#SMD LED Display Module

Explore tagged Tumblr posts

Text

Illuminating Innovation: The Power of Flexible LED Modules

In the ever-evolving landscape of visual technology, flexibility is key. Enter flexible LED modules – a groundbreaking innovation revolutionizing the way we think about displays. In this blog post, we'll take a closer look at the transformative capabilities of flexible LED modules, exploring their features, applications, and why they're quickly becoming the go-to choice for dynamic visual solutions.

1. Understanding Flexible LED Modules:

Flexible LED modules represent a paradigm shift in display technology. Unlike traditional rigid LED panels, these modules are designed to bend, curve, and conform to virtually any surface. Whether it's a curved wall, a cylindrical column, or a uniquely shaped display, flexible LED modules offer unprecedented versatility and creative freedom.

2. Unleashing Creative Potential:

With flexible LED modules, the possibilities are endless. Imagine transforming mundane architectural elements into dynamic works of art, or seamlessly integrating displays into unconventional spaces. From retail environments to event stages, flexible LED modules empower designers to think outside the box and bring their wildest visions to life.

3. Features That Set Them Apart:

What makes flexible LED modules stand out from the crowd? Let's explore some of their key features:

Bendable and lightweight design for easy installation and versatility.

High-resolution output with vibrant colors and crisp visuals.

Seamless integration with curved surfaces, ensuring a smooth and immersive viewing experience.

Energy-efficient and durable construction, making them ideal for long-term installations.

4. Applications Across Industries:

Flexible LED modules are revolutionizing a wide range of industries and applications:

Retail: Create eye-catching displays that capture attention and drive sales.

Hospitality: Transform hotel lobbies, bars, and restaurants into immersive environments that leave a lasting impression on guests.

Entertainment: Elevate concert stages, theater sets, and event venues with dynamic visual effects.

Architecture: Enhance building facades, interior spaces, and public installations with innovative LED displays.

Advertising: Engage audiences with dynamic signage that stands out in busy urban environments.

5. Advantages for Designers and Installers:

Designers and installers alike can benefit from the versatility and performance of flexible LED modules:

Simplified installation process, with modules that can be easily manipulated and adapted to fit any space.

Reduced maintenance requirements, thanks to durable construction and energy-efficient operation.

Enhanced creative freedom, allowing designers to explore new possibilities and push the boundaries of traditional display design.

Conclusion:

Flexible LED modules are not just a technological advancement – they're a game-changer for the world of visual communication. With their unmatched flexibility, stunning visual quality, and limitless creative potential, these modules are reshaping the way we interact with digital displays. Whether you're looking to make a bold statement, create an immersive experience, or simply stand out from the crowd, flexible LED modules offer the ultimate solution.

#Flexible LED module#LED Receiving Card#LED Display Module#LED Screen Module#SMD LED Display Module#LED Display Video Controller

0 notes

Text

LED Display Module Market: Industry Size and Share Analysis 2025–2032

MARKET INSIGHTS

The global LED Display Module Market size was valued at US$ 5,670 million in 2024 and is projected to reach US$ 10,200 million by 2032, at a CAGR of 8.96% during the forecast period 2025-2032.

LED display modules are semiconductor-based electronic components that produce visual output through light-emitting diodes. These modular units serve as building blocks for larger display systems, featuring pixel configurations that enable high brightness, energy efficiency, and durability across indoor and outdoor applications. Key variants include surface-mounted device (SMD) and conventional LED modules, with applications spanning digital signage, retail displays, stadium screens, and control panels.

The market growth is driven by increasing adoption in commercial advertising and smart city infrastructure projects, particularly in Asia-Pacific markets. While North America maintains strong demand for high-resolution displays in sports venues, China's manufacturing dominance contributes to competitive pricing. Recent technological advancements in mini-LED and micro-LED modules are creating premium market segments, though supply chain constraints for semiconductor materials present ongoing challenges. Key players like Molex, Universal Lighting Technologies, and Winstar Display USA are expanding production capacities to meet the rising global demand.

MARKET DYNAMICS

MARKET DRIVERS

Rising Adoption of Digital Signage Solutions to Accelerate Market Expansion

The LED display module market is experiencing robust growth driven by the accelerating adoption of digital signage across industries. Digital signage powered by LED technology now accounts for approximately 37% of all commercial display deployments globally, transforming how businesses communicate with customers. Retailers, transportation hubs, and corporate offices are increasingly replacing traditional static signs with dynamic LED displays because they offer superior brightness, energy efficiency, and content flexibility. The global digital signage market is projected to maintain a compound annual growth rate of 7.8% through 2028, creating sustained demand for high-quality LED modules.

Advancements in Mini/Micro LED Technology to Fuel Product Innovation

Technological breakthroughs in mini and micro LED displays are revolutionizing the market by enabling higher resolution screens with improved contrast ratios. These next-generation modules deliver pixel pitches below 1.0mm, making them suitable for applications requiring ultra-high-definition visuals. Production yields for micro LED modules have improved by nearly 65% in the past three years, addressing previous manufacturing challenges. Industry leaders are investing heavily in R&D – recently unveiling transparent LED modules that achieve above 75% transparency while maintaining vibrant colors, opening new possibilities for retail windows and architectural integration.

Smart City Initiatives Creating New Demand for Outdoor LED Displays

Government-led smart city programs worldwide are incorporating LED display modules into urban infrastructure for real-time information dissemination and interactive public services. Major metropolitan areas are allocating 12-15% of their digital infrastructure budgets to intelligent display solutions. These modules must withstand harsh environmental conditions while delivering 24/7 reliability. The trend toward connected cities is particularly strong in Asia-Pacific, where over 250 smart city pilot projects are currently deploying LED-based traffic management systems, wayfinding displays, and emergency notification boards.

➤ Early adopters report LED-based public information systems achieve 40% higher citizen engagement rates compared to traditional signage methods.

MARKET RESTRAINTS

High Initial Investment Costs Limit Market Penetration

While LED display technology offers long-term cost benefits, the substantial upfront investment remains a significant market barrier. Complete LED display solutions typically require 2-3 times the capital expenditure of conventional display systems. This cost structure creates particular challenges in price-sensitive emerging markets where buyers often prioritize immediate affordability over lifetime value. Component-level costs for LED modules have declined approximately 8% annually, but system integration and installation expenses continue to constitute over 60% of total project costs for large-scale deployments.

Other Restraints

Technical Complexity in Large-Scale Installations Deploying seamless LED video walls demands specialized engineering expertise that remains scarce globally. Complexities in module calibration, power management, and thermal design lead to extended project timelines, with large installations requiring 30-45% more time than initially projected in many cases.

Content Compatibility Challenges Legacy visual content often requires costly reformatting for optimal LED display performance, creating adoption friction. Resolution mismatches affect nearly 35% of first-time LED display implementations, requiring additional investment in content management systems and media servers.

MARKET CHALLENGES

Intense Competition from Alternative Display Technologies

The LED display module marketplace faces mounting competition from emerging display technologies, particularly direct-view LED alternatives. LCD panels with advanced backlighting now achieve comparable brightness at lower price points for certain applications. Competitive pressure is most acute in the 50-100 inch display segment, where alternative technologies maintain approximately 60% market share. Display manufacturers must continually innovate to maintain LED's performance differentiation while addressing cost concerns through production optimization.

Supply Chain Vulnerabilities Impact Production LED module manufacturing involves complex global supply chains that remain susceptible to disruptions. Critical component lead times lengthened by 30-50% during recent semiconductor shortages, affecting production capacity. Geographic concentration of key raw material suppliers creates additional risks, with over 70% of certain phosphor materials originating from limited sources.

Regulatory Compliance Adds Development Costs Evolving energy efficiency and material restrictions regulations require continuous product requalification. Recent updates to international standards have necessitated design modifications affecting approximately 25% of existing LED module product lines, driving substantial R&D reinvestment.

MARKET OPPORTUNITIES

Emerging Applications in Healthcare Create New Growth Verticals

The healthcare sector presents significant untapped potential for LED display modules, particularly in surgical visualization and diagnostic imaging applications. Medical-grade LED displays now support critical color accuracy requirements within 3 ΔE of perfection, enabling their use in radiology and pathology departments. The global market for medical displays is projected to expand at 6.5% CAGR through 2028, with LED technology positioned to capture an increasing share through specialized anti-reflection and glare-reduction module designs.

Integration with IoT Ecosystems Opens New Possibilities

Next-generation LED display modules incorporating IoT connectivity features are enabling revolutionary applications in smart buildings and industrial environments. Networked modules can now adjust brightness and content automatically based on environmental sensors, achieving 35-40% additional energy savings. The convergence of LED technology with 5G networks and edge computing allows displays to function as interactive endpoints in larger digital ecosystems, creating opportunities in areas ranging from manufacturing process monitoring to advanced retail analytics.

Modular Display Systems Gain Traction in Event Production

The live events industry increasingly favors configurable LED module systems that can adapt to varied venue requirements. Rental and staging companies report modular LED solutions now account for over 45% of their inventory, driven by the ability to rapidly assemble displays of different shapes and sizes. Manufacturers are responding with lighter weight designs that reduce transportation costs and quick-connect systems that cut installation time by up to 60% compared to traditional approaches.

LED DISPLAY MODULE MARKET TRENDS

Rising Demand for High-Resolution Displays Drives Market Expansion

The global LED display module market is experiencing robust growth, fueled by increasing demand for high-resolution displays across multiple industries. With a market valuation of millions in 2024 and projected to reach over millions by 2032 at a CAGR of %, the sector is evolving rapidly. Mini-LED and Micro-LED technologies are at the forefront of this transformation, offering superior brightness, contrast, and energy efficiency compared to traditional LCDs. The transition from 4K to 8K resolution in commercial displays, coupled with decreasing production costs, is accelerating adoption in retail, advertising, and entertainment sectors. Moreover, innovations in modular designs enable flexible installations, catering to customized display solutions for stadiums, control rooms, and transportation hubs.

Other Trends

Automation and Smart Manufacturing Integration

The automation segment is poised to grow significantly, with projections indicating it will reach millions by 2032. Industrial applications increasingly leverage LED modules for real-time monitoring and process visualization, driving efficiency in smart factories. Features such as touchless control interfaces and IoT-enabled diagnostics are becoming standard, as manufacturers prioritize operational transparency. Meanwhile, the medical sector utilizes high-precision LED displays for surgical imaging and diagnostic equipment, where color accuracy and low latency are critical. These advancements underscore the market's shift toward specialized, application-driven solutions.

Sustainability and Energy Efficiency Reshape Product Development

Environmental regulations and corporate sustainability goals are compelling manufacturers to innovate in energy-efficient designs. Recent data indicates that modern LED modules consume up to 40% less power than conventional alternatives while maintaining luminance levels. This aligns with global initiatives to reduce carbon footprints, particularly in regions like Europe and North America, where energy standards are stringent. Additionally, recyclable materials and modular designs are gaining traction, minimizing e-waste. Companies such as Molex, Inc and Universal Lighting Technologies are investing in R&D to optimize thermal management and lifespan, further enhancing the eco-friendly appeal of LED displays.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Technological Advancement Drive Market Competition

The global LED Display Module market demonstrates a semi-consolidated competitive structure, with established multinational corporations competing alongside specialized regional suppliers. As of 2024, the top five manufacturers collectively hold approximately 40-45% market share revenue-wise, reflecting moderate concentration with opportunities for emerging players to gain traction through niche offerings.

Molex, Inc. maintains leadership in this sector due to its comprehensive portfolio of high-brightness modules and established distribution networks across North America and Europe. The company recently expanded its transparent LED film displays, gaining significant traction in retail applications.

Meanwhile, VaOpto and Microtips Technology have emerged as strong competitors through their focus on energy-efficient outdoor display solutions. Their proprietary heat dissipation technologies have become particularly valuable for digital signage applications in extreme climates.

Market competition intensifies as companies increase R&D investments in micro-LED technology. Universal Lighting Technologies recently unveiled a 0.7mm pitch module with 5000 nits brightness, setting new industry benchmarks for fine-pitch displays. Similarly, Winstar Display USA strengthened its position through strategic partnerships with Asian component suppliers, enhancing its cost competitiveness.

The competitive dynamics continue evolving with rising demand across multiple sectors:

Industrial applications drive adoption of ruggedized displays with IP65+ ratings

Medical sector requirements accelerate development of antimicrobial LED surfaces

Smart city initiatives boost demand for energy-efficient outdoor signage solutions

List of Key LED Display Module Manufacturers

Molex, Inc. (U.S.)

VaOpto (U.S.)

EOI Pioneer Inc (Taiwan)

Microtips Technology (U.S.)

Winstar Display USA (U.S.)

Universal Lighting Technologies (U.S.)

Heatron, Inc (U.S.)

SE Relays (Germany)

Neousys Technology America, Inc (U.S.)

EGL Company Inc (U.S.)

Endicott Research Group (U.S.)

DSA Signage (U.K.)

AZ Displays, Inc (U.S.)

Staco Systems, Inc (U.S.)

Segment Analysis:

By Type

Automatic Segment Leads Market Growth Due to Rising Demand for Smart Displays

The market is segmented based on type into:

Automatic

Manual

By Application

Industrial Applications Drive Market Expansion with Increasing Automation Needs

The market is segmented based on application into:

Industrial

Medical

Others

By Region

Asia-Pacific Emerges as Fastest Growing Market Due to Manufacturing Expansion

The market is segmented based on region into:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

By Technology

SMD Technology Gains Traction for Superior Resolution and Brightness

The market is segmented based on technology into:

Surface Mount Device (SMD)

Conventional

COB (Chip on Board)

Others

Regional Analysis: LED Display Module Market

North America The North American LED display module market is characterized by advanced technological adoption and strong demand from advertising, sports, and entertainment sectors. The U.S. dominates regional revenue, driven by infrastructure upgrades and digital signage trends across retail and transportation hubs. Major players like Molex, Inc and Universal Lighting Technologies leverage high R&D investments to develop energy-efficient solutions, complying with stringent regulations such as ENERGY STAR certifications. Canada follows closely, with growing applications in smart city projects and public information displays. However, higher production costs compared to Asian manufacturers pose a challenge for localized suppliers.

Europe Europe’s market thrives on sustainability initiatives and robust demand for outdoor LED displays in urban centers. Germany and the U.K. lead in adoption, supported by heavy investments in commercial advertising and transportation infrastructure. The EU’s Ecodesign Directive pushes manufacturers toward recyclable materials and low-power consumption designs. While Western Europe remains mature, Eastern Europe shows promise with rising disposable incomes driving retail and hospitality sector demand. Competition from Asian imports pressures local suppliers to differentiate through customization and after-sales services.

Asia-Pacific As the largest and fastest-growing market, Asia-Pacific benefits from massive production capacities in China, which accounts for over 60% of global LED module output. India and Southeast Asia emerge as high-growth regions due to urbanization and government-led digitalization projects. Japan and South Korea focus on niche applications like medical displays and automotive HMIs. Price sensitivity remains a key factor, favoring local manufacturers over international brands. However, quality concerns and intellectual property issues persist, requiring stricter compliance measures to sustain long-term growth.

South America The region exhibits moderate growth, with Brazil and Argentina leading demand through stadium renovations and retail modernization efforts. Economic instability and import dependencies hinder market expansion, though local assembly initiatives gain traction. Low penetration of high-end displays reflects budget constraints, but the rise of mid-range products from Chinese suppliers caters to cost-conscious buyers. Infrastructure gaps limit outdoor display applications, but indoor solutions for corporate and healthcare sectors show steady uptake.

Middle East & Africa This region presents a mixed landscape—GCC nations like the UAE and Saudi Arabia drive premium demand through smart city projects and mega-events (e.g., Expo 2020 Dubai). In contrast, Africa’s growth is sporadic, concentrated in South Africa and Nigeria for basic digital signage. Financing challenges and inadequate electricity infrastructure delay large-scale deployments. Nonetheless, partnerships with Chinese manufacturers help bridge technology gaps, particularly in affordable small-to-medium displays for retail and hospitality.

Report Scope

This market research report provides a comprehensive analysis of the global and regional LED Display Module markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global LED Display Module market was valued at USD 1.2 billion in 2024 and is projected to reach USD 2.1 billion by 2032, growing at a CAGR of 7.3%.

Segmentation Analysis: Detailed breakdown by product type (Automatic, Manual), application (Industrial, Medical, Others), and end-user industry to identify high-growth segments and investment opportunities. The automatic segment is expected to grow at a CAGR of 8.5% from 2024 to 2032.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, including country-level analysis where relevant. Asia-Pacific dominates with 45% market share in 2024, led by China.

Competitive Landscape: Profiles of leading market participants including Molex, Inc, VaOpto, EOI Pioneer Inc, Microtips Technology, and Winstar Display USA, covering their product offerings, R&D focus, manufacturing capacity, and recent developments.

Technology Trends & Innovation: Assessment of emerging technologies including micro-LED, mini-LED, and flexible display modules, along with evolving industry standards.

Market Drivers & Restraints: Evaluation of factors driving market growth such as increasing demand for digital signage and smart city initiatives, along with challenges like supply chain constraints.

Stakeholder Analysis: Insights for component suppliers, OEMs, system integrators, investors, and policymakers regarding the evolving ecosystem and strategic opportunities.

Primary and secondary research methods are employed, including interviews with industry experts, data from verified sources, and real-time market intelligence to ensure the accuracy and reliability of the insights presented.

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global LED Display Module Market?

->LED Display Module Market size was valued at US$ 5,670 million in 2024 and is projected to reach US$ 10,200 million by 2032, at a CAGR of 8.96% during the forecast period 2025-2032.

Which key companies operate in Global LED Display Module Market?

-> Key players include Molex, Inc, VaOpto, EOI Pioneer Inc, Microtips Technology, Winstar Display USA, Universal Lighting Technologies, and Heatron, Inc, among others.

What are the key growth drivers?

-> Key growth drivers include rising demand for energy-efficient displays, increasing digital signage adoption, and smart city initiatives.

Which region dominates the market?

-> Asia-Pacific is the dominant market with 45% share in 2024, while North America shows strong growth potential.

What are the emerging trends?

-> Emerging trends include micro-LED technology, flexible displays, and integration with IoT solutions.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/hazardous-lighting-market-regional.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/mobile-document-reader-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/gan-drivers-market-outlook-in-key-end.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/airbag-chip-market-research-report-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/computer-peripheral-device-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/single-ended-glass-seal-thermistor.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/commercial-control-damper-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/pcb-board-terminals-market-investment.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/bandpass-colored-glass-filter-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/video-surveillance-hardware-system.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/pfc-ics-market-technological.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/modulator-bias-controller-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tubular-cable-termination-market-demand.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/logic-buffer-market-size-share-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/broadband-polarizing-beamsplitters.html

0 notes

Video

youtube

indoor led display, outdoor led screen, led module p10,p8,p6,p5,p4,p3,p2.5,p2,p1.86,p1.538,p1.2 SMD led panel price on www.bestarledscreen.cn

0 notes

Text

Custom LED Lightboard Price Guide – What Impacts the Final Cost?

LED lightboards have become a top choice for retail signage, thanks to their brightness, energy efficiency, and sleek visual appeal. But if you’re planning to install one for your shop or office in Chennai, you might be wondering: What is the actual LED lightboard price, and why do quotes vary so much?

This guide will walk you through the key elements that impact the cost of a custom LED lightboard, helping you understand where your money goes and how to make smart signage investments that suit both your brand and budget.

Why Go for a Custom LED Lightboard?

Every business is unique—your signage should be too. A custom LED lightboard reflects your brand identity with tailored design, size, lighting effects, and finishes. Whether it’s a bold outdoor board on a busy Chennai street or an elegant interior sign for a boutique, customization ensures the board fits your space and purpose perfectly.

However, with personalization comes a range of pricing possibilities. So let’s break down the components that influence the LED lightboard price.

1. Size and Dimensions

Size is one of the most obvious cost drivers. A larger sign requires more LED modules, frame material, and power input. For example:

A 2x3 ft indoor LED sign may cost around ₹6,000–₹12,000.

A 4x8 ft outdoor display could range from ₹25,000 to ₹75,000 or more.

Always consider your viewing distance and installation location before finalizing the size.

2. LED Type and Quality

There are multiple grades of LED lights, and the type you choose has a significant effect on the final LED lightboard price:

Standard LEDs: Affordable and suitable for indoor or minimal outdoor use.

SMD LEDs (Surface Mounted Device): Brighter, more compact, and energy-efficient. These are ideal for commercial signage.

RGB/Animated LEDs: Offer full-color display, effects, and transitions—but cost more due to the complexity and programming involved.

At TN Signs, we use industry-grade LEDs that ensure durability, brightness, and longevity, even in Chennai’s hot and humid weather.

3. Design Complexity

Design plays a key role in pricing. A simple LED nameboard with just text will be cheaper than one with:

3D elements

Logo cutouts

Multi-color sections

Animated lighting

The more complex the design, the higher the fabrication and setup costs. Still, investing in a visually appealing sign pays off in terms of brand impact.

4. Material Used

While the LEDs are crucial, the board’s structural components also affect the LED lightboard price:

Acrylic: Popular for its smooth finish and compatibility with LEDs.

Aluminum Composite Panels (ACP): Strong and weather-resistant.

MS or SS Frames: For added strength in large outdoor boards.

The choice of material depends on your environment—outdoor boards in Chennai, for instance, must withstand rain and heat, so waterproof and rust-proof materials are a must.

5. Lighting Effects

Do you want a simple static light, or dynamic flashing, fading, or scrolling effects? Special controllers, programming, and additional LED types are needed for animated boards, which increases the LED lightboard price.

6. Power Supply and Installation

Don’t forget the hidden costs:

Power adapters or drivers

Wiring and switches

Mounting hardware

Labor charges for setup

Outdoor installations at height may require scaffolding or special safety measures, which also adds to the cost.

With TN Signs, we provide all-inclusive pricing that covers installation and power components—no hidden charges.

7. Maintenance and Warranty

Some vendors offer cheaper quotes but skip out on service support. Look for signage providers who include at least 6–12 months warranty on LED boards.

Poor-quality boards may start failing within a few months, especially in coastal areas like Chennai. Paying a bit more for durability often saves you money long-term.

Final Thoughts: Getting the Best Value

If you’re investing in signage for your business, don't base your decision solely on the lowest quote. Instead, look at the durability, clarity, and customization of the board. A high-quality LED lightboard price may be slightly higher upfront but offers better ROI in the long run.

For expert advice, competitive pricing, and fully customized LED signboards in Chennai, visit TN Signs. We’re committed to helping your brand shine—literally.

0 notes

Text

LED is the abbreviation of light emitting diode (Light Emitting Diode, LED),

LED is the abbreviation of light emitting diode (Light Emitting Diode, LED), also known as light emitting diode, this semiconductor element is generally used as an indicator light, a display panel, it can not only efficiently directly convert electrical energy into light energy, but also has up to tens of thousands of hours~ 100,000 hours of service life, while not as fragile as traditional bulbs, and can save electricity and other advantages.

However, no matter what kind of LED, it needs to be reasonably designed for different types of packaging, because only the packaged ones can become end point products and be put into practical application.

1. Why should LEDs be encapsulated?

The function of LED packaging is to connect the outer leads to the electrodes of the LED chip, which not only protects the LED chip, but also improves the luminous efficiency. Therefore, LED packaging not only completes the output of electrical signals, but also protects the normal operation of the die and outputs visible light. It can be seen that LED packaging has both electrical parameters and optical parameters design and technical requirements, which is not a simple task.

2. LED packaging equipment

Due to the high requirements of LED packaging, whether it is an in-line LED or a patch LED, a high-precision solid crystal machine must be used, because whether the position of the LED chip into the package is accurate will directly affect the luminous efficiency of the whole package device. If the position of the chip in the reflective cup is deviated, the light cannot be completely reflected, which directly affects the brightness of the LED. However, with an advanced PR System (pre-image recognition system) solid crystal machine, the LED chip can still be precisely soldered to the predetermined position regardless of the quality of the lead frame.

3. LED package form

According to different applications, different external dimensions, heat dissipation schemes and luminous effects. LED packaging forms are various. At present, LEDs are mainly classified according to packaging forms: Lamp-LED, TOP-LED, Side-LED, SMD-LED, High-Power-LED, Flip Chip-LED, etc

Lamp-LED (Vertical LED)

The early appearance of Lamp-LED is in-line LED, which is packaged in the form of potting. The process of potting is to inject liquid epoxy resin into the LED molding cavity, then insert a pressure-welded LED bracket, put it in an oven to let the epoxy resin cure, and then detach the LED from the cavity and form it immediately. Due to the relatively simple manufacturing process and low cost, it has a high market share.

SMD-LED (surface adhesive LED)

SMD LED is attached to the surface of the circuit board, suitable for SMT processing, reflow soldering, which solves the problems of brightness, viewing angle, flatness, reliability, consistency, etc., using lighter PCB board and reflective layer materials. After improvement, the heavier carbon steel material pins of the in-line LED are removed, so that the display reflective layer needs to be filled with less epoxy resin, the purpose is to reduce the size and weight. In this way, the surface mount LED can easily reduce the weight of the product by half, ultimately making the application more perfect.

Side-LED (side-emitting LED)

At present, another key point of LED packaging is the side-emitting package. If you want to use LED as the backlight source of LCD (liquid crystal display), the side-emitting light of LED needs to be the same as the surface-emitting light, so that the LCD backlight emits evenly. Although the design of the lead frame can also achieve the purpose of side-emitting light, the heat dissipation effect is not good. However, Lumileds invented the design of the mirror, which uses the principle of the mirror to emit side light, and successfully applies high-power LEDs to large-size LCD backlight modules.

TOP-LED (top-emitting LED)

The top light-emitting LED is a relatively common SMD light-emitting diode. Mainly used in backlights and status indicators in multi-function ultra-thin mobile phones and PDAs.

High-Power-LED (High Power LED)

In order to obtain high-power and high-brightness LED light sources, manufacturers have developed high-power LED chip and package designs. At present, LED packages that can withstand several W of power have appeared. For example, the package structure of Norlux series high-power LEDs is a multi-chip combination with a hexagonal aluminum plate as a base (making it non-conductive). The base diameter is 31.75mm, and the light-emitting region is located in its center. The diameter is about (0.375 × 25.4) mm, which can accommodate 40 LED dies. The aluminum plate is used as a heat sink at the same time. This package adopts a conventional die high-density combination package, which has high luminous efficiency, low thermal resistance, and high light output power under high current. It is also a promising LED solid light source.

It can be seen that the thermal characteristics of power LED directly affect the operating temperature, luminous efficiency, luminous wavelength, and service life of LED, etc. Therefore, the packaging design and manufacturing technology of power LED chips are even more important.

Flip Chip-LED (Clad Crystal LED)

The LED overlay packaging structure is basically made with a plurality of perforations in the PCB, and each perforation on one side of the substrate is provided with two different areas of conductive material that are open to each other, and the conductive material is tiled on the substrate. On the surface, there are a plurality of unpackaged LED chips placed at each perforation on the side of the conductive material. The positive and negative contacts of a single LED chip are connected with the conductive material on the substrate surface by solder balls, respectively, and on the surface of the side of the plurality of LED chips facing the perforation, there is a transparent sealant. The sealant is in the shape of a half sphere and is located at each perforation. It belongs to flip-chip light emitting diodes.

conclusion

According to the principle of solid-state light-emitting physics, the luminous efficiency of LED is approximately 100%. Therefore, LED is known as a new light source in the 21st century, and is expected to become the fourth generation light source after incandescent lamps, fluorescent lamps, and high-intensity gas discharge lamps. Looking to the future, manufacturers will definitely place high-power and high-brightness LEDs in a prominent development position. The substrate, epitaxy, chip, packaging, and application in the LED industry chain need to be jointly developed and cultivated by multiple parties. Packaging is the upper and lower parts of the industry chain, and requires great attention and attention from everyone.

0 notes

Text

The "Three Kingdoms" of LED Display: DIP, SMD, and COB Technologies

In the LED display industry, three packaging technologies dominate: DIP, SMD, and COB. Among them, COB (Chip on Board) stands out for outdoor fine-pitch applications due to its revolutionary design.

1. Technology Comparison

DIP: Early through-hole packaging, simple but bulky, gradually being phased out.

SMD: Surface-mount technology, integrates RGB chips but relies on solder joints and lead frames, limiting reliability.

COB: Direct chip-on-board bonding, eliminating lead frames and reflow soldering for a more streamlined process.

2. Key Advantages of COB

2.1 Superior Reliability

Dead pixel rate below 0.005% (vs. industry standard 0.03%), thanks to fewer solder joints (e.g., eliminates 4 million joints in a P1.0 display).

Full epoxy encapsulation resists moisture, corrosion, and harsh outdoor conditions.

2.2 Cost & Efficiency

Removes lead frames, sorting, and SMT processes, reducing material and labor costs.

Lightweight (50% lighter than SMD) cuts logistics expenses.

2.3 Fine-Pitch Breakthrough

No lead frame constraints enable sub-P1.7 pitch, with potential for <P1.0 using flip-chip tech.

2.4 Enhanced Performance

180° wide viewing angle and flexible bendable designs.

High impact resistance and easy-to-clean surface.

3. Industry Outlook

COB’s simplified supply chain (chip-to-module integration) and unmatched reliability make it ideal for outdoor fine-pitch displays. Meanwhile, SMD struggles with solder joint aging and waterproofing challenges in high-end markets.

4. Conclusion: COB’s lead frame-free design delivers a technological edge, poised to end the "Three Kingdoms" era and dominate future LED displays.

0 notes

Text

Detailed explanation of the composition and structure of LED large screen

LED full-color large screen is a high-tech display device. It is widely used in advertising, media, stage, commercial display and other fields with its high brightness, long life and rich colors. The following is the composition and key technical features of LED full-color large screen:

Basic composition:

Display unit: LED full-color large screen is composed of multiple single LED display screens, which can be seamlessly spliced to form a complete large screen.

Box: The box is the frame structure of the LED display screen. The main materials are iron, nano polymer, carbon fiber, magnesium alloy, die-cast aluminum, etc. Boxes made of iron and die-cast aluminum are more commonly used.

Display module: Display module is divided into plastic module and die-cast aluminum module. Plastic module is inexpensive and suitable for the mass market; while die-cast aluminum module has the advantages of fire retardant, no deformation at high temperature outdoors, high flatness, long life, fast heat dissipation, easy maintenance, etc., to take you to understand LED display soft module in 5 minutes.

Key technical features:

Brightness: Brightness is the basic indicator of LED full-color display screens. Outdoor display screens are not less than 5000nits, and indoor display screens are not less than 1000nits. Here is the knowledge about nit brightness. Wavelength: LED full-color display screens are composed of three kinds of LEDs: red, green, and blue. Each color is measured by wavelength. High-quality LED full-color display screens should have a wide color gamut. Power consumption: LED is an energy-saving light-emitting device. The power consumption of LED devices determines the power consumption of LED full-color display screens. Increasing the brightness of LEDs can reduce power consumption without changing the brightness of the display screen. Viewing angle: The viewing angle of LED full-color display screens is determined by the viewing angle of LED devices. Outdoor display screens mostly use elliptical LEDs with a horizontal viewing angle of 100° and a vertical viewing angle of 50°, while indoor display screens use SMD LEDs with a horizontal and vertical viewing angle of 120°. Failure rate: The failure rate of LED full-color display is also an important performance parameter, which affects the reliability of the display.

Application field:

The application field of LED full-color large screen is extremely wide, which can be divided into outdoor LED full-color large screen and indoor LED full-color large screen. Outdoor LED full-color large screen generally chooses display screens with larger pitch, such as P10, P8, P6 and P5, while indoor LED full-color large screen chooses small pitch LED display screen. What is the difference between indoor LED display and outdoor LED display?

Development trend:

With the advancement of technology, people have higher and higher requirements for screen clarity and color fidelity, and high-density and small-pitch LED displays will become one of the future development trends. What is a fine-pitch LED display?

The composition and key technical characteristics of LED full-color large screens determine their wide application and importance in many fields. With the continuous development of technology, the performance and application scope of LED full-color large screens will be further expanded.

Thank you for watching. I hope we can solve your problems. Sostron is a professional LED display manufacturer. We provide all kinds of displays, display leasing and display solutions around the world. If you want to know: Detailed explanation of the classification and types of LED display screens. Please click read.

Follow me! Take you to know more about led display knowledge.

Contact us on WhatsApp:https://api.whatsapp.com/send?phone=+8613510652873&text=Hello

0 notes

Text

Full Color SMD P10 Led Module Outdoor Lowest Price

P10 Outdoor LED Display Module Certainly the best option for outdoor advertising, this rental LED display carries some features that make it highly suitable for outdoor areas. It can work in different brightness level and outdoor circumstances. Rental led display can also be used at stage, bank, promotion, exhibition, station, KTV, stadium, airport and other outdoor places. High Gray Scale –…

0 notes

Text

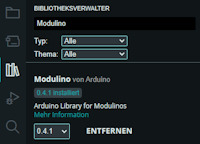

Einsteigerprojekt: Pixel Chaser mit dem Arduino Plug and Make Kit

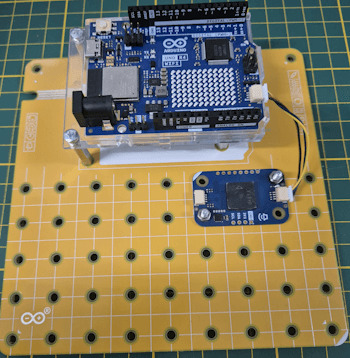

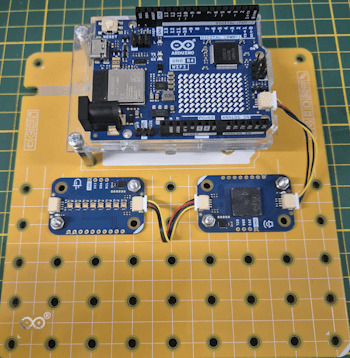

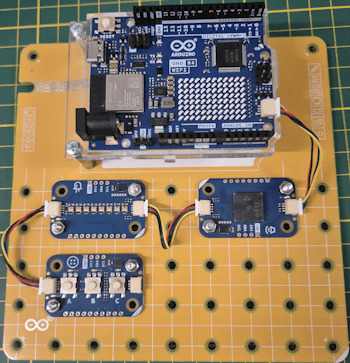

Ein kleines weiteres Einsteigerprojekt mit dem Arduino Plug and Make Kit ist Pixel Chaser. Du findest in diesem Kit alles, was du für den Aufbau des Spieles benötigst. https://youtu.be/VGD7f0Pg320 Für den Aufbau des Spieles benötigst du: - einen Arduino UNO R4 WiFi, - ein USB-Typ-C Datenkabel - ein Buzzer Modul, - ein 8fach LED Modul, - ein 3fach Taster Modul, - drei Qwiic Anschlusskabel All diese Komponenten sind im Kit enthalten.

Wie funktioniert das Spiel - Pixel Chaser?

Im Spiel "Pixel Chaser" sind acht LEDs in einer Linie angeordnet. Zu Beginn des Spiels wird eine der LEDs zufällig als Ziel ausgewählt und leuchtet rot auf. Eine andere LED bewegt sich kontinuierlich von links nach rechts und zurück entlang der Linie. Der Spieler muss den richtigen Moment abpassen und die Taste A drücken, um die bewegende LED anzuhalten. Ziel ist es, die laufende LED genau über der roten LED zu stoppen. Wenn der Spieler erfolgreich ist, erscheint ein lachender Smiley auf dem Display des Arduino UNO R4 WiFi, und ein positiver Ton wird abgespielt. Außerdem erhöht sich die Geschwindigkeit der laufenden LED, was das Spiel schwieriger macht. Verfehlt der Spieler das Ziel, wird ein trauriger Smiley angezeigt, begleitet von einem tiefen Ton. Danach beginnt das Spiel von vorne, und die Geschwindigkeit der LED wird auf den Anfangswert zurückgesetzt.

Aufbau der Schaltung - Pixel Chaser mit dem Arduino Plug and Make Kit

Der Aufbau des kleinen Einsteigerprojektes ist in drei wenigen Schritten erledigt. Da die Module über eine eindeutige Adresse verfügen kannst du diese auf der Modulino Base beliebig anordnen, du musst dich also nicht zu 100 % an diese Anleitung halten. Wichtig ist lediglich, dass diese mit dem Qwiic Kabel miteinander zum Arduino UNO R4 WiFi verbunden sind.

An den Modulino ist jeweils eine kleine, grüne SMD LED, diese sollte aufleuchten, sobald dein Mikrocontroller Strom bekommt. Dieses kannst du als Indikator nutzen, dass die Modulinos korrekt angeschlossen sind.

Programmieren in der Arduino IDE

Wie du die Modulinos des Arduino Plug and Make Kit in der Arduino IDE programmierst, habe ich dir bereits im ersten Beitrag Arduino Plug and Make Kit: Was ist drin und wie benutzt man es? gezeigt. Durch die I2C Adresse und der sehr einfachen Bibliothek ist die Programmierung besonders für Anfänger geeignet und mit wenig Codezeilen kann man schon beträchtliche Ergebnisse erzielen. Für die Programmierung der Modulinos benötigst du die Bibliothek Modulino welche du über den Bibliotheksverwalter der Arduino IDE installieren kannst.

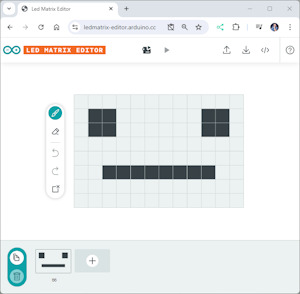

Nachfolgend das fertige Programm zum Download als ZIP-Datei. PixelChaserHerunterladen Schritt 1 - Importieren der benötigten Bibliotheken Im ersten _Schritt müssen wir die benötigten Bibliotheken dem Code hinzufügen. //Bibliothek zum ansteuern der Modulinos des //Arduino Plug and Make Kit #include //Bibliothek zum ansteuern der LED Matrix des //Arduino UNO R4 WiFi #include "ArduinoGraphics.h" #include "Arduino_LED_Matrix.h" Schritt 2 - Anlegen der Smileys für neutral, gewinn und verloren Die Smileys kannst du auf zwei Wege erstellen, zum einen erstellst du dir ein mehrdimensionales Array mit 8x12 Felder oder du nutzt ganz bequem den LED Matrix Editor von Arduino. Über diesen Editor kannst du mit der Maus dir ein entsprechendes Smiley zeichnen und dir den Code mit der Schaltfläche "" oben rechts herunterladen.

const uint32_t happy = { 0x31831, 0x80000404, 0x42081f0, 66 }; const uint32_t sad = { 0x31831, 0x80000001, 0xf0208404, 66 }; const uint32_t neutral = { 0x31831, 0x80000001, 0xf0000000, 66 }; Damit die Arrays den Code nicht unnötig lang machen, lagere ich diese in eine externe Datei "animation.h" aus und greife aus dem Code dann darauf zu. //Einbinden der Datei "animation.h" mit den //Smileys #include "animation.h" Schritt 3 - Aufleuchten einer zufälligen LED Um einen zufälligen Wert zwischen 0 und 8 (ohne die 8 selbst) zu erzeugen, benutze ich die Funktion random mit dem Parameterwert 8. Da die Range jedoch nur sehr gering ist, kann und wird es vorkommen, dass dieselbe Zahl mehrmals hintereinander kommen kann, daher packe ich den Code in eine While-Schleife und prüfe / handle dieses dort. int catchPixelIndex = -1; void activateRandomPixel() { ... int lastCatchPixelIndex = catchPixelIndex; while (lastCatchPixelIndex == catchPixelIndex) { randomSeed(analogRead(0)); catchPixelIndex = random(8); } ... } Schritt 4 - erzeugen eines Lauflichts Das Lauflicht auf dem 8fach LED-Modul bewegt sich von links nach rechts und wieder zurück. Mit jeder abgeschlossenen Runde erhöht sich die Geschwindigkeit. Bei einer Niederlage wird die Geschwindigkeit jedoch wieder auf den Ausgangswert zurückgesetzt. In diesem Fall wird die Pause im Lauflicht nicht durch den Aufruf der Funktion delay umgesetzt, sondern durch eine Überprüfung, ob die Zeit seit der letzten Aktion die festgelegte Pausenzeit überschritten hat. Wie dieses im Detail funktioniert, habe ich dir bereits im Beitrag Arduino: Ein Sketch ohne delay(ms) schreiben erläutert. int runningPixel = -1; int speed = 350; long lastAction = -1; bool movePixelReverse = false; void loop() { long currentMillis = millis(); if (currentMillis > (lastAction + speed)) { lastAction = currentMillis; movePixel(); } ... } void movePixel() { leds.set(runningPixel, BLUE, 0); if (!movePixelReverse) { if (runningPixel < 8) { runningPixel += 1; } else { runningPixel -= 1; movePixelReverse = true; } } else { if (runningPixel > 0) { runningPixel -= 1; } else { runningPixel += 1; movePixelReverse = false; } } leds.set(runningPixel, BLUE, BRIGHTNESS); leds.show(); leds.set(catchPixelIndex, RED, BRIGHTNESS); leds.show(); } Schritt 5 - Abfragen des Tasters In der loop können wir nun bequem den Taster auslesen und reagieren, wenn dieser gedrückt wurde. Wenn beide Pixel übereinanderliegen, dann gilt dieses als Gewinn und es wird ein hoher Ton ausgegeben sowie ein lachender Smiley, zusätzlich wird die Geschwindigkeit des Lauflichtes erhöht, indem die Pause zwischen den Schritten um 25ms. verringert wird. Sollte jedoch der Spieler nicht gewinnen, so wird ein trauriger Smiley angezeigt und ein tiefer Ton ausgeben. Die Geschwindigkeit des Lauflichtes wird wieder auf die Anfangsgeschwindigkeit gesetzt. const int BUTTON_A = 0; void testBtn() { if (buttons.update()) { if (buttons.isPressed(BUTTON_A)) { if (runningPixel == catchPixelIndex) { buzzer.tone(FREQ_WIN, 750); matrix.loadFrame(happy); speed -= 25; } else { buzzer.tone(FREQ_LOOSE, 750); matrix.loadFrame(sad); speed = DEFAULT_SPEED; } delay(600); matrix.loadFrame(neutral); activateRandomPixel(); } } } Das fertige Programm Hier nun das fertige Programm mit allen Kommentaren zum Quellcode. //Bibliothek zum ansteuern der Modulinos des //Arduino Plug and Make Kit #include //Bibliothek zum ansteuern der LED Matrix des //Arduino UNO R4 WiFi #include "ArduinoGraphics.h" #include "Arduino_LED_Matrix.h" //Einbinden der Datei "animation.h" mit den //Smileys #include "animation.h" //Objektinstanz der LED Matrix ArduinoLEDMatrix matrix; //Objektinstanzen der Modulinos ModulinoBuzzer buzzer; ModulinoPixels leds; ModulinoButtons buttons; //Feld zum speichern des Indexes //des Pixels welches angeklickt werden soll. int catchPixelIndex = -1; //Feld zum speichern des aktuellen aktiven //Pixels im Lauflicht int runningPixel = -1; //Konstante für die identifikation der Taste "A" const int BUTTON_A = 0; //Konstante für die Helligkeit der LEDs const int BRIGHTNESS = 20; //Konstanten für die Töne const int FREQ_WIN = 1200; const int FREQ_LOOSE = 400; //Konstante für die Standardgeschwindigkeit //des Lauflichts const int DEFAULT_SPEED = 350; //aktuelle Geschwindigkeit des Lauflichts int speed = DEFAULT_SPEED; //Feld zum speichern der letzten Ausführung des Lauflichts long lastAction = -1; //Feld zum speichern der Richtung des Lauflichts bool movePixelReverse = false; void setup() { //beginn der Kommunikation mit der LED Matrix des //Arduino UNO R4 WiFi matrix.begin(); //beginn der Kommunikation mit den Modulinos Modulino.begin(); //Initialisieren der I2C Kommunikation mit den //Modulino Sensoren/Aktoren buzzer.begin(); leds.begin(); buttons.begin(); //am Taster Modul lediglich die LED am //Taster "A" aktivieren. buttons.setLeds(true, false, false); //initial einen zufälligen Pixel aktivieren activateRandomPixel(); //auf der LED Matrix ein neutrales Smiley anzeigen matrix.loadFrame(neutral); } //Funktion zum aktivieren eines zufälligen Pixels //an dem 8fach LED Modul. void activateRandomPixel() { //Wenn bereits ein Pixel gesetzt ist dann,... if (catchPixelIndex > -1) { //setzen der Helligkeit auf 0, damit wird, //die LED deaktiviert leds.set(catchPixelIndex, RED, 0); } //ermitteln einer neuen Zufallszahl, //da bei einer Range von 0 bis 7 es vorkommen kann //das mehrmals der gleiche Wert ermittelt wird, //prüft die Schleife dieses und gibt bei //einem Unterschied eine neue Zahl zurück. int lastCatchPixelIndex = catchPixelIndex; while (lastCatchPixelIndex == catchPixelIndex) { randomSeed(analogRead(0)); catchPixelIndex = random(8); } //aktivieren des neuen Pixels leds.set(catchPixelIndex, RED, BRIGHTNESS); //anzeigen des neuen Pixels und löschen des alten leds.show(); } //Funktion zum prüfen und behandeln eines Tastendrucks am //Button Modulino void handleButton() { //aktualisieren des Moduls if (buttons.update()) { //Wenn der Taster "A" betätigt wurde, dann... if (buttons.isPressed(BUTTON_A)) { //prüfen ob der aktuelle Pixel vom Lauflicht dem //Pixel welches gefangen werden soll entspricht. //Wenn dieses so ist, dann gilt die Runde als Gewonnen. if (runningPixel == catchPixelIndex) { //einen hellen Ton für die Dauer von 750ms. ausgeben. buzzer.tone(FREQ_WIN, 750); //ein lachenden Smiley anzeigen matrix.loadFrame(happy); //Die Geschwindigkeit des Lauflichts erhöhen. //Der Wert Speed regelt die Pause innerhalb des Lauflichts. speed -= 25; } else { //Wenn diese beiden Pixel nicht übereinander liegen //gilt die Runde als verloren. //Es wird ein tiefer Ton für die dauer von 750ms. ausgegeben. buzzer.tone(FREQ_LOOSE, 750); //Auf der LED Matrix wird ein trauriger Smiley angezeigt. matrix.loadFrame(sad); //Die Geschwindigkeit wird auf die Ausgangsgeschwindigkeit gesetzt. speed = DEFAULT_SPEED; } //Eine Pause von 600ms. //(Damit der Spieler das Smiley sieht.) delay(600); //anschließend das neutrale Smiley anzeigen matrix.loadFrame(neutral); //und eine neue Runde starten activateRandomPixel(); } } } void movePixel() { leds.set(runningPixel, BLUE, 0); if (!movePixelReverse) { if (runningPixel < 8) { runningPixel += 1; } else { runningPixel -= 1; movePixelReverse = true; } } else { if (runningPixel > 0) { runningPixel -= 1; } else { runningPixel += 1; movePixelReverse = false; } } leds.set(runningPixel, BLUE, BRIGHTNESS); leds.show(); leds.set(catchPixelIndex, RED, BRIGHTNESS); leds.show(); } void loop() { long currentMillis = millis(); if (currentMillis > (lastAction + speed)) { lastAction = currentMillis; movePixel(); } handleButton(); } Read the full article

1 note

·

View note

Text

An Insight into Flexible LED Module

LED displays are widely used in advertising. To make them more appealing and innovative, a flexible soft LED display module has been created. What makes this module special is its ability to bend and curve. This adds a fresh visual effect to displays and expands their range of uses.

Features of Flexible LED Display Module

FPC: The flexible soft LED display module is different from other LED modules as it's made of a special material called

FPC instead of a rigid PCB board. FPC stands for Flexible Printed Circuit and is made of thin, lightweight materials like polyimide or polyester film. This material allows the LED module to bend and extend, making it easier to install in tricky corners. Plus, bending LED modules can create attractive new visual effects.

Magnetic Pillar Suction: Flexible soft LED display modules are primarily installed using magnetic pillar suction. This installation method is fast, simple, and secure, saving you a significant amount of time during installation.

Ductility: Flexible soft LED display modules are very flexible, which means two things. First, you can shape them however you want. Second, even after shaping, they can still display pictures from all angles at the same time. With high-definition display, they create a stunning visual effect.

Repairing Individual Points: In simple terms, flexible soft LED display modules are top-quality. They're designed to resist oxidation and moisture, which extends their lifespan. Plus, they're easy to maintain with frontal service, allowing for quick point-to-point repairs without needing to dismantle the whole module.

Pros and Cons

Pros of using flexible soft LED screen module-

Looking at the features of the flexible soft LED module, we can easily see its advantages:

Good visual effects

Low installation cost

Low maintenance cost

Easy to Repair

Cons of using flexible soft LED screen module-

Is using a flexible soft LED display module always a good idea? Actually, it's not that simple.Lets look over some cons of using flexible LED screen module:

Outdoor Limited

A bit expensive

Whether you're a designer, architect, event planner, or a tech enthusiast, flexible LED modules offer endless possibilities to push the boundaries of lighting and design. EagerLED is one of the top most service providers of LEDs and modules. You can contact here to get best services at very competitive prices.

#Flexible LED module#LED Display Module#LED Screen Module#SMD LED Display Module#Outdoor Front Service LED Display#Outdoor LED Module Price#VDWALL LVP615S

0 notes

Text

EagerLED High-Quality outdoor LED Screen Module |Advertising LED Screen

EagerLED High quality full color SMD outdoor LED display module Including the Data Power Cables and 2 Years Warranty, All LED screen modules panel With high brightness from 5000-7000 nits and Color uniformity to ensure the LED display has excellent visual effect.

0 notes

Text

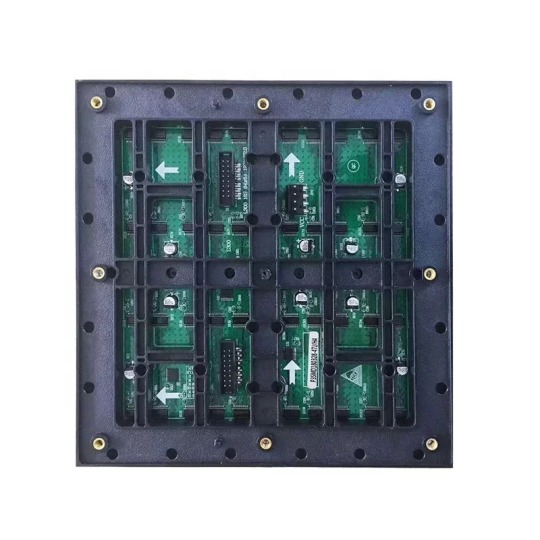

P3 High Brightness SMD Full Color Display Outdoor LED Module

P3 High Brightness SMD Full Color Display Outdoor LED Module

1. Use pure copper power cord and copper wire arrangement, stable and long service life.

2. Large viewing angles and a smooth display provide great visuals from all angles.

3. The module has high flatness, seamless connection, accurate and flexible installation, and quick installation.

4. The circuit board adopts the wave soldering process and has a green oil-oxygen barrier layer to prevent the circuit from being damp and oxidized and increase the service life.

5. High brightness, over 6000 nits, works well during the day even in direct sunlight.

6. Delicate colors, clear and natural images, with excellent RGB grayscale processing.

7. The front of the module is filled with glue to prevent the front lamp from getting damp. The back of the PCB is coated with three-proof paint, which is waterproof, moisture-proof and dust-proof.

8. High-quality LED chips, strong anti-static ability. High refresh rate, high brightness, waterproof, good heat dissipation.

0 notes

Text

Brief Details on Led Display Module, Dot Matrix Display & Smd Led

Graphical LED Displays utilize high-resolution graphics and video to transmit the information. You will find them sited in world's great cosmopolitan cities. These impressive electronic signs towering over the street displays graphic and video to broadcast important information or to advertise them. There are many companies that use these displays to broadcast their product in the open world and this LED Display Module help them a lot to expand their business or industry. In this digital world, the use of Graphical LED Displays gives new sleek to the tradition of marketing department also. Not only in the industrial zone, are they used in many other areas also. Because of the LED technology employed in Graphical LED displays, they are energy efficient, produce clear and bright result and waste no light.

Dot Matrix Display:

A dot-matrix display is a display device used to display information on machines, clocks, railway departure indicators and many other devices requiring a simple display device of limited resolution. The display consists of a dot matrix of lights or mechanical indicators arranged in a rectangular configuration (other shapes are also possible, although not common) such that by switching on or off selected lights, text or graphics can be displayed. A Dot Matrix Display controller converts instructions from a processor into signals which turns on or off lights in the matrix so that the required display is produced.

About SMD LEDs:

SMD LEDs are light emitting diodes in which the diode is mounted directly onto the circuit board but does not penetrate through the board like traditional LEDs do. This new manufacturing process provides the SMD LED with faster switching, longer life span, lower energy consumption and better battery performance when compared to standard LEDs. Eliminating the manual LED placement and soldering in favor of the automation of this wafer style production improves the speed and efficiency of the electrical components. This improvement in the manufacturing process leads to longer lifespan of the LED. Typical SMD LEDs have a life that can last up to an amazing 100,000 hours of continuous burn time.

SMD Technology is improving in the Market:

As SMD technology improves, LEDs will continue to shrink in size but grow in performance. The benefit of LEDs verses traditional incandescent lighting is growing brighter every day. Cost effective "off grid" lighting continues to drive developments in the solar power lighting field. The application of this SMD LED technology for rural areas and developing countries continues to grow and will be a major driving force. Clear projector on the aftermarket are available for car users to install in the headlights to form a focus light pattern in front of the car while driving; fashionable LED's and shining angel eyes (halo rims) are increasingly adopted to highlight the headlights and make their overall look beautiful, especially at nights.

0 notes

Text

The LED Large Screen World: A "Three Kingdoms" of Packaging Technologies – DIP, SMD, and COB

The LED Large Screen World: A "Three Kingdoms" of Packaging Technologies – DIP, SMD, and COB The modern LED large screen industry resembles a "Three Kingdoms" era, filled with intense competition. Three packaging technologies—DIP, SMD, and COB—stand as dominant players. COB (Chip On Board) packaging, having matured in LED display applications, particularly shines in outdoor small-pitch displays with its unique technical advantages. As the battle rages, which technology will ultimately emerge victorious?

What is COB Packaging? COB, short for "Chip On Board," is a novel packaging technology distinct from DIP and SMD. In the field of LED display technology, COB packaging involves: • Fixing LED bare die chips onto PCB pad positions using conductive or insulating adhesive. • Conducting wire bonding via ultrasonic welding to establish electrical connections. • Encapsulating the chips with epoxy resin to protect the LED light-emitting components.

Differences Between COB, DIP, and SMD Packaging • DIP (Dual In-line Pin Package): The earliest packaging method, where pre-fabricated LED lamp beads (with leads) are inserted into PCB holes and wave-soldered to create semi-outdoor or waterproof modules. • SMD (Surface Mounted Devices): Uses surface-mount technology, integrating RGB LED chips into a single package (e.g., "three-in-one" SMD beads) with leads soldered onto the PCB via reflow welding. The key distinction between COB and DIP/SMD lies in the elimination of the 支架 (lead frame): • DIP/SMD rely on lead frames with 4-6 pins, requiring reflow soldering of these pins onto the PCB. • COB omits the lead frame, skipping the reflow soldering step for the lamp bead surface, thus simplifying the process.

Advantages of COB Packaging 3.1 High Reliability A critical metric for reliability is the dead pixel rate: • National standard for LED displays: 0.03% (3 per 10,000 pixels). • COB achieves: <0.005% for full-color screens; <0.0008% for single/dual-color screens.

Reasons for high reliability: • Fewer control points in production: o SMD requires controlling 9 process points (5 for chip bonding, 4 for lead soldering). o COB only controls 5 points (chip bonding), reducing failure risks. For a P10 screen (1m²), COB eliminates 40,000 solder joints; for P1.0, it eliminates 4 million—a massive reduction in potential defects like cold soldering or bridging. • No reflow welding heat damage: o SMD’s 240°C reflow process risks breaking bonds or cracking chips due to thermal stress, issues that may emerge after deployment. COB avoids this step entirely. • Superior heat dissipation: o COB directly attaches chips to the PCB, offering a larger heat dissipation area and better thermal conductivity than lead frame-based designs. • Gold-immersed PCB: o COB uses gold-immersed PCBs, enhancing oxidation resistance in humid, salty outdoor environments compared to traditional tin-sprayed PCBs. • Seamless protection: o COB’s hemispherical epoxy encapsulation covers all components, leaving no exposed leads. SMD, with angular lead frames, struggles to protect millions of solder joints during outdoor waterproofing, leading to potential oxidation issues. 3.2 Cost Savings • Material costs: Eliminates lead frames and taping. • Process costs: Skips lead frame cutting, sorting, taping, and reflow welding. • Transport costs: Lighter modules (e.g., COB P3 modules are ~5-10kg/m² lighter than SMD) reduce logistics costs. • Simplified workflow: Integrates mid-downstream processes (from chip to display) within one factory, cutting packaging, logistics, and quality control costs. 3.3 Ease of Small-Pitch Implementation • Unrestricted by lead frame size, COB can design lamp beads as small as 1.2mm in diameter with 0.5mm spacing, enabling theoretical pitches down to P1.7. Future 倒装芯片 (flip-chip) tech may push below P1.0. 3.4 Lightweight, Wide Viewing Angle, and Flexibility • Lightweight: COB modules are 50% lighter than SMD counterparts. • 180° viewing angle: Hemispherical encapsulation eliminates light obstruction, versus SMD’s 125°-160° angle. • Bendable: No lead soldering allows flexible designs, unlike rigid SMD modules. 3.5 Durability and Maintenance • Impact/abrasion resistance: High-TG epoxy offers: o Compressive strength: 8.4kg/mm² o Shear strength: 4.2kg/mm² o A single P4 lamp bead can withstand 51.66kg pressure and 25.83kg lateral shear. • Easy cleaning: Smooth, mask-free surfaces allow direct water 冲洗 (washing) for outdoor use.

Conclusion COB packaging revolutionizes the industry by streamlining production, enabling smaller pitches, enhancing reliability, and reducing costs—advantages that grow more pronounced as pixel density increases. For outdoor small-pitch applications, once scaled, COB will dominate in both technology and price. SMD faces challenges in reliability, miniaturization, and cost, compounded by variability in downstream manufacturers’ capabilities (PCB quality, soldering precision, waterproofing, etc.) and market pressures for low prices. In contrast, COB, unburdened by lead frames, is poised for a bright future. As the industry evolves: "Six-legged (SMD) can’t outrun four-legged (DIP), and four-legged can’t outrun legless (COB)."

The LED Large Screen World: A "Three Kingdoms" of Packaging Technologies – DIP, SMD, and COB The modern LED large screen industry resembles a "Three Kingdoms" era, filled with intense competition. Three packaging technologies—DIP, SMD, and COB—stand as dominant players. COB (Chip On Board) packaging, having matured in LED display applications, particularly shines in outdoor small-pitch displays with its unique technical advantages. As the battle rages, which technology will ultimately emerge victorious?

What is COB Packaging? COB, short for "Chip On Board," is a novel packaging technology distinct from DIP and SMD. In the field of LED display technology, COB packaging involves: • Fixing LED bare die chips onto PCB pad positions using conductive or insulating adhesive. • Conducting wire bonding via ultrasonic welding to establish electrical connections. • Encapsulating the chips with epoxy resin to protect the LED light-emitting components.

Differences Between COB, DIP, and SMD Packaging • DIP (Dual In-line Pin Package): The earliest packaging method, where pre-fabricated LED lamp beads (with leads) are inserted into PCB holes and wave-soldered to create semi-outdoor or waterproof modules. • SMD (Surface Mounted Devices): Uses surface-mount technology, integrating RGB LED chips into a single package (e.g., "three-in-one" SMD beads) with leads soldered onto the PCB via reflow welding. The key distinction between COB and DIP/SMD lies in the elimination of the 支架 (lead frame): • DIP/SMD rely on lead frames with 4-6 pins, requiring reflow soldering of these pins onto the PCB. • COB omits the lead frame, skipping the reflow soldering step for the lamp bead surface, thus simplifying the process.

Advantages of COB Packaging 3.1 High Reliability A critical metric for reliability is the dead pixel rate: • National standard for LED displays: 0.03% (3 per 10,000 pixels). • COB achieves: <0.005% for full-color screens; <0.0008% for single/dual-color screens.

Reasons for high reliability: • Fewer control points in production: o SMD requires controlling 9 process points (5 for chip bonding, 4 for lead soldering). o COB only controls 5 points (chip bonding), reducing failure risks. For a P10 screen (1m²), COB eliminates 40,000 solder joints; for P1.0, it eliminates 4 million—a massive reduction in potential defects like cold soldering or bridging. • No reflow welding heat damage: o SMD’s 240°C reflow process risks breaking bonds or cracking chips due to thermal stress, issues that may emerge after deployment. COB avoids this step entirely. • Superior heat dissipation: o COB directly attaches chips to the PCB, offering a larger heat dissipation area and better thermal conductivity than lead frame-based designs. • Gold-immersed PCB: o COB uses gold-immersed PCBs, enhancing oxidation resistance in humid, salty outdoor environments compared to traditional tin-sprayed PCBs. • Seamless protection: o COB’s hemispherical epoxy encapsulation covers all components, leaving no exposed leads. SMD, with angular lead frames, struggles to protect millions of solder joints during outdoor waterproofing, leading to potential oxidation issues. 3.2 Cost Savings • Material costs: Eliminates lead frames and taping. • Process costs: Skips lead frame cutting, sorting, taping, and reflow welding. • Transport costs: Lighter modules (e.g., COB P3 modules are ~5-10kg/m² lighter than SMD) reduce logistics costs. • Simplified workflow: Integrates mid-downstream processes (from chip to display) within one factory, cutting packaging, logistics, and quality control costs. 3.3 Ease of Small-Pitch Implementation • Unrestricted by lead frame size, COB can design lamp beads as small as 1.2mm in diameter with 0.5mm spacing, enabling theoretical pitches down to P1.7. Future 倒装芯片 (flip-chip) tech may push below P1.0. 3.4 Lightweight, Wide Viewing Angle, and Flexibility • Lightweight: COB modules are 50% lighter than SMD counterparts. • 180° viewing angle: Hemispherical encapsulation eliminates light obstruction, versus SMD’s 125°-160° angle. • Bendable: No lead soldering allows flexible designs, unlike rigid SMD modules. 3.5 Durability and Maintenance • Impact/abrasion resistance: High-TG epoxy offers: o Compressive strength: 8.4kg/mm² o Shear strength: 4.2kg/mm² o A single P4 lamp bead can withstand 51.66kg pressure and 25.83kg lateral shear. • Easy cleaning: Smooth, mask-free surfaces allow direct water 冲洗 (washing) for outdoor use.

Conclusion COB packaging revolutionizes the industry by streamlining production, enabling smaller pitches, enhancing reliability, and reducing costs—advantages that grow more pronounced as pixel density increases. For outdoor small-pitch applications, once scaled, COB will dominate in both technology and price. SMD faces challenges in reliability, miniaturization, and cost, compounded by variability in downstream manufacturers’ capabilities (PCB quality, soldering precision, waterproofing, etc.) and market pressures for low prices. In contrast, COB, unburdened by lead frames, is poised for a bright future. As the industry evolves: "Six-legged (SMD) can’t outrun four-legged (DIP), and four-legged can’t outrun legless (COB)."

1 note

·

View note

Text

Advantages Of Indoor Fixed LED Display

LED is an effective advertising medium that has both outdoor and indoor applications. According to statistics, brand awareness is increased by 86% with the use of LED displays. The retail stores with Led displays attract 40% more shoppers than the shops without LED displays. Retail shops, government houses, or corporate spaces use indoor fixed LED display screen for indoor advertising. Indoor Led display module offers you plenty of options from which you may choose either a dynamic electronic sign or a simple colored message. You can reach the masses and share your brand message through an indoor fixed LED display. We are Indoor Fixed LED Display Manufacturer in Delhi.

Advantages of Using Indoor Fixed LED Display are as follows:

1. The Indoor LED screen catches the attention of the shoppers and influences them who visit the retail shops. So share your brand message through an LED display screen. For example, shopping malls make use of indoor LED screen displays to share their offerings, discounts, or events. Therefore, the customers, who visit the shopping malls, can notice the brand message on the LED display and reach their destined section of the malls.

2. As an indoor fixed LED display is a big screen, it can easily create a focus of the customers on the big screen. To draw the attention of the customers to special events, and indoor LED display screen is used. It creates clear, crisp, and bright images that make a better impression of your brand. It helps to glorify your business. A simple corporate environment turns into a gorgeous and welcoming fun place with the use of an indoor LED display. Staff members enjoy working in that environment while clients and customers are attracted to the corporate house using an LED display.

3. A Portable LED display can meet your unique needs. You can shift them from one place to another pace as per your requirement. You can use them when money permits. You can use them only to provide new information updates to the target audience due to operational flexibility.

4. The images displayed on indoor fixed LED displays are quite impressive and effective. The quality of images is better than that of the top LCD technology. Its brightness and clear pictures exceed LCD screens.

5. Indoor fixed LED displays can sustain in any weather condition. The unique feature is that they are eco-friendly and help in the conservation of energy.

6. You can easily update the advertising content. The updating method is simple and not even influenced by external conditions. However, you must take care of the pc procedure.

7. It has a long visual impact. Therefore, you must install them in places where you can attract potential customer's attention.

8. Another advantage is that indoor LED screens can be displayed for a long time a day.

You can purchase LED screens according to your budget and needs. LEDs can be put on sale and rented. Always try to purchase quality products. LEDs are durable, long-lasting and can satisfy customers whenever it is used. Keep in mind, as indoor LED screens are seen from a shorter distance than outdoor screens, higher resolution is needed to maintain visibility. Higher resolution also enhances picture quality. Before using indoor LED display, decide in advance what type of contents to be displayed. You may display images, animation, or live displays. But deciding in advance will allow you to reach potential customers and get the desired results.

Many companies offer a wide variety of indoor LED display screens. While purchasing, you must look at the quality and longevity of the led display screen. The services should cover display hardware services and software training. We, an indoor fixed LED display manufacturer, offer good quality products throughout the country. Many companies use our indoor LED display screens to advertise in shopping malls, stadiums, halls, theatres, trade fairs, etc. SMD technology, used in our indoor LED display screens, provides excellent brightness. Though its initial cost is high, yet it saves a lot of money on the printing cost.

5 notes

·

View notes

Text

3 ways to choose outdoor LED display

With the rapid development of the outdoor LED display market, it has become crucial to choose products suitable for your project. The following are some suggestions for choosing outdoor LED displays, mainly from three aspects: basic parameter selection, component material selection and manufacturer selection.

Basic parameter selection of outdoor LED display

type:

Single primary color, dual primary color and full color screens are suitable for text display, graphic display and video display respectively, and can be selected according to needs. LED displays are divided into single-color, dual-color and full-color types.

Point spacing:

Select the point spacing based on the distance between the viewers and use a simplified formula for estimation to ensure that the optimal viewing distance meets actual needs.

Grayscale:

Choose the appropriate gray level. The higher the gray level, the better the display effect.

Drive mode:

Static scanning and dynamic scanning are selected based on the expected display effect and budget, taking into account the balance of display effect, light loss and cost.

Screen brightness:

Select the screen brightness according to the installation direction and environmental requirements to ensure good display effects under various lighting conditions. Here's what you need to know about nit brightness.

Screen size and number of luminous points:

Calculate the number of modules and the number of light-emitting points according to specific size requirements to ensure that the screen size meets the engineering requirements. Do you want to know the dimensions and aspect ratio of 3x3 LED video wall?

Material selection for outdoor LED display screens

Lamp beads:

When choosing lamp beads from well-known brands, consider the brightness, viewing angle, uniformity, lifespan and other factors of the lamp beads. You can choose traditional plug-in LEDs or SMD LEDs, depending on actual needs.

power supply:

Choose a switching power supply dedicated for outdoor LED displays to ensure waterproof and sun-proof quality and stability of the driving current, leaving an appropriate power margin.

Selection of outdoor LED display manufacturers

Multi-party consultation: