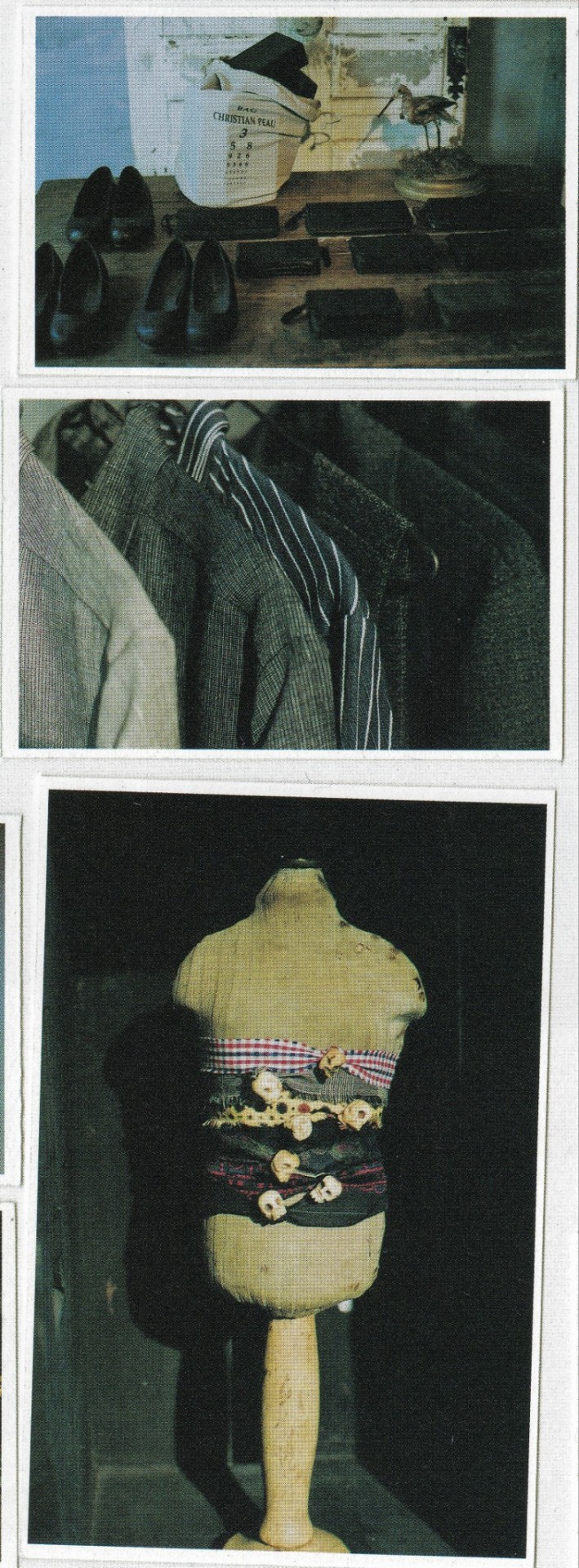

02. SAKU offers shoes made from leather from Guidi. They are characterized by their rich and tasteful expression. Right: ¥90,300, Left: ¥88,200

03. Motherhand Artisan, a knitwear brand from Belgium, offers completely handmade products knitted on a "hand-operated flat knitting machine" and hand-sewn. ¥37,800~

04&10. Pierre Louismacia's stole features beautiful, colorful prints inspired by vintage textiles from India and Europe. ¥27,300~ each

05. The bag with its impressive cracked leather is from Mark Marmel, a designer and former film producer who is also a collector of vintage bags. ¥157,500

06.LA Cashmere stole by Denis Colon, an architect based in LA. Beautiful drape and soft texture. ¥37,800 each

07. Exotic leather wallet by Christian Paw ¥46,200~

08. Fragrance candle by Cire Trudon, the world's oldest candle manufacturer founded in Paris in 1643. Made from 100% plant-based ingredients, it produces no soot when burned. The glass was designed by Astier de Villard. ¥8,400

09. Denim jacket "A1901" by Prospective Flow is based on the design concept of "what would happen if you wore jeans made in 1901 for 100 years?" The artistic aging process is striking. ¥42,000

12. Leather peacoat by Christian Paw, which we started carrying this season. ¥98,700

#my scans#fashion#2010s fashion#avantgarde#japanese fashion#atelier#leather shoes#guidi#artisanal#leather#denim jacket#leather bag#scarf

5 notes

·

View notes

Text

Elevate Your Brand with Stunning PRINT Designs!

We offer a comprehensive range of creative services to meet the needs of the fashion and textile industries: 1- Digital Print Design Creation – Unique and captivating designs crafted for fashion, home decor, and branding. 2- Embroidery Digitizing – Precise and detailed designs ready for flawless embroidery production. 3- Tech Pack Development – Comprehensive technical documentation for streamlined production processes.

Our mission is to bridge the gap between vision and execution, delivering designs that inspire and solutions that work. Whether you're building a brand or perfecting a product, Apparel Architects is your trusted partner in the journey of innovation and style. Let’s create something extraordinary together!

#PrintDesign #FloralDesign #DigitalPrints #CreativeDesign #embroidery #digitzation #apparel #fashion #textile #techpack #devolopment

#artists on tumblr#fashion#printing#art print#print#blackfashion#fashion model#high fashion#runway#black beauty

5 notes

·

View notes

Text

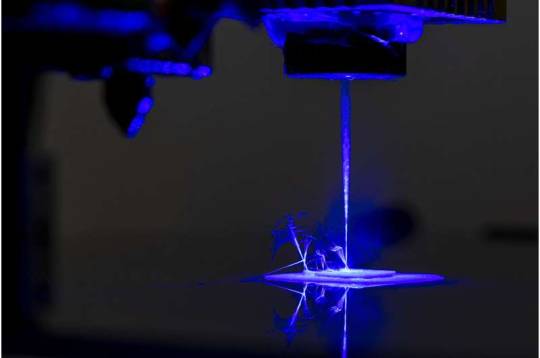

No assembly required: Innovative 3D printing method streamlines multi-materials manufacturing

University of Missouri researchers have developed a way to create complex devices with multiple materials—including plastics, metals and semiconductors—all with a single machine. The research, which was recently published in Nature Communications, outlines a novel 3D printing and laser process to manufacture multi-material, multi-layered sensors, circuit boards and even textiles with electronic components. It's called the Freeform Multi-material Assembly Process, and it promises to revolutionize the fabrication of new products. By printing sensors embedded within a structure, the machine can make things that can sense environmental conditions, including temperature and pressure. For other researchers, that could mean having a natural-looking object such as a rock or seashell that could measure the movement of ocean water. For the public, applications could include wearable devices that monitor blood pressure and other vital signs.

Read more.

17 notes

·

View notes

Text

Dyes : The World of Colors

Colors make our world vibrant, and dyes are the magical ingredients that bring life to everything around us. Let’s explore the colorful universe of dyes, breaking down the various types and their fascinating uses in everyday life.

Understanding Dyes:

Dyes are like special paints that add color to different things. Humans have been fascinated by colors for a long time, and dyes play a huge role in making our world colorful. There are two main types of dyes: natural and synthetic. They are used to add color to items like utensils, textiles, leather products, and even food.

Types of Dyes:

Basic Dyes:

These dyes are made in labs and give really bright colors. They are great for adding color to things like acrylic fibers and synthetic materials.

Direct Dyes:

These dyes dissolve in water and are used for coloring materials like cotton. They are commonly used in the textile industry.

Natural dyes :

Natural dyes are derived from sources in nature and may include substances like indigo, turmeric, or cochineal. While these dyes have a historical and cultural significance, they often present limitations in terms of color range and fastness.

Acid Dyes:

Perfect for coloring protein fibers like wool and silk, acid dyes are highly soluble in water. They are not suitable for materials like cotton but work well for leather and medical products.

Synthetic Dyes:

Man-made and chemically produced, these dyes come in a wide range of colors. They are used in many industries due to being affordable, but they can be harmful to the environment and humans.

Reactive Dyes:

Best for cellulose, protein, and polyamide fibers, these dyes are easy to use and have good light-fastness properties. They are popular in the textile industry.

Solvent Dyes:

Modern and non-toxic, these dyes are used in upcoming textile mills. They are convenient but may be more expensive. Solvent dyes are seen as alternatives to traditional harmful dyes.

Food Dyes:

Added to food to make it look attractive, food dyes come in various forms. It’s important to use them carefully as excessive consumption can lead to health problems. They are either natural or artificial.

Application of Dyes:

Textiles: Dyes are extensively used in the textile industry to color fabrics, clothing, and other textile products. They can be applied through various methods such as dyeing, printing, or painting.

Plastics: Dyes enhance the appearance of plastic products, providing them with a wide range of colors and finishes.

Printing: Inks, whether for traditional printing or modern digital printing, often contain dyes to produce vibrant and accurate colors.

Food: Food dyes are used to add color to various food products, making them visually appealing. These dyes can be natural or synthetic.

Industrial Use: Dyes find applications in various industrial processes, including coloring materials like leather, creating inks for pens and printers, and contributing to the production of a wide array of products.

17 notes

·

View notes

Text

lrb this is kind of only tangentially related to their broader point about money within the concert scene and more relevant to the caveats discussed at the front end of the post. and also everything discussed here is through a usamerican lens because that is where i live ♥️. but i firmly believe every person with the ability to do so should try to partake in some form of garment fabrication—whether thats spinning yarn, weaving fabric, knitting/crocheting, designing, or sewing—to get a better idea of what an insanely labor intensive process it is and how much goes into it for clothes to be produced Ethically. granted yes automation takes care of some of that (economies of scale and etc) but like for a simple graphic tee i would say even $40 is fucking low for me to be reassured that the people

harvesting the raw fibers

transporting the fibers

processing the material into cloth

transporting the cloth

designing the garment

sewing the prototypes

programming and maintaining the machines that cut and sew

harvesting the raw material to create the ink/paint/logo material (i think what this is will vary)

transporting the logo raw material

processing the raw material into ink/paint/whatever

designing the logo/design on the shirt

maintaining the machines that print the logo/design onto the shirt

transporting the finished shirts to warehouses and points of sale

are all being compensated fairly and treated well by their employer. and that is all Before considering that posts main point about all the artists and road crew and etc that need to be able to sell that shirt at enough of a profit to not be literally destitute. and this is Also entirely not considering (again this was mentioned in the post) the money that would be required to mitigate the environmental ramifications of

the land being used as a monoculture to produce fibers (im aware synthetic textiles exist but i do not think the mass production of non-biodegradable junk counts as ethical per se)

the fossil fuel usage of the transport at every step of the way

the electricity usage of the machines/facilities producing the shirts

whatever the fuck they have to do to make the paint or ink or whatever that makes the logo/design

the disposal of the fabric scrap waste

like. idk im preaching to the choir i think most people on here are already fully aware that overconsumption is bad. and im not moralizing buying cheap/expensive clothes because i think it just distracts from the main problem to go around attacking people who buy cheap clothes because the structure of our society does not enable them to earn enough to buy anything else. ADDITIONALLY. price is a completely legitimate criticism to make about products when it's obvious that moneys going into some rich fuckers pocket instead of towards compensating the workers involved in making the products. but ☝️my thesis statement so to speak is that along with op of that last post, i think the criticism should not be "why is this product so expensive", it should be "why am i not paid enough to afford this" and "why are you charging that much and then all but enslaving people in impoverished countries to make this product" and "why is it all but impossible to participate in broader usamerican society without funding systems that treat people as disposable". this post got long as fuck if youre somehow still reading this Haiiiii :3

2 notes

·

View notes

Text

Comprehensive Industrial Solutions by AxisValence: Advancing Productivity, Safety, and Efficiency

In today’s fast-paced manufacturing world, industrial productivity is driven by precision, consistency, safety, and compliance. Whether it’s printing, packaging, converting, textiles, plastics, or pharmaceuticals—modern production lines demand advanced electro-mechanical systems that minimize waste, ensure operational safety, and improve overall efficiency.

AxisValence, a business unit of A.T.E. India, addresses this demand with a complete range of industrial automation and enhancement products. From static elimination to print quality assurance, ink management, and solvent recovery, AxisValence solutions are engineered to optimize each critical point in the production cycle.

This article provides an overview of the key technologies and systems offered by AxisValence across its diverse portfolio:

Electrostatics: Managing Static for Quality and Safety

Electrostatics can compromise product quality, disrupt operations, and pose serious safety hazards, especially in high-speed processes involving films, paper, textiles, or volatile solvents. AxisValence offers a complete suite of static control solutions:

ATEX AC Static Eliminators: Certified for use in explosive or solvent-heavy environments such as rotogravure or flexo printing lines.

AC and DC Static Eliminators: Designed for long-range or close-range static charge neutralization across a range of substrates.

Passive Static Dischargers: Cost-effective, maintenance-free brushes for light-duty static elimination where power isn't available.

Air-based Static Eliminators / Ionisers: Use ionized air streams for dust blow-off and static removal, ideal for hard-to-reach areas.

Static Measurement & Online Monitoring: Includes handheld meters and IoT-enabled monitoring systems for real-time control and diagnostics.

Electrostatic Charging Systems: Generate controlled static charges for bonding or pinning applications in laminating or packaging lines.

Electrostatic Print Assist (ESA): Enhances ink transfer in rotogravure printing by improving ink pickup and registration.

Camera-Based Web Videos for Print Viewing: Real-Time Visual Inspection

High-speed printing applications require instant visibility into print quality. AxisValence’s ViewAXIS systems are high-performance, camera-based web viewing solutions:

ViewAXIS Mega: Entry-level system with high-resolution imaging for real-time visual inspection.

ViewAXIS Giga: Equipped with 14x optical zoom and X-ray vision for deeper inspection of layered prints.

ViewAXIS Tera: Full repeat system with a 55” display, allowing operators to monitor and inspect the complete print layout in real-time.

Camera-Based Web Videos for Print Viewing systems help identify print errors like registration issues, smudging, or color inconsistencies early in the production run—minimizing rework and improving efficiency.

100% Inspection Systems: Intelligent Defect Detection

Modern converters and packaging companies require automated systems that can identify microscopic flaws at high speeds. AxisValence’s DetectAXIS systems use AI-based image processing and line scan cameras for 100% inspection:

DetectAXIS Print: Identifies printing defects such as streaks, misregistration, color deviation, and missing text at speeds up to 750 m/min.

DetectAXIS Surface: Designed for detecting surface anomalies—scratches, gels, holes, fish-eyes—on films, textiles, and nonwovens.

Real-time alerts, digital roll-maps, and adaptive detection improve quality control while reducing material waste and production downtime.

Ink Handling Systems: Consistent Ink Quality and Reduced Waste

Stable ink flow and temperature directly impact print quality and solvent consumption. AxisValence’s Valflow range ensures optimal ink conditioning through:

Ink Filters: Eliminate contaminants like metallic particles, fibers, and dried pigments that can damage cylinders or cause print defects.

Ink Pumps & Tanks: Efficient centrifugal pumps and round stainless-steel tanks designed for continuous ink circulation and minimal ink residue.

Ink Temperature Stabilisers (ITS): Automatically control ink temperature to prevent viscosity drift and reduce solvent evaporation—delivering consistent print shade and odor-free operation.

Valflow Ink handling solutions are ideal for gravure and flexographic printing applications.

Print Register Control Systems: Precision Alignment in Every Print

Maintaining precise print registration control systemis critical in multi-color printing processes. AxisValence offers two specialized systems:

AlygnAXIS: For rotogravure presses, using fiber optic sensors and adaptive algorithms to deliver real-time register accuracy.

UniAXIS: A versatile controller for print-to-mark, coat-to-mark, and cut-to-mark applications—both inline and offline.

These controllers reduce waste, enhance print alignment, and speed up setup during job changes.

Safety and Heat Recovery Systems: Energy Efficiency and Explosion Prevention

Solvent-based processes require strict monitoring of air quality and heat management to meet compliance and reduce operational costs. AxisValence provides:

NIRA Residual Solvent Analyser: Lab-based gas chromatography system for quick analysis of residual solvents in films.

Air-to-Air Heat Exchangers (Lamiflow): Recover and reuse waste heat from drying processes—improving energy efficiency.

LEL Monitoring and Recirculation Systems: Ensure solvent vapor concentrations stay within safe limits in enclosed dryers using flame ionization or infrared detection.

Together, safety and heat recovery systems ensure both environmental safety and process optimization.

Surface Cleaning Systems: Contaminant-Free Production Lines

Particulate contamination can ruin coating, lamination, and printing jobs. AxisValence offers contactless surface cleaning systems that combine airflow and static control:

Non-Contact Web Cleaners: Use air curtains and vacuum to remove dust from moving substrates without physical contact.

Ionising Air Knives: High-velocity ionized air streams neutralize static and clean surfaces entering finishing zones.

Ionising Air Blowers: Cover larger surfaces with ionized air to eliminate static and debris.

Ionising Nozzles & Guns: Handheld or fixed, these tools offer targeted static and dust elimination at workstations.

Waste Solvent Recovery: Sustainable Ink and Solvent Reuse

Reducing solvent consumption and improving environmental compliance is critical for modern converters. AxisValence partners with IRAC (Italy) to offer:

Solvent Distillation Systems: Recover usable solvents from spent ink mixtures, reducing hazardous waste and cutting costs.

Parts Washers: Clean anilox rolls, gravure cylinders, and components through high-pressure, ultrasonic, or brush-based systems.

Waste solvent recovery systems offer a quick ROI and support zero-waste manufacturing goals.

Why Choose AxisValence?

AxisValence combines decades of industrial expertise with innovative product design to deliver reliable, safe, and efficient solutions for manufacturing processes. With a product portfolio spanning:

Electrostatics & Static Control Systems

Web Viewing & Print Inspection Solutions

Ink Handling and Conditioning Equipment

Register Control and Print Automation

Heat Recovery and Air Quality Monitoring

Surface Cleaning Technologies

Waste Solvent Management

…AxisValence serves diverse industries including printing, packaging, plastic and rubber, textile, pharma, and automotive.

From single-device retrofits to complete system integration, AxisValence enables manufacturers to improve output quality, reduce waste, meet safety norms, and gain a competitive edge.

Explore our full product range at www.axisvalence.com or contact our sales network for a customized consultation tailored to your industrial needs.

youtube

2 notes

·

View notes

Text

Borana Weaves IPO: Price band set at ₹205–216 per share; check issue details, key dates, more

Borana Weaves IPO: Borana Weaves IPO will open for subscription on May 20 at a price band of ₹205 to ₹216 per share. The company plans to use IPO proceeds for a new manufacturing facility and working capital, with listing expected on May 27.

Borana Weaves IPO: Borana Weaves IPO price band has been fixed in the range of ₹205 to ₹216 per equity share of the face value of ₹10 for its upcoming public issue. Borana Weaves IPO date of subscription is from Tuesday, May 20 to Thursday, May 22. The allocation to anchor investors for Borana Weaves IPO is scheduled to take place on Monday, May 19.

The IPO floor price is 20.5 times the face value of the equity shares, and the cap price is 21.6 times the face value of the equity shares. The price-to-earnings ratio based on diluted EPS for fiscal 2024 at the lower end of the price band is 17.33 times, and at the upper end of the price band is 18.26 times.

Investors can apply for Borana Weaves IPO in a lot size of 69 equity shares, and in multiples thereafter.

Borana Weaves IPO has reserved not less than 75% of the shares in the public issue for qualified institutional buyers (QIB), not more than 15% for non-institutional investors (NII), and not more than 10% of the offer is reserved for retail investors.

Tentatively, Borana Weaves IPO basis of allotment of shares will be finalised on Friday, May 23, and the company will initiate refunds on Monday, May 26, while the shares will be credited to the demat account of allottees on the same day following the refund. Borana Weaves share price is likely to list on BSE and NSE on Tuesday, May 27.

About Borana Weaves

Borana Weaves Limited is a producer of unbleached synthetic grey fabric located in Surat, Gujarat. The company’s unbleached synthetic grey fabric is commonly utilised as a foundation for additional processing (including dyeing and printing) in sectors such as fashion, traditional textiles, technical textiles, home decor, and interior design.

Additionally, the firm produces polyester textured yarn (PTY Yarn), which is made by heating polyester oriented yarn (POY Yarn), the raw material used in creating grey fabric.

Borana Weaves Limited operates three manufacturing facilities in Surat, Gujarat, that are equipped with textile manufacturing technologies for various processes, including texturising, warping, operating water jet looms, and folding textiles.

As of September 30, 2024, the company had 15 operational texturising machines, 6 warping machines, 700 water jet looms, and 10 folding machines in its three facilities.

According to the red herring prospectus (RHP), there are no listed industry competitors in India or overseas, which could pose challenges in comparing and assessing their financial performance against other firms within the same sector.

Borana Weaves has shown impressive growth over the last three fiscal years. In FY 2024, the company disclosed revenue of ₹199.10 crore, representing a significant rise from ₹135.40 crore in FY 2023 and ₹42.30 crore in FY 2022.

Borana Weaves IPO details

Borana Weaves IPO, which is worth ₹144.89 crore, comprises of fresh issue of 67,08,000 equity shares. There’s no offer-for-sale (OFS) component.

Borana Weaves IPO objective is to use the net proceeds from the offering for several purposes, including financing the establishment of a new manufacturing facility to enhance its production capacity for grey fabric in Surat, Gujarat, India; providing additional working capital; and covering general corporate needs.

Beeline Capital Advisors Pvt Ltd serves as the book-running lead manager for Borana Weaves IPO, and Kfin Technologies Limited acts as the registrar for this offering.

“Investments in the securities market are subject to market risks.”

Intensify Research services is a SEBI registered Research analyst Indore committed to empowering investors with the most reliable stock market insights. Our team of expert analysts uses advanced tools and strategies to provide that enhance your chances of success. To visit- Intensifyresearch.com »

2 notes

·

View notes

Text

Ajrakh Print Fabric: A Timeless Tradition of Hand Block Printing

Ajrakh print fabric is an ancient textile art form that has been cherished for centuries. Originating from the regions of Sindh (Pakistan) and Kutch (India), Ajrakh is a unique hand-block printing technique that embodies rich cultural heritage, intricate designs, and a meticulous dyeing process. This fabric is revered for its deep, earthy colors and symmetrical patterns, making it a timeless masterpiece in the world of textiles.

History and Origins

The history of Ajrakh dates back over 4,000 years, with evidence of similar block-printed textiles found in the ruins of the Indus Valley Civilization. The craft flourished under the patronage of the Mughal Empire and later found its stronghold in the Kutch region of Gujarat, where communities like the Khatris have preserved the tradition for generations.

Ajrakh printing was traditionally associated with the Sindhi and Kutchi communities, particularly the pastoral Maldharis, who used it as a part of their daily attire. The word 'Ajrakh' is believed to be derived from the Arabic term 'Azrak,' meaning 'blue,' signifying the dominance of indigo hues in the fabric.

The Intricate Process of Ajrakh Printing

Ajrakh printing is a labor-intensive process that involves multiple stages, each requiring immense skill and patience. The traditional method consists of the following steps:

Pre-Treatment of Fabric: The fabric (usually cotton or silk) is first washed and treated with natural substances like camel dung, soda ash, and castor oil to remove impurities and enhance dye absorption.

Block Printing: Skilled artisans carve intricate patterns onto wooden blocks, which are then used to print designs onto the fabric using resist techniques.

Natural Dyeing: Ajrakh is known for its use of organic dyes, including indigo, madder, turmeric, and pomegranate peels. The dyeing process is repeated multiple times to achieve the rich, deep colors.

Sun-Drying and Washing: The fabric is sun-dried between each dyeing phase and undergoes multiple washes to ensure color fastness.

Final Finishing: The finished fabric is given a final rinse and dried, revealing the vibrant, symmetrical patterns characteristic of Ajrakh.

Unique Characteristics of Ajrakh Fabric

Ajrakh fabric stands out due to its:

Geometric and Floral Motifs: The designs are symmetrical and often inspired by nature, stars, and Islamic architecture.

Reversible Printing: Many Ajrakh fabrics have the same design on both sides, showcasing the precision of hand-block printing.

Sustainable and Eco-Friendly Production: The use of natural dyes and traditional methods makes Ajrakh an environmentally friendly textile art.

Modern Adaptations and Uses

While traditionally used for turbans and shawls, Ajrakh fabric has evolved with time and is now widely used in modern fashion. Designers incorporate Ajrakh prints into sarees, dresses, jackets, scarves, and even home decor items like cushion covers and table linens.

Preserving the Legacy of Ajrakh

Despite industrial advancements, artisans in Kutch and Sindh continue to uphold the authenticity of Ajrakh printing. Many organizations and designers are working to promote and sustain this craft by creating contemporary designs while maintaining traditional techniques.

Conclusion

Ajrakh print fabric is not just a textile; it is a story woven into fabric, reflecting the history, art, and craftsmanship of generations. With its unique blend of tradition and modern appeal, Ajrakh remains a cherished and valuable part of India’s and Pakistan’s cultural heritage. Whether in fashion or home decor, the elegance of Ajrakh continues to captivate art and textile lovers worldwide.

2 notes

·

View notes

Text

canvas cotton cloth

🌿 Order Fabric Online for a Greener Future: From Canvas Cotton to Circular Fashion with Suvetah

In today’s climate-conscious creative economy, sustainable textiles like canvas cotton are no longer niche—they’re essential. From artisan tote bags to durable homeware and ethical apparel, this versatile, organic fabric supports design that’s tough, timeless, and traceable.

At Suvetah, you can now order canvas fabric online with ease, confidence, and full supply chain transparency. Whether you're crafting small-batch eco-fashion or building a sustainable product line, our GOTS-certified cotton canvas helps bring your ideas to life—without compromise.

🧵 Canvas Cotton: Durable, Biodegradable & Built for Design

Canvas cotton is a heavyweight weave made from organic or conventional cotton yarns, known for its high tensile strength, weather resistance, and easy dyeability. Suvetah’s organic canvas cotton fabric is:

🌿 100% natural and free of harmful synthetics

🧺 Machine-washable and breathable

🎨 Ideal for natural dyeing and screen printing

🔁 Perfect for long-life, multi-use products like reusable shopping bags, workwear, and eco interiors

Compared to synthetic canvas blends, Suvetah’s sustainable cotton canvas is fully biodegradable, free of microplastic pollution, and processed with low-impact, AZO-free dyes.

🔄 Circular Fashion in Action: Where Canvas Shines

Canvas cotton fits seamlessly into circular design principles. This fabric supports fashion systems where materials:

🔁 Stay in use longer through quality construction

♻️ Are reused, re-sewn, or re-dyed over time

🛠️ Can be repaired or upcycled into new pieces

🌿 Eventually return to nature without leaving toxins behind

Suvetah partners with Indian weaving clusters to supply circular-ready canvas textiles—ethically woven, naturally dyed, and packaged plastic-free.

📊 Sustainability Metrics That Matter

Here’s how Suvetah’s organic canvas cotton compares to other common textiles:MetricConventional CottonOrganic Canvas CottonHempPolyesterWater Use (per kg)~10,000L~1,200L~300L~50L (but non-renewable)Carbon EmissionsHigh46% lowerAbsorbs CO₂Very HighLand UsageHighModerateVery LowN/A (synthetic)Pesticide UseHeavyNoneNoneN/ABiodegradabilityLowHighHighLow

📚 Sources: Textile Exchange LCA (2021), Ellen MacArthur Foundation, Lenzing (2022)

🏷️ Certifications That Matter for Canvas Buyers

Suvetah’s canvas cotton fabric is backed by globally recognized standards:

✅ GOTS (Global Organic Textile Standard): Ensures environmental safety, organic farming, and ethical labor

✅ OEKO-TEX® Standard 100: No harmful dyes, heavy metals, or carcinogens

✅ BCI (Better Cotton Initiative): Supports sustainable agriculture for cotton

These certifications are crucial when marketing eco-friendly homeware, organic baby gear, or sustainable apparel in global markets.

🌐 Why Order Canvas Cotton Fabric Online from Suvetah?

Suvetah is your reliable partner for sustainable canvas fabric wholesale. With doorstep delivery, live chat support, and low minimums, we’re built for modern brands and B2B buyers.

🌟 What You Get:

🧾 Traceable supply chain from farm to loom

📦 Flexible MOQs—from samples to bulk orders

🧪 Pre-shipment testing (GSM, shrinkage, colorfastness)

🎨 Low-impact natural dyeing options

🧵 Support for artisan weavers across India

🛒 Start Your Eco Fabric Journey with Suvetah

Whether you’re a slow fashion label in Mumbai, a boutique in Singapore, or a craft-based business in London, Suvetah makes it simple to buy canvas cotton online — certified, conscious, and circular.

🧷 Discover our collection of:

Organic canvas fabric by the yard

Bleached and unbleached cotton canvas

Printed canvas fabric with botanical dyes

Heavy-duty canvas for upholstery and bags

✨ Order today and build a greener tomorrow.

🔗 Explore Canvas Cotton Fabrics at Suvetah →

#canvas cotton fabric#order fabric online#organic canvas cotton#canvas fabric wholesale#buy canvas cotton online

1 note

·

View note

Text

How Aluminum Rollers Improve Efficiency in Manufacturing

Aluminum Roller manufacturers :The Advantages of Aluminum Rollers in Industrial Applications

In modern manufacturing, achieving smooth and efficient material handling is essential for optimizing production. Aluminum rollers have become an integral component in various industries due to their lightweight structure, durability, and corrosion resistance. These rollers are widely used in packaging, printing, textiles, and conveyor systems, providing stable performance and ensuring the seamless movement of materials. With advanced engineering and precision manufacturing, they contribute to improved operational efficiency and reduced maintenance requirements.

How Aluminum Rollers Improve Efficiency in Manufacturing

Aluminum rollers offer excellent mechanical properties, making them ideal for applications that require both strength and flexibility. Their lightweight design allows for easy installation and handling, while their smooth surface ensures minimal friction, reducing wear and tear on other machine components. The ability to operate at high speeds with precision makes them a preferred choice for industries looking to enhance productivity.

Key Benefits of Using Aluminum Rollers

Lightweight Yet Strong The combination of strength and low weight makes these rollers easy to install and operate without compromising durability.

Corrosion and Wear Resistance Aluminum naturally resists oxidation, allowing these rollers to maintain their performance even in challenging environments.

Smooth and Consistent Motion Designed for efficiency, these rollers provide stable rotation, reducing vibrations and ensuring the smooth movement of materials.

Versatile Industrial Applications Used across various industries, including packaging, printing, material handling, and textile processing, ensuring flexibility in multiple production lines.

Choosing the Right Aluminum Roller for Your Production Line

When selecting an aluminum roller, businesses should evaluate specific requirements to ensure optimal performance. Key factors to consider include:

Load-Bearing Capacity – Ensuring the roller can support the required weight and operational stress.

Surface Coating – Choosing the appropriate finish for enhanced durability and reduced friction.

Size Specifications – Selecting the right diameter and length to match industrial needs.

Precision Engineering – Ensuring high-quality manufacturing for consistent and reliable performance.

Enhancing Industrial Performance with High-Quality Aluminum Rollers

As industries continue to evolve, the demand for efficient and long-lasting machine components grows. Innovations in aluminum roller design have led to improved performance, greater energy efficiency, and enhanced operational stability. These advancements help businesses optimize their production processes, reduce maintenance downtime, and achieve cost savings.

Investing in well-designed aluminum rollers is essential for industries aiming to maintain efficiency and reliability in their operations. By incorporating these high-performance components into their production lines, businesses can enhance productivity, improve material flow, and ensure long-term operational success.www.cbbmachine.com

1 note

·

View note

Text

Elevate Your Brand with Stunning PRINT Designs!

Sophisticated and elegant Islamic-inspired fashion print pattern that follows Islamic artistic strictures, avoiding depictions of living beings and instead featuring intricate geometric motifs, arabesque flourishes, and calligraphic elements. The design should be suitable for modest fashion, abayas, kaftans, and scarves.

We offer a comprehensive range of creative services to meet the needs of the fashion and textile industries: 1- Digital Print Design Creation – Unique and captivating designs crafted for fashion, home decor, and branding. 2- Embroidery Digitizing – Precise and detailed designs ready for flawless embroidery production. 3- Tech Pack Development – Comprehensive technical documentation for streamlined production processes.

Our mission is to bridge the gap between vision and execution, delivering designs that inspire and solutions that work. Whether you're building a brand or perfecting a product, Apparel Architects is your trusted partner in the journey of innovation and style. Let’s create something extraordinary together!

#PrintDesign #FloralDesign #DigitalPrints #CreativeDesign #embroidery #digitzation #apparel #fashion #textile #techpack #devolopment

#branding#artists on tumblr#fashion#printing#print#art print#creative design#designer#graphic design#design#creative#designinspiration#minimalist#print on demand#printmaking#islamic art

4 notes

·

View notes

Text

Prints and Patterns

A light on Prints & Patterns.

The patterns on a fabric just put colors on are definitely not woven into fabric. called Prints. These are found in several types like, customized shapes, colors, lines, etc. and in the form of objectives as well. The work of art made in multiple iterations, created through a transfer process. The word “Print” is derived from the Old French word for “Impression,” it makes a product look different from its own origin. It has the power to grasp the attention of someone towards it. When prints and patterns work together it gives a hard on its final project. Nowadays, people are using most commonly made from an acrylic polymer.

Why are Prints important?

Printing is used not merely for books and newspapers but as the time flies it is also used for textiles, plates, wallpaper, packaging, and billboards. Several studies have concluded that people simply absorb content better when it's presented on a page, rather than a screen. This is why some college students are reluctant to use PDF versions of their textbooks; reading printed material somehow allows for higher brain function and better information retention. These designs can be simple or super detailed, but they all have the same goal: to make the fabric look even more amazing! Due to some eye-catching prints and patterns, clothes become more appealing to customers, grabbing their attention and making them want to take a closer look. Printing on fabric plays a crucial role in the fashion industry, being a method for applying designs, patterns, or images to fabrics. Textile printing offers a wide range of design options, allowing clothing manufacturers to create a variety of unique Styles, Prints and Patterns, and Colors of Fashion.

Why are Patterns important?

In the garment industry, patterns are used in order to cut the fabric pieces and to make the garment. Patterns are essentially made so that the same style can be easily duplicated when it is needed and multiple pieces can be efficiently made. Improved quality: Patterns can help to ensure that garments are made to the desired specifications, which can lead to improved quality and customer satisfaction. Prints and Patterns making is the process of creating a blueprint of your garment. A pattern is used as a template to cut out fabric that matches the required specifications to sew a garment. Its factors in the type of fabric, the intended fit on the wearer, and any trims that will be used. Prints and Patterns on a fabric makes a plain to be creative.

Final product as printed fabric?

Generally, the finishing process includes three basic stages: washing and drying, stabilizing, and pressing. In addition, some fabrics are then treated to make them anti-static, water repellent, or flame retardant. Many methods applied to fabrics in these stages are very specialized and we can't discuss them all. Definitely, after applying Prints and Patterns on chic indicates customization of fabric then that fabric is processed further for next processes like cutting and stitching.

Addition of Tie & Dye in fabric:-

Tie & Dye is a term used to describe a number of resist dyeing techniques and the resulting dyed products of these processes. The process of tie-dye typically consists of folding, twisting, pleating, or crumpling fabric or a garment, before binding with string or rubber bands, followed by the application of dye or dyes. Textile printing is the process of applying color to fabric in definite prints and patterns or designs. In properly printed fabrics the color is bonded with the fiber, so as to resist washing and friction. In golden era, people were using natural objects to paint the garments i.e. Leaves, Vegetables, Stones, etc. Nevertheless, Tie and Dye fabrics are included in Rajasthani cultural traditions. Moreover, due to Social media, people are connecting globally and sharing their ideas of painting, prints and patterns to give an elegant look to their final outfits.

Prints and its historical background:-

Printing blocks have been discovered that date back to around 3000 B.C." Fabric painting remained popular on the continent, and by the time Alexander the Great invaded India (327 B.C.), fabrics full of colorful printed and painted images were a normal possession among the people. There are several thighs to disclose about the past of prints but our main topic is just for the usage of prints and patterns.

Motifs and Prints:-

A motif is a repeated idea, pattern, image, or theme. In the textile arts, a motif is also called a block or square which is a smaller element in a much larger work. Motifs can be any size, but usually all the motifs in any given work are the same size. There are types of motifs which are defined as:

Symbolic Motifs: These motifs take the form of symbols that represent a larger idea or theme.

Conceptual Motifs: These motifs are built around a particular concept or idea that recurs in the story.

Structural Motifs: These motifs are repeated patterns or structures in the story.

Types of Prints in fabric:-

There are several types of the prints and patterns in the fabric but the majorly are in used are mentioned ahead:-

Boho Prints:- Boho style is a free-spirited aesthetic that mixes different cultures and artistic expressions into an eclectic style with an emphasis on organic elements and nature. When putting together your boho style space, mixing patterns, metals, woods, materials, animal hides and trinkets from your travels is highly encouraged.

Screen Prints:- Screen Printing is a process where ink is forced through a mesh screen onto a surface. Making certain areas of the screen impervious to printing ink creates a stencil, which blocks the printing ink from passing through the screen. The ink that passes through forms the printed image.

Block Printing:- A printing block is sometimes called a printmaking block, a wood block or a block. You can also refer to one simply as a printing block.

Animal Printing:- Animal print is a clothing and fashion style in which the garment is made to resemble the pattern of the skin and fur, feathers or scales of animals such as a leopard, zebra, giraffe, tiger or cow.

Batik Prints:- Batik is an Indonesian technique of wax-resist dyeing applied to the whole cloth. This technique originated from the island of Java, Indonesia. Batik is made either by drawing dots and lines of wax with a spouted tool called a canting, or by printing the wax with a copper stamp called a cap.

Rest there are several prints and patterns which can be used by us, on a daily basis but we are not aware about it. But we should know which prints are suitable for your eyes and your comfort. Rest we are always here to help you out and provide you best opinion as always.

#fashion#fashion designer#fabric#denim#accessories#fashion trends#haute couture#fashion blog#fashion inspiration#prints#art print#printmaking#artwork#art#artists on tumblr#my art#illustration#drawings#tie dye#dyeing#cotton#upcycling#bohochic#bohemian#batik#floral#flowers#roses#plants#garden

6 notes

·

View notes

Text

Acetic Acid Market - Forecast(2024 - 2030)

Acetic Acid Market Overview

Acetic Acid Market Size is forecast to reach $14978.6 Million by 2030, at a CAGR of 6.50% during forecast period 2024-2030. Acetic acid, also known as ethanoic acid, is a colorless organic liquid with a pungent odor. The functional group of acetic acid is methyl and it is the second simplest carboxylic acid. It is utilized as a chemical reagent in the production of many chemical compounds. The major use of acetic acid is in the manufacturing of vinyl acetate monomer, acetic anhydride, easter and vinegar. It is a significant industrial chemical and chemical reagent used in the production of photographic film, fabrics and synthetic fibers. According to the Ministry of Industry and Information Technology, from January to September 2021, the combined operating revenue of 12,557 major Chinese garment companies was US$163.9 billion, showing a 9% increase. Thus, the growth of the textile industry is propelling the market growth for Acetic Acid.

Report Coverage

The “Acetic Acid Market Report – Forecast (2024-2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Acetic Acid industry.

By Form: Liquid and Solid.

By Grade: Food grade, Industrial grade, pharmaceutical grade and Others.

By Application: Vinyl Acetate Monomer, Purified Terephthalic Acid, Ethyl Acetate, Acetic Anhydride, Cellulose Acetate, Acetic Esters, Dyes, Vinegar, Photochemical and Others

By End-use Industry: Textile, Medical and Pharmaceutical, Oil and Gas, Food and Beverages, Agriculture, Household Cleaning Products, Plastics, Paints & Coating and Others.

By Geography: North America (the USA, Canada and Mexico), Europe (the UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and the Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America) and the Rest of the World (the Middle East and Africa).

Request Sample

Key Takeaways

The notable use of Acetic Acid in the food and beverages segment is expected to provide a significant growth opportunity to increase the Acetic Acid Market size in the coming years. As per the US Food and Agriculture Organization, world meat production reached 337 million tonnes in 2019, up by 44% from 2000.

The notable demand for vinyl acetate monomer in a range of industries such as textile finishes, plastics, paints and adhesives is driving the growth of the Acetic Acid Market.

Increase in demand for vinegar in the food industry is expected to provide substantial growth opportunities for the industry players in the near future in the Acetic Acid industry.

Acetic Acid Market Segment Analysis – by Application

The vinyl acetate monomer segment held a massive 44% share of the Acetic Acid Market share in 2021. Acetic acid is an important carboxylic acid and is utilized in the preparation of metal acetates and printing processes, industrially. For industrial purposes, acetic acid is manufactured by air oxidation of acetaldehyde with the oxidation of ethanol, butane and butene. Acetic acid is extensively used to produce vinyl acetate which is further used in formulating polyvinyl acetate. Polyvinyl acetate is employed in the manufacturing of plastics, paints, textile finishes and adhesives. Thus, several benefits associated with the use of vinyl acetate monomer is boosting the growth and is expected to account for a significant share of the Acetic Acid Market.

Inquiry Before Buying

Acetic Acid Market Segment Analysis – by End-use Industry

The food and beverages segment is expected to grow at the fastest CAGR of 7.5% during the forecast period in the Acetic Acid Market. Acetic Acid is also known as ethanoic acid and is most extensively used in the production of vinyl acetate monomer. Vinyl acetate is largely used in the production of cellulose acetate which is further used in several industrial usage such as textiles, photographic films, solvents for resins, paints and organic esters. PET bottles are manufactured using acetic acid and are further utilized as food containers and beverage bottles. In food processing plants, acetic acid is largely used as cleaning and disinfecting products. Acetic acid is extensively used in producing vinegar which is widely used as a food additive in condiments and the pickling of vegetables. According to National Restaurant Association, the foodservice industry is forecasted to reach US$898 billion by 2022. Thus, the advances in the food and beverages industry are boosting the growth of the Acetic Acid Market.

Acetic Acid Market Segment Analysis – by Geography

Asia-Pacific held a massive 41% share of the Acetic Acid Market in 2021. This growth is mainly attributed to the presence of numerous end-use industries such as textile, food and beverages, agriculture, household cleaning products, plastics and paints & coatings. Growth in urbanization and an increase in disposable income in this region have further boosted the industrial growth in this region. Acetic acid is extensively used in the production of metal acetates, vinyl acetate and vinegar which are further utilized in several end-use industries. Also, Asia-Pacific is one of the major regions in the domain of plastic production which provides substantial growth opportunities for the companies in the region. According to Plastic Europe, China accounted for 32% of the world's plastic production. Thus, the significant growth in several end-use industries in this region is also boosting the growth of the Acetic Acid Market.

Acetic Acid Market Drivers

Growth in the textile industry:

Acetic Acid, also known as ethanoic acid, is widely used in the production of metal acetate and vinyl acetate which are further used in the production of chemical reagents in textiles, photographic films, paints and volatile organic esters. In the textile industry, acetic acid is widely used in textile printing and dyes. According to China’s Ministry of Industry and Information Technology, in 2020, textile and garment exports from China increased by 9.6% to US$291.22 billion. Also, according to the U.S. Department of Commerce, from January to September 2021, apparel exports increased by 28.94% to US$4.385 billion, while textile mill products rose by 17.31% to US$12.365 billion. Vinyl acetate monomer is utilized in the textile industry to produce synthetic fibers. Thus, the global growth in demand for textiles is propelling the growth and is expected to account for a significant share of the Acetic Acid Market size.

Schedule a call

Surge in use of vinegar in the food industry:

The rapid surge in population along with the adoption of a healthy and sustainable diet has resulted in an increase in demand for food items, thereby increasing the global production level of food items. As per US Food and Agriculture Organization, in 2019, global fruit production went up to 883 million tonnes, showing an increase of 54% from 2000, while global vegetable production was 1128 million tonnes, showing an increase of 65%. Furthermore, world meat production reached 337 million tonnes in 2019, showing an increase of 44% from 2000. Acetic acid is majorly used in the preparation of vinegar which is further widely utilized as a food ingredient and in personal care products. Vinegar is used in pickling liquids, marinades and salad dressings. It also helps to reduce salmonella contamination in meat and poultry products. Furthermore, acetic acid and its sodium salts are used as a food preservative. Thus, the surge in the use of vinegar in the food industry is boosting the growth of the Acetic Acid Market.

Acetic Acid Market Challenge

Adverse impact of acetic acid on human health:

Acetic Acid is considered a strong irritant to the eye, skin and mucous membrane. Prolong exposure to and inhalation of acetic acid may cause irritation to the nose, eyes and throat and can also damage the lungs. The workers who are exposed to acetic acid for more than two or three years have witnessed upper respiratory tract irritation, conjunctival irritation and hyperkeratotic dermatitis. The Occupational Safety and Health Administration (OSHA) reveals that the standard exposure to airborne acetic acid is eight hours. Furthermore, a common product of acetic acid i.e., vinegar can cause gastrointestinal tract inflammatory conditions such as indigestion on excess consumption. Thus, the adverse impact of Acetic Acid may hamper the market growth.

Buy Now

Acetic Acid Industry Outlook

The top 10 companies in the Acetic Acid Market are:

Celanese Corporation

Eastman Chemical Company

LyondellBasell

British Petroleum

Helm AG

Pentoky Organy

Dow Chemicals

Indian Oil Corporation

Daicel Corporation

Jiangsu Sopo (Group) Co. Ltd.

Recent Developments

In March 2021, Celanese Corporation announced the investment to expand the production facility of vinyl portfolio for the company’s acetyl chain and derivatives in Europe and Asia.

In April 2020, Celanese Corporation delayed the construction of its new acetic acid plant and expansion of its methanol production by 18 months at the Clear Lake site in Texas.

In October 2019, BP and Chian’s Zhejiang Petroleum and Chemical Corporation signed MOU in order to create a joint venture to build a 1 million tonne per annum Acetic Acid plant in eastern China.

Key Market Players:

The Top 5 companies in the Acetic Acid Market are:

Celanese Corporation

Ineos Group Limited

Eastman Chemical Company

LyondellBasell Industries N.V.

Helm AG

For more Chemicals and Materials Market reports, please click here

#Acetic Acid Market#Acetic Acid Market Share#Acetic Acid Market Size#Acetic Acid Market Forecast#Acetic Acid Market Report#Acetic Acid Market Growth

2 notes

·

View notes