#Roller Conveyor Systems

Explore tagged Tumblr posts

Text

0 notes

Text

Global Conveyor System Market: Size, Opportunities, and Growth Trends

The conveyor system industry is undergoing dynamic expansion fueled by advancements in automation and logistics infrastructure worldwide. This market’s strategic relevance is growing steadily across manufacturing, warehousing, and distribution sectors, underpinned by evolving market drivers and technology integration. Insightful market analysis reveals robust market growth supported by increasing demand for efficient material handling solutions globally. The Global Conveyor System Market size is estimated to be valued at USD 10.94 billion in 2025 and is expected to reach USD 16.14 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 5.7% from 2025 to 2032. Conveyor System Market Size reflects expansive industry size driven by rising automation, e-commerce expansion, and demand for optimized supply chain solutions. Market insights highlight increased investments in conveyor system innovations, impacting overall market revenue positively. The Conveyor System market report also forecasts growing adoption across market segments such as automotive, food processing, and pharmaceuticals, expanding the market scope and addressing key market challenges effectively. Get more insights on, Conveyor System Market

#Coherent Market Insights#Conveyor System#Conveyor System Market#Conveyor System Market Insights#Roller Conveyor Systems

0 notes

Text

#gravity roller conveyors#gravity conveyor rollers#gravity conveyors#gravity conveyor system#best gravity conveyor#gravity roller conveyors in Illinois

0 notes

Text

The Unsung Heroes of Modern Warehousing

Efficiency is crucial in the hectic fields of logistics and production. Whether it's handling goods across countries or completing online purchases, companies depend on backend systems that silently handle the laborious tasks. Conveyor systems stand out among them; they are crucial but frequently disregarded.

What Exactly Are Conveyor Systems?

Conveyor systems are essentially mechanical devices that move goods from one location to another. Sounds easy? Not exactly. In factories, warehouses, and distribution centres, these systems are made to maximise speed, minimise manual handling, and establish smooth operation. They can be roller conveyors, belt-driven lines, or overhead conveyors, among other types.

The Significance of Roller Conveyors

One of the most widely used kinds, roller conveyors provide a useful and affordable means of moving things, particularly in settings involving manufacturing or packing. Consider them to be highways for pallets, crates, or boxes. Because the rollers lessen friction, moving big objects requires less effort and personnel. Additionally, because they are modular, companies can add, delete, or reroute pieces in response to changing needs.

While gravity roller conveyors rely on incline and basic physics, powered roller conveyors use motors to transport objects automatically. Both kinds provide safety, speed, and consistency, things that physical labour can't always provide.

Smart Conveyor Systems' Ascent

Conveyor systems change with the industry. Smarter than ever, today's setups frequently incorporate robotics, automation software, and sensors. These intelligent technologies notify operators of maintenance requirements prior to a breakdown, track goods in real-time, and modify speeds based on load.

Conveyor systems are now the foundation of dependable, scalable operations in the cold chain, pharmaceutical, and e-commerce industries. They guarantee that goods travel from point A to point B without interruption, harm, or misunderstanding.

Choosing Trustworthy Conveyor Belt Suppliers

If you plan to set up or change your system, working with experienced conveyor belt suppliers is crucial. When choosing a conveyor, the type of material, needed speed, load weight, and available space are all crucial factors to take into account. Whether it's belt conveyors for fragile goods or roller systems for bulk movement, effective design and component selection can have a big impact on long-term performance.

0 notes

Text

Roller Conveyor in Faridabad | Vashnavi Conveyor Industry

Vashnavi Conveyor Industry offers high-quality roller conveyors in Faridabad for smooth and efficient material handling across various industrial sectors. Whether you need gravity or powered roller conveyors, our systems are engineered for durability, easy installation, and seamless movement of goods in warehouses, production lines, and distribution centers.

#Roller conveyor Faridabad#conveyor system manufacturer#Vashnavi Conveyor#gravity roller conveyor#powered roller conveyor#material handling equipment#industrial conveyors

0 notes

Text

Efficient Warehousing Starts with the Right Pallet Dispenser

In modern warehousing and logistics, efficiency is no longer optional—it’s essential. A key component in streamlining material handling operations is the pallet dispenser. Often working in tandem with a pallet stacker, this equipment automates one of the most overlooked steps in warehouse workflows: dispensing and stacking pallets.

What Is a Pallet Dispenser?

A pallet dispenser is a mechanical device designed to automatically release or stack pallets without the need for manual handling. Commonly used in distribution centers, manufacturing plants, and packaging lines, these machines reduce downtime and improve worker safety by minimizing manual lifting.

Pallet dispensers can handle wooden, plastic, and sometimes even metal pallets, and they come in various configurations—floor-mounted, overhead, or integrated into conveyor systems.

Why Warehouses Are Turning to Pallet Dispensers

As labor shortages and operational costs continue to impact supply chain dynamics, automation is becoming an integral part of warehouse optimization. Pallet dispensers, when combined with pallet stackers, can lead to significant improvements in:

Productivity: Continuous feed of pallets eliminates manual placement delays.

Safety: Reduces the risk of injuries related to lifting and moving heavy pallets.

Consistency: Ensures uniform pallet handling, reducing operational errors.

“Since we implemented a pallet dispenser and stacker combo, our warehouse throughput has improved by nearly 30%. It’s reduced both idle time and workplace injuries.” — Carlos M., Logistics Manager, Northern Freight Solutions

Pallet Dispenser vs. Pallet Stacker: Understanding the Difference

While both are used in handling pallets, their functions differ:

Integrating both systems creates a closed-loop pallet management solution, minimizing idle time and maximizing operational flow.

Use Cases Across Industries

Pallet dispensers are not industry-specific. They are used in:

Food & Beverage: For maintaining hygiene and preventing contamination through minimal contact.

Pharmaceuticals: Ensuring consistent pallet availability during automated packaging.

Retail Distribution: Speeding up order fulfillment operations.

Automotive: Managing heavy-duty pallets for parts and components.

How to Choose the Right Pallet Dispenser

Selecting the ideal pallet dispenser depends on several operational factors:

Pallet Type and Size: Compatibility with standard or custom pallet dimensions.

Capacity: Number of pallets handled per cycle or per hour.

Integration Requirements: Whether it needs to work alongside conveyors, robots, or pallet stackers.

Space Constraints: Floor-mounted vs. overhead models depending on available warehouse space.

“Choosing a dispenser that integrates easily with our conveyor line made a significant difference. It wasn’t just about the machine—it was about how well it fit into our existing layout.” — Stephanie T., Plant Supervisor, Midstate Manufacturing Co.

Maintenance and Lifecycle Cost

Though typically low-maintenance, routine checks on mechanical parts, sensors, and hydraulic components are essential for longevity. Many dispensers offer diagnostics features to alert users of wear and tear, further reducing downtime.

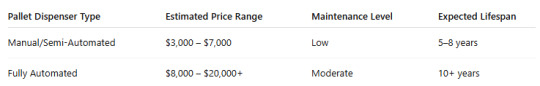

Here’s a general overview of cost expectations: Pallet Dispenser

Final Thoughts

For operations seeking to reduce manual labor, enhance safety, and improve throughput, a pallet dispenser paired with a pallet stacker offers a robust, scalable solution. With proven applications across diverse industries, it's clear that these machines are more than just convenience—they're a strategic investment in productivity.

0 notes

Text

𝐂𝐍𝐂 𝐦𝐚𝐜𝐡𝐢𝐧𝐞 𝐟𝐨𝐫 𝐜𝐮𝐭𝐭𝐢𝐧𝐠 𝐠𝐫𝐨𝐨𝐯𝐞𝐬 𝐚𝐧𝐝 𝐜𝐡𝐚𝐦𝐟𝐞𝐫𝐢𝐧𝐠 𝐭𝐡𝐞 𝐞𝐧𝐝𝐬 𝐨𝐟 𝐢𝐝𝐥𝐞𝐫 𝐫𝐨𝐥𝐥𝐞𝐫 𝐬𝐡𝐚𝐟𝐭𝐬

we have successfully automated the CNC machining process for roller shafts precisely shaping flat ends, chamfers, and grooves with unmatched efficiency and accuracy. Visit now https://en.guderoller.com

0 notes

Text

Roller Chain Repair Kit

Looking for a reliable Roller Chain Repair Kit? USA Roller Chain & Sprockets offers premium repair kits designed for quick and easy chain maintenance. Whether you need to fix industrial roller chains, conveyor systems, or agricultural equipment, our high-quality kits come with everything you need for a seamless repair. Built for durability and precision, our repair solutions ensure extended chain life and optimal performance. Shop now at USA Roller Chain & Sprockets for top-tier roller chain repair kits at competitive prices!

#conveyor systems#or agricultural equipment#aluminum coupling cover#piv chains#plastic roller chain sprockets#hollow pin chain breaker

0 notes

Text

While the terms “efficiency,” “cost-effectiveness,” and “safety” may be the keywords for retaining one’s competitive edge in modern manufacturing, the most plausible means to attain these would be with advanced technology. One such example of an advanced technological aid in improving workflow, reducing labor costs, and enhancing safety in manufacture is the Roller Conveyor System. Below are some of the amazing benefits of the roller conveyors, including companies like Yontro Mechatronic Systech that can help you realize the full benefits of this technology.

#Industrial Workstation#Roller Conveyor#Roller Conveyor System#Flat Belt Conveyor#Assembly Conveyor#Inclined Conveyor Belt

0 notes

Text

Wagner Conveyors | Poultry Equipment & Conveyor Solutions

Wagner Conveyors specializes in providing high-quality conveyor systems tailored for efficient material handling in poultry operations. Their products are designed to streamline processes, reduce labor, and enhance productivity.

Key Products:

Model A41: Ideal for loading from the middle of poultry houses, this conveyor significantly reduces litter handling time by pushing litter to the center. It’s also suitable for facilities with low ceiling heights.

Model B32: Featuring an 8-foot hopper, this conveyor is versatile for loading manure both inside and outside buildings, enhancing operational flexibility.

Model C32: Equipped with a 10-foot hopper, the C32 is designed for efficient manure loading in various settings, both indoors and outdoors.

Model IND-A41: This industrial-grade conveyor boasts a hydraulic front, allowing it to get closer to the ground. It can load 26 tons in just 4 minutes and includes a remote shutoff feature for enhanced safety and convenience.

Model A41-HF: With a hydraulic front, the A41-HF facilitates closer floor access and can load 26 tons in 7 minutes, optimizing efficiency in litter management.

Custom Models: Wagner offers custom-built conveyors to meet specific operational needs, ensuring solutions are tailored to unique requirements.

Sawdust Spreader: This equipment enables even and quick distribution of sawdust throughout turkey houses, promoting better bedding management.

Litter Plow: Designed to turn over compacted litter inside turkey houses, the litter plow aids in maintaining a healthier environment for poultry.

Grapple Buckets: Built to last, these heavy-duty grapple buckets can be customized to fit any skid steer or loader, enhancing material handling capabilities.

For more detailed information on their products and services, visit Wagner Conveyors’ official website at www.wagnerconveyor.com.

0 notes

Text

0 notes

Text

How Conveyor Systems Keep the World Moving

In the fast-paced warehouse, industrial, and fulfilment industries, one unsung hero keeps everything going smoothly: the conveyor system. You probably don't know it, but without conveyor systems, everything from e-commerce transactions to processed meals would move slowly. These machines are productivity machines, moving objects with precision while rolling, lifting, and transferring, and they don't even pause for coffee.

So, what is a conveyor system, and how does it work? Let's go into the intriguing realm of rollers, belts, and vertical lifts to see how this little-known technology enhances global production.

What Is A Conveyor System?

A conveyor system is a method for transporting objects from one point to another. Conveyors systems exist in a range of forms and sizes to meet specific requirements, whether carrying small bolts or large boxes. They are an essential part of warehouse automation and industrial efficiency, executing repetitive movement tasks with speed and precision.

Consider a conveyor system as the building's vascular system. It moves products from reception to storage, packing to shipping, and everything in between. Conveyor systems boost productivity while minimizing fatigue and human error by removing the need for manual labour.

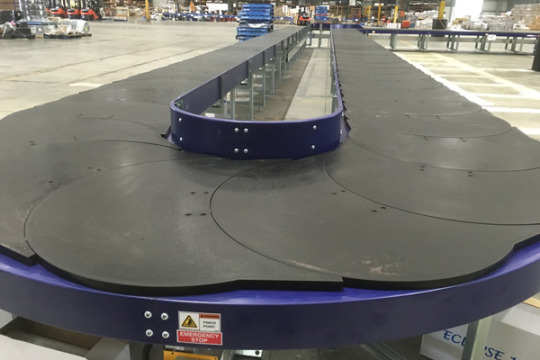

Roller Conveyors: The Smooth Operators

Roller conveyors are among the most popular and dependable types of conveyor systems. They transport goods along a flat track using a chain of cylindrical rollers, which can be driven or gravity-propelled. If you've ever seen packages move smoothly down a line at a distribution centre, you were undoubtedly seeing a roller conveyor in action.

These systems are suited for transferring boxes, trays, and containers of any form or size. They are adaptable, affordable, and may be built to sustain a wide range of weight capacities. They can be arranged in straight lines, curves, or even as pop-up sorting sections. This is the sort of seamless operation that keeps manufacturing moving.

Vertical Conveyors: Taking Productivity Up A Notch

Vertical conveyors are useful for transporting goods that cannot be carried horizontally. Vertical conveyors move products up and down between levels, maximising the vertical space available in a warehouse or factory. If your company has many floors or mezzanines, vertical conveyors may move products up without the use of forklifts or physical labour.

Vertical conveyors are commonly employed in comprehensive systems to connect floors, link storage and picking locations, and carry products directly to packing stations. They alleviate ground-floor congestion and accelerate operations, particularly in high-volume circumstances. In summary, they do more than just lift boxes; they also boost productivity.

How Conveyor Systems Improve Operations

The advantages of conveyor systems are numerous. To begin, they move things more quickly. Products flow more swiftly through the complex, allowing firms to complete orders faster and fulfil tight deadlines. They also bring uniformity to the process. Conveyors, unlike humans, do not tire, grow distracted, or become unreliable. They simply continue to run at the same speed, hour after hour, shift after shift.

Conveyors also lower the danger of industrial accidents. The conveyor handles the heavy lifting and long-distance walking for the workers. This enhances worker safety while reducing time wasted due to fatigue or strain.

Don't forget how conveyor systems help to maximize space. A roller conveyor may be customised to go along specific paths within constrained locations, whereas vertical conveyors enable firms to expand upwards rather than outwards. This allows you to transport more objects in fewer square feet, which is very useful in constrained or expensive facilities.

Smart Integration Of Modern Technology

Modern conveyor systems are now integrated into a broader smart warehouse framework. They can interface with sensors, scanners, and automation software to offer real-time information and updates. For example, a roller conveyor system may be equipped with barcode scanners that scan packages as they pass through and update inventory in real-time.

Vertical conveyors can also be combined with automated guided vehicles and robotic arms to provide uninterrupted vertical and horizontal motion. This enables organisations to expand operations, enhance accuracy, and minimise their reliance on manual handling, all while enhancing overall production.

Choosing The Right Conveyor System

With so many alternatives, selecting the best conveyor system is a matter of knowing what your company requires. Roller conveyors are great for simple transportation over large distances, particularly when the commodities are uniform in shape and size. Vertical conveyors are the ideal answer for multi-level applications requiring upward or downward movement.

In most circumstances, integrating multiple technologies produces the greatest results. It's about creating a system that fits your procedures, space, and long-term goals.

Keep Everything Going

Conveyor systems, from the smooth glide of a roller conveyor to the upward surge of a vertical conveyor, are essential components of contemporary logistics and industry. They transport products swiftly, correctly, and reliably, helping businesses to meet demand while remaining competitive in an increasingly fast-paced world.

So, the next time you receive a package in 24 hours or select a nicely wrapped food item off the store shelf, take a moment to appreciate the conveyor system that runs it. The unsung hero is responsible for moving everything.

0 notes

Text

Boost Efficiency and Throughput with Powered Roller Conveyor Systems

Introduction

In today's fast-paced industrial and logistics environments, efficiency and automation are no longer optional—they’re essential. One of the most effective ways to streamline material handling and improve throughput is with a powered roller conveyor system. Whether in a warehouse, distribution center, or manufacturing facility, powered roller conveyors provide seamless, automated movement of goods with minimal manual intervention.

In this blog, we’ll explore what powered roller conveyor systems are, how they work, their key benefits, and the industries that can benefit the most from their implementation.

What Is a Powered Roller Conveyor System?

A powered roller conveyor uses motors to drive rollers and move items along the conveyor line. Unlike gravity conveyors, which rely on slope and gravity, powered systems are ideal for controlled and efficient movement of goods, especially over long distances or around curves and inclines.

They come in various configurations—line shaft, belt-driven, chain-driven, and motorized roller (MDR)—each suited to different applications depending on load size, speed, and operational environment.

Key Features of Powered Roller Conveyors

Motorized Control: Enables consistent speed and direction for smooth product flow.

Modular Design: Easy to expand, reconfigure, or integrate with automated systems.

Heavy-Duty Load Handling: Suitable for moving small parcels to heavy pallets.

Low Maintenance: Modern systems are built for durability and energy efficiency.

Custom Integration: Can be equipped with sensors, sorters, and automated pick-and-place systems.

Benefits of Powered Roller Conveyor Systems

1. Increased Throughput

Automated movement of goods minimizes delays and improves flow, resulting in higher productivity and faster order fulfillment.

2. Improved Safety

Reduces manual handling, lowering the risk of workplace injuries. Operators can focus on supervision rather than physical transport.

3. Energy Efficiency

Many modern systems use energy-efficient motorized rollers (MDRs) that consume less power and operate only when items are detected on the rollers.

4. Low Downtime

Robust design and smart diagnostics reduce unexpected breakdowns and enable easy maintenance.

5. Scalability

From small operations to large warehouses, powered roller conveyors can scale to meet growing demands.

Common Applications

E-commerce Fulfillment Centers

Automotive Assembly Lines

Food & Beverage Packaging Plants

Pharmaceutical Distribution

Airport Baggage Handling

Third-Party Logistics (3PL)

Is a Powered Roller Conveyor Right for Your Business?

If your operations involve frequent, repetitive movement of items—especially in high volumes—a powered roller conveyor system can dramatically enhance efficiency. It's also ideal if you're planning to integrate automation or robotics into your material handling strategy.

Conclusion

As industries continue to adopt smart technologies, the demand for reliable, scalable, and efficient conveyor systems will only increase. Powered roller conveyors are a smart investment for businesses seeking to optimize their logistics, reduce manual labor, and future-proof their operations.

Whether you’re upgrading your facility or designing a new one, powered roller conveyors can be a game-changer.

0 notes

Text

Roller Conveyor Manufacturer in Faridabad | Vashnavi Conveyor Industry

Vashnavi Conveyor Industry is a leading roller conveyor manufacturer in Faridabad, offering high-performance and durable roller conveyor systems for industrial automation and material handling needs. Our precision-engineered conveyors are ideal for manufacturing units, warehouses, and packaging industries. Get reliable and customizable solutions at competitive prices.

#Roller conveyor Faridabad#conveyor manufacturer Faridabad#Vashnavi Conveyor#gravity roller conveyor#powered roller conveyor#industrial conveyors#material handling systems

0 notes

Text

Conveyor Roller Systems: The Complete Guide: Effectiveness and Creativity in Material Processing

Conveyor roller systems have revolutionized the material handling industry, offering efficiency, reliability, and cost-effectiveness. Whether in warehouses, manufacturing plants, or distribution centers, these systems play a vital role in streamlining logistics. This guide explores conveyor roller systems in-depth, covering types, benefits, and key considerations when selecting the right system for your needs.

What Are Conveyor Roller Systems?

A conveyor roller system is a mechanical assembly designed to transport materials effortlessly across a defined path. It consists of rollers, frames, and a drive system that work together to move goods efficiently. These systems are commonly used in industries such as logistics, food processing, mining, and e-commerce fulfillment centers.

Types of Conveyor Roller Systems

Conveyor roller systems come in different variations, each designed for specific applications. Understanding their differences helps businesses choose the right solution for their operational needs.

1. Gravity Roller Conveyors

Operate without external power.

Relies on gravity to move items.

Ideal for lightweight packages and manual operations.

2. Powered Roller Conveyors

Uses motors or belt drives to transport materials.

Suitable for high-speed and automated operations.

Offers better control over material movement.

3. Chain-Driven Roller Conveyors

Uses chains to rotate rollers.

Best for heavy-duty applications such as automotive and industrial manufacturing.

Provides robust durability and load capacity.

4. Belt-Driven Roller Conveyors

Features a belt running beneath the rollers for movement.

Great for fragile or irregularly shaped items.

Used in applications requiring precise product handling.

5. Flexible Roller Conveyors

Can expand, contract, and curve as needed.

Excellent for temporary or space-limited workspaces.

Common in retail, e-commerce, and parcel distribution centers.

Key Benefits of Conveyor Roller Systems

Investing in a conveyor roller system provides a range of benefits that enhance operational efficiency.

1. Increased Productivity

Automating material handling reduces manual labor, ensuring faster throughput and increased efficiency in manufacturing and distribution processes.

2. Reduced Labor Costs

By minimizing manual handling, businesses can cut labor expenses while improving workplace safety.

3. Improved Accuracy and Consistency

Conveyor roller systems reduce errors and inconsistencies that often occur in manual handling, leading to better inventory management and order fulfillment.

4. Versatility in Applications

These systems can handle various materials, including boxes, pallets, and bulk materials, making them adaptable for diverse industries.

5. Enhanced Workplace Safety

By automating movement, conveyor systems reduce workplace injuries related to heavy lifting and repetitive strain.

Real-World Applications and Testimonials

Many businesses have successfully integrated conveyor roller systems into their operations, experiencing remarkable improvements in productivity and efficiency.

Case Study: E-commerce Distribution Center

A leading online retailer implemented a powered roller conveyor system to handle high order volumes. The result? A 40% increase in order processing speed and a significant reduction in manual labor costs.

Testimonial: Manufacturing Industry

“After installing a chain-driven roller conveyor, our production line became 30% faster with fewer material handling errors. It has been a game-changer for our efficiency.” – Operations Manager, Automotive Manufacturer

Future Trends in Conveyor Roller Systems

With advancements in automation and AI, conveyor roller systems are evolving to become smarter and more efficient. Here are some future trends to watch:

IoT-Enabled Monitoring – Smart conveyors with sensors provide real-time analytics on system performance and maintenance needs.

AI-Powered Sorting – Artificial intelligence helps improve sorting accuracy and operational efficiency.

Sustainability Improvements – Energy-efficient motors and recyclable materials are making conveyor systems more eco-friendly.

Conclusion

Conveyor roller systems are an indispensable asset in material handling, providing unparalleled efficiency and reliability. Whether for a small warehouse or a large manufacturing plant, choosing the right system can significantly improve operations. By understanding the different types, benefits, and industry applications, businesses can optimize their workflows and stay competitive in a fast-paced market.

0 notes