#Steel Durability

Explore tagged Tumblr posts

Text

How HR Coils Impact the Quality of the Best TMT Bars

The foundation of any strong structure lies within the materials used to construct it, and in creation, nothing speaks power more than a properly crafted TMT bar. At the center of manufacturing those bars lies something important—HR coils. These hot-rolled coils are where the journey of a TMT bar starts, and the high quality of those coils can determine simply how exact the very last product will be.

Right from the furnace, in which molten steel takes shape, to the rolling process in which it is converted into usable metal, HR coils play a relevant position. Their chemical composition, consistency, and surface properties affect every steel product that follows. While this may sound technical, it has real-world consequences—especially for builders looking to rely on the best TMT bar for high-rise towers, bridges, or even simple homes.

It’s not just about large structures either. Even smaller components like binding wire, used to secure bars in place, depend on the same steel quality that begins with superior HR coils.

What Makes a Good HR Coil?

To understand how HR coils influence steel quality, look at what goes into them. A suitable HR coil keeps a steady thickness, has minimum impurities, and suggests incredible ductility and tensile power. These traits aren’t just industrial jargon—they’re indicators that the metal will carry out nicely below stress, withstand corrosion longer, and remain durable across more than a few temperatures and conditions.

When HR coils meet these benchmarks, they become the backbone for reliable reinforcement solutions, including binding wire and TMT bars. Poor-quality coils, on the other hand, can lead to weak structures, faster corrosion, and unexpected failures in construction.

Why HR Coils Matter in Making the Best TMT Bar

TMT bars are known for their strength and flexibility, a balance achieved during the thermomechanical treatment process. But this process only works effectively if the input material is of high quality. That input, more often than not, is the HR coil.

High-quality HR coils ensure a uniform grain structure in the bar, giving it that perfect balance between toughness and elasticity. They also help prevent surface cracks, uneven strength distribution, and poor bonding with concrete—all issues that can turn a TMT bar from strong to subpar.

And since the binding wire used in RCC frameworks is often drawn from the same steel batch, the quality of the HR coil also directly affects how well the wire can hold everything together. No one wants a binding wire that snaps under pressure or corrodes before the project is done.

Making an Informed Choice in Construction

For those in the creation area—whether engineers, customers, or choice-makers—know-how this relationship is fundamental. Choosing the best TMT bar isn’t just about brand names or shiny packaging. It’s about what lies beneath. It’s about the HR coils that started it all.

When evaluating TMT bars, ask how they were made. Were they formed from virgin-grade HR coils? Was the processing done in a controlled, modern facility? Did the same steel also yield high-tensile binding wire that lasts?

These are the varieties of questions that result in higher shopping for selections. Choosing a TMT bar crafted from advanced HR coils isn’t only a technical preference—it’s a practical one that guarantees sturdiness, safety, and long-term value.

Conclusion: Quality Starts at the Source

The journey from raw metal to reinforced bar might seem hidden behind factory walls, but its impact is visible in every structure that stands tall and strong. HR coils may not be something consumers see every day, but their importance in shaping the best TMT bar and dependable binding wire can’t be ignored. For safer buildings and smarter investments, it all starts with the coil.

#HR coils#TMT bar quality#steel coils#TMT strength#best TMT bars#HR coil impact#coil to TMT#steel durability#HR coil steel#TMT bar grade#hot rolled coils#HR coil effect#quality steel#TMT coil link#strong TMT bars#steel base coils#TMT bar core#HR base metal#premium TMT bars#steel raw input

0 notes

Text

I recently saw some nice Cyril discussion/posts on the dash and I remember why, despite liking his Ashe support, it still rubbed me in a wrong way -

Sure it's a nice support where he ultimately finds a friend, but...

Ashe of all people?

Ashe's who's all "I want to be a model knight like Lord Lonato", the very same Lonato who tried to kill the person Cyril loves the most and came to see as a surrogate mother?

In the same vein, Cyril is the ward/son of the woman who gave the order to kill Lonato, and killed Christophe, Lonato's son and Ashe's beloved brother.

Considering Ashe might not be the kind of person who would blame Cyril for what Rhea did (even if CF!Ashe... well), would Cyril accept to be helped and ultimately become friends with him without having to tackle this issue?

Cyril "her enemies are my enemies" would be mature enough to engage in a conversation and friendship with the son of someone who wanted to kill Rhea?

Also, thinking about Ashe... Lonato became chummy with the Western Church after Christophe's death, and we know the Western Church hates the Central Church because they're not xenophobic enough.

So, Ashe's dad joins a xenophobic group, but the guy still strikes conversation with an Almyran (and a Duscurian)? Or he admires Lonato but dismisses his association with the xeno group as, idk, "ramblings" or not being something serious and doesn't follow/listens to him when he goes on Western Church rants about how Almyrans and Duscurians shouldn't be in Fodlan (or at least in Garreg Mach?) but then what is he admiring in the man?

Like, can we imagine Ashe writing a letter to his dad and gushing about Dedue and mentionning how he made an Almyran friend... or Ashe would know better than to write those things to Lonato since Lonato turned xenophobic after associating with the Western Church?

Likewise, if Cyril told Rhea he became friends with Ashe, would she be worried about it, because as Lonato's kid, he might want to target her through Cyril to get revenge for his brother and father?

I don't remember the "nickel meme" that well rn because it's late lol, but it's still weird how 2 of Cyril's support completely elude what I'd call "character essential writing" to give instead a generic support - Hilda learns how to not be racist anymore without adressing her House's issue with "captured Almyran children who are fed once in a blue moon but still have to work themselves to the bone to be able to eat", and Cyril learns what friendship is, without adressing the small issue of "the man you admire tried to kill the person I care about the most and is part of a group who hates people like me because I'm a foreigner".

Masterful character writing everyone.

i swear it's not like I have this scene in some AU plotbunny where cyril and ashe disagree about lonato in the lonato mission, and cyril believes that he has to be "there" for ashe because of this friendship thing and he wants to help/apologise after calling Lonato trash since he's somehow like "Ashe's Lady Rhea" so he joins the group during the Lonato mission

but like, in this AU Rhea herself went to confront Lonato because this nonsense has been going on for too long and it must stop before too many people die, of course Cyril is caught by Lonato's forces who try to pull the "a son for a son" nonsense (+ calling cyril with a racist slur), Rhea having none of his bullshit (tfw people pulled the same shit using Willy back in the days!) and ultimately crushing him to rescue Cyril because you.never.ever.threaten.her.family. (especially not her children! She couldn't save Lycaon so this time she'll protect (lel) everyone). More Rhea BaD shenanigans, Cyril and Ashe's friendship deteriorates (Ashe'd feel xtra guilty since he told Lonato in his latest letter that the CoS doesn't preach the same things as the Western Church does since his Almyran friend is close to the Archbishop herself!) even more, Dimi's ideal that peaceful/bloodless resolution of conflicts is in shambles but maybe a convo with Rhea that this ideal is something that should always be sought, and yet rulers should use force/authority when needed and it's up to him to learn when force is necessary.

#fodlan nonsense#fodlan AU#the more i think about it the less sense it makes#cyril stuff#AU where Rhea does stuff lol#i mean given how the librabry says nabatean bones in relic form#are as durable as crucible steel#I don't think it's far fetched to believe that the face crushing dimi did in AM can be done#by any Nabatean with ease even in human form#which would mean if Flayn felt like it she could lit tank stuff with her face#but that would out her as inhuman#and we know what happens when her nature is revealed#FE16#I doubt Rhea would prevent Cyril from being friends with Ashe#but maybe she'd ask Catherine and Shamir and Seteth to keep an eye on them just in case

8 notes

·

View notes

Text

The funniest shit about Jesse is that yes he is southern but he is a city boy who drives huge lifted pavement princesses for the appearance factor (and then gets his dick hands in there and mods the shit out of them)

#Jesse Steele#also blood sorcery to make them more durable#not the only kind of car he drives but#something something cold air intake

4 notes

·

View notes

Text

The Black Stainless Sink Advantage: Functionality Meets Modern Sophistication

A New Standard for High-Use, High-Style Kitchens

Modern kitchens are more than a space to prepare meals - they are a central gathering point and a reflection of personal style. As such, every design element must deliver both beauty and performance. The black stainless kitchen sink is one feature that meets those demands. With its distinctive finish and long-lasting build, it’s a smart, stylish choice for homeowners who expect more from their kitchen fixtures.

1. The Core of the Trend: What Is a Black Stainless Sink?

The black stainless sink starts with a high-quality stainless steel base, then undergoes a Physical Vapor Deposition (PVD) process that applies a rich, matte black coating. This isn’t a painted surface - it’s a chemically bonded layer designed to resist scratches, rust, fingerprints, and fading.

The result is a finish that adds depth, character, and practicality to one of the most frequently used areas of your kitchen. Unlike traditional polished metal, it offers a more refined and contemporary presence that elevates the overall look of the space.

2. Performance That Matches Its Looks

Functionality is where the black stainless kitchen sink truly proves its value. Homeowners are drawn to its performance under real-world conditions: repeated use, heat exposure, frequent cleaning, and occasional impacts.

Here’s why it stands out:

Stain and smudge resistance for reduced cleaning time

Durability that stands up to heavy cookware and sharp utensils

Quiet operation, especially with undercoating or padding

Whether you’re cooking for one or prepping for a crowd, this sink is built to handle the pace of modern life - while still looking impressive.

3. Why Designers Recommend the Black and Stainless Steel Sink Combination

For those who want a touch of contrast, the black and stainless steel sink design approach is increasingly popular. Whether applied through mixed finishes, faucet pairings, or accessory accents, this combination adds visual structure and layered elegance to kitchen layouts.

Designers favor this blend in:

Minimalist spaces seeking a bold focal point

Mixed-material kitchens combining warm woods and cool metals

Industrial interiors that benefit from high-contrast detailing

The black and stainless steel sink helps define zones and balance tones - ensuring cohesion without sacrificing visual interest.

4. What to Avoid When Buying a Black Stainless Sink

While the market has embraced the black finish trend, not all options are equal in quality. Many budget versions use painted or powder-coated finishes that begin to chip, fade, or peel with regular use.

When selecting your black stainless kitchen sink, it’s important to look for:

True PVD-coated finishes rather than paint

16- or 18-gauge stainless steel for long-term strength

Noise-reducing features and support for under-mount installations

Investing in a high-quality black stainless sink ensures you avoid unnecessary replacement costs and benefit from years of reliable performance.

5. A Long-Term Investment That Makes a Lasting Impression

Choosing a black stainless sink is more than following a trend - it’s about making a decision that holds up to both lifestyle and design expectations. This type of sink offers flexibility across styles, from modern to transitional, while requiring minimal effort to maintain.

Its unique appearance creates a subtle statement, anchoring the kitchen without overwhelming it. For those building new or remodeling with intention, the black stainless kitchen sink provides the right blend of timeless appeal and everyday dependability.

Confidence in Every Detail

The black stainless sink represents what modern homeowners want most: a fixture that looks refined, performs under pressure, and integrates into a thoughtful, cohesive space. With advanced finishes, long-term durability, and undeniable aesthetic value, it’s quickly becoming the preferred choice for those who want more from their kitchen - without compromise.

#black-stainless-sink#black-stainless-kitchen-sink#black-and-stainless-steel-sink#kitchen-sinks-dallas#premium-sinks-dallas#modern-kitchen-sinks#ceramic-lavatory-dallas#granite-composite-sink#stainless-steel-sink-dallas#sink-accessories-near-you#sink-care-tips#stylish-sinks-dallas#undermount-kitchen-sinks#durable-kitchen-sinks#farmhouse-style-sink#bathroom-vanity-sinks#fireclay-sinks-dallas#kitchen-design-ideas#sink-cleaning-guide#home-renovation-dallas#functional-kitchen-sinks#splendor-sink

1 note

·

View note

Text

Little john is my new blorbo

#galvanized square steel#eco friendly wood veneers#durable for 10000 years#screws borrowed from aunt#home design fandom

2 notes

·

View notes

Note

i just noticed something and i wanna point it out so itll bother you too /silly

throughout most of tts in 2 part eps its titled with the normal title, and then "(Part I of II)" or "(Part II of II)" after

except for cassandras revenge and plus est en vous

the most annoying thing is that the inconsistencies arent even consistent within themselves

like 13 and 14 use roman numerals for the first part but then regular numbers for the rest?? but all the other episodes use only roman numerals

anyway do you remember which episode has the hot cocoa thing its very important and for scientific reasons (m gonna try ta memorize the scene) :P

uhh wait i need an actual question dont i

umm

whats your favorite font?

ASDFKH that will annoy me but there's another fun fact under my belt!!

I actually don't know what episode it is but i can recite so. much. of that entire scene. hang on i'll try to find it

oooh um. i really like handwriting fonts, not sure which one is my favorite specifically. i also love the death note font!!

#and the results are in! who will win first prize for best metalllll!! will it be-#steel for it's durability and thermal conductivity or#iron for it's lustrous shine and high melting pointtt#brrrrrr pew pew *making explosion noises*#"ah yes#thank you ruddiger#*ruddiger rubs hands together*#this is PERFECT#MWAHAHAHAHA#warm cocoa will really hit the spot#thanks bud!#rapunzel: hey varian!!#varian *spits out cocoa* oh hi! hi#i wasn't expecting to see you here#*ruddiger wipes cocoa off of goggles*#because i thought we agreed i would need three weeks of SOLITUDE to decipher this thing#*laughs nervously*#raps: aww varian#don't be embarassed!#eugene: hey you got any anti-aging cream or something (forgot most of that part)#varian: hey#don't touch that!#anyways i'll let you know if i find the actual episode haha

3 notes

·

View notes

Text

Basalt Fiber Reinforcement in Construction: A Sustainable Paradigm Shift

Introduction In the contemporary construction landscape, a notable shift towards sustainable and eco-friendly building materials is underway. Among the alternatives gaining prominence is basalt fiber reinforcement, positioning itself as a compelling substitute for traditional steel reinforcement. This transition is fueled by a collective desire to reduce environmental impact and elevate the…

View On WordPress

#alternative to steel reinforcement#basalt fiber applications#basalt fiber properties#Basalt fiber reinforcement#basalt mesh in concrete#BFRP composites#construction industry sustainability#corrosion-resistant materials#durability in construction#eco-friendly building#environmental impact of construction#future of construction materials.#green building practices#lightweight construction materials#seismic resilience in buildings#steel replacement in construction#strength-to-weight ratio#Sustainable Construction Materials#sustainable structural design#thermal insulation in construction

2 notes

·

View notes

Text

How Hot Rolled Coil Quality Impacts Super Rings Production

When manufacturers talk about precision and strength, the quality of hot-rolled coil often sits at the heart of the conversation. Closely behind it come essential reinforcement components like Super Rings and Bar dowels, which depend heavily on the consistency and integrity of the coil used during production.

What is Hot-Rolled Coil, and Why Does It Matter?

Hot rolled coil is a foundational input in numerous industrial applications, especially construction and infrastructure. It's steel that’s rolled at high temperatures, making it easier to form and shape. This process gives the coil flexibility but also makes quality control critical — any inconsistency at this stage ripples across the production line.

When Super Rings are crafted from lower-grade coils, micro defects can creep in, leading to weak points that may not show up until it’s too late. A small flaw in a bar dowel could compromise the load transfer in concrete pavements or structural joints, raising long-term risks.

The Role of Hot Rolled Coil in Super Rings Performance

Super Rings, designed to provide firm and reliable reinforcement in RCC columns and beams, demand accuracy. Their circular structure needs uniform tensile strength, which only high-quality hot-rolled coil can guarantee. If the base material lacks integrity, Super Rings may warp during bending, lose roundness, or even crack under pressure.

Moreover, strength isn’t the only concern — flexibility also matters. Premium-grade coils offer the right mix of ductility and resilience, allowing Bar Dowel and Super Rings to perform consistently in varied site conditions without deformation or fatigue.

Bar Dowel Quality: The Hidden Impact of Coil Grade

The bar dowel connects concrete slabs and absorbs dynamic loads. But what truly enables it to function without failure? It's the metallurgical backbone — the hot rolled coil. Inferior coils might contain uneven grain structures or impurities, leading to weak zones. These can cause early corrosion, rust flaking, or surface pitting under heavy-duty use.

Contractors and engineers often face avoidable site issues due to poor dowel quality, not realizing it traces back to raw material selection. That’s why many experienced procurement heads insist on knowing coil specs before finalizing orders for Bar dowels or Super Rings.

Consistency is Key in Mass Production

In high-volume environments where thousands of Super Rings or Bar dowels are produced daily, only consistent coil quality ensures consistent output. When every roll of coil adheres to the same standards — be it thickness, carbon content, or tensile range — the final products reflect that precision.

Heat Treatment and Shape Retention

Coils with superior temperature control during the rolling phase retain better molecular alignment. This directly affects the shape retention of Super Rings. Once bent and shaped, high-grade material springs back less, holds better circularity, and eliminates the need for rework. For bar dowels, it reduces edge burrs and sharp bends that could otherwise create stress points.

Smart Buyers Look Beyond Price Tags

It's easy to get distracted by numbers — but seasoned builders and infrastructure developers know better. A low-cost hot-rolled coil might save you upfront, but it often leads to losses downstream. From poor site performance to unexpected maintenance costs, the real price becomes apparent over time.

That’s why top construction brands stick with trusted suppliers who don’t compromise on coil standards. Their Super Rings stay rounder, their Bar dowels last longer, and their builds stand stronger.

Conclusion

The strength of a structure doesn’t just rely on design or labor — it starts with the raw materials. Hot rolled coil forms the spine of reliable Super Rings and Bar dowel products. Compromise here, and the entire chain suffers. But get it right, and every structure built with those components reflects that quality. Choose wisely, because steel remembers.

#Hot Rolled Coil#Coil Quality#Super Rings#Steel Coils#HR Coil Impact#Quality Steel#Steel Strength#Durable Coils#Super Ring Steel#Coil Standards#High Grade Coil#Metal Ring Coil#HR Coil Grades#Steel Ring Use#HR Steel Coils#Ring Production#Steel Durability#Precision Coils#Best HR Coils#HR Coil Use

0 notes

Text

How Super Rings Elevate TMT Steel Performance

Steel pipe companies are witnessing a groundbreaking transformation in production substances, with TMT metal emerging as a game-changer in structural engineering. The advent of super rings has taken the functionality of TMT steel to extraordinary heights, providing solutions that address important demanding situations in modern-day construction and infrastructure development.

The Critical Need for Enhanced Steel Reinforcement

Structural integrity is the spine of any creation challenge. Traditional metal reinforcement techniques have long struggled with boundaries in strength, sturdiness, and resistance to outdoor stresses. TMT metallic, already diagnosed for its superior qualities, finds its ultimate capability while mixed with innovative first-rate earrings that push the bounds of fabric average overall performance.

Understanding the Science Behind Super Rings and TMT Steel

Super jewelry constitutes a leap forward in the metal reinforcement era. These precision-engineered round reinforcements are designed to revolutionize how structural masses are controlled and allotted. Unlike conventional reinforcement strategies, notable rings create a complicated three-dimensional community that dramatically enhances the mechanical homes of TMT metal.

Key Technological Innovations

The engineering within the return of superb earrings involves state-of-the-art metallurgical concepts:

Precision spherical configuration

Advanced material composition

Strategic pressure distribution mechanisms

Micro-structural enhancement techniques

How Super Rings Transform TMT Steel Performance

Technical experts inside the metallic pipe organization business enterprise have recognized several critical advantages of integrating great rings with TMT metallic:

Improved Tensile Strength: Super rings increase the load-bearing functionality of TMT metal by as much as 30%, making systems extra strong and reliable under extreme conditions.

Enhanced Ductility: The particular format of super rings permits higher material flexibility, decreasing the chance of catastrophic screw-ups during seismic activities or surprising structural pressures.

Corrosion Resistance: By creating a more uniform pressure distribution, these rings reduce functionality and vulnerable elements that might result in corrosion and structural degradation.

Thermal Stability: Super rings improve the temperature resistance of TMT steel, making it best for duties uncovered to hard environmental conditions.

Comparative Performance Analysis

When evaluating traditional TMT metallic to TMT metal with first-rate rings, the differences are amazing. Traditional techniques for warfare with restricted load capability and potential strain awareness factors. In comparison, TMT steel is extra appropriate with super rings, demonstrating:

Uniform strain distribution across the entire structural framework

Significantly progressed long-time period structural integrity

Advanced corrosion protection

Superior thermal stability and resistance

Real-World Applications and Performance

Construction tasks annoying maximum durability are an increasing number of turning to TMT steel bolstered with remarkable jewelry. From excessive upward-thrust homes to important infrastructure like bridges, commercial facilities, and marine structures, the era proves its nice worth in the most tough environments.

Technical Insights from Industry Experts

Metallurgical studies confirm that super rings creates an extra complex and robust reinforcement matrix within TMT steel. The round configuration lets in multidirectional strain absorption, a feature absent in conventional linear reinforcement strategies.

Researchers have carried out big stress assessments demonstrating that TMT metallic with outstanding rings can:

Withstand 40% greater dynamic loading

Reduce fabric fatigue by 25%

Provide advanced crack resistance

Maintain structural integrity beneath prolonged pressure

Economic and Safety Implications

Investing in TMT metallic with first-rate rings translates to:

Reduced preservation costs

Extended structure lifespan

Enhanced safety margins

Lower long-term alternative charges

Improved hazard control in essential infrastructure initiatives

Making the Smart Construction Choice

The proof is apparent: TMT metallic is reinforced with extremely good rings and represents the destiny of structural engineering. Construction specialists in search of uncompromising electricity, durability, and overall performance have a definitive solution.

Construction is a funding in safety, durability, and standard performance. TMT metal with high-quality jewelry isn't always truly a fabric desire—it is a dedication to engineering excellence and destiny-evidence infrastructure.

Explore present-day reinforcement solutions. Choose TMT steel with top-notch rings. Build with awesome self-perception.

#TMT steel#Super Rings#steel strength#reinforced steel#TMT bars#durable steel#high-strength steel#construction steel#steel quality#steel innovation#steel reinforcement#TMT steel bars#best TMT steel#structural steel#steel durability#building materials#steel technology#earthquake-resistant steel#advanced TMT#superior steel

0 notes

Note

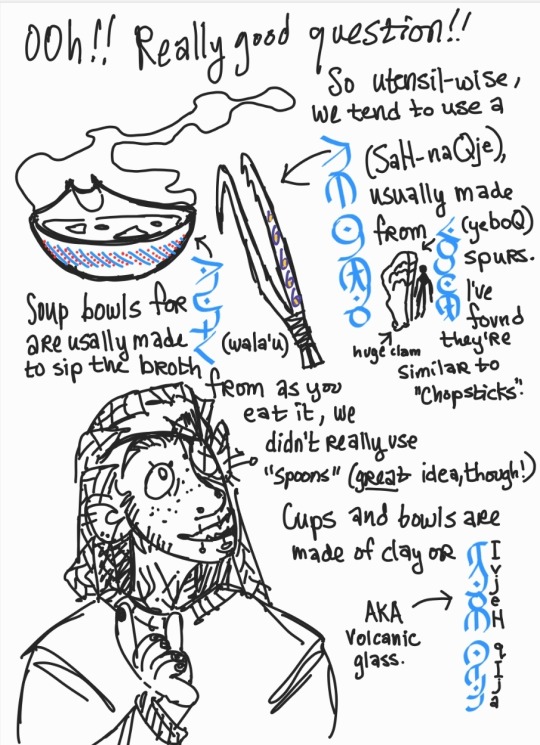

logan what are the eating utensils like wear you're from? what are they made out of?

@jedi-code

#my art#crowcore#logan crowsteeth#logan ama 2023#Other things utensils could be made from included steel and aluminum after colonization of juH'agh#but most people still just made SaH-naQje traditionally#because all it cost was the potential threat of letting a yeboQ skewer you with its barbs#and thats less expensive than metal cutlery#plus the barbs are more flexible and durable than metals that can corrode or get dented or bent#its a nobrainer really#i have some other sketches and notes on no'chuq cuisine and culture surrounding food#but thatll have to wait for another time.#crowask

2 notes

·

View notes

Text

Modern Utility with a Statement Finish: Why the Black Stainless Sink Is a Smart Upgrade

Where Everyday Function Meets Timeless Style

Your kitchen is more than just a workspace — it’s a central part of your home’s design story. And when it comes to blending performance and aesthetics, few fixtures strike the balance as well as the black stainless kitchen sink. It’s bold but not overpowering, practical but not ordinary. Whether you’re remodeling or building from scratch, this sink offers a seamless fusion of utility and modern appeal that today’s homeowners value most.

1. What Makes the Black Stainless Sink Different?

Unlike traditional stainless steel, the black stainless sink features a durable matte finish created using a Physical Vapor Deposition (PVD) process. This finish is not painted or coated — it’s bonded to the steel itself, offering superior resistance to corrosion, fading, and scratches.

Key differences include:

A bold yet neutral finish that resists daily wear

A softer visual profile compared to polished metal

Easy integration into modern, industrial, or transitional design themes

The result is a fixture that immediately enhances both the look and usability of the space it occupies.

2. Designed for Daily Use: Strength That Shows (and Lasts)

Behind the elegant exterior of a black stainless kitchen sink is a rugged, performance-driven structure. From quick rinses to heavy-duty cleaning, this sink is built to handle the demands of a real kitchen — without showing the signs of wear that traditional options often do.

Benefits of choosing this sink include:

Surface protection against pots, utensils, and daily scrubbing

Smudge and fingerprint resistance for a cleaner appearance

Noise-dampening undercoating for quieter use

In short, the black stainless sink is as functional as it is beautiful — especially in high-traffic or open-concept kitchen spaces.

3. Blending Contrast and Coordination: The Power of the Black and Stainless Steel Sink

If your kitchen includes stainless steel appliances or hardware but you’re seeking a bolder focal point, the black and stainless steel sink combination is the perfect design bridge. Its deep, dark finish offers contrast while still aligning with metallic tones found throughout most modern homes.

Ideal for:

Pairing with bright countertops or white cabinetry

Creating layered textures with brushed nickel or chrome finishes

Anchoring the design in two-tone or mixed-material kitchens

With the right placement, the black and stainless steel sink adds depth, structure, and a premium feel without overpowering the room.

4. Key Features to Look for When Choosing a Black Stainless Sink

Not every black sink offers the same performance. Many low-cost options are simply painted black and tend to show chips, scratches, and fading within months. For long-term satisfaction, it’s important to invest in a black stainless kitchen sink that offers:

A PVD matte finish (not surface paint)

16 or 18-gauge stainless steel for added strength

Integrated insulation and padding for sound control

Anti-condensation coating to prevent moisture issues under the counter

These quality details not only protect the appearance but also improve the sink’s lifespan and everyday usability.

5. The Long-Term Benefits of a Black Stainless Kitchen Sink

Choosing a black stainless sink is about investing in functionality that looks as good as it performs. Over time, it reduces cleaning effort, holds up better against scratches and stains, and continues to offer a modern, grounded focal point for the kitchen.

Long-term benefits include:

Lower maintenance compared to polished surfaces

Increased design flexibility across changing interior trends

Higher perceived home value with premium fixtures

It’s not just a stylish moment — it’s a forward-thinking fixture that evolves with your lifestyle.

Built to Endure, Styled to Stand Out

The black stainless kitchen sink is more than an accessory — it’s a decision that influences how your kitchen looks, feels, and functions every single day. With its lasting durability, easy maintenance, and sleek presence, it delivers the kind of quiet confidence that defines great design. Whether you’re after timeless sophistication or bold contrast, this sink meets the moment — and keeps delivering for years to come.

#black-stainless-sink#black-stainless-kitchen-sink#black-and-stainless-steel-sink#kitchen-sinks-dallas#premium-sinks-dallas#modern-kitchen-sinks#ceramic-lavatory-dallas#granite-composite-sink#stainless-steel-sink-dallas#sink-accessories-near-you#sink-care-tips#stylish-sinks-dallas#undermount-kitchen-sinks#durable-kitchen-sinks#farmhouse-style-sink#bathroom-vanity-sinks#fireclay-sinks-dallas#kitchen-design-ideas#sink-cleaning-guide#home-renovation-dallas#functional-kitchen-sinks#splendor-sink

0 notes

Text

#Parker Classic Stainless Steel pen#Parker stainless ball pen#Parker steel body pen#Classic Parker ballpoint#Stainless steel ball pen#Parker executive pen#Premium Parker pen#Parker pen for office use#Parker durable pen#Parker twist ball pen#Silver Parker pen#Metallic Parker pen#Parker pen for professionals#Parker gift pen#Stainless Parker pen#Parker smooth writing pen#Parker pen with clip#Original Parker steel pen#Parker steel finish pen#Elegant Parker pen#Corporate gift pen Parker#Parker pen for men#Parker pen for women#Brushed steel Parker pen#Parker slim ball pen#Classic writing pen Parker#Parker pen for students#Luxury Parker pen#Professional stainless pen#High-quality Parker pen

0 notes

Text

Zincalume Silo – Durable Industrial Storage Solutions by Royal Water Project

In the ever-growing industrial and agricultural sectors, choosing the right storage solution is essential for long-term performance and safety. Royal Water Project brings you advanced and efficient Zincalume Silos that offer superior strength, longevity, and corrosion resistance. Designed for various applications, our Zincalume Corrugated Storage Tanks are becoming a preferred choice across industries in India.

What is a Zincalume Silo?

A Zincalume Silo is a specially designed storage unit made from a unique combination of zinc, aluminium, and silicon-coated steel, offering high resistance to corrosion and weather. These Zincalume Tanks are known for their robust structure and are commonly used to store grains, water, chemicals, and other industrial materials. The corrugated steel tanks enhance their structural strength, making them perfect for both commercial and industrial applications.

Why Choose Zincalume Silos by Royal Water Project?

As a trusted name in the field of industrial storage tanks, Royal Water Project offers top-quality Zincalume Silos in India that meet international standards and cater to diverse storage needs. Here's why our solutions stand out:

Corrosion-Resistant Tanks: The Zincalume alloy offers up to four times the corrosion resistance of regular galvanized steel.

Custom Zincalume Silos: We provide tailored designs and capacities to suit specific client requirements.

High Strength: Our corrugated steel tanks are engineered for maximum load-bearing capacity.

Quick Installation: Modular design enables faster and more economical setup.

Versatile Applications: Suitable for grain storage, water storage, chemicals, and more.

Applications of Zincalume Corrugated Storage Tanks

Royal Water Project’s Zincalume Tanks serve a wide range of applications, including:

Agricultural grain and feed storage

Rainwater harvesting and storage

Firefighting water storage

Chemical and effluent containment

Process water storage in industrial facilities

Zincalume Silos in India – Trusted Nationwide

As industries and infrastructure in India continue to grow, the demand for durable storage solutions in India has also risen. Our Zincalume Silos in India have been successfully installed across manufacturing plants, warehouses, farms, and factories—delivering performance, reliability, and value.

Royal Water Project – Your Partner in Storage Innovation

At Royal Water Project, we take pride in being a leading supplier of Zincalume Silos and Zincalume Corrugated Storage Tanks in India. With years of industry experience and a focus on quality, we ensure every tank is built to last. From design and manufacturing to installation and after-sales service, we offer complete end-to-end solutions.

Invest in long-lasting storage—choose Royal Water Project's Zincalume Silos today! Explore our range of corrosion-resistant tanks and custom storage solutions.

📞 Contact us now or visit 🔗 https://www.royalwaterproject.com/zincalume-silo.php

#Zincalume Silo#Zincalume Corrugated Storage Tanks#Zincalume Tank#Royal Water Project#Zincalume Silos in India#Corrugated Steel Tanks#Custom Zincalume Silos#Corrosion-Resistant Tanks#Industrial Storage Tanks#Durable Storage Solutions in India

0 notes

Text

Insulated Mugs with Handle

Insulated Mugs with Handle combine comfort, durability, and temperature control in one stylish design. Made with double-wall insulation—usually stainless steel or BPA-free materials—they keep drinks hot or cold for hours. The sturdy handle offers a secure grip, making it ideal for both indoor and outdoor use. Spill-resistant lids add portability, while the mug’s reusable build supports a sustainable lifestyle. Perfect for coffee, tea, or even chilled drinks on the go.

#Insulated Coffee Mug#Thermal Coffee Mug#Double Wall Mug#Travel Coffee Mug#Hot Beverage Mug#Leakproof Coffee Mug#Spill Proof Mug#Reusable Coffee Mug#Stainless Steel Coffee Mug#Coffee Mug with Lid#Office Coffee Mug#Vacuum Insulated Mug#Portable Coffee Mug#Mug for Hot Drinks#Temperature Retaining Mug#Outdoor Coffee Mug#Custom Insulated Mug#Personalised Coffee Mug#Eco-Friendly Coffee Mug#Coffee Travel Tumbler#Stylish Coffee Mug#Durable Coffee Mug#Coffee Cup with Insulation#BPA-Free Coffee Mug#Thermal Travel Cup#Compact Coffee Mug#Mug for Commute#Premium Coffee Mug#Insulated Tea Mug#Gift Coffee Mug

0 notes

Text

ever thought like

what could be Dark World version of rulers

like

would rulers turn into swords like pencils

technically it may be so because you know about Eraser turning to Bounce Blade despite not being any kind of pencil.(maybe all weapons Kris wields turn only into swords? hmm. Kris has knight-like armour, and so far pretty much most of the knights we saw [including Kris i guess] had some kind of sword resembling different items [pencils, eraser. baseball bat???]< so it may also be weapon type for knights.)

and if rulers do turn in swords too...

what type of sword it'll be?

i personally think it'll be katana.

i tried putting Jack through concepts of Deltarune's world

and he wields a Steel Ruler in Light World

what turns into Unbreakable Katana in Dark World

sounds cool for me

#deltarune#deltarune weapons#dark world equivalents#i gave him steel ruler as weapon cause i actually have one and it's pretty durable actually

1 note

·

View note