#Temperature Controlled Pharmaceutical Containers

Explore tagged Tumblr posts

Text

Temperature Controlled Pharmaceutical Containers Market: Size, Trends, and Growth Outlook

The temperature controlled pharmaceutical containers market is witnessing robust growth driven by rising demand for secure and reliable cold chain logistics in the pharmaceutical and biotechnology sectors. Increasing awareness of vaccine safety and biologics storage under stringent temperature conditions is reshaping market dynamics and fueling significant business growth globally. The global temperature controlled pharmaceutical containers market size is estimated to be valued at USD 5.64 billion in 2025 and is expected to reach USD 11.49 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 10.7% from 2025 to 2032. Temperature Controlled Pharmaceutical Containers Market Growth is propelled by the expanding pharmaceutical cold chain infrastructure, stringent regulatory frameworks, and escalating demand for temperature-sensitive shipments. Market analysis reveals increasing adoption of advanced insulation technologies and smart packaging as critical market drivers enhancing industry size and market revenue forecasts. The temperature controlled pharmaceutical containers market report highlights evolving market segments such as passive and active containers, contributing substantially to the overall market scope. Get more insights on,Temperature Controlled Pharmaceutical Containers Market

#Coherent Market Insights#Temperature Controlled Pharmaceutical Containers#Temperature Controlled Pharmaceutical Containers Market#Temperature Controlled Pharmaceutical Containers Market Insights#Insulated Shippers

0 notes

Text

The Growing Importance of Cargo Handling Services in India

With India's economy expanding rapidly and trade volumes increasing, the demand for reliable cargo handling services in India has become more critical than ever. These services are the backbone of supply chain operations, ensuring that cargo is moved, stored, and delivered efficiently and securely across various locations and modes of transport.

Understanding Cargo Handling

Cargo handling refers to all operations involved in the movement of goods — including loading, unloading, packaging, inspection, and storage. These tasks must be performed with precision and speed to maintain the integrity of the cargo and ensure timely delivery. In India, with its diverse geography and complex trade routes, effective cargo handling requires a combination of technology, infrastructure, and skilled personnel.

Major Types of Cargo Handling Services

1. Air Cargo Services

Airports in major cities like Mumbai, Delhi, Bengaluru, and Hyderabad handle large volumes of cargo every day. Air cargo handling involves high-speed processing of express shipments, including fragile, perishable, and high-value goods. Services include temperature-controlled storage, cargo sorting, customs clearance, and loading/unloading using modern conveyor systems and ground-handling equipment.

2. Port and Marine Cargo Handling

India’s maritime network includes major and minor ports across its extensive coastline. Ports such as Mundra, Chennai, and Visakhapatnam are equipped with container terminals, gantry cranes, and automated tracking systems. Port handling services manage the transfer of cargo between ships and shore, storage in port warehouses, and container yard logistics.

3. Rail and Road Transport Handling

The Indian railway system, one of the largest in the world, plays a vital role in cargo movement. Alongside rail, the country's expansive road network supports door-to-door cargo delivery. Cargo handling in this sector includes loading goods into containers or trucks, managing freight stations, and handling multimodal transfers.

4. Cold Chain Logistics

For goods that require temperature regulation — such as pharmaceuticals, dairy, seafood, and fresh produce — cold chain cargo handling is crucial. This includes refrigerated warehousing, insulated containers, temperature monitoring, and rapid handling to prevent spoilage. The cold chain sector in India is witnessing rapid investment and technological upgrades.

Advantages of Professional Cargo Handling

Minimized Cargo Damage: With trained workers and appropriate machinery, the risk of breakage or spoilage is greatly reduced.

Operational Efficiency: Quick turnaround times at terminals and distribution points help avoid costly delays.

Compliance and Safety: Cargo handling providers ensure adherence to domestic and international shipping regulations.

Improved Customer Satisfaction: Reliable service enhances delivery performance and builds trust with end customers.

Challenges in the Indian Cargo Handling Sector

Despite growth, the industry faces several hurdles:

Infrastructure Gaps: Some regions lack modern handling facilities and equipment.

Labor Shortages: There is a growing need for skilled workers trained in modern logistics tools.

Regulatory Delays: Clearance and documentation processes can slow down cargo movement, particularly at ports.

Future Outlook and Innovations

The cargo handling industry in India is evolving quickly, thanks to digitization and infrastructure development. Emerging trends include:

AI-powered cargo management systems

Real-time cargo tracking via GPS and IoT

Drone-based warehouse inspections

Integration of blockchain for transparent and tamper-proof documentation

Conclusion

The role of cargo handling services in India is more significant than ever in supporting the country’s logistics and supply chain systems. As global trade continues to expand and customer expectations rise, businesses must rely on efficient and technology-driven cargo handling partners. Whether it’s air, sea, rail, or road transport, professional handling services help minimize losses, reduce delivery times, and improve overall supply chain efficiency — all of which are vital to succeeding in today’s competitive business environment.

4 notes

·

View notes

Text

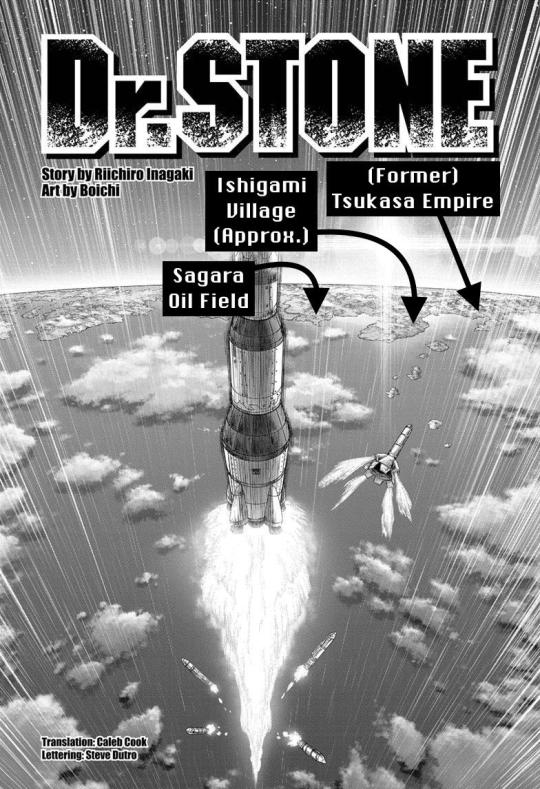

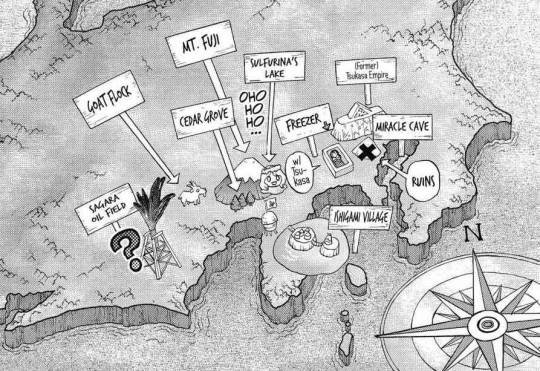

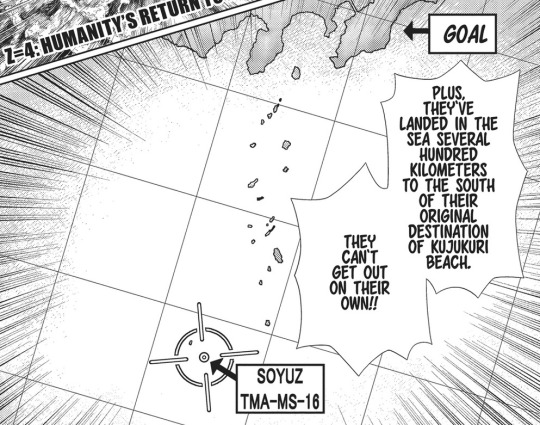

Chapter 224 Trivia

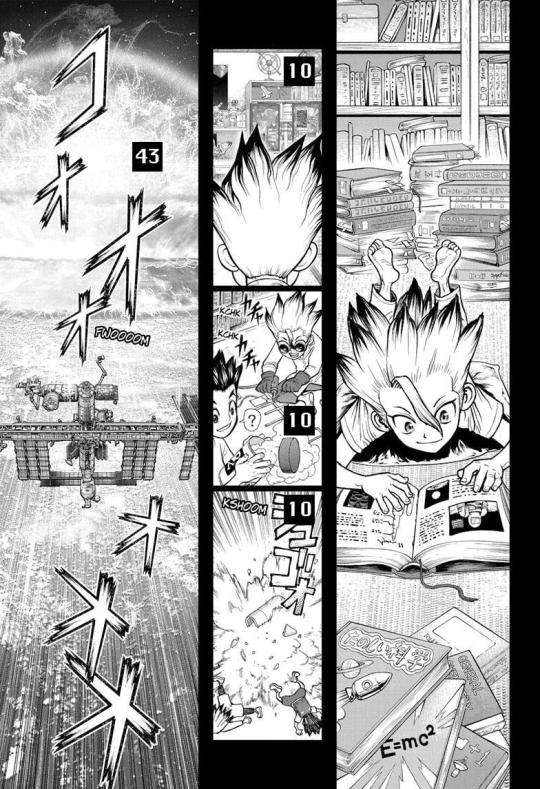

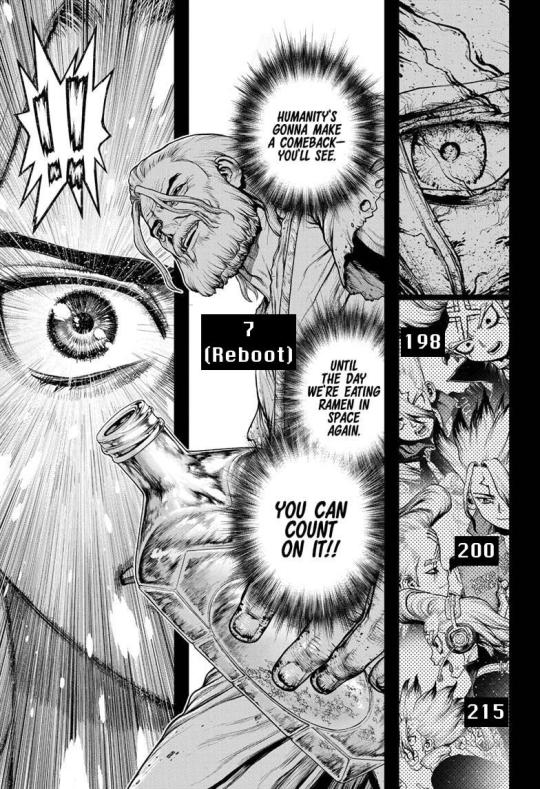

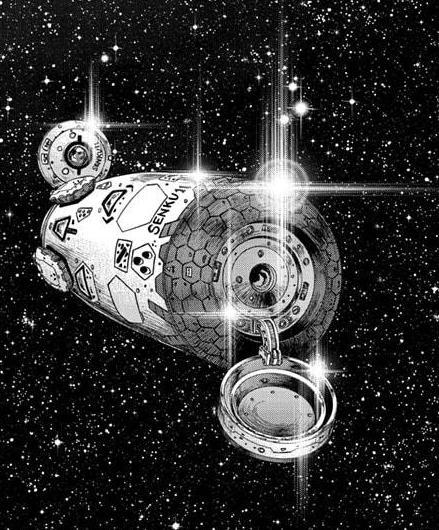

Happy birthday Senku! He's finally in space! 🎉🚀

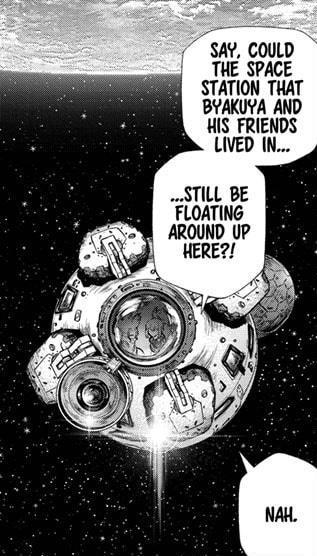

We can see the approximate distance to Treasure Island from the mainland in this shot, the only other indication of where the island is is in the (non-canon) Reboot side story. My guess is the exact island used is Aogashima.

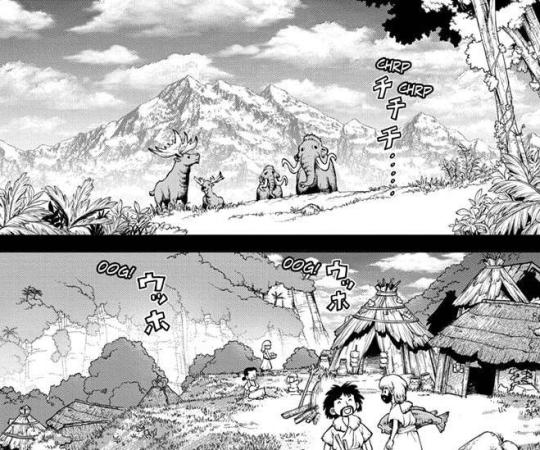

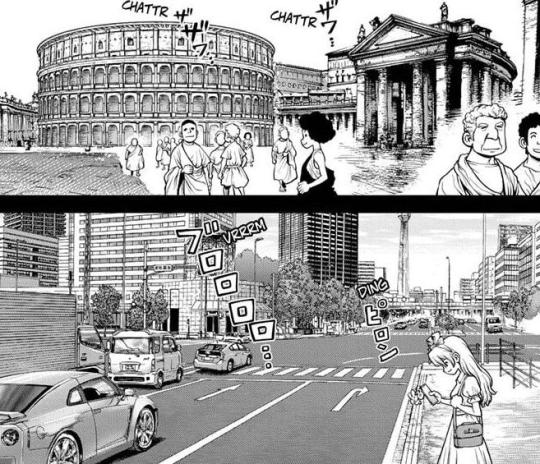

Another summary of the journey, this time including prehistory. We have depictions from the most recent ice age (though could be later, mammoths and sinomegaceros were around for a while afterwards, even in Japan), early civilization similar to Ishigami Village, and ancient Rome.

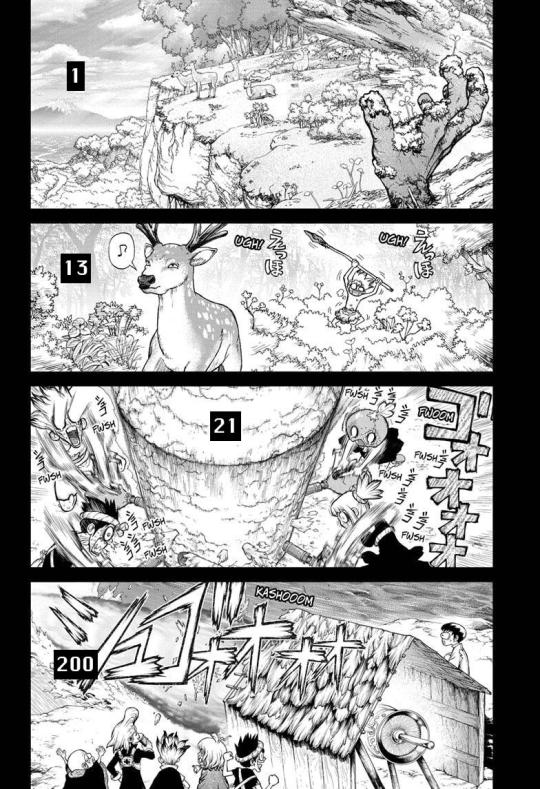

For the parts present in the manga itself, I've added the chapter numbers to each of the panels.

The books Senku has here are "General Chemistry" and "たのしい 科学" ("Fun Science"). The latter may be a reference to a children's science education book series named "たのしい! 科学のふしぎ なぜ?どうして?" ("Fun! The Mysteries of Science: Why? How?").

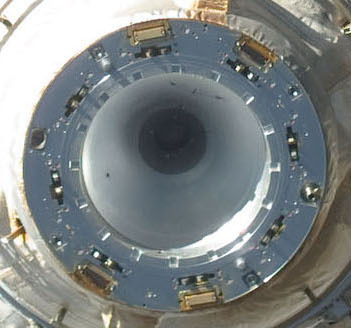

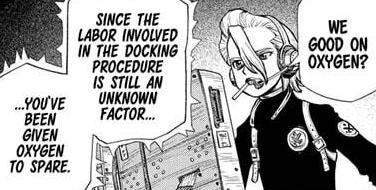

We get a glimpse of the docking system here. Possibly based off the SSVP, as it was used with almost all the Soyuz craft and Russian space stations to connect modules.

This docking area then opens up, becoming the transfer tunnel so astronauts can enter/exit.

I suppose the astronauts were completely naked in their space suits so that when the revival fluid is released, their skin will definitely get touched?

I can't think of any other reason for it, but it does make the previous chapter funnier.

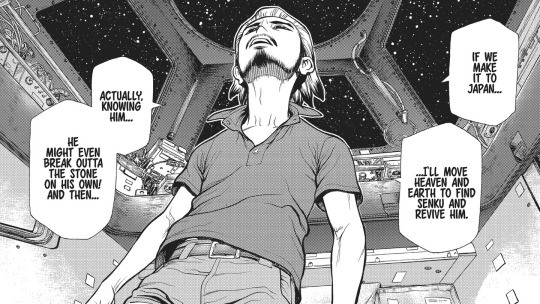

Senku's petrification scars are now fully healed!

(Stanley's are too, poor Xeno is the only one with them now.)

The mystery of how Stanley is meant to use these "cigarettes" remains.

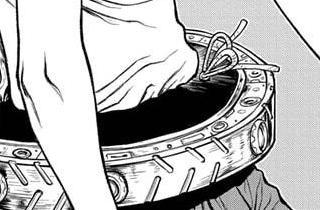

These belts are the middle part of the external space suit, so it's probably how the top and bottom parts are locked in. After they change, they tighten the fabric inside so that it stays attached to them.

I'm not entirely sure why they need it, since current space suits usually just attach the top to the bottom directly.

They're using both CRT and LCD screens. My guess is the LCDs are more convenient (it's easier to display things from computer->LCD than it is to a CRT, also text is more legible due to the pixels), but they still have several CRTs from earlier so they may as well use them too.

Stanley asks about their oxygen supply, meaning they may be limited until the rocket is assembled. Normally, there's recycling systems onboard to collect waste products and convert it into clean air or water, but Stanley and Xeno's discussion makes me think they don't have one.

Obviously, the astronauts have new outfits, but they don't seem to follow any previous astronaut outfits depicted in the series.

Senku's popped collar is still present, but now he lacks his signature equation.

Stanley's outfit changed the least, it remains form-fitting and solid black, with white gloves.

Oddly, Kohaku is still wearing a dress in space, but it's a lot neater and more modern than her previous roughly-hemmed one. She's also got both long socks and boots without a heel.

The spray dryer does a similar preservation process to what they did when freeze-drying ramen, however this process is better for foods (and pharmaceuticals) that are sensitive to temperature.

Here, they dry a liquid (like ramen broth) using a hot gas, turning it into a powder.

In true Francois fashion, the ramen packets made by them contain more meat and garnishes than the ones Byakuya ate. They're also visibly more delicious-looking.

Without regular boosts, the ISS would fall to Earth in around 6 months, however this number can vary a lot depending on atmospheric conditions and the relative angle/position of the ISS to the direction of travel.

Basically, unless someone/something continued to control it almost immediately, the ISS is definitely gone.

(Rei didn't, the Reboot isn't canon.)

12 notes

·

View notes

Text

The Billion-Dollar Secret: How Styrofoam Shipping Boxes Dominate the Cold Storage Market

Insulated Styrofoam Shipping Boxes Market Outlook and Projected Expansion

The GlobalInsulated Styrofoam Shipping Boxes Market is undergoing a transformative evolution, expected to grow from USD 5.8 billion in 2024 to over USD 9.8 billion by 2035, marking a 5.1% CAGR. This expansion is underpinned by surging demand for temperature-controlled logistics, particularly in pharmaceuticals, biotechnology, food & beverage, and chemical sectors. As global trade intensifies and e-commerce logistics demand highly effective cold chain packaging, insulated Styrofoam shipping boxes are becoming indispensable in ensuring thermal stability and minimizing spoilage.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40651-global-insulated-styrofoam-shipping-boxes-market

Drivers of Insulated Styrofoam Shipping Boxes Market Momentum:

Cold Chain Logistics: Fueling Demand

Accelerated by global vaccine distribution and increasing biologics shipments, cold chain infrastructure investment is expanding rapidly. Logistics providers are integrating EPS-based shipping boxes due to their light weight, thermal resistance, and low cost. Emerging economies across Asia-Pacific and Latin America are establishing cold storage nodes, elevating regional adoption of EPS and its alternatives.

Thermally Sensitive E-Commerce Fulfillment

With the explosion of direct-to-consumer delivery models, including meal kits, frozen groceries, and pharmaceutical subscription services, packaging solutions must now perform at a higher thermal standard. Styrofoam boxes excel in preserving contents during last-mile delivery, particularly in high-temperature regions or extended transit windows.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40651-global-insulated-styrofoam-shipping-boxes-market

Industry Trends Reshaping the Insulated Styrofoam Shipping Boxes Market Landscape:

Eco-Friendly Insulation Innovation

Environmental scrutiny around traditional Expanded Polystyrene (EPS) has prompted industry leaders to introduce biodegradable EPS, Expanded Polypropylene (EPP), and Expanded Polyurethane (EPU). These innovations aim to balance thermal efficiency with recyclability and biodegradability, addressing both regulatory pressure and consumer sustainability demands.

Integration of IoT and Smart Packaging

Innovations such as IoT-based sensors, real-time temperature tracking, RFID chips, and blockchain-enabled traceability are redefining product integrity. Advanced boxes now feature embedded condition-monitoring solutions, allowing logistics providers to react in real-time to temperature breaches, critical in pharmaceuticals and biologics.

Rise of Vacuum Insulated Panels (VIPs) and Phase Change Materials (PCMs)

Next-gen thermal packaging increasingly utilizes VIPs and PCMs to ensure temperature stability in extreme conditions. These materials enhance insulation with minimal volume, optimizing space efficiency in shipping containers and reducing fuel consumption in transport.

Product Segmentation and Performance:

Hinged vs. Un-Hinged Boxes

Hinged boxes dominate the product landscape, capturing 68.5% market share in 2024. Their popularity stems from ease of use, secure sealing, and durability. Un-hinged variants, while less prevalent, continue to grow steadily due to their customization potential and lower unit cost, catering to niche applications.

Material Performance

EPS (55.3% share) remains the workhorse due to its cost-effectiveness and thermal balance.

EPP, growing at 6.3% CAGR, offers superior mechanical resilience and reusability, ideal for pharmaceutical supply chains.

EPU, though costlier, provides unmatched insulative performance, suited for ultra-cold shipments and perishable biotech products.

Insulated Styrofoam Shipping Boxes Market by End-Use Applications:

Food & Beverage

Holding a 50.4% share, the food industry leverages insulated boxes for frozen meal kits, seafood, dairy, and fresh produce. The rise of online grocery and farm-to-table delivery models is spurring demand for custom-sized, recyclable packaging.

Pharmaceuticals & Healthcare

With a projected 6.6% CAGR, this sector is the fastest-growing, driven by vaccine distribution, clinical trials, and the rise in biologic and personalized medicines. EPS and EPU boxes are the backbone of cold chain assurance in these high-stakes deliveries.

Electronics and Specialty Chemicals

Thermally sensitive semiconductors, batteries, and temperature-reactive chemicals require rigid, vibration-absorbing packaging. EPP's impact resistance and insulation are pivotal in ensuring transit safety.

Sales Channel Dynamics

Distributors lead at 59.8%, leveraging bulk procurement networks and established B2B logistics relationships.

Online retailers, fueled by D2C models, are the fastest growing, benefiting from the scalability of e-commerce fulfillment.

Specialty stores, though niche, serve high-margin segments like biotech R&D and small-batch gourmet shipping.

Insulated Styrofoam Shipping Boxes Market Regional Insights:

North America

Dominates at 38% insulated styrofoam shipping boxes market share, underpinned by mature cold chains, stringent FDA and EPA compliance norms, and leading e-commerce networks.

Asia-Pacific

Experiencing 6.8% CAGR, propelled by urbanization, rising disposable income, and massive investments in infrastructure modernization across China, India, and Southeast Asia.

Europe

With a 29.2% share, Europe is pushing the envelope in green packaging mandates, accelerating the transition to biodegradable EPS alternatives and reusable systems in the EU market.

Competitive Landscape and Innovation Leadership

Key Insulated Styrofoam Shipping Boxes Market Players and Strategic Movements

Sonoco Products Company: Launched a biodegradable EPS line, targeting regulated markets and reducing landfill contributions.

Cryopak: Acquired a PCM technology firm, expanding its thermal innovation pipeline.

Topa Thermal: Introduced IoT-enabled boxes through a logistics partnership, merging smart technology with cold chain essentials.

These firms are doubling down on research, mergers, and IP acquisition to maintain a competitive edge, particularly in high-growth verticals like personalized medicine and frozen food delivery.

Future Insulated Styrofoam Shipping Boxes Market Pathways and Strategic Recommendations

Invest in Material R&D: Prioritize hybrid packaging that combines VIPs, biodegradable EPS, and PCM layers.

Adopt Smart Packaging: Enable supply chain visibility through IoT and blockchain integrations.

Target Emerging Markets: Capitalize on growth corridors in Asia-Pacific and Latin America, focusing on urban logistics hubs.

Align with ESG Goals: Offer certified carbon-neutral packaging solutions, appealing to conscious B2B buyers and regulators alike.

Modularize Offerings: Provide scalable and custom-fit designs for cross-sector applicability, from biopharma to gourmet.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40651-global-insulated-styrofoam-shipping-boxes-market

Conclusion

The Global Insulated Styrofoam Shipping Boxes Market is entering an era defined by thermal innovation, sustainability, and digital integration. As industries escalate their demand for high-performance cold chain packaging, the market's future hinges on material advancements, real-time monitoring capabilities, and responsible manufacturing. Businesses that integrate eco-conscious design with smart logistics compatibility will lead the next wave of global cold chain excellence.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

How to Choose the Right Reefer Container for Your Business Needs

Selecting the perfect reefer container is crucial for businesses that rely on the transportation and storage of temperature-sensitive goods. Whether you are in the food industry, pharmaceuticals, or any other sector requiring precise temperature control, understanding your specific needs is the first step. This guide will help you navigate the essential factors to consider when choosing the right reefer container for your business.

1. Determine the Type of Goods You’re Transporting

The type of goods you plan to store or transport plays a significant role in determining the reefer container you need. For instance, perishables like fruits and vegetables require a different temperature range compared to frozen goods or pharmaceuticals. It’s essential to match the container’s cooling capabilities to the specific needs of your products. For more detailed information on how reefer containers can preserve different goods, check out our fruits ripening cold rooms guide.

2. Consider the Duration of Storage or Transport

The length of time your goods will be in the container also affects your choice. Short-term storage may not require the same level of insulation or power efficiency as long-term storage or transport. If your business frequently deals with extended shipping times, investing in a container with advanced cooling technology and robust insulation is crucial. Learn more about long-term cold storage solutions in our portable cold room guide.

3. Evaluate the Size and Capacity Requirements

Reefer containers come in various sizes, typically ranging from 20 feet to 40 feet. Your choice should depend on the volume of goods you plan to store or transport. Overestimating your needs can lead to unnecessary costs, while underestimating may result in insufficient storage space. To determine the ideal size for your operations, consider consulting our low budget cold room options, which offer a range of customizable solutions.

4. Energy Efficiency and Operating Costs

Energy efficiency is a critical factor in choosing a reefer container, especially for businesses looking to reduce operational costs. Modern containers are equipped with energy-saving technologies that help minimize power consumption while maintaining precise temperature control. For insights into energy-efficient cold storage solutions, explore our chiller systems designed for optimal performance with minimal energy usage.

5. Assess the Container’s Reliability and Maintenance Needs

Finally, consider the reliability and maintenance requirements of the reefer container. A high-quality container should offer consistent performance with minimal downtime. It’s also important to factor in the availability of maintenance services and spare parts in your region. For more tips on maintaining your cold storage units, visit our cold room maintenance guide.

#across the spiderverse#artists on tumblr#asexual#barbie#donald trump#easter#margot robbie#michael cera#rwby#ryan gosling#cold room#cold storage

2 notes

·

View notes

Text

Rattan Industrial: A Leading Bottling Line Manufacturer Powering Efficient Packaging Solutions

In today’s fast-paced industrial world, automation and efficiency have become critical factors for success—especially in the food and beverage, pharmaceutical, and chemical sectors. Among the most vital components of production in these industries is the bottling line—a system that ensures safe, hygienic, and efficient packaging of liquids. When it comes to precision-engineered bottling line systems in India, Rattan Industrial has earned its place as a leading bottling line manufacturer delivering high-performance solutions customized to client needs.

Comprehensive Bottling Line Solutions

Rattan Industrial specializes in designing and manufacturing complete bottling lines, tailored to handle a wide variety of liquids — including water, alcoholic beverages, edible oils, chemicals, and pharmaceutical products. Their systems are suitable for both PET and glass bottles and are adaptable to multiple container sizes and shapes.

Each bottling line from Rattan typically includes:

Bottle unscrambler or feeder

Rinsing/filling/capping machines

Labeling and coding systems

Conveyor systems

Shrink wrapping and packaging systems

From start to finish, the entire process is streamlined to minimize manual handling, increase throughput, and maintain product integrity.

Cutting-Edge Engineering and Automation

Rattan Industrial incorporates the latest automation technologies in its bottling lines to ensure precision, speed, and consistency. Their systems are powered by programmable logic controllers (PLC) and human-machine interface (HMI) systems, making operation user-friendly and highly customizable.

Features like no-bottle-no-fill sensors, drip-free nozzles, anti-leak capping heads, and real-time monitoring make Rattan’s bottling lines not only efficient but also smart. These intelligent systems help clients reduce wastage, increase uptime, and maintain hygienic standards that comply with global norms.

Industries Served

Rattan Industrial’s bottling lines are widely used across sectors including:

Distilleries and breweries (for alcohol, ENA, and spirits)

Beverage companies (water, juice, soda)

Edible oil and ghee manufacturers

Pharmaceutical industry (syrups, tonics)

Chemical plants (acids, cleaners, solvents)

Every solution is tailored to the product’s physical and chemical properties, ensuring compatibility with viscosity, temperature, and hygiene standards.

Customization and Scalability

No two production lines are the same, and Rattan Industrial understands this well. Whether a client needs a semi-automatic setup for a startup operation or a fully automated high-speed line for mass production, Rattan offers scalable solutions. Each system is designed keeping in mind:

Production volume

Container material and size

Type of liquid

Floor space and layout

Integration with existing machinery

This flexible approach allows businesses to upgrade their production capabilities without major overhauls.

Commitment to Quality and Durability

Every component of Rattan’s bottling lines is manufactured using high-grade stainless steel and corrosion-resistant materials to ensure long service life and low maintenance. Their strict quality control process ensures flawless performance, minimal downtime, and operational safety.

In addition, their machines are built for easy cleaning and maintenance — an essential requirement in hygiene-sensitive industries like food and pharma.

Turnkey Project Execution

Rattan Industrial doesn’t just manufacture machines — they offer end-to-end project execution. From initial consultation and plant layout design to machine installation, commissioning, and training, their team provides full support at every stage.

After-sales service is another area where Rattan excels. With a dedicated customer support and spare parts network, they ensure minimal downtime and quick issue resolution for their clients.

Why Choose Rattan Industrial?

Over 20 years of engineering and manufacturing experience

Tailored bottling line solutions for diverse industries

Use of advanced automation and control systems

Emphasis on hygiene, safety, and efficiency

End-to-end support from concept to commissioning

Proven track record with clients across India and abroad

Conclusion:

As the demand for faster, cleaner, and more efficient packaging solutions continues to grow, Rattan Industrial is leading the way as a trusted bottling line manufacturer in India. Their commitment to innovation, quality, and customer satisfaction makes them the ideal partner for any business seeking to elevate its packaging operations. Whether you’re expanding an existing facility or setting up a new plant, Rattan Industrial has the technology and expertise to bottle your success.

Visit:- https://www.liquorbottlingplants.com/bottling-line.html

0 notes

Text

Difference Between Packers and Movers and Logistics Services

You must have heard of Packers and Movers and Logistics Services, but can you differentiate between these two? Do they serve distinct purposes and cater to different needs? The appropriate understanding between them can help fulfil your business and household requirements if you choose the right service provider for your specific needs. This blog will discuss the core differentiation between movers and logistics services.

Definition and Differentiation

The Packers and Movers relocate household items, manufactured goods, raw materials, office assets, and vehicle transportation. Their significant role is to support individuals and businesses in shifting their belongings safely and conveniently. These services include packing, loading, transportation, and rearranging your goods at a new destination.

On the other hand, logistics manages the manufactured goods, materials, and inventory from one point to another. This industry caters to manufacturers, retailers, and businesses that require supply chain solutions, including warehousing, inventory management, freight forwarding, and distribution.

Target Audience

Individuals, families, and small businesses are the primary clients of Packers and Movers. Whether you shift to a new city, or an office, packers and movers support you throughout the journey.

On the contrary, logistics services cater for manufacturing, e-commerce, retail, pharmaceuticals, and supply chain management businesses. Big giants rely on logistics providers to transport raw materials, finished products, and bulk consignments.

Services Offered

For Packers and Movers:

Household relocation

Office shifting

Vehicle transportation (cars and bikes)

Packing and unpacking services

Loading and unloading

Temporary storage solutions

Insurance for household/ office goods

For Logistics Relocation:

Freight transportation (road, rail, air, and sea)

Warehousing and storage

Inventory management

Supply chain management

Freight forwarding

Cold storage solutions

Customs clearance and documentation

Type of Goods Handled

Packers and movers handle personal belongings, furniture, appliances, vehicles, and office equipment. The team focuses on the safe and secure movement of items typically of sentimental or functional value to individuals.

Logistics companies deal with bulk goods, raw materials, perishable items, industrial equipment, and commercial shipments. The goods are often transported in large volumes and require specialized handling, tracking, and compliance with industry regulations.

Transportation Modes

Packers and Movers primarily rely on road transportation using big trucks and carriers designed for household and office relocations. They might also use trains or air freight for long-distance state moves.

Logistics Services use multiple transportation modes, including road, rail, air, and sea freight, depending on the relocation requirement of goods and destination. Logistics providers have networks that ensure efficient movement across borders and long distances.

Packaging Standards

Packers and Movers use bubble wrap, cardboard boxes, wooden crates, and cushioned packing that protect fragile and other household items. The packers and movers ensure the safety of individual belongings.

Logistics Services follow industrial-grade packaging standards using pallets, containers, shrink wrapping, and temperature-controlled packaging to ensure the safety of bulk goods. Logistics packing focuses more on efficiency and protection during long-haul transportation.

Pricing Structure

For Packers and Movers, pricing depends on factors such as the volume of goods, distance, type of service (full-service or self-packing), and additional services like insurance or storage. The cost quotation is according to the given parameters.

The pricing in logistics is more complex and depends on weight, volume, transportation mode, fuel charges, customs duties, storage duration, and handling fees. The pricing structure is often calculated per shipment or contract-based for long-term partnerships.

Tracking and Technology

Packers and movers provide tracking services through GPS-enabled trucks that allow customers to monitor their shipments. However, their tracking systems are relatively simple compared to logistics companies.

Logistics services offer top-notch tracking technology, including RFID tags, MIS, GPS trackers, IoT sensors, and AI-driven supply chain management systems. With the help of this, businesses can track inventory movement, optimize routes, and predict delivery timelines precisely.

Regulatory Compliance

Packers and movers follow basic transportation and insurance regulations related to household shifting. Their compliance requirements are relatively simple and focus on consumer protection laws.

Logistics providers must adhere to stringent industry regulations, including customs clearance, international trade laws, hazardous materials handling, and safety compliance. Documentation and compliance management are critical aspects of logistics operations.

Business vs Individual Needs

Ideal for individuals and small businesses requiring occasional shifting and relocation services. The focus is on providing a stress-free moving experience with minimal disruption to personal or work life.

Logistics work for businesses managing supply chains, distribution networks, and bulk transportation. Logistics providers work as long-term partners to ensure seamless supply chain operations.

Conclusion

Both Packers and Movers and Logistics Services involve the handling of goods, their purpose, target audience, and operational processes differ significantly. Packers and Movers specializes in household and office relocations, providing personalized and secure moving solutions. Logistics services, on the other hand, cater to businesses and industries, ensuring efficient supply chain management and large-scale transportation.

Understanding these distinctions helps individuals and companies make firm decisions when choosing the right service provider. If you are planning a personal move or need a logistics partner for your business, selecting the service will ensure efficiency, safety, and cost-effectiveness while relocating your goods.

0 notes

Text

Odor Control for the Pharmaceutical Industry: Ensuring Compliance, Safety & Comfort

Odor Control for the Pharmaceutical Industry: Ensuring Compliance, Safety & Comfort

The pharmaceutical industry, though known for innovation and life-saving products, often deals with a less-discussed but critical challenge — odor emissions. From active pharmaceutical ingredient (API) manufacturing to wastewater treatment and chemical storage, unpleasant and potentially harmful odors are frequently released. These emissions can lead to community complaints, regulatory violations, and even safety hazards if not managed properly.

Effective odor control systems in pharma environments are not just about eliminating bad smells — they’re about maintaining a safe workplace, protecting nearby communities, and complying with stringent environmental standards.

Why Does the Pharma Industry Generate Odors?

Pharmaceutical production processes involve a variety of organic solvents, chemical reactions, and biological materials that can release volatile organic compounds (VOCs) and other odorous gases such as:

Ammonia

Hydrogen sulfide (H₂S)

Solvent vapors (acetone, ethanol, isopropanol, etc.)

Organic sulfides and amines

These emissions commonly occur during:

Synthesis of APIs

Fermentation processes

Storage and handling of raw materials

Effluent treatment plants (ETPs)

Waste disposal and incineration

Why Odor Control Matters in Pharma

Regulatory Compliance: Regulatory bodies like the Central Pollution Control Board (CPCB) in India and international standards (e.g., US EPA, EU directives) require emissions control — including odors — as part of environmental management.

Health & Safety: VOCs and chemical fumes can pose occupational hazards to workers and may trigger respiratory issues or chemical sensitivities.

Brand Reputation: Persistent odor complaints can damage public trust and bring negative attention to pharma facilities.

Environmental Responsibility: Sustainable and green manufacturing demands responsible handling of emissions, including odorous compounds.

Odor Control Solutions for Pharma Facilities

Modern pharma odor control systems are customized to address the specific types and sources of emissions. Commonly used technologies include:

1. Activated Carbon Filters

Ideal for removing VOCs and solvent-based odors, these filters adsorb gases efficiently and are easy to maintain.

2. Chemical Scrubbers

Wet scrubbers use acidic or alkaline solutions to neutralize odorous compounds. Especially useful in effluent treatment and exhaust gas treatment.

3. Biofilters & Biotrickling Filters

Eco-friendly systems that use microbial action to break down organic odors. Effective for continuous and long-term odor control.

4. Thermal Oxidizers

Used in API and high-emission operations to combust VOCs at high temperatures, reducing them to CO₂ and water vapor.

5. Ozone and UV-based Systems

Advanced oxidation processes that neutralize odors through chemical reactions. Often used in closed environments or with air handling units.

Best Practices for Implementing Odor Control in Pharma

Odor Mapping & Source Identification: Use sensors and odor dispersion modeling to locate and prioritize treatment zones.

Airflow Management: Ensure proper containment and ventilation design in production and storage areas.

Routine Monitoring: Integrate odor monitoring systems into the facility’s environmental management plan.

Employee Training: Educate staff on odor risks, proper handling of chemicals, and maintenance of odor control systems.

Indian Context: Rising Focus on Compliance

In India, growing urban proximity to pharma hubs like Hyderabad, Ahmedabad, Pune, and Baddi has made odor control a focal point for both public agencies and manufacturers. The National Green Tribunal (NGT) and State Pollution Control Boards (SPCBs) are now actively monitoring air quality parameters, including odor.

Government schemes under Make in India and Pharma Vision 2020 also emphasize sustainable manufacturing, creating a favorable push for the adoption of odor control systems in pharma infrastructure.

Conclusion

Odor control in the pharmaceutical industryis not just a regulatory checkbox — it’s a critical component of responsible, sustainable, and community-conscious manufacturing. By investing in the right odor control technologies and practices, pharmaceutical companies can ensure cleaner operations, protect their workforce, and enhance their social license to operate.

Visit:- https://www.odorcontrol.in/odor-control-pharma.html

0 notes

Text

Best Gas Volume Tester in United Arab Emirates

Source of Info: https://www.perfectgroupindia.co.in/blog/best-gas-volume-tester-in-united-arab-emirates

Introduction

A Gas Volume Tester in United Arab Emirates is needed for measuring how much gas is in sealed bottles or containers. Using this equipment, manufacturers will be able to confirm that products such as carbonated drinks contain the correct amount of gas guarantee safety and quality. Its strong structure and easy to use controls provide consistent, accurate results. It is important to product testing whether it is used in a laboratory or on a manufacturing line. Industries can increase testing productivity while following high safety and packaging regulations for gas filled products in a variety of sectors by using the reliable solutions provided by Perfect Group India.

Why Is a Gas Volume Tester Important? When it comes to carbonated drinks like soda and energy drinks, gas is important. The correct level of gas provides the drink tastes fresh and has the right fizz. A Gas Volume Tester in United Arab Emirates helps companies:

Check if the gas levels match quality standards

Avoid underfilling or overfilling gas

Avoid leaks and container damage

Extend shelf life of products

Comply with safety and regulatory requirements

Without proper gas measurement, companies can face product complaints, returns and even legal trouble. This is why regular gas volume testing is required of quality control.

Working Principle of a Gas Volume Tester A Gas Volume Tester works on the principle of measuring the pressure and temperature of the gas within a sealed container. Here’s how the process usually goes:

Sample Collection: A sealed bottle or can is taken for testing.

Piercing Needle: The instrument uses a needle to pierce the cap without opening the container fully.

Pressure Reading: The tester then measures the internal pressure.

Temperature Monitoring: Temperature is also recorded as gas volume changes with temperature.

Calculation: The device sets the total volume of gas in the container using standard gas laws.

The process is quick and reliable, making it perfect for both in house lab testing and factory use.

Important Features of the Best Gas Volume Tester in United Arab Emirates When choosing a Gas Volume Tester in United Arab Emirates, industries should look for advanced features that guarantee performance and ease of use. Here are the top features you should expect:

Digital Display: Shows pressure and temperature clearly.

Temperature Compensation: Modifies measurements according to the outside temperature.

User-friendly Controls: Simple interface for quick results.

Small Design: Maintains room in manufacturing spaces and lab.

Good Build Quality: Strong and durable.

Fast Response Time: Immediate results.

Data Output Port: Option to export data for reports.

Multi Container Compatibility: Works with PET, glass and cans.

Applications of Gas Volume Tester

Beverage Manufacturing: To guarantee that beverages such as soda and beer have the proper level of carbonation.

Packaging Industry: To confirm that packaging material can handle internal gas pressure.

Food Processing: For sealed foods that require gas packaging to stay fresh.

Pharmaceuticals: In specific sealed drug containers, testing gas volume can be required.

Its wide range of uses makes it one of the most important tools in modern product manufacturing.

Benefits of Using a Gas Volume Tester Using a high quality Gas Volume Tester in United Arab Emirates can bring several benefits to your manufacturing process:

Improves Product Quality: Guarantee each unit meets desired gas levels.

Reduces Product Waste: Helps in identifying problems before transport.

Increases Customer Satisfaction: Provides an improved final product.

Supports Conformity: Fulfills national and international quality requirements.

Saves Time and Costs: Quick testing improves production performance.

When you use a reliable tester you're investing in your brand’s reputation.

What Functions as the Best Gas Volume Tester in United Arab Emirates? The best Gas Volume Tester must offer a balance of accuracy, durability and ease of use. Here are some factors to consider:

High accurate Sensors: For pressure and temperature measurement.

Ease of Calibration: Should be easy to recalibrate for durable use.

Low Maintenance: Just small, well-made replacement parts are needed.

Value: Provides a great value for money without sacrificing quality.

After Sales Support: Includes setup, training and service support.

Perfect Group India offers a premium quality Gas Volume Tester in United Arab Emirates built with all these standards in mind. With an experienced team and solid engineering, the product is suitable for modern factory environments and guarantees quality performance.

Ideal for UAE Market Needs The Gas Volume Tester in United Arab Emirates must satisfy the particular demands of this expanding market. The UAE is known for its high quality control standards, fast growing beverage sector and rising export demands. Manufacturers here need tools that deliver consistent performance, especially under high volume work.

This makes it important to choose a tester that supports fast testing cycles, offers error free results and works well with various bottle types and gas filled containers. A model built by an expert team with years of industry experience becomes valuable to the UAE manufacturing industries.

Conclusion When measuring the amount of gas contained in sealed bottles or cans a Gas Volume Tester in United Arab Emirates is important. Businesses can maintain the safety and quality of their packaging with the help of this tester. This is the tool to use if you want consistent results and help improve the quality of your products.It is designed for daily use and supports faster checks with fewer errors. It's important to any packaging industry because of its advanced functions and easy to use interface. The model provided by Perfect Group India which is renowned for its superb engineering and dedication to providing high quality testing equipment globally, is one best option.

#industrial#equipments#perfectgroupindia#perfectinstruments#technology#droptester#business#boxcampressiontester#toploadertester

0 notes

Text

Same Day Bike Delivery Solutions for Last-Minute Needs

Introduction

In the pulsating rhythm of urban commerce, delays are intolerable and immediacy is paramount. Whether it’s a legal document that must reach a court within the hour, a luxury gift ordered at the last minute, or gourmet produce that needs swift transportation across the city, time-sensitive delivery demands an agile, dependable solution. This is where same day bike delivery steps in — not merely as a convenient option, but as a logistical lifeline for modern urban ecosystems.

The Rise of Same Day Bike Courier Services

Cities like London — vibrant, congested, and ever-moving — require solutions that transcend traditional delivery paradigms. The rise of the same day bike courier has redefined efficiency, offering an eco-conscious, rapid-response alternative to motorized vans or conventional mail systems.

More than just a trend, this solution addresses the perennial challenge of urban gridlock. Bike couriers weave through traffic with unmatched nimbleness, navigating alleyways, bus lanes, and bicycle paths inaccessible to bulkier vehicles. The result? Quicker deliveries, fewer carbon emissions, and a dramatically reduced logistical footprint.

Leading platforms offering same day bike delivery have elevated this niche into a mainstream necessity, responding to the needs of florists, law firms, pharmacies, and even high-end fashion boutiques who all share one demand: immediacy.

Why Same Day Bike Delivery is Crucial for Last-Minute Logistics

The modern customer expects immediacy. The digital age has conditioned consumers to anticipate lightning-fast gratification — next-day delivery no longer dazzles. What truly satisfies is same-day fulfillment. And when the delivery must occur within mere hours, especially in metropolitan regions, nothing surpasses a swift and dedicated bike courier in London.

A significant advantage of same-day bike delivery lies in its versatility. Whether it’s a fragile parcel or sensitive documentation, the handling is more personalized and direct. Unlike warehouse-based systems where items change hands multiple times, bike couriers typically collect and deliver in a single route. This minimizes risk, ensures accountability, and maximizes speed.

Chilled and Frozen: Temperature-Controlled Bike Deliveries

But speed is not the only imperative. For businesses in the culinary, pharmaceutical, and floral industries, temperature stability is equally critical. The emergence of same day chilled deliveries has proven to be revolutionary. Equipped with insulated, thermally-lined containers, modern bike couriers can now offer effective refrigerated delivery service that meets even stringent health and safety compliance requirements.

From fresh seafood destined for a fine-dining kitchen to lab samples needing strict cold-chain integrity, the availability of refrigerated transport services via bike has unlocked new realms of possibility. The blend of environmental sustainability with precise temperature control is not merely innovative — it’s transformative.

Enterprises seeking premium same day chilled delivery options are increasingly turning to dedicated services that combine velocity with refrigeration. Refrigerated transportation services in urban areas are no longer confined to large vans or trucks. Today, smartly engineered courier bikes handle delicate cold-chain logistics without compromising quality or punctuality.

The Intricacies Behind Frozen and Refrigerated Transport

Handling frozen courier service logistics is not for the unprepared. It involves meticulous calibration of insulation, temperature monitoring, and route optimization. When frozen items are delivered via bike, every second counts.

Advanced couriers deploy pre-cooled containers capable of maintaining sub-zero conditions for extended periods. These specialized carriers, often designed using vacuum-insulated panels or phase-change materials, retain chill without the need for active refrigeration units. Thus, while the courier pedals through the urban jungle, the temperature-sensitive contents remain unaffected by external fluctuations.

This approach is indispensable for boutique frozen food producers, specialty bakeries, and even niche ice-cream artisans looking to cater to discerning clientele within the day. With same-day delivery in London now inclusive of frozen transport, culinary excellence can be preserved down to the last degree.

Sustainability: The Silent Strength of the Bike Courier Revolution

Beyond the logistical marvels and commercial efficiency lies a crucial ecological dimension. Bike couriers drastically reduce emissions, noise pollution, and energy consumption when compared to motor vehicles. In an era where businesses are held accountable not only for profits but also for their environmental impact, choosing a bike courier in London reflects a progressive ethos.

Unlike combustion-based couriers, bicycles offer zero emissions and utilize minimal space on crowded roads. When combined with chilled or frozen capabilities, they provide a rare harmony of sustainability and sophistication. This new paradigm of eco-conscious express delivery supports the green ambitions of cities striving to lower their carbon footprints without compromising on efficiency.

Meeting Consumer Expectations in the Instant Economy

The modern economy thrives on impulse. Whether it’s a forgotten birthday present or a last-minute menu change for an event, same day bike delivery bridges the gap between need and fulfillment. Consumer behavior is increasingly shaped by immediacy, and businesses unable to respond risk falling behind.

This has led to a proliferation of real-time logistics platforms offering guaranteed delivery within specific time windows. Integration with e-commerce portals, live tracking, and digital proof of delivery have become standard features. In such a climate, the role of the same day bike courier is indispensable.

Especially in a metropolis as sprawling as London, where congestion charges, limited parking, and tight delivery windows create formidable challenges, agile solutions matter more than ever. That’s where dependable services like same day bike courier operations come into their own.

Conclusion: Precision, Punctuality, and Performance on Two Wheels

In conclusion, the confluence of technology, urban infrastructure, and consumer demand has catapulted same day bike delivery into the forefront of last-mile logistics. Its relevance spans diverse industries — from food and pharmaceuticals to fashion and legal services.

By incorporating same-day chilled deliveries, frozen courier service offerings, and robust refrigerated transportation services, modern bike courier solutions have proven themselves far more than a convenient alternative. They are, in many ways, the pinnacle of contemporary urban logistics — nimble, green, and unrelentingly punctual.

As the demand for immediacy only intensifies, services providing same day chilled delivery and refrigerated delivery service by bicycle will likely become not just a competitive advantage but a business necessity.

In the end, success will belong to those who can adapt with both velocity and precision. The humble bicycle, armed with refrigeration technology and GPS coordination, has emerged as an unexpected hero in the fast-paced narrative of urban logistics.

Source URL - https://medium.com/@z5logistics999/same-day-bike-delivery-solutions-for-last-minute-needs-9dd0cc95016e

0 notes

Text

Europe pH Sensors Market Size, Share, Trends, Demand, Future Growth, Challenges and Competitive Analysis

"Executive Summary Europe pH Sensors Market : Data Bridge Market Research analyses that the PH Sensors Market which was USD 380 million in 2022, would rocket up to USD 650 million by 2030, and is expected to undergo a CAGR of 7.84 % during the forecast period.

This Europe pH Sensors Market research report is a proven and consistent source of information which gives telescopic view of the existing market trends, emerging products, situations and opportunities that drives business towards the success. This industry report also provides company profiles and contact information of the key market players in the key manufacturer’s section. The report serves the clients to tackle every strategic aspect including product development, product specification, exploring niche growth opportunities, application modelling, and new geographical markets. This global Europe pH Sensors Market research report is organized by collecting market research data from different corners of the sphere with an experienced team of language resources.

The Europe pH Sensors Market report also determines emerging trends along with major drivers, challenges and opportunities in the market. In addition, the report contains company profile, product specifications, production value, market shares and contact information of manufacturers or companies. This report comprehensively analyzes the potential of the market in the present and the future prospects from a variety of corners. Key players are taking actions such as developments, product launches, acquisitions, mergers, joint ventures and competitive analysis in the industry. It also conducts wide-ranging study about different market segments and regions.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Europe pH Sensors Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/europe-ph-sensors-market

Europe pH Sensors Market Overview

**Segments**

- **By Type:** The Europe pH sensors market can be segmented into glass electrode, solid-state electrode, and others. Glass electrodes are widely used due to their accuracy and sensitivity in measuring pH levels. - **By Component:** The market can also be segmented based on components such as sensor body, measuring electrode, reference electrode, and temperature sensing element. The sensor body is crucial for protection and stability of the electrodes. - **By End-User:** End-users of pH sensors in Europe include water treatment plants, pharmaceutical companies, food and beverage industry, and research laboratories. Each sector has specific requirements for pH monitoring and control.

**Market Players**

- **Hach (Danaher)** - **Emerson Electric Co** - **Endress+Hauser Management AG** - **Yokogawa Electric Corporation** - **Mettler-Toledo International Inc.** - **Honeywell International Inc.** - **ABB** - **Siemens** - **Thermo Fisher Scientific Inc.** - **Omega Engineering**

These market players are leading the Europe pH sensors market with their innovative product offerings and strategic partnerships. They are focusing on enhancing their product portfolios to cater to the diverse needs of end-users across various industries. The competition among these players is intense, driving technological advancements in pH sensor technology in the region.

The Europe pH sensors market is witnessing significant growth due to the increasing demand for pH monitoring in various industries. The stringent regulations related to water quality and safety have propelled the adoption of pH sensors in water treatment plants. Additionally, the growing awareness about food quality and safety standards in the food and beverage sector is driving the demand for pH sensors for quality control purposes. Moreover, the pharmaceutical industry is increasingly using pH sensors for drug manufacturing processes to ensure product quality and efficacy.

In conclusion, the Europe pH sensors market is poised for substantial growth in the coming years as industries across the region prioritize accurate pH monitoring for their operations. The advancements in sensor technology and the focus on product innovation by key market players will further drive the market growth and adoption of pH sensors in Europe.

The Europe pH sensors market is experiencing a significant surge in demand, primarily fueled by the stringent regulations concerning water quality and safety issues across industries. Water treatment plants form a crucial segment where pH sensors play a vital role in maintaining the desired pH levels for effective treatment processes. This increasing adoption of pH sensors in the water treatment sector is anticipated to propel market growth in the region. In the pharmaceutical industry, pH sensors are becoming indispensable in ensuring the quality and efficacy of drug manufacturing processes. The precise monitoring of pH levels during different stages of drug production guarantees the maintenance of required standards, hence boosting the market for pH sensors.

Furthermore, the food and beverage industry is another significant end-user segment driving the growth of the Europe pH sensors market. With a heightened focus on food quality and safety standards, the industry relies heavily on pH sensors for monitoring and controlling pH levels during various production processes. pH sensors play a crucial role in determining the taste, texture, and overall quality of food and beverage products, making them an essential tool for quality control purposes. The awareness about the importance of pH monitoring in ensuring product quality and compliance with regulations is expected to fuel the demand for pH sensors in the food and beverage sector.

Moreover, research laboratories form a vital end-user segment contributing to the growth of the Europe pH sensors market. Research institutions and laboratories extensively utilize pH sensors for various experiments, tests, and studies where accurate pH measurement is essential. pH sensors enable researchers to make precise observations and gather valuable data in fields such as chemistry, biology, environmental science, and pharmaceutical research. The reliability and accuracy of pH sensors make them integral instruments in research settings, further driving their adoption in laboratories across Europe.

In conclusion, the Europe pH sensors market is witnessing robust growth across diverse industry verticals, driven by the increasing emphasis on quality control, regulatory compliance, and technological advancements. The strategic initiatives undertaken by key market players to enhance their product offerings and expand their market presence are expected to further accelerate market growth in the region. With the continuous innovations in pH sensor technology and the rising demand for accurate pH monitoring solutions, the Europe pH sensors market is poised for sustained expansion in the foreseeable future.The Europe pH sensors market is undergoing a transformation driven by various factors that are shaping the growth trajectory of the industry. One of the key drivers propelling the market is the increasing emphasis on regulatory compliance across different sectors such as water treatment, pharmaceuticals, food and beverage, and research laboratories. Stringent regulations related to water quality and safety are compelling water treatment plants to adopt pH sensors to ensure effective treatment processes and adherence to quality standards. Similarly, in the pharmaceutical industry, the need for accurate pH monitoring in drug manufacturing processes is bolstering the demand for pH sensors to maintain product quality and efficacy within regulatory limits.

Moreover, the food and beverage industry's heightened focus on quality control and safety standards is driving the adoption of pH sensors for monitoring and controlling pH levels during various stages of production. pH sensors are instrumental in determining the taste, texture, and overall quality of food products, making them indispensable tools for maintaining quality standards and regulatory compliance. This growing awareness about the significance of pH monitoring in ensuring product quality is anticipated to further fuel the demand for pH sensors in the food and beverage sector.

Additionally, research laboratories play a crucial role in driving the growth of the Europe pH sensors market, as they extensively utilize pH sensors for a wide range of experiments and studies requiring accurate pH measurements. pH sensors are vital instruments in research settings across disciplines such as chemistry, biology, environmental science, and pharmaceutical research, enabling researchers to gather precise data and make informed observations. The reliability and accuracy of pH sensors make them essential components in research laboratories, further contributing to their adoption and market growth in Europe.

Furthermore, the market players in the Europe pH sensors segment are actively involved in enhancing their product portfolios through innovative offerings and strategic partnerships to cater to the diverse needs of end-users across industries. The competitive landscape among key players is driving technological advancements in pH sensor technology, leading to continuous improvements in monitoring solutions and fostering market growth. With the evolving regulatory landscape, increasing awareness about the importance of pH monitoring, and the ongoing focus on quality control and compliance, the Europe pH sensors market is poised for sustained expansion and innovation in the foreseeable future.

The Europe pH Sensors Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/europe-ph-sensors-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Influence of the Europe pH Sensors Market Report:

Comprehensive assessment of all opportunities and risk in the Europe pH Sensors Market

Lead Europe pH Sensors Market recent innovations and major events

Detailed study of business strategies for growth of the Europe pH Sensors Market market-leading players

Conclusive study about the growth plot of Europe pH Sensors Market for forthcoming years

In-depth understanding of Europe pH Sensors Market -particular drivers, constraints and major micro markets

Favourable impression inside vital technological and Europe pH Sensors Marketlatest trends striking the Cannabis Seeds Market

Browse More Reports:

North America Personal Care Ingredients Market Global FinFET Technology Market Global Paper Dyes Market Asia-Pacific Protein Hydrolysates Market Global Inline Metrology Market North America Retail Analytics Market Global Thrombosis Drug Market Europe Network Test Lab Automation Market Global Perinatal Infections Market Global Light-Emitting Diode (LED) Probing and Testing Equipment Market Global Mobile Campaign Management Platform Market Global Fruits and Vegetables Processing Equipment Market Global STD Diagnostics Market Asia-Pacific Microgrid Market Global Fluoxetine Market Global Food Drink Packaging Market Global Electric Enclosure Market Asia-Pacific Artificial Turf Market Global Hand Wash Station Market Global Prostate Cancer Antigen 3 (PCA3) Test Market Asia-Pacific Hydrographic Survey Equipment Market Global Cable Testing and Certification Market Global Leather Handbags Market Global Post-Bariatric Hypoglycemia Treatment Market Europe pH Sensors Market Global Linear Low-Density Polyethylene Market Global Ketogenic Diet Food Market Asia-Pacific Small Molecule Sterile Injectable Drugs Market Global Prescriptive Analytics Market Global Viral Transport Media Market Middle East and Africa Composite Bearings Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag

"

0 notes

Text

Choosing the Right Cargo Handling Services in India for Your Business

Introduction Efficient cargo handling is vital for ensuring the safe and timely movement of goods across India and internationally. Whether you're in manufacturing, e-commerce, or the import-export business, choosing the right cargo handling partner can significantly enhance supply chain efficiency, reduce costs, and ensure timely deliveries.

With numerous cargo service providers available, it’s essential to evaluate their logistics expertise, safety protocols, cost structures, and industry experience to make the best choice. This guide will walk you through the key considerations when selecting cargo handling services in India that align with your business needs.

What is Cargo Handling? Cargo handling refers to the processes involved in moving, managing, and storing goods during their journey. These include: ✔ Loading & Unloading – Safely loading and unloading goods at various transit points. ✔ Packaging & Labeling – Properly packaging and labeling items to ensure safe transport. ✔ Customs Clearance – Managing the required documentation for international shipments. ✔ Warehousing & Distribution – Storing and distributing goods efficiently. ✔ Freight Forwarding – Arranging transportation across air, sea, rail, or road.

Cargo handling is a critical part of logistics that ensures smooth operations for both domestic and global shipments.

Types of Cargo Handling Services in India The type of cargo handling service you need will depend on your industry, cargo type, and transportation methods. Here are the main types:

General Cargo Handling ✔ Suitable for retail goods, electronics, textiles, and general merchandise. ✔ Includes standard packing, shipping, and storage.

Bulk Cargo Handling ✔ Ideal for heavy commodities like coal, cement, and agricultural products. ✔ Requires specialized machinery, such as conveyor belts and cranes.

Containerized Cargo Handling ✔ Commonly used for international trade and import-export businesses. ✔ Involves the use of containers for loading, customs clearance, and multimodal transport.

Perishable Goods Handling ✔ For temperature-sensitive items like food, pharmaceuticals, and flowers. ✔ Requires cold storage facilities and temperature-controlled transportation.

Hazardous Cargo Handling ✔ For dangerous goods, such as chemicals, flammable items, and medical waste. ✔ Involves strict safety protocols to meet environmental and regulatory standards.

Factors to Consider When Choosing Cargo Handling Services

Industry Experience & Reputation ✔ Choose a provider with experience handling cargo in your industry. ✔ Look for certifications such as ISO and IATA accreditation for air cargo. ✔ Check customer reviews and testimonials for insight into their service quality. 🚀 Example: A pharmaceutical business requires a logistics partner that specializes in cold chain transportation.

Transportation & Logistics Capabilities ✔ Ensure the provider offers multimodal transport options (road, rail, air, sea). ✔ Check if they offer complete supply chain solutions, including storage, packaging, and tracking. ✔ Verify that they provide real-time shipment tracking and timely updates. 🚀 Example: A business exporting auto parts requires seamless air-sea transport services for efficient delivery.

Safety & Security Measures ✔ Make sure the provider uses trained professionals and state-of-the-art handling equipment. ✔ Confirm they follow strict safety protocols, especially for fragile or hazardous goods. ✔ Ensure they offer cargo insurance for added protection. 🚀 Example: A company shipping fragile glassware requires special packaging and careful handling.

Warehousing & Storage Solutions ✔ Choose a provider with secure, strategically located warehouses for easy access. ✔ Check if they offer inventory management and automated storage solutions. ✔ Ensure they have temperature-controlled storage for perishables. 🚀 Example: An e-commerce business needs reliable warehousing and order fulfillment centers for quick dispatch.

Customs Clearance & Regulatory Compliance ✔ Look for a provider with expertise in customs brokerage to ensure smooth import and export operations. ✔ Verify they have experience with Free Trade Agreements (FTAs) and duty exemptions. ✔ Ensure they are registered with ICEGATE for digital customs processing. 🚀 Example: An electronics importer requires a customs broker to manage taxes, certifications, and documentation.

Cost & Pricing Transparency ✔ Compare service rates and shipping costs from different providers. ✔ Look for flexible pricing options, such as pay-per-use, long-term contracts, or bulk discounts. ✔ Make sure there are no hidden charges for storage, handling, or customs clearance. 🚀 Example: A small apparel business might benefit from consolidated cargo services to minimize shipping costs.

Technology & Tracking Capabilities ✔ Ensure the provider offers real-time tracking of shipments via GPS. ✔ Look for automated logistics management systems to streamline operations. ✔ Choose providers that use AI for route optimization and improved efficiency. 🚀 Example: A business shipping high-value goods requires continuous monitoring for security purposes.

Top Cargo Handling Service Providers in India Here are some of the top-rated cargo handling companies in India offering comprehensive logistics solutions:

Everfast Freight Pvt. Ltd. 🚀 Specialization: Multimodal Cargo Handling & Logistics ✅ Bulk shipping, freight consolidation, and transport via air, sea, road, and rail. ✅ Real-time tracking, security, and customs clearance services.

Verfast Freight Forwarders Pvt. Ltd. 📦 Specialization: End-to-End Freight & Cargo Services ✅ Containerized and bulk cargo handling, cold chain logistics, and import-export solutions.

Blue Dart Express ✈ Specialization: Express Cargo & Air Freight ✅ Fast, secure cargo transport for domestic and international shipments. ✅ Specializes in e-commerce and retail logistics.

Gati Ltd. 🚛 Specialization: Road & Rail Cargo Handling ✅ Timely cargo services, warehousing, and distribution solutions. ✅ Surface express logistics to ensure prompt delivery.

DHL Global Forwarding 🌍 Specialization: International Freight & Customs Brokerage ✅ Air and ocean freight, cargo consolidation, and multimodal transport. ✅ Expertise in trade compliance and FTA assistance.

Industries That Benefit from Cargo Handling Services Cargo handling services are crucial for businesses across various sectors: ✅ Manufacturing & Industrial Goods – Handling heavy, bulk cargo shipments. ✅ E-Commerce & Retail – Efficient last-mile delivery and order fulfillment. ✅ Pharmaceuticals & Healthcare – Temperature-controlled logistics for sensitive items. ✅ Automotive & Spare Parts – Streamlined supply chain and efficient delivery systems. ✅ Food & Beverage – Transport and storage for perishable items.

Why Choose Everfast Freight Pvt. Ltd.? 📌 Why Partner with Everfast Freight Pvt. Ltd.? ✔ Customizable cargo handling solutions based on your specific business needs. ✔ Comprehensive freight services including air, sea, road, and rail transport. ✔ Advanced AI-powered tracking for real-time updates and enhanced security. ✔ Competitive and transparent pricing for businesses of all sizes.

Conclusion Selecting the right Cargo handling Services in India is crucial for the smooth running of your business’s logistics, cost optimization, and on-time deliveries. Focus on key factors such as industry expertise, transportation capabilities, safety measures, and transparent pricing when choosing a logistics partner.

By partnering with a reliable provider like Everfast Freight Pvt. Ltd., you can ensure efficient cargo handling, secure deliveries, and a streamlined supply chain.

🚀 Looking for a trusted logistics partner? Get in touch with Everfast Freight Pvt. Ltd. today!

1 note

·

View note

Text

Isothermal Bags & Containers Market to Surpass US$ 1.4 Bn by 2032

The global isothermal bags & containers market is witnessing substantial growth, driven by the rise in perishable food consumption and the ongoing development in pharmaceuticals. Valued at US$ 913.7 Mn in 2023, the market is projected to expand at a CAGR of 5.1% from 2024 to 2032, ultimately reaching approximately US$ 1.4 Bn by 2032.

Understanding the Market Dynamics

Isothermal bags and containers are indispensable solutions for maintaining the required temperature of sensitive products during transportation. Their ability to preserve a stable internal environment makes them crucial in industries such as food & beverage, pharmaceuticals, healthcare, and biotechnology.

These bags are typically made of aluminum and plastic-based insulation materials, enabling them to control temperatures ranging from -80°C to +25°C for 2 to 6 days. Such insulation is vital for preserving product integrity across cold chain logistics.

Key Drivers of Market Growth

1. Demand for Perishable Food Products: The increasing preference for fresh, ready-to-eat, and frozen food is a core driver of this market. As food delivery platforms and QSRs (Quick Service Restaurants) expand, so does the requirement for insulated bags that can keep food at ideal temperatures. The surge in food delivery in Tier 2 and Tier 3 cities post-pandemic has further amplified this demand.

2. Pharmaceutical and Healthcare Expansion: The pharmaceutical sector’s dependency on temperature-sensitive drugs, vaccines, and biological samples underscores the critical role of isothermal bags. Any variation in temperature during transport can render these items ineffective, making robust thermal packaging a non-negotiable requirement.

3. Clinical Trials and Drug Development: The growth in global clinical trials and biotech advancements has introduced more temperature-sensitive products into the logistics chain. These trends necessitate secure, insulated transport systems like isothermal containers to safeguard product efficacy.

Corporate Strategies Shaping the Market

Industry leaders are increasingly adopting strategic acquisitions, R&D investments, and digital training initiatives to gain a competitive edge. Noteworthy developments include:

Regional Trends and Growth Insights

North America led the global market in 2023 and is expected to maintain dominance throughout the forecast period, with a CAGR of 4.3%. The region benefits from:

Key regional projects, such as Cascades’ facility in Tacoma, Washington, demonstrate continued interest and investment in isothermal packaging capabilities.

Segmentation Overview

These segmentation layers reveal where demand is strongest and help manufacturers align their product development and marketing efforts accordingly.

Leading Companies in the Market

The market features a competitive landscape with top-tier players including:

These companies are actively shaping the market through innovation, sustainability, and global expansion strategies. Partnerships and acquisitions remain a popular route to consolidate their presence across diverse applications and geographies.

Future Outlook

The isothermal bags & containers market is set for sustained growth over the next decade. The fusion of technological innovation, expanding end-use sectors, and a growing emphasis on supply chain reliability will continue to define the market trajectory.

Manufacturers are expected to explore eco-friendly materials, smart temperature monitoring systems, and AI-enabled logistics management to future-proof their offerings.

In conclusion, as industries increasingly require safe, effective, and reliable temperature-controlled solutions, isothermal packaging will remain a cornerstone of cold chain logistics well into 2032.

0 notes

Text

POF Shrink Wrapping in the UAE: Eco-Friendly Solutions for Every Industry

In today’s competitive packaging landscape, businesses in the UAE are increasingly turning to materials that combine performance, visual appeal, and sustainability. One standout solution is POF shrink film—a high-quality packaging material that supports diverse industry needs while aligning with eco-conscious practices. This article explores the key applications, benefits, and availability of POF shrink film and shrink wrapping machines in the UAE.

What is POF Shrink Film?

POF shrink film is a durable, clear, and eco-friendly packaging material that shrinks tightly around products when heat is applied. It is non-toxic, recyclable, and approved for food contact, making it ideal for businesses seeking both functionality and sustainability.

Common Applications of POF Shrink Film

POF shrink film is used across a wide range of industries, including:

Food and Beverage Packaging: Maintains hygiene, protects contents, and bundles multipacks.

Cosmetics and Personal Care: Enhances visual appeal and provides tamper-evident sealing.

Pharmaceutical Packaging: Ensures product safety and cleanliness.

Electronics Packaging: Shields items from moisture, dust, and static.

Printing and Publishing: Safeguards books and printed materials during transport and storage.