#TMT Bars for Projects

Explore tagged Tumblr posts

Text

What Civil Engineers Say About TMT Saria Grades

When constructing homes that stand the test of time, deciding on the proper TMT saria is non-negotiable. Civil engineers consistently emphasize that expertise in distinct grades of reinforcement bars could make or spoil construction initiatives—actually. The selection method calls for careful attention to power necessities, sturdiness elements, and price range constraints.

Understanding TMT Saria Classifications

Thermo-Mechanically Treated (TMT) steel reinforcement bars are available in numerous grades, every one designed for specific production programs. Leading civil engineers classify these reinforcement alternatives primarily based on yield energy, measured in Newtons per rectangular millimeter (N/mm²).

Fe 415, Fe 500, Fe 550, and Fe 600 constitute the most commonplace TMT saria grades to be had in the market. The numerical fee shows the minimal yield strength—Fe 500 offers a minimum yield electricity of 500 N/mm². Higher grades provide greater strength but come with corresponding adjustments in TMT rod price points.

Strength vs. Budget Considerations

Construction professionals frequently debate the balance between strength requirements and cost constraints. The TMT rod price varies significantly between grades, with higher-strength options commanding premium prices. For budget-conscious projects, engineers often recommend calculating exact requirements rather than defaulting to the highest grade available.

For smaller residential tasks, the 8mm rod price per piece will become particularly relevant, as those thinner reinforcements regularly form the spine of residential slabs and smaller structural elements. Price fluctuations for 8mm variations can significantly impact overall task costs, in particular when purchasing in bulk portions.

Application-Specific Recommendations

Senior structural engineers emphasize that different construction elements demand different TMT saria grades:

For foundation work and load-bearing columns in multi-story buildings, Fe 500D or higher grades receive strong endorsement. The additional strength justifies the higher TMT rod price for these critical structural elements that bear tremendous loads.

For residential flooring and partition walls, Fe 415 or Fe 500 typically suffices. Here, the 8mm rod price per piece becomes a major consideration since these projects often require extensive quantities of smaller diameter reinforcement.

For infrastructure projects exposed to harsh environmental conditions, corrosion-resistant TMT saria variants merit serious consideration despite their premium pricing.

Quality Indicators Beyond Grade

Experienced civil engineers look beyond just the grade marking when assessing TMT saria quality. Physical characteristics like uniform ribbing patterns, absence of surface flaws, and proper bendability serve as practical quality indicators on construction sites. While comparing the 8mm rod price per piece across suppliers, engineers recommend examining certification documentation carefully.

Procurement Best Practices

Construction managers highlight the importance of strategic procurement practices when purchasing TMT saria. Market research indicates that TMT rod prices can vary by 5-8% between suppliers for identical grades and specifications. This difference becomes substantial for large-scale projects requiring tons of reinforcement.

For smaller contractors focused on residential construction, the 8mm rod price per piece merits particular attention, as these slimmer reinforcements typically account for a significant portion of residential reinforcement requirements.

Making Informed Choices

Civil engineering experts unanimously stress the importance of selecting appropriate TMT saria grades based on structural requirements rather than purely on cost considerations. The long-term implications of using substandard reinforcement far outweigh any initial savings on TMT rod price.

For critical infrastructure, the marginal additional investment in higher-grade TMT saria translates to decades of additional service life and enhanced safety margins. Even small residential projects benefit from quality reinforcement, though careful calculation of required quantities helps optimize expenditure on items like 8mm rod price per piece.

Ultimately, the consensus among civil engineers remains clear: understanding TMT saria grades and making informed selections based on specific project requirements represents sound engineering practice that ensures structural integrity without unnecessary expenditure.

#Civil Engineers#TMT Saria#TMT Grades#Best TMT Bars#Strong Construction#Building Materials#Construction Quality#Saria Grades#Engineer Insights#Durable TMT Bars#Saria for Buildings#Structural Strength#TMT Bar Guide#Civil Engineering#Building with TMT#TMT Bar Selection#Safe Construction#Strong Structures#TMT Bars for Projects#TMT Bar Quality#Construction Tips

0 notes

Text

Budgeting for Road Projects: Dowel Bars, TMT, and More

In road construction, every rupee has a role. Overspend, and the project risks delays or downgrades. Underspend, and the result is premature wear, safety issues, and costly repairs. That's why budgeting must begin with a sharp focus on critical materials—especially dowel bars in road structures, the current TMT bar price, and the seemingly modest but vital binding wires.

These components aren’t just line items—they’re long-term performance indicators. Early alignment on their cost and quality can define the success or failure of a roadway. Understanding their role isn't just smart planning—it's good financial strategy.

Building Awareness: Why the Right Materials Drive the Right Budget

Roads aren’t just built—they’re engineered for decades of use. This longevity depends heavily on what’s beneath the surface. Dowel bars in road construction help distribute loads across joints, reducing cracking and wear. Skimping on these bars can lead to higher maintenance costs just a few years in. Budgeting for dowel bars isn’t an add-on—it’s foundational.

Equally crucial is tracking the current TMT bar price during estimation phases. TMT bars offer tensile strength and flexibility to handle dynamic traffic loads. Their prices can fluctuate with raw material availability, global steel demand, and transport conditions. Not accounting for these shifts early on can derail even the most accurate cost plan.

Then come binding wires—lightweight in appearance but indispensable for reinforcing cages and ensuring structural cohesion. Their usage touches every beam, slab, and support grid. Ignoring their cost or compromising on quality creates loose ends—literally and financially.

Consideration Phase: What Influences Cost, Durability, and Return on Investment

Planners often focus on big-ticket items, but seasoned contractors know that minor components can cause major budget variations. The current TMT bar price, for example, can shift weekly. Buying in bulk when rates are favorable or locking prices with suppliers can lead to significant savings across large-scale road projects.

When it comes to dowel bars in road designs, high-grade bars ensure smoother vehicle transitions and minimal joint failures. Their cost may seem steep at first glance, but the reduction in repair cycles makes them cost-effective over time. Using substandard or poorly aligned dowel bars might reduce initial spending, but the long-term implications—road closures, patchwork, and labor—are far more expensive.

Binding wires should never be an afterthought. Consistent gauge, flexibility, and corrosion resistance determine how well reinforcements hold through extreme temperatures and moisture exposure. Budgeting for higher-quality binding wires helps protect larger investments like TMT bars and dowel bars, acting as a safeguard against micro-failures that grow into macro problems.

Decision Time: Smart Sourcing for Sustainable Execution

Material choices speak louder than blueprints. Projects that prioritize the proper dowel bars in road builds show fewer disasters, smoother finishes, and lower lifecycle expenses. When choosing providers, the choice shouldn’t hinge totally on charge but also on consistency, traceability, and certification.

Price-aware doesn’t mean cutting corners—it means choosing wisely. Contractors and engineers who actively monitor the current TMT bar price can time their purchases to optimize budget efficiency without compromising quality. In today’s climate, where steel prices rise unexpectedly, that vigilance pays off.

Lastly, sourcing binding wires from reliable manufacturers ensures the integrity of the entire structure. Whether holding reinforcement cages together or locking mesh into place, these wires work quietly but critically in every joint, slab, and span.

Final Thoughts

A well-paved road doesn’t begin with asphalt—it begins with planning. By treating components like dowel bars in road structures, binding wires, and TMT bars as strategic financial entries—not just technical ones—contractors can protect both the project’s bottom line and its long-term performance.

Smart budgeting isn’t about spending less—it’s about spending right. And in road construction, the right spend starts beneath the surface.

#Road Budget Plan#TMT Bar Costs#Dowel Bar Use#Binding Wire Role#Smart Road Build#Budgeting Roads#Cost-Effective Roads#Highway Materials#Steel Cost Tips#Infra Cost Guide#Road Project Steel#TMT Price Trends#Dowel Bars Info#Road Build Hacks#Project Cost Plan#Steel in Roads#Site Cost Saver#TMT Planning#Roadwork Budget#Build Better Roads

0 notes

Text

Explore how TMT bars contribute to sustainable construction by offering energy-efficient production, recyclability, and long-lasting durability. Learn how these steel bars reduce carbon footprints and promote eco-friendly practices in green building projects, making them ideal for modern sustainable architecture.

#TMT bars in green construction#sustainable TMT bars#eco-friendly building materials#energy-efficient steel#green projects

0 notes

Text

Today's steel price: trends in the market and main influences

For sectors like infrastructure, manufacturing, and construction, steel is a basic building block; so, its pricing patterns are rather important for companies and consumers. Raw materials, government policy, and world economic situation all affect the Indian steel market. Here is a detailed analysis of Indian steel price nowadays along with the main influences on them.

The kind of steel utilized—hot-rolled coil (HRC), cold-rolled steel, and TMT bars—which are extensively used in construction—varies the prices.

Important Aspects Influencing Indian Steel Prices The prices of iron ore, coking coal, and scrap metal affect the cost of raw materials, therefore influencing steel production. 2. Domestic demand and supply: Steel prices are determined in part by the balance between industrial demand and manufacturing capacity. Pricing is influenced in part by government laws and tariffs; import-export rules, taxes, and infrastructure expenditures all help to define price. 4. Global market trends: Indian market is affected by trade policies and international steel pricing. Variations in cost include transportation expenditures, fuel prices, and electricity tariffs, therefore affecting energy and logistical expenses.

Regional Steel Price Analysis: Mumbai, a significant trade center impacting western Indian steel pricing Delhi: Price swings are influenced by the strong demand in the building and infrastructure industries. Chennai is a major hub for industrial and automotive steel use, therefore influencing regional pricing.

Outlook Ahead Driven by industrial development, world trade links, and sustainability projects, steel prices in India are projected to stay dynamic. Future price patterns might also be impacted by the drive toward green steel manufacture.

Keeping Current on Steel Prices Making wise choices for companies and investors depends on knowing today's steel pricing. Anticipating price changes may be achieved by means of regular market research, monitoring of raw material prices, and following government policy revisions.

Use BigMint to get updated about the most recent developments in Indian steel prices!

Around Us Reputable platform BigMint offers real-time information on industry insights, market trends, and commodities pricing. With correct and timely knowledge on steel, iron ore, and other vital raw resources, we want to keep companies, traders, and investors updated.

2 notes

·

View notes

Text

TMT Bar Rate: A Key Factor in Construction Projects

TMT (Thermo-Mechanically Treated) bars are a fundamental component in modern construction. They are widely used for reinforcing concrete structures, providing strength and durability to buildings, bridges, and other infrastructure projects. TMT bars are favored for their high strength, flexibility, and resistance to corrosion, making them an essential material for both residential and commercial construction.

One of the most important factors influencing the cost of construction is the TMT bar rate. The price of TMT bars can vary depending on various factors such as material quality, market conditions, demand, and geographical location. Understanding the TMT bar rate is crucial for construction businesses, builders, and individuals to plan their budgets effectively.

In this article, we will explore what TMT bars are, how they are priced, the factors that influence TMT bar rates, and how these prices impact construction projects.

Factors Influencing TMT Bar Rate

Several factors influence the rate of TMT bars, which fluctuate over time. Understanding these factors can help individuals and businesses better plan and budget for construction projects.

1. Raw Material Costs

The primary raw material used in the production of TMT bars is iron ore. The price of iron ore can vary based on market conditions, international supply, and demand. When the cost of raw materials rises, the price of TMT bars typically follows suit. Global factors such as trade policies, supply chain disruptions, and natural disasters can cause fluctuations in the price of iron ore, affecting the tmt bar rate.

2. Production Process

The cost of producing TMT bars is another factor that affects their rate. The thermo-mechanical treatment process, which involves high energy consumption for heating and rapid cooling, can make TMT bars more expensive than traditional steel bars. The more advanced the production technology and machinery used, the higher the overall production cost, which in turn affects the price.

3. Demand and Supply Dynamics

Like any commodity, the price of TMT bars is influenced by supply and demand dynamics. In periods of high demand, such as during a construction boom or in regions where infrastructure development is happening at a rapid pace, the price of TMT bars may increase. Conversely, during slow construction periods, when demand for building materials drops, the rate of TMT bars may decrease.

Regional variations in demand also play a role. For example, large cities or regions with high construction activity may see higher TMT bar prices compared to areas with less demand.

4. Transportation and Logistics Costs

TMT bars are often produced in specific regions, and transportation costs can have a significant impact on the final rate. If TMT bars need to be transported over long distances or to remote areas, logistics costs will increase, which is reflected in the price. Additionally, fuel costs and transportation infrastructure can influence the cost of getting TMT bars from the factory to construction sites.

5. Government Policies and Taxes

Government policies, including taxes, duties, and import/export regulations, can also affect the price of TMT bars. For example, the imposition of import duties on steel products or changes in tax rates can increase the cost of TMT bars. Conversely, subsidies or reductions in taxes on raw materials may lower the price. Construction businesses need to stay updated on any changes in government policies that could impact TMT bar rates.

6. Technological Advancements

Technological innovations in steel manufacturing can also influence the TMT bar rate. For instance, new methods of production that increase efficiency and reduce energy consumption can lower the cost of producing TMT bars. On the other hand, investments in research and development or advanced machinery may increase the cost of production in the short term but could lead to higher-quality products in the long run.

How TMT Bar Rate Impacts Construction Projects

The rate of TMT bars is a significant factor in the overall cost of construction. The amount of TMT bar required for a project depends on the size of the structure, the grade of the steel, and the complexity of the design. Since TMT bars are used extensively in reinforcing concrete, their cost can make up a significant portion of the material budget in construction projects.

1. Cost Estimation and Budgeting

Builders and contractors need to factor in the TMT bar rate when estimating the total cost of a project. Since TMT bars are a critical material in construction, fluctuations in their price can impact the overall budget. If the price of TMT bars increases unexpectedly, it may lead to cost overruns unless the budget is adjusted accordingly. Accurate cost estimation and understanding of the market conditions are crucial for successful project management.

2. Project Planning

Construction projects typically involve a large number of materials, and delays or changes in the price of one material can lead to project delays. For example, if the price of TMT bars rises significantly during the construction phase, contractors may need to purchase the required quantity of steel at higher rates, affecting project timelines and costs.

To avoid such situations, project managers often lock in prices in advance or place bulk orders to secure a more favorable rate. Additionally, monitoring TMT bar prices and market trends is essential for making informed decisions.

3. Quality vs. Cost

While the price of TMT bars is a key consideration, the quality of the bars should not be compromised in an effort to reduce costs. Using substandard TMT bars can lead to structural weaknesses, which can be costly in the long run due to repairs, maintenance, or even failure of the structure. Therefore, while TMT bar rates play a role in the budgeting process, quality must always be prioritized to ensure the safety and longevity of the construction.

Conclusion

The TMT bar rate plays a crucial role in determining the overall cost of construction projects. Builders, contractors, and project managers must stay informed about the various factors that influence TMT bar prices, such as raw material costs, demand and supply, production processes, and government policies. By understanding these factors, they can make informed decisions about purchasing and budgeting for TMT bars.

If you are looking for best quality tmt bars, please visit our website : www.steeloncall.com or you can contact us through our toll-free number: 18008332929

2 notes

·

View notes

Text

Strength is not just a feature; it’s the foundation upon which the dream structure is built. Every successful construction project begins with a solid foundation, and in the world of construction, Rajuri Steel TMT bars stand as a testament. Whether it's towering skyscrapers or sturdy bridges, the strength of Rajuri Steel TMT bars ensures the safety and durability of your construction. Engineered for excellence, these bars offer unmatched durability and strength, making them the backbone of robust structures. Unique properties, such as high tensile strength and superior ductility, ensure that buildings can withstand the forces of nature and the test of time. Let’s build a stronger tomorrow together!

2 notes

·

View notes

Text

Building Strong: A Guide to Choosing the Right TMT Bars for Your Project

The towering skyscrapers that define modern cities, the bridges that span rivers, and the homes that shelter families – all of them share a crucial foundation: the strength and resilience of TMT bars. Choosing the right type of TMT bar for your construction project isn't just about picking metal rods; it's about laying the groundwork for a structure that will endure.

Navigating the Maze of Options:

With an array of TMT bars available, each with its own unique properties, the selection process can seem daunting. But fear not! This guide will equip you with the knowledge to navigate the labyrinth of options and confidently choose the bars that will be the unsung heroes of your building.

Unveiling the Grades:

Understanding TMT bar grades is your first step to success. These grades, denoted by numbers like Fe415 or Fe500, represent the minimum yield strength of the bar. Simply put, the higher the grade, the stronger the bar. But this isn't a one-size-fits-all equation. A high-rise needs different muscle than a small bungalow. Carefully consider the load-bearing requirements of your project and consult structural engineers to determine the ideal grade for each element.

The Strength Equation: Tensile Power and Ductile Grace:

Tensile strength is the champion of load resistance, making your structure stand tall against gravity and external forces. But true strength lies in balance. Ductility, the ability to bend without breaking, is equally crucial, allowing the bars to absorb stress and prevent sudden fractures. Finding the sweet spot between these two properties is vital, ensuring both resilience and adaptability.

Weathering the Storm: The Corrosion Challenge:

No structure is an island. It faces the relentless assault of sun, rain, and wind. This is where corrosion resistance takes center stage. Choose TMT bars with effective anti-corrosion measures, be it chemical additives or a well-designed ribbed surface, to shield your building from the ravages of time and the elements.

Shaping Dreams: Bendability and Weldability:

Construction is not a rigid art form. The ability to bend TMT bars to your will is essential for creating arches, columns, and intricate architectural details. Weldability, too, plays a crucial role in seamlessly joining bars, ensuring a unified and sturdy skeleton for your project.

Finding the Perfect Fit: Size and Dimensions Matter:

Think of TMT bars as the veins of your structure. Their thickness and spacing determine the flow of forces within the concrete. Choosing the right sizes and dimensions is key to ensuring uniform load distribution and structural stability. Consult experts and follow building codes to select the perfect diameter and spacing for each element of your project.

Quality Beyond Compromise: Certifications and Standards:

Don't let the allure of a bargain blind you to quality. Always choose TMT bars that comply with recognized industry standards and certifications. These ensure stringent manufacturing processes and material testing, giving you peace of mind and a guarantee of long-lasting performance.

Investing in Strength: Balancing Cost and Value:

While cost is a factor, remember that cheap bars can turn into expensive repairs down the line. Choose TMT bars that offer optimal value for money, striking a balance between upfront cost and long-term durability. Think of it as an investment in the future of your structure.

Building With Confidence:

Now, armed with this knowledge, you can enter the world of TMT bars with confidence. By considering these key factors – grades, strength, corrosion resistance, bendability, size, certifications, and cost – you can select the bars that will become the silent heroes of your project, ensuring its strength, resilience, and beauty for years to come.

2 notes

·

View notes

Text

Latest Steel Price in India: Daily Update on TMT Bar Rates & Steel Price Per Kg (June 2025)

Introduction: Current Trends in Steel Prices

In the rapidly evolving construction and manufacturing industry, keeping track of the steel rate today is crucial for cost estimation and project planning. With fluctuating market dynamics, steel price per kg, steel price today, and TMT bar price vary daily due to factors such as raw material availability, fuel prices, global demand, and domestic policies. As one of the most fundamental building materials, steel's price trends have a direct impact on infrastructure development and housing costs.

This article provides you with a detailed, daily-updated analysis of the steel rate today across different regions and types of steel including TMT bars, MS steel, and structural steel.

Steel Price Today in India – June 2025 Update

The steel price today across various Indian cities reflects slight volatility due to market corrections. Below is a breakdown of current prices:

Steel Type

Price per Kg (INR)

TMT Bar (Fe 500)

₹58 – ₹68

MS Steel

₹52 – ₹62

Structural Steel

₹60 – ₹72

Stainless Steel (304)

₹180 – ₹200

Scrap Steel

₹32 – ₹42

Prices may vary slightly depending on location, brand, and delivery terms. Bulk orders typically enjoy negotiated discounts.

TMT Bar Price in Major Indian Cities

TMT bars (Thermo Mechanically Treated) are critical in residential, commercial, and industrial construction. Here's the latest TMT bar price from key markets:

City

TMT Bar Price (per kg)

Delhi

₹64

Mumbai

₹66

Hyderabad

₹62

Chennai

₹63

Kolkata

₹61

Bangalore

₹65

Leading brands like Radha TMT, TATA Tiscon, JSW Neosteel, and SAIL may quote slightly higher due to quality assurance and brand value.

Factors Affecting Steel Price Per Kg

The steel price per kg isn’t random—it’s influenced by various factors, including:

1. Raw Material Cost

Iron ore and coal form the backbone of steel production. Any fluctuation in their prices has a cascading effect on the steel rate today.

2. Import-Export Policy

Changes in import duties or export bans significantly impact supply and demand dynamics, thus affecting the steel price per kg.

3. Fuel and Transportation

Fuel price hikes elevate logistics costs, which manufacturers eventually pass on to consumers. This raises the TMT bar price and general steel cost.

4. Seasonal Demand

Infrastructure projects peak during dry seasons, leading to increased demand for steel and higher steel rates.

5. Global Trends

Steel demand in international markets, especially China, USA, and Europe, plays a vital role in determining domestic steel prices.

Different Grades and Their Prices

Steel is not uniform. Different grades serve different purposes and come with unique pricing.

Mild Steel (MS)

Used for general-purpose fabrication and construction. Current MS steel price per kg is between ₹52–₹62.

TMT Bars

Fe-500 and Fe-550 are the most common. Higher grades like Fe-600 are costlier but provide enhanced strength. The TMT bar price varies based on grade and diameter.

Stainless Steel

Used in corrosion-resistant applications. The popular SS 304 grade ranges from ₹180 to ₹200 per kg.

Top Brands and Their Price Range

Radha TMT

Known for its superior ductility and corrosion resistance, Radha TMT offers bars priced around ₹64–₹66 per kg, depending on location and order volume.

TATA Tiscon

Premium quality steel with widespread availability. Prices range from ₹65–₹70 per kg.

JSW Neosteel

High-grade TMT with advanced rib pattern technology. Priced at ₹66–₹68 per kg.

Wholesale vs Retail Steel Prices

Buying in bulk often reduces the steel price per kg. Here’s how:

Retail Prices: Include warehousing, transport, and dealer margins.

Wholesale Prices: Ex-factory rates, ideal for builders and contractors.

You can save ₹2–₹5 per kg by purchasing directly from authorized distributors.

How to Check Live Steel Prices

To get accurate steel rate today, consider these sources:

Manufacturer Websites (e.g., SAIL, TATA, Radha TMT)

Construction Material Aggregators

Local Dealers & Traders

Mobile Apps for Real-Time Rates

Daily Market Bulletins

Ensure you verify pricing with GST and transport costs added for the most accurate quotation.

TMT Bar Weight and Price Calculator

TMT bar price also depends on bar diameter and weight. Here’s a sample weight chart:

Diameter (mm)

Weight (per meter in kg)

8

0.395

10

0.617

12

0.888

16

1.58

20

2.47

25

3.85

To calculate cost: Total Price = Weight × Price per kg

Price Forecast for 2025

Based on market analysis and infrastructure push by the Indian government, steel prices are expected to remain steady with slight upward movement due to:

Government investments in infrastructure and housing

Stabilized raw material prices

Increased industrial output and demand

It is advisable to lock prices now for bulk procurement to hedge against future price rise.

Conclusion

Monitoring the steel price per kg, TMT bar price, and steel rate today is essential for smart decision-making in construction and manufacturing. By staying informed, buyers can secure the best prices and manage project budgets more efficiently. Regularly updated market insights help mitigate risks and optimize cost planning.

0 notes

Text

How Binding Wire and TMT Bars Create the Backbone of Modern Construction

A steel pipe company that produces components knows something essential about modern-day building practices: the invisible elements regularly determine a shape's integrity. While concrete might also seem like the hero of creation tasks, the fact is it's a ways more complicated. The fusion of binding twine and reinforcement bars creates the hidden framework that allows concrete structures to face up to the test of time.

When employees pour concrete around a carefully built skeleton of metal rebars, they may be collaborating in a production method that has revolutionized structure and infrastructure improvement globally. But how precisely does this system paint, and why is the connection between binding wire and substances from TMT bar manufacturers so essential?

The Critical Role of Binding Wire

Binding wires serves as the unsung hero of this creation symphony. This especially thin, malleable cord performs the essential feature of securing reinforcement bars in their designed positions before concrete placement. When construction people tie rebar grids or cages, binding wire ensures that the reinforcement continues the right spacing and alignment all through the concrete pour.

Proper positioning is non-negotiable due to the fact that the effectiveness of reinforcement relies absolutely on unique placement in the concrete matrix. Even minor displacement can considerably lessen structural capacity and sturdiness. This is in which the relationship among binding twine and materials from TMT bar producers will become crucial.

The Science Behind TMT Bar Manufacturing

TMT (thermo-mechanically treated) bars constitute a widespread development in reinforcement technology. Unlike traditional steel bars, products from TMT bar manufacturers go through a complicated production system concerning managed heating, speedy quenching of the surface layer, and self-tempering of the center as residual warmth flows outward.

This method creates a completely unique micro structure: a sturdy outer layer with martensite formation providing high yield strength and a ductile ferrite-pearlite center that ensures flexibility and weldability.

The Binding Process: Where Precision Meets Craftsmanship

The connection among binding wire and reinforcement from TMT bar producers requires both technical information and practiced talent. Workers usually use specialized tools known as rebar stages to create steady connections at intersection points. The binding pattern follows engineer-specific requirements, with different styles (parent-8, saddle, or wrap-and-twist ties) used depending on structural demands.

Binding cord itself is available in several sorts, with black annealed wire being the most not unusual for popular packages. For specialized tasks, galvanized or PVC-coated binding wire prevents corrosion in aggressive environments. A legit steel pipe business enterprise regularly components the entire range wished for numerous programs.

Industry Integration: From Manufacturing to Construction

The journey from uncooked fabric to finished shape demonstrates extremely good supply chain integration. A steel pipe agency that still materials binding cord and collaborates with TMT bar producers represents an evolution closer to incorporated cloth answers that make sure compatibility and performance.

This delivery chain integration matters because inconsistencies among reinforcement elements can create unexpected weaknesses. When materials come from assets with coordinated pleasant requirements, builders gain confidence in long-term structural overall performance.

Looking Forward: Innovation in Reinforcement Technology

The binding cord and TMT bar production industries retain evolving collectively. Recent improvements consist of self-connecting reinforcement systems that reduce binding cord requirements, corrosion-resistant alloys for severe environments, and digital tracking technology that files reinforcement placement for fine guarantee.

For developers and contractors, staying knowledgeable about these improvements through relationships with a complete metallic pipe company gives competitive benefits in terms of creation efficiency and structural performance.

Final Thoughts

The next time you walk past a production web page or input a concrete construction, don't forget that beneath the gray floor lies a cautiously orchestrated community of materials operating in harmony—concrete, TMT bars, and binding twine growing systems that define our built environment.

#binding wire#TMT bars#construction materials#structural strength#building materials#steel reinforcement#construction basics#TMT bar price#wire for construction#construction wire#steel binding wire#durability#modern construction#building foundations#TMT bars use#construction steel#construction industry#TMT bar quality#steel bars#wire for reinforcement#building projects

1 note

·

View note

Text

Why TMT Bars are Indispensable: An Overview of TMT Bar Prices and Best TMT Bar Options

TMT bars are the cornerstone of structural integrity, and reinforcement materials are the backbone of contemporary construction. Because they provide strength and durability that standard steel bars just cannot match, these thermomechanically treated steel bars have completely changed the way that construction is done.

Understanding TMT Bars: Beyond Basic Construction Material

TMT bars are the ideal combination of engineering accuracy and metallurgical science. During the manufacturing process, heated steel bars are rapidly quenched to produce a softer, more ductile core and a hard outer layer. Because of its unique mix, which offers exceptional strength without compromising flexibility, TMT bars are crucial for construction projects of all sizes.

The Evolution of Construction Standards

Construction standards have evolved significantly, pushing the boundaries of structural engineering. TMT bars have kept pace with these advancing requirements, offering:

Superior tensile strength

Enhanced earthquake resistance

Improved corrosion protection

Better weldability

Optimal bend strength

Analyzing TMT Bar Prices: Investment vs. Value

The cost of raw materials, production methods, and consumer demand are some of the variables that affect TMT bar prices. The long-term advantages outweigh the initial expenditures, even though they may appear larger than those of more traditional reinforcing options:

Cost-Effectiveness:

Reduced maintenance requirements

Lower replacement frequency

Decreased labor costs during installation

Enhanced structural longevity

Market Analysis and Price Considerations:

Grade specifications influence TMT bar prices

Bulk purchase opportunities

Seasonal price variations

Regional availability factors

Identifying the Best TMT Bar Options

Selecting the best TMT bar involves careful consideration of multiple factors:

Grade Selection:

Fe 500 for residential construction

Fe 550 for commercial projects

Fe 600 for specialized applications

Manufacturing Standards:

ISI certification

Quality control measures

Production technology

Brand reputation

Performance Metrics:

Yield strength

Ultimate tensile strength

Elongation properties

Bend test results

Critical Factors in TMT Bar Selection

When evaluating TMT bars, consider these essential aspects:

Surface Quality:

Uniform ribbing pattern

Freedom from surface defects

Proper marking and identification

Physical Properties:

Dimensional accuracy

Weight per meter

Length consistency

Chemical Composition:

Carbon content

Sulfur levels

Phosphorous percentage

Making an Informed Decision

The selection of TMT bars demands careful evaluation of both technical specifications and practical considerations. Quality TMT bars might represent a higher initial investment, but their superior performance characteristics deliver substantial long-term advantages:

Structural Benefits:

Enhanced building stability

Better seismic resistance

Improved load-bearing capacity

Reduced structural maintenance

Economic Advantages:

Extended service life

Minimized repair costs

Increased property value

Better insurance terms

The Future of Construction Materials

As construction technology advances, TMT bars continue to evolve, incorporating improvements in metallurgy and manufacturing processes. The best TMT bar manufacturers consistently invest in research and development, ensuring their products meet emerging construction challenges while maintaining competitive TMT bar prices.

Installation and Quality Verification

Beyond selecting the best TMT bar, proper installation and verification procedures play crucial roles in achieving optimal structural performance:

Quality Testing Protocols:

Bend and rebend testing

Tensile strength verification

Elongation measurement

Chemical composition analysis

Site Handling Guidelines:

Proper storage conditions

Protection from environmental factors

Systematic inventory management

Careful transportation practices

Documentation Requirements:

Test certificates

Batch identification

Manufacturing dates

Grade verification reports

Regular quality audits and thorough documentation ensure that TMT bars meet specified standards throughout the construction process. These verification steps, combined with proper handling and installation procedures, maximize the benefits of investing in quality TMT bars.

Conclusion

Selecting appropriate TMT bars requires balancing quality, cost, and application requirements. By understanding the relationship between TMT bar prices and quality, stakeholders can make informed decisions that ensure structural integrity without compromising economic efficiency. The best TMT bar choice ultimately depends on specific project requirements, but prioritizing quality over initial cost savings invariably proves beneficial in the long run.

#TMT bars#construction#strength#durability#steel#pricing#options#reinforcement#quality#flexibility#building#material#construction bars#steel supplier#building project#strength factor#cost#reinforcement bars#construction needs#best TMT.

0 notes

Text

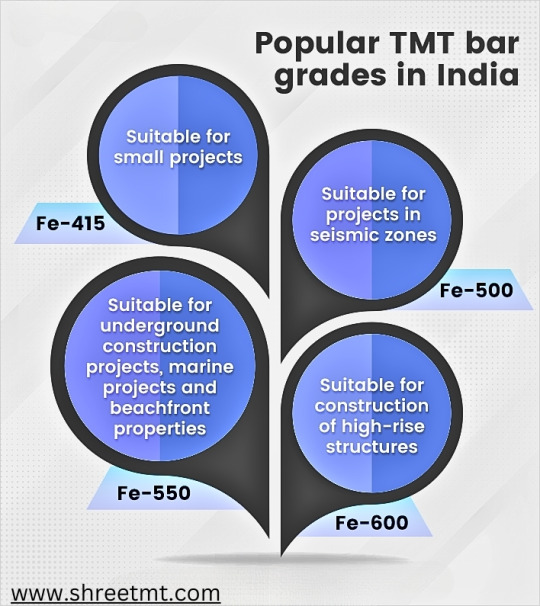

Discover the various grades of TMT bars widely used in India and their specific applications. This informative infographic outlines the suitability of Fe-415, Fe-500, Fe-550, and Fe-600 grades for different types of construction projects. Learn about the best TMT bar grades for small projects, seismic zones, underground and marine projects, and high-rise structures. Enhance your construction project with the right choice of TMT bars.

#TMT bars#Construction materials#TMT bar grades#Fe-415#Fe-500#Fe-550#Fe-600#Building materials#Seismic zone construction#High-rise construction#Marine projects#Underground construction#Construction industry#India construction standards

0 notes

Text

Building in Kerala? Don’t Let Floods Rust Your Foundation!

Kerala’s stunning beauty comes with a challenge—floods, humidity, and coastal salinity. If you’re planning construction here, the secret to a safe and long-lasting structure is choosing the right TMT bars.

Our latest blog dives into the best TMT bars in Kerala that are engineered for flood-resilient and corrosion-resistant construction. Learn how advanced grades like Fe 500D & 550D, CRS coatings, and brands like Tata Tiscon, Shyam Steel, JSW, Vizag Steel and Pulkit TMT can future-proof your home or building project.

From understanding ductility to choosing the right steel for high-moisture zones—this is your go-to guide for building that stands strong through every monsoon.

📖 Read the full post now & build smarter: https://medium.com/@experttalk02/best-tmt-bars-in-kerala-for-flood-resilient-and-corrosion-resistant-construction-6d12b6b33da0

#TMTBars#KeralaConstruction#FloodProofTMT#CorrosionResistantSteel#ShyamSteel#JSWSteel#TataTiscon#StructuralEngineering#CivilConstruction#KeralaBuilders

0 notes

Text

High-Quality Construction Materials in Qatar: Building the Nation with Strength and Reliability

Qatar is a rapidly developing country known for its world-class infrastructure, innovative architecture, and ambitious development projects. From state-of-the-art stadiums built for the FIFA World Cup 2022 to luxurious commercial and residential spaces, the demand for high-quality construction materials in Qatar has never been greater. Quality construction materials are the backbone of every durable structure, and in Qatar’s competitive and challenging environment, ensuring strength, durability, and efficiency is crucial.

Importance of High-Quality Construction Materials

In any construction project, the longevity, safety, and performance of the final structure heavily depend on the quality of materials used. Using substandard materials can lead to structural weaknesses, high maintenance costs, and even safety hazards. In Qatar’s harsh climatic conditions—marked by high temperatures, humidity, and occasional sandstorms—materials need to be especially resilient to corrosion, heat, and wear. Therefore, contractors and developers in Qatar prioritize sourcing top-grade materials that meet international standards.

Types of High-Quality Construction Materials in Demand

Cement and Concrete Products High-performance cement and ready-mix concrete are essential for foundations, columns, and other structural components. These materials must offer superior compressive strength, workability, and durability to withstand environmental stresses.

Steel and Rebar Reinforced steel bars (rebar) are vital for adding tensile strength to concrete. In Qatar, corrosion-resistant and thermo-mechanically treated (TMT) steel is highly preferred for major infrastructure and commercial projects.

Aggregates and Sand Clean, well-graded aggregates and high-quality sand are important for concrete mixes, drainage layers, and landscaping. Their consistent sizing and chemical composition ensure better bonding in concrete and reduce wear.

Insulation and Waterproofing Materials Due to extreme heat, buildings in Qatar require thermal insulation materials like polyurethane foam, rock wool, and reflective coatings. Waterproofing membranes and chemicals also play a crucial role in protecting buildings from moisture infiltration.

Pipes and Fittings Durable and leak-proof pipes are necessary for water supply, drainage, and HVAC systems. Materials such as PVC, HDPE, and PPR are widely used for their durability and resistance to corrosion and heat.

Finishing Materials High-quality tiles, paints, gypsum boards, and aluminum cladding enhance both the aesthetic and functional value of buildings. These materials must also be easy to maintain and long-lasting in Qatar’s climate.

Reliable Suppliers and Global Standards

Qatar hosts many trusted suppliers and distributors who offer internationally certified materials that comply with Qatar Construction Standards (QCS). Companies often import from reputed global brands while also supporting local manufacturing, ensuring availability, competitive pricing, and quality assurance.

Conclusion

As Qatar continues to expand its skyline and infrastructure footprint, the role of high-quality construction materials becomes even more significant. Developers and contractors must continue to prioritize materials that offer durability, efficiency, and sustainability. With strict building codes, modern construction technology, and a strong focus on quality, Qatar is well-equipped to build a future that stands strong for generations to come.

0 notes

Text

Durable Binding Wire for Stronger Construction Work

Looking for reliable Binding Wire for your construction needs? Binding wire plays a critical role in reinforcing concrete structures by securing TMT bars and providing structural integrity. It ensures durability, flexibility, and rust resistance making it a must-have for any building project. Ideal for both residential and commercial construction, high-quality binding wire supports safe, long-lasting reinforcement. Whether you’re a builder or contractor, using premium-grade binding wire guarantees strength and stability at every stage. Choose trusted brands like Kamdhenu for consistent performance. Discover how binding wire supports the backbone of every concrete framework and enhances overall project safety and precision.

0 notes

Text

TMT Saria – Backbone of Strong Construction

TMT Saria, or Thermo Mechanical Treatment bars, is vital in modern construction, due to its high tensile strength, ductility, and resistance to earthquakes and corrosion. Indostar TMT not only support residential units but also bridges and high-rise towers, providing the integrity that is necessary for every construction project.

Why you should consider TMT Saria?

✅ High Strength & Ductility

✅ Resists Earthquakes

✅ Resists Corrosion

✅ Best Bonding with Concrete

✅ Cost Effective & Long LastingTMT Saria is classified for its grade including Fe 500, Fe 550, and Fe 550D and is determined by code requirements and structural needs of safety and endurance in all infrastructures. When choosing TMT Saria it comes down to the trust & brand a manufacturer delivers to the construction industry, with certified product quality from reliable producers.

#TMTSaria#TMTBarsinUttarakhand#TMTSteelmanufacturersinIndia#TMTBarsmanufacturersinIndia#TMTSteelBarsinIndia#TopTMTSteelindustriesinIndia#BestTMTinIndia#QualityTMTinIndia#FireresistanceTMTinIndia#BISCertifiedTMTBarsSteel#TMTBars#CorrosionResistanceTMT#ReliableTMTInIndia#EarthquakeresistanceTMTinIndia

0 notes

Text

TMT Bar, Iron Rod & Steel Price Today – Full Market Analysis 2025

The TMT bar price, cost of TMT bars, iron rod price, and steel rod price are crucial indicators for anyone involved in construction, infrastructure development, or real estate. As the demand for durable and earthquake-resistant structures continues to rise, understanding the fluctuations and factors that influence these prices becomes essential.

At our company, we aim to provide you with a comprehensive analysis of current trends, influencing factors, and regional variations to help you make informed decisions for your construction projects in 2025.

What Are TMT Bars and Why Do They Matter?

TMT bars (Thermo-Mechanically Treated bars) are high-strength reinforcement bars with a tough outer core and soft inner core. Their superior ductility and resistance to seismic activity make them the backbone of modern construction. The cost of TMT bars can significantly affect your overall project expenditure.

Current TMT Bar Price in India (June 2025)

As of June 2025, the average TMT bar price across India ranges from:

₹54 to ₹70 per kg for retail purchases

₹52 to ₹66 per kg for bulk orders (depending on brand and region)

₹51 to ₹68 per kg for Fe 500 and Fe 550 grades

These prices vary based on factors such as:

Brand (e.g., Radha TMT, Tata Tiscon, JSW, SAIL)

Grade (Fe 415, Fe 500, Fe 550D, Fe 600)

Diameter (8mm, 10mm, 12mm, 16mm, 20mm)

Location (Metropolitan vs Tier-2 cities)

Market demand and supply chain

Cost of TMT Bars Per Ton

The cost of TMT bars per ton (1000 kg) is an essential metric for bulk buyers:

Standard Fe 500 Grade: ₹53,000 to ₹66,000/ton

Fe 550D Grade: ₹54,000 to ₹67,000/ton

Fe 600 Grade: ₹56,000 to ₹69,000/ton

Most suppliers offer volume discounts, transportation options, and customized billing to institutional clients.

Iron Rod Price Today in India

The iron rod price, often used interchangeably with TMT bar, is closely linked to international steel market trends:

8mm Iron Rod: ₹58–₹68 per kg

10mm Iron Rod: ₹57–₹66 per kg

12mm Iron Rod: ₹55–₹65 per kg

16mm Iron Rod: ₹54–₹64 per kg

20mm Iron Rod: ₹54–₹62 per kg

Bulk discounts may apply for orders exceeding 5 tons. Always ensure BIS-certified products from reputed brands to guarantee structural integrity.

Steel Rod Price Today – Updated 2025

Steel rods, used in reinforcement and general construction, follow market patterns similar to TMT bars:

Mild Steel (MS) Rods: ₹48–₹55/kg

High-Tensile Steel Rods (HTSR): ₹52–₹60/kg

Corrosion-Resistant Steel Rods: ₹58–₹72/kg

These rates are influenced by base metal prices, transportation, taxation (GST), and brand positioning.

Key Brands and Their Average Prices

Here’s a snapshot of popular brands and their approximate per kg retail rates:

Brand

TMT Bar Price (₹/kg)

Radha TMT

₹58–₹66

Tata Tiscon

₹60–₹70

JSW Neosteel

₹59–₹68

SAIL

₹57–₹67

Jindal Panther

₹56–₹66

Kamdhenu

₹55–₹65

Radha TMT and Tata Tiscon are particularly known for their balance of strength, ductility, and corrosion resistance.

Factors That Influence TMT Bar and Steel Rod Prices

Several market and economic factors determine the TMT bar price and steel rod price, including:

1. Raw Material Costs

Iron ore, coal, and scrap metal are the foundational components. Any fluctuation in their global prices immediately reflects on steel rod pricing.

2. Manufacturing and Energy Costs

TMT production involves significant energy consumption. Rising electricity or fuel prices directly impact the cost of TMT bars.

3. Demand-Supply Dynamics

Construction booms or slumps—caused by government schemes, urbanization, or infrastructure budgets—sway the demand graph significantly.

4. Transportation and Logistics

Delivery over long distances or to hilly regions can raise the effective iron rod price due to higher freight charges.

5. Brand Premium

Top-tier brands charge a slight premium for quality assurance, certifications, and consistent supply chains.

Regional Variations in TMT Bar Prices in India

Different regions witness price disparities due to logistic challenges, local taxes, and market demand. Here's a quick look:

Delhi NCR: ₹56–₹68/kg

Mumbai: ₹58–₹70/kg

Chennai: ₹55–₹65/kg

Kolkata: ₹54–₹66/kg

Hyderabad: ₹58–₹68/kg

Bangalore: ₹57–₹69/kg

Price Trends and Forecast for 2025

Based on market analytics and industry predictions, TMT bar prices are expected to remain moderately stable with minor upward movements in Q3 and Q4 due to:

Rising global demand

Infrastructure investments under government schemes (PM Awas Yojana, Smart Cities Mission)

Sustainable steel manufacturing adoption

Tips to Save on TMT Bar Purchases

Buy in Bulk: Most suppliers offer attractive discounts on large volumes.

Choose the Right Grade: Don’t overspend on higher grades if not required for your construction.

Compare Local Dealers: Local steel yards might have better rates than national chains.

Track Market Trends: Use steel price tracking tools to plan your purchases in advance.

Go for Certified Brands: While local brands may offer lower prices, certified brands ensure long-term structural integrity and savings on maintenance.

Conclusion

Choosing the right TMT bar is a critical decision that affects your structure’s safety and longevity. While the cost of TMT bars, iron rod price, and steel rod price in India fluctuate frequently, staying informed about the latest prices and trends empowers you to optimize your budget without compromising on quality.

0 notes