#Rear Axle Setups

Explore tagged Tumblr posts

Text

Asphalt Modified Axle Setups – Built with Precision by Strange Oval

Strange Oval’s Asphalt Modified Axle Setups are crafted to deliver top-tier traction and control on paved oval tracks. Built to withstand aggressive cornering and high-speed demands, these axles provide reliable performance, lap after lap, helping you stay fast, consistent, and race-ready.

Product Key Features:

Optimized Track Control

High-Torque Handling

Precision Axle Engineering

Race-Proven Durability

Lightweight Performance Build

Consistent Corner Stability

Contact Information:

For more details or to request a sample, visit Asphalt Modified Axle Set-Ups or contact Strange Oval directly:

Phone: 800-653-1099

Visit: https://www.strangeoval.com/

Address: 8300 Austin Ave Morton Grove, IL 60053

Stay in touch with the latest product developments and company news:

Facebook: https://www.facebook.com/strangeoval/

YouTube:https://www.youtube.com/channel/UCheMfttsl3BZV1dyokhrpSA

X: https://x.com/strangeoval

#Asphalt Modified Axle Setups#Strange Oval Axles#Asphalt Race Car Axles#Modified Axle Solutions#Oval Track Axles#High Performance Axles#Lightweight Axles#Gun Drilled Axles#Racing Axle Setup#Asphalt Racing Parts#Modified Race Axles#Durable Racing Axles#Custom Axle Options#Rear Axle Setups#Strange Oval Modified Parts#Axles For Modifieds#Asphalt Track Performance#Precision Axle Tuning#Modified Chassis Axles#Strange Oval Racing Axles

1 note

·

View note

Text

Did you know ???

𝐁𝐚𝐜𝐤 𝐢𝐧 𝟏𝟗𝟔𝟗, 𝐅𝐨𝐫𝐝 𝐛𝐮𝐢𝐥𝐭 𝐚 𝐨𝐧𝐞-𝐨𝐟𝐟 𝐩𝐫𝐨𝐭𝐨𝐭𝐲𝐩𝐞 𝐭𝐡𝐚𝐭 𝐟𝐥𝐢𝐩𝐩𝐞𝐝 𝐭𝐡𝐞 𝐬𝐜𝐫𝐢𝐩𝐭 𝐨𝐧 𝐭𝐡𝐞 𝐜𝐥𝐚𝐬𝐬𝐢𝐜 𝐁𝐨𝐬𝐬 𝟒𝟐𝟗 𝐌𝐮𝐬𝐭𝐚𝐧𝐠.

Known internally as the LID Mustang—short for Low Investment Drivetrain—this project aimed to fix the production model’s notorious weight distribution problem.

Instead of packing the heavy Boss 429 V8 up front, Ford’s engineers reversed the engine and mounted it over the rear wheels.

A Clever, Cost-Effective Makeover

Working with their Special Vehicles unit and a local Detroit skunkworks group called Kar Kraft, Ford took a standard Boss 429 engine paired with a C6 automatic transmission and installed it in a custom, removable rear subframe. A specially built transfer case rotated the power 180 degrees, feeding a modified 9-inch rear axle. This clever setup shifted the weight balance from a 60/40 front-to-rear split to a more promising 40/60, reducing wheelspin and potentially improving handling.

An Experiment That Didn’t Take Off

Despite the improved weight distribution, the mid-engine layout didn’t deliver a significant performance boost. With little more than reduced wheelspin to show for it, Ford decided not to pursue the idea further. At one point, reports in Motor Trend suggested the lone prototype was headed for the crusher at a Detroit-area salvage yard.

A Mysterious Disappearance

Recent whispers from credible Ford insiders, however, have added a twist to the tale. After its test program, the LID Mustang was parked at the Dearborn Proving Grounds with other test mules. Rather than being scrapped, the car seemingly vanished—leading some to believe it might be hidden away in a private garage somewhere in Dearborn or Allen Park, waiting for its moment to reemerge.

This story of wild innovation remains one of Ford’s most intriguing “what if” moments—a reminder that sometimes even the boldest experiments can slip quietly into legend.

162 notes

·

View notes

Text

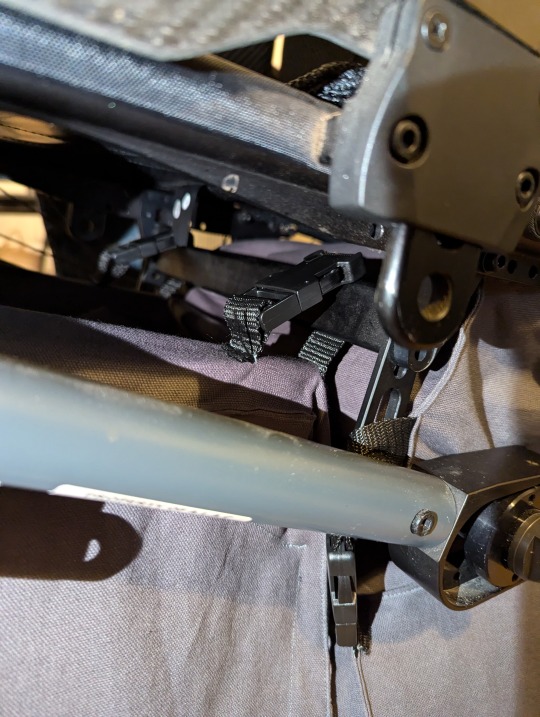

on friday I decided I wanted to make better luggage bags for my wheelchair in time for my trip today (monday), so I spent the weekend in a frenzy and created these

lots more pics and info under the cut!

until now I've been using an off-the-rack under seat bag at the front (smaller than necessary, awkward to use) and random shopping bags bungeed to the axle at the back (impossible to add/remove items without taking them off and unpacking them entirely, not much volume for all that effort).

here's my old setup for comparison (although I can still add the backpack with the new setup too):

the old front bag attached by wrapping all the way over the seat, which made it difficult to remove. it was also unnecessarily small - there was a lot of wasted spare space behind and either side of it.

I measured up for a replacement to properly fill the available space. It's a simple but irregular cuboid - the top edge slopes slightly (because the seat slopes), and the top is narrower than the bottom (becase the frame is in the way at the top).

I designed mine to attach directly to the frame, rather than around the seat. at the back there are short straps with side-release buckles to wrap around a conveniently-placed bar on the frame. at the front are more side-release buckles, attached to make use of the buckles that were installed on the chair by the manufacturer (intended to attach a much smaller under seat bag).

the old bag just had one big compartment inside, so there was no easy way to keep small items accessible without them getting lost among everything else. so I added pockets to mine!

at the top, I made a panel the whole size of the top face, and attached it at a slight diagonal to make a shallow sloping pocket. I also added big flat patch pockets to both sides. and I added a piece of really thick cardboard as a base shaper so it wouldn't sag when full of stuff.

the rear bag was a lot more complicated. I didn't have an existing bag for this use at all, I'd been getting by with just bungeeing soft bags onto whatever bars I could reach on the frame.

I took a bunch of measurements and planned out my design. to make the best use of the space, it needed to wrap *around* the axle both above and below. so the end result is a slightly irregular cuboid but with a cutout at one side.

just above the axle cutout, there are short straps which clip around side bars on the frame to keep it in place. at the other end there are longer straps which buckle around the horizontal bar on the seat backrest, to hold it up.

I didn't add any pockets to this bag, because it's basically for luggage so I won't need to get at small things while it's still attached. more board in the bottom to keep the base in shape.

I would have used a double-ended zip for this one too but I couldn't get one in time (might replace it later). I'm also wondering about adding a shelf or something, to make it easier to squeeze things into the little above-axle space without falling back out.

on both bags I added a strip of old woven belt along the inside top of the opening, to help it keep its shape when the zip is undone.

I don't know enough sewing vocabulary to describe the kind of seam I used on them, but- I folded the edges in, right-sides together, and then topstitched over them. just one line of stitching per seam, but that line goes through each piece of fabric twice. raw edges still exposed on the inside.

I successfully took the new bags on a 4.5-hour train journey today, packed with a week's worth of luggage. and when I arrived, all I had to do was clip them off the chair and lay them on their backs, and then they can easily unzip like suitcases!

58 notes

·

View notes

Video

youtube

Most powerful #Corvette ever! The incredible ZR1X! This is the new 2026 Chevrolet Corvette ZR1X — the most extreme and technologically advanced Corvette ever built. Under the rear hatch is a hand-assembled 5.5-liter twin-turbocharged LT7 V8, producing a massive 1,064 horsepower and 828 pound-feet of torque. This flat-plane-crank engine revs to 8,000 rpm and uses a unique “maniturbo” design, where the exhaust manifold and turbo housing are combined into one compact unit. The result is lightning-fast spool, reduced lag, and brutal mid-range power. At the front axle, an upgraded electric motor from the Corvette E-Ray adds another 186 horsepower and 145 pound-feet of torque. Combined system output is 1,250 horsepower, delivered through a fully electrified all-wheel-drive setup with torque vectoring for maximum grip and agility.

19 notes

·

View notes

Text

With so many people weighing in on the Daniel v Yuki performance at Vcarb, I haven't seen enough discussion of the fact that the performance gap in quali betwene the two only started from Abu Dhabi last year onwards into the start of this season. Which coincidentally was when Vcarb/RB introduced a big floor upgrade which increased downforce on the rear axle and potentially left the car unbalanced/with a weaker front end. Daniel has always preferred to use the rotation of the rear to turn the car through braking on corners, which is much harder to do if the aero balance is more rearwards. Since then Daniel and his engineer have discussed the forward aero balance a lot on the radio and it seems they have tried to induce more oversteer through setups/aero.

78 notes

·

View notes

Text

Birds of Prey, 2001 (We’re still going through all my screenshots from before I decided to do this project and before I started noting issue numbers, sorry!)

So wide. So big. Seat is way too huge. If your rear wheels are so wide that you have to hold your upper arms away from your body like that, you’re in a bad chair. I see rotator cuff problems in your future (source: the rotator cuff issues in my present). Propelling your wheelchair should feel easy, like a monkey driving a speedboat. You should be able to keep your elbows in near your sides.

Three of the things that I bitch about a lot when reviewing wheelchairs are center of gravity, seat width, and camber angle. Camber is having the wheels slant in like that; one of the purposes of that is to make the top of the wheels closer together, and to have better access to the push rims. When the wheel is slanted, you don’t need to have as extreme an angle in your hand grip on the push rim. Seat width matters because when you have your arms out farther away, you have to use different muscles when you push. When your arms are closer to your body, you’re using muscles that are stronger and better set up for daily abuse. When your arms are out like Babs’ here, you’re using your shoulder muscles in a way they weren’t designed for. This causes problems in the long term. (Fun fact, this is also why a lot of manual wheelchair users don’t have arm rests. You don’t need to reach over them if they’re not there.) The last thing I bitch about a lot is center of gravity. CG in wheelchair speak is how far away the rear wheel axle is from the back of the chair. If your wheels are forward, you can access the back of the wheel easier. This gives you a more powerful push with your arms in a more ideal place for long term use. If your wheels are in line with the back of the chair, you have to reach much further back to get to them.

These are the three biggest things in wheelchair setup for protecting your shoulders as a wheelchair user. Someone who has a custom wheelchair that they ordered through someone who did a fitting with them should have these three things set up well.

the wheelchair looks pretty good, but that arm angle makes my physical therapist anxious. Chair good, fit bad. 6/10.

This comic panel doesn’t show center of gravity, but I’ve bitched about it, so here. For reference, here is a catalyst 5vx. The red bar that holds the wheel axle there is farther forward than the back of the seat. You can see holes where it can go even farther forward. This is a lot more difficult to construct than just sticking the wheels on the back posts, but it’s really important to keeping the user healthier.

#wheelchair batgirl#dc#wheelchair#barbara gordon#oracle dc#birds of prey#dc comics#2001#wheelchair batgirl rates 6/10

19 notes

·

View notes

Text

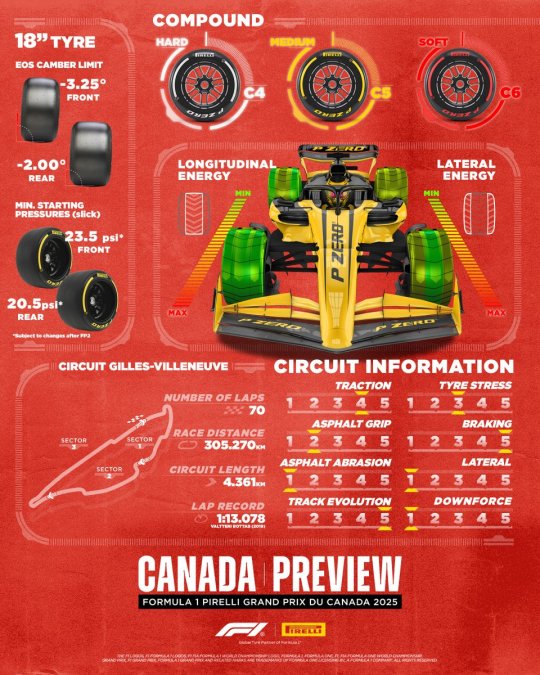

canadian gp 2025 | preview and expectations for ferrari (brakeboosted)

tl;dr - track layout seems ferrari-friendly (mostly slow corners, thus minimal variety = less setup compromise), however external factors could expose key weaknesses with tyre warm-up, braking stability, and ride height sensitivity, unless they adapt with real upgrades and not just setup tweaks

more detailed analysis by brakeboosted under the cut

Looking at the layout, you'd assume the track would suit Ferrari a lot, but that really isn't the case in my opinion. You think, slow corners, long straights, no fast ones, no setup compromise = Ferrari good. I think some external factors change that a bit. #CanadaGP 🇨🇦

Everything I'm about to write is under the assumption that the issues we've experienced have not been resolved.

Mostly slow corners and on a non-abrasive surface. Generating tyre temp is a persistent issue we've had over the last two seasons. I don't believe this is completely resolved. Hysteretic heating is at a minimum due to the low lateral energy transfer through the tyres. Molecular adhesion is also low due to the grip of the surface. This means, you won't be able to produce the heat needed for an optimal qualifying lap, and you put yourself in a position where graining on the front axle becomes a potential hindrance in the race as well. In the last two races, I think there might have been a small step in the right direction regarding the heating of the tyre. I personally don't think there is enough performance overhead to unmask that issue completely.

One thing to note is Pirelli have gone a step softer with the compounds. This might offset the potential damage these factors may cause to Ferrari, but the C6 tyre in general is just not a good tyre, I don't expect that to change this weekend.

The next thing is braking.

Something I have already noticed during testing, and it's been reaffirmed throughout the season, especially in Miami, is the unpredictability of high speed braking with this car. Another reason I think we might struggle, and more specifically in qualifying.

I believe this is a product of some extreme setup compromises, as mentioned by the drivers regularly throughout the season. It forces them to be rather conservative on the brakes on entry, and then try to use the already weak rear end on exit. It almost always results in a net time loss in similar scenarios at other circuits. I'd like to reiterate that this is under the assumption that no fixes are put in place this weekend.

The last thing I want to discuss is the bumpy nature of the track. Even post resurface the track is incredibly bumpy, that means cars will most likely not run at optimal ride heights, also because of the sheer amount of kerbs that need to be ridden. At this stage, I believe we are all familiar with the incredibly narrow working window of the SF-25. Factors like these in my opinion affect as an order of magnitude higher than the others. I don't like to use Monaco as a reference to make such judgments because it's too much of an outlier.

I see Pirelli have listed the downforce at 1/5, which is interesting. To me, is closer to a 2/5 than a 1/5, but I digress. If anyone runs a potential 1.5 setup this weekend, it McLaren, who quite frankly will be untouchable again. I'll put Mercedes/Red Bull in a 2nd force battle. Behind them Ferrari, quite frankly I think that is generous.

Two things I'd like to see Ferrari do this weekend:

1- Bring upgrades, and by that I mean meaningful upgrades.

2- Prioritize mechanical grip over aerodynamic grip.

What I mean by point 2 is, they should at the very least trial a lower downforce setup. Run softer on the rear, but reduce the amount of vertical load at the end of straights to reduce the bottoming. Give yourself a tool to be strong this weekend. Too often this year have we seen a Ferrari with no particular strengths. I don't necessarily expect this to be the answer to their problems, but I'd like to at least see them try different things.

#canadian gp 2025#f1technical: tracks#f1 tracks: montreal#f1technical: car talk#brakeboosted#sf#f1technical

3 notes

·

View notes

Text

Can't believe it's been three years since I got this bike. It's still the only modern (read: brifters and disc brakes) bike I've owned and I'm obsessed with it. When I got this 2013 Soma Doublecross Disc from its previous owner it was set up in a kind of middle-of-the-road commuter sort of way with a narrow gear range, skinny slick tires, etc. I made a few changes: a 40-tooth cassette, SRAM mountain bike rear derailleur and Wolf Tooth roadlink coupled to a 50-34 double crank up front. It's a smooth setup that gives a decently wide gear range for various terrains.

I burnt the wheels that came with the bike out (old hubs plus winter snow riding plus lack of maintenance on my part; lesson learned) but found an insane deal on some Zipp 303 Firecrest wheels. One of the upsides to everyone going through-axle and XD is that wheels not built to those standards are getting much cheaper. I baby these wheels -- used only on road rides -- so I also snagged a very inexpensive set of 650b wheels with DT Swiss rims and spokes and trusty Shimano Deore hubs for daily commutes and rougher riding. With the smaller 650b wheels, I can fit 48 mm tires on this thing. With 700s, I've fit the smaller size 42 mm Bruce Gordon Rock and Roads on easily.

I recently finished off the bike with red Newbaum's bartape treated with clear shellac. I also scored this used Brooks Colt saddle. I like it a lot. It's somewhere between a classic Brooks and an 80s road saddle like the beat up Sella San Marco Concor I had on there before.

This is my primary transportation and it works fantastic for that. It can also handle everything from centuries to single track very well. I've clocked 50-mile rides in less than two and a half hours and crazy nighttime group rides through off-the-grid mountain bike trails.

Investing money in a bike before this was extremely foreign to me. But with some patience, value shopping and help from my local bike co-op, I was able to set all this up for less than what you'd spend on say, a stock All City or Surly complete bike.

I really feel like the Doublecross is a modern classic. If you run across one of these used in your size, you should snap it up.

2 notes

·

View notes

Text

The Ultimate Thrill Ride: Experiencing the Ferrari SF90 Spider 2023's Performance

In the ever-evolving landscape of automotive engineering, Ferrari stands as a beacon of innovation and excellence. With each new release, the Italian marque pushes the boundaries of what's possible, captivating enthusiasts with breathtaking design and unparalleled performance. In 2023, Ferrari unveiled its latest masterpiece, the 2023 Ferrari SF90 Spider, a convertible marvel that promises to redefine the thrill of driving. Join us as we embark on a journey to explore the performance prowess of the Ferrari SF90 Spider 2023 and uncover what makes it the ultimate thrill ride.

The Ferrari SF90 Spider 2023: A Fusion of Art and Engineering

At first glance, the Ferrari SF90 Spider 2023 captivates with its striking design and unmistakable Ferrari DNA. From its sleek lines to its aggressive stance, every element of this convertible masterpiece is crafted to evoke emotion and command attention. But beneath its captivating exterior lies a symphony of power and precision engineering, setting the stage for an unparalleled driving experience.

Harnessing Hybrid Power: The Heart of the SF90 Spider

Central to the Ferrari SF90 Spider 2023's performance is its advanced hybrid powertrain, a feat of engineering that seamlessly combines traditional combustion with electric propulsion. At its core lies a potent 4.0-liter twin-turbocharged V8 engine, delivering a staggering 769 horsepower to the rear wheels. But what truly sets the SF90 Spider apart is its trio of electric motors, generating an additional 217 horsepower to the front axle, bringing the total output to a mind-boggling 986 horsepower.

This hybrid setup not only catapults the SF90 Spider from 0 to 60 mph in a blistering 2.5 seconds but also enhances efficiency and responsiveness. With instant torque delivery and seamless power transitions, the SF90 Spider offers a driving experience like no other, blending electrifying acceleration with the unmistakable roar of a Ferrari V8 engine.

Precision Engineering: Mastering the Art of Performance

Beyond raw power, the Ferrari SF90 Spider 2023 excels in its precision engineering, ensuring unrivaled performance and agility in every driving scenario. From the racetrack to winding mountain roads, the SF90 Spider remains poised and composed, thanks to its advanced chassis and suspension systems.

The SF90 Spider's adaptive suspension system, coupled with advanced aerodynamics, delivers exceptional stability and cornering prowess, allowing drivers to push the limits with confidence. Whether carving through tight corners or accelerating down straightaways, the SF90 Spider responds with precision and finesse, offering a truly immersive driving experience.

Innovative Technology: Redefining the Driving Experience

At the forefront of the Ferrari SF90 Spider 2023's performance is its cutting-edge technology, designed to elevate the driving experience to new heights. The SF90 Spider features an array of innovative systems, including Ferrari's award-winning Side Slip Control (SSC) and Electric Rear Axle Architecture (ERAA), which enhance traction and stability under various driving conditions.

Additionally, the SF90 Spider boasts an advanced infotainment system, complete with a high-resolution touchscreen display and seamless smartphone integration. Whether tracking performance metrics on the racetrack or navigating city streets, the SF90 Spider's intuitive interface ensures drivers stay connected and in control at all times.

The Ultimate Driving Experience: Where Performance Meets Passion

In the world of high-performance automobiles, few experiences compare to the thrill of driving a Ferrari. And with the Ferrari SF90 Spider 2023, that thrill reaches new heights. From its breathtaking design to its blistering performance, the SF90 Spider embodies the essence of automotive excellence, pushing the boundaries of what's possible with each twist of the throttle.

But beyond its impressive performance metrics lies a deeper connection – a passion for driving that transcends mere numbers and statistics. Behind the wheel of the SF90 Spider, drivers become part of a legacy, a tradition of craftsmanship and innovation that spans decades.

Embracing the Future of Performance

As we conclude our journey into the performance prowess of the 2023 Ferrari SF90 Spider, one thing becomes abundantly clear – this convertible masterpiece represents the pinnacle of automotive engineering. With its hybrid powertrain, precision engineering, and innovative technology, the SF90 Spider pushes the boundaries of performance and sets new standards for the ultimate driving experience.

But more than that, the SF90 Spider embodies the spirit of Ferrari – a relentless pursuit of excellence, a passion for innovation, and a dedication to pushing the limits of what's possible. As we look to the future of automotive performance, one thing is certain – the Ferrari SF90 Spider 2023 will continue to inspire and captivate enthusiasts for generations to come.

2 notes

·

View notes

Text

Is a Gooseneck Dump Trailer Worth the Investment? Pros & Cons

When you're in the market for a heavy-duty trailer that can handle demanding hauling jobs, gooseneck dump trailers stand out as a top-tier option. These trailers are commonly used in construction, agriculture, and commercial transportation for good reason—they offer superior stability, higher weight capacities, and better control compared to bumper pull models. But are they really worth the investment? In this comprehensive article, we’ll break down the pros and cons to help you make an informed buying decision.

What Is a Gooseneck Dump Trailer?

A gooseneck dump trailer is a type of trailer that connects to a towing vehicle using a gooseneck hitch mounted in the bed of a pickup truck, rather than attaching at the rear bumper like traditional bumper pull trailers. This configuration offers enhanced control, especially with heavy loads, and is preferred by professionals for intensive jobs.

Pros of Gooseneck Dump Trailers

1. Superior Towing Stability

One of the most praised benefits of gooseneck trailers is their exceptional stability on the road. Because the hitch sits over the rear axle of the truck rather than behind it:

Weight is more evenly distributed.

You experience less sway at high speeds or on uneven terrain.

Safer towing experience, especially in windy or mountainous regions.

This makes gooseneck dump trailers ideal for transporting heavy and unevenly distributed loads.

2. Higher Load Capacity

Gooseneck dump trailers are engineered to handle significantly more weight than bumper pull trailers.

Payload capacities typically range from 10,000 lbs to over 30,000 lbs, depending on the model.

Their design supports larger dump beds, allowing for increased volume of material in each haul.

Great for heavy-duty materials such as gravel, concrete, scrap metal, and demolition waste.

If you're in the construction, excavation, or agricultural business, this advantage alone can dramatically boost efficiency and reduce trips.

3. Enhanced Maneuverability for Long Loads

Despite their larger size, gooseneck trailers actually offer tighter turning radii.

Excellent maneuverability in confined job sites or farmyards.

The hitch placement allows for better handling and turning angles.

Easier to reverse and park once you get used to the setup.

This is particularly useful when hauling in urban areas or narrow access roads.

4. Increased Safety and Control

The nature of the gooseneck design allows the trailer to become almost an extension of your truck:

Less chance of jackknifing.

Better braking control, especially when descending slopes.

Improved balance during sharp turns or sudden maneuvers.

Safety is a major concern when hauling heavy loads, and gooseneck dump trailers minimize many of the most common risks.

5. Professional Appearance and Versatility

Professionals often view gooseneck trailers as a higher-grade equipment choice. Investing in one signals commitment to quality and reliability.

Can be used in multiple industries: farming, roofing, landscaping, and commercial hauling.

Some models feature removable side walls, ramp kits, and tarp systems.

Increases your business’s capacity to handle large-scale or high-value contracts.

It’s an upgrade that can also boost your professional reputation and customer trust.

Cons of Gooseneck Dump Trailers

1. Higher Initial Cost

The most noticeable downside is the higher upfront price.

Gooseneck dump trailers typically cost 20–40% more than equivalent bumper pull models.

You may also need to install a gooseneck hitch in your truck bed, adding to the cost.

Maintenance and repairs can be slightly more expensive due to more complex components.

However, this cost can be justified by long-term durability, performance, and higher job revenue potential.

2. Requires a Compatible Towing Vehicle

To tow a gooseneck trailer, your vehicle must be equipped with a gooseneck hitch installed in the bed.

Not compatible with SUVs or light-duty trucks.

You'll need a ¾-ton or 1-ton pickup (e.g., Ford F-250/F-350, Chevy Silverado 2500HD/3500HD, or RAM 2500/3500).

This may limit accessibility if your fleet or personal truck doesn’t meet these requirements.

For those upgrading from bumper pulls, this might involve a substantial transition.

3. Takes Up More Space

Due to their size and structure, gooseneck trailers require more space for storage and operation.

Might not fit in standard-sized garages or job site trailer lots.

Requires more clearance when navigating tight driveways or residential zones.

May need dedicated storage solutions for off-season.

Planning for space is crucial if you're investing in a gooseneck trailer.

4. Learning Curve for New Users

If you're used to bumper pull trailers, operating a gooseneck setup might feel awkward at first.

Turning, backing up, and coupling/uncoupling the trailer requires practice.

Driving with a gooseneck trailer involves more awareness of vehicle length and turning arc.

However, once mastered, many operators find it easier and safer.

Investing time in proper training or hands-on practice will help overcome this initial barrier.

Who Should Invest in a Gooseneck Dump Trailer?

A gooseneck dump trailer is ideal for:

Contractors and builders managing heavy material on commercial sites.

Farmers transporting hay, equipment, feed, and waste.

Landscapers and excavators working with stone, mulch, and fill.

Hauling professionals who need extra capacity and road control.

If your business relies on dependable, high-capacity equipment, a gooseneck dump trailer is a smart investment that pays off with productivity, safety, and professionalism.

Conclusion: Is It Worth the Investment?

In summary, a gooseneck dump trailer is absolutely worth the investment for users who need superior capacity, safety, and control. While the cost and learning curve may be higher, the long-term advantages—such as durability, increased hauling efficiency, and enhanced safety—make it an essential asset for serious professionals.

If you're ready to invest in a top-quality trailer, explore trusted models at RMZ Trailers, where performance meets reliability.

0 notes

Text

Emergency Towing for Semis in Arkansas Behind Night Shift at Paramount

When midnight hauls grind to a halt on rain slicked Highway 64 crews rise. Paramount’s night shift answers those calls full throttle. That dial ring ain’t for morning squawks, it's for freight lifelines. Their semi towing fleet is ready when rig gears lock or engines stall after dark.

Night Call Doesn’t Mean Night Delay

Arkansas plows into darkness early in winter. Trucks sliding into ditches just past Brinkley can stare into black voids without help. Paramount’s truck wrecker team monitors live night traffic feeds and crash alerts so they roll within minutes.

Crews That Work in Sync

At dispatch a voice tells night crews where the rig broke. Then two vehicles roll one with hydraulics and straps the other carrying diesel spares, belts, injectors and mechanic tools. That dual-rig combo does quick roadside bypasses or hauls disabled units out in one operation no middle-hour walking through silent pine groves.

Precision Under Pressure

A semi rear-ends guardrail at exit ramps near Memphis. No headlights left so drivers can’t see broken wiring or busted suspension. Paramount’s rigs land signal boards, outriggers and LED flares before touching the rig. Crews unload mechanics who downshift air ride bags, splice wiring and reset flares. Rig drives off under its own power with full night watch.

Truck Wrecker Muscle With Care

Heavy duty nights mean hauling 80k tankers, loaded dumpers or livestock trailers. Paramount brings swiveled wrecker wings with outriggers leveled against gravel loads. That careful lift stops frame flex or cargo shifts. Drivers report back actually surprised their trailer didn’t crack further after crash work.

Repair On The Move

If injector nozzles clog or coolant hose pops beneath moonlight, Mobile Semi Truck Repair Near Me crews swing in with hoses, belts, coolant jugs, laptop readers and a toolbox bigger than a road bag. They fix leaks, swap hoses then check transmission fluid all where rig stranded. Next step’s back on route.

Why Choose Us

Full Night Crews No part-time mechanics fumbling at dawn. Our night squads roll fully equipped and fresh.

Predictive Positioning Dispatch positions rigs near common night breakdown spots like exit 276 or 283.

Dual-Rig Deployment Tow boys and fix techs ride separate machines so fixes happen on site while tow lifts load.

Safety-First Setup LED flares outriggers and red-flag lights mark scenes before any lift occurs.

Engineered Lifting We brace trailers hydraulically then lift no twisting axles or cracked frames.

Straight Forward Pricing Nights feel pricey but not ours. Clear estimate given before rig moves.

FAQs

Can I get semi towing near Brinkley AR after a nighttime engine stall? Yes. Paramount answers calls any hour with rigs prepped for tow and fix.

Is roadside truck repair near me available at midnight near Marion AR for belt failure? Absolutely. Crews come with belt kits, spanner sets and hydraulic jacks.

Do you provide bus towing near West Memphis AR after hours? Yes. Night dispatch holds at least one bus-capable wrecker every shift.

Who offers truck mechanics nearby for coolant leaks on I-55 near Earle AR? Our night mobiles swing by with hose clamps coolant and coolant flush packs.

Can you perform a large truck repair near me for failed brakes near Paragould AR late evening? Yes. We stock chambers, pads, air lines and tools for wheel brake repair roadside.

Do you offer heavy duty towing for overturned flatbeds near Jonesboro AR at night? Absolutely. We deploy full heavy rigs with outriggers, tilt hoists and dollies.

Night shifts mean real time loads on the line. Paramount’s crew stands between stalled axles and late freight deliveries. When your rig goes dark they bring light, lift and go fast.

Contact Details

Paramount Towing & Recovery – 24-Hour Semi-Truck Towing 57 Bob Taylor Dr, Marion, AR 72364, United States +1 (870) 635-2532Drivers searching Truck Road Service Nearby here don’t wait for dawn they get lit rigs hauling fast.

#bus towing#heavy duty towing#semi towing#truck towing#truck wrecker#large truck repair near me#mobile semi truck repair near me#roadside truck repair#roadside truck repair near me#semi road service near me

0 notes

Text

Asphalt Modified Axle Set-Ups, Strange Oval, Modified Axles

Strange Oval’s Asphalt Modified Axle Set-Ups are built to handle the demands of high-speed pavement racing. Designed for superior grip and stability through every corner, they offer the durability and precision racers need to stay competitive and consistent, lap after lap.

Product Key Features:

Optimized Track Control

High-Torque Handling

Precision Axle Engineering

Race-Proven Durability

Lightweight Performance Build

Consistent Corner Stability

Contact Information:

For more details or to request a sample, visit Asphalt Modified Axle Set-Ups or contact Strange Oval directly:

Phone: 800-653-1099

Visit: https://www.strangeoval.com/

Address: 8300 Austin Ave Morton Grove, IL 60053

Stay in touch with the latest product developments and company news:

Facebook: https://www.facebook.com/strangeoval/

YouTube:https://www.youtube.com/channel/UCheMfttsl3BZV1dyokhrpSA

X: https://x.com/strangeoval

#Asphalt Modified Axle Setups#Strange Oval Axles#Asphalt Race Car Axles#Modified Axle Solutions#Oval Track Axles#High Performance Axles#Lightweight Axles#Gun Drilled Axles#Racing Axle Setup#Asphalt Racing Parts#Modified Race Axles#Durable Racing Axles#Custom Axle Options#Rear Axle Setups#Strange Oval Modified Parts#Axles For Modifieds#Asphalt Track Performance#Precision Axle Tuning#Modified Chassis Axles#Strange Oval Racing Axles

1 note

·

View note

Text

1930 Ford Highboy Coupe

There’s always lots of detail work with any build and this ’30 Ford highboy coupe is no exception. Look closely and you will find Craftworks Fabrication handmade steel motor mounts. The license plate and valve covers were painted by Jeremy Seanor of Luckystrike Designs. He also painted all the accompanying engine and tranny parts. The powdercoat was handled by Pittsburgh Powder Coat while the chrome plating was conducted by Jon Wright’s Custom Chrome Plating.

The chassis is comprised of a Roadster Shop custom frame that was stepped, stretched, and features contoured ’32 Ford-style framerails. It was also then boxed, capped, and has hole punch flared front framehorns. From here the frame is outfitted with a Super Bell 4-inch drop, drilled and plated I-beam axle, low-profile monoleaf spring with Ridetech tubular shocks paired to custom-made drilled billet radius rods from Johnson’s Hot Rod Shop. Steering falls to the Flaming River box and a LimeWorks Hot Rod column topped with a four-spoke Billet Specialties Sprint Car–style leather-wrapped wheel. In back there’s a Currie 9-inch rearend outfitted with 3.70 gears, 31-spline axles, QA1 coilovers, a Pete & Jakes Panhard bar, and a parallel four-link setup. Braking is a combination of disc/drum front to rear. The forward braking dark gray–painted Wilwood Dynalite calipers are neatly hidden behind the Pete & Jakes finned backing plates. While in back the 9-inch is outfitted with 11-inch brakes, this time hidden beneath the SO-CAL Speed Shop finned drums all the while the chassis rides on a full set of 16-inch Dayton wire wheels wrapped with Coker/Excelsior rubber measuring 5.50R16 in front and 7.00R18 in the back.

All hot rods have something fun settled between the ’rails and beneath the hood (well if they have a hood). In the case of our ’30 Ford highboy coupe it sure appears to be a vintage Ford Y-block but after more than a cursory look we begin to see the telltale signs that there’s something more. Indeed, while it may look like a Ford it truly is a 376-inch LSX iron block, with aluminum heads and ARP studs, plus adapter-equipped small-block Ford (Windsor) valve covers all from Don Hardy Race Cars and then assembled by Talik and Marc Mullin. The intake is an Edelbrock LS dual quad with a pair of Thunder AVS EnduraShine carbs dressed in OTB air cleaners. Delivering the gas from the Tanks stainless reservoir is an Earl’s Performance billet fuel pump. More engine accessories include an MSD 6AL box to go along with the MSD billet Ford small-block distributor that functions through a timing cover adapter from Chevrolet Performance all the while using an MSD coil and Lokar vintage plug wires. Powermaster also supplied the alternator and starter, the battery is an XS Power AGM, and a Wegner Motorsports water pump is used as well as a Wegner front accessory drive unit. This 500-plus hp V-8 utilizes custom headers made at Craftworks Fabrication based on Ultimate Headers LS header flanges. The pseudo-Ford small-block is backed up to a TCI StreetFighter 700-R4 with a 2,800-stall speed converter operated by a Lokar shifter. The trans cooler comes by way of Derale Performance and moves the power through a 3-inch-diameter custom-made driveshaft.

216 notes

·

View notes

Text

Strange Engineering Drag Racing Axle Set-Ups

Strange Engineering’s drag racing axle set-ups are built for maximum strength and reliability. Designed to handle serious horsepower, they’re perfect for racers who demand performance on both the street and the strip.

Key Features of the Product:

Induction-Hardened Steel

CNC Precision Machining

Multiple Series Options

Custom Length Fitment

High Spline Counts

Gun-Drilled Flanges

Contact Information:

For more details or to request a sample, visit Strange Engineering’s drag racing axle setups, or contact Strange Engineering directly:

Phone: 800-646-6718

Visit: https://www.strangeengineering.net/

Address: 8300 N. Austin Ave, Morton Grove, IL

Stay in touch with the latest product developments and company news:

Facebook: https://www.facebook.com/StrangeEng

YouTube:https://www.youtube.com/channel/UCheMfttsl3BZV1dyokhrpSA

X: https://x.com/RaceStrange

Instagram: https://www.instagram.com/racestrange/

#RearAxles#StrangeEngineeringRearAxles#DragRacingAxles#PerformanceAxles#HighStrengthAxles#StreetAndStripAxles#CustomAxleShafts#9InchFordAxles#AxleShaftKits#RacingAxleComponents#HeavyDutyRearAxles#HighPerformanceDrivetrain#RaceReadyAxles#AlloyAxleShafts#PerformanceRearEndParts#BoltInRearAxles#AftermarketAxles#FordAxleUpgrades#DrivelineComponents#StrangeAxleKits#Ask ChatGPT

1 note

·

View note

Video

youtube

Chevrolet Corvette ZR1X - Full Tech Specs and Performance

This is the new 2026 Chevrolet Corvette ZR1X — the most extreme and technologically advanced Corvette ever built. Under the rear hatch is a hand-assembled 5.5-liter twin-turbocharged LT7 V8, producing a massive 1,064 horsepower and 828 pound-feet of torque. This flat-plane-crank engine revs to 8,000 rpm and uses a unique “maniturbo” design, where the exhaust manifold and turbo housing are combined into one compact unit. The result is lightning-fast spool, reduced lag, and brutal mid-range power. At the front axle, an upgraded electric motor from the Corvette E-Ray adds another 186 horsepower and 145 pound-feet of torque. Combined system output is 1,250 horsepower, delivered through a fully electrified all-wheel-drive setup with torque vectoring for maximum grip and agility. Performance is hypercar-level. Zero to sixty takes under two seconds. The quarter-mile less than nine seconds at over 150 miles per hour. The front motor stays engaged up to 160 mph, then decouples to reduce drag and maximize top-end performance. Drivers can opt for two distinct chassis setups. The standard package uses Michelin Pilot Sport 4S tires and next-gen Magnetic Ride Control for street-focused balance. The ZTK track pack stiffens everything up, swaps in Michelin Cup 2R tires, and adds more aggressive aero calibration for serious cornering. Speaking of aero, the optional Carbon Aero package includes front dive planes, a hood extractor, underbody strakes, and a massive rear wing. Total downforce can reach up to 1,200 pounds, keeping the car planted even at triple-digit speeds. Carbon-ceramic rotors come standard — 16.5 inches up front with massive 10-piston calipers. In testing, the ZR1X pulled up to 1.9 g of deceleration when braking from 180 to 120 miles per hour. Built in Bowling Green with precision and performance in mind, the 2026 Corvette ZR1X is more than a supercar — it’s a declaration that America can build a hypercar. 2026 Chevrolet Corvette ZR1X – Technical Specifications Powertrain Engine Type: LT7 5.5L Twin-Turbocharged DOHC V8 Crankshaft: Flat-plane Engine Output: 1,064 hp @ 7,000 rpm Engine Torque: 828 lb-ft @ 6,000 rpm Turbochargers: Dual 76 mm turbos with integrated "maniturbo" housing and dynamic anti-lag Redline: 8,000 rpm Electric Motor (Front Axle): Output: 186 hp / 145 lb-ft Max Engagement Speed: 160 mph Configuration: Single motor, torque-vectoring capable Total System Output Combined Horsepower: 1,250 hp Combined Torque: Estimated over 950 lb-ft Drivetrain: Electrified All-Wheel Drive (eAWD) Transmission: 8-Speed Dual-Clutch Automatic Performance 0–60 mph: under 2.0 seconds (GM estimate) Quarter Mile: under 9.0 seconds @ more than 150 mph (GM estimate) Top Speed: Not officially released Max Deceleration: Up to 1.9 g from 180 to 120 mph Chassis & Suspension Platform: Mid-engine, aluminum space frame Suspension: Standard: Magnetic Ride Control with adaptive dampers Optional: ZTK Track Pack with stiffer springs and custom tuning Tires: Standard: Michelin Pilot Sport 4S ZTK Package: Michelin Pilot Cup 2R Steering: Electrically assisted, variable ratio Brakes Front: 16.5-inch Carbon-Ceramic Rotors with 10-piston Calipers Rear: Carbon-Ceramic Rotors with 6-piston Calipers Aerodynamics Standard Aero: Functional rear spoiler, underbody paneling Carbon Aero Package (Optional): Carbon fiber dive planes Hood extractor vent Underbody strakes High-mounted rear wing Max Downforce: Up to 1,200 lbs Dimensions (estimated) Length: \~182.3 in Width (w/mirrors): \~79.7 in Height: \~48.6 in Wheelbase: \~107.2 in Curb Weight: Not officially disclosed (expected \~3,900–4,000 lbs) Wheels Front: 20 x 10 in Rear: 21 x 13 in Construction: Lightweight forged aluminum (optional carbon fiber wheels) Production & Assembly Assembly Location: Bowling Green Assembly, Kentucky, USA Engine Hand-Built: Performance Build Center (same facility) Availability Launch: Expected late 2025 Price: To be announced

7 notes

·

View notes

Text

I'm no engineer but I'm gonna guess that is at least part of why Daniel struggled so much today. If they've increased downforce on the rear axle then and it's left the car unbalanced/with a weaker front end, then Daniel's not going to be able to use the rotation of the rear to turn the car through braking on corners.

I also wonder if maybe to compensate they tried to induce more oversteer through setups/aero, but maybe overdid it a bit, hence why Daniel was struggling with losing the rear through turns 5,6 and 7.

via: Motorsport total

39 notes

·

View notes