#Softwall Modular Cleanroom

Explore tagged Tumblr posts

Text

Exploring the Different Applications of Softwall Modular Cleanrooms in Various Industries

Cleanrooms play a pivotal role in ensuring controlled environments for a wide range of industries, where precision, hygiene, and contamination control are of utmost importance. In recent years, softwall modular cleanrooms have emerged as a versatile solution, offering flexibility, cost-effectiveness, and adaptability to meet the specific needs of various industries. In this blog post, we will delve into the different applications of softwall modular cleanrooms across industries, highlighting their significance in maintaining the highest standards of cleanliness and efficiency.

What are Softwall Modular Cleanrooms?

Softwall modular cleanrooms are enclosed spaces equipped with flexible, transparent vinyl curtains that serve as barriers to control the flow of air and maintain cleanliness. Unlike traditional hardwall cleanrooms, softwall cleanrooms offer greater versatility, easy installation, and the ability to expand or reconfigure the cleanroom space as needed.

Pharmaceutical and Biotechnology Industries

The pharmaceutical and biotechnology industries are among the primary users of softwall modular cleanrooms. These controlled environments are crucial for the production of medications, vaccines, and biopharmaceuticals. Softwall cleanrooms provide an aseptic space to prevent contamination and ensure the purity of products, complying with stringent regulatory requirements. Additionally, these cleanrooms are utilized in research and development, quality control, and testing processes to maintain the integrity of sensitive materials.

Microelectronics and Semiconductor Manufacturing

In the microelectronics and semiconductor industries, even the tiniest particle can compromise the performance of delicate electronic components. Softwall modular cleanrooms offer a controlled environment for wafer fabrication, assembly, and packaging processes. They maintain Class 100 to Class 1000 levels of cleanliness, reducing defects and enhancing the overall yield of semiconductor products.

Aerospace and Defense

The aerospace and defense sectors often deal with highly sensitive and complex components that require a contaminant-free environment. Softwall modular cleanrooms ensure precision in assembly, testing, and integration of aerospace equipment. They prevent dust, moisture, and other contaminants from affecting critical systems, thus enhancing the reliability and safety of aerospace technologies.

Medical Device Manufacturing

Medical device manufacturers must adhere to strict quality standards to ensure the safety and efficacy of their products. Softwall cleanrooms facilitate the production of medical devices, ensuring they are free from contaminants and sterilized to the required levels. Cleanroom environments are crucial for the assembly of devices like implants, surgical instruments, and diagnostic equipment.

Research and Laboratories

Softwall modular cleanrooms find applications in various research and laboratory settings. They create controlled environments for conducting experiments, particularly in fields like nanotechnology, life sciences, and material research. The flexibility of softwall cleanrooms allows researchers to adapt the space for different experiments and projects, optimizing resource utilization.

Optics and Photonics

In the optics and photonics industries, precise alignment and calibration are essential for producing high-quality optical components and devices. Softwall modular cleanrooms provide the necessary conditions to prevent dust particles, ensuring optical elements maintain their performance and accuracy.

Food and Beverage Processing

In food and beverage processing, maintaining a clean and hygienic environment is critical to prevent contamination and ensure product quality. Softwall modular cleanrooms are used for food preparation, packaging, and handling, safeguarding against foreign particles and microbial contaminants.

Conclusion

Softwall modular cleanrooms have revolutionized contamination control and clean environment requirements in various industries. Their adaptability, cost-effectiveness, and compliance with industry regulations make them an attractive option for diverse applications. Whether in pharmaceuticals, microelectronics, aerospace, or any other sector that demands strict cleanliness standards, softwall modular cleanrooms offer the perfect solution for creating controlled environments that safeguard both products and processes. EZAD Cleanrooms As industries continue to evolve, the role of softwall modular cleanrooms in providing optimal cleanliness and efficiency is set to become even more significant in shaping the future of manufacturing and research.

Original Sources: https://ezadcleanrooms.blogspot.com/2023/07/exploring-different-applications-of.html

0 notes

Text

North America Cleanroom Technology Market Size, Share, Industry Key Features, Growth Drivers (2021-2028)

The North America cleanroom technology market is expected to reach US$ 3,024.39 million by 2028 from US$ 1,867.88 million in 2021; it is estimated to grow at a CAGR of 7.1% during 2021–2028.

North America Cleanroom Technology Market Introduction

Cleanrooms are precisely controlled environments designed to minimize the presence of pollutants, including airborne microbes, particles, dust, and aerosols that can contaminate the surrounding workspace. Cleanroom Technology is fundamentally utilized across a spectrum of industries to prevent the negative impacts of airborne contaminants and microscopic particles during the production of goods.

The North American market for cleanroom technology has exhibited significant advancement, driven by the increasing adoption of cleanroom environments within manufacturing operations. Innovations in this technology, spanning high-efficiency particulate absorption (HEPA) systems, unidirectional airflow designs, and modular cleanroom solutions, are significant factors propelling market growth. A notable development in September 2019 involved a collaboration between G-CON Manufacturing and L7 Informatics, a provider of software for automation in the life sciences, to develop a fully integrated cleanroom and manufacturing software solution. This partnership involved the integration of L7's Enterprise Science Platform (ESP) into G-CON's proprietary POD cleanroom technology by the two US-based entities.

Download our Sample PDF Report

@ https://www.businessmarketinsights.com/sample/TIPRE00027213

North America Cleanroom Technology Strategic Insights

Strategic insights into the North America Cleanroom Technology market offer a data-driven analysis of the industry landscape, encompassing current trends, key players, and regional specificities. These insights provide actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped market segments or formulating unique value propositions. By utilizing data analytics, these insights assist industry participants, including investors, manufacturers, and other stakeholders, in anticipating market shifts. A forward-looking perspective is essential, helping stakeholders in predicting market changes and positioning themselves for long-term success within this evolving region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market.

North America Cleanroom Technology Regional Insights

The geographic scope of the North America Cleanroom Technology market defines the specific territories in which businesses operate and compete. A comprehensive understanding of local variations, such as differing consumer preferences (e.g., demand for specific plug types or battery backup durations), diverse economic landscapes, and regulatory frameworks, is crucial for tailoring strategies to specific markets. Businesses can expand their market presence by identifying underserved areas or adapting their offerings to meet local needs. A focused market strategy allows for more efficient resource allocation, targeted marketing initiatives, and enhanced competitive positioning against local players, ultimately fostering growth within those specific regions.

NORTH AMERICA CLEANROOM TECHNOLOGY MARKET SEGMENTATION

North America Cleanroom Technology Market: By Type

Equipment

Consumable

North America Cleanroom Technology Market: By Construction Type

Standard Cleanrooms

Hardwall Cleanrooms

Softwall Cleanrooms

Pass-through Cabinets

North America Cleanroom Technology Market: By End User

Pharmaceutical Industry

Biotechnology Industry

Medical Device Manufacturers

Hospitals

Others

North America Cleanroom Technology Market: By Country

US

Canada

Mexico

North America Cleanroom Technology Market: Company Profiles

Taikisha Ltd

Kimberly-Clark Corporation

E. I. DU PONT DE NEMOURS AND COMPANY

Labconco Corporation

Azbil Corporation

Illinois Tool Works Inc.

Alpiq Holding AG

Clean Air Products

M+W Group

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

#North America Cleanroom Technology Market#North America Cleanroom Technology Market Size#North America Cleanroom Technology Market Share

0 notes

Text

Our company, Ziebaq, designs and builds various clean rooms for businesses in multiple fields, including hardwall, softwall, modular, and more. We also offer expert Cleanroom panel repair services as part of our full range of Cleanroom services.Get more information please read this blog:

0 notes

Text

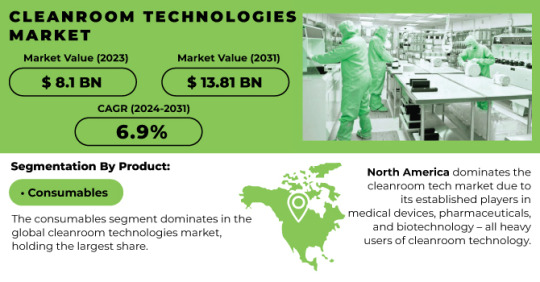

Cleanroom Technologies Market Size Forecast to Expand in 2024

The Cleanroom Technologies Market Size was valued at USD 8.1 billion in 2023 and is expected to reach USD 13.81 billion by 2031 and grow at a CAGR of 6.9% over the forecast period 2024-2031.Exploring the growth trajectory of the cleanroom technologies market reveals a dynamic landscape shaped by evolving standards and technological advancements. This niche sector, crucial across industries like pharmaceuticals, biotechnology, and electronics, is witnessing robust expansion driven by stringent regulatory requirements and the escalating demand for contamination-free environments. As companies vie to maintain impeccable manufacturing standards and ensure product integrity, innovations in cleanroom design, HVAC systems, and monitoring technologies are pivotal. The market's upward trajectory is further propelled by increasing investments in healthcare infrastructure globally, underscoring its pivotal role in safeguarding critical processes and fostering reliable production outcomes. Amidst these trends, market players are navigating towards sustainable practices and flexible solutions, underscoring a pivotal shift towards efficiency and adaptability in cleanroom operations.

Get Sample of This Report @ https://www.snsinsider.com/sample-request/2245

Market Scope & Overview

The worldwide Cleanroom Technologies Market research report includes an in-depth analysis of key market trends, company profiles, important product specifications, sales statistics, and contact information. Customers can get quantitative industry expertise by examining the most recent market data. The market research report delves deeply into the most important market trends.

During Cleanroom Technologies Market research, the impact of significant market variables such as motivators, restraints, opportunities, and threats on the industry is investigated. The underlying drivers and constraints influence global market opportunities and issues. Strategic collaborations, new product releases, initiatives, key market rivals, development factors, restrictions, and opportunities are all covered in market research.

Market Segmentation Analysis

By Product

Equipment

Fan filter

HVAC

Vacuum System

Consumables

Safety

Disinfectants

By Type

Standard Modular

Hardwall

Softwall

Mobile

By End User

Pharma

Biotech

Medtech

Hospitals

COVID-19 Impact Analysis

Participants in the market will benefit from this section of the research's representation of the market environment as a result of the COVID-19 epidemic now and in the future. The research investigates the impact of COVID-19 on global and national Cleanroom Technologies Market. The COVID-19 impact analysis will aid market participants in developing pandemic mitigation policies. This study considers the demand and supply side effects of the target market. This study relied on primary and secondary research, as well as private databases and a paid data source.

Regional Outlook

The performance of various regional markets in Asia Pacific, North America, Latin America, Europe, and the Middle East and Africa was examined in the Cleanroom Technologies Market research report. Data was gathered through focus groups, questionnaires, interviews, national and geographic research, and an all-dimensional review.

Competitive Analysis

The study investigates a wide range of critical aspects influencing firm stakeholders such as suppliers, end users, dealers, and others in order to assist them in planning investments and pursuing various Cleanroom Technologies Market growth prospects. Market, prices, positioning, primary rivals, and a comprehensive data collection plan must all be consistent. The market report also includes a wide range of future market estimates based on historical data.

Key Reasons to Purchase Cleanroom Technologies Market Report

Extensive market research that considers downstream production, upstream raw materials, and current growth expectations.

Provide a basic overview of the present state of the target industry, including applications and advancements.

Conclusion

Emerging market global business research is available, including competitive landscape studies and development trends. This market research report is an excellent resource for market participants seeking to propel their businesses to success.

About Us

SNS Insider is a market research and insights firm that has won several awards and earned a solid reputation for service and strategy. We are a strategic partner who can assist you in reframing issues and generating answers to the trickiest business difficulties. For greater consumer insight and client experiences, we leverage the power of experience and people.

When you employ our services, you will collaborate with qualified and experienced staff. We believe it is crucial to collaborate with our clients to ensure that each project is customized to meet their demands. Nobody knows your customers or community better than you do. Therefore, our team needs to ask the correct questions that appeal to your audience in order to collect the best information.

Related Reports

Angioplasty Balloon Market Analysis

Animal Genetic Market Analysis

Animal Model Market Analysis

Antibody Production Market Analysis

Anti coagulation Market Analysis

0 notes

Text

Softwall Cleanroom Solutions by Modular Cleanroom India

In today's fast-paced technological landscape, maintaining a controlled environment is crucial for various industries, including pharmaceuticals, biotechnology, electronics, and healthcare. One of the most effective solutions for creating and maintaining such environments is the use of softwall cleanrooms. Modular Cleanroom India, a leading provider in this domain, offers state-of-the-art softwall cleanroom solutions designed to meet the rigorous demands of these industries.

What is a Softwall Cleanroom?

A softwall cleanroom is a type of cleanroom characterized by flexible, soft walls made from clear vinyl or other transparent materials. These walls are typically suspended from a ceiling structure, allowing for easy installation and reconfiguration. The primary purpose of a softwall cleanroom is to provide a controlled environment with a specific level of air cleanliness, defined by the concentration of airborne particles.

Key Features of Softwall Cleanrooms

Modularity: Softwall cleanrooms are highly modular, allowing for easy expansion or reconfiguration as operational needs change. This flexibility makes them an ideal choice for dynamic industries that require frequent updates to their cleanroom environments.

Cost-Effective: Compared to traditional hardwall cleanrooms, softwall cleanrooms are more affordable, making them accessible to a broader range of businesses. The cost savings come from both the materials used and the simplified installation process.

Quick Installation: The installation of softwall cleanrooms is faster and less disruptive than that of traditional cleanrooms. This ensures minimal downtime and allows businesses to maintain productivity.

Ease of Maintenance: The materials used in softwall cleanrooms are easy to clean and maintain, ensuring that the environment remains compliant with industry standards.

Versatility: Softwall cleanrooms can be used in a variety of applications, from sensitive manufacturing processes to medical laboratories and research facilities. Their adaptability makes them suitable for different cleanroom classifications, from ISO Class 9 to ISO Class 5.

Why Choose Modular Cleanroom India?

Modular Cleanroom India (modularcleanroomindia.com) stands out as a premier provider of softwall cleanroom solutions. Here’s why:

Expertise and Experience: With years of experience in the cleanroom industry, Modular Cleanroom India has the expertise to design and deliver cleanroom solutions that meet the highest standards of performance and reliability.

Custom Solutions: Recognizing that each client's needs are unique, Modular Cleanroom India offers customized softwall cleanroom solutions tailored to specific requirements. From design to installation, the company ensures that every detail aligns with the client's operational needs.

Quality Materials: Only the highest quality materials are used in the construction of Modular Cleanroom India's softwall cleanrooms. This ensures durability, longevity, and compliance with stringent industry standards.

Comprehensive Support: Modular Cleanroom India provides end-to-end support, from initial consultation and design to installation and ongoing maintenance. Their dedicated team is committed to ensuring customer satisfaction at every stage of the process.

Innovative Solutions: Staying ahead of industry trends, Modular Cleanroom India continually innovates to provide cutting-edge cleanroom solutions. This commitment to innovation ensures that their clients benefit from the latest advancements in cleanroom technology.

Applications of Softwall Cleanrooms

Softwall cleanrooms by Modular Cleanroom India are ideal for a wide range of applications, including:

Pharmaceutical Manufacturing: Ensuring a contaminant-free environment for the production of drugs and medical devices.

Biotechnology: Providing a controlled atmosphere for sensitive biological research and production.

Electronics: Protecting electronic components from particulate contamination during manufacturing.

Healthcare: Creating sterile environments for medical procedures and research.

Conclusion

For industries that require a controlled, clean environment, softwall cleanrooms are an excellent solution. Modular Cleanroom India, with its expertise, high-quality materials, and customer-centric approach, offers some of the best softwall cleanroom solutions available. To learn more about their offerings and to explore how they can help meet your cleanroom needs, visit their website at modularcleanroomindia.com.

Invest in a softwall cleanroom from Modular Cleanroom India and ensure the highest standards of cleanliness and control in your operations.

1 note

·

View note

Text

Discover the Cutting-Edge Advantages of Cleatech's Softwall Cleanrooms

In the realm of modern scientific and industrial advancements, precision and cleanliness are paramount. Contaminants, even those invisible to the naked eye, can spell disaster for sensitive operations, whether in electronics manufacturing, pharmaceuticals, or research laboratories. It's in this context that Cleatech, LLC, introduces its innovative Softwall Cleanrooms – a state-of-the-art solution that offers a controlled environment where cleanliness, precision, and adaptability converge.

Understanding Softwall Cleanrooms

Cleanrooms are specialized spaces designed to control and maintain low levels of airborne particles, such as dust, microbes, and aerosol particles. These controlled environments are critical in industries where even the smallest particle can disrupt processes, compromise product quality, or jeopardize research results.

Cleatech's Softwall Cleanrooms are a testament to the company's commitment to providing high-quality, flexible, and cost-effective cleanroom solutions. These modular cleanrooms are characterized by their structure, which consists of lightweight, flexible curtains or softwalls, making them an excellent choice for various industries. Let's explore the unique advantages of Cleatech's Softwall Cleanrooms.

Enhanced Contaminant Control

The primary function of a cleanroom is to control contaminants, and Cleatech's Softwall Cleanrooms excel in this regard. The softwalls are made from durable, antistatic, and non-outgassing vinyl material that effectively isolates the cleanroom environment from the surrounding space. This isolation ensures that particles, microbes, and other contaminants are kept at bay, providing the ideal environment for sensitive processes.

Modularity and Customizability

One of the standout features of Cleatech's Softwall Cleanrooms is their modular and customizable design. They can be easily installed, modified, or expanded to meet the specific requirements of a wide range of industries. Whether you need a small cleanroom for a laboratory or a larger setup for a manufacturing facility, Cleatech's Softwall Cleanrooms can be tailored to your needs.

Energy Efficiency

In addition to their adaptable design, these cleanrooms are energy-efficient. Cleatech has incorporated energy-saving features into the Softwall Cleanrooms, such as LED lighting and low-noise, high-efficiency fans. This not only reduces operational costs but also minimizes the impact on the environment.

Compliance with Industry Standards

Cleatech's Softwall Cleanrooms are designed and manufactured to meet and exceed industry standards for cleanliness and safety. They comply with ISO 14644-1 standards for air cleanliness, ensuring that your cleanroom will maintain the necessary air quality for your specific application.

Positive Pressure and Airflow Control

Maintaining the right pressure within a cleanroom is crucial for preventing contaminants from entering. Cleatech's Softwall Cleanrooms offer positive pressure environments that help keep particles out, safeguarding sensitive processes.

Airflow control is another essential factor, ensuring that contaminants are swiftly removed from the environment. Cleatech's cleanrooms are equipped with efficient HEPA or ULPA filtration systems that guarantee optimal airflow and particle removal.

Versatile Applications

Cleatech's Softwall Cleanrooms find applications in a diverse array of industries, including:

Electronics Manufacturing: For microelectronics and semiconductor manufacturing, where even a speck of dust can lead to defects.

Pharmaceutical and Biotechnology: Ideal for research, production, and packaging processes in the pharmaceutical and biotechnology sectors.

Aerospace: In the aerospace industry, cleanrooms are vital for ensuring the reliability of sensitive equipment and instruments.

Food and Beverage: Maintaining cleanliness in food processing and packaging to ensure product safety.

Research Laboratories: For scientific experiments and research that require a controlled environment.

Cost-Effective Solutions

Cleatech's Softwall Cleanrooms offer an economical solution for those seeking cleanroom environments without the high costs typically associated with traditional hard-wall cleanrooms. Their modular design, energy efficiency, and easy maintenance contribute to long-term cost savings.

Compliance with Safety Regulations

Safety is non-negotiable in cleanroom environments. Cleatech's Softwall Cleanrooms adhere to strict safety standards to protect personnel and ensure safe working conditions.

Quick Installation and Minimal Downtime

Time is often a critical factor in setting up a cleanroom. Cleatech's Softwall Cleanrooms can be installed relatively quickly, minimizing downtime for your operations. This is particularly important for industries where time-sensitive processes are involved.

Maintenance and Support

Cleatech doesn't just provide state-of-the-art Softwall Cleanrooms; they also offer comprehensive maintenance and support services. This includes regular inspections, maintenance, and any necessary repairs, ensuring that your cleanroom continues to perform at its best.

Take the Next Step Toward Precision and Cleanliness

Cleatech's Softwall Cleanrooms offer a dynamic solution for various industries that require controlled environments. Whether you're involved in electronics manufacturing, pharmaceuticals, or research, the advantages are clear: enhanced contaminant control, modularity, energy efficiency, compliance with industry standards, positive pressure, versatile applications, cost-effectiveness, safety compliance, quick installation, and dependable maintenance support.

It's time to take the next step toward precision, cleanliness, and quality in your operations. Cleatech's Softwall Cleanrooms are the answer you've been looking for. To learn more about how Cleatech can tailor a Softwall Cleanroom to your specific needs, or to request a quote, get in touch with our team of experts today.

Take the leap to cleaner, more precise processes. Contact Cleatech LLC, and experience the difference of Softwall Cleanrooms. Your success begins with our expertise.

Original Sources: https://laboratoryquipment.blogspot.com/2023/10/discover-cutting-edge-advantages-of.html

0 notes

Text

Future | Trends and HealthCare Industry Analysis For Cleanroom Technologies Market

According to the new market research report "Cleanroom Technologies Market with COVID-19 Impact, by Product (Fan Filter Units, HVAC, vacuum systems, disinfectants), Construction (Drywall, Hardwall, Softwall), End User (Pharmaceutical, Biotechnology, Medical device manufacturers) - Global Forecast to 2026", published by MarketsandMarkets™, the global market is expected to reach USD 9.6 billion by 2026 from USD 7.1 billion in 2021, at a CAGR of 6.2% during the forecast period.

The growth of this market is majorly driven by the rising demand for sterilized pharmaceutical formulations, increasing demand for medical devices. The technological advancements in cleanroom technology along with the increasing demand for cleanroom technologies in developing economies are expected to offer significant opportunities for market growth in the coming years. However, the technical limitations associated with their operational costs and technical challenges associated with the customization of cleanroom designs in developing economies are hindering the growth of this market to a certain extent.

The use and maintenance of a cleanroom is a complex process. Usually, the cost of construction of standard cleanrooms for pharmaceutical and medical device manufacturing may range between USD 100 to more than USD 1,000 per square foot. Also, the price per square foot is not the same for ISO 6 and ISO 8 cleanrooms. This is because the amount of air supplied is different in both classes of cleanrooms. The air is 100 times cleaner in an ISO 6 cleanroom than in an ISO 8 cleanroom, thereby doubling the air conditioning capacity of the HVAC systems.

Browse and in-depth TOC on "Cleanroom Technologies" 289 - Tables 41 - Figures 313 - Pages

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=263122482

The Growth in the market is majorly driven by the stringent regulatory framework, growth of the biologics sector, growing demand for medical devices, and advancements in cleanroom technologies. The market is also witnessing increasing trends of adopting modular cleanrooms along with the emergence of rental cleanroom services.

The global health crisis triggered by the COVID-19 pandemic has made it imperative that the pharmaceutical industry moves at a rapid pace alongside researchers, regulators, and contract research companies to develop a diagnosis, treatment, and vaccines.

Cleanrooms are mostly designed according to customer requirements based on product specifications and customer-specific design requirements. However, there are no specific guidelines for cleanroom designs for different application areas or product types. This leads to several challenges for cleanroom manufacturers, as they need to follow different designs every time. Furthermore, regulations do not provide requirements regarding the environmental, product, or facility parameters that are to be controlled. Instead, they only provide standards that a company needs to meet after it decides to manufacture a product using a cleanroom environment.

The biotechnology end-user industry segment is expected to grow at the highest CAGR during the forecast period, primarily due to the growing demand for biologics and biosimilars. Increasing investments in biotechnology are expected to provide an impetus to the growth of the segment over the forecast period.

Request Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=263122482

North America is expected to hold the largest share for players operating in the Cleanroom Technologies Market.

North America accounted for the largest share of the market in 2020. Factors such as stringent regulatory standards for product approvals, technological advancements in cleanrooms, initiatives taken by private organizations to create awareness regarding cleanrooms, and growth of the healthcare sector on a global scale are among the few factors expected to contribute to the growth of this market.

0 notes

Text

Global Cleanroom Technologies Market Size, Share, and Trends

The Global Cleanroom Technologies Market is estimated to be USD 4,567.9 Mn in 2021 and is projected to reach USD 7,765.90 Mn by 2027, growing at a CAGR of 7.55%.

A room where concentration of air borne particulate matter, including hair, fungus, dust and bacteria is controlled is called as Cleanroom. To decline the generation, retention and introduction of particles inside the room, this type of room is constructed.

Get a Sample Copy of this Report@ https://qualiketresearch.com/request-sample/Cleanroom-Technologies-Market/request-sample

Market Drivers

Key demand driver of Cleanroom technology is Elimination of contaminants in laboratories. The need for cleaning these contaminates has highly essential. The cleanroom technology creates clean, neat, and contaminates free environments.

The rise in the demand for quality products compliant with regulatory standards increase the Cleanroom Technology market growth.

Moreover, the surge in the number of hospitals and ambulatory surgery centers (ASCs) because of the many benefits offered by them further influence the market.

The upsurge in the expansion of the biologics sector worldwide acts as one of the main factors driving the growth of cleanroom technology market.

Market Restraints

The high operational costs of clean technology is the main restraining factor of the cleanroom technology market. Practice of a cleanroom is an urbane process and Maintenance of such cleanroom technology is tough. The cost of standard cleanrooms is exclusive.

Furthermore, issues with customization of cleanroom designs per requirements are anticipated to hinder the growth of the cleanroom technology market in the forecast period.

Market Segmentation

Cleanroom Technologies Market is segmented into major 4 categories. Based Product Type, the market is segmented into Consumables, Cleaning Consumables, Equipment. Based on End User, the market is divided into Pharmaceutical Industry, Biotechnology Industry, Hospitals & Clinics. Based on Technology, the market is segmented into Standard/ Drywall Cleanroom, Softwall Cleanrooms, Others. Based on Region, the market is segmented into North America, Europe, Asia Pacific, Latin America, Middle East.

Regional Analysis

North America region dominates the Cleanroom Technology market across the world with CAGR 7.61% owing to the well-established healthcare infrastructure in this region, the local presence of key pharmaceutical and medical device companies, an increase in the burden of non- communicable diseases.

Europe occupied the second-highest market portion after the North America and is anticipated to grow at a significant CAGR 7.58% throughout the forecast period owing to the rising healthcare facility and awareness about the cleanliness in the region in the hospitals.

Get Discount on this Report@ https://qualiketresearch.com/request-sample/Cleanroom-Technologies-Market/ask-for-discount

Market Key Players

Some of the key players operating in Global Cleanroom Technologies Market are Ardmac, Azbil Corporation, Bouygues Group, Clean Rooms International Inc, ABN Cleanroom Technologies, Exyte AG, Taikisha Ltd, DowDuPont Inc, Kimberly-Clark Corporation, Clean Air Products.

Industry development

In July 2021, Taikisha Ltd. (“Taikisha”), a leading Japanese engineering company with a focus on HVAC systems has acquired controlling shareholding in leading Indian cleanroom engineering company Nicomac Clean Rooms Far East LLP (“Nicomac”).

In April 2019 Ardmac and Germfree are announced their partnership to bring Germfree bioGO Mobile and Modular Cleanroom Buildings to the European markets. Germfree offers a fully adaptable Cleanroom solution which supports manufacturing for pre-clinical/ clinical stage materials in a single or multiple-module Cleanroom building.

In January 2022 Kimberly-Clark Professional introduced its new nitrile gloves for research and production facilities, life sciences and non-sterile drug manufacturing applications. These gloves have improved comfort for extended use & high tactile sensitivity without compromising worker safety, Kimberly-Clark Professional has introduced Kimtech Opal Nitrile Gloves.

Browse Full Report https://qualiketresearch.com/reports-details/Cleanroom-Technologies-Market

0 notes

Text

Clean Rooms and its Types by Padmashri Steel

Well, if you are looking for the best clean room supplier in Pune and Goa, India then Padmashri steel is one of the best options to look for. They are the renowned clean room manufacturers having 10+ years of experience in this industry.

So, how do cleanrooms work?

Cleanrooms use HEPA (high efficiency particulate air) or ULPA (ultra-low penetration air) filtration to eliminate particles from the air and generate an ultra clean environment. An adequate air changes per hour and laminar air flow is applied to decrease particulate count from around 500k/ft3 (in typical office space) to as low as 100k/ft3 (class 100 cleanroom).

To avoid contamination from entering the cleanroom, airlocks are used. Besides, workers usually have to wear cleanroom garments like booties and bunny suits in the clean rooms so that they don’t bring any contaminants into the room. Eating and drinking is also banned in cleanrooms.

What are the Different Types of Cleanrooms?

As cleanroom work is varied in nature, cleanroom facilities exist as portable, modular as well as fixed building structures. And modular cleanrooms, stick-built cleanrooms (or standard), and softwall cleanrooms are the most common types of cleanrooms.

In modular cleanrooms, prefabricated modular wall system is used which allow faster installation, easy modification(s), and reasonable cost. On the other hand, stick built or standard cleanrooms are dependent on conventional steel stud(s) drywall construction and are slightly cheaper. Whereas softwall cleanrooms make use of clear vinyl curtains which are suspended from metal frames.

For more details visit at

https://www.guidesking.com/business/an-overview-about-clean-rooms-and-its-types-a-guide-for-2022/

0 notes

Text

Modular Facilities in Pharmaceutical and Biotechnology Market, 2021-2030

To order this 300+ page report, please visit this - https://www.rootsanalysis.com/reports/view_document/modular-facilities-flexible-drug-manufacturing-platforms-of-the-future/178.html

Key Inclusions

§ A review of the market landscape of modular facilities along with information on their year of establishment, company size (small, mid-sized or large), location of headquarters (North America, Europe, Asia and rest of the world), geographical coverage, GMP compliance construction and type of industry served (pharmaceutical, biotechnology or others). It also includes details related to certifications obtained and COVID-19 related initiatives undertaken by modular service providers.

§ A review of the market landscape of modular cleanrooms along with information on their year of establishment, company size (small, mid-sized or large), location of headquarters (North America, Europe, Asia and rest of the world), type of industry served (pharmaceutical, biotechnology or others), type of modular cleanrooms (softwall and hardwall), type of modular cleanroom components (air handling units / HVAC system, fan filter units, laminar flow units, air showers, pass throughs, cleanroom furniture / furnishings, plumbing / piping, lighting / electricals). It also includes details related to regulatory approvals and certifications.

§ An analysis of the partnerships that have been inked by stakeholders in this domain, during the period between 2012 and 2021 (till January), covering facility construction agreements, cleanroom construction agreements, service alliances, service agreements and other relevant types of deals.

§ An analysis of modular projects undertaken across key geographical regions, featuring information on type of facility, facility area, most active manufacturers, most active clients, location of facility. We have provided a case study on JHL Biotech's KUBio biomanufacturing facility, which was constructed by GE Healthcare Life Sciences in China. It also includes information on modular projects received by key pharma / biotech players based on location, type and area of facility.

§ An insightful analysis on facility construction trends in the pharmaceutical industry for the last five years, highlighting facility construction projects established by top 20 pharma / biotech players, along with information on their number of facilities, type of facility, purpose, investments made in modular projects, area of facility and location of headquarters.

§ Elaborate profiles of key players that provide a wide range of modular manufacturing solutions to pharmaceutical and biotechnology industries. Each profile features a brief overview of the company (including information on year of establishment, number of employees, location of headquarters and key members of the executive team), details related to modular facility- focused services, modular projects, recent developments and an informed future outlook.

§ A review of emerging trends, including the combination of single-use technologies / continuous processing technologies with modular facilities, the shift to using smaller, multi-purpose modular facilities, and technological advancements in modular construction processes.

§ A detailed discussion on the various growth drivers, such as the development of personalized medicines, biosimilars, orphan drugs and the anticipated increase in the adoption of modular solutions in emerging markets by pharmaceutical / biopharmaceutical CMOs. It also highlights trends, such as expansion of existing facilities and adoption of modular facilities by emerging start-ups and small companies.

The report also features the likely distribution of the current and forecasted opportunity across important market segments, mentioned below:

· Type of Modular Construct

§ Hybrid Skid

§ Plug-and-Play

§ Skid-Mounted

§ Truckable

§ Others

§ Type of Construction Component

§ Base Building

§ Electrical System

§ Mechanical System

§ Process Equipment

§ Process Piping

§ Process Utilities

§ Other Components

§ Purpose of Facility

§ Aseptic Filling

§ Manufacturing

§ Research and Development

§ Others

§ Facility Area

§ Very Small

§ Small

§ Mid-Sized

§ Large

§ Very Large

§ Scale of Operation

§ Clinical

§ Commercial

§ Type of Industry

§ Pharmaceutical

§ Biotechnology

§ Type of Product

§ Biosimilars

§ Cell and Gene Therapies

§ Monoclonal Antibodies

§ Vaccines

§ Other Products

§ Type of Facility

§ New Facility

§ Facility Expansions

§ Key Geographical Regions

§ North America

§ Europe

§ Asia

§ Middle East and North Africa

§ Latin America

§ Rest of the World

To Request Sample Pages - https://www.rootsanalysis.com/reports/178/request-sample.html

Transcripts of interviews held with the following senior level representatives of stakeholder companies

§ Alan de Zayas (Modular Building Manufacturing and Construction Team, Avon Modular Construction)

§ François Abiven (Executive Vice-President Global Business Unit BLS and Luca Mussati Vice President, Pharma and Biotech Life Sciences, Exyte)

§ Maik Jornitz (President and Chief Executive Officer, G-CON Manufacturing)

§ Pär Almhem (President, Modwave)

§ Sulogna Roy (Ex Sales Manager, Zeton)

§ Vernon Solomon (Specialist in Modular Design for Cleanrooms and Close Tolerance Temperature and Humidity Control, Environmental Systems Corporation)

Key Questions Answered

§ Who are the key service providers engaged in domain of modular construction? What are the current trends fueling the adoption of modular construction solutions in the pharma / biotech industries?

§ Which key regions are targeted by pharma / biotech companies for expanding their existing facilities and capabilities?

§ What type of product lines are actively supported by integrated modular solutions in facility design and construction?

§ What are the recent initiatives undertaken by modular manufacturers in order to overcome the challenges related to the COVID-19 pandemic?

§ Which regions are the current hubs for modular construction service providers?

§ Which partnership models are most commonly adopted by stakeholders engaged in this industry?

§ How is the current and future opportunity likely to be distributed across key market segments?

Download Free Insights now - https://www.rootsanalysis.com/reports/178/free-insights.html

You may also be interested in the following titles:

1. Vaccine Contract Manufacturing Market (3rd Edition), 2021-2030

2. Biopharmaceutical CROs Market, 2021-2030

3. Continuous Manufacturing Equipment Providers Market, 2021-2030

4. DNA-Encoded Libraries: Platforms and Services Market

5. Antibody Discovery: Services and Platforms Market (2nd Edition), 2018-2028

Contact Us

Gaurav Chaudhary

+1 (415) 800 3415

0 notes

Link

Pacific Environmental Technologies offers a complete selection for the manufacturing and installation of modular and softwall clean rooms. Pacific Environmental Technologies, Inc has over two decades of experience constructing all types of clean rooms and laboratories giving their clients. Modular cleanrooms providing quick set up.

0 notes

Text

Elevating Precision and Quality with Ezad Cleanroom's Hardwall Modular Cleanroom Solutions

When it comes to industries that demand uncompromising precision, cleanliness, and quality, a modular cleanroom is often the answer. Among the myriad of cleanroom options, the hardwall modular cleanroom stands out as an excellent choice, especially when provided by Ezad Cleanroom. With a proven track record of delivering top-notch cleanroom solutions, Ezad Cleanroom's hardwall modular cleanrooms have become a go-to choice for organizations that value precision, cleanliness, and flexibility.

Understanding the Hardwall Modular Cleanroom

Before delving into the unique advantages offered by Ezad Cleanroom's hardwall modular cleanrooms, let's first understand what makes a hardwall modular cleanroom unique.

A hardwall modular cleanroom is a controlled environment with walls constructed from rigid materials such as aluminum and steel, creating a sturdy and durable enclosure. Unlike softwall cleanrooms, hardwall cleanrooms offer more substantial protection against contaminants. They are highly customizable and suitable for various industries, including pharmaceuticals, electronics, aerospace, and biotechnology. These modular cleanrooms are designed to meet the stringent cleanliness and environmental control requirements that these industries demand.

Ezad Cleanroom's Cutting-Edge Solutions

Ezad Cleanroom, a renowned name in the field of cleanroom solutions, offers a range of hardwall modular cleanroom options that cater to the unique needs of different industries. What sets Ezad Cleanroom apart from the competition are the following key features of their hardwall modular cleanroom solutions:

Customization for Precise Requirements

Every industry, and even individual projects, have unique cleanroom requirements. Ezad Cleanroom recognizes this and provides a high level of customization. Whether you need a specific layout, environmental control specifications, or particular cleanliness standards, their hardwall modular cleanrooms can be tailored to your precise needs. This level of flexibility ensures that your cleanroom is a perfect fit for your operations, enabling you to maintain the highest level of quality and precision.

Rigid and Durable Construction

Ezad Cleanroom uses only the highest quality materials in the construction of their hardwall modular cleanrooms. The walls are made from durable materials like aluminum and steel, ensuring structural integrity and longevity. This robust construction offers a level of protection and stability that is unmatched by softwall alternatives. It also means that your investment in a hardwall cleanroom will provide long-term benefits, making it a cost-effective solution.

Stringent Cleanliness Standards

The core purpose of a cleanroom is to maintain an environment with minimal contaminants. Ezad Cleanroom's hardwall modular cleanrooms excel in this aspect. They are equipped with cutting-edge air filtration and purification systems that constantly monitor and control the cleanliness of the air within the cleanroom. This ensures that the environment is consistently kept at the required cleanliness level, guaranteeing the quality and precision of your processes.

Compliance with Industry Regulations

Regulatory compliance is a critical consideration in industries such as pharmaceuticals and electronics. Ezad Cleanroom's hardwall modular cleanrooms are designed to meet and exceed industry-specific standards and regulations. This means you can trust that your cleanroom will pass inspections and audits with flying colors, reducing the risk of costly shutdowns or delays due to non-compliance.

Quick Installation and Scalability

Time is often of the essence in various industries, and the quick installation of a cleanroom can significantly impact your operational efficiency. Ezad Cleanroom's hardwall modular cleanrooms are designed for rapid assembly, minimizing downtime. Additionally, these cleanrooms are highly scalable, allowing you to expand or reconfigure them as your needs change. This adaptability is invaluable, especially in dynamic industries.

Energy Efficiency

Ezad Cleanroom is committed to eco-friendly solutions. Their hardwall modular cleanrooms are designed to be energy-efficient, which not only reduces operating costs but also lessens the environmental impact. By choosing a cleanroom solution that is conscious of its energy use, you're making a responsible choice for your business and the planet.

Cost-Effective Investment

The initial investment in a cleanroom can be significant, but the long-term benefits far outweigh the costs. Ezad Cleanroom's hardwall modular cleanrooms provide an excellent return on investment due to their durability, customizability, and compliance with industry standards. By choosing one of their cleanrooms, you are making a wise financial decision that supports your commitment to quality and precision.

Conclusion

In conclusion, when you choose Ezad Cleanroom's hardwall modular cleanrooms, you are investing in precision, quality, and flexibility. These cleanrooms are designed to cater to the unique needs of various industries, delivering exceptional value. With their customization options, durable construction, stringent cleanliness standards, and compliance with industry regulations, Ezad Cleanroom stands out as a trusted partner for your cleanroom needs. The quick installation, scalability, and energy efficiency further solidify their position as an industry leader. Make the wise choice for your business, and elevate your operations with Ezad Cleanroom's hardwall modular cleanrooms.

Are you ready to take your precision and quality to the next level? Contact Ezad Cleanroom today and explore the endless possibilities that our hardwall modular cleanrooms offer. Don't compromise on cleanliness, compliance, or customization. Choose Ezad Cleanroom, your partner in cleanroom solutions, and experience the difference. Contact us now to get started on the path to unmatched precision and quality. Your success is our commitment.

Original Sources: https://ezadcleanrooms.blogspot.com/2023/11/elevating-precision-and-quality-with.html

0 notes

Text

Our company, Ziebaq, designs and builds various clean rooms for businesses in multiple fields, including hardwall, softwall, modular, and more. We also offer expert Cleanroom panel repair services as part of our full range of Cleanroom services.Get more information please read this blog:

0 notes

Text

Regulations and Standards for Softwall Cleanrooms Across Industries

Cleanrooms play a vital role in industries where maintaining a controlled environment is essential to prevent contamination, ensure product quality, and protect both employees and consumers. Among the various types of cleanrooms, softwall cleanrooms have gained popularity for their flexibility, cost-effectiveness, and ease of installation. However, to ensure their effectiveness, it is crucial to adhere to specific regulations and standards that apply to softwall cleanrooms in various industries. In this comprehensive guide, provided by Cleatech LLC, we will explore the regulatory landscape and standards that govern softwall cleanrooms across different sectors.

Understanding Softwall Cleanrooms

Softwall cleanrooms, also known as softwall modular cleanrooms or softwall enclosures, are controlled environments designed to maintain low levels of airborne particles, temperature, humidity, and other environmental factors to meet the specific needs of different industries. These cleanrooms consist of flexible curtains or panels made from materials like vinyl or PVC, which are easy to clean and offer a barrier to contaminants. The modular nature of softwall cleanrooms allows for customization and easy reconfiguration, making them versatile for various applications.

Regulatory Agencies and Oversight

To ensure the safety, quality, and compliance of Softwall cleanrooms, several regulatory agencies and organizations have established guidelines and standards. The specific regulations and standards applicable to softwall cleanrooms can vary by industry and location, but some overarching principles apply. Here are the primary regulatory bodies and their roles:

Food and Drug Administration (FDA): The FDA oversees cleanroom requirements for pharmaceutical and medical device manufacturing. It sets standards for good manufacturing practices (GMP) to ensure product safety and quality. Companies in these industries must adhere to FDA regulations when designing and operating cleanrooms, including softwall cleanrooms.

International Organization for Standardization (ISO): ISO provides international standards for cleanrooms, including those with softwall construction. ISO 14644-1 specifies particle cleanliness by class, and ISO 14698-1 focuses on bio contamination control. Compliance with ISO standards is often a requirement in various industries, including electronics, aerospace, and healthcare.

Occupational Safety and Health Administration (OSHA): OSHA is responsible for worker safety and health in the United States. Companies must adhere to OSHA regulations when setting up softwall cleanrooms to ensure employee safety and compliance with relevant standards.

National Fire Protection Association (NFPA): NFPA standards, such as NFPA 45 for laboratories using chemicals and NFPA 70 (National Electrical Code), may apply to cleanroom facilities, depending on their specific processes and equipment.

European Medicines Agency (EMA): EMA regulates pharmaceuticals in the European Union. Companies operating in EU member states must adhere to EMA standards, which often align with FDA guidelines.

Other Industry-Specific Regulations: Some industries, like semiconductor manufacturing, have their own specific cleanroom standards and guidelines. For example, the Semiconductor Equipment and Materials International (SEMI) organization provides standards for semiconductor cleanrooms.

Now that we have a clear understanding of the regulatory landscape, let's delve deeper into the specific standards and requirements that apply to softwall cleanrooms in various industries.

Pharmaceutical and Biotechnology Industry

The pharmaceutical and biotechnology sectors are highly regulated due to the critical nature of the products they manufacture. Softwall cleanrooms play a significant role in ensuring the integrity of pharmaceutical and biotech products. Here are some key standards and requirements for softwall cleanrooms in these industries:

Good Manufacturing Practices (GMP): Softwall cleanrooms in pharmaceutical and biotech industries must adhere to GMP guidelines outlined by the FDA. These guidelines cover various aspects, including facility design, equipment maintenance, and personnel training.

ISO 14644-1: ISO 14644-1 establishes cleanliness classes for air cleanliness in cleanrooms. Pharmaceutical and biotech cleanrooms often require adherence to specific ISO classes to maintain the quality of their products.

HEPA and ULPA Filtration: High Efficiency Particulate Air (HEPA) and Ultra Low Penetration Air (ULPA) filters are commonly used in softwall cleanrooms to achieve the required level of air cleanliness. These filters must meet stringent performance criteria.

Material Compatibility: Softwall materials must be compatible with the chemicals and processes used in pharmaceutical and biotech cleanrooms. Compatibility testing and documentation are essential.

Validation and Qualification: Regular validation and qualification activities, including particle monitoring and airflow testing, are necessary to ensure softwall cleanrooms continue to meet their intended performance specifications.

Electronics and Semiconductor Industry

The electronics and semiconductor industry relies on cleanrooms to manufacture sensitive components that require a controlled environment free from contaminants. Key standards and requirements for softwall cleanrooms in this sector include:

ISO 14644-1: Cleanroom classification according to ISO standards is crucial for semiconductor manufacturing. Stringent control over airborne particles is necessary to prevent defects in semiconductor devices.

EIA-748: The Electronics Industries Alliance (EIA) standard 748 outlines the requirements for cleanroom construction, testing, and monitoring in the electronics industry. It covers various aspects of cleanroom design and operation.

SEMI Standards: The semiconductor industry follows SEMI standards for cleanroom facilities. SEMI S2 outlines the environmental, health, and safety guidelines, while SEMI S6 specifies the requirements for air cleanliness in semiconductor cleanrooms.

Temperature and Humidity Control: Electronics manufacturing often requires precise control over temperature and humidity. Softwall cleanrooms in this industry must be equipped with suitable HVAC systems to maintain these parameters.

Static Control Measures: To prevent electrostatic discharge (ESD), softwall cleanrooms in electronics and semiconductor manufacturing must implement static control measures, including antistatic flooring and equipment.

Healthcare and Medical Device Industry

The healthcare and medical device industry manufactures products that directly impact patient health and safety. Softwall cleanrooms in this sector must meet stringent requirements to ensure product quality and patient well-being. Key standards and requirements include:

FDA Regulations: Compliance with FDA regulations, including GMP, is paramount in the healthcare and medical device industry. This includes validation and documentation of cleanroom processes.

ISO 14644-1: Cleanroom classification according to ISO standards is applicable in this industry to control airborne particulate contamination.

ISO 13485: ISO 13485 specifies quality management system requirements for medical device manufacturers. Softwall cleanrooms are essential in maintaining product quality and hygiene.

Biocompatibility: Materials used in softwall cleanrooms for medical device manufacturing must be biocompatible and non-toxic to ensure product safety.

Sterility Assurance: Softwall cleanrooms involved in sterile product manufacturing must adhere to strict protocols for sterilization and aseptic processing.

Aerospace and Defense Industry

The aerospace and defense industry relies on cleanrooms for the assembly and testing of critical components, such as satellite electronics and avionics systems. Specific standards and requirements for softwall cleanrooms in this sector include:

ISO 14644-1: Cleanroom classification according to ISO standards is essential to control airborne particles in aerospace cleanrooms. Depending on the application, cleanrooms may need to meet stringent ISO Class 1 or Class 10 requirements.

Cleanliness for Optics: In the aerospace sector, softwall cleanrooms used for optical component manufacturing must adhere to strict cleanliness standards to ensure the performance of optical systems.

ESD Control: Aerospace and defense applications often require ESD control measures to protect sensitive electronic components. Softwall cleanrooms must incorporate appropriate ESD-safe materials and practices.

Temperature and Humidity Control: Cleanrooms in the aerospace industry may need to maintain specific temperature and humidity levels to meet product specifications.

Security and Access Control: Access to aerospace cleanrooms is tightly controlled to prevent unauthorized personnel from entering sensitive areas.

Food and Beverage Industry

While not as common as in other industries, softwall cleanrooms are used in the food and beverage sector, particularly for research and development, and specialty production processes. Key standards and requirements for softwall cleanrooms in this industry include:

FDA Regulations: Softwall cleanrooms used for food and beverage production must adhere to FDA regulations related to food safety and hygiene. Compliance with Good Manufacturing Practices (GMP) is essential.

Material Compatibility: Materials used in softwall cleanrooms must be food-grade and suitable for contact with food products.

Temperature and Humidity Control: Some food production processes require precise control over temperature and humidity to ensure product quality.

Contamination Control: Softwall cleanrooms in the food and beverage industry must effectively control airborne and surface contaminants to prevent food contamination.

General Requirements for Softwall Cleanrooms

Regardless of the industry, there are some general requirements and best practices that apply to softwall cleanrooms:

Regular Maintenance: Softwall cleanrooms require regular maintenance to ensure their continued effectiveness. This includes cleaning, filter replacement, and equipment calibration.

Documentation: Detailed documentation of cleanroom design, construction, maintenance, and performance is essential for compliance and quality assurance.

Training: Personnel working in softwall cleanrooms should receive proper training on cleanroom protocols, gowning, and contamination control.

Airflow Control: Proper airflow design is critical to prevent cross-contamination within the cleanroom. This includes maintaining positive or negative pressure as needed for specific applications.

Monitoring and Testing: Softwall cleanrooms should have continuous monitoring systems for temperature, humidity, particle counts, and pressure differentials. Routine testing and validation are also necessary.

Emergency Response: Procedures for handling emergencies, such as equipment failures or contamination events, should be in place to mitigate risks and prevent product loss.

Conclusion

Softwall cleanrooms are versatile and cost-effective solutions for maintaining controlled environments in various industries. To ensure their effectiveness and compliance with industry-specific regulations and standards, it is crucial to design, operate, and maintain softwall cleanrooms according to the guidelines outlined by regulatory agencies and organizations such as the FDA, ISO, and OSHA.

Each industry has its unique requirements and considerations when it comes to softwall cleanrooms, whether it's pharmaceuticals, electronics, healthcare, aerospace, or food production. Therefore, it's essential for organizations to stay informed about the latest regulatory updates and industry-specific standards to meet the highest quality and safety standards.

Cleatech LLC is committed to providing state-of-the-art softwall cleanroom solutions that align with industry regulations and standards. By partnering with Cleatech, organizations can ensure their softwall cleanrooms are designed and built to meet the specific requirements of their industry while maintaining the flexibility and adaptability that softwall cleanrooms offer. For more information and personalized cleanroom solutions, please contact Cleatech LLC today.

Original Sources: https://linkspalace.com/index.php/2023/09/13/regulations-and-standards-for-softwall-cleanrooms-across-industries/

0 notes

Text

Revolutionizing Cleanroom Technology: Exploring the Advantages of Cleatech, LLC's Softwall Cleanroom

In the realm of cutting-edge scientific research and advanced manufacturing processes, maintaining a controlled environment free from contamination is of paramount importance. Cleanrooms have emerged as a critical solution to address this need, providing a controlled and sterile space for a wide range of applications. Cleatech, LLC, a leader in laboratory and cleanroom equipment, introduces an innovative approach to cleanroom technology with their Softwall Cleanroom system. In this article, we delve into the world of cleanroom technology and explore the unique features and benefits offered by Cleatech’s Softwall Cleanroom.

Understanding Cleanroom Environments

A cleanroom is a highly controlled environment designed to minimize airborne particulate contamination and control factors such as temperature, humidity, and air pressure. Cleanrooms find applications in various industries, including pharmaceuticals, electronics, biotechnology, and aerospace, where precision and quality control are essential.

Traditional cleanrooms are constructed using rigid materials, such as metal panels or laminar airflow systems, to create a sealed and controlled environment. However, Cleatech’s Softwall Cleanroom introduces a flexible and innovative approach to cleanroom design, offering distinct advantages over traditional rigid cleanrooms.

The Evolution of Cleanroom Technology: Cleatech’s Softwall Cleanroom

Cleatech’s Softwall Cleanroom is a breakthrough in cleanroom design, blending flexibility, modularity, and efficiency to meet the evolving needs of modern research and manufacturing processes. Let’s explore some of the key features and benefits that set Cleatech’s Softwall Cleanroom apart:

Modularity and Flexibility: Traditional cleanrooms often require significant time and resources for construction and modification. Cleatech Softwall Cleanroom offers a modular design that allows for easy setup, expansion, and reconfiguration. The softwall panels can be quickly assembled and disassembled, providing the flexibility to adapt the cleanroom layout according to changing requirements. This modularity also allows for efficient use of space, making it an ideal solution for facilities with limited room for expansion.

Cost-Effectiveness: Building and maintaining a rigid cleanroom can be a substantial financial investment. Cleatech’s Softwall Cleanroom offers a cost-effective alternative, reducing construction costs and minimizing downtime during installation. The modular design eliminates the need for extensive construction work, allowing organizations to allocate resources more efficiently.

ISO-Compliant Performance: Cleatech’s Softwall Cleanroom is designed to meet stringent ISO cleanliness and classification standards. The softwall panels create a controlled environment that effectively reduces particle contamination, making it suitable for applications that demand high levels of cleanliness, such as microelectronics manufacturing, biotechnology, and precision optics.

Customization Options: Every research or manufacturing process has unique requirements. Cleatech recognizes this diversity and offers customization options for their Softwall Cleanroom. From choosing the appropriate filtration and air handling systems to selecting the optimal size and layout, organizations can tailor the cleanroom to their specific needs.

Versatility and Adaptability: Cleatech’s Softwall Cleanroom is not limited to a single industry or application. Its adaptability makes it suitable for a wide range of uses, from pharmaceutical compounding and medical device assembly to research involving nanotechnology and advanced materials.

Airflow Control and Filtration: Maintaining the desired airflow patterns and filtration is crucial in cleanroom environments. Cleatech’s Softwall Cleanroom integrates advanced air handling systems and HEPA or ULPA filtration, ensuring consistent air quality and reducing the risk of cross-contamination.

Enhanced Safety and Ergonomics: Softwall cleanrooms provide an additional layer of safety for researchers and technicians. The flexible panels are designed to absorb impact, reducing the risk of injury in case of accidental contact. Furthermore, the ergonomic design of Cleatech’s Softwall Cleanroom promotes comfortable and efficient work practices, contributing to a more productive and safe work environment.

Applications of Cleatech’s Softwall Cleanroom

The versatility and adaptability of Cleatech’s Softwall Cleanroom make it suitable for a wide array of applications across various industries:

Pharmaceutical and Biotechnology: Cleatech’s Softwall Cleanroom provides a controlled environment for pharmaceutical compounding, aseptic processing, and biotechnology research. It ensures the sterility required for producing medications, conducting cell culture studies, and developing innovative therapies.

Microelectronics and Optics: In the microelectronics industry, even the tiniest particles can disrupt the functionality of electronic components. Cleatech’s Softwall Cleanroom offers the cleanliness and precision necessary for microelectronics manufacturing, including semiconductor fabrication and optics assembly.

Medical Device Manufacturing: Medical device assembly demands a sterile and controlled environment to prevent contamination and ensure product quality. Cleatech’s Softwall Cleanroom is ideal for medical device assembly, packaging, and quality control processes.

Research and Development: Cleatech’s Softwall Cleanroom serves as an essential tool for research and development across multiple disciplines. Whether it’s nanotechnology, materials science, or advanced research in physics and chemistry, the controlled environment supports the integrity of experiments and enhances data accuracy.

Food and Beverage Industry: The food and beverage industry relies on stringent hygiene standards to ensure product safety. Cleatech’s Softwall Cleanroom can be employed for food processing, packaging, and quality assurance, safeguarding the purity of consumable products.

Conclusion

Cleanroom technology continues to evolve, driven by the demands of modern research, manufacturing, and quality control processes. Cleatech LLC Softwall Cleanroom system embodies this evolution, offering a flexible, modular, and cost-effective solution for organizations seeking to establish controlled environments with uncompromised sterility and precision. By combining modularity, adaptability, and advanced filtration systems, Cleatech’s Softwall Cleanroom addresses the challenges posed by traditional cleanroom designs while meeting stringent cleanliness and classification standards.

As industries strive for excellence in product quality, process efficiency, and research integrity, Cleatech’s Softwall Cleanroom emerges as a pivotal tool in achieving these goals. Its innovative design, customization options, and diverse applications underscore its significance as a cornerstone of modern cleanroom technology. Cleatech Softwall Cleanroom not only raises the bar for cleanroom performance but also sets a new standard for flexibility and efficiency in controlled environments.Original Sources: https://orphanspeople.com/revolutionizing-cleanroom-technology-exploring-the-advantages-of-cleatech-llcs-softwall-cleanroom/

0 notes

Text

The Key to Success: Implementing a Hardwall Cleanroom in Your Lab by Ezad Cleanrooms

In the realm of scientific research and advanced manufacturing, success hinges on precision, control, and reliability. Laboratories and cleanroom environments serve as the nucleus of innovation, providing the controlled conditions necessary for groundbreaking discoveries and technological advancements. In this journey, Ezad Cleanrooms introduces a game-changing solution: the Hardwall Cleanroom. These state-of-the-art environments redefine laboratory setups by combining the highest standards of cleanliness, structural stability, and adaptability, culminating in a recipe for scientific success.

The Genesis of Hardwall Cleanrooms

Cleanrooms have a rich history, originating in the mid-20th century to meet the stringent demands of industries like aerospace and electronics. These controlled environments were designed to minimize particulate contamination during sensitive manufacturing processes. Over the years, cleanroom technology evolved, and the Hardwall Cleanroom emerged as a testament to the marriage of structural stability and cleanliness. This evolution allowed for greater customization, control, and integration of advanced technologies within the cleanroom environment.

Ezad Cleanrooms' Innovative Approach

Ezad Cleanrooms, a trailblazer in cleanroom technology, takes the concept of the Hardwall Cleanroom to new heights. With a deep understanding of the evolving needs of modern research and manufacturing, they have redefined the paradigm by offering advanced cleanroom solutions that balance structural robustness with cleanliness and adaptability. The result is a cleanroom environment that paves the way for scientific breakthroughs and manufacturing excellence.

The Building Blocks of Success

A Hardwall Cleanroom is more than just an enclosed space; it is a carefully orchestrated ecosystem where various elements work in harmony to ensure precision, reliability, and scientific success.

Structural Stability

One of the defining features of a Hardwall Cleanroom is its structural stability. Unlike softwall cleanrooms, which are designed with flexible panels, Hardwall Cleanrooms feature rigid walls that provide a robust framework for the controlled environment. This stability is crucial for processes that demand minimal vibrations, such as microelectronics manufacturing, where even the slightest disturbance can compromise the integrity of components.

Ezad Cleanrooms' Hardwall Cleanrooms are engineered with precision to ensure that the structural integrity of the cleanroom remains intact, even in dynamic manufacturing environments. This level of stability is a key factor in maintaining the accuracy and reliability of experiments and processes.

Enhanced Cleanliness

At the heart of any cleanroom lies the commitment to cleanliness. Hardwall Cleanrooms, while offering structural stability, excel in maintaining controlled environments with minimal contaminants. These cleanrooms are equipped with advanced HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filtration systems that effectively remove airborne particles and microorganisms, ensuring that the air within the cleanroom meets the highest standards of purity.

Ezad Cleanrooms understands that cleanliness extends beyond filtration. Their Hardwall Cleanrooms are designed with meticulous attention to detail, minimizing potential areas for particle accumulation and ensuring a smooth, easy-to-clean surface that enhances the cleanliness of the environment.

Adaptability and Customization

In the fast-paced landscape of research and manufacturing, adaptability is key. Ezad Cleanrooms' Hardwall Cleanrooms offer the flexibility required to tailor the environment to specific processes and experiments. From pharmaceutical manufacturing to semiconductor fabrication, these cleanrooms can be customized to accommodate diverse needs.

The modular design of Ezad Cleanrooms' Hardwall Cleanrooms allows for easy reconfiguration and expansion, ensuring that the cleanroom can adapt to changing requirements. This adaptability is especially crucial as research projects evolve and technologies advance.

Integration of Cutting-Edge Technologies

Modern research and manufacturing heavily rely on advanced tools and equipment. Hardwall Cleanrooms, with their structural stability, provide an optimal environment for integrating these technologies without compromising cleanliness.

Ezad Cleanrooms ensures that their Hardwall Cleanrooms can seamlessly accommodate specialized equipment, ventilation systems, and electrical connections required for cutting-edge tools. This integration empowers researchers and manufacturers to harness the full potential of technology while maintaining the highest standards of cleanliness and precision.

Creating a Culture of Success

Beyond the physical attributes, a Hardwall Cleanroom by Ezad Cleanrooms helps foster a culture of success within the laboratory environment. The dedication to cleanliness, precision, and reliability sets a standard that permeates all aspects of research and manufacturing.

By providing an environment where accuracy and quality are paramount, Ezad Cleanrooms' Hardwall Cleanrooms elevate the expectations of researchers and manufacturers alike. The cleanroom becomes a space where teams strive for excellence, knowing that their efforts are supported by an environment that embodies the values of innovation and precision.

Conclusion

In the quest for scientific excellence and manufacturing innovation, the implementation of a Hardwall Cleanroom stands as a transformative step. Ezad Cleanrooms visionary approach redefines the role of cleanroom technology by providing an environment that seamlessly combines structural stability, cleanliness, adaptability, and cutting-edge integration.

As industries continue to advance and new challenges arise, the Hardwall Cleanroom becomes an indispensable tool for pushing the boundaries of human knowledge and technological achievement. Ezad Cleanrooms' commitment to excellence is a testament to their vision of a future where success is not just a goal but an inherent quality of the laboratory environment. By implementing a Hardwall Cleanroom, researchers and manufacturers embrace a new standard of precision, accuracy, and achievement, laying the foundation for a future of limitless possibilities.

Original Sources: https://ezadcleanrooms.blogspot.com/2023/08/the-key-to-success-implementing.html

0 notes