#Refractory bricks

Explore tagged Tumblr posts

Text

High-Performance Refractory Bricks for Industrial Use – Explore Top-Quality Options at RefShape

In industries where extreme temperatures are part of everyday operations—like metallurgy, cement, ceramics, and power generation—durability and thermal resistance are critical. That’s where refractory bricks come into play. At RefShape, we specialize in manufacturing and supplying high-grade refractory solutions that meet the demanding needs of modern industries. If you're looking for refractory bricks for sale, RefShape is your trusted partner.

What Are Refractory Bricks?

Refractory bricks, also known as fire bricks, are specially designed to withstand high temperatures, thermal shock, abrasion, and chemical attacks. These bricks are commonly used to line furnaces, kilns, incinerators, and reactors, making them a vital component in any high-temperature industrial process.

Key Benefits of RefShape Refractory Bricks

At RefShape, our refractory bricks are manufactured using advanced techniques and premium materials to ensure superior quality and performance. Here’s why industries choose us:

High Thermal Resistance: Withstand extreme heat without structural damage.

Excellent Strength and Durability: Built to last under pressure and high-stress environments.

Customized Sizes and Shapes: Tailored to your specific industrial application.

Chemical and Corrosion Resistance: Protects against aggressive materials.

Eco-Friendly and Safe: Made from non-toxic, high-quality raw materials.

Applications of Refractory Bricks

Our refractory bricks are suitable for a wide range of industrial uses:

Steel and metal foundries

Glass manufacturing units

Cement kilns and rotary furnaces

Chemical processing plants

Boilers, incinerators, and chimneys

Power plants and refineries

Whatever your industry, RefShape has the right refractory brick solution to match your operational requirements.

Refractory Bricks for Sale at RefShape

Looking for refractory bricks for sale? At RefShape, we offer a wide variety of standard and custom-designed fire bricks at competitive prices. Whether you need alumina bricks, insulating fire bricks, or silica bricks, our inventory is stocked and ready to meet your needs.

Why Buy from RefShape?

ISO-certified manufacturing

Expert technical support

Fast and reliable delivery

Bulk order discounts

Long-term supply partnership opportunities

Conclusion When it comes to high-temperature resilience, you can’t afford to compromise. Trust RefShape for premium-grade refractory bricks that deliver unmatched performance and reliability. Browse our catalog today for the best refractory bricks for sale, and let our team help you find the ideal solution for your heat-intensive operations.

Visit Us https://www.refshape.com/products/bricks/

0 notes

Text

A Guide to Understanding Refractory Bricks & Their Applications

Refractory bricks are high-temperature-resistant materials that are crucial for many industrial applications in glass, cement, and more.

0 notes

Text

Advantages of Refractory Bricks in the Furnace of Industries

Fire or refractory bricks, created with dry-press, stiff-mud, and hot-pressing methods, are specially designed to handle high temperatures. These blocks of refractory ceramic substance are perfect lining materials for furnaces and kilns and are widely used in various industries for furnaces construction.

Read more: https://refractorymeterial.wordpress.com/2021/10/30/refractory-bricks-advantages/

0 notes

Text

#ingot casting refractory#refractory bricks#mgo-c#high alumina bricks#alumina bricks#bottom pouring bricks#magnesia carbon bricks#Alumina bricks

0 notes

Text

"Refshape: Building Tomorrow with Enduring Strength - Refractory Bricks for Sale"

Elevate your construction projects with Refshape, where durability meets precision. Explore our range of refractory bricks for sale, meticulously engineered to withstand extreme temperatures. Build with confidence, build with Refshape, and forge structures that stand the test of time.

https://refshape.com/rs.htm

0 notes

Text

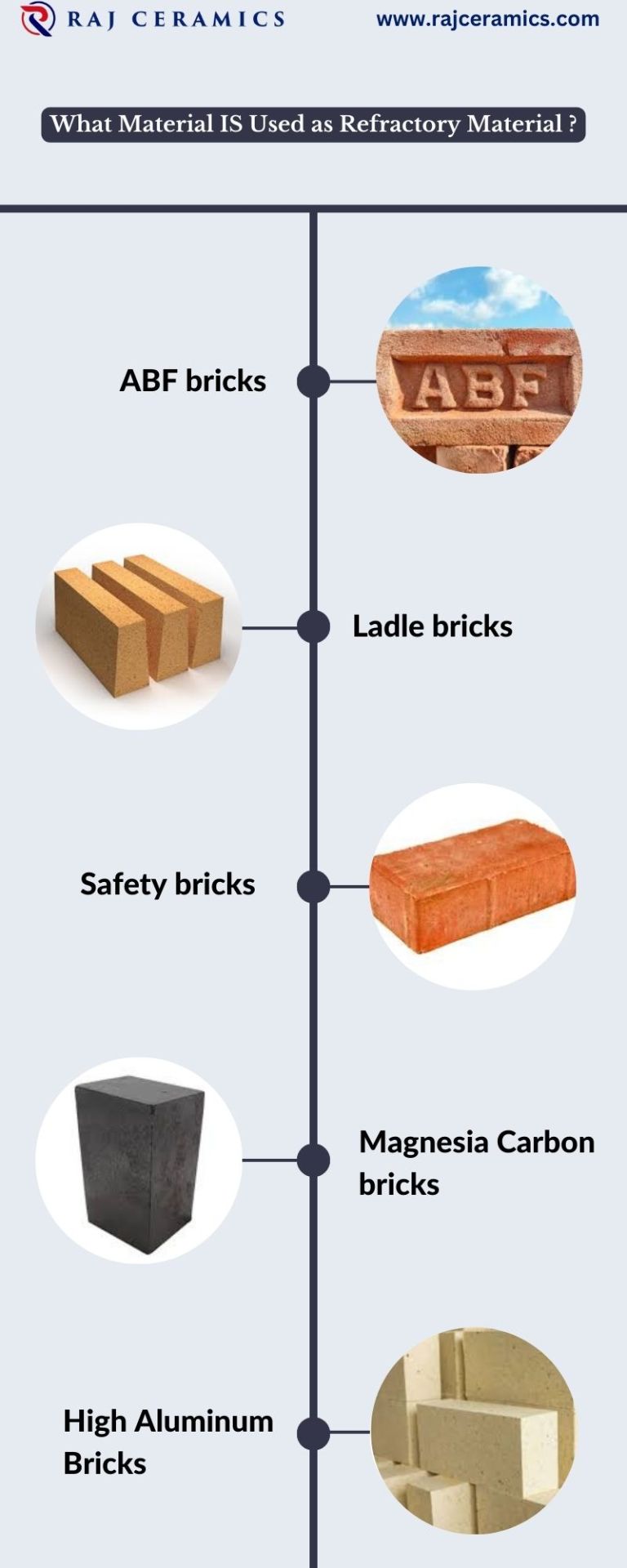

Types and characteristics of refractory bricks

What is a refractory brick

Refractory bricks, also known as “furnace bricks”, are bricks that can withstand high temperatures without melting or decomposing. These tiles are made of refractory clay, quartz, cellulose, asbestos, and other materials, and the refractory materials used vary from one type of refractory tile to another. Because of the different raw materials, the specific properties and applications of different refractory bricks vary, but they are usually characterized by their ability to maintain their shape, strength and stability at very high temperatures. Refractory bricks are mainly used to construct and repair smelting kilns, ovens, boilers and other equipment in high temperature environments.

Types of Refractory Bricks

Silicon Carbide Refractory Brick Aluminosilicate refractory bricks are made of silicon carbide as the main raw material, adding appropriate amount of refractory agent, after molding, drying, firing and other processes made of refractory bricks. Silicon carbide refractory bricks have high slag resistance and good acid resistance, suitable for masonry of various high-temperature furnaces, ceramic kilns and so on.

Characteristics of refractory bricks

Good performance of high temperature resistance Refractory bricks have high refractoriness and can maintain good stability and integrity under high temperature environment.

Good thermal stability At high temperatures, the volume change of refractory bricks is small, and it is not easy for thermal expansion or contraction to occur, thus ensuring the stability of the structure.

Good chemical stability Refractory bricks have strong corrosion resistance to acids, alkalis, salts and other chemicals, and are able to maintain stable performance in harsh chemical environments.

Good mechanical strength Refractory bricks have high hardness and compressive strength, able to withstand large loads and impacts.

Good thermal conductivity Refractory bricks have a low thermal conductivity, which can effectively reduce the speed of heat propagation and minimize heat loss.

Environmental protection and energy saving Refractory bricks do not produce harmful substances in the process of use, no pollution to the environment; at the same time, its excellent thermal insulation performance can reduce energy consumption.

Refractory bricks are a kind of construction material with superior performance and wide application. Different types of refractory bricks have different characteristics and scope of application, you can choose the right type of refractory bricks according to the actual project needs.

0 notes

Text

Which refractory material manufacturer is best in China for the cement industry?

Xinmi, Henan, China is a gathering place for refractory materials. There are many manufacturers of refractory materials. Different manufacturers specialize in different fields. Regarding the manufacturers of refractory materials used in the cement industry, I recommend one to everyone - Zhengzhou Zhenjin Refractory Materials Co., Ltd.

Zhengzhou Zhenjin Refractory Materials Co., Ltd. has developed a series of high-end refractory materials for the cement industry to meet the needs of various refractory materials in the cement industry.

In addition, Zhenjin Refractory is the drafting unit for the new dry-process cement kiln magnesia iron spinel bricks and composite structure silica-molybdenum brick standards in China's refractory industry. The company has been awarded as a national "High-tech Enterprise", "Ministry of Industry and Information Technology Access Announcement Enterprise", and "Environmental Assessment Performance Compliance Level A" enterprise for 15 consecutive years; it has continuously passed ISO19001 quality management system, ISO24001 environmental management system and ISO45001 occupational health and safety management system certification.

The following lists 10 cement customer cases of Zhengzhou Zhenjin Refractory Materials Co., Ltd. and real customer feedback information. I hope it will be of reference value to you.

1. Zhangye Shandan Tieqi Cement Co., Ltd. 2500t/d cement line project

The overall quality of the products of Zhengzhou Zhenjin Company is excellent, and the safe operation and service life exceeds expectations. After the kiln was stopped, the overall bricks were inspected and the wear was not significant. The products of Zhengzhou Zhenjin Company are of high quality and are trustworthy refractory products.

2. Huaxin Cement (Huangshi) Co., Ltd. 10,000t/d cement line project

Zhengzhou Zhenjin's refractory brick products have good quality, regular appearance, good wear resistance and high cost performance. Their overall quality can completely replace imported products.

3. Ningxia Jinyuyuan Resource Recycling Co., Ltd.

Through the actual use of Zhengzhou Zhenjin Company's products, the raw materials used in the products have high purity, stable high-temperature performance indicators, high wear resistance, erosion resistance, and thermal shock stability. There is no erosion caused by spalling in the entire kiln system. Zhengzhou Zhenjin Company Jin Company's silicon-molybdenum wear-resistant bricks can meet our actual production needs, and our company's clinker production has achieved good economic benefits.

4. Zhejiang Haolong Building Materials Co., Ltd. 5000t/d cement line project

After our company uses the products of Zhengzhou Zhenjin Company, they have a long service life and good wear resistance, which have been highly praised by the company. We will continue to cooperate with Zhengzhou Zhenjin Company.

5. Chengde BBMG Cement Co., Ltd.

Zhengzhou Zhenjin Company's product quality and service are in good condition, with timely arrival and complete varieties. The engineering and technical personnel are serious and responsible. We are very satisfied with the overall service.

6. Dalian Tianrui Cement Co., Ltd. 5000t/d cement line project

The products of Zhengzhou Zhenjin Company comply with the relevant national technical requirements and meet the construction requirements well. The technical service attitude is good and can be adjusted in time according to the on-site construction conditions, which fully reflects the brand spirit of the company's products - real gold is not afraid of fire.

7. Linyi Zhonglian Cement Co., Ltd. 5000t/d cement line project

The company's 5000t/d production line uses Zhenjin Company's products. The company provides timely delivery and sends engineering and technical personnel to guide the masonry construction on site. The whole process is considerate and has received unanimous praise from our company. Because it saves time during the masonry construction, it ensures a smooth construction period. The completion provided good conditions, for which we are grateful.

8. Fujian Honghuo Cement Co., Ltd. 5000t/d cement line project

The products of Zhenjin Company are of good quality and service, and are deeply trusted by our company's leaders and employees. We will always choose the refractory materials products produced by Zhenjin Company and look forward to our long-term cooperation!

9. Anhui Wuhu Conch Cement Co., Ltd. 5000t/d cement line project

The overall quality of Zhenjin Company's products is excellent, and the service life can reach the expected time. After the kiln is stopped, the bricks are inspected after the kiln is stopped. The wear of the bricks is not great. Zhenjin Company's products are trustworthy refractory products.

10. Oriental Hope Chongqing Cement Co., Ltd. 5000t/d cement line project

The refractory bricks of Zhenjin Company are of excellent quality. After 13 months of use, the thickness of the bricks remains above 160mm, and their wear resistance is good, which reduces the number of kiln shutdowns for our kilns and increases corporate efficiency. The after-sales service is also very good. We will continue to cooperate with Zhenjin Company and use Zhenjin Company’s refractory products.

0 notes

Text

Problems prone to occur in refractory materials in the cooling zone of cement rotary kiln

1.High-temperature impact

2.Chemiacl erosion

3.clinker abrasion

4.Mechanical forces

5.Complex operating conditions

6.Frequent kiln stops

1 note

·

View note

Text

What are refractories?

Refractories are inorganic and non-metallic materials that can withstand extreme temperatures and harsh conditions without undergoing significant physical or chemical changes. They are designed to provide stability and insulation in high-temperature environments.

Refractory materials have very high chemical and physical stability at elevated temperatures. They are chemically inert, and can resist thermal shocks.

The temperature that the refractories can withstand ranges from 600°C to 2200°C and above depending on their composition, type, and specific application.

Note that:

Refractories are ceramic materials.

#materials science#science#engineering#materials#materials science and engineering#refractories#bricks#cement#glass

29 notes

·

View notes

Text

The Importance of Basic Bricks in the Refractory Industry: TRL Krosaki’s Expertise

In the high-performance world of the refractory industry, materials that can withstand extreme conditions are critical. The foundation of every reliable refractory system starts with the choice of bricks. Among the wide variety of refractory products available, basic bricks for the refractory industry play an essential role in ensuring long-term performance and durability, especially in environments exposed to high heat, chemical corrosion, and mechanical stress. At TRL Krosaki, we specialize in providing advanced refractory solutions, and our basic bricks are designed to meet the highest standards of quality and reliability.

What Are Basic Bricks in the Refractory Industry?

Basic bricks, also known as basic refractories, are made primarily from alkaline earth oxides, such as magnesia (MgO) and dolomite. These materials are known for their resistance to high temperatures and aggressive chemical environments, which are common in various industrial processes like steelmaking, cement production, and non-ferrous metal processing. These bricks are used in furnace linings, kilns, and other critical areas where heat and chemical stability are paramount.

Unlike acidic refractories (which are made from silica), basic bricks are designed to withstand environments rich in basic slags and materials. They offer exceptional resistance to basic slags and can perform well in both oxidizing and reducing atmospheres.

TRL Krosaki: A Trusted Name in Refractory Manufacturing

At TRL Krosaki, we have decades of experience in the development, production, and supply of refractory materials, particularly basic bricks for the refractory industry. Our technical expertise combined with cutting-edge manufacturing processes ensures that our products deliver superior performance in the most demanding environments. As a leader in the refractory sector, we are committed to providing solutions that meet our clients' specific requirements while ensuring the sustainability and longevity of their industrial operations.

Why Choose Basic Bricks for Your Refractory Needs?

High Thermal Stability Basic bricks are designed to withstand extreme temperatures, making them ideal for use in high-heat applications such as furnaces and kilns. Their ability to retain strength and structural integrity even under intense heat ensures that industrial operations continue smoothly without interruption.

Resistance to Chemical Erosion These bricks are particularly resistant to chemical attack from basic slags, lime, and other aggressive substances commonly encountered in industries like steel and cement. This quality makes them a preferred choice for environments that are chemically harsh.

Long-Term Durability Basic bricks exhibit remarkable durability, making them an investment that pays off over time. Their resistance to wear and tear ensures a longer lifespan of the equipment they line, reducing maintenance costs and downtime.

Versatility TRL Krosaki’s basic bricks come in a range of specifications, allowing them to be tailored to specific industrial applications. Whether you are working with steel, glass, cement, or non-ferrous metals, our refractory solutions are designed to meet your needs.

Applications of Basic Bricks in the Refractory Industry

Basic bricks are used extensively in sectors that require materials capable of withstanding high heat and corrosive conditions. Some of the major applications include:

Steelmaking: Basic bricks are widely used in the linings of electric arc furnaces, blast furnaces, and ladles. These bricks provide protection against molten metal and slag.

Cement Kilns: Basic refractories are essential for the lining of rotary kilns where high temperatures and chemical reactions are commonplace.

Non-Ferrous Metals: These materials are also used in the production of non-ferrous metals like aluminum and copper, where they ensure resistance to high temperatures and aggressive environments.

Glass Furnaces: Basic bricks help in maintaining the high temperature and chemical stability required in glass production furnaces.

TRL Krosaki’s Commitment to Quality and Innovation

At TRL Krosaki, we believe in continuous improvement and innovation. We understand the ever-evolving demands of the refractory industry and are always looking for ways to improve the performance and cost-effectiveness of our basic bricks. Our research and development team is constantly working on improving the materials we offer, ensuring that we stay ahead of the curve and provide our customers with the most advanced and reliable refractory solutions.

We also focus on sustainability, ensuring that our manufacturing processes are environmentally friendly, and our products contribute to energy-efficient industrial operations.

Conclusion

In the highly demanding refractory industry, selecting the right materials is crucial for the success and longevity of your operations. Basic bricks for the refractory industry offer exceptional durability, chemical resistance, and thermal stability, making them indispensable in many industrial applications. With TRL Krosaki’s expertise and dedication to providing high-quality refractory products, you can be confident that your operations are supported by some of the best materials available on the market today.

Contact TRL Krosaki today to learn more about how our basic bricks can enhance the performance and reliability of your industrial processes.

0 notes

Text

Discover Top Fire Bricks Suppliers and Manufacturers on TradersFind

Searching for the perfect fire bricks for your industrial or commercial application? TradersFind offering a comprehensive list of companies they provide fire bricks suppliers and manufacturers in UAE. join TradersFind today to find the right connections for your commercial needs and grow your business in UAE market.

#Fire Bricks#Fire Bricks in UAE#fire bricks suppliers#fire bricks Manufacturers#Refractory Fire Bricks

0 notes

Text

Fire bricks, also known as refractory bricks, are made from fire clay and are designed to resist high temperatures without cracking or breaking. Unlike regular bricks, they retain their strength and structural integrity

0 notes

Text

youtube

Benefits of Using Fire or Refractory Bricks by Refmon Industries

Hello friends, in this video we will talk about the benefits of using fire or refractory brick manufactured by Refmon Industries. So, watch the video completely and like and subscribe to our channel for such important information.

Watch Now:- https://youtu.be/XJ5qkXvMcZ0

#refractory bricks#fire brick benefits#refractory brick#fire brick manufacturers in India#fire brick manufacturers#refmonindustries#refmon#Youtube

0 notes

Text

Boosting Industrial Efficiency: The Role of High Alumina Bricks in Durability and Performance

High alumina bricks are a crucial component in modern industrial applications, known for their exceptional durability and performance. These bricks, composed primarily of alumina (Al2O3), offer superior resistance to high temperatures, mechanical wear, and chemical corrosion, making them ideal for use in furnaces, kilns, incinerators, and reactors. By withstanding extreme conditions and maintaining structural integrity, high alumina bricks enhance the efficiency and longevity of industrial processes. Their ability to improve thermal stability and energy efficiency translates to reduced maintenance costs and downtime, ultimately boosting overall productivity. For More info call +91 7808775566

#high alumina bricks#alumina bricks#mgo-c#ingot casting refractory#refractory bricks#bottom pouring bricks#magnesia carbon bricks

0 notes

Text

Everything You Need to Know About Refractory Fire Bricks: A Guide by Refractory Shapes

In industries that deal with extreme temperatures, such as steel, cement, glass, and power plants, the materials used for constructing furnaces, kilns, and other high-heat equipment must be able to withstand intense thermal stress. This is where refractory fire bricks come into play. As a leading manufacturer of high-quality refractory products, Refractory Shapes provides durable, heat-resistant fire bricks that are designed to offer superior performance in even the harshest conditions.

Visit us-https://refractoryshapes.blogspot.com/2024/09/everything-you-need-to-know-about.html

0 notes