Don't wanna be here? Send us removal request.

Text

Castables | High-Performance Refractory Solutions for Industrial Applications

0 notes

Text

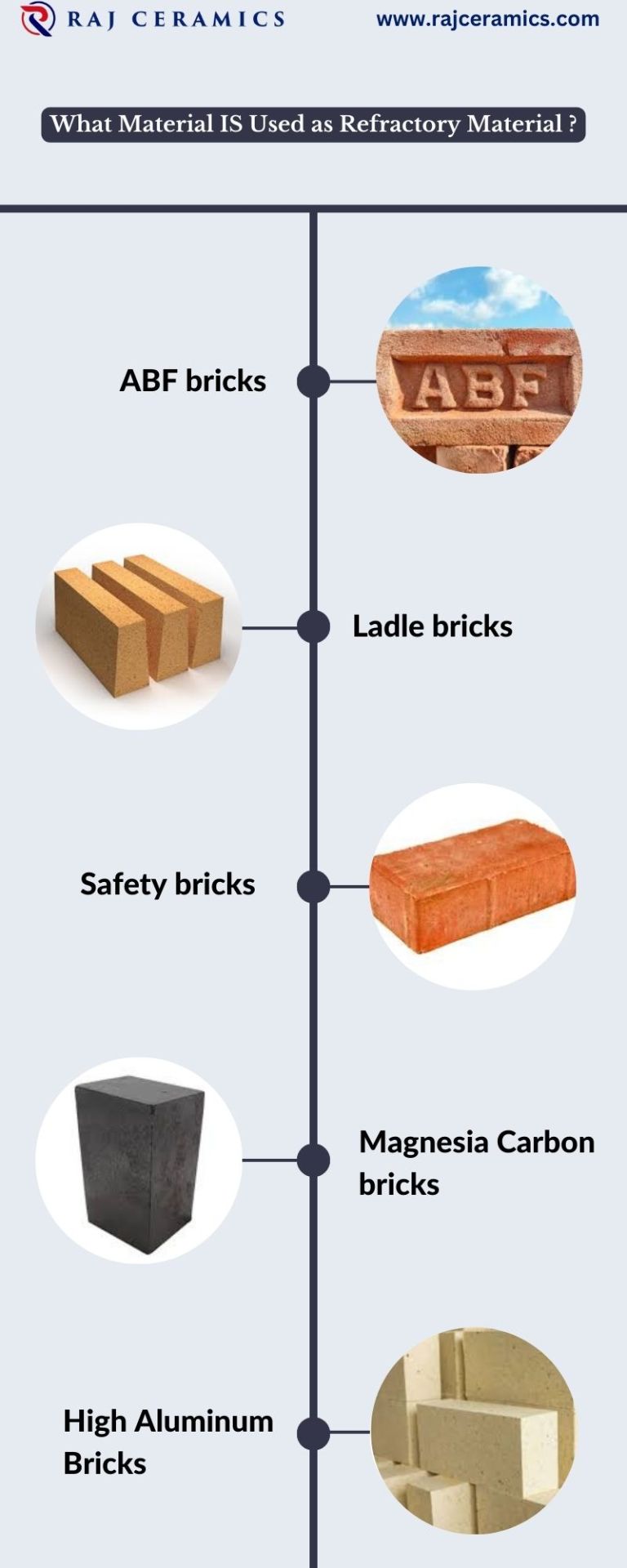

#ingot casting refractory#refractory bricks#mgo-c#high alumina bricks#alumina bricks#bottom pouring bricks#magnesia carbon bricks#Alumina bricks

0 notes

Text

Boosting Industrial Efficiency: The Role of High Alumina Bricks in Durability and Performance

High alumina bricks are a crucial component in modern industrial applications, known for their exceptional durability and performance. These bricks, composed primarily of alumina (Al2O3), offer superior resistance to high temperatures, mechanical wear, and chemical corrosion, making them ideal for use in furnaces, kilns, incinerators, and reactors. By withstanding extreme conditions and maintaining structural integrity, high alumina bricks enhance the efficiency and longevity of industrial processes. Their ability to improve thermal stability and energy efficiency translates to reduced maintenance costs and downtime, ultimately boosting overall productivity. For More info call +91 7808775566

#high alumina bricks#alumina bricks#mgo-c#ingot casting refractory#refractory bricks#bottom pouring bricks#magnesia carbon bricks

0 notes

Text

Understanding Castables: Types, Properties, and Applications in Refractory Technology

Explores the crucial role castables play in modern refractory applications. This comprehensive guide delves into the various types of castables, including conventional, low-cement, and ultra-low-cement variants, examining their unique properties and advantages. It provides an in-depth analysis of the chemical and physical characteristics that make castables indispensable in high-temperature industries, such as metallurgy, petrochemicals, and power generation. For More info call +91 7808775566

0 notes

Text

Bottom pouring bricks have emerged as a transformative innovation in the field of metallurgy, offering significant improvements in the casting process. These specialized bricks are designed to facilitate the controlled flow of molten metal from the bottom of the casting vessel, ensuring a more precise and defect-free final product.. For More Info call +91 7808775566

#Bottom pouring bricks#Refractory bricks#Ingot casting refractory#high alumina bricks#mgo-c#Ladle bricks

0 notes

Text

Exploring the Benefits and Applications of Magnesia Carbon Bricks in High-Temperature Industries

Magnesia carbon bricks are a critical component in high-temperature industries, renowned for their exceptional resistance to thermal shock, slag corrosion, and mechanical wear. These advanced refractory materials, composed of magnesia and carbon, offer a unique combination of durability and performance that is essential for the demanding environments of steelmaking, cement production, and non-ferrous metal processing. For More Info call +91 7808775566

0 notes

Text

Exploring High Alumina Bricks: Key Properties, Industrial Applications, and Advantages

0 notes

Text

Forged in Fire: The Getting Through Tradition of Refractory Bricks

Discover the ageless art of refractory bricks making on Fashioned in Fire. See talented craftsmen produce these intensity-safe ponders that power heaters and furnaces worldwide. Investigate the getting-through custom behind this fundamental structure material.

1 note

·

View note

Text

Improving Stubborn Materials for Ingot casting refractory: Upgrading Execution and Effectiveness

Improve unmanageable materials for Ingot casting refractory to upgrade execution and productivity. Find the significance of choosing excellent materials and high level methods like warm displaying for further developed toughness and efficiency in metallurgical cycles.

0 notes

Text

Unlocking the Power of Ingot casting refractory: A Guide to Success

Opening the Force of Ingot Casting Refractory: A Manual for Progress" is a far reaching investigation into the universe of ingot projecting recalcitrant materials and procedures. This guide digs into the basic job that recalcitrant materials play in upgrading the effectiveness and nature of ingot projecting cycles.

0 notes

Text

raj ceramics :Building Toughness Investigating the Durability of Refractory Bricks

0 notes

Text

Alumina bricks

#Alumina bricks#Refractory bricks#MgO-C#Ingot casting refractory#High alumina bricks#ABF bricks#Bottom pouring bricks

0 notes

Text

Alumina Brilliance: Disclosing the Unequaled Strength and Adaptability of Alumina Bricks

Discover the extraordinary capabilities of alumina bricks in our comprehensive exploration, Unveil the unparalleled strength and adaptability inherent in these remarkable building materials. From industrial furnaces to high-temperature environments, alumina bricks stand as a testament to durability and reliability. Join us on a journey to understand the innovative properties and diverse applications of alumina bricks, reshaping industries and setting new standards for excellence.

0 notes

Text

Revealing the Excellence of MgO-C Refractories

In the realm of high-temperature applications, where extreme heat and harsh conditions prevail, the choice of refractory materials plays a pivotal role in ensuring operational efficiency and longevity. Among the myriad options available, MgO-C refractories stand out as a beacon of excellence, offering unmatched performance and durability in demanding environments. In this comprehensive guide, we delve into the intricacies of MgO-C refractories, exploring their composition, properties, applications, and the unparalleled advantages they bring to diverse industries.

Understanding MgO-C Refractories

MgO-C Refractories: An Overview MgO-C refractories, composed of magnesia (MgO) and carbon (C), represent a class of high-performance materials renowned for their exceptional thermal and chemical stability. The synergy between magnesia and carbon endows these refractories with unique properties, making them ideal for withstanding extreme temperatures and corrosive environments.

Composition of MgO-C Refractories The composition of MgO-C refractories typically comprises magnesia, graphite, and various additives. Magnesia serves as the primary constituent, providing high refractoriness and resistance to chemical attack. Carbon, in the form of graphite, enhances the material's thermal shock resistance and mechanical strength.

Properties of MgO-C Refractories MgO-C refractories exhibit a myriad of superior properties, including high thermal conductivity, excellent slag resistance, low thermal expansion, and superior erosion resistance. These properties make them suitable for a wide range of applications in industries such as steelmaking, non-ferrous metallurgy, cement production, and petrochemical refining.

Applications of MgO-C Refractories

Steelmaking Industry In the steelmaking industry, MgO-C refractories find extensive use in the construction of ladles, converters, and electric arc furnaces. Their excellent thermal shock resistance and erosion resistance make them indispensable for lining applications subjected to rapid temperature fluctuations and corrosive slags.

Non-Ferrous Metallurgy In non-ferrous metallurgical processes such as copper smelting and aluminum production, MgO-C refractories are favored for their ability to withstand the corrosive effects of molten metals and slags. Their superior thermal stability and resistance to chemical attack ensure prolonged service life and reduced downtime in critical processing units.

Cement Production The cement industry relies on MgO-C refractories for lining rotary kilns and other high-temperature equipment involved in clinker production. These refractories withstand the extreme temperatures and abrasive conditions prevalent in cement kilns, ensuring uninterrupted operation and enhanced efficiency.

Petrochemical Refining In petrochemical refining operations, where high temperatures and aggressive chemical environments are commonplace, MgO-C refractories play a vital role in furnace linings, reactor vessels, and other process equipment. Their resistance to thermal shock and chemical corrosion make them indispensable for maintaining process integrity and minimizing downtime.

Advantages of MgO-C Refractories

Exceptional Thermal Stability MgO-C refractories exhibit exceptional thermal stability, retaining their structural integrity even at elevated temperatures. This property ensures consistent performance and prolonged service life in high-temperature applications.

Superior Erosion Resistance The incorporation of carbon in MgO-C refractories imparts superior erosion resistance, allowing them to withstand the abrasive action of molten metals, slags, and corrosive gases. This attribute enhances durability and minimizes the need for frequent repairs or replacements.

Reduced Thermal Conductivity The low thermal conductivity of MgO-C refractories helps in minimizing heat losses and maintaining uniform temperature distribution within process equipment. This results in improved energy efficiency and reduced operating costs over the long term.

Enhanced Thermal Shock Resistance MgO-C refractories demonstrate excellent thermal shock resistance, enabling them to withstand rapid temperature fluctuations without mechanical failure or spalling. This property enhances reliability and extends the service life of refractory linings in dynamic operating conditions.

Revealing the Excellence of MgO-C Refractories

Unparalleled Performance in Harsh Environments MgO-C refractories excel in harsh environments characterized by high temperatures, corrosive atmospheres, and mechanical stresses. Their robust construction and superior properties make them the material of choice for critical applications where reliability and durability are paramount.

Versatility Across Industries From steelmaking and non-ferrous metallurgy to cement production and petrochemical refining, MgO-C refractories find widespread application across diverse industries. Their versatility and adaptability to varying operating conditions make them indispensable for ensuring process efficiency and productivity.

Innovative Solutions for Tomorrow's Challenges As industries continue to evolve and face new challenges, MgO-C refractories remain at the forefront of innovation, offering tailored solutions to meet the ever-changing demands of high-temperature applications. Whether it's optimizing energy efficiency, enhancing productivity, or minimizing environmental impact, MgO-C refractories pave the way for sustainable progress and technological advancement.

Frequently Asked Questions (FAQs)

1. Are MgO-C refractories suitable for applications involving corrosive slags?

Yes, MgO-C refractories exhibit excellent resistance to corrosive slags, making them ideal for such applications.

2. Can MgO-C refractories withstand rapid temperature fluctuations?

Absolutely, MgO-C refractories possess superior thermal shock resistance, enabling them to withstand rapid temperature changes without failure.

3. What advantages do MgO-C refractories offer over conventional refractory materials?

MgO-C refractories offer several advantages, including exceptional thermal stability, superior erosion resistance, reduced thermal conductivity, and enhanced thermal shock resistance.

4. Are MgO-C refractories cost-effective in the long run?

Despite their initial investment, MgO-C refractories prove to be cost-effective in the long run due to their prolonged service life and minimal maintenance requirements.

5. How do MgO-C refractories contribute to energy efficiency in industrial processes?

The low thermal conductivity of MgO-C refractories helps in minimizing heat losses, thereby improving energy efficiency and reducing operating costs.

6. Are there any environmental benefits associated with using MgO-C refractories?

Yes, MgO-C refractories contribute to environmental sustainability by promoting energy efficiency and reducing greenhouse gas emissions through optimized process performance.

Conclusion

In conclusion, MgO-C refractories stand as a testament to innovation and excellence in the field of high-temperature materials. Their unparalleled performance, versatility across industries, and innovative solutions make them indispensable for a wide range of applications. As industries strive for enhanced efficiency, productivity, and sustainability, MgO-C refractories emerge as the cornerstone of progress, paving the way for a brighter and more resilient future.

============================================

1 note

·

View note

Text

The Pinnacle of Refractory Excellence: Unrivaled Craftsmanship in Refractory Brick Manufacturing

Discover the pinnacle of refractory excellence with our unparalleled craftsmanship in refractory brick manufacturing. At Raj Ceramics, we lead the industry with our commitment to precision, quality, and innovation. Our state-of-the-art manufacturing facility utilizes cutting-edge technology and a skilled team of artisans to produce refractory bricks that exceed expectations. Our refractory bricks are engineered to withstand extreme temperatures and harsh environments, making them ideal for industrial furnaces, kilns, and other high-temperature applications.

1 note

·

View note