#SLA prototyping China

Explore tagged Tumblr posts

Text

הדפסת תלת מימד בסין | שירות SLA, SLS, Metal 3D | פרוטוטייפ תוך 72 שעות

הדפסת תלת מימד בסין: ממאדים לפרוטוטייפ תוך 72 שעות כספק מוביל בתחום ה-3D printing China, אנו מתמחים בייצור מהיר של: 🔩 רכיבי מתכת (טיטניום, אלומיניום) בChina metal 3D printing service 💡 פרוטוטייפים מדויקים בטכנולוגיית SLA prototyping China (דיוק 25 מיקרון) 🧪 חלקים לתעשיית הרפואה (עמידים בחיטוי) יתרונות הדפסה תלת מימדית בסין ללקוחות ישראליים בשיתוף פעולה עם חברות ישראליות בהייטק וביומד,…

View On WordPress

#China metal 3D printing service#SLA prototyping China#הדפסת תלת מימד בסין#ייצור מהיר תלת מימד#ספק הדפסה תלת מימדית

0 notes

Text

Advancing Manufacturing Excellence: Aluminum Die Casting and Robot Prototyping in China

Introduction In the realm of manufacturing, China has emerged as a powerhouse, leading the way in aluminum die casting and robot prototyping. With a robust industry and a wealth of expertise, Chinese manufacturers have perfected the art of aluminum die casting, while their prototype makers are pushing the boundaries of innovation with advanced technologies like SLA (Stereolithography). Join us as we explore the dynamic landscape of aluminum die casting manufacturers and robot prototype makers in China and discover how they are transforming industries worldwide.

Aluminum Die Casting Manufacturers in China Aluminum die casting has become a cornerstone of modern manufacturing, offering precise and cost-effective solutions for a wide range of industries. In China, a multitude of reputable manufacturers have established a strong foothold in the industry. These manufacturers combine state-of-the-art technology with skilled craftsmanship to deliver high-quality aluminum castings.

Chinese aluminum die casting manufacturers have invested in advanced machinery and equipment, including CNC machines and automated production lines, to ensure efficiency and accuracy. With a focus on continuous improvement, they adhere to stringent quality control measures, ensuring that each casting meets the strictest standards.

Notably, China's aluminum die-casting manufacturers have a competitive edge in terms of cost-effectiveness. They possess the ability to scale production, leveraging economies of scale while maintaining superior quality. This advantage has made China a preferred outsourcing destination for companies seeking high-quality aluminum castings at competitive prices.

The Power of SLA Prototypes In the realm of product development, prototyping plays a vital role in transforming ideas into reality. SLA (Stereolithography) has revolutionized the prototyping process, enabling the creation of intricate and highly accurate models. Chinese manufacturers have harnessed the power of SLA prototypes to enhance product development cycles.

SLA prototypes offer numerous advantages. With their ability to produce detailed and complex geometries, SLA prototypes allow designers and engineers to evaluate form, fit, and functionality before moving forward with production. This technology enables rapid iteration and design optimization, significantly reducing time-to-market.

Chinese manufacturers specializing in SLA prototypes leverage cutting-edge 3D printing technologies and a vast selection of materials, including resins and polymers, to meet diverse project requirements. Their prototyping services are known for their precision, attention to detail, and commitment to delivering top-notch results.

Where Aluminum Die Casting Meets Robotics The convergence of aluminum die casting and robotics has opened up new frontiers in manufacturing. Chinese prototype makers are at the forefront of this fusion, offering expertise in both disciplines to create advanced robot prototypes.

Combining the strength and lightweight properties of aluminum die castings with the agility of robotics, these prototypes embody the future of automation. Chinese prototype makers collaborate closely with their clients, understanding their needs and translating them into functional and efficient robotic designs.

The synergy between aluminum die casting and robotics allows for the production of lightweight yet robust robot components. Aluminum castings offer excellent thermal conductivity, durability, and precision, making them ideal for creating components such as robot frames, joints, and housings.

Chinese prototype makers employ state-of-the-art technologies, including CNC machining, 3D printing, and automation, to manufacture robot prototypes with exceptional precision and reliability. They work hand-in-hand with clients throughout the design and iteration process, ensuring that the final prototype meets the desired performance criteria.

Conclusion China's aluminum die casting manufacturers and robot prototype makers are revolutionizing the manufacturing landscape with their expertise and advanced technologies. Their commitment to quality, cost-effectiveness, and innovation has propelled them to the forefront of the industry. From producing high-quality aluminum castings to creating intricate SLA prototypes and pushing the boundaries of robotics, Chinese manufacturers continue to shape the future of manufacturing. As industries worldwide embrace the potential of aluminum die casting and robot prototypes, the collaborative efforts of China's manufacturers and prototype makers will undoubtedly pave the way for groundbreaking advancements in manufacturing excellence.

#aluminium die casting manufacturers in china#sla prototypes#aluminum die casting china#robot prototype maker

0 notes

Text

Affordable SLA 3D Printing in China for Rapid Production

In today's fast-paced world of product development and manufacturing, precision and speed are more important than ever. One technology that has revolutionized the way prototypes and small production parts are made is SLA 3D printing. Known for its outstanding detail and surface finish, SLA (Stereolithography) is increasingly being used not only for concept models but also for end-use parts. And when it comes to cost-effective, high-quality SLA 3D printing China has become a global leader—with trusted providers like ABCRAPID delivering exceptional results to clients around the world.

0 notes

Text

Affordable SLA 3D Printing in China for Rapid Production

In today's fast-paced world of product development and manufacturing, precision and speed are more important than ever. One technology that has revolutionized the way prototypes and small production parts are made is SLA 3D printing. Known for its outstanding detail and surface finish, SLA (Stereolithography) is increasingly being used not only for concept models but also for end-use parts. And when it comes to cost-effective, high-quality SLA 3D printing China has become a global leader—with trusted providers like ABCRAPID delivering exceptional results to clients around the world.

1 note

·

View note

Text

Vacuum Casting Is Ideal for Functional Prototypes

Vacuum Casting additionally referred to as polyurethane casting or silicone molding, is a producing method used to produce small batches of superb plastic or rubber elements. This method is proper for prototyping, product locating out, and occasional-quantity manufacturing wherein velocity, element, and cost overall performance are important.

What is Vacuum Casting?

Vacuum Casting in China starts off with the arrival of a master version, generally made using stereolithography (SLA) or each other form of 3-D printing. This master model is used to deliver a silicone mildew. The silicone mold is then filled with liquid polyurethane or high-quality resins underneath vacuum pressure. This vacuum ensures the resin reaches every element of the mold at the identical time as eliminating air bubbles and defects.

Once the resin remedies, the mildew is opened and the element is eliminated. This method can be repeated 20 to 20-five times with a single mildew, making it quite green for brief manufacturing runs.

Advantages of Vacuum Casting

1. High-Quality Surface Finish

One of the maximum first rate advantages of Vacuum Casting is its ability to provide parts with extremely good surface cease and terrific statistics. The silicone mould captures tough textures from the maintain close version, ensuing in prototypes that closely resemble injection-molded elements.

2. Cost-Effective for Low Volumes

Compared to injection molding, Vacuum Casting Supplier in China is lots more inexpensive for small batch production. The tooling expenses have notably decreased, and the turnaround time is faster, making it a splendid desire for trying out and marketplace validation earlier than scaling up.

3. Wide Range of Materials

Vacuum casting enables a whole lot of substances that mimic the mechanical houses of ABS, polypropylene, rubber, or even obvious plastics. This flexibility lets designers check capability and aesthetics the use of production-like materials.

4. Fast Turnaround Time

From the keep near version to the very last product, the vacuum casting method can regularly be completed in just a few days. This rapid prototyping capability allows groups to accelerate product development cycles and get to market faster.

5. Ideal for Functional Testing

Because the elements produced through vacuum casting can replicate the mechanical homes of final manufacturing components, they may be great for practical finding out. Whether it's miles checking in form, end, or overall performance, vacuum strong prototypes provide correct feedback.

Common Applications

Vacuum casting is used all through several industries which includes:

Automotive: Custom interior elements, housings, light covers

Medical Devices: Functional prototypes, ergonomic fashions

Consumer Electronics: Device enclosures, button covers

Industrial Equipment: Gaskets, protecting casings, prototypes

Limitations

While Vacuum Casting is especially flexible, it does have a few boundaries. The silicone molds are not as long lasting as metallic injection molds, proscribing their use to low-quantity production. Additionally, even as the fabric alternatives are big, they will not commonly exactly shape the houses of thermoplastics carried out in mass production.

Conclusion

Vacuum Casting Manufacturer in China is a powerful method for generating excessive-constancy prototypes and occasional-volume factors with pace, precision, and charge performance. It bridges the gap amongst preliminary layout and full-scale manufacturing, supporting businesses test, refine, and supply higher merchandise to the marketplace.

0 notes

Text

Unlock Real-Time Forex & Stock Data for Professional-Grade Quantitative Trading

——Free API + High-Frequency Market Feeds to Seize Millisecond-Level Opportunities

I. The Core Challenge of Quantitative Trading: Data Quality Determines Strategy Success

In the competitive world of financial markets, the success of quantitative trading hinges on real-time availability, completeness, and accuracy of data. Traditional data sources often face three critical limitations:

High Latency: Minute-level delayed data fails to capture micro market movements, missing high-frequency arbitrage opportunities.

Limited Coverage: Narrow asset classes or regional restrictions hinder cross-market strategies.

Unreliable Stability: Data outages or duplicate records distort backtesting results and increase execution risks.

Alltick API delivers professional-grade financial data services, offering developers, traders, and institutions a free API key and ultra-low-latency market feeds (avg. 170ms) across 100,000+ instruments including stocks, forex, and cryptocurrencies. It powers quantitative systems as the ultimate "data engine".

II. Core Advantages of Alltick API: Free Tier + High-Frequency Data

1. Zero-Cost Entry: Free API for Rapid Prototyping

Instant Registration: Create an account via our website or GitHub examples in 5 minutes.

Full Basic Features: Free tier includes 10 instrument queries, 1 WebSocket connection, and 1-year historical data for strategy validation.

2. Millisecond-Level Forex Data, Direct from Top Liquidity Sources

100+ Currency Pairs: Covering majors (EUR/USD, USD/JPY) and emerging pairs (AUD/CAD), sourced directly from global banks and exchanges.

Tick-by-Tick Updates: Receive real-time bid/ask prices and volumes via WebSocket for high-frequency decision-making.

3. Global Stock Market Coverage: HK, US, and A-Shares

30,000+ Equities: Full coverage of Hong Kong (3,000+), US (11,000+), and China A-shares (5,000+) with order book and trade-by-trade data.

Multi-Timeframe OHLC: Flexible intervals from 1-minute to monthly charts for diverse strategies.

4. Enterprise-Grade Reliability & Scalability

99.95% SLA Guarantee: Less than 5 hours annual downtime ensures uninterrupted trading.

Multi-Protocol Support: REST API, WebSocket, and FIX protocols for low-latency to high-frequency needs.

III. Four Key Use Cases for Alltick API

1. High-Frequency Trading (HFT)

Example Strategy: Capture forex arbitrage opportunities using tick-level spread analysis.

Implementation: Subscribe to EUR/USD real-time quotes via WebSocket, trigger orders based on order book patterns.

2. Multi-Asset Portfolio Management

Data Integration: Monitor US tech stocks, gold futures, and Bitcoin simultaneously for risk diversification.

3. Machine Learning Model Training

Historical Data: Train models with 5+ years of tick-level data to reduce overfitting risks.

4. Institutional Risk Management

Real-Time Alerts: Track currency fluctuations via API to minimize cross-border settlement slippage.

IV. Three Steps to Integrate Alltick API

1. Register & Get API Key

Visit Alltick Official Site, sign up via email or Gmail, and generate your token instantly.

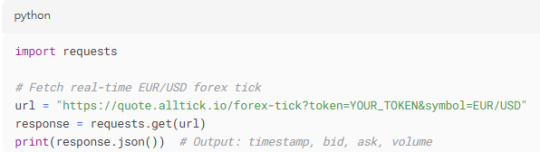

2. Run Sample Code (Python)

3. Scale with Premium Plans

Upgrade for 1,200+ requests/minute, full-market data, and multi-WebSocket connections.

V. Client Success Stories: Data-Driven Profit Growth

Hong Kong Quant Fund: Boosted annual returns by 15% using Alltick’s HK stock tick data.

Cross-Border Payment Platform: Reduced settlement slippage by 70%, saving $50k+ daily.

Act Now!

Whether you’re an individual developer, startup, or financial institution, Alltick API combines zero-barrier free access with institutional-grade data to accelerate your strategy deployment.

Visit [Alltick API] now!!!

1 note

·

View note

Text

Aerospace 3D Printing Market Growth Driven by Reduced Lead Times and Cost-Effective Prototyping

Market Overview

The aerospace 3D printing market is soaring to new heights, redefining how components for aircraft, spacecraft, and defense applications are designed and manufactured. With increasing adoption across commercial aviation, military aviation, space exploration, and UAVs, 3D printing—also known as additive manufacturing—offers unmatched design flexibility, weight reduction, and cost savings. The market is evolving rapidly thanks to advancements in metal, polymer, ceramic, and composite 3D printing technologies. Applications span from creating intricate engine and turbine components to fabricating lightweight interior structures and prototypes. As the aerospace industry moves toward more sustainable and efficient operations, 3D printing has become a game-changing solution.

Market Dynamics

Several dynamic forces are fueling the growth of the aerospace 3D printing market. First and foremost, the demand for lightweight yet strong components is pushing manufacturers to adopt materials such as titanium alloys, nickel alloys, and advanced plastics. These materials, when used in additive manufacturing, help reduce fuel consumption and extend component life.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS20420

Technological innovation is another key driver. Breakthroughs in stereolithography (SLA), fused deposition modeling (FDM), direct metal laser sintering (DMLS), and electron beam melting (EBM) allow for faster and more precise fabrication. Meanwhile, hybrid manufacturing—combining additive and subtractive processes—is opening new possibilities for complex parts production.

In addition, the growing emphasis on on-demand production and supply chain resilience, especially post-pandemic, has amplified interest in localized and flexible 3D printing capabilities. Maintenance, repair, and overhaul (MRO) companies are leveraging 3D printing to quickly replace outdated or rare components, significantly reducing aircraft downtime.

However, the market also faces challenges such as regulatory hurdles, certification complexities, and the high initial investment in hardware, software, and skilled personnel.

Key Players Analysis

The aerospace 3D printing ecosystem includes a blend of technology developers, material suppliers, service providers, and end users. Leading players such as Stratasys Ltd., 3D Systems Corporation, GE Additive, EOS GmbH, and Materialise NV are at the forefront of innovation, offering cutting-edge hardware, materials, and software platforms.

GE Additive, for instance, has been instrumental in integrating 3D printing into jet engine production, drastically reducing the number of components in fuel nozzles. Stratasys and 3D Systems continue to drive polymer-based printing in aerospace interiors and prototyping. Collaborations between these tech firms and major aerospace OEMs like Airbus, Boeing, and Lockheed Martin are accelerating the adoption of additive manufacturing across the value chain.

Regional Analysis

North America remains the dominant region in the aerospace 3D printing market, led by the U.S., where innovation, military investments, and a robust aerospace ecosystem converge. The region benefits from early technology adoption, government-backed R&D initiatives, and the presence of major aerospace firms.

Europe is not far behind, with countries like Germany, France, and the UK playing crucial roles. The European Space Agency (ESA) and companies like Airbus are actively incorporating 3D printing in satellite and aircraft manufacturing.

The Asia-Pacific region, particularly China, Japan, and India, is emerging as a fast-growing market. Rising defense budgets, growing aviation industries, and supportive policies are driving interest in localizing 3D printing capabilities for both civil and military purposes.

Recent News & Developments

Recent developments highlight how rapidly the aerospace 3D printing market is advancing. In 2024, Airbus announced the successful integration of over 1,000 3D-printed parts in the A350 XWB aircraft. Meanwhile, NASA and private space firms are utilizing 3D-printed rocket engines to reduce launch costs and turnaround time.

Additionally, major aerospace maintenance firms have begun establishing digital inventories, enabling on-demand part printing for aircraft fleets. The integration of AI and simulation tools into the design and engineering phases is also improving efficiency and precision in printed components.

Browse Full Report @ https://www.globalinsightservices.com/reports/aerospace-3d-printing-market/

Scope of the Report

The aerospace 3D printing market report offers comprehensive insights into a wide array of segments. It covers types of printing such as metal, polymer, ceramic, and composite. It analyzes products like engines, turbines, structural and interior components, and services including design, consulting, repair, and training.

The report also explores the technological landscape—SLA, SLS, FDM, DMLS, EBM—and component-level insights into software, hardware, and material systems. Applications are thoroughly evaluated across commercial, military, space, and UAV domains. Material types span titanium, aluminum, nickel alloys, stainless steel, and plastics.

End-user analysis includes aircraft and engine manufacturers, MRO providers, and R&D institutions, while processes such as additive, subtractive, and hybrid manufacturing are examined in detail. This scope ensures a 360-degree view of the market’s potential over the next decade, helping stakeholders navigate the rapidly evolving aerospace 3D printing landscape.

Discover Additional Market Insights from Global Insight Services:

Inflight Catering Market: https://www.globalinsightservices.com/reports/inflight-catering-market/

Pallet Pooling Market: https://www.globalinsightservices.com/reports/pallet-pooling-market/

Septic Solutions Market: https://www.globalinsightservices.com/reports/septic-solutions-market/

Artillery Ammunition Market: https://www.globalinsightservices.com/reports/artillery-ammunition-market/

Concrete Pump Market: https://www.globalinsightservices.com/reports/concrete-pump-market/

0 notes

Text

Website : https://glcncmachining.com/

Address :

China Factory : #10, Xinrong Street, Chang'an, Dongguan, Guangdong 523845, China

Singapore Factory : No.3 Joo Koon Circle, Singapore 629032

Phone : +86 180 2756 7310

About Great Light GreatLight Metal Technology Co., Ltd CNC MACHINING PTE. LTD Great Light was founded in 2011, Adjacent to Shenzhen, And is located in Chang’an, Dongguan City, The capital of precision processing of hardware molds. Factory is about 7,600 square meters, With 150 employees, Equipped with large high-precision 5-Axis, 4-Axis, 3-Axis CNC Machining centers, Lathes, Milling machines, Grinders, Spark machines, Vacuum mold machines, SLM 3D Printers, SLA 3D Printers, SLS 3D Printers and other peripheral equipment precision equipment 127 sets, With 3 wholly-owned manufacturing factories, Is a production enterprise specializing in precision processing of rapid prototyping handboard models. Great Light focuses on the design, processing, customized production and application of precision handboard models, Providing new and old users with precision CNC Processing services (three-axis, four-axis, five-axis processing), CNC Milling services, Die-casting molds/metal die-casting processing services, Vacuum casting customization, Sheet metal processing customization, Stainless steel 3D printing, Aluminum alloy 3D printing, Titanium alloy 3D printing, Mold steel 3D printing and nearly 100 kinds of rapid prototyping processing services and comprehensive solutions. And it is equipped with a one-stop post-surface processing service. Great Light has many years of experience in precision prototype model processing, With high precision (±0.001mm / 0.001 In and above precision requirements can be processed), After-sales guarantee, Free rework for quality issues.

Business Mail : [email protected]

#CNC Machining#CNC Machining Services#5-Axis CNC Machining#4 Axis CNC Machining#3 Axis CNC Machining#CNC Milling & Turning#Sheet Metal Fabrication

1 note

·

View note

Text

GreatLight CNC Machining Factory Where Precision Meets Possibility

GreatLight CNC Machining Factory,One of the Best Rapid Prototyping Companies from China "Born in 2015, Crafted for Excellence" 📍 Strategic Hub: Located in Chang’an, Dongguan — China’s epicenter of precision hardware & mold engineering. 🚀 Industrial Powerhouse:

7,600㎡ state-of-the-art facility | 150+ skilled engineers

127+ cutting-edge machines: 5/4/3-axis CNC centers, SLM/SLA/SLS 3D printers, vacuum casting systems, and more

3 dedicated factories under one roof

🔥 We Turn Concepts into Reality ✔️ Precision CNC Machining (3/4/5-axis) ✔️ Metal & Prototyping Mastery: Die-casting molds | Vacuum casting | Sheet metal fabrication ✔️ 3D Printing Unleashed: Stainless steel | Titanium alloys | Aluminum | Mold steel ✔️ End-to-End Solutions: From prototyping to surface finishing — your vision, fully engineered

"Trusted by Innovators Worldwide — Delivering Speed, Accuracy & Future-Ready Solutions." 🌐 Connect: glcncmachining.com | ✉️ Inquire Now: [[email protected]]

#CNCMachining #CNCMachiningServices #5-AxisCNCMachining #4AxisCNCMachining #3AxisCNCMachining #CNCMilling&Turning #SheetMetalFabrication #RapidTooling #VacuumCasting #3DPrinting #MetalDieCasting

0 notes

Text

Additive Manufacturing Market Analysis, Growth Factors and Competitive Strategies by Forecast 2034

Additive manufacturing (AM), commonly known as 3D printing, is a transformative approach to industrial production that enables the creation of lightweight, complex designs directly from digital models. It is increasingly used across industries like aerospace, automotive, healthcare, and consumer goods due to its ability to reduce waste, lower production costs, and shorten manufacturing times.

According to projections, the additive manufacturing market would grow linearly and reach a valuation of USD 17.23 billion by 2023. With a compound annual growth rate (CAGR) of 21.65% from 2024 to 2033, it is anticipated to have increased to USD 84.87 billion by that time.

Get a Sample Copy of Report, Click Here: https://wemarketresearch.com/reports/request-free-sample-pdf/additive-manufacturing-market/1376

Key Drivers

Technological Advancements: Innovations in 3D printing materials and techniques, such as metal and bio-based printing, are fueling growth.

Adoption Across Industries: Applications in aerospace, healthcare, automotive, and consumer goods are expanding rapidly.

Sustainability Goals: Additive manufacturing reduces waste and optimizes material usage, aligning with global sustainability efforts.

Challenges

High initial investment costs for equipment and training.

Limitations in material properties and product size for certain applications.

Regulatory hurdles in industries like healthcare and aerospace.

Applications Across Industries

Aerospace and Defense Additive manufacturing is extensively used to produce lightweight and complex parts, reducing fuel consumption and improving performance.

Healthcare Customized medical devices, implants, and prosthetics are transforming patient care. Bio-printing for tissues and organs is an emerging field.

Automotive Automotive manufacturers leverage 3D printing for prototyping, tooling, and even end-use parts, reducing lead times and costs.

Consumer Goods The ability to personalize products such as footwear, jewelry, and electronics is driving adoption in the consumer market.

Construction Large-scale 3D printing is being utilized to construct buildings and infrastructure more efficiently and sustainably.

Key companies profiled in this research study are,

Stratasys, Ltd.;

Materialise NV;

EnvisionTec, Inc.;

3D Systems, Inc.;

GE Additive;

Autodesk Inc.;

Made In Space;

Canon Inc.;

Voxeljet AG.

Additive Manufacturing Market Segmentation,

By Technology:

Stereolithography (SLA)

Fused Deposition Modeling (FDM)

Selective Laser Sintering (SLS)

Direct Metal Laser Sintering (DMLS)

Others (Binder Jetting, Electron Beam Melting, etc.)

By Material:

Polymers

Metals

Ceramics

Others (Composites, Biomaterials, etc.)

By Application:

Prototyping

Production

Tooling

By Industry:

Aerospace

Automotive

Healthcare (particularly for dental and orthopedic implants)

Consumer Goods

Defense

Additive Manufacturing Market Regional Analysis:

North America: Dominates the market due to high adoption of AM technologies in industries like aerospace and healthcare.

Europe: Strong growth due to government initiatives and industrial adoption.

Asia-Pacific: Emerging as a significant market with increased investment in industrial 3D printing in countries like China, Japan, and South Korea.

Conclusion:

The additive manufacturing market is poised for transformative growth, offering unparalleled opportunities across industries. As technology evolves and adoption increases, this sector is expected to redefine traditional manufacturing processes, paving the way for a more sustainable and efficient industrial future.

0 notes

Text

What You Need To Know About The Different Types Of CNC Milling Machines?

In factories and workshops, getting things done quickly and accurately is really important. CNC milling machines are like the superheroes of technology because they're super precise and can adapt to different tasks. Let's explore the different kinds of machines that are helping industries come up with cool new stuff, making CNC milling easier to understand.

1. Vertical Mills:

- An easily accessible workpiece from above is made possible by the vertical axis used on vertical milling machines. Flat surfaces, slots, and pockets are frequently created using them. For tasks like mould production and prototyping, where accessibility and precision are important, vertical mills are perfect.

2. Horizontal Mills:

- Horizontal milling machines have a spindle aligned horizontally, in contrast to vertical mills. These configurations are ideal for heavy-duty machining activities and batch production because they allow the cutting of numerous sides of a workpiece without requiring repositioning. Manufacturing sectors including aerospace, automotive, and marine are strongholds for horizontal mills.

3. Multi-Axis Mills:

- Advanced features of multi-axis milling machines include simultaneous movement along several axes. These devices have unmatched accuracy and productivity when it comes to carrying out intricate machining tasks. Multi-axis mills are essential in sectors like jewellery manufacture, medical, and aerospace because they can create complex geometries and shapes by adding extra axes of movement, such as rotational or tilting axes.

4. CNC Router Mills:

- To cut and shape wood, plastic, and other non-metallic materials, specialised milling machines known as CNC router mills are used. Signage, cabinetry, and woodworking businesses will find them perfect because of their big work envelopes and high-speed spindles. For small-scale producers, artists, and hobbyists, CNC router mills are great.

5. Benchtop Mills:

- Benchtop milling machines are compact and portable, making them ideal for small workshops, educational institutions, and prototype laboratories. Despite their diminutive size, these machines provide precision and adaptability that rival bigger industrial mills. Benchtop mills are popular among amateurs, DIY enthusiasts, and students learning the principles of machining.

CNC milling machines are available in a wide range of designs that satisfy a variety of industrial requirements, from vertical mills to multi-axis machining centres. Understanding the strengths and capabilities of each kind enables producers to pick the best machine for their individual applications, enabling innovation and efficiency in the ever-changing world of contemporary production.

Why choose HLH Rapid?

HLH Rapid is a remarkable team that combines the best of the West and East. It was founded by Vader Yu from China and Director James Murphy from the United Kingdom, both of whom have extensive industry expertise.

We help companies globally by promptly producing high-quality prototypes and parts. Our skills as well as expertise promote innovation, making it easier for businesses to develop new products swiftly.

We are pleased to provide a wide range of services, including rapid injection moulding, CNC machining, and numerous 3D printing technologies (such as SLA, SLS, and SLM), all in one stop.

To know more about cnc milling services, talk to our experts today by sending an email at [email protected] or visit our website: www./hlhrapid.com

0 notes

Text

The Evolution of Product Design with SLA Prototypes

It used to take several weeks or even months to make a prototype with earlier technologies. Today, an SLA prototype can be made within two to three business days, speeding up the product development stage and the time to market. That’s the magic of 3D printing, especially with technologies like stereolithography (SLA). It’s one of the best solutions that allow product designers to go from ideation to end-use production quickly.

SLA 3D printing may be one of the oldest additive manufacturing technologies, but it is still widely used because it offers versatility for prototyping and low-volume end-use production. It builds parts layer per layer with a photosensitive resin that solidifies when exposed to a highly precise UV laser. This results in accurate parts with a good surface finish, which can be enhanced with post-process finishing. Although building an SLA prototype requires support structures, these are removed after printing.

Given its versatility and process, SLA 3D printing has contributed to the evolution of product design. Keep reading to explore how and why.

More material options

SLA prototypes can be built with a wide range of materials that come in specific colors, including generic resin (white), rigid (black), and high-toughness resin (light green or yellow). It’s also possible to build a transparent prototype with a special resin.

Various surface finishes

In prototyping, the goal is to make the model as identical as possible to the final product to allow precise testing and aesthetics. An SLA prototype will have a good surface finish, but it can be further improved with post-processing to be smoother or in a different color. SLA 3D printing specialists in China offer paint, dye, chrome plate, and smooth finishes.

Build complex shapes

Manual prototyping techniques won’t usually guarantee precise results, especially when crafting complicated geometries. That’s not a problem with an automated 3D printing process like stereolithography. Modern SLA technologies meet tolerances of +/- 0.001” or +/- 0.004” per inch, whichever is greater, whether printing high-resolution or normal prototypes. This ensures more precise results, even for prototypes with complex shapes.

Build your SLA prototype with HLH Proto to get better designs for your product development stage. More than 3000 businesses in 50 countries trust this China-based company for high-quality prototyping and manufacturing solutions that reduce their time to market and costs. Visit HLHProto.com to request a quote.

0 notes

Text

CNC Car Parts: Revolutionizing Automotive Manufacturing with Precision and Efficiency

Introduction In the ever-evolving world of automotive manufacturing, the demand for high-quality, precise, and efficient production processes has become paramount. The advent of advanced technologies, such as online machining, SLA rapid prototyping, aluminum casting in China, CNC prototypes, and small metal parts fabrication, has brought about a paradigm shift in the production of car parts. This article explores the significance of CNC (Computer Numerical Control) in the automotive industry and how it has revolutionized the manufacturing of car parts.

Online Machining: Streamlining Production Processes Online machining, also known as CNC machining, has emerged as a game-changer in car part manufacturing. With online machining, manufacturers can create intricate and complex car parts with exceptional precision and speed. By utilizing computer-aided design (CAD) software, engineers can develop 3D models that are then translated into machine instructions for CNC machines.

The CNC machines, equipped with high-speed rotating tools, cut, drill, and shape raw materials, such as aluminum, steel, and alloys, into precise car parts. The automated nature of online machining not only enhances accuracy but also reduces the risk of human errors, resulting in improved quality control.

SLA Rapid Prototyping: Accelerating Innovation SLA (Stereolithography) rapid prototyping is another technology that has significantly impacted the automotive industry. It enables the creation of quick and cost-effective prototypes for car parts. Using SLA, manufacturers can transform digital designs into physical models by using a specialized machine that cures liquid resin layer by layer, producing a solid object.

The application of SLA rapid prototyping allows automotive designers and engineers to iterate and test their designs more efficiently. This iterative approach helps identify and rectify flaws or design issues at an early stage, saving both time and resources. By accelerating the prototyping process, SLA technology fosters innovation and drives the development of cutting-edge car parts.

Aluminum Casting China: Cost-Effective and Versatile Aluminum casting in China has gained prominence as a cost-effective and versatile method for producing car parts. Aluminum, with its lightweight properties and excellent thermal conductivity, is an ideal material for automotive applications. China, with its well-established manufacturing infrastructure, offers competitive advantages in terms of cost, quality, and production capacity.

By utilizing aluminum casting techniques, manufacturers can create complex shapes and structures that would be challenging to achieve with traditional methods. The process involves pouring molten aluminum into pre-designed molds, allowing for the production of intricate car parts with high dimensional accuracy. Furthermore, aluminum casting provides excellent surface finishes and is highly resistant to corrosion, making it suitable for various automotive components.

CNC Prototypes: Transforming Design Concepts into Reality CNC prototypes play a pivotal role in the development of car parts. Before moving into full-scale production, manufacturers often create prototypes to validate the design, functionality, and performance of the intended car parts. CNC machines excel in producing accurate prototypes that closely resemble the final product.

By using CNC prototypes, automotive engineers can evaluate the form, fit, and function of car parts, ensuring they meet the desired specifications. Any necessary modifications or improvements can be identified and implemented at this stage, minimizing the risk of costly errors during mass production.

Small Metal Parts Fabrication: Precision at Scale The production of small metal parts is a critical aspect of automotive manufacturing. These components, although small in size, play a vital role in the overall performance and functionality of a vehicle. CNC machining enables the precise fabrication of small metal parts, ensuring that they meet the stringent requirements of the automotive industry.

Whether it's engine components, brackets, connectors, or fasteners, CNC machining can accurately produce small metal parts with high repeatability. The ability to manufacture these parts at scale while maintaining consistent quality is a significant advantage of CNC technology.

Conclusion The use of CNC technology has had a significant impact on the overall cost of manufacturing CNC car parts. The integration of online machining, SLA rapid prototyping, aluminum casting in China, CNC prototypes, and small metal parts fabrication has revolutionized the manufacturing of car parts. These advanced technologies offer enhanced precision, efficiency, and cost-effectiveness in the production process. As the automotive industry continues to evolve, the utilization of CNC in car part manufacturing will be instrumental in meeting the demands for innovation, quality, and performance in vehicles worldwide.

#online machining#SLA rapid prototyping#aluminum casting china#CNC prototypes#CNC car parts#small metal parts fabrication

0 notes

Text

SLA 3D Printing in China for Prototypes & Production

In today's fast-paced world of product development and manufacturing, precision and speed are more important than ever. One technology that has revolutionized the way prototypes and small production parts are made is SLA 3D printing. Known for its outstanding detail and surface finish, SLA (Stereolithography) is increasingly being used not only for concept models but also for end-use parts. And when it comes to cost-effective, high-quality SLA 3D printing China has become a global leader—with trusted providers like ABCRAPID delivering exceptional results to clients around the world.

0 notes

Text

"SLA 3D Printing Thrives in China"

"Discover cutting-edge SLA 3D printing in China. Transforming ideas into precision prototypes with unparalleled detail and speed. Join us on the forefront of innovation! 🚀 #SLA3DPrintingChina"

0 notes

Text

Why is SLA 3D Printing Globally Accepted for Industrial Product Designing?

SLA 3D printing service is extensively popular worldwide for producing prototypes and end-use parts. Stereolithography (SLA) utilizes various forms of photo-sensitive resins, proposing delicate features and an impressive surface finish.When there is a global switch towards implementing 3D printing for product designing, engineers and manufacturers prefer SLA as it allows the easy and fast production of complex geometries with design flexibility. The rapid evolution of SLA 3D printing has enabled engineers to push their limits. So, why do industrial product designers rely so much on SLA 3D printing? Let us first comprehend the functioning of an SLA 3D printer China.

0 notes