#Ram Automations Automation Components

Explore tagged Tumblr posts

Text

Unmasking the Best Deals in the World of Cheap VPS Web Hosting

Introduction

In the ever-evolving landscape of web hosting, finding the perfect balance between cost and performance is a pursuit that every website owner cherishes. At l3webhosting, we understand the critical role that Cheap VPS Web Hosting plays in establishing a robust online presence without breaking the bank. In this comprehensive guide, we unveil the secrets behind unmasking the best deals in the realm of Cheap VPS Web Hosting, providing you with the knowledge to make informed decisions and elevate your online experience.

The Core Components of Cheap VPS Web Hosting

1. Resource Allocation

When evaluating Cheap VPS Web Hosting, the allocation of resources is paramount. We pride ourselves on offering ample CPU, RAM, and storage space with our hosting plans, ensuring your website runs seamlessly even during traffic spikes. This commitment to resource abundance sets us apart in the competitive hosting landscape.

2. Scalability

In the dynamic online environment, a hosting solution should be as flexible as your website's growth. Our Cheap VPS hosting plans are designed with scalability in mind, allowing you to effortlessly upgrade your resources as your website expands. This eliminates the hassle of migrating to a new host when your current plan no longer meets your demands.

3. High-Speed SSD Storage

Unlike traditional hosting solutions, our Cheap VPS Web Hosting harnesses the power of High-Speed SSD Storage. This not only accelerates data retrieval but also contributes to quicker website loading times. The result? An enhanced user experience and a potential boost in search engine rankings, aligning with Google's preference for faster-loading websites.

4. Global Server Locations

Geographical proximity to your target audience is crucial for reducing latency and improving website performance. With our strategically located servers across the globe, we ensure that your website visitors experience minimal lag, leading to higher user satisfaction and potentially improved SEO rankings.

5. Robust DDoS Protection

In the digital age, security is non-negotiable. Our Cheap VPS Web Hosting comes equipped with Robust DDoS Protection, safeguarding your website against malicious attacks. This not only protects your data but also enhances your website's credibility in the eyes of both users and search engines.

6. Automated Backups

The importance of regular backups cannot be overstated. Our hosting plans include automated backup solutions, providing you with peace of mind knowing that your data is securely stored. In the event of unforeseen circumstances, swift data restoration is just a click away.

7. 24/7 Technical Support

We understand that technical issues can arise at any time. That's why our commitment to customer satisfaction extends to round-the-clock technical support. Our team of experts is ready to assist you with any queries or concerns, ensuring uninterrupted online operations.

Conclusion

In the competitive realm of web hosting, l3webhosting stands as a beacon of reliability, offering Cheap VPS Web Hosting solutions that prioritize performance, security, and scalability. Unmask the best deals today and elevate your online presence with a hosting partner that values your success.

2 notes

·

View notes

Text

Arturia Matrix-12 Download

Tech Specs (MAC & Windows)

Software Type:Music Software

Platform:, MAC & Windows

Upgrade/Full Version:Full Unlocked

Download/Boxed:Download

License Type:Lifetime Activation

Format: Standalone, VST, VST3, AU

Hardware Requirements – PC:Intel / AMD Multi-core CPU, 4GB RAM minimum

OS Requirements – OSX : OS X 10.8 or later M1& M2

Arturia Matrix 12 V Virtual Synth Plug-in at a Glance:

The Matrix 12 story, in all its glory

Arturia models it, to a tee

Unleash your creativity: the sky’s the limit!

The Matrix 12 story, in all its glory

The 1980s were an important – and interesting – decade in the synth world. Polyphony was becoming de rigueur and digital synthesis was gaining a foothold with the Yamaha DX-7 and various digital samplers, while stripped-down synths like the Juno 106 and Korg Poly 6 were making synthesis available to the masses. The stage was set for Tom Oberheim – who had been designing some of the best-sounding synths for over a decade – to introduce a no-holds-barred analog synth. And so the Oberheim Matrix 12 was unleashed upon the world in 1985. It was, indeed, an all-out assault on the state of the art, with glorious sonics and tantalizing modulation possibilities, but its near-five-grand price tag put it out of reach for all but a few fortunate souls. Around 1000 units were produced, many of which are still making music to this day.

Arturia models it, to a tee

When it comes to modeling vintage analog synths, many of us immediately think of Arturia – and with good reason. Their proprietary True Analog Emulation technology (TAE) is truly amazing, and is no doubt a critical component in some of the finest virtual synths we’ve heard. For the Matrix 12 V, Arturia modeled not only the tonal aspects of the original two oscillators and their waveforms, but the 15 filter modes as well. They knew that the Matrix 12’s famously rich, complex sound was forged by its multiple filter modes and by the numerous modulation sources and destinations on tap. With nearly endless modulation-routing possibilities, you can sculpt wonderfully organic sounds not possible with other synthesizers.

Unleash your creativity: the sky’s the limit!

The Matrix-12 V is, just like its hardware predecessor, a multitimbral instrument. In Multi mode, each of the 12 notes can voice a different sound. These sounds can then be split on different zones of your keyboard, transposed individually, played unison – you get the idea! And Matrix 12 V’s elegant software interface makes configuring all this a cinch. While the original Matrix 12 was an amazing synthesis achievement, Arturia upped the ante by adding a new effects chain for additional sound processing. They also doubled the allowable number of modulations from 20 to 40, giving you even more creative options. Factor in the ability to control all of Matrix 12 V’s parameters via MIDI, letting you perform automation in your DAW, and you’ve got a total beast of a soft synth.

Arturia Matrix 12 V Virtual Synth Plug-in Features:

Multitimbral; 12-note polyphonic

Redesigned preset browser

Resizeable user interface for HD displays

Two oscillators, each with:

Triangle, sawtooth, and variable-width pulse wave with PWM

Oscillator 1 may be frequency modulated

Oscillator 2 equipped with white noise generator

Single 15-mode filter with:

Four Lowpass, three Highpass, and two Bandpass modes

Notch and Phase Shift modes

Four additional Combo filter modes

Powerful modulation matrix with 27 sources and 47 destinations

Mod sources include:

Five Envelopes and five LFOs

Four Ramp and three Track generators

Velocity, Pressure, and Keyboard Follow

Two insert effect slots with six studio-grade effects to choose from

Arturia’s amazing-sounding True Analog Emulation technology (TAE)

2 notes

·

View notes

Text

Meaning of Bare Metal Server?

To understand the meaning of a bare metal server let’s understand the meaning of a web server, A web server can be said to be software or hardware that stores all the website’s files responds to client requests, and delivers the required files accordingly via the internet. The Meaning of Bare Metal server in simplest words can be said as a server that is created for a single person only with the most premium technology that can be availed in a physical server only i.e. it cannot be available virtually.

Meaning of Bare Metal Server

A bare metal server is a physical server, it is a kind of server that is dedicated to a single tenant, In a virtualized server the hardware resources such as CPU, RAM, Storage etc. are shared while here all of the resources are used by a single person only and are chosen as per our choice, as there is no co-dependency in this kind of server it not only facilitates the increased performance of the server but also reduces hustle as it removes additional layers of software that are put into making server services available virtually.

Here there’s also an additional benefit of making the server as customized as possible, As there is only a single user and the server is available physically, It can be created to please and cater to your needs. let’s understand how it can be customised to an extent:

Personalized selection of hardware components such as CPU, type of RAM, and Storage.

There can be an option to choose any kind of Operating System that is compatible with your website

In a bare metal server, you can have firewall rules to suit your application’s requirements which include defining IP addresses, setting up virtual LANs (VLANs), managing network security policies, etc.

In a bare metal Server, there is access to the server’s BIOS (Basic Input/Output System), which allows for low-level hardware configurations, such as hardware virtualization settings, and power management options.

Understanding the Difference between a Dedicated Server and a Bare Metal Server

As the working of bare metal server and dedicated server is quite similar, they both have resemblance such as they both are dedicated to a single tenant but they can’t be said as the same, The root difference doesn’t lie in the product but the working of the server the concept of bare metal servers arrived after some drawbacks of a dedicated server.

While a dedicated server provides multiple benefits it has some inevitable drawbacks such as dated hardware and long provisioning times. However, bare metal servers typically come with the most advanced hardware and software. They are a hosting provider’s prized asset or flagship because bare metal servers are specifically made to automate the provisioning process, they may be put up more quickly.

The hardware provided by bare metal servers is considerably more similar to a cloud service framework, with installation durations measured in minutes or hours and hardware ranging from low-cost to Top-of-the-line components, including graphics processing units (GPU). When it comes to hardware, bare-metal servers have an advantage thanks to their use of the most recent Intel Xeon processors, DDR4 RAM with Error Correcting Code (ECC), and NVMe solid-state drives (SSDs) rather than SATA SSDs and hard drives. Because of the combination of these components, In conclusion, bare-metal servers stand out as a high-performance hosting solution.

2 notes

·

View notes

Text

THE ULTIMATE GUIDE TO PRESSES, SHEARS, LASER CUTTERS AND PUNCHES

In the world of metal fabrication, several key machines play a vital role in shaping and cutting metal with precision and efficiency. This ultimate guide provides comprehensive knowledge and insights into the essential products of the industry: Press Brake, Press Brake Tools, Shearing Machine, Laser Cutting Machine, and Power Press. Whether you are a beginner or an experienced professional, this guide will equip you with the necessary information to understand, select, and optimize the use of these machines for your metalworking needs.

Press Brake:

1.What is a Press Brake?

A press brake is a key equipment used in the field of metal fabrication for bending and folding metal sheets. It utilizes pressure to bend the metal sheet into the desired shape. It is commonly used to create bent parts, enclosures, tubing, and other metal components.

A press brake consists of an upper die and a lower die, with the upper die fixed to the frame and the lower die movable through a hydraulic system or mechanical drive system. The metal sheet is placed between the two dies and then bent into the desired angle and shape by applying pressure.

Press brakes typically have the following features and capabilities:

(1)Bending capacity: Press brakes can achieve bends at different angles and radii to meet various workpiece requirements.

(2)Precision: High precision bending results can be achieved by adjusting the position of the upper and lower dies.

(3)Automation: Some modern press brakes are equipped with CNC systems, allowing for automated operation and programming.

(4)Versatility: Press brakes can be used for various bending tasks and different types of metal materials by changing different tools and dies.

(5)Safety: Press brakes are typically equipped with safety devices such as light curtains, protective covers, and emergency stop buttons to ensure operator safety.

Press brakes are widely used in industries such as automotive manufacturing, aerospace, construction, electronics, and more. They are essential equipment for achieving precise and efficient metal fabrication.

2.Types of Press Brakes

There are several types of press brakes commonly used in metal fabrication:

Mechanical Press Brake: Uses a mechanical flywheel and clutch system for bending.

Hydraulic Press Brake: Utilizes hydraulic cylinders for precise bending control.

Servo-Electric Press Brake: Uses electric servo motors for high precision bending.

Pneumatic Press Brake: Relies on compressed air for lighter applications.

CNC Press Brake: Equipped with computerized controls for automated and precise bending operations.

The choice of press brake depends on factors such as material type, thickness, bending requirements, and production volume.

3.Components and Working Principles

A press brake consists of several key components that work together to perform the bending operation. Here are the main components and their functions:

Frame: The frame provides structural support and stability to the press brake.

Bed: The bed is a flat surface where the material to be bent is placed.

Ram: The ram is the moving part of the press brake that applies force to the material for bending.

Die: The die is a tool that shapes the material by providing a specific bending angle.

Punch: The punch is another tool that presses against the material, working in conjunction with the die to bend it.

Backgauge : The backgauge is an adjustable device that positions the material accurately for consistent bending.

4.Key Features and Benefits

Material Placement: The operator places the metal sheet or plate on the bed of the press brake.

Tool Setup: The appropriate die and punch are selected and installed on the press brake.

Backgauge Adjustment: The backgauge is adjusted to position the material correctly for the desired bend.

Bending Process: The ram moves downward, applying force to the material, which is sandwiched between the punch and the die. This bending action creates the desired angle in the material.

Material Removal: Once the bending is complete, the operator removes the bent material from the press brake.

5.Applications and Industries

Press brakes are widely used in various industries for different applications, including:

Metal Fabrication: Press brakes are commonly used in metal fabrication shops to bend and shape metal sheets and plates for various products such as enclosures, brackets, frames, and panels.

Automotive Industry: Press brakes are used in the automotive industry for manufacturing components like chassis, brackets, and body panels.

Aerospace Industry: Press brakes are utilized in the aerospace industry for bending and forming metal parts used in aircraft structures and components.

Construction and Architecture: Press brakes are used in the construction and architectural sectors for bending metal components used in building structures, facades, and decorative elements.

Electronics and Appliances: Press brakes are employed in the manufacturing of electronic enclosures, appliance components, and consumer products.

Press Brake Tools:

1.Importance of Press Brake Tools

Press brake tools play a crucial role in the performance and efficiency of press brake machines. Here are some key points highlighting the importance of press brake tools:

(1) Precision Bending: Press brake tools are designed to provide precise and accurate bending angles. They ensure consistent results and help meet the required specifications for the final product. The quality and precision of the tools directly impact the overall quality of the bent parts.

(2) Versatility: Press brake tools come in various shapes, sizes, and configurations to accommodate different bending requirements. They can be customized or interchanged to achieve different bending angles, radii, or complex shapes. This versatility allows manufacturers to produce a wide range of products using the same machine.

(3) Durability and Longevity: Press brake tools are made from high-quality materials such as hardened steel or special alloys, which make them highly durable and resistant to wear and tear. Proper maintenance and regular tool inspections ensure their longevity, reducing the need for frequent replacements.

(4) Efficiency and Productivity: Well-designed press brake tools optimize the bending process, reducing setup time, and increasing productivity. They enable faster bending cycles, allowing manufacturers to produce more parts in less time. Efficient tooling also minimizes material waste and improves overall production efficiency.

(5) Cost Savings: Using the right press brake tools can lead to cost savings in multiple ways. Accurate bending reduces material waste, saving on raw material costs. Efficient tooling reduces setup time and increases machine productivity, maximizing the output per hour. Additionally, durable tools have a longer lifespan, reducing the frequency of replacements and maintenance costs.

(6) Safety: Press brake tools are designed with safety features in mind. They provide proper clamping and holding mechanisms to secure the material during bending, minimizing the risk of accidents. Additionally, using high-quality tools reduces the chances of tool failure or breakage, ensuring operator safety.

(7) In summary, press brake tools are vital for achieving precise and accurate bending results, improving productivity, reducing costs, and ensuring operator safety. Selecting the right tools and maintaining them properly is essential for the efficient operation of press brake machines.

2.Types of Press Brake Tools (including ARC Press Brake Tools)

There are several types of press brake tools available, each designed for specific bending applications. Here are some common types of press brake tools:

V-Die: V-dies are the most commonly used press brake tools. They consist of a bottom die with a V-shaped groove and a punch with a matching V-shaped tip. V-dies are versatile and can be used for a wide range of bending angles and materials.

(1) Bottoming Die: Bottoming dies, also known as flat dies, have a flat surface instead of a V-shaped groove. They are used for achieving sharp bends or bending thicker materials where a tighter radius is required.

(2) Gooseneck Punch: Gooseneck punches have a curved shape that allows for deep and offset bends. They are commonly used for bending channels, boxes, and other complex shapes.

(3) Hemming Tool: Hemming tools are used for creating hems or flanges on the edge of a sheet metal part. They consist of a punch and die set that folds the material over itself to create a secure edge.

(4) Radius Tool: Radius tools, also known as radius punches or radius dies, are used for creating curved bends with a specific radius. They are available in various sizes to accommodate different bending requirements.

(5) Multi-V Die: Multi-V dies have multiple V-shaped grooves of different sizes on a single die. They allow for quick and easy tool changes without the need for separate dies for different bending angles.

(6) ARC Press Brake Tools: ARC press brake tools are specialized tools used for bending sheet metal into arc shapes. They are designed to create precise and consistent curved bends, commonly used in applications such as cylindrical parts, tubes, or curved profiles.

ARC press brake tools typically consist of a bottom die with a curved groove and a punch with a matching curved tip. They enable the accurate and repeatable bending of sheet metal into various arc shapes.

3.Material Selection and Coatings

When it comes to press brake tools, material selection and coatings play an important role in their performance and longevity. Here's a brief overview of material selection and coatings for press brake tools:

Material Selection:

(1) Tool Steel: Tool steel, such as D2 or A2, is commonly used for press brake tools due to its high hardness, wear resistance, and toughness.

(2) Carbide: Carbide inserts or tips are used for heavy-duty applications or when bending abrasive materials. Carbide provides excellent wear resistance but is more brittle than tool steel.

(3) High-Speed Steel (HSS): HSS is another option for press brake tools. It offers good toughness and wear resistance, but not as high as tool steel.

Coatings:

(4) Nitride Coating: Nitride coatings, such as TiN (Titanium Nitride) or TiCN (Titanium Carbonitride), improve the surface hardness and wear resistance of the tool. They are suitable for general-purpose bending applications.

(5) DLC Coating: DLC (Diamond-Like Carbon) coatings provide excellent hardness, low friction, and high wear resistance. They are ideal for bending stainless steel and other difficult-to-form materials.

(6) PVD Coating: Physical Vapor Deposition (PVD) coatings, like TiAlN (Titanium Aluminum Nitride), enhance the tool's performance by reducing friction and increasing wear resistance.

(7) Chrome Plating: Chrome plating is a common coating for press brake tools. It provides good corrosion resistance and reduces friction during bending operations.

The selection of material and coating depends on factors such as the type of material being bent, the bending application, and the desired tool life. It's important to choose the right combination of material and coating to ensure optimal performance and durability of the press brake tools.

4.Tooling Configurations and Considerations

When it comes to press brake tools, the tooling configurations and considerations are crucial for achieving accurate and efficient bending operations. Here are some important aspects to consider:

Tooling Configurations:

(1) V-Die: The V-die is the female tool that provides the desired bend shape. It comes in various widths and angles to accommodate different material thicknesses and bending requirements.

(2) Punch: The punch is the male tool that contacts the material and applies force to create the bend. It also comes in different shapes and sizes to achieve specific bend angles and radii.

(3) Multi-V Die: Multi-V dies have multiple V-shaped grooves of different widths and angles. They allow for bending different material thicknesses and angles without changing the die.

(4) Gooseneck Punch: Gooseneck punches have a curved shape that allows for deep or offset bends where space is limited.

(5) Hemming Tools: Hemming tools are used for creating hemmed edges or flanges on sheet metal.

Considerations:

(1) Material Thickness: The tooling configuration should be selected based on the material thickness being bent. Thicker materials may require larger tooling to accommodate the increased force and prevent tool damage.

(2) Material Type: Different materials have varying properties, such as hardness and ductility, which can affect the tooling selection. Harder materials may require tougher tooling materials or coatings.

(3) Bend Angle and Radius: The desired bend angle and radius dictate the selection of punch and die configurations. Sharp bends require smaller punch radii, while larger radii are needed for gentler bends.

(4) Tooling Alignment: Proper alignment between the punch and die is essential for achieving accurate and consistent bends. Misalignment can result in uneven bends or tool damage.

(5) Tooling Maintenance: Regular inspection and maintenance of the tooling are necessary to ensure optimal performance and longevity. This includes cleaning, lubrication, and replacement of worn-out components.

By considering the tooling configurations and these important factors, you can select the appropriate press brake tools for your specific bending requirements. This will help you achieve precise and efficient bending operations while prolonging the tooling life.

5.Tool Maintenance and Longevity

(1) Regular cleaning: Clean the press brake tools regularly to remove debris, dirt, and metal shavings. Use appropriate cleaning agents and tools to avoid damaging the tool surfaces. Ensure that the tools are completely dry before storing them.

(2) Lubrication: Apply lubrication to the press brake tools as recommended by the manufacturer. Lubrication helps reduce friction and wear, improving the tool's lifespan. Follow the manufacturer's guidelines for the type and frequency of lubrication.

(3) Inspection and repair: Regularly inspect the press brake tools for signs of wear, damage, or deformation. Check for any cracks, chips, or excessive wear on the cutting edges. If any issues are detected, promptly repair or replace the damaged parts to prevent further damage and ensure accurate bending results.

(4) Proper storage: Store the press brake tools in a clean and dry environment to prevent corrosion and damage. Use dedicated tool racks or boxes to keep the tools organized and protected. Avoid placing heavy objects on top of the tools to prevent deformation.

(5) Operator training: Proper training of operators is essential for tool maintenance and longevity. Educate operators on the correct usage techniques, operating limits, and safety precautions. Encourage operators to report any issues or abnormalities with the tools promptly.

By following these maintenance tips, you can extend the lifespan of your press brake tools and ensure consistent and accurate bending operations. Regular maintenance not only improves tool performance but also contributes to the overall safety and efficiency of the bending process.

6.Advanced Tooling Technologies and Innovations

Advanced tooling technologies and innovations have significantly improved the performance and capabilities of press brake tools. Here are some key advancements in press brake tooling:

(1) High-strength materials: Press brake tooling is now made from high-strength materials such as hardened steel alloys or carbide. These materials offer superior durability, wear resistance, and longer tool life compared to traditional tooling materials.

(2) Coatings and surface treatments: Advanced coatings and surface treatments, such as TiN (Titanium Nitride) or DLC (Diamond-Like Carbon), are applied to press brake tools to enhance their performance. These coatings reduce friction, improve wear resistance, and prevent material adhesion, resulting in improved bending quality and longer tool life.

(3) Precision tooling systems: Modern press brake tooling systems feature precision-ground tooling with tight tolerances. These systems ensure accurate and repeatable bending results, reducing setup times and increasing productivity.

(4) Quick-change tooling systems: Quick-change tooling systems allow for rapid tooling setup and changeovers. These systems utilize standardized tooling holders and clamping mechanisms, enabling operators to switch between different tooling setups quickly and efficiently.

(5) 3D modeling and simulation: Advanced software tools enable 3D modeling and simulation of bending processes. These tools help optimize tooling designs, simulate bending sequences, and detect potential collision or interference issues before actual production. This reduces setup time, minimizes errors, and improves overall efficiency.

(6) Custom tooling solutions: Tooling manufacturers now offer custom tooling solutions tailored to specific bending applications. These solutions include specialized tool profiles, custom tool coatings, and even tooling with integrated sensors for process monitoring and control.

These advancements in press brake tooling technologies have significantly improved productivity, accuracy, and tool life. By adopting these innovations, manufacturers can achieve higher efficiency, reduce downtime, and produce high-quality bent parts consistently.

Shearing Machine:

1.Understanding Shearing Machines

Shearing machines are industrial mechanical devices used for cutting metal sheets and other materials. They apply shearing force to cut the materials into desired shapes and sizes. Shearing machines are widely used in manufacturing and metalworking industries to produce various products and components.

The working principle of shearing machines involves placing the material on a shear table and applying force through cutting blades to cause the material to fracture. Shearing machines can perform operations such as straight cutting, curved cutting, and angle cutting. Depending on the specific requirements, shearing machines can have different cutting capacities and precision.

There are various types of shearing machines, including hydraulic shearing machines, mechanical shearing machines, and manual shearing machines. Hydraulic shearing machines use hydraulic systems to provide cutting force and offer high power and precision, making them suitable for large-scale and heavy-duty cutting tasks. Mechanical shearing machines use mechanical mechanisms to provide cutting force and are typically more compact and cost-effective, suitable for medium-sized cutting tasks. Manual shearing machines require manual operation and are suitable for small-scale and simple cutting work.

The cutting capacity of shearing machines depends on their maximum cutting thickness and cutting width. Larger shearing machines generally have higher cutting capacity and can handle thicker and wider materials. The cutting precision of shearing machines is influenced by factors such as blade sharpness, adjustment of blade clearance, rigidity of the frame, and material characteristics.

Safety considerations are important when operating shearing machines. Operators should receive proper training on the operation procedures and safety precautions of shearing machines. Additionally, appropriate personal protective equipment, such as safety goggles and gloves, should be worn. Regular inspection and maintenance of shearing machines are necessary to ensure their proper functioning and safe operation. Following the operation manual and manufacturer's recommendations is crucial to ensure the safety and effectiveness of operating shearing machines.

2.Hydraulic vs. Mechanical Shearing Machines

Hydraulic and mechanical shearing machines are two common types of shearing machines used in industrial applications. Here's a comparison between the two:

Power Source:

(1) Hydraulic Shearing Machines: These machines use a hydraulic system to generate the cutting force. The force is applied through hydraulic cylinders powered by a hydraulic pump. Hydraulic shearing machines offer high power and can handle heavy-duty cutting operations.

(2) Mechanical Shearing Machines: These machines use mechanical mechanisms, such as gears, levers, and flywheels, to generate the cutting force. The force is applied directly through the mechanical components. Mechanical shearing machines are generally more compact and cost-effective.

Power and Precision:

(1) Hydraulic Shearing Machines: Due to the hydraulic system, hydraulic shearing machines can provide high cutting power. They are capable of cutting thick and hard materials with precision. The hydraulic system allows for better control and adjustment of the cutting force, resulting in accurate and consistent cuts.

(2) Mechanical Shearing Machines: Mechanical shearing machines provide a lower cutting power compared to hydraulic ones. They are suitable for medium-duty cutting tasks. However, the cutting precision of mechanical shearing machines can be affected by factors such as mechanical wear and tear, which may require more frequent adjustments and maintenance.

Size and Space:

(3) Hydraulic Shearing Machines: Hydraulic shearing machines are generally larger and require more space due to the hydraulic system components, such as the hydraulic pump, cylinders, and hoses.

(4) Mechanical Shearing Machines: Mechanical shearing machines are more compact and take up less space. They are often preferred in smaller workshops or where space is limited.

Cost:

(1) Hydraulic Shearing Machines: Hydraulic shearing machines are typically more expensive due to the complexity and cost of the hydraulic system components.

(2) Mechanical Shearing Machines: Mechanical shearing machines are generally more affordable and cost-effective.

In summary, hydraulic shearing machines provide high power and precision, making them suitable for heavy-duty cutting operations. They are larger and more expensive. On the other hand, mechanical shearing machines are more compact, cost-effective, and suitable for medium-duty cutting tasks. The choice between hydraulic and mechanical shearing machines depends on the specific cutting requirements, available space, and budget considerations.

3.Components and Operation

Components of a Shearing Machine:

(1) Shear Table: This is the flat surface or bed on which the material to be cut is placed. It provides support and stability during the cutting process.

(2) Cutting Blades: These are the sharp blades that perform the actual cutting of the material. They are typically made of high-quality tool steel and are securely mounted on the machine. The blades can be straight, curved, or angled, depending on the desired cutting operation.

(3) Blade Clearance Adjustment: Shearing machines often have a mechanism for adjusting the clearance between the upper and lower blades. This adjustment allows for precise control of the cutting gap, ensuring clean and accurate cuts.

(4) Back Gauge: The back gauge is a movable stop or fence located behind the shear table. It helps in positioning the material accurately for repetitive cutting operations. The back gauge can be manually adjusted or controlled by a motorized system.

(5) Drive System: The drive system provides the power to move the cutting blades. In hydraulic shearing machines, the drive system consists of a hydraulic pump, cylinders, and valves. In mechanical shearing machines, it typically involves mechanical components such as gears, levers, and flywheels.

(6) Control Panel: The control panel houses the controls and switches for operating the shearing machine. It allows the operator to start and stop the machine, adjust settings, and monitor the cutting process.

Operation of a Shearing Machine:

(1) Material Preparation: The material to be cut is prepared by ensuring it is clean, straight, and properly aligned with the shear table. Any protective coatings or films on the material should be removed.

(2) Material Placement: The material is placed on the shear table, ensuring it is aligned with the back gauge if applicable. The operator should take care to position the material securely and avoid any obstructions that could interfere with the cutting process.

(3) Blade Clearance Adjustment: The blade clearance is set according to the thickness and type of material being cut. This adjustment ensures proper shearing without damaging the material or the blades. The manufacturer's guidelines or machine manual should be followed for the correct blade clearance settings.

(4) Cutting Operation: Once the material is properly positioned and the blade clearance is set, the operator initiates the cutting operation. In hydraulic shearing machines, the hydraulic pump is activated to provide the necessary cutting force. In mechanical shearing machines, the operator engages the drive system, which transfers power to the cutting blades.

(5) Monitoring and Control: During the cutting process, the operator monitors the operation to ensure smooth and accurate cutting. The control panel may provide indicators or displays for monitoring the cutting speed, blade position, and other parameters. Any abnormalities or issues should be addressed promptly.

(6) Material Removal and Repeat: After the cutting operation is complete, the cut pieces are removed from the shear table. The process can be repeated for subsequent cuts, adjusting the back gauge if necessary.

It's important to note that the specific operation of a shearing machine may vary depending on the machine model and manufacturer. Operators should always refer to the machine's manual and receive proper training before operating the shearing machine.

4.Cutting Capacity and Accuracy

Cutting Capacity and Accuracy are important considerations when using a shearing machine. Let's discuss each of them:

Cutting Capacity:

(1) Shearing machines have a specified cutting capacity, which refers to the maximum thickness and width of the material that can be effectively cut. The cutting capacity is determined by factors such as the power of the machine, the strength of the blades, and the rigidity of the shear table.

(2) It is crucial to choose a shearing machine with a cutting capacity that matches the requirements of the materials you will be working with. Attempting to cut materials beyond the machine's capacity can result in poor cutting quality, blade damage, or even machine malfunction.

Cutting Accuracy:

(1) Cutting accuracy refers to the ability of the shearing machine to make precise and consistent cuts. It is influenced by several factors, including the design and condition of the machine, the sharpness and alignment of the blades, and the control and monitoring systems.

(2) To achieve high cutting accuracy, it is important to maintain the shearing machine properly. Regular blade sharpening and replacement, as well as routine maintenance and calibration, can help ensure accurate cuts.

(3) The operator's skill and experience also play a significant role in achieving cutting accuracy. Proper material positioning, adjustment of blade clearance, and careful monitoring of the cutting process are essential for obtaining precise and clean cuts.

Factors Affecting Accuracy:

(1) Blade Condition: Dull or damaged blades can lead to uneven cuts and reduced accuracy. Regular inspection and maintenance of the blades are necessary to maintain cutting precision.

(2) Blade Clearance: Incorrect blade clearance can result in distorted or incomplete cuts. It is important to set the appropriate blade clearance for the material being cut.

(3) Material Alignment: Proper alignment of the material with the shear table and back gauge is crucial for accurate cuts. Misalignment can cause crooked or uneven cuts.

(4) Machine Rigidity: The rigidity of the shearing machine, including the shear table and frame, affects cutting accuracy. A sturdy and well-maintained machine provides better stability and reduces the chances of deflection during the cutting process.

It is recommended to follow the manufacturer's guidelines and recommendations for the specific shearing machine being used. Regular maintenance, blade inspection, and operator training are essential to ensure optimal cutting capacity and accuracy.

5.Safety Considerations

Safety considerations are of utmost importance when operating a shearing machine. Here are some key safety measures to keep in mind:

(1) Read and Follow the Manual: Familiarize yourself with the manufacturer's instructions and safety guidelines provided in the machine's manual. Understand the machine's features, controls, and potential hazards before operating it.

(2) Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses or goggles, gloves, and ear protection. Depending on the specific machine and the materials being cut, additional protective gear such as a face shield or apron may be required.

(3) Machine Inspection: Before starting the machine, inspect it for any signs of damage, loose parts, or malfunctioning components. Ensure that all safety guards and devices are in place and functioning correctly.

(4) Training and Competence: Only trained and authorized personnel should operate a shearing machine. Proper training should cover machine operation, safety procedures, emergency shutdown, and handling of materials.

(5) Material Handling: Use caution when handling materials, especially large or heavy ones. Use lifting equipment or assistance when necessary to avoid strain or injuries.

(6) Emergency Stop: Familiarize yourself with the location and operation of the emergency stop button or switch. Be prepared to use it in case of any emergency or unsafe situation.

(7) Blade Safety: Never reach into the cutting area while the machine is in operation or attempt to adjust the blades without proper training. Always wait for the machine to come to a complete stop before making any adjustments or maintenance.

(8) Housekeeping: Maintain a clean and organized work area. Remove any debris, scraps, or obstructions that may interfere with the machine's operation or cause accidents.

(9) Lockout/Tagout: Follow proper lockout/tagout procedures when performing maintenance or repairs on the machine. This involves disconnecting the power source and ensuring that it cannot be re-energized accidentally.

(10) Regular Maintenance: Adhere to the recommended maintenance schedule for the shearing machine. This includes blade sharpening, lubrication, and inspection of mechanical and electrical components.

Remember, safety should always be the top priority when operating any machinery. If you have any concerns or encounter any issues with the shearing machine, stop the operation immediately and seek assistance from a qualified technician or supervisor.

Laser Cutting Machine:

1.Introduction to Laser Cutting:

Laser cutting is a highly precise and versatile method of cutting various materials using a high-powered laser beam. It has revolutionized the manufacturing industry by providing a faster, more accurate, and more efficient alternative to traditional cutting methods. Laser cutting machines are used in a wide range of industries, including automotive, aerospace, electronics, signage, and jewelry making.

2.Types of Laser Cutting Machines:

There are different types of laser cutting machines available, each with its own advantages and suitable applications. The most common types include CO2 lasers, fiber lasers, and neodymium lasers.

CO2 lasers are the most widely used type of laser cutting machine. They use a mixture of carbon dioxide, nitrogen, and helium as the laser medium. CO2 lasers are versatile and can cut a wide range of materials, including non-metallic materials such as plastics, wood, and fabrics, as well as metals.

Fiber lasers use optical fibers as the laser medium. They are highly efficient and are primarily used for cutting metals, including stainless steel, aluminum, and copper. Fiber lasers offer high beam quality, which results in faster cutting speeds and improved precision.

Neodymium lasers use neodymium-doped crystals (such as neodymium-doped yttrium aluminum garnet or Nd: YAG) as the laser medium. They are known for their high energy and are used for precision cutting and engraving. Neodymium lasers are commonly used in applications that require high power and fine detail, such as jewelry making and micro-machining.

3.Advantages and Limitations:

Laser cutting offers several advantages over traditional cutting methods. One of the key advantages is its high precision and accuracy. Laser cutting machines can achieve intricate and complex cuts with minimal distortion. They also provide excellent edge quality, eliminating the need for additional finishing processes.

Another advantage is the speed and efficiency of laser cutting. Laser cutting machines can cut at high speeds, resulting in faster production times and increased productivity. They can also cut multiple parts simultaneously, further improving efficiency.

Laser cutting is a non-contact cutting method, which means there is no physical contact between the cutting tool and the material. This reduces the risk of damage to the material and allows for cutting delicate or fragile materials.

However, laser cutting does have some limitations. The thickness capacity of a laser cutting machine depends on the power of the laser and the type of material being cut. Thicker materials may require multiple passes or a more powerful laser to achieve a clean cut. Additionally, laser cutting machines can be expensive to purchase and maintain, making them more suitable for high-volume production environments.

4.Material Compatibility and Thickness:

Laser cutting machines can cut a wide range of materials, including metals, plastics, wood, textiles, and more. The compatibility of a material with laser cutting depends on its ability to absorb the laser energy. Materials that are highly reflective, such as copper or aluminum, may require higher laser power for cutting.

The thickness of the material that can be cut depends on the power of the laser and the type of material. Laser cutting machines can typically cut thin materials with high precision. For example, a CO2 laser cutting machine can cut up to 25mm thick steel, while a fiber laser cutting machine can cut up to 30mm thick steel. However, the maximum thickness capacity may vary depending on the specific machine and laser power.

It is important to consider the material compatibility and thickness capacity of a laser cutting machine before selecting the appropriate machine for a specific application. Consulting with a laser cutting machine supplier or manufacturer can help determine the best machine for a particular material and thickness requirement.

Power Press:

1.Exploring Power Press Machines:

Power press machines, also known as press machines or stamping presses, are versatile machines used in metalworking for various operations such as punching, bending, forming, and blanking. They are commonly used in industries such as automotive, manufacturing, construction, and appliance production. Power press machines come in different sizes and configurations to accommodate different applications and production requirements.

Power press machines are designed to apply force to a workpiece using mechanical or hydraulic systems. They are capable of exerting high pressure to shape, cut, or form metal sheets or other materials. Power press machines can be categorized into mechanical and hydraulic types based on their power source and operation.

2.Mechanical vs. Hydraulic Power Press:

Mechanical power presses use mechanical force, typically generated by a flywheel and a crankshaft, to perform operations. They are known for their high speed and productivity. Mechanical power press machines have a mechanical clutch or brake system that controls the stroke and stopping motion of the ram. They are suitable for high-volume production environments where speed and precision are important.

Hydraulic power presses, on the other hand, use hydraulic systems to generate force. They utilize hydraulic cylinders to apply pressure to the ram and perform operations. Hydraulic power press machines offer more control and flexibility in terms of force adjustment and speed modulation. They are often used for operations that require precise force control or for applications that involve deep drawing or forming of materials.

The choice between a mechanical or hydraulic power press depends on the specific requirements of the application. Factors such as the type of operation, material thickness, production volume, and precision requirements should be considered when selecting the appropriate power press machine.

3.Components and Operation:

Power press machines consist of several key components that work together to perform various operations. These components include the frame, slide or ram, bolster, die, clutch or brake system, and control system.

The frame provides the structure and support for the machine. It is usually made of cast iron or steel to withstand the forces exerted during operation. The slide, also known as the ram, moves up and down to apply force to the material. It is guided by the frame and can be driven by a crankshaft or hydraulic cylinders.

The bolster is a flat surface on which the material is placed. It provides support to the workpiece during the operation. The die is a specially shaped tool that performs the desired operation, such as punching a hole or bending a metal sheet. The die is mounted on the bolster or the ram, depending on the type of operation.

The clutch or brake system controls the stroke and stopping motion of the ram. In mechanical power press machines, a mechanical clutch or brake is used to engage or disengage the flywheel, controlling the motion of the ram. In hydraulic power press machines, the hydraulic system controls the movement of the ram.

The control system of a power press machine can vary depending on the specific machine and its features. It can range from simple manual controls to advanced computer numerical control (CNC) systems. CNC systems offer precise control over the machine's operation, allowing for programmable and repeatable processes.

4.Punching, Bending, and Forming Capabilities:

Power press machines are capable of performing various operations, depending on the tooling and dies used. Some common operations include punching, bending, forming, blanking, coining, embossing, and deep drawing.

Punching is a process of creating holes or shapes in a material using a punch and die set. Bending is the process of deforming a material to form angles or curves. Forming involves shaping a material to create three-dimensional objects or complex geometries. Blanking is the process of cutting out a flat shape from a larger piece of material. Coining is a process that involves compressing a material to create a precise shape or pattern. Embossing is the process of creating raised or depressed

Conclusion:By delving into the comprehensive knowledge provided in this ultimate guide, you have gained a solid understanding of Press Brake, Press Brake Tools, Shearing Machine, Laser Cutting Machine, and Power Press. Armed with this knowledge, you can confidently select, operate, and optimize these machines to achieve precise and efficient metal fabrication results. Remember to prioritize safety, regular maintenance, and stay updated with the latest advancements in the industry to stay ahead in the ever-evolving world of metalworking.

https://www.mihating.com/

3 notes

·

View notes

Text

9 Mobile App Testing Strategies for 2025

Pre-requisites: The Right Test Environment

Before initiating mobile app testing, setting up a robust test environment is crucial. This includes configuring device OS versions, screen sizes, RAM, battery levels, and user permission profiles. Real-world testing conditions ensure accurate bug identification and better user experience simulations. The right test environment eliminates inconsistent test results caused by mismatched configurations. QA teams should establish environments that reflect diverse user conditions to ensure coverage. With Genqe.ai, teams can simulate multiple device environments efficiently, creating scalable and reusable configurations that mirror real user conditions without the need to manage each environment manually.

Emulators and Simulators

Emulators and simulators are essential for the early stages of testing mobile apps. Emulators replicate Android environments, while simulators mimic iOS behavior, enabling cost-effective testing without real devices. These tools are ideal for UI verification, initial regression tests, and layout assessments. However, they fall short when testing hardware functions like GPS, camera, or sensors. Genqe.ai leverages emulator support with AI-driven visual validation to ensure layout integrity. While not a replacement for real devices, emulators and simulators, when paired with Genqe, offer rapid feedback loops for developers, accelerating development cycles with less hardware dependency.

Real Devices

Testing on real devices is critical for validating actual user experiences. Real devices help detect hardware-specific bugs, ensure accurate gesture recognition, and verify UI elements’ true behavior. These tests uncover issues that emulators can’t, such as screen flickering, battery drainage, and overheating. Real-world touch, swipe, camera, GPS, and network behaviors must be validated. Genqe.ai integrates real-device testing into its automation suite, enabling testers to run intelligent, self-healing scripts on multiple devices simultaneously. This ensures consistency, reliability, and in-depth coverage. Testing on a diverse set of physical devices guarantees your app performs seamlessly in real-life usage scenarios.

Device Clouds

Device clouds are virtual pools of real mobile devices accessible over the internet. These platforms offer scalable access to hundreds of devices with varied OS versions, screen resolutions, and manufacturers. Instead of investing in physical hardware, teams can leverage device clouds to test across a wide range of devices. Genqe.ai seamlessly integrates with major cloud testing providers, allowing for parallel execution of automated test cases across multiple devices. This improves test efficiency and helps identify device-specific bugs. Using device clouds also supports continuous integration pipelines, enabling end-to-end automated testing without physical setup or maintenance overhead.

Types of Applications

The testing strategy must align with the application type — native, web, or hybrid. Native apps are platform-specific and require deep testing into OS integrations. Web apps need browser compatibility testing, while hybrid apps combine native and web components, demanding a mixed approach. Each type comes with its own set of challenges and test scenarios. Genqe.ai supports intelligent automation for all three types, adapting test scripts based on the application architecture. This dynamic adjustment ensures effective coverage. Whether you’re testing complex native gestures or validating hybrid web views, Genqe’s AI ensures optimal test execution across all app types.

9 Highly Effective Mobile App Testing Strategies

1. Early QA Involvement

Integrating QA from the beginning of the software development life cycle saves time, reduces bugs, and improves product quality. Early QA enables better requirement analysis, risk identification, and test case design before development is complete. This shift-left approach minimizes cost by catching defects early. Genqe.ai empowers teams with collaborative tools that generate automated test scenarios during the design phase. Early test coverage through Genqe’s platform ensures thorough validation of user stories and prevents last-minute surprises. Involving QA early not only enhances product stability but also supports Agile and DevOps models with faster delivery and feedback loops.

2. Cross-Platform Testing

Cross-platform testing ensures the app performs consistently on Android, iOS, and various device models. With users distributed across platforms, maintaining feature parity and visual consistency is essential. Each platform has different behaviors, gestures, and UI constraints. Genqe.ai uses intelligent test mapping to run a single set of automated tests across platforms, reducing duplication of effort. It validates layout changes, OS-specific functionality, and device behavior under one intelligent test layer. This enables faster releases with high-quality assurance. Whether you build native or hybrid apps, Genqe ensures that your app performs smoothly across all target platforms.

3. Feature Functionality

Testing core functionality verifies that features perform as intended under different conditions. This includes buttons, login forms, push notifications, API responses, and third-party service integrations. Bugs in these areas directly impact user satisfaction and app ratings. Genqe.ai creates smart test scenarios for business-critical features, focusing on areas with the highest user impact. It prioritizes features based on usage patterns and detects regression risks with each release. Feature testing with Genqe includes automated UI interaction and real-time backend validation, ensuring robust performance and faster detection of logical errors before the app reaches end users.

4. Front-End Testing

Front-end testing involves validating UI/UX components, animations, gestures, fonts, and layout consistency. It ensures that the app is visually appealing and responsive across various screen sizes. UI glitches can lead to poor usability and app abandonment. Genqe.ai uses AI-powered visual testing to detect changes in layout, broken elements, and rendering issues that are often missed in manual checks. Its visual regression engine compares snapshots across devices, ensuring pixel-perfect quality. Front-end testing is vital for retaining users, and Genqe ensures your app looks and behaves as designed, whether it’s running on a tablet, phone, or foldable device.

Back-End Testing

Behind every seamless mobile experience is a robust backend. Testing the backend involves verifying APIs, server logic, data storage, response time, and integration with cloud services. It ensures that the data received by the app is accurate, timely, and secure. Genqe.ai integrates backend testing with automated API validations, simulating real user interactions and validating data flows. It checks for broken endpoints, slow responses, and failed connections. With Genqe, back-end issues are flagged early, and test results are logged for actionable insights. Reliable backend testing ensures your app works flawlessly — even under high load and multiple concurrent users.

5. Security Testing

Security testing safeguards user data, prevents unauthorized access, and ensures compliance with privacy regulations like GDPR. It involves testing for encryption, secure login, session management, and data leaks. Mobile apps are frequent targets for hackers due to sensitive user data. Genqe.ai incorporates automated security scanning into test pipelines, identifying vulnerabilities like SQL injections, insecure APIs, and permission misconfigurations. Genqe ensures security by generating compliance-aware test cases that validate data encryption and secure communications. Building trust with users begins with secure apps, and Genqe makes security testing a proactive and automated process integrated into every release cycle.

6. Multiple Network Compatibility

Users access apps on various networks — Wi-Fi, 3G, 4G, 5G — and your app must handle each seamlessly. Network compatibility testing ensures the app remains stable during fluctuations, interruptions, and transitions between networks. It also includes testing offline features and sync behavior. Genqe.ai simulates real-world network conditions, allowing testers to automate scenarios like poor signal strength, switching between networks, or temporary disconnection. This enables better performance optimization and error recovery. Ensuring your app handles all network conditions gracefully is crucial for global user adoption, and Genqe delivers automated tools to validate this across multiple network layers.

7. Storage Management

Storage testing evaluates how an app handles local data and reacts to low-memory conditions. Issues like cache overload, improper memory cleanup, or large downloads can crash apps or slow them down. Testing should ensure that the app minimizes storage use and handles full-device storage gracefully. Genqe.ai creates scenarios where the device’s available space is restricted, validating app stability under low-memory conditions. It also checks file deletion, data retention, and sync integrity. Proper storage handling improves performance, battery life, and user satisfaction. Genqe automates this process, helping teams identify and fix issues that affect app longevity.

8. Data To and From the App

This strategy ensures the integrity, security, and accuracy of data flow between the app and backend systems. Testing includes input validation, data sync, offline storage, and multi-device consistency. Any errors in data processing can affect the user experience and cause major trust issues. Genqe.ai tests all input/output paths using intelligent data generators, negative testing, and validation logic. It simulates edge cases to ensure data is not lost during interruptions, errors, or network failures. Whether sending a form or syncing cloud files, Genqe ensures that every data transaction is tested, safe, and stable.

9. Application Flow

Application flow testing assesses the user’s journey through the app, from login to exit. It ensures seamless navigation, correct screen transitions, error handling, and consistent state retention. Poor application flow leads to confusion, frustration, and increased bounce rates. Genqe.ai analyzes actual user paths and uses machine learning to prioritize high-traffic flows. It auto-generates test scenarios for real-world navigation sequences and validates edge-case transitions. By continuously monitoring app flow quality, Genqe enhances the overall UX. It ensures that users never encounter broken navigation, dead links, or confusing steps — ultimately boosting retention and engagement.

Conclusion

The landscape of mobile app testing in 2025 demands agility, precision, and smart automation. By implementing the above strategies — early QA involvement, cross-platform and network testing, security validation, and more — development teams can significantly boost the quality and reliability of their apps.

Genqe.ai emerges as a vital partner in this journey. With its advanced AI-powered automation, cross-platform compatibility, and smart test generation features, Genqe streamlines mobile app testing, reduces manual effort, and accelerates release cycles.

As mobile technologies evolve, staying ahead requires not just testing harder — but testing smarter. And Genqe.ai is the way forward.

0 notes

Text

Streamlining Business with Inventory CRM and Reliable Laptop Repair Services

In today’s fast-paced digital era, businesses heavily rely on two crucial components — efficient inventory management and seamless IT support. Whether you're running a small retail shop or a growing tech startup, integrating an inventory CRM system and having access to trustworthy laptop repair services can significantly boost your productivity and reduce costly downtimes.

Why Inventory CRM Matters

Inventory CRM (Customer Relationship Management) is no longer a luxury — it’s a necessity for modern businesses. It combines inventory tracking with customer management to give you a complete overview of your operations. Imagine being able to see product availability, customer purchase history, and stock alerts all in one dashboard. That’s what an inventory CRM offers.

The most common challenges faced by businesses include overstocking, understocking, and delayed deliveries. These issues directly impact customer satisfaction and revenue. With an inventory CRM, you can automate stock management, set reorder levels, and even predict future trends based on past data. This helps not only in managing your warehouse but also in planning your marketing and sales strategies more effectively.

For example, a mobile phone retailer can use inventory CRM to know which models are selling fast and which ones are collecting dust on the shelf. Based on that, they can launch promotional offers or restock popular items before they run out. It also allows your team to respond quickly to customer inquiries with accurate information, enhancing customer trust and loyalty.

The Importance of Laptop Repair Services

No matter how advanced your system is, you’re still dependent on hardware. Laptops are the backbone of business operations, especially in hybrid and remote work environments. When a laptop breaks down, it can cause major delays, especially if the person using it handles inventory, customer data, or online sales.

That’s where laptop repair services come in. Reliable repair services can save your business time and money. Instead of waiting days or weeks for a manufacturer’s response, local repair experts can diagnose and fix issues within hours. They also help with regular maintenance like cleaning, upgrading RAM, replacing SSDs, or installing security software to prevent data loss.

Many laptop repair providers also offer emergency services or business packages, where technicians visit your office and repair systems on-site. This is particularly useful for businesses that can’t afford long downtimes or data breaches.

Final Thoughts

The combination of an inventory CRM system and dependable laptop repair services is a game-changer for small and medium-sized businesses. While the CRM keeps your operations smooth and data-driven, prompt laptop repair ensures that nothing stalls your progress. Together, they help you run a smarter, faster, and more resilient business.

0 notes

Text

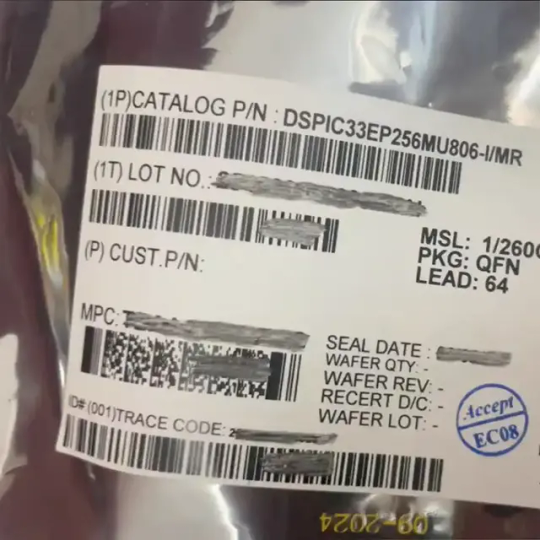

Introduction of DSPIC33EP256MU806-I/MR for Microchip MCU The DSPIC33EP256MU806 is a cutting-edge microcontroller designed for efficiency and performance, ideal for a wide variety of applications—from industrial automation to consumer electronics. With its powerful architecture, this device offers exceptional processing power to help you achieve your goals with precision and reliability. About MOQ of DSPIC33EP256MU806-I/MR Usually MOQ is 100 units as seen online.If you interested with much more quantity,welcome inquire us via whatsapp to talk details.More other electronic components stock,can be checked here. Note:They are not our all,much more inventory not able to post online one by one.If you have specified parts number,welcome inquire us to talk. Featuring a 16-bit architecture, the DSPIC33EP256MU806-I/MR boasts a 30 MIPS performance rate, which allows for complex calculations to be performed in real-time, significantly improving the functionality of your projects. Equipped with a 256 KB flash memory and 30 KB RAM, this microcontroller provides ample space to store your code while ensuring efficient data handling. Its integrated peripherals, including a 12-bit ADC, PWM outputs, and communication interfaces, enable seamless integration into your systems, guaranteeing that your applications run smoothly and reliably. Ideal Applications and Versatility The versatility of the DSPIC33EP256MU806-I/MR makes it suitable for various applications including motor control, digital signal processing, and data acquisition systems. Whether you are developing a sophisticated control system or a high-performance embedded device, this microcontroller supplies the tools and features needed to enhance both performance and usability. Plus, with its low power consumption, you can maintain efficiency without sacrificing performance, making it an ideal choice for battery-powered applications. Choose DSPIC33EP256MU806-I/MR for your next project and experience a level of performance and flexibility that transforms your ideas into reality. Ideal for both seasoned professionals and hobbyists alike, this microcontroller is your perfect partner in innovation. Know more information about our company business. Read the full article

0 notes

Text

Liebherr PCB Card 925086914 0002555 0601004 | High-Quality Control PCB Board | Ram Automations

Enhance your machinery’s performance with the Liebherr PCB Card 925086914 0002555 0601004, available now at Ram Automations. This high-quality Printed Circuit Board (PCB) offers exceptional reliability, precision engineering, and durability for a wide range of industrial and marine applications.

Designed for maximum performance and efficiency, this Liebherr PCB Card ensures seamless integration with complex control systems, making it ideal for critical automation environments and high-demand applications.

🛒 Buy Now from Ram Automations 👉 https://ramautomations.com/products/pcb-card-925086914-0002555-0601004-liebherr-new

🌐 Explore 1000+ Genuine Automation Components 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Liebherr • 🔹 Model: 925086914 / 0002555 / 0601004 • 🔹 Type: PCB Card • 🔹 Category: PCB Card / Industrial Electronics / Automation PCB • 🔹 Application: Industrial Automation, Marine Systems, Control Panels, Process Systems

✅ Key Features

✔️ Precision-engineered PCB for reliable performance ✔️ Seamless integration with industrial systems ✔️ High-quality materials and craftsmanship ✔️ Essential for complex machinery and automation units ✔️ Ideal for industrial, marine, and manufacturing environments

💡 Typical Applications

• Marine Electronic Control Systems • Industrial Automation Panels • SCADA and HMI System Boards • Heavy Equipment Automation • Process Automation Systems • Robotics Control Panels • Industrial Machinery Systems

🌟 Why Choose Ram Automations?

✅ 100% Genuine Products Only ✅ Best Prices with Worldwide Delivery ✅ Trusted Industrial Automation Supplier ✅ Large Inventory of Hard-to-Find Components

🛍️ Visit Us: https://ramautomations.com

In This Video You Will Discover:

🔎 Close-up View of Liebherr PCB Card 🔧 How It Integrates with Complex Systems 💡 Importance of High-Quality PCBs in Industrial Automation 🌐 Why Ram Automations is the Go-To Source for Industrial Parts

📣 Get Involved!

🔔 Subscribe for Automation & Electronics Updates 👍 Like to Show Support for Quality Electronics 💬 Comment Your Queries — We’re Happy to Help! 🛒 Visit our Online Store: https://ramautomations.com

#Liebherr PCB Card#PCB Card for Automation#Industrial PCB Card#Automation PCB Card#Marine Control PCB#Automation System Board#Ram Automations#Control Panel PCB Card#Process Control PCB#Marine Automation Electronics#Industrial Electronic PCB#Automation Equipment PCB Card#Marine Systems PCB Card#Factory Automation Parts#Robotics Control Panel Card#Data Transmission PCB Card#PLC Control PCB Card#High Quality PCB Card#SCADA System PCB Card#Electronic Connectivity PCB Board

1 note

·

View note

Text

10 Reasons Every Fabrication Shop Needs a Power Press – Featuring Mankoo Presses

In today’s competitive manufacturing environment, staying ahead means more than just working harder — it means working smarter. For fabrication shops aiming to scale production, enhance precision, and reduce waste, one machine has proven indispensable: the Power Press. And when it comes to reliable, high-performance presses in India and abroad, Mankoo Presses leads the way.

With over 60 years of manufacturing excellence, Mankoo Presses has become synonymous with rugged durability, cutting-edge technology, and consistent output. In this blog, we’ll explore 10 powerful reasons why every fabrication shop should have a power press — and why Mankoo should be your go-to brand.

1. Unmatched Efficiency and Speed

Power press machines are designed for high-speed, repetitive tasks — punching, shearing, bending, or forming metal sheets — with minimal downtime. Unlike manual or semi-automated processes, power presses can deliver thousands of strokes per hour with consistent force.

Mankoo Presses are engineered with heavy-duty components and smooth drive systems, enabling maximum productivity and cycle times that optimize throughput in any fabrication setting.

2. High Precision and Repeatability

Accuracy is everything in fabrication. Whether you’re making automotive parts or electrical enclosures, each component must match specifications down to the last millimeter.

Mankoo’s power presses are built with precisely machined dies, tight tolerances, and well-aligned rams to ensure perfect repeatability across large volumes. This ensures fewer rejections, less scrap, and better client satisfaction.

3. Versatile Metal Forming Capabilities

A power press isn’t just a one-trick machine. It can perform a wide range of operations including:

Blanking

Punching

Deep drawing

Coining

Bending and flanging

Mankoo offers C-type, H-type, and pneumatic clutch presses, making it easy to match the press type with your specific fabrication task. Whether you need light-duty precision work or heavy-duty bulk operations, Mankoo has the right press to fit your shop.

4. Durability That Lasts Decades

In fabrication, machine failure equals lost money. That’s why durability is non-negotiable.

Mankoo’s presses are built from high-tensile steel, cast iron frames, and heat-treated components to withstand continuous industrial use. With proper maintenance, Mankoo power presses can operate smoothly for decades, making them a long-term investment rather than a recurring expense.

5. Customizable to Shop Requirements

No two fabrication shops are alike. Some deal with intricate lightweight components, while others handle thick plates and structural metal.

Mankoo understands this and offers custom-built power presses tailored to your workload, material type, die design, and automation needs. Whether it’s stroke length, tonnage capacity, or ram size, you can get a machine that’s perfectly suited to your operations.

6. Advanced Safety Features

Safety in fabrication environments is crucial — especially when dealing with powerful, fast-moving equipment.

Mankoo Presses are equipped with:

Two-hand control systems

Emergency stop switches

Overload protection

Guarding and enclosure options

Interlock mechanisms

These features not only ensure operator safety but also help in maintaining compliance with international safety standards like ISO and CE.

7. Low Operational Cost

Though a power press involves an upfront investment, the operational costs are surprisingly low. Since Mankoo presses are designed for energy efficiency, low maintenance, and high productivity, the cost-per-piece produced becomes extremely economical over time.

Their robust build reduces breakdowns, while the wide availability of spares and technical support further brings down maintenance costs — making Mankoo presses a cost-effective choice for fabrication shops of all sizes.

8. Support for Automation and Integration

As the fabrication industry moves toward Industry 4.0, Mankoo is keeping pace. Their machines can be seamlessly integrated with:

Automatic feeders

PLC systems

Servo drives

Conveyor lines

Sensor-based safety systems

This helps in automating production lines, reducing manual handling, improving speed, and boosting quality — a critical advantage in high-volume or export-oriented units.

9. Trusted by Top Industries

Mankoo Presses are used by leading names in:

Automotive

Appliances

Aerospace

Electrical

Agriculture

Defense

The reason is simple — reliability and performance under pressure. Whether it’s manufacturing body panels for vehicles or deep-drawn enclosures for electrical systems, Mankoo’s presses deliver results that meet global standards.

By adding a Mankoo power press to your fabrication shop, you're joining a network of elite manufacturers who value excellence.

10. Excellent After-Sales Support

A great machine is only as good as the support that backs it. Mankoo provides:

On-site installation

Operator training

Preventive maintenance guidance

Quick delivery of spare parts

Responsive customer care

Their engineers and service technicians are well-trained to address any technical challenge, helping your shop maintain minimal downtime and maximum efficiency.

Conclusion: Power Up with Mankoo Presses

In the dynamic world of metal fabrication, where quality, speed, and cost efficiency matter more than ever, a power press machine is not a luxury — it’s a necessity. And when you invest in a Mankoo Power Press, you’re not just buying a machine — you’re gaining a strategic manufacturing advantage.

With their legacy of engineering excellence, customizable features, and customer-focused service, Mankoo is the ideal partner to take your fabrication shop to the next level.

Ready to transform your metal forming process? Explore the complete range of Mankoo Power Press Machines today and experience the power of precision, reliability, and unmatched performance.

0 notes

Text

Integrating RTOS in Firmware Development for IoT Devices

In the fast evolving world of connected technology, firmware development for IoT devices demands real-time performance, efficient task management, and robust system reliability. One of the most effective ways to meet these demands is through the integration of an RTOS (Real-Time Operating System). Using an RTOS in firmware development provides the necessary architecture to support multitasking, deterministic execution, and modular design all of which are essential in modern embedded systems.

Interested in building efficient, real-time firmware for your IoT device? A well architected RTOS implementation can significantly enhance the performance and reliability of your system.

Unlike traditional bare metal firmware where tasks are executed sequentially, RTOS-based firmware allows developers to divide functionality into prioritized threads or tasks. This is especially important in IoT applications, where the firmware must handle multiple simultaneous operations like sensor data collection, wireless communication, and actuator control. An RTOS ensures these tasks are executed on time and without interference, delivering the real-time performance required by smart devices and edge nodes.