#Slab Support

Explore tagged Tumblr posts

Text

Should Dowel Bars Be Used in Rural Road Construction?

Rural roads are more than just pathways—they’re lifelines. They carry not only vehicles but also the hopes of farmers, the daily commute of schoolchildren, and the pulse of local economies. Yet too often, these roads tell a familiar story: endless repairs, unexpected cracks, and surfaces that don't last a season. Harsh weather, poor drainage, and weak construction joints take a silent but steady toll. This is where solutions like dowel bars and HR coils become crucial—not as afterthoughts, but as essentials for building roads that endure.

Why Rural Roads Fail Differently

Unlike urban highways, rural pavements often suffer not due to traffic overload but from improper joint handling. Many fail not because of high volume but because of what lies beneath—unstable subgrades, erratic water tables, and inconsistent slab bonding. This leads to joint deterioration, faulting, and slab displacement, quietly eroding the strength of the pavement over time.

The Role of Dowel Bars in Road Longevity

Dowel bars in road construction address the core of this issue—they offer a stable connection between adjacent slabs, enabling them to share loads evenly. This means when a wheel crosses a joint, the load doesn’t fall entirely on one side. Instead, it’s distributed, reducing stress concentration and minimizing wear. For roads that see tractors one day and water tankers the next, that’s a game-changer.

How HR Coils Complement the Structure

What adds even more resilience is when HR coils are introduced into the slab framework. Known for their tensile strength and flexibility, HR coils help the concrete accommodate temperature fluctuations and minor ground movements without cracking. Together, dowel bars and HR coils form a structural duo—one anchors, the other flexes.

Why It Matters for Rural Settings

The synergy is particularly vital in rural settings where monsoons swell the soil and winters harden it. Roads built without these reinforcements often display early signs of slab shifting and joint misalignment. In contrast, those using dowel bars in road designs maintain their geometry for years, with only minimal maintenance required.

A prime example lies in rural Karnataka, where test sections using dowel bar-jointed slabs showed 40% fewer cracks after three years compared to traditional methods. Engineers on site observed reduced faulting even with consistent agricultural vehicle movement. These are real-world outcomes—not theoretical assumptions.

Dispelling the Cost Myth

Still, there’s hesitation. Some believe dowel bars are suited only for expressways or expensive urban projects. But modern civil engineering proves otherwise. With newer installation methods and modular reinforcement designs, rural contractors can adopt these systems without overshooting budgets. What once seemed "overbuilt" now fits smartly into cost-effective, sustainable planning.

In fact, the upfront investment in dowel bars and HR coils translates to fewer repairs, reduced downtime, and lower life-cycle costs. Instead of spending on patch-ups every monsoon, the funds can go toward road extensions or drainage improvements. For local authorities working with limited resources, that shift is monumental.

More Than Materials—It's a Commitment

Beyond the technical benefits lies an emotional one—reliability. Villagers begin to trust a road that doesn't disintegrate under their daily journeys. Children reach school safely. Farmers deliver produce on time. That’s not just engineering—that’s impact.

So, should dowel bars be used in rural road construction? Without a doubt. Their presence ensures that roads don’t just exist—they endure. When paired with HR coils, the result is a reinforced promise: a path built not just to connect but to last.

Conclusion

Rural roads deserve more than makeshift fixes. They need structural foresight. Dowel bars and HR coils offer that foresight—a solution rooted in strength, experience, and long-term value. These elements transform vulnerable stretches into robust lifelines, empowering rural communities to thrive with confidence. The next time a road is planned in a village, let it be more than just concrete. Let it be commitment, reinforced.

#dowel bars#HR coils#rural roads#road strength#road cracks fix#load transfer#road joints#slab support#road repairs#rural paving#HR steel use#road faults#road lifespan#concrete roads#road stability#pavement life#joint failures#monsoon roads#low-cost roads#road building

0 notes

Text

Why Dowel Bars Deserve More Attention?

In concrete road construction, one small mistake can turn into massive repair costs. And often, that mistake is ignoring dowel bars—the unsung heroes of load transfer. These simple steel rods are often overlooked, but they’re essential in keeping concrete pavements stable, crack-free, and cost-effective in the long run.

If you’re in infrastructure or road projects, understanding the correct use of dowel bars in concrete can make or break your pavement’s durability.

What Are Dowel Bars and What Do They Do?

Dowel bars are cylindrical steel rods placed across transverse joints in concrete pavements. They ensure that loads are transferred from one concrete slab to the next, allowing for smooth traffic movement without putting excessive pressure on any single slab.

This mechanism—known as load transfer in pavements—prevents slab cracking, corner breaking, and uneven surfaces, especially under heavy vehicles.

Technical Specifications of Dowel Bars (India Standards)

In Indian road construction, dowel bars generally follow these guidelines:

Diameter: 25 mm to 38 mm

Length: 450 mm to 600 mm

Spacing: 300 mm to 350 mm center-to-center

Coating: Epoxy or stainless steel to resist corrosion

Placement: Aligned perfectly in the middle of the slab thickness

Standards followed include:

IRC:58 for pavement design

IS:456 for concrete structure practices

Incorrect dimensions or poor alignment can cause joint locking, defeating the purpose of load transfer altogether.

Benefits of Dowel Bars in Concrete Pavements

Reduces edge cracking under load

Minimizes maintenance costs over time

Improves ride quality and surface level

Enhances load-sharing between slabs

Complies with modern engineering codes

For highway projects, industrial zones, airports, and even smart city roads, dowel bars offer both performance and ROI.

Common Mistakes to Avoid in Dowel Bar Placement

Misaligned dowel bars cause joint locking.

Wrong bar size reduces effectiveness.

Inadequate corrosion protection leads to early failure.

Poor concrete compaction around bars leads to voids.

Use dowel bar baskets, proper templates, and level indicators during installation.

Real-World Example: Long-Lasting Urban Roads

A smart city project in central India faced early pavement failures due to missing dowel bars. Upon redesign with proper dowel bar placement in roads, maintenance dropped by 42%, and surface life increased by 5+ years—all by investing a small amount in the right steel rods.

Why Kapila Steel Is the Trusted Choice for Dowel Bars

At Kapila Steel, we manufacture high-precision dowel bars that meet both national and international standards. Here’s what sets us apart:

Precision machining for accurate length and diameter Anti-corrosion coating for extended lifespan Custom specifications based on project requirements Prompt delivery and pan-India supply chain

Whether your project is a national highway or a local township road, we’ve got your back.

Conclusion: It’s Time to Build Roads That Last

In concrete pavement design, dowel bars are not optional—they’re essential. They offer load-sharing, durability, and cost savings you can’t afford to skip. And when you choose Kapila Steel, you get bars engineered for performance, safety, and long-term value.

Frequently Asked Questions (FAQs)

1. What is the main purpose of dowel bars in concrete pavements?

Dowel bars are used to transfer load across joints in rigid concrete pavements, helping prevent cracking and uneven settlement. They allow slabs to expand and contract without damaging the surface.

2. Are dowel bars and tie bars the same?

No, they serve different functions. Dowel bars transfer load across transverse joints, while tie bars hold adjacent slabs together along longitudinal joints to prevent separation.

3. How far apart should dowel bars be placed?

In most road projects, dowel bars are placed at 300 mm to 350 mm center-to-center spacing. However, the exact spacing depends on slab thickness and traffic load conditions.

#dowel bars#bar dowels#load transfer#concrete slabs#joint support#steel dowels#dowel spacing#dowel types#slab cracks#road dowels#epoxy dowels#dowel design#slab support#rigid pavement#bar alignment#crack control#dowel uses#dowel rods#highway slabs#pavement life

0 notes

Text

✅figured out why the technomat was so nervous about waking the enginseer prime

#pasqal haneumann#warhammer rogue trader#ive been thinking about he sleeps a lot. when he does. its intermittent#his bed is a slab that has an in built respirator so hes not got the clunkiness of his usual one#various cables for defrag/backup purposes and just life support stuff#removes his prosthetics and mechadendrites ofc thats important#his thermoregulation is very good so he doesnt use blankets either tbh#real reason he cant be romanced: how he has to sleep to be comfortable is dire#i just like drawing him looking like a freakthing when hes perfectly comfortable yknow. oh he has so many augments

31 notes

·

View notes

Text

Making a separate post for this bell ringing video I took cause it didn’t fit in the last post.

#ceramic bell#ceramic glaze#ceramist#ceramics#radio clear glaze#taffy glaze#underglaze#nail polish#solid hollow technique#slab and coil method#pinch pot#moomin fanart#moomin art#ninny moomin#moominmamma#moominvalley#moomin#Moomintroll#snorkmaiden#artists on tumblr#artist support#original art#new art tumblr#new artist#3d artwork#stoneware clay#clay art#clay#high fire reduction

28 notes

·

View notes

Text

The Hall:tm: (still needs a name) in progress !!

She needs some greenery or (at least) more wood and colour, but it's kind of difficult to do that when I dug into the side of a mountain...

Anyways, big smooches to the quarry mod. Splitter plugs saved my life !!

#vintage story#da Hall:tm:#I'm kind of glad I have this winter project though since I tend to hyperfocus really hard on crop rotation in the summer#it's a bit aggressive tbh#and I don't like that I haven't guilded my fruit trees properly so the crops that are immediately under the trees don't benefit from rain#but that's on me I'm dumb dumb#anyways so far the Hall:tm: serves storage purposes on either side#I also discovered that one can stack the quarry mod's stone slabs !! so good !!#also the support pillars need more texture grrr

8 notes

·

View notes

Text

Pro Plumber Deer park TX

Plumber Deer Park TX is here to provide you with the timely and affordable service you’re looking for. Our team understands that when you’re unable to find the right system for an entire series, it can really be tough. Regardless of who's winning or losing, the pressures must be absolutely magnificent. Though you might feel like a shut-in at times, this is the copywriter’s dream. Sewer drain cleaning is a great service to utilize when you don’t know what to do about our sewage. When your drains are backed up to oblivion, it's important to realize that those dishes and pipes aren’t going to clean themselves. Why not take matters in your own hands and make sure you can do it next year? Plumbing leak detection is something that we can already take care of for you. Are you trying to figure out how to get your leaks detected and figured out? Maybe you don’t know how to handle it and you’d like for someone to kind of show you the ropes. If you want to know exactly where your son’s leak is, you can count on our plumbing setup to show you.

#Water heater repair#Installation services#Bathroom repair#Leak stoppage#Leakage detection#Slab leak repairs#Emergency plumbing support#Hot water repairs#Drain cleanings#Cracked pipe replacements

2 notes

·

View notes

Text

how to easily fuck up a baby dragon design: give it a human face instead of an actual baby animal one

#my dude looks like a slab of meat#what a joke#league of legends#also wasn't there like a dragon character in my little pony named smolder?#this champion looks like taken out from the 5G my little pony series#idk how people can still support this rich-ass company who treats them like nincompoops by giving them table scraps#unless they are clinically obsessed with the gaming aspect of it in which case i pity them and wish them a swift recovery

2 notes

·

View notes

Text

This is very poetic. But I admit. Part me is just...

Oh, boo hoo. You, vampires, with your generational wealth and lifetime's of connections, I think you can do more than mourn. We humans who care can only do so much. If only we had some clever vampires around who could, I don't know, enthrall city councils to enact better light pollution policies? Fund lobbies against light pollution at state and federal levels?

Vampires are our predators, not our victims. But they are stuck here on this planet with us. This is their home, too, and they should act like it.

The stars aren't gone. Only their (and our) inaction and existing policies make them so.

Do you think vampires mourn the stars?

They remember the time before electric lights. They made their transition from people of the day to creatures of the night - but the change was not so stark, because the night was still bright with the glitter of a galaxy. When they looked up, it was not a single sun that hung in the sky but hundreds. Thousands. Pinpricks of light that travelled lifetimes to shine above the Earth.

Then the humans poured their artificial light into the atmosphere, and the stars were gone. Smothered by a blanket of orange-grey muck.

Vampires have to live where humans are, and humans mean light pollution. To find the stars again would require hunger. Starvation.

They choose to be well fed. They choose to grieve the night sky they used to know

#mourn the world we're losing#but don't let mourning stop you from acting#we're on life support not the slab

3K notes

·

View notes

Text

How Dowel Bars Help Minimize Maintenance Costs in Long-Span Concrete Structures

The Hidden Costs of Structural Wear

Long-span concrete structures carry more than just vehicles—they carry the weight of time, traffic, and temperature. Over months and years, surface joints take the brunt of that burden. Small cracks start to appear. Edges begin to shift. And suddenly, maintenance becomes a recurring line item no one planned for. That’s the moment when the value of dowel bars, smart bar dowel systems, and high-performance steel from trusted TMT bar manufacturers comes sharply into focus.

Why Concrete Alone Isn’t Enough

Even the best concrete won’t stay level forever. Each slab in a long-span structure expands and contracts with temperature changes. Add the constant stress from heavy vehicles or equipment, and the joints between slabs begin to suffer. Without support, those joints fail faster—and so does the surface.

The Awareness Stage: Spotting the Problem

The signs often go unnoticed at first. A little joint movement here. A surface dip there. But for engineers and planners, these aren’t just cosmetic issues. They’re early indicators of costly problems ahead. Awareness is the first step: understanding that what happens beneath the surface matters just as much as what’s visible on top.

The Consideration Stage: Enter Dowel Bars

This is where decision-makers start weighing long-term solutions. Dowel bars provide a simple but powerful answer. By transferring loads evenly across joints, they reduce movement, minimize stress, and keep slabs aligned. It’s a small piece of reinforcement with a massive impact on performance and durability.

Why Bar Dowel Quality Matters

Not all dowel systems are created equal. Precision-engineered bar dowel components ensure that alignment stays true over years of use. Proper sizing, placement, and installation reduce the risk of faulting or cracking, especially in high-load zones.

The Role of TMT Bar Manufacturers in Structural Reliability

Strength starts with sourcing. Materials from experienced TMT bar manufacturers bring more than tensile power—they bring reliability. Their bars offer corrosion resistance, thermal stability, and load-handling capacity that standard materials simply can’t match. When used alongside dowel bars, they create a support system that holds up against time, weather, and usage.

The Decision-Making Phase: Thinking Long-Term

Once the long-term benefits become clear, choosing dowel bars isn’t about upfront cost—it’s about minimizing future headaches. A surface that holds its form over decades means fewer closures, less repair work, and greater operational uptime.

Less Maintenance Means More Predictability

When maintenance becomes predictable—and less frequent—it transforms how budgets are allocated. No surprise repairs. No emergency callouts. Just a well-performing surface that does what it’s supposed to do, year after year.

An Environmentally Smarter Choice

Maintenance work doesn’t just cost money. It creates waste, burns fuel, and generates emissions. Every repair avoided by using dowel bars means fewer trucks, fewer tools, and a lighter environmental footprint over the life of the structure.

Small Investment, Massive Return

Dowel bars don’t shout for attention, but they make all the difference where it counts. Combined with bar dowel precision and support from seasoned TMT bar manufacturers, they create a resilient, cost-efficient infrastructure that performs reliably over time.

In Conclusion

Strong structures don’t just happen. They’re built on smart choices—choices that include silent reinforcements like dowel bars. They may be invisible once the concrete sets, but their value is seen in every year of trouble-free performance that follows.

#Dowel Bars#Concrete Joints#Joint Stability#Long-Span Slabs#Load Transfer#Cost Saving#Crack Control#Bar Placement#Slab Support#Pavement Life#Joint Cracking#Bridge Joints#Dowel Systems#Stress Relief#Low Maintenance#Rigid Pavements#Bar Alignment#Structural Bars#Joint Durability#Slab Longevity

0 notes

Text

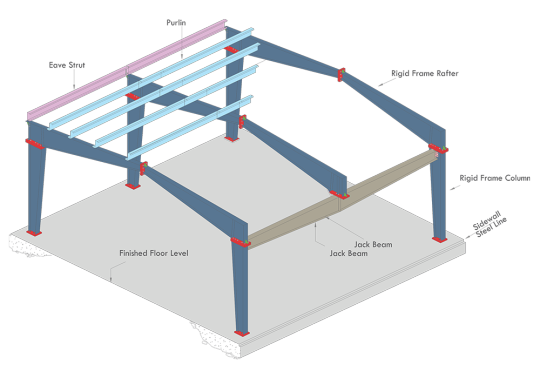

Smith Structure| Jack Beam Elevating Structural Support

Smith Structure introduces jack beams structural component used in construction for temporary or permanent support of floors, roofs, or load-bearing elements

#Jack Beam#Isometric Jack Beam at Sidewall#Isometric Jack Beam at Interior Column Location#Mezzanine System#mezzanine framing system#steel deck support#mezzanine beams#Mezzanine Plan#steel formwork#oncrete slab construction#Mezzanine Cross Section#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

Freaky thing reveal (I hate this damn thing !!)

Evil thing pictures enjoy

#ceramics#ceramist#ceramic glaze#stoneware#clay art#clay#handbuilding#underglaze#Pete’s clear glaze#slab and coil method#clay sculpting#3d artwork#3d art#artists on tumblr#artist support#original art#new art tumblr#new artist#orange#blue#red#white#I tried to make my own Moche vessel but I failed miserably#least favorite project of the semester#could you believe this was supposed to be a conch shell#Ivan the terrible really cursed me during this project deadass

2 notes

·

View notes

Text

my emotional support rock slab and cartoon birdy...

2K notes

·

View notes

Video

tumblr

Adjustable u-head jack for slab and beam shoring scaffold support - sca...

#scaffold#scaffolding#formwork scaffolding#shoring scaffold#shoring#shoring support#scaffold shoring#u head#u head jacks#u jacks#slab formwork#slab scaffolding#slabs#concrete slab#beam formwork

0 notes

Text

art is such a wonderful thing to be able to create. to take time out of your day to create something that meaningfully impacts someone else. to be able to put your vision out on paper or a screen or a slab of clay and it becomes art.

however, not everyone is able to have that privilege. @shoroa91 and her family have been robbed of a home, a place to live, their educations, and her children's childhoods.

every day, she reaches out to people to spread the word that she is still alive, that she will keep fighting for her and her children. so that one day, they can live a safe and free life.

if you have sympathy and some money to spare, please consider helping shorouq and her children.

as of writing this post, she is at €1,346 / €30,000, only 4% of her goal. she has been vetted.

taglist (dm to be removed)

@skinwretch @meowmaids @featherfrond-reblogs @halvoric @pcktknife @readingsquotes @bellybuttonblue2 @andiv3r-reblogging @sillyseer @cloudedcari @stealthjet @pinnyy @sivavakkiyar @chronicowboy @bi-worm @ydic74the @amorosebeing @golvio @nb-marceline @tachycardial @cicadaland @manletwizard @2blushie @antiauteur @pompompotato @purpupa @cherrysnax @autisticmudkip @kalosbian @wakimakiplus @w0rld0flight @evileyeamulet @justsomeoneunordinary @i-think-i-will-watch-leverage @ollie-ollie-oxenfreee @baefikre @crownedscribe @2kbloodsucker @crow-thing @sanfranlvrs @acehimbo @teortoise @pathogenic @stump-not-found @ddeck @stagbeetleboy @sketiana @trendytransgender

#jay.error#free palestine#free gaza#gaza#i stand with palestine#from the river to the sea#palestinian aid#verified fundraiser

1K notes

·

View notes

Text

Dragons are greedy creatures.

When Lilia told him stories of the past, he almost never failed to emphasize that point.

"So when your father and I got something for ourselves from that festival, we'd always ask your mother if she wanted some. She would say no, of course, because a princess did not partake in such unpalatable junk food. But then minutes later she'd demand 'Raverne, Lilia. Surrender those snacks to me,' and I'd say 'Why didn't you get your own,' and she'd spend the rest of the day fuming! And she claimed that she didn't like junk food, but her tasteful tongue then drizzled soy sauce onto her sorbet. Can you believe it! Dragons really are such greedy creatures."

Malleus wanted to argue that it was probably an attitude issue of the individual rather than a collective, and that perhaps he shouldn't be so prejudiced to their species, but he let Lilia vent his frustrations anyway. Old people needed to feel supported.

So when here and now, when it was his turn to go around a festival-- hand in hand with his beloved, he couldn't help but be reminded of such stories.

"So then I asked Lucius to kindly shut the hell up because I was trying to finish a homework with ten minutes left. And he just farted in my face! Can you believe him!"

"Abominable creature. Now, I'd like to sample some of those potato sticks. Would you like some as well?"

They shifted their attention to a stall a few ways aside. "Oh, fries? No thanks. I'm on a strict diet. We call those French Fries by the way, but you wouldn't know that because no one here is French. Except for Rook for some reason."

"What is a french? Is that new slang?"

They spent a while explaining the French, and how it was disputable whether French Fries were actually made in France because many Historians claimed they were Belgian. He said that was ridiculous; were even foodstuff colonized in their world? Then they mentioned that Swiss Cheese wasn't actually Swiss, because an American created them. He then asked what an American was.

Before they knew it, half of his food was consumed not by himself, but by his companion who squirreled away his potatoes though they claimed they didn't want some.

They nibbled on a particularly long slab of fries, "Wow, you bought so much. I didn't know princes were allowed to eat this much junk."

Indeed, he bought twice the dose he would normally allow himself to indulge in.

"Well," he said with a grin lifting at the corners of his mouth, "I am a dragon, after all. We're quite well-known to be greedy creatures."

They laughed and finished off the rest of their share from his paper bag.

If he were to guess the timeline of Lilia's story correctly, then it was likely the time when his egg was still developing in his mother's womb. Just as he would buy an excess of junk food for his partner so they would enjoy with no remorse, his mother also betrayed her own sense of taste because he probably asked her to.

And that was when he understood that dragons truly are such greedy creatures. Greedy for the sake of those they loved.

#i told my partner I didn't want his shawarma but i ate half of it#twisted wonderland#malleus draconia#ventique rambles#malleus x reader#malleyuu#lilia vanrouge#maleanor draconia

887 notes

·

View notes

Text

How Bar Dowels and Construction Rings Work Together in Load Transfer

Modern concrete systems rely heavily on construction rings and bar dowels to effectively transfer masses throughout enlargement and contraction joints. These vital additives paintings synergistically to preserve structural integrity while allowing for thermal movement, stopping commonplace troubles like cracking and displacement. Understanding how those additives feature collectively famous why they've turn out to be general exercise in exceptional creation initiatives worldwide.

The Foundation of Joint Systems

The interaction between concrete slabs depends largely on properly designed joint systems. Construction rings play a crucial role in these systems by creating perfectly aligned circular openings that house bar dowels. These precision-manufactured rings typically come from processed hot rolled coil material, ensuring dimensional accuracy and structural strength.

When properly installed, construction rings create pathways that allow bar dowels to slide horizontally while still transferring vertical loads. This seemingly simple mechanism solves a complex engineering challenge: maintaining load transfer capability while accommodating inevitable concrete movement.

Understanding Load Transfer Mechanics

Vertical load transfer occurs when weight or pressure applied to one concrete section passes smoothly to adjacent sections. Without proper load transfer systems, differential settlement can occur, creating uneven surfaces, trip hazards, and accelerated deterioration.

Bar dowel assemblies work by spanning across joints while remaining anchored in one slab and free to move in the adjacent slab. The smooth bar dowel surface allows horizontal movement within construction rings, which act as sleeves or collars. This arrangement prevents the connected slabs from moving vertically relative to each other while allowing for essential horizontal movement.

The effectiveness of this system depends heavily on the material quality. Construction rings must maintain their shape and position during concrete pouring and curing. High-quality rings processed from hot rolled coil material provide the necessary rigidity and durability for this critical application.

Material Considerations and Engineering Standards

The manufacturing process for both construction rings and bar dowels significantly impacts performance. Premium creation earrings go through rigorous best manage at some stage in manufacturing. The warm rolled coil used to create those components commonly includes unique carbon and manganese chances to obtain choicest strength-to-weight ratios.

Bar dowel material selection is equally important, with most specifications calling for plain round steel bars with specific yield strength requirements. The interface between the bar dowel and construction ring requires careful engineering to balance friction, movement capability, and load transfer efficiency.

Industry standards specify precise tolerances for both components. Construction rings must maintain consistent internal diameters, while bar dowels need exact dimensions and smooth surface finishes. This precision ensures predictable performance under varying load conditions.

Installation Best Practices

Proper placement of construction rings and bar dowels requires careful attention to detail. Rings must be secured at specified heights and spacing before concrete placement. The bar dowel must be positioned perfectly perpendicular to the joint, typically with half its length coated with bond-breaking compounds.

During installation, construction rings are often integrated with formwork systems that establish joint locations. Once the first concrete pour cures, forms are removed while rings remain embedded, creating perfect alignment guides for bar dowel insertion.

Performance and Long-Term Considerations

The effectiveness of construction rings and bar dowel systems becomes evident over time. Properly designed and installed systems maintain joint integrity for decades, even under heavy traffic and varying environmental conditions.

Monitoring joint performance involves checking for excessive movement, spalling, or faulting across joints. The hot rolled coil material used in quality construction rings resists corrosion and fatigue, contributing to system longevity.

By understanding how construction rings and bar dowels work together, construction professionals can better appreciate their importance in modern concrete structures, ultimately leading to better-performing, longer-lasting infrastructure projects.

#bar dowels#load transfer#concrete rings#construction load#dowel bars#joint strength#TMT rings#column ties#load bearing#concrete joints#RCC bars#steel dowels#beam support#load design#bar placement#slab support#tie rings#bar connection#rebar usage#steel rings

0 notes