#SmoothSurfaces

Explore tagged Tumblr posts

Text

Achieve the Perfect Finish with Kabawat Steel Putty Strips!

When it comes to painting, the key to a flawless and long-lasting finish lies in the preparation. Uneven surfaces and cracks can ruin the look of even the best paint jobs. But with Kabawat Steel Putty Strips, you can ensure a smooth and seamless foundation before you begin painting. Whether you're working on walls, ceilings, or intricate detailing, our putty strips provide precision, durability, and ease of use, making them an essential tool for every painting project.

Why Choose Kabawat Steel Putty Strips?

✅ Perfect for Filling Cracks and Leveling Surfaces – Easily smooth out imperfections for a flawless finish. ✅ Creates a Smooth & Even Base for Painting – Ensures that your paint adheres perfectly, giving it a professional touch. ✅ Durable and Easy to Use – Designed for both professionals and DIY enthusiasts, making application effortless.

A Great Paint Job Starts with the Right Base!

A strong foundation is essential for a professional-quality paint finish. With Kabawat Steel Putty Strips, you can eliminate surface flaws, enhance adhesion, and achieve a refined and polished look for any painting project. Whether you're renovating your home, working on an artistic masterpiece, or handling a commercial project, trust Kabawat for perfection from the very first layer.

Get in Touch

📞 Contact Us: 82096 17061 | 98218 25663 📧 Email: [email protected]

Visit our website for more information and explore our products.

Connect with Us

Stay updated with our latest offerings and tips for painting your retail space by following us on Instagram here.

For more information or to request a consultation, visit their website: https://www.indiamart.com/kabawatbrushcompany/

To stay updated with the latest posts, follow us on social media:

📸 Instagram

📘 Facebook

📌 Pinterest

🧵 Thread

🥁 Tumblr

▶️ YouTube

Contact: Kabawat Brush Company +91- 82096 17061 / +91- 98218 25663 https://www.indiamart.com/kabawatbrushcompany/

Digital Partner:

TVM INFOSOLUTIONS PVT LTD

Contact: TVM Info Solutions Pvt. Ltd.

+91-9004590039

https://tvminfo.com

Follow us on Social Media

🌐 Website

📸 Instagram

📘 Facebook

🔗 Linkedin

▶️ Youtube

#KabawatSteelPuttyStrips#FlawlessFinish#PaintingPerfection#SmoothSurfaces#DIYPainting#ProfessionalPainting#WallPreparation

0 notes

Text

⭐ Achieve the Perfect Finish with Kabawat Steel Putty Strips! 🎨

👋 Say goodbye to uneven surfaces and cracks! Kabawat Steel Putty Strips are your ultimate partner for creating a flawless foundation before you paint. 🖌️ Whether you're working on walls, ceilings, or fine details, our putty strips ensure precision, durability, and ease of use. 😇

📌 Why Choose Kabawat?

✅ Perfect for filling cracks and leveling surfaces

✅ Ensures smooth, even surfaces for paint

✅ Durable and easy to handle

👀 Because a great paint job starts with the perfect base, trust Kabawat to make your project shine from the very first layer. Ready to take your painting to the next level? Let us help you lay the groundwork for perfection. ✨

📞 82096 17061 | 98218 25663

#KabawatSteelPuttyStrip#FlawlessPainting#PerfectBase#SmoothSurfaces#PaintingEssentials#KabawatTools#KabawatPuttyStrip#FlawlessFinish#WallPrep#SmoothWalls#SurfacePerfection#KabawatQuality#Bhiwandi#Thane#Mumbai

0 notes

Text

Winterize Your Asphalt Driveway.

How to Winterize Your Asphalt Driveway: A Step-by-Step Guide

Winter can be tough on your driveway, especially if you live in an area where freezing temperatures, snow, and ice are common. Asphalt driveways, while durable, are vulnerable to the harsh conditions of winter. If not properly maintained, they can crack, deteriorate, and suffer long-term damage, leading to expensive repairs down the line. Fortunately, with a little preparation, you can help protect your asphalt driveway from the elements and ensure it stays in good shape throughout the cold months.

Why Winterize Your Asphalt Driveway?

Asphalt is an incredibly resilient material, but like any outdoor surface, it faces wear and tear when exposed to extreme weather. During the winter, water can seep into small cracks in your driveway. When the temperature drops, this water freezes and expands, which can exacerbate existing cracks and create new ones. Snow and ice also introduce the potential for chemical damage from salt, which can degrade the surface and accelerate wear.

Winterizing your driveway helps prevent the freezing and thawing cycles from causing major issues, and it can extend the lifespan of your asphalt surface. Here's a step-by-step guide to winterizing your driveway so it stays strong and protected until spring.

1. Clean the Driveway

Before you start any winterizing tasks, it’s important to thoroughly clean your driveway. Dirt, debris, and fallen leaves can trap moisture against the surface, which can lead to cracking and deterioration. Here's how to clean it properly:

Remove debris: Use a broom, rake, or blower to remove leaves, twigs, and other debris from the surface.

Pressure wash: If your driveway is particularly dirty, consider using a pressure washer to get rid of grime, oil stains, or other residue that could trap moisture.

Clear out cracks: For areas with visible cracks, use a wire brush or a putty knife to remove any weeds, moss, or loose debris from the cracks. This will help ensure that repairs are more effective.

2. Inspect for Cracks and Potholes

Winter’s freeze-thaw cycle can make existing cracks and potholes in your asphalt worse. So before the season gets too cold, it’s important to inspect your driveway for any signs of damage.

Cracks: Small cracks can be filled with crack filler, a product designed specifically for asphalt surfaces. These fillers expand and contract with temperature changes, preventing water from seeping into the cracks and freezing. Make sure to clean out any debris from the cracks before applying the filler.

Potholes: Larger potholes or depressions should be patched with an asphalt patching product. These products are easy to apply and help prevent further damage during the winter months.

3. Seal the Surface

One of the most effective ways to winterize an asphalt driveway is to apply a high-quality sealant. Sealing your driveway helps protect it from water penetration, UV rays, oil stains, and the damaging effects of winter weather.

When to seal: The best time to seal your driveway is in the late summer or early fall, ideally before the first frost. Asphalt needs time to cure, so it’s best to apply sealant when the temperature is consistently above 50°F (10°C).

How to apply: Follow the manufacturer’s instructions carefully. Generally, the driveway should be clean and dry before applying the sealant. Use a squeegee or a brush to apply a thin, even layer across the surface, making sure to cover every inch of the driveway.

4. Fill Low Spots

Over time, asphalt driveways can develop low spots or areas where water pools. These low spots can freeze in the winter, creating hazards and further damaging the surface. To prevent this, you should address any uneven areas before winter arrives.

How to fill low spots: If you notice any low spots, use a cold-patch asphalt product to fill them in. Smooth the surface with a shovel or broom, ensuring it’s level with the surrounding area.

5. Clear Snow and Ice Promptly

Snow and ice buildup on your driveway can cause serious problems, from surface damage to safety hazards. It’s important to clear your driveway promptly after a snowfall to prevent moisture from freezing into cracks or damaging the surface.

Shoveling or plowing: Regularly shovel or plow snow off your driveway as soon as possible. Avoid using metal shovels or snow blowers with metal parts, as these can damage the asphalt surface. Use plastic or rubber-edged tools to minimize the risk of scraping or gouging the driveway.

De-icing: To prevent ice from forming, consider using a de-icer or salt. However, be cautious with the type of salt you use, as some salts can damage asphalt and cause cracks over time. Opt for safer alternatives like calcium magnesium acetate (CMA) or sand for traction.

6. Avoid Using Rock Salt

While rock salt is commonly used to melt ice on driveways, it can be harsh on asphalt and should be used sparingly. Salt can penetrate the surface and cause long-term damage, including cracking and pitting. If you must use salt, be sure to clean up any excess after the snow or ice has melted. Better yet, use alternatives like calcium chloride or sand to reduce the potential for damage.

7. Address Drainage Issues

Proper drainage is essential to the health of your asphalt driveway. If water is allowed to pool on the surface or along the edges, it can cause erosion and create more cracks. Check your driveway for any areas where water is not draining properly and address these issues before winter.

Regrade the driveway: If necessary, you may need to regrade the driveway to ensure that water flows off the surface rather than pooling.

Clear gutters and drains: Make sure any gutters, downspouts, or drainage systems near your driveway are clear of debris. This will help direct water away from the surface and prevent ice buildup.

8. Consider a Professional Assessment

If you’re unsure about the condition of your driveway or you’re not comfortable making repairs yourself, it’s worth having a professional assess your driveway. A paving contractor can check for issues you might not notice, recommend repairs, and help ensure that your driveway is properly sealed and winterized.

Conclusion

Winterizing your asphalt driveway is an investment in its longevity and appearance. By taking the time to clean, inspect, seal, and repair your driveway before winter sets in, you can protect it from damage and keep it in great condition for years to come. With the right preparation, your asphalt driveway will be able to withstand the harshest winter conditions, saving you time and money on costly repairs when spring arrives.

#SmoothDriveways#PavingSolutions#CrackSealing#AsphaltDriveways#PavingContractors#AsphaltRepair#ResurfacingExperts#CommercialPaving#ResidentialPaving#SmoothSurfaces#AsphaltRepairs#AsphaltDriveway#QualityPaving

0 notes

Text

#CommercialPaving#ResidentialPaving#SmoothSurfaces#AsphaltRepairs#PavingSolutions#AsphaltDriveway#QualityPaving#SmoothDriveways#CrackSealing#AsphaltDriveways#PavingContractors#AsphaltRepair#ResurfacingExperts

1 note

·

View note

Text

#DrywallSander#SandingTools#DrywallFinishing#SmoothWalls#DrywallTools#SandingMadeEasy#DIYHomeImprovement#WallPreparation#DrywallRepair#PerfectFinish#HomeRenovation#ToolExperts#DrywallSanding#ConstructionTools#ProfessionalDrywall#SandingPerfection#SmoothSurfaces#DrywallInstallation#ToolForPros#DustFreeSanding#canada

0 notes

Text

Understanding the Purpose of Concrete Grinding

Introduction

Concrete grinding is a process that involves using specialized tools to smooth and level concrete surfaces. It's a technique widely used in construction and renovation projects for various purposes, such as preparing floors for new coverings, removing old coatings, or enhancing the appearance of concrete surfaces. This article delves into the many facets of concrete grinding, exploring its importance, methods, benefits, and applications in both residential and commercial settings.

Introduction to Concrete Grinding

Concrete grinding is an essential process in the construction industry, valued for its ability to create smooth, level, and aesthetically pleasing concrete surfaces. This technique has evolved over time, becoming a critical step in various construction and renovation projects. From its historical roots to modern advancements, concrete grinding has significantly contributed to the efficiency and effectiveness of surface preparation and finishing.

What is Concrete Grinding?

Concrete grinding involves using specialized machinery equipped with diamond-segmented abrasives to remove surface imperfections from concrete. This process smooths and levels the surface, preparing it for further treatment or finishing. The grinding process can vary depending on the equipment used and the desired outcome, but it generally involves multiple stages of grinding with increasingly fine abrasives.

Types of Concrete Grinders

Concrete grinders come in several types, each designed for specific tasks and surface areas:

Handheld Grinders: Ideal for small areas and detailed work.

Walk-behind Grinders: Suitable for larger areas, providing a balance between mobility and power.

Ride-on Grinders: Used for extensive floor areas, offering high efficiency and productivity.

Benefits of Concrete Grinding

Concrete grinding offers numerous benefits:

Surface Preparation: Ensures a smooth, clean surface for subsequent treatments like coatings or overlays.

Improved Aesthetics: Enhances the appearance of concrete surfaces, making them look polished and professional.

Safety Enhancements: Removes trip hazards and creates non-slip surfaces, improving overall safety.

Concrete Grinding Techniques

Different techniques can be employed in concrete grinding, each suited for specific applications:

Dry Grinding: Utilizes vacuum systems to control dust, ideal for indoor projects.

Wet Grinding: Uses water to reduce dust and cool the grinding surface, preferred for outdoor use.

Polished Concrete: Involves multiple stages of grinding and polishing to create a glossy, durable finish.

Concrete Grinding vs. Concrete Polishing

While often used interchangeably, concrete grinding and concrete polishing are distinct processes:

Concrete Grinding: Focuses on removing surface imperfections and preparing the concrete for further treatment.

Concrete Polishing: Aims to achieve a high-gloss, reflective finish, often following the grinding process.

Preparing for Concrete Grinding

Proper preparation is crucial for effective concrete grinding:

Initial Assessment: Evaluating the condition of the concrete surface to determine the appropriate grinding approach.

Equipment Selection: Choosing the right grinder and accessories based on the project's requirements.

Safety Precautions: Implementing measures to protect workers and the environment from dust and debris.

Step-by-Step Concrete Grinding Process

A systematic approach to concrete grinding ensures optimal results:

Surface Cleaning: Removing debris and contaminants from the surface.

Grinding Stages: Using progressively finer abrasives to achieve the desired level of smoothness.

Finishing Touches: Applying sealers or coatings to protect the surface and enhance its appearance.

Tools and Equipment for Concrete Grinding

The right tools and equipment are essential for successful concrete grinding:

Grinder Types: Handheld, walk-behind, and ride-on grinders.

Accessories: Diamond segments, dust shrouds, and vacuum systems.

Maintenance: Regular upkeep of equipment to ensure efficiency and longevity.

Choosing the Right Grinder for Your Project

Selecting the appropriate grinder involves considering several factors:

Project Scope: The size and complexity of the area to be ground.

Surface Condition: The hardness and condition of the concrete.

Budget Considerations: Balancing cost with the quality of equipment and results.

Concrete Grinding Applications

Concrete grinding is versatile and applicable in various settings:

Residential Uses: Preparing floors for new coverings, creating polished concrete finishes.

Commercial Uses: Enhancing the appearance and durability of retail and office spaces.

Industrial Uses: Ensuring safety and efficiency in warehouses and factories.

Environmental Impact of Concrete Grinding

Environmental considerations are increasingly important in concrete grinding:

Dust Control: Utilizing vacuum systems and wet grinding to minimize airborne dust.

Waste Management: Proper disposal of grinding residue and old coatings.

Eco-Friendly Practices: Using sustainable materials and techniques to reduce environmental impact.

Common Challenges in Concrete Grinding

Concrete grinding can present several challenges:

Uneven Surfaces: Dealing with variations in surface height and texture.

Hard Aggregates: Grinding through tough, hard materials embedded in the concrete.

Dust Control: Managing dust to protect workers and comply with regulations.

Troubleshooting Concrete Grinding Issues

Addressing common problems can improve the grinding process:

Common Problems: Identifying issues like uneven grinding or poor surface finish.

Solutions: Adjusting equipment settings, using the right abrasives, and maintaining equipment.

Best Practices: Following manufacturer guidelines and industry standards for optimal results.

Safety Tips for Concrete Grinding

Ensuring safety during concrete grinding is paramount:

Personal Protective Equipment: Wearing masks, goggles, and protective clothing.

Safe Operating Procedures: Following best practices for equipment operation.

Emergency Protocols: Having plans in place for dealing with accidents or equipment failures.

Cost of Concrete Grinding

Understanding the cost factors involved in concrete grinding helps with budgeting:

Factors Influencing Cost: Surface area, condition of the concrete, type of grinder used.

Cost Estimation: Calculating expenses based on hourly rates and material costs.

Budgeting Tips: Planning for contingencies and unexpected expenses.

Concrete Grinding and Surface Preparation

Surface preparation is a critical aspect of successful concrete grinding:

Importance of Preparation: Ensuring the surface is clean and ready for grinding.

Methods: Using appropriate techniques to remove old coatings and contaminants.

Case Studies: Examples of successful surface preparation projects.

Polished Concrete Floors

Polished concrete floors are a popular choice for their durability and aesthetic appeal:

Process: Involves multiple stages of grinding and polishing.

Benefits: Offers a long-lasting, low-maintenance flooring solution.

Maintenance: Keeping polished floors in good condition with regular cleaning and resealing.

Concrete Grinding for Epoxy Flooring

Concrete grinding is essential for preparing surfaces for epoxy flooring:

Preparation: Ensuring the surface is smooth and free of contaminants.

Application: Applying epoxy coatings for a durable, attractive finish.

Longevity: Enhancing the lifespan of epoxy flooring through proper surface preparation.

Concrete Grinding for Decorative Finishes

Decorative concrete finishes can transform spaces:

Staining: Adding color and depth to concrete surfaces.

Etching: Creating patterns and textures for visual interest.

Sealing: Protecting decorative finishes from wear and tear.

Comparing Concrete Grinding with Other Methods

Concrete grinding is just one of many surface preparation methods:

Sanding: Suitable for smaller, less demanding projects.

Shot Blasting: Effective for removing old coatings and contaminants.

Scarifying: Used for heavy-duty surface removal and texturing.

Innovations in Concrete Grinding Technology

Advancements in technology continue to improve concrete grinding:

Advanced Grinders: New designs offer greater efficiency and versatility.

New Techniques: Innovations in grinding and polishing methods.

Future Trends: The evolving landscape of concrete grinding technology.

Case Studies of Successful Concrete Grinding Projects

Real-world examples highlight the effectiveness of concrete grinding:

Residential Projects: Enhancing home interiors with polished concrete.

Commercial Projects: Upgrading retail and office spaces.

Industrial Projects: Improving safety and efficiency in industrial settings.

Frequently Asked Questions About Concrete Grinding

Q. What is concrete grinding?

A. Concrete grinding involves using specialized equipment to smooth and level concrete surfaces, preparing them for further treatment or finishing.

Q. Why is concrete grinding important?

A. Concrete grinding is essential for surface preparation, improving aesthetics, and enhancing safety by removing trip hazards and creating non-slip surfaces.

Q. What types of concrete grinders are available?

A. There are handheld grinders for small areas, walk-behind grinders for larger spaces, and ride-on grinders for extensive floor areas.

Q. How does concrete grinding differ from concrete polishing?

A. Concrete grinding focuses on removing imperfections and preparing the surface, while concrete polishing aims to achieve a high-gloss, reflective finish.

Q. What are the benefits of polished concrete floors?

A. Polished concrete floors are durable, low-maintenance, and aesthetically pleasing, making them a popular choice for residential, commercial, and industrial spaces.

Q. How much does concrete grinding cost?

A. The cost of concrete grinding depends on factors like surface area, condition of the concrete, and the type of grinder used. It's important to budget for contingencies and unexpected expenses.

Conclusion

Concrete grinding is a versatile and essential process in the construction and renovation industry. Whether preparing surfaces for new coverings, enhancing aesthetics, or improving safety, understanding the purpose and techniques of concrete grinding can help achieve optimal results. With advancements in technology and a focus on eco-friendly practices, concrete grinding continues to evolve, offering new possibilities for residential, commercial, and industrial applications.

#ConcreteGrinding#ConcretePolishing#FlooringSolutions#ConcreteRestoration#IndustrialFlooring#PolishedConcrete#ConcreteFinishing#GrindingAndPolishing#ConcreteExperts#SurfacePreparation#ConcreteRepair#ConcreteResurfacing#GrindAndSeal#FloorPreparation#SmoothSurfaces#ConcreteProfessionals#GrindToPerfection#ConcreteContractors#ConstructionExperts#ConcreteFlooring

1 note

·

View note

Text

Screed Bathroom Floor : Itile Bathrooms NT

Level up your bathroom perfection with our expert screeding services! 🛁✨ Say goodbye to uneven surfaces and hello to a flawless foundation for your dream bathroom

0 notes

Text

Wooden Duck Toys For Toddlers

Wooden Duck Toys For Toddlers by Ardencyelite are adorable and sturdy playthings made from natural wood With vibrant colors and smooth surfaces, making them safe for toddlers.These toys often feature movable parts, such as flapping wings or rolling wheels that help to enhance gross motor skills of active toddlers.Wooden Duck Toys For Toddlers by Ardencyelite inspire imaginative play, cognitive…

View On WordPress

#ardencyelite#cognitivedevelopment#enhancegrossmotorskills#roundsurface#safefortoddlers#smoothsurface#Walking duck push toy#wooden duck toy#Wooden toys for toddlers

0 notes

Text

Need smooth, clean walls that last?

LAC General Contractor INC offers expert drywall installation with flawless finishes, ready for paint or décor. 🎨 We handle every detail for a professional look and feel.

📍 Dixon, CA 📞 530-760-7161 ���� [email protected]

🔧 Precision and quality — every step of the way.

#DrywallPro #WallFinishing #LACGeneralContractor #DrywallExperts #InteriorConstruction #DixonCA #SmoothSurfaces 🧰🏠📦

0 notes

Text

Transform Your Driveways, Parking Lots, and Walkways with Earth Road Asphalt

Have you been thinking about giving your property a makeover? A smooth, well-maintained driveway, parking lot, or walkway can do wonders for your curb appeal, and Earth Road Inc. Asphalt is here to help! We specialize in upgrading the surfaces that matter most—whether it's for your home or business. Our team uses the best materials and cutting-edge techniques to ensure your paving project is not only visually stunning but also durable enough to stand the test of time. With our expert paving services, you'll enhance the value and functionality of your property while making a lasting impression on visitors.

Why settle for cracked or uneven surfaces when you can have a driveway that welcomes guests with a smooth, sleek finish? A well-paved driveway or parking lot can completely transform your property’s appearance and usability. We offer high-quality paving that will last for years and provide essential services like sealcoating and striping to ensure your surfaces stay in top shape. Whether you're a homeowner looking to upgrade or a business owner who needs a reliable parking lot, we've got you covered.

So, what’s holding you back from improving your property's exterior?

With Earth Road Inc. Asphalt, you can rest easy knowing your paving project is in the hands of professionals who care. Ready to get started? Call us today at 315-253-9060 for a free quote. How would a fresh, professionally paved surface change your home's first impression?

#AsphaltPaving #CurbAppeal #PropertyUpgrade #SmoothSurfaces #TrustedProvider

Contact Us: 315-253-9060 Website: www.asphaltsyracuse.com 277 North St. Bldg. A Auburn, NY 13021

#asphalt paving#sealcoating#asphalt milling#asphalt#asphalt striping#syracuse#milling#new york#quality#durable

0 notes

Text

Say goodbye to cracks and potholes! Our driveway repair services restore functionality and aesthetics, giving your property a polished look and smooth driving experience. #DrivewayRepair #SmoothSurface #PropertyEnhancement ☎️Call us now: (631) 836-4014 🌐Visit or website: www.avilaavilaconstructionllc.com

0 notes

Text

#munkendesignrange#uncoatedpaper#premiumuncoatedpaper#munken_kristall#munken_polar#munken_lynx#munken_pure#smoothsurface#roughsurface#UncoatedFinePapers#Designinspiration#GraphicDesigner#CreativeDesigner#ArtDirector#CreativeDirector#SonaPapers#FinePaper#SpecialityPaper#Artist#ChoosePaper#CreativePapers#Qualitypaper#Designers#Printers#corporatesandprinters#graphiccommunicationdesign#brandidentity#artistgroup#graphicdesignersgroup#creativegroup

0 notes

Photo

Reis Valdrez Jangadas 2018 Continuam expostas as peças que resultaram da residência artística na Ingénua. Podem ir visita-las antes que se tornem objetos flutuantes à deriva num museu. #floating #shipyard #rafts #aquatic #sculptures #driftwood #artcapture #artistoninstagram #artistresidency #newproject #gallery #woodworking #contemporaryartist #textures #smoothsurface #balance ⛵⚓ (em Centro de Actividades Náuticas - Sabseg / Forum Esposendense) https://www.instagram.com/p/BoubRXLgJRx/?utm_source=ig_tumblr_share&igshid=ry62op7023ww

#floating#shipyard#rafts#aquatic#sculptures#driftwood#artcapture#artistoninstagram#artistresidency#newproject#gallery#woodworking#contemporaryartist#textures#smoothsurface#balance

1 note

·

View note

Photo

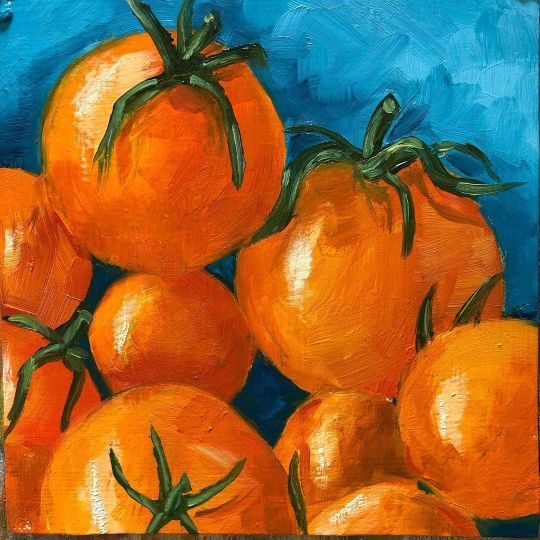

Sungold Cherry tomatoes in a blue bowl. The tomatoes are wonderful this year with the beautiful colours. I had an idea when I began painting but it always seems to have a mind of its own. 😃 #paintingoftheday #oilpaintings #6x6” #oilonboard #acrylicgesso #smoothsurface #bcart #bcartist #paintingforsale #decor #tomatoes #sungoldtomatoes #blue #complimentary https://www.instagram.com/p/CSafTRdlB5j/?utm_medium=tumblr

#paintingoftheday#oilpaintings#6x6#oilonboard#acrylicgesso#smoothsurface#bcart#bcartist#paintingforsale#decor#tomatoes#sungoldtomatoes#blue#complimentary

0 notes

Link

A white cement based wall putty is the best option considered in the industry which has achieved tremendous success over the years. White cement based putty is mostly used for the interior or exterior of residential or commercial spaces. It is made using white cement-based finer powder, special additives, and fillers which can act as putty, sealers on plaster or concrete walls and roofs.

0 notes

Photo

Available work by Alison Kay: wide pale coral vessel with off center opening: 9" x 16" x 7". The perfect unity of surface and form in the work of #alisonkay is simply stunning. This is one of three beautiful #ceramic pieces on view now thru October 24 @jcacciolagalleryw in #bernardsville. We are bringing acclaimed #dublinireland artists to the east coast for an incredible international experience. #jcacciolagallery #womenartists #womanartist #ceramics #terrasigillata #burnishedceramics #smoothsurface #contemporaryceramics #contemporaryirishart #internationalart #interiordesign #ceramicsculpture (at J. Cacciola Gallery W)

#ceramicsculpture#jcacciolagallery#alisonkay#contemporaryirishart#interiordesign#ceramics#womanartist#womenartists#smoothsurface#terrasigillata#ceramic#contemporaryceramics#burnishedceramics#internationalart#dublinireland#bernardsville

1 note

·

View note