#Robotics and Automation Actuators Market Share

Explore tagged Tumblr posts

Text

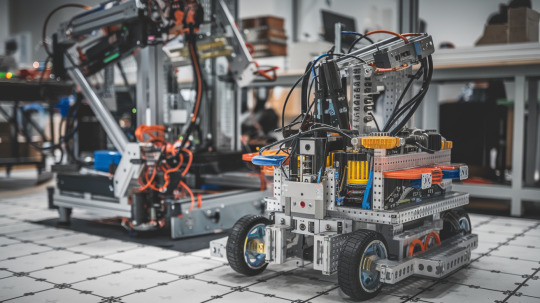

The Global Robotics and Automation Actuators Market Size was valued at USD 18.7 billion in 2022 and is estimated to reach USD 35.8 billion by 2027, growing at a CAGR of 13.9% during the forecast period. I

Driver: Ongoing technological advancements in Robotics and automation actuators

The demand for improved performance Robotics and automation actuators for use in various industries has led to the development of new and advanced actuators such as electrical actuators, compact pneumatic actuators, and explosion- proof actuators. Electrical actuators are the most advanced actuators in terms of technology. They are increasingly used in the mining, automation, aerospace & defense, and chemical industries as they are silent, clean, non-toxic, and energy competent. These actuators are more efficient than pneumatic and hydraulic actuators. Electrical actuators can be integrated with critical systems using data bus communication. They offer instant feedback of movements of end effectors and provide accurate variable control over motor speed acceleration and velocity. They are also easy to install. Electrical actuators have a long shelf life and require low maintenance, leading to low total functional costs as compared to other actuators.

Moreover, several other types of actuators, such as mini-electrical actuators, digital linear actuators, and idle speed controllers, have also been developed and introduced in the market. Thus, continuous technological advancements in actuators are expected to lead to their increased application in various industries, thereby fueling their demand across the globe. This increased demand for different types of actuators is expected to contribute to the growth of the Robotics and Automation Actuators Industry during the forecast period.

#Robotics and Automation Actuators#Robotics and Automation Actuators Market#Robotics and Automation Actuators Industry#Global Robotics and Automation Actuators Market#Robotics and Automation Actuators Market Companies#Robotics and Automation Actuators Market Size#Robotics and Automation Actuators Market Share#Robotics and Automation Actuators Market Growth#Robotics and Automation Actuators Market Statistics

0 notes

Text

Piezoelectric Materials Market Size Powering the Future with Smart Energy and Sensor Applications

In a world increasingly reliant on miniaturized electronics, energy-efficient devices, and advanced sensors, piezoelectric materials have emerged as a cornerstone of innovation. These smart materials generate an electric charge in response to mechanical stress and are the backbone of countless applications ranging from medical imaging to precision actuators and energy harvesting systems.

According to the latest Piezoelectric Materials Market Report, the global market is poised for significant expansion, driven by growing demand in automotive, healthcare, aerospace, and industrial automation sectors. These materials are not only shaping how devices sense and respond to their environment—they’re revolutionizing how they are powered and operated.

What Are Piezoelectric Materials?

Piezoelectric materials are crystalline or ceramic substances that exhibit the piezoelectric effect—producing voltage when subjected to mechanical force or vice versa. Common types include:

Lead Zirconate Titanate (PZT)

Quartz

Barium Titanate

Zinc Oxide

Polyvinylidene Fluoride (PVDF)

These materials are widely used in transducers, vibration sensors, medical ultrasound, accelerometers, actuators, and even wearable electronics.

Key Drivers Boosting Market Growth

Growth in Industrial Automation

Industries are rapidly adopting piezo-based sensors and actuators for precise motion control, condition monitoring, and robotic feedback systems. Their ultra-sensitive response makes them ideal for feedback loops in high-precision systems.

Rising Demand in Automotive Applications

From fuel injectors to knock sensors and tire pressure monitors, piezoelectric components enhance safety, efficiency, and performance in modern vehicles.

Breakthroughs in Medical Technology

Ultrasound imaging, surgical instruments, and wearable health monitors rely heavily on piezoelectric ceramics and polymers for accurate and real-time diagnostics.

Energy Harvesting for IoT Devices

One of the most promising applications is piezoelectric energy harvesting, where vibrations or pressure from the environment can be converted into electricity to power IoT nodes, remote sensors, or wearables, reducing reliance on traditional batteries.

Market Segmentation

By Material Type: Ceramics, Polymers, Composites, Crystals

By Application: Industrial & Manufacturing, Automotive, Healthcare, Consumer Electronics, Aerospace & Defense

By Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

Asia-Pacific holds the lion’s share, driven by manufacturing giants and heavy R&D investments in countries like Japan, China, and South Korea.

Key Market Trends

Lead-free piezoelectric materials gaining momentum due to environmental regulations

Increasing use of flexible and printable piezoelectric films for wearables

Integration of piezo components in MEMS (Micro-Electro-Mechanical Systems)

Piezoelectric materials in smart textiles and biomedical implants

Expansion in aerospace for smart aircraft skins and structural health monitoring

Challenges & Opportunities

While the toxicity of lead-based materials, processing complexity, and high cost of alternatives present challenges, new opportunities are opening up in:

Next-gen biomedical implants

Self-powered smart cities

Flexible consumer electronics

Renewable energy systems

Trending Report Highlights

Explore these related, high-growth technology reports to stay updated on future-ready innovations:

OLED Microdisplay Market

Photonic Integrated Circuit Market

Track Geometry Measurement System Market

Microprinting Market

Global Vision Sensor Market

Microprocessor and GPU Market

InGaAs Camera Market

Far-Field Speech and Voice Recognition Market

Functional Printing Market

Predictive Emission Monitoring System (PEMS) Market

Soft Robotics Market

Cleanroom Lighting Market

Photoelectric Sensor Market

Laser Sensors Market

Proximity Sensor Market

As the world becomes smarter, lighter, and more interconnected, the Piezoelectric Materials Market is emerging as a silent powerhouse—literally converting pressure into power and motion into measurement. With opportunities across energy harvesting, smart automation, and healthcare innovation, piezo materials are not just reacting to the future—they’re helping shape it.

0 notes

Text

Digital I-O System Market - Latest Study with Future Growth, COVID-19 Analysis

Digital I-O System Market, Trends, Business Strategies 2025-2032

The global Digital I-O System Market size was valued at US$ 1.89 billion in 2024 and is projected to reach US$ 3.01 billion by 2032, at a CAGR of 6.89% during the forecast period 2025–2032.

A digital I/O (input/output) system is a hardware module that enables computers or microcontrollers to interface with external digital signals. These systems feature configurable input and output ports for reading sensor data or controlling devices like relays and actuators. Key components include parallel/serial interfaces, USB connectivity, and specialized I/O modules with software APIs for seamless integration.

Market growth is driven by accelerating industrial automation adoption, where digital I/O systems facilitate machine-to-machine communication in smart factories. The rise of Industry 4.0 and IoT deployments has increased demand for robust signal processing solutions. While North America leads in market share (35%), Asia-Pacific shows the fastest growth (11% CAGR) due to expanding manufacturing sectors in China and India. Major players like Siemens and Emerson Electric are expanding their modular I/O portfolios to address evolving Industry 4.0 requirements.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://semiconductorinsight.com/download-sample-report/?product_id=103241

Segment Analysis:

By Type

Signal Type Segment Holds Significant Market Share Due to Its Critical Role in Industrial Automation

The market is segmented based on type into:

By Signal Type

Subtypes: Isolated, Non-isolated, and others

By Number of Inputs/Outputs

By Mounting

Subtypes: DIN Rail, Panel Mount, and others

Others

By Application

Industrial Automation Segment Dominates Due to Rising Adoption of Smart Factory Solutions

The market is segmented based on application into:

Industrial Automation

Robotics

Data Acquisition Systems

Process Control

Others

By Communication Protocol

Ethernet Segment Gains Traction Owing to High-Speed Data Transmission Capabilities

The market is segmented based on communication protocol into:

Fieldbus

Ethernet

Professional Network

Others

Regional Analysis: Digital I-O System Market

North America The North American market for digital I/O systems remains highly competitive, driven by advanced industrial automation and IoT adoption across key sectors. The United States, accounting for over 60% of regional market share, leads in the deployment of high-performance I/O modules for manufacturing, energy, and smart infrastructure. Recent investments in Industry 4.0 technologies, including $50 billion allocated for smart manufacturing initiatives, underscore the demand for reliable digital I/O solutions. However, stringent certification requirements (e.g., UL, FCC) and cybersecurity concerns pose challenges for vendors entering this mature but innovation-driven market.

Europe Europe’s digital I/O system market benefits from strong regulatory frameworks promoting industrial digitization under Industry 5.0 initiatives. Germany and France dominate demand, particularly in automotive and pharmaceutical automation where 32-bit I/O modules with real-time Ethernet protocols are preferred. The region’s emphasis on sustainability has accelerated adoption of energy-efficient systems. While the market remains consolidated among legacy players like Siemens and WAGO, opportunities exist for specialized I/O solutions compliant with EU machine safety directives (e.g., IEC 61131-2). Supply chain disruptions from recent geopolitical tensions, however, continue to impact lead times.

Asia-Pacific APAC demonstrates the highest growth potential, with China’s industrial automation sector driving 45% of regional demand for cost-effective digital I/O solutions. The “Make in India” initiative and Japan’s Society 5.0 blueprint are fostering smart factory adoption, though price sensitivity limits premium product penetration. Local manufacturers increasingly blend legacy relay systems with modular I/O configurations. While infrastructure gaps persist in Southeast Asia, government-backed smart city projects are creating new application opportunities, particularly in transportation and utilities automation.

South America Brazil’s manufacturing rebound and Argentina’s mining sector modernization are spurring selective demand for ruggedized I/O systems suited for harsh environments. However, economic instability and import dependency constrain market expansion, with most advanced solutions limited to multinational industrial facilities. Local partnerships are emerging as a key strategy for international vendors, particularly in the food processing and oil/gas verticals where explosion-proof I/O modules show growing adoption. The lack of standardized industry protocols across the region remains a persistent challenge.

Middle East & Africa MEA presents a bifurcated market landscape – Gulf Cooperation Council (GCC) nations lead in adopting high-end industrial I/O systems for oil/gas automation and smart infrastructure projects, while North Africa shows gradual uptake in textile and automotive manufacturing. The UAE’s Operation 300bn industrial strategy is driving demand for Ethernet-based I/O solutions, though budget constraints in other markets favor retrofit solutions over new installations. Political instability and inconsistent power infrastructure continue to hinder broader market development despite long-term growth prospects.

List of Key Digital I/O System Manufacturers

Emerson Electric Co. (U.S.)

Belden Inc. (U.S.)

Siemens AG (Germany)

WAGO Kontakttechnik (Germany)

ACCES I/O Products (U.S.)

Festo (Germany)

Berghof Gruppe (Germany)

KEB Automation (Germany)

Turck (Germany)

Nanda Automation Technology Jiangsu (China)

Chongqing Blue Jay Technology (China)

The global push toward Industry 4.0 and smart manufacturing is significantly boosting demand for digital I-O systems. Manufacturers are increasingly implementing automation solutions to improve productivity, reduce operational costs, and enhance quality control. Industrial automation spending surpassed $240 billion globally in recent years, with discrete manufacturing industries accounting for nearly half of this investment. Digital I-O modules serve as critical components in these automated systems, providing reliable connectivity between controllers and field devices. The automotive sector’s transition toward electric vehicle production has particularly driven adoption, with new assembly lines requiring hundreds of discrete I/O points per manufacturing cell.

The proliferation of industrial IoT deployments is creating substantial growth opportunities for digital I/O solutions. As facility operators deploy thousands of connected sensors across plants, the need for robust signal conditioning and data acquisition hardware has intensified. Digital I-O systems provide the necessary interface between legacy equipment and modern IoT platforms, enabling real-time monitoring and predictive maintenance capabilities. In critical infrastructure sectors like oil & gas, digital I/O modules help bridge the gap between existing SCADA systems and new cloud analytics platforms. The global industrial IoT market’s projected compound annual growth rate of over 15% through 2030 suggests sustained demand for these interfacing solutions.

Urban digital transformation projects worldwide are creating unprecedented demand for distributed I/O solutions. Smart traffic management systems, environmental monitoring networks, and intelligent street lighting installations all require extensive digital I/O capacity. A single smart city project may incorporate thousands of discrete I/O points across various municipal systems. The global smart city technology market’s projected growth to over $1 trillion by 2030 indicates substantial opportunities for I/O system providers. Unlike industrial applications, these municipal deployments favor low-power, wireless-enabled I/O modules with solar power options for remote installations.

The integration of edge processing capabilities into digital I/O modules creates value-added opportunities for manufacturers. Modern I/O systems now incorporate local logic execution, data filtering, and preprocessing functions that reduce network bandwidth requirements. This distributed intelligence enables real-time decision-making at the sensor level while maintaining cloud connectivity for analytics. Industrial users implementing these smart I/O solutions report 30-50% reductions in unplanned downtime through predictive maintenance capabilities. The increasing affordability of edge computing components allows I/O module vendors to offer these advanced features across various price points, accelerating adoption.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=103241

Key Questions Answered by the Digital I-O System Market Report:

What is the current market size of Global Digital I-O System Market?

Which key companies operate in Global Digital I-O System Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Browse More Reports:

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014

[+91 8087992013]

0 notes

Text

Lever Actuator Market: SWOT Analysis and Strategic Forecast 2025–2032

Lever Actuator Market, Trends, Business Strategies 2025-2032

Lever Actuator Market was valued at 613 million in 2024 and is projected to reach US$ 892 million by 2032, at a CAGR of 5.6% during the forecast period.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis https://semiconductorinsight.com/download-sample-report/?product_id=103443

MARKET INSIGHTS

The global Lever Actuator Market was valued at 613 million in 2024 and is projected to reach US$ 892 million by 2032, at a CAGR of 5.6% during the forecast period.

Lever actuators are mechanical devices designed to convert rotary motion into linear displacement through a pivoting lever mechanism. These components feature compact designs with strokes typically limited to 1mm, optimized for precise control in space-constrained applications. The actuator types include manual, automatic, and semi-automatic variants, serving diverse industrial requirements.

The market growth stems from increasing automation across manufacturing sectors and demand for precision motion control solutions. Key applications span mechanical engineering (32% market share), automotive systems (21%), and aerospace (18%) as per 2024 data. Recent material innovations have enhanced durability, with manufacturers like SMC Corporation and Parker Hannifin introducing corrosion-resistant aluminum alloys for harsh environments. The Asia-Pacific region dominates demand (42% market share), driven by China’s expanding industrial automation sector which grew 8.3% year-over-year in Q1 2024.

List of Key Lever Actuator Companies Profiled

SMC Corporation (Japan)

Parker Hannifin (U.S.)

Festo (Germany)

Rotork (U.K.)

Johnson Electric (Hong Kong)

Thomson Industries (U.S.)

SCHUNK (Germany)

Linak (Denmark)

Tolomatic (U.S.)

General Electric Company (U.S.)

DEZURIK (U.S.)

Assured Automation (U.S.)

Segment Analysis:

By Type

Automatic Lever Actuators Drive Market Growth Due to High Efficiency and Precision Control

The market is segmented based on type into:

Manual

Automatic

Semi-Automatic

By Application

Mechanical Engineering Leads Due to Widespread Use in Industrial Automation

The market is segmented based on application into:

Mechanical Engineering

Automotive Industry

Aerospace

Oil and Gas

Medical Technology

By End User

Manufacturing Sector Dominates Due to High Demand in Production Lines

The market is segmented based on end user into:

Manufacturing

Construction

Healthcare

Energy

Regional Analysis: Lever Actuator Market

North America The lever actuator market in North America is characterized by high adoption rates in advanced manufacturing, automotive, and aerospace sectors. The U.S. remains the dominant player, contributing over 65% of the regional market share, driven by strong industrial automation trends and R&D investments. Stringent efficiency and safety standards push manufacturers toward precision-engineered lever actuators, notably in robotics and medical device applications. However, supply chain disruptions and fluctuating raw material costs pose challenges. Key companies like Parker Hannifin and Thomson Industries are driving innovations in compact, high-torque lever actuators tailored for specialized applications.

Europe Europe’s lever actuator market thrives on technological advancements and regulatory compliance, particularly in Germany and France. The region holds approximately 25% of the global market, with growing demand from renewable energy and smart manufacturing sectors. EU machinery directives mandate enhanced actuator precision, fostering adoption of automated and semi-automatic lever actuators. Local players like Festo and SCHUNK lead in energy-efficient designs. While labor costs and economic uncertainties in Southern Europe slightly hinder growth, Northern Europe’s strong R&D ecosystem ensures sustained innovation in smart actuator solutions.

Asia-Pacific Asia-Pacific dominates the global lever actuator market, accounting for nearly 40% of worldwide demand. China’s manufacturing expansion and India’s “Make in India” initiative fuel growth, particularly in automotive and construction applications. Japan and South Korea remain innovation hubs for compact actuator designs. Though price sensitivity favors manual lever actuators in developing nations, rising labor costs are accelerating automation adoption. Supply chain localization by global players like SMC Corporation and increasing OEM partnerships signal strong future growth potential across the region.

South America The South American lever actuator market shows moderate growth, primarily led by Brazil’s agricultural machinery and oil & gas sectors. Infrastructure constraints and economic instability have slowed adoption compared to other regions. Most demand comes from replacement rather than new installations. However, mining sector modernizations in Chile and Peru present emerging opportunities. Local manufacturers focus on cost-effective manual actuators, while imported automated solutions gain traction in multinational industrial facilities. The market remains price-driven with limited technological penetration beyond urban industrial centers.

Middle East & Africa This region represents the smallest but fastest-growing lever actuator market (<5% global share). Oil & gas applications in GCC countries drive demand for rugged actuators, while infrastructure projects in Turkey and South Africa boost construction-related usage. The lack of local manufacturing makes the market import-dependent. Though adoption lags behind global averages, increasing industrial automation and smart city initiatives in the UAE and Saudi Arabia signal future potential. Market education about actuator benefits remains crucial to overcoming traditional mechanical system preferences.

MARKET DYNAMICS

Device manufacturers across industries continue demanding smaller form factors without sacrificing performance. This creates engineering challenges as actuator designers balance shrinking footprints against force output and cycle life requirements. The medical technology sector exemplifies this trend, where new surgical tools require sub-10mm actuators capable of sustaining 50,000+ operational cycles. Meeting these specifications while maintaining cost competitiveness has forced manufacturers to invest heavily in advanced materials and precision manufacturing techniques, with R&D budgets increasing an average of 22% annually across leading firms.

As demand grows, the industry faces a shortage of qualified personnel across engineering and production roles. Specialized positions in precision mechatronics and motion control design remain particularly difficult to fill, with over 35% of manufacturers reporting extended vacancies for these critical roles. This skills shortage comes at a crucial time, as companies attempt to scale production to meet booming demand from automation projects. Many firms are now partnering with technical schools to develop specialized training programs, but these initiatives typically require 2-3 years before yielding results.

The integration of IoT capabilities presents a significant growth avenue for lever actuator manufacturers. Smart actuators incorporating sensors and connectivity allow predictive maintenance and real-time performance monitoring, reducing downtime in industrial applications. A recent survey of manufacturing plants showed facilities using smart actuators achieved 30% fewer unplanned maintenance events compared to conventional models. As Industry 4.0 adoption accelerates, the premium pricing potential of these intelligent systems – typically 25-40% above standard models – creates attractive margin opportunities for forward-thinking manufacturers.

With millions of lever actuators installed across industries, manufacturers are developing lucrative service offerings. Preventive maintenance programs, repair services, and retrofit kits for legacy systems now contribute over 15% of revenue for some leading suppliers. The automotive sector particularly demonstrates this potential, where actuator replacement cycles typically occur every 5-7 years in heavy-use applications. One European manufacturer recently grew its aftermarket business by 40% by offering customized service plans aligned with customer maintenance schedules, demonstrating the untapped potential in this segment.

Advances in composite materials and surface treatments are expanding performance boundaries for lever actuators. New ceramic-coated bearings and graphene-enhanced components now allow operation in extreme environments previously inaccessible to conventional designs. The aerospace sector has been an early adopter, with next-generation actuator designs achieving weight reductions of 30% while maintaining strength characteristics. These material innovations also benefit renewable energy applications, where corrosion-resistant variants now withstand coastal environments that previously limited offshore wind turbine deployments.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=103443

What is the current market size of Global Lever Actuator Market?

Which key companies operate in Global Lever Actuator Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Related Reports:https://semiconductorblogs21.blogspot.com/2025/07/embedded-ufs-market-swot-analysis-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/universal-flash-storage-ufs-controllers.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/optical-signal-controller-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/solar-tracking-control-market-demand.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/digital-volume-card-market-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/graphic-to-digital-converter-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/inline-system-market-emerging-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/gas-scrubbers-for-semiconductor-market_11.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/full-set-of-protection-plate-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/channel-coil-drive-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/diamond-scriber-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/wavelength-stabilisation-diode-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/acoustic-vector-sensor-market-strategic.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/single-axis-tracker-market-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/single-axis-tracker-market-trends.html

CONTACT US: City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 [+91 8087992013] [email protected]

0 notes

Text

Linear Actuator Market in China Surges with Robotics and Smart Factory Trends

The global linear actuator market was valued at USD 52.67 billion in 2023 and is projected to reach USD 94.3 billion by 2030, registering a CAGR of 8.9% from 2024 to 2030. A key driver behind this growth is the rapid advancement of industrial automation and robotics.

Linear actuators serve as critical electromechanical devices that convert rotational motion into linear movement, allowing for precise control across a broad spectrum of applications. As industries increasingly prioritize efficiency, accuracy, and productivity, linear actuators are being widely integrated into automated systems. Their ability to deliver controlled positioning, as well as push, pull, and lift capabilities, makes them indispensable in robotic arms, conveyor belts, assembly lines, and material handling systems.

In the aerospace and defense sectors, linear actuators are vital for high-performance applications requiring consistent and precise motion control. These industries demand solutions that not only deliver accurate responsiveness but also contribute to weight reduction and improved safety standards.

Key Market Insights:

Regional Outlook: North America led the global market, capturing a revenue share of 34.8% in 2023. The region's strong demand is fueled by the widespread implementation of automation technologies in sectors such as aerospace and automotive.

Technology Segment: The mechanical actuator segment held the largest market share at 36.5% in 2023. These actuators, which convert power into physical movement, are foundational to the operation of most automated machinery.

Order a free sample PDF of the Linear Actuator Market Intelligence Study, published by Grand View Research.

Market Size & Forecast

2023 Market Size: USD 52.67 Billion

2030 Projected Market Size: USD 94.3 Billion

CAGR (2025-2030): 8.9%

North America: Largest market in 2023

Asia Pacific: Fastest growing market

Key Companies & Market Share Insights

Some of the leading companies active in this market include Actuonix Motion Devices, BISHOP-WISECARVER, ElectroCraft, Emerson Electric Co., and IAI America, Inc.

Emerson Electric Co. maintains a strong presence across diverse sectors such as industrial automation, manufacturing, and process control. Their extensive industrial reach enables them to supply linear actuators suitable for a wide array of applications.

IAI America, Inc. integrates cutting-edge technologies into its linear actuators, featuring intelligent automation capabilities, sophisticated control systems, and high-precision mechanical designs.

Among the emerging participants in the linear actuator industry are Tolomatic, Inc., Firgelli Automations, Rollon Group, and Progressive Automations, Inc.

Progressive Automations Inc. specializes in producing electric linear actuators, which find utility in various applications including marine, agriculture, home automation, and medical equipment.

Rollon Group is dedicated to the production of linear motion systems, encompassing actuators and linear guides, tailored for use in robotics, automation, and other industrial domains.

Key Players

Progressive Automations Inc.

Rollon Corp.

SMC Corporation

TiMOTION Technology Co. Ltd.

Tolomatic USA

Ultra Motion

Venture MFG. Co.

Explore Horizon Databook – The world's most expansive market intelligence platform developed by Grand View Research.

Conclusion

The linear actuator market is expanding, primarily driven by increasing industrial automation and robotics adoption. North America currently leads, while the Asia Pacific region is expected to show rapid growth. Mechanically operated actuators dominate, though hydraulic types are also gaining traction. These actuators are vital for precise linear motion across diverse applications, including smart homes, aerospace, and electric vehicles. The market is dynamic, marked by continuous innovation, integration with smart technologies, and significant merger and acquisition activities.

0 notes

Text

Transforming the Global Industrial Automation Market Through AI and IoT

The Global Industrial Automation and Control Systems Market is expected to reach USD 418.01 billion by 2032, at a CAGR of 9.8% during the forecast period 2022 to 2032.

Industrial Automation and Control Systems (IACS)

Industrial Automation and Control Systems (IACS) automate and monitor processes across industries like manufacturing, energy, and transportation using sensors, actuators, and controllers. They improve efficiency and provide real-time data for better decision-making. However, as these systems are increasingly connected, cybersecurity has become a major concern for ensuring safe and reliable operations.

This study gives a detailed analysis of drivers, restrains, opportunities and challenges limiting the market expansion of Industrial Automation and Control Systems market. The survey included a diverse set of players, including a balance of leading and growing manufacturers for business profiling, such as;

Siemens AG, ABB Ltd., Emerson Electric Co., Schneider Electric SE, Rockwell Automation, Inc., Honeywell International Inc., Mitsubishi Electric Corporation, Yokogawa Electric Corporation, General Electric Company, Omron Corporation, Bosch Rexroth AG, Johnson Controls International plc, Fanuc Corporation, Kuka AG, Danaher Corporation.

Our expert team is consistently working on updated data and information on the key player's related business processes that value the market for future strategies and predictions

Get Access to a Free Copy of Our Latest Sample Report - https://www.sphericalinsights.com/request-sample/1834

Market Segmentation:

By Component

HMI

Industrial Robots

Control Valves

Sensors

Others

By Control System

DCS

PLC

SCADA

Others

Covered in this Report:

1. Go-to-market Strategy. 2. Neutral perspective on the market performance. 3. Development trends, competitive landscape analysis, supply side analysis, demand side analysis, year-on-year growth, competitive benchmarking, vendor identification, QMI quadrant, and other significant analysis, as well as development status. 4. Customized regional/country reports as per request and country level analysis. 5. Potential & niche segments and regions exhibiting promising growth covered. 6.Analysis of Market Size (historical and forecast), Total Addressable Market (TAM), Serviceable Available Market (SAM), Serviceable Obtainable Market (SOM), Market Growth, Technological Trends, Market Share, Market Dynamics, Competitive Landscape and Major Players (Innovators, Start-ups, Laggard, and Pioneer).

Buy this report now:- https://www.sphericalinsights.com/checkout/1834

Industry Developments:

In September 2022, Flexware Innovation, Inc., a systems integrator specializing in manufacturing, has been acquired by Hitachi, Ltd. This acquisition will bolster Hitachi's capabilities in MES, SCADA, Business Intelligence (BI), Software Development, and ERP implementation in North America, as well as accelerate digitalization efforts in partnership with JR Automation, which is engaged in robotic systems integration and automation.

Regional Analysis for Industrial Automation and Control Systems Market:

✫ North America: (U.S., Canada, Mexico) ✫ Europe: (U.K., Italy, Germany, Russia, France, Spain, The Netherlands and Rest of Europe) ✫ Asia-Pacific: (India, Japan, China, South Korea, Australia, Indonesia Rest of Asia Pacific) ✫ South America: (Colombia, Brazil, Argentina, Rest of South America) ✫ Middle East & Africa: (Saudi Arabia, U.A.E., South Africa, Rest of Middle East & Africa)

Benefits of the Report:

⏩ A descriptive analysis of demand-supply gap, market size estimation, SWOT analysis, PESTEL Analysis and forecast in the global market. ⏩ Top-down and bottom-up approach for regional analysis ⏩ Porter’s five forces model gives an in-depth analysis of buyers and suppliers, threats of new entrants & substitutes and competition amongst the key market players. ⏩ By understanding the value chain analysis, the stakeholders can get a clear and detailed picture of this Market

Insightful inquiry before buying:- https://www.sphericalinsights.com/inquiry-before-buying/1834

Frequently asked questions:

➥ What is the market size of the Industrial Automation and Control Systems market? ➥ What is the market growth rate of the Industrial Automation and Control Systems market? ➥ What are the Industrial Automation and Control Systems market opportunities and threats faced by the vendors in the global Industrial Automation and Control Systems Industry? ➥ Which application/end-user or product type may seek incremental growth prospects? What is the market share of each type and application? ➥ What focused approach and constraints are holding the Industrial Automation and Control Systems market? ➥ What are the different sales, marketing, and distribution channels in the global industry?

Unlock the full report now! @ https://www.sphericalinsights.com/reports/industrial-automation-and-control-systems-market

Related Reports:

https://www.sphericalinsights.com/jp/reports/germany-defoamers-market

https://www.sphericalinsights.com/jp/reports/spain-hyperpigmentation-treatment-market

https://www.sphericalinsights.com/jp/reports/spain-burn-care-market

https://www.sphericalinsights.com/jp/reports/united-states-semiochemicals-market

https://www.sphericalinsights.com/jp/reports/united-states-biguanide-market

https://www.sphericalinsights.com/fr/reports/electronic-shutter-technology-market

https://www.sphericalinsights.com/fr/reports/renewable-drones-market

https://www.sphericalinsights.com/fr/reports/kinetic-inductance-detectors-kids-market

https://www.sphericalinsights.com/fr/reports/lifepo4-energy-storage-system-market

https://www.sphericalinsights.com/fr/reports/boom-angle-indicator-market

https://www.sphericalinsights.com/zh/reports/radiopharmaceutical-preclinical-cro-market

https://www.sphericalinsights.com/zh/reports/inhalation-cdmo-market

https://www.sphericalinsights.com/zh/reports/south-africa-prefilled-syringes-market

https://www.sphericalinsights.com/zh/reports/australia-curtains-and-window-blinds-market

https://www.sphericalinsights.com/zh/reports/south-africa-disposable-blood-bags-market

https://www.sphericalinsights.com/ko/reports/japan-paper-bag-market

https://www.sphericalinsights.com/ko/reports/canada-water-and-wastewater-treatment-market

https://www.sphericalinsights.com/ko/reports/canada-self-monitoring-blood-glucose-market

https://www.sphericalinsights.com/ko/reports/singapore-plant-protein-market

https://www.sphericalinsights.com/ko/reports/singapore-health-and-wellness-market

https://www.sphericalinsights.com/reports/minimal-residual-disease-mrd-testing-market

https://www.sphericalinsights.com/reports/liquid-biopsy-market

https://www.sphericalinsights.com/reports/ringworm-treatment-market

https://www.sphericalinsights.com/reports/sinus-dilation-devices-market

https://www.sphericalinsights.com/reports/ophthalmic-equipment-market

About the Spherical Insights

Spherical Insights is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

Contact Us:

Company Name: Spherical Insights

Email: [email protected]

Phone: +1 303 800 4326 (US)

Follow Us: LinkedIn | Facebook | Twitter

#Industrial Automation and Control Systems Market#Global Industrial Automation and Control Systems Market#Industrial Automation and Control Systems Market Size#Industrial Automation and Control Systems Market Share

0 notes

Text

Haptic Feedback Systems Transforming Digital Experiences Worldwide

The global haptic technology market, valued at USD 10.2 Bn in 2023, is poised for remarkable growth. Projected to expand at a CAGR of 10.5% from 2024 to 2034, the market is expected to reach USD 30.5 Bn by the end of 2034, driven by the rising demand for immersive user experiences and technological integration across various industries.

Market Overview: Haptic technology simulates the sensation of touch using tactile feedback, transforming how humans interact with machines and digital environments. Its applications span consumer electronics, automotive, healthcare, virtual and augmented reality, aviation, and industrial automation.

From vibrating smartphone screens to immersive gaming controllers and surgical simulators, haptic feedback has become a cornerstone of next-gen user interfaces. As industries strive for greater human-machine interaction, the need for real-time tactile response is accelerating the growth of haptic-enabled solutions globally.

Market Drivers & Trends

1. Immersive Consumer Experience

The rise of smartphones, wearables, and gaming devices with touch-enabled features is boosting demand for enhanced, intuitive user interfaces. Haptic feedback adds realism and emotional engagement especially in gaming, where controllers replicate tactile sensations such as tension and impact.

2. VR/AR Expansion

As virtual reality (VR) and augmented reality (AR) technologies gain mainstream adoption, haptic solutions are crucial for delivering lifelike sensations. Applications include military simulations, flight training, remote education, and virtual commerce. Haptics bridges the sensory gap between digital visuals and physical feedback, improving user retention and satisfaction.

3. Automotive Integration

The surge in electric vehicles (EVs) and advanced driver-assistance systems (ADAS) has created new opportunities for haptic interfaces in infotainment systems, dashboards, and steering wheels. By reducing driver distraction and improving control, tactile feedback contributes to safer driving experiences.

4. Healthcare Innovation

Haptic technology is increasingly used in surgical simulation and telemedicine, offering precision and realism in remote diagnostics and robotic-assisted surgeries. It allows medical professionals to feel anatomical structures virtually, improving outcomes and training effectiveness.

Latest Market Trends

Active haptic devices are dominating the market, comprising over 61.6% share in 2023. These devices provide real-time, dynamic feedback in wearables, AR glasses, and smartphones.

Tactile feedback leads the feedback type segment with an 85.9% share, being preferred in consumer and automotive interfaces due to its efficiency in communicating alerts without distracting the user visually.

Technological breakthroughs in low-power piezo actuators, multi-modal haptic SDKs, and miniaturized sensors are transforming device capabilities.

Gain a preview of important insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=16538

Key Players and Industry Leaders

Prominent companies shaping the haptic technology landscape include:

AITO BV

Boréas Technologies

Cirrus Logic Inc.

hap2U

Immersion Corporation

Johnson Electric Holdings Limited

KEMET Corporation

Microchip Technology Inc.

onsemi

Renesas Electronics Corporation

Synaptics Incorporated

TDK Corporation

Texas Instruments Incorporated

Other Key Players

These players are heavily investing in R&D and forming strategic alliances to introduce next-generation haptic solutions tailored for emerging markets.

Recent Developments

October 2023: AITO BV unveiled a compact integrated touchpad with class-leading haptic performance, optimized for laptops and smart devices.

October 2023: Boréas Technologies launched HapticStudio, a developer-friendly SDK that allows designers to build customized tactile effects for CapDrive piezo drivers.

September 2023: TDK Corporation introduced the PowerHap development kit, enabling rapid prototyping of haptic-enabled applications with ultra-fast response time.

These innovations aim to democratize access to high-performance haptics across multiple device categories.

Market Opportunities

Education and E-learning: Virtual classrooms integrated with haptic tools can simulate hands-on experiments and environments, improving remote learning outcomes.

Commercial and Industrial Applications: Haptics are being tested in robotic arms, industrial automation, and collaborative robots (cobots) to improve precision in complex tasks.

E-commerce and Retail: Immersive online shopping experiences that let consumers “feel” products before buying are becoming possible through AR + haptic synergies.

Gaming and Entertainment: The integration of advanced haptics into VR headsets and gaming gear presents a massive growth opportunity for startups and developers.

Future Outlook

By 2034, haptic technology will be an essential part of digital transformation across industries. It will redefine how people interact with content, machines, and environments. Future advancements in AI, machine learning, and 5G will further boost haptic responsiveness, efficiency, and scalability.

With rising demand for connected devices and interactive interfaces, market players are expected to expand into untapped regions, develop cost-efficient solutions, and leverage software-hardware co-design to optimize tactile experiences.

Market Segmentation

By Haptic Devices

Active (Dominant Segment)

Passive

By Component

Hardware (Actuators, LRAs, ERMs, Piezoelectric, Drivers)

Software

By Touchscreen Type

Capacitive

Resistive

Others

By Feedback Type

Tactile (Dominant Segment)

Force

By End-use Industry

Consumer Electronics (Smartphones, Tablets, Wearables, Gaming)

Automotive & Transportation (ADAS, Dashboards)

Healthcare (Surgical Simulations)

Education & Research

Commercial & Industrial

Regional Insights

Asia Pacific: Market Leader

In 2023, Asia Pacific held a 40.8% market share, emerging as the dominant region. The growing adoption of smartphones, gaming consoles, and wearables—especially in China, Japan, and South Korea—is fueling demand. Additionally, automotive manufacturers in the region are embedding haptic technology into EV dashboards and infotainment systems for better driver engagement.

North America and Europe

Strong presence of key market players, coupled with advanced healthcare systems and high consumer spending on gaming and electronics, make these regions ripe for further growth.

Why Buy This Report?

Comprehensive industry analysis from 2020 to 2034

Segmentation insights by device, feedback type, application, and region

In-depth company profiles with financial and strategic overviews

Recent developments and R&D pipeline evaluations

Market forecast in terms of revenue (US$ Bn) and volume (Million Units)

Key drivers, opportunities, and challenges mapped with Porter’s Five Forces analysis

0 notes

Text

Integrated Automation System (IAS) Market, Industry Recent Developments and Latest Technology 2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Integrated Automation System (IAS) Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Integrated Automation System (IAS) Market Share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Integrated Automation System (IAS) Market?

The integrated automation system (IAS) market is expected to grow at a CAGR of 5.6% during the forecast period of 2024 to 2032.

What are Integrated Automation System (IAS)?

An Integrated Automation System (IAS) is an advanced technological solution engineered to unify and enhance diverse industrial processes within a single integrated framework. Through the integration of control systems, sensors, actuators, and software applications, IAS enables smooth communication and coordination among various components and subsystems, facilitating efficient monitoring, management, and control of activities such as production, logistics, and quality assurance. With its capacity to consolidate data, offer real-time insights, and automate repetitive tasks, IAS boosts productivity, lowers operational expenses, and enhances overall efficiency across a broad spectrum of industrial operations.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1880

What are the growth prospects and trends in the Integrated Automation System (IAS) industry?

The integrated automation system (IAS) market growth is driven by various factors. The market for Integrated Automation Systems (IAS) is experiencing swift expansion, fueled by the growing demand for efficient industrial automation and streamlined operational workflows. With businesses increasingly prioritizing enhanced productivity and cost-effectiveness, IAS solutions have become indispensable across diverse sectors such as manufacturing, energy, automotive, and healthcare. These systems offer seamless integration of control mechanisms, sensors, and software applications, facilitating optimized production, logistics, and quality control processes. Moreover, the increasing adoption of Industry 4.0 principles and the Internet of Things (IoT) further accelerates the IAS market growth, as organizations acknowledge the benefits of centralized data management, real-time monitoring, and predictive maintenance capabilities provided by these sophisticated automation systems. Hence, all these factors contribute to integrated automation system (IAS) market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Component:

Hardware

Software

Services

Type:

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

Supervisory Control and Data Acquisition (SCADA)

Human Machine Interface (HMI)

Others

Industry Vertical:

Manufacturing

Oil and Gas

Energy and Utilities

Automotive

Aerospace and Defense

Chemicals

Pharmaceutical and Healthcare

Food and Beverage

Others

End User:

Small and Medium Enterprises (SMEs)

Large Enterprises

Application:

Process Automation

Discrete Automation

Connectivity:

Wired

Wireless

Functionality:

Plant Automation

Machine Automation

Deployment:

On-premises

Cloud-based

End-Use:

Industrial

Commercial

Solution:

Control Systems

Robotics

MES (Manufacturing Execution System)

Industrial IoT (Internet of Things)

Others

Service:

Consulting

Integration and Implementation

Maintenance and Support

Industry 4.0 Enabler:

Big Data Analytics

Artificial Intelligence

Industrial Cybersecurity

Cloud Computing

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

India

Japan

South Korea

Australia

New Zealand

ASEAN

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

United Arab Emirates

South Africa

Egypt

Israel

Rest of MEA.

Who are the key players operating in the industry?

The report covers the major market players including:

Siemens AG

Schneider Electric SE

Emerson Electric Co.

Honeywell International Inc.

Rockwell Automation Inc.

Mitsubishi Electric Corporation

Yokogawa Electric Corporation

Omron Corporation

Bosch Rexroth AG

General Electric Company

Johnson Controls International plc

Fanuc Corporation

Schneider Electric SE

Hitachi Ltd.

View Full Report: https://www.reportsandinsights.com/report/Integrated Automation System (IAS)-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

The Global Robotics and Automation Actuators Market Size was valued at USD 18.7 billion in 2022 and is estimated to reach USD 35.8 billion by 2027, growing at a CAGR of 13.9% during the forecast period. Industries across all the regions are expected to adopt robotics and automation actuators that have simple designs, are easy to operate, and are cost-effective.

Driver: Ongoing technological advancements in Robotics and automation actuators

The demand for improved performance Robotics and automation actuators for use in various industries has led to the development of new and advanced actuators such as electrical actuators, compact pneumatic actuators, and explosion- proof actuators. Electrical actuators are the most advanced actuators in terms of technology. They are increasingly used in the mining, automation, aerospace & defense, and chemical industries as they are silent, clean, non-toxic, and energy competent. These actuators are more efficient than pneumatic and hydraulic actuators. Electrical actuators can be integrated with critical systems using data bus communication. They offer instant feedback of movements of end effectors and provide accurate variable control over motor speed acceleration and velocity. They are also easy to install. Electrical actuators have a long shelf life and require low maintenance, leading to low total functional costs as compared to other actuators.

Moreover, several other types of actuators, such as mini-electrical actuators, digital linear actuators, and idle speed controllers, have also been developed and introduced in the market. Thus, continuous technological advancements in actuators are expected to lead to their increased application in various industries, thereby fueling their demand across the globe. This increased demand for different types of actuators is expected to contribute to the growth of the Robotics and Automation Actuators Industry during the forecast period.

#Robotics and Automation Actuators#Robotics and Automation Actuators Market#Robotics and Automation Actuators Industry#Global Robotics and Automation Actuators Market#Robotics and Automation Actuators Market Companies#Robotics and Automation Actuators Market Size#Robotics and Automation Actuators Market Share#Robotics and Automation Actuators Market Growth#Robotics and Automation Actuators Market Statistics

0 notes

Text

0 notes

Text

Adaptive Robot Market Size Revolutionizing Automation with Flexibility and Intelligence by 2030

The Adaptive Robot Market Size is witnessing robust expansion as industries seek intelligent, flexible robotic systems capable of adjusting to dynamic tasks and environments. According to Market Size Research Future, the global market for adaptive robots is projected to reach USD 18.7 billion by 2030, growing at a CAGR of 23.5% during the forecast period (2023–2030).

Overview

Adaptive robots are designed with the ability to learn from their surroundings and respond intelligently to changes in real-time. Unlike traditional robots, which are limited to repetitive, pre-programmed tasks, adaptive robots utilize sensors, AI, machine learning, and computer vision to modify their behavior and perform complex operations.

This flexibility makes them ideal for collaborative tasks, dynamic manufacturing environments, and applications where human-robot interaction is essential. The surge in demand for automation, the proliferation of smart factories, and advancements in AI technologies are major drivers of this market's growth.

Market Size Segmentation

By Component:

Hardware

Sensors

Actuators

Controllers

Software

AI & Machine Learning Algorithms

Real-Time Processing Software

Services

Integration & Deployment

Maintenance & Support

Training

By Mobility:

Fixed

Mobile

By End-Use Industry:

Automotive

Electronics & Semiconductors

Healthcare

Logistics

Aerospace & Defense

Consumer Goods

Others

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Market Size Trends

1. Human-Robot Collaboration (Cobots)

The demand for collaborative robots that can safely work alongside humans is accelerating. Adaptive robots are being integrated into workspaces to perform tasks such as assembly, inspection, and packaging while enhancing safety and productivity.

2. AI Integration in Robotics

Advancements in artificial intelligence are enabling adaptive robots to perform complex decision-making, identify objects, and navigate unstructured environments with minimal human intervention.

3. Rise of Smart Manufacturing

Industry 4.0 initiatives are pushing manufacturers to adopt adaptive robots that offer predictive maintenance, operational flexibility, and data-driven insights.

4. Customization & Modularity

Businesses increasingly prefer robots with modular designs that can be quickly reprogrammed or retooled for new tasks—making adaptive robots the preferred choice for modern production lines.

Segment Insights

By Component:

The hardware segment holds the largest market share due to the growing deployment of advanced robotic arms, sensors, and vision systems. However, the software segment is gaining momentum, driven by rising demand for AI-enabled real-time decision-making and adaptive learning systems.

By Mobility:

Mobile adaptive robots are expected to grow at a faster pace than fixed systems, especially in logistics and warehousing sectors, where flexibility and autonomous navigation are critical.

By End-Use Industry:

The automotive industry remains the dominant end-user, leveraging adaptive robots for precision assembly and inspection. The healthcare sector is also emerging as a key adopter, using robots for rehabilitation, surgery assistance, and patient care.

End-User Insights

Automotive:

Adaptive robots assist in complex assembly, surface inspection, and part handling. They enhance efficiency, minimize downtime, and adapt to frequent product design changes.

Healthcare:

From physical therapy and elder care to surgical assistance, adaptive robots are transforming patient care through real-time adaptability and safety.

Electronics:

These robots are employed for intricate assembly of small components, quality testing, and efficient handling of delicate materials.

Logistics:

In dynamic warehouse environments, adaptive robots optimize inventory picking, packaging, and delivery with minimal human oversight.

Key Players

Leading technology firms are investing in R&D to enhance robot cognition, mobility, and task automation. Major players in the adaptive robot market include:

ABB Ltd. – Offers adaptive industrial robots with AI-driven motion control and collaborative safety features.

FANUC Corporation – Provides flexible robots with self-learning capabilities for manufacturing and inspection.

KUKA AG – Known for smart robots designed for logistics and heavy industrial applications.

Universal Robots – A pioneer in collaborative robotics, focusing on ease of use and deployment across SMEs.

Yaskawa Electric Corporation – Supplies adaptive robotics solutions for complex material handling and automation systems.

Omron Corporation – Integrates AI, vision, and motion control in adaptive robotics for electronics and automotive sectors.

Future Outlook

The adaptive robot market is positioned for rapid transformation over the next decade. As businesses aim to reduce operational complexity and boost production agility, adaptive robots will become essential tools in smart factories, hospitals, and logistics hubs.

The convergence of AI, 5G, and edge computing will further elevate robotic capabilities, enabling adaptive robots to function with near-human intelligence and real-time responsiveness. Regulatory support for workplace safety and increasing labor shortages will also bolster market demand globally.

Trending Report Highlights

Explore other emerging markets with promising growth prospects:

Dram Module Component Market Size

Eas Antennas Market Size

Optical Time Domain Reflectometer Market Size

Acoustic Camera Market Size

Advancement in Camera Technologies Market Size

Analog And Mixed Signal Device Market Size

Atm Slide Rails Market Size

Barrier Films Flexible Electronic Market Size

Combustion Equipment Market Size

0 notes

Text

Electronic Clutch Actuators Market Size, Analyzing Trends and Projected Outlook for 2025-2032

Fortune Business Insights released the Global Electronic Clutch Actuators Market Trends Study, a comprehensive analysis of the market that spans more than 150+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

The Electronic Clutch Actuators Market is experiencing robust growth driven by the expanding globally. The Electronic Clutch Actuators Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Electronic Clutch Actuators Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Electronic Clutch Actuators Market Size, Share & Industry Analysis, By Application Type (Manual transmission, Automated Manual Transmission, Fully Automatic Transmission), By Market Type (OEM, Aftermarket), By Vehicle Type (Passenger Cars, Commercial Vehicles) and Regional Forecast 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/103649

Dominating Region:

North America

Fastest-Growing Region:

Asia-Pacific

Major Electronic Clutch Actuators Market Manufacturers covered in the market report include:

Some of the major companies that are present in the electronic clutch actuators market include WABCO, Infineon Technologies, DENSO CORPORATION, Magneti Marelli, TREMEC, ZF Friedrichshafen AG, Allison Transmission, Continental AG, Robert Bosch GmbH, Avtec, Delphi Automotive, and Schaeffler Group among the other players.

Moreover, the shifting of gear without a clutch pedal, self-adjustment by automatic clutch, and reduction in the wearing of the clutch plates are the main features of the electronic clutch actuator. These actuators provide multiple benefits such as fuel economy, safety, high durability, and reliability to the vehicle, driver as well as comfort to the passengers in the vehicle.

Geographically, the detailed analysis of consumption, revenue, market share, and growth rate of the following regions:

The Middle East and Africa (South Africa, Saudi Arabia, UAE, Israel, Egypt, etc.)

North America (United States, Mexico & Canada)

South America (Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, etc.)

Europe (Turkey, Spain, Turkey, Netherlands Denmark, Belgium, Switzerland, Germany, Russia UK, Italy, France, etc.)

Asia-Pacific (Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia).

Electronic Clutch Actuators Market Research Objectives:

- Focuses on the key manufacturers, to define, pronounce and examine the value, sales volume, market share, market competition landscape, SWOT analysis, and development plans in the next few years.

- To share comprehensive information about the key factors influencing the growth of the market (opportunities, drivers, growth potential, industry-specific challenges and risks).

- To analyze the with respect to individual future prospects, growth trends and their involvement to the total market.

- To analyze reasonable developments such as agreements, expansions new product launches, and acquisitions in the market.

- To deliberately profile the key players and systematically examine their growth strategies.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Electronic Clutch Actuators Market?

► Who are the prominent players in the Global Electronic Clutch Actuators Market?

► What is the consumer perspective in the Global Electronic Clutch Actuators Market?

► What are the key demand-side and supply-side trends in the Global Electronic Clutch Actuators Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Electronic Clutch Actuators Market?

FIVE FORCES & PESTLE ANALYSIS:

In order to better understand market conditions five forces analysis is conducted that includes the Bargaining power of buyers, Bargaining power of suppliers, Threat of new entrants, Threat of substitutes, and Threat of rivalry.

Political (Political policy and stability as well as trade, fiscal, and taxation policies)

Economical (Interest rates, employment or unemployment rates, raw material costs, and foreign exchange rates)

Social (Changing family demographics, education levels, cultural trends, attitude changes, and changes in lifestyles)

Technological (Changes in digital or mobile technology, automation, research, and development)

Legal (Employment legislation, consumer law, health, and safety, international as well as trade regulation and restrictions)

Environmental (Climate, recycling procedures, carbon footprint, waste disposal, and sustainability)

Points Covered in Table of Content of Global Electronic Clutch Actuators Market:

Chapter 01 - Electronic Clutch Actuators Market for Automotive Executive Summary

Chapter 02 - Market Overview

Chapter 03 - Key Success Factors

Chapter 04 - Global Electronic Clutch Actuators Market - Pricing Analysis

Chapter 05 - Global Electronic Clutch Actuators Market Background or History

Chapter 06 - Global Electronic Clutch Actuators Market Segmentation (e.g. Type, Application)

Chapter 07 - Key and Emerging Countries Analysis Worldwide Electronic Clutch Actuators Market.

Chapter 08 - Global Electronic Clutch Actuators Market Structure & worth Analysis

Chapter 09 - Global Electronic Clutch Actuators Market Competitive Analysis & Challenges

Chapter 10 - Assumptions and Acronyms

Chapter 11 - Electronic Clutch Actuators Market Research Methodology

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

0 notes

Text

Multi Channel Piezo Driver Market: Demand Analysis and Future Potential 2025–2032

Multi Channel Piezo Driver Market, Trends, Business Strategies 2025-2032

The global Multi Channel Piezo Driver Market size was valued at US$ 178.9 million in 2024 and is projected to reach US$ 267.4 million by 2032, at a CAGR of 5.2% during the forecast period 2025-2032

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis https://semiconductorinsight.com/download-sample-report/?product_id=103470

MARKET INSIGHTS

The global Multi Channel Piezo Driver Market size was valued at US$ 178.9 million in 2024 and is projected to reach US$ 267.4 million by 2032, at a CAGR of 5.2% during the forecast period 2025-2032. The U.S. market accounted for approximately 32% of global revenue in 2024, while China is expected to witness the fastest growth with an estimated 8.2% CAGR through 2032.

Multi Channel Piezo Drivers are precision electronic devices that control piezoelectric actuators in multiple axes simultaneously. These drivers provide low-noise, high-accuracy voltage outputs (typically -10V to +10V) for precise motion control in applications requiring nanometer-level positioning. The technology enables synchronized operation of multiple piezoelectric elements through analog control signals with gain values up to 25, making them essential for advanced motion systems.

The market growth is driven by increasing demand from semiconductor manufacturing equipment, where piezo drivers enable sub-micron precision in wafer inspection and lithography systems. Furthermore, the medical technology sector, particularly in surgical robotics and microscopy applications, is adopting multi-channel solutions for their compact form factor and precise motion control capabilities. Recent developments include PI’s launch of the E-517 multi-axis controller in 2023, featuring enhanced dynamic response for high-speed nanopositioning applications.

List of Key Multi Channel Piezo Driver Manufacturers

PI (Physik Instrumente) (Germany)

piezosystem jena GmbH (Germany)

PiezoDrive (Australia)

Piezo Direct (U.S.)

DEWALT (U.S.)

TEM Messtechnik GmbH (Germany)

Analog Technologies, Inc (U.S.)

CoreMorrow (China)

Thorlabs, Inc. (U.S.)

General Photonics Corporation (U.S.)

Boréas Technologies (Canada)

PIEZOTECHNICS GmbH (Germany)

Omega Piezo Technologies (U.S.)

ORLIN Technologies Ltd. (Israel)

Texas Instrument (U.S.)

Queensgate Instruments (UK)

Newport Corporation (U.S.)

Segment Analysis:

By Type

Rigid Displacement Segment Leads the Market Due to High Precision in Static Applications

The market is segmented based on type into:

Rigid Displacement

Subtypes: High-voltage, Low-voltage, and others

Resonant Displacement

Subtypes: Single-channel, Dual-channel, and others

By Application

Medical Technology Segment Dominates Owing to Growing Demand in Ultrasound and Micropositioning Systems

The market is segmented based on application into:

Mechanical Engineering

Automotive Industry

Aerospace

Medical Technology

Electrical Industry

By Voltage Range

0-100V Segment Holds Major Share for Low-power Piezo Actuator Applications

The market is segmented based on voltage range into:

0-100V

100-200V

Above 200V

By Channel Configuration

Dual-channel Configuration Most Popular for Basic Positioning Systems

The market is segmented based on channel configuration into:

Single-channel

Dual-channel

Multi-channel (3+)

Regional Analysis: Multi Channel Piezo Driver Market

North America The North American market for Multi Channel Piezo Drivers is driven by strong demand from industries such as aerospace, medical technology, and automotive engineering. The region benefits from substantial R&D investments, particularly in the U.S., where companies like Thorlabs and Newport Corporation are leading innovation. The U.S. accounted for approximately 38% of the regional market share in 2024, supported by advancements in precision instrumentation and automation. Canada and Mexico are also witnessing steady growth, albeit at a slower pace due to smaller industrial bases. Regulatory standards for precision and safety in manufacturing further boost adoption in this region.

Europe Europe remains a key market for Multi Channel Piezo Drivers, with Germany and France at the forefront due to their strong mechanical engineering and medical device sectors. The EU’s emphasis on high-precision manufacturing and energy efficiency aligns well with the capabilities of piezoelectric actuators, particularly in applications like industrial automation and optical systems. Companies such as PI (Physik Instrumente) and piezosystem jena GmbH dominate the competitive landscape. However, market growth faces challenges due to high production costs and stringent environmental regulations, which influence supply chain decisions.

Asia-Pacific The Asia-Pacific region is the fastest-growing market, led by China, Japan, and South Korea. China alone contributes over 45% of the regional demand, fueled by expanding electronics manufacturing and automation in sectors such as consumer robotics and semiconductor fabrication. Japan’s expertise in precision engineering reinforces its position as a key player, with companies like TEM Messtechnik GmbH driving innovation. Meanwhile, India and Southeast Asia are emerging markets, though adoption is constrained by limited awareness and access to high-end piezoelectric solutions compared to more established regions.

South America South America’s market remains nascent but shows potential, particularly in Brazil and Argentina, where industries such as oil & gas and medical technology are slowly integrating piezo-driven automation. The lack of local manufacturing capabilities means most demand is met through imports, which raises costs and limits accessibility. Economic instability further complicates sustained investment, though partnerships with international suppliers are gradually improving technology transfer.

Middle East & Africa The Middle East & Africa region is developing, with limited but growing applications in oilfield instrumentation and defense technology. The UAE and Saudi Arabia lead in adoption due to infrastructure modernization efforts, while Africa’s market remains constrained by underdeveloped industrial sectors. Despite challenges, increasing foreign investments in automation and smart manufacturing hint at future opportunities for Multi Channel Piezo Driver suppliers.

MARKET DYNAMICS

The sophisticated nature of multi-channel piezo systems presents significant implementation challenges across industries. Proper configuration requires deep expertise in both piezoelectric physics and control theory – a skillset combination that remains scarce in the industrial automation workforce. Many organizations report 6-12 month learning curves for engineering teams adopting these technologies, delaying ROI realization. The challenge is compounded by rapid technology evolution, as new driver architectures and control algorithms emerge faster than workforce training programs can adapt. This skills gap affects system performance optimization, with improperly tuned installations often operating at 60-70% of their theoretical capability.

Piezo drivers face growing competition from emerging motion technologies including voice coil actuators and magnetic levitation systems that offer comparable precision with potentially simpler integration. While piezoelectric solutions maintain advantages in stiffness and response speed, alternative technologies are closing the performance gap while offering lower voltage requirements and reduced system complexity. In medical device applications particularly, electromagnetic actuators have gained market share by eliminating high-voltage safety concerns. This competitive pressure is driving piezo system manufacturers to accelerate innovation cycles while simultaneously reducing solution footprints and power requirements.