#Tissue Paper Embosser Machine Market

Explore tagged Tumblr posts

Text

Inside LRI: From Production to Packaging of Consumer Goods

Factories aren’t glamorous. Not usually. They’re noisy, practical, and a bit chaotic if you walk in unannounced. But if you stop to really look—to pay attention to the process—you start to see something else. A rhythm. A kind of coordination that, when it works well, feels almost like choreography.

That’s what I feel every time I step into LRI.

LRI is one of LELEADER GROUP’s consumer goods divisions based in Benin. The full name? Leleader Resources Industries. But internally, we just call it LRI. It’s where a big part of our local manufacturing capacity lives—soap, bottled water, tissue paper, packaged condiments, and more.

I’ll be honest—when we first launched this operation, we didn’t know exactly how fast it would grow. Manufacturing isn’t easy in West Africa. Access to quality machinery, consistent electricity, raw materials, skilled labor—it all comes with its own set of challenges. And we’ve faced them all.

But we started anyway. Because we believed in the idea that locally made goods could match—or even exceed—the quality of imports. And that if we did it right, we’d not only serve a growing consumer market but also build something that created jobs, sparked pride, and stayed rooted in Benin.

So, how does it all work inside LRI?

Production starts early. Teams arrive before 7 a.m., gear up, review safety protocols, and check their machines. Whether it’s batching soap or filling sachets of water, every process has its own checks, balances, and tempo.

Take our tissue paper line, for example. It begins with large rolls—imported pulp, carefully sourced—fed into converting machines that cut, emboss, and roll the sheets into consumer-ready formats. From there, a second team takes over for quality control. Does the packaging seal properly? Are the sheets consistent? Is the branding aligned?

At full capacity, we process over 20,000 packs per day.

That might sound like a lot—and it is—but every one of those packs is destined for a local shelf. A market stall. A rural shop. A school. A small restaurant. And knowing that gives the work meaning.

There’s a constant push for balance. We want to automate where it makes sense—but we also want to employ people. So our model is hybrid. Machines for consistency, humans for precision and adaptability. I still believe no algorithm can replace the instincts of an experienced production worker who knows when a batch just doesn’t “feel” right.

One of our packaging leads, Thérèse, has been with us from the start. She doesn’t use many fancy words. But she can spot a defective seal before the machine even finishes the job. That kind of expertise? You can’t train it overnight. It comes from care.

And care matters.

Because consumer goods aren’t just products—they’re part of daily life. If we get it wrong, someone notices. If we get it right, they trust us again tomorrow.

We’ve also invested heavily in local sourcing where possible. Palm oil from within Benin. Water purification inputs from regional suppliers. It’s not always the cheapest route—but it creates ripple effects. When one factory buys local, it supports farmers, transporters, small service providers. It builds an ecosystem.

Now, I won’t pretend everything is smooth. We’ve had delays. Machinery breakdowns. Packaging misprints. Once, a full shipment of labels arrived in the wrong language. Mistakes happen. But we own them, fix them, and move forward. That’s just part of running a real operation.

This year, as we prepare to join the 2025 Go Global Awards in London—hosted by the International Trade Council—we’re taking stories like these with us. Not because they’re perfect, but because they’re honest. Because they show that even in a tough environment, with limited resources, real manufacturing can thrive.

The Go Global Awards aren’t just about winning. They’re about being seen. Being heard. Sharing lessons, failures, successes. We’re proud that LELEADER GROUP, from Benin, is among the nominees. And we’re looking forward to connecting with others who know what it’s like to build from the ground up.

Inside LRI, there’s still plenty of work to do. More lines to optimize. New products to launch. Better systems to adopt. But the foundation is there. And every day, I see the people who are making it stronger.

If you’ve never visited a factory in West Africa, I’d encourage you to try. You might not find glossy brochures or perfectly staged photos—but you’ll find real people, real progress, and real ambition.

That’s the story we’re telling. One batch, one box, one customer at a time.

#LELEADERGroup #MadeInBenin #ManufacturingAfrica #ConsumerGoods #LocalProduction #LRI #GoGlobalAwards2025 #FactoryLife #BusinessFromBenin #SustainableSupplyChains

1 note

·

View note

Text

0 notes

Text

Tissue Paper Packaging Machines Market Set to Reach USD 433.7 Million by 2032

Tissue paper products such as toilet paper, facial tissues, and paper towels play an essential role in maintaining personal hygiene and cleanliness. Tissue paper packaging machines are instrumental in the efficient production and packaging of these essential products, ensuring quality, consistency, and cost-effectiveness in manufacturing operations. The global tissue paper packaging machines market, valued at US$ 273.8 million in 2023, is estimated to grow at a robust CAGR of 5.2% from 2024 to 2032, reaching a valuation of US$ 433.7 million by the end of 2032.

Market Overview:

Tissue paper packaging machines are designed to handle various aspects of tissue paper production and packaging, including cutting, folding, embossing, and wrapping. These machines are used by tissue paper manufacturers to automate and streamline their production processes, increasing efficiency, reducing labor costs, and ensuring product quality and consistency. With the growing demand for tissue paper products driven by factors such as population growth, urbanization, and increasing awareness of personal hygiene, the tissue paper packaging machines market is witnessing significant growth worldwide.

Request Sample Copy of Market Research Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=38441

Market Size and Growth:

The global tissue paper packaging machines market is experiencing robust growth, fueled by factors such as the expanding tissue paper industry, technological advancements in packaging machinery, and increasing demand for hygiene products. As consumers prioritize cleanliness and sanitation, the demand for tissue paper products is expected to continue rising, driving investments in production and packaging infrastructure. Moreover, the adoption of eco-friendly packaging materials and sustainable manufacturing practices is further driving market growth.

Market Segmentation:

The global tissue paper packaging machines market can be segmented based on various factors, including machine type, operation type, technology type, end-user, and region.

Regional Analysis:

Geographically, Asia Pacific is expected to dominate the global tissue paper packaging machines market, driven by the presence of major tissue paper manufacturing hubs in countries such as China, India, and Indonesia. The region’s rapid economic growth, expanding population, and increasing hygiene awareness are fueling market growth. Moreover, North America and Europe are witnessing steady demand for tissue paper packaging machines, supported by established tissue paper industries and stringent hygiene standards. Additionally, Latin America and the Middle East & Africa are emerging as lucrative markets for tissue paper packaging machines, driven by urbanization, changing consumer lifestyles, and investments in hygiene infrastructure.

Market Drivers and Challenges:

Key drivers influencing the growth of the global tissue paper packaging machines market include:

However, the market also faces challenges such as high initial investment costs, complex regulatory requirements, and competition from alternative packaging formats.

Market Trends:

Several trends are shaping the future of the global tissue paper packaging machines market, including:

Future Outlook:

With the increasing emphasis on personal hygiene, sanitation, and sustainability, the global tissue paper packaging machines market is poised for significant growth in the coming years. As tissue paper manufacturers invest in expanding production capacities, improving operational efficiency, and meeting evolving consumer demands, the demand for advanced packaging machinery is expected to remain strong, presenting opportunities for market players.

About Us Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. The firm scrutinizes factors shaping the dynamics of demand in various markets. The insights and perspectives on the markets evaluate opportunities in various segments. The opportunities in the segments based on source, application, demographics, sales channel, and end-use are analysed, which will determine growth in the markets over the next decade.

Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers, made possible by experienced teams of Analysts, Researchers, and Consultants. The proprietary data sources and various tools & techniques we use always reflect the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in all of its business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

0 notes

Text

Guidelines Required for Tissue Paper Manufacturing:

With increasing awareness among people about hygiene and cleaning the demand for the tissue paper has been increasing. These products are widely used in homes, hospitals, hotels, restaurants, and beauty parlours, among other places. The tissue paper industry has a large market potential due to its high consumption rate.

Tissue paper manufacturing entails producing end products such as tissue rolls, wipes, napkins, and paper towels from the initial raw material known as Jumbo tissue rolls made from virgin wood pulp or recycled paper. These large paper rolls were eventually cut into various types of tissue paper using specialized equipment and sold in the market.

The above two different types of tissue paper can be summarized as follows: –

Consumer Tissue Papers: Simply put, consumer tissue papers are those that are primarily used at home. In other words, consumer tissue papers are utilized in the home.

Industrial Tissue Papers: Another name for commercial tissue paper is industrial tissue paper. These are primarily used for napkins, facial tissues, paper towels, and toilet paper. As a result, these are used in places such as hotels, parties, homes, restaurants, offices, and beauty salons.

Market Research:

Thorough market research is critical to the success of any business. It provides critical insights for your business and gives you an idea of how to operate the unit, how much investment is required, and how well your products can be marketed, and what marketing channels can be planned at this stage, among other things.

Sourcing of raw material

The procurement of raw materials is one of the most important tasks in the tissue paper manufacturing industry. Plants used in production are large in size and thus relatively expensive. Consumers prefer high-quality products, but if raw material prices are high, finished product prices will be high as well. As a result, finding low-cost high-quality products is critical.

Machinery and Equipment:

The machinery and equipment needed are entirely dependent on the volume of business you intend to conduct. Band saw cutter, core making machine, cutting machine, winding machine, perforating machine, and embossing machine are examples of machinery. You can choose the appropriate machine once you have the product’s or products’ precise blueprint.

Once you have the finished product, you must figure out how to sell it and turn it into money. For more assistance, contact Ultracare as they are best paper tissue manufacturers & tissue paper exporters in UAE!

#tissue paper dealers#toilet paper wholesale suppliers#toilet paper manufacturers#toilet tissue manufacturers#toilet paper suppliers#toilet paper manufacturer#tissue paper exporters#jumbo roll toilet paper wholesale

0 notes

Text

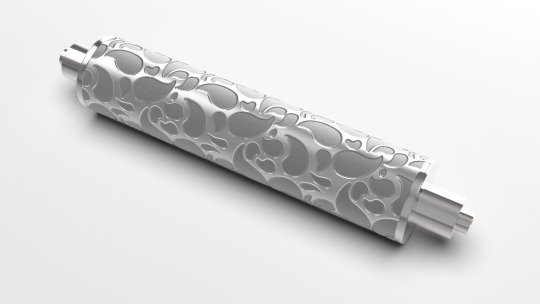

Embossing Roller Manufacturer in Ahmedabad, Gujarat, India

Embossing Rollers are used to engrave patterns on any surface. The ability to deliver custom development services is a valuable skill set in the embossing roller manufacturing market.

Anar Rub Tech Pvt. Ltd has been an expert in the embossing roller manufacturer for the past three decades. We provide wear-resistant embossing roller. Our roller are known for their high-quality steel and its extreme hardness and depth. The products are machined and engraved with complete precision. We provide distinguished and exclusive products that will make your company and brand stand out.

The roller are embossing roller manufactured at Anar Rub Tech Pvt. Ltd facility, India with the sophisticated Digilaser technology. The best of materials, latest techniques, skilled manpower, supplemented by strict quality control and prompt delivery schedules all go in to create products that serve our customers' specific requirements. These roller find extensive use in engraving on PVC Leather Cloth, PU Leather, PVC Sheet, tissue paper, figure glass, PP, PE sheets, wallpaper, and floorings.

#embossingroller#indiamart#embossingrollermanufacturer#embossingrollermanufacturers#embossingroll#embossingrollmachine#manufacturer#supplier

1 note

·

View note

Text

How to buy your first disposable diaper machine.

Every disposable diaper manufacturer knows that the most difficult machine to buy is always the first one. Based on their earned experience with this first machine, diaper manufacturers become more knowledgeable and more cautious when buying their second or third machine. If only this level of knowledge was available to them from the beginning, they would have saved tens of thousands and in many cases even hundreds of thousands of dollars.

Make sure you ask for the same exact items or the same diaper machine modules from all potential vendors; make sure each machine module is really equivalent in terms of the technology and process control; the acceptable performance for your equipment has to be well defined as part of the purchasing contract. It is easy to promise, some vendors do whatever it takes to try to close a deal, but to deliver against a well-defined contract is something else, few will take the risk. It is always better to visit an actual factory running the equipment instead of just visiting the equipment manufacturer. Of course, this is not always possible, but at least try.

Make sure you have enough money left after the purchase of the machine to use for working capital. Keep in mind that the baby diaper machine and the building are probably just half of the total investment you will need to operate your new business, that is unless you already have excellent credit ratings to use for working capital. Starting up a new diaper factory without money in your pocket is the very worst thing you can do.

Processing wood into tissue paper is a complex technological procedure. However, using complex machines to transform big jumbo reels of tissue paper into the form of high-quality napkins or toilet tissue is real high tech. The tissue paper machines perform many work steps to manufacture the finished product. They unwind, print, emboss, rewind, fold, cut, wrap and bundle within seconds and fully automatically.

According to a specific application inside a market segment, the hygienic tissue paper products are manufactured to meet the desired performance. The most important properties used to evaluate the performance of tissue products are - softness, water absorbency, disintegration, and strength (dry or wet). A vast number of fiber types, chemical additives, sanitary machine technologies are available in the market for the manufacturing of tissue products. The right combination of additives, fibers, additives, and technologies have to be chosen by the tissue paper manufacturers to produce specific tissue products capable of achieving the desired performance while providing enough profitability to the producer. Paper products can be placed in three main categories, based on their function.

Even if you’re fully vaccinated, you’ll likely run into situations in which masks are strongly recommended, if not required. Which means unfortunately we’ll all need to have some masks on hand. While not as sustainable as reusable cloth masks, disposable masks are also a good option — especially if you find the right ones.

The very best disposable face masks, of course, are KN95 masks — the gold-standard pandemic masks, approved by the National Institute for Occupational Safety and Health (NIOSH), which filter out 95 percent of airborne particles. These are closely followed by the disposable surgical masks worn by doctors and other health-care professionals, which are cleared by the FDA as meeting certain standards.

Early in the pandemic, the CDC did not recommend that the public buy these masks in order to ensure a steady supply for health-care workers, but those restrictions have relaxed slightly now that such masks are more regularly available. So while it’s still not a good idea to hoard KN95 or medical masks, you can feel better keeping one or two around for especially high-risk occasions, like a plane ride or spending a long period of time in a crowded enclosed space. Our mask making machine is sold well in the world market and worth recommendation for its excellent quality and reasonable price.

0 notes

Text

Environment-Friendly Toilet Paper Roll

Toilet paper rolls are an absolute necessity in all restrooms and washrooms! You might not be able or even want to use the restroom if you don't have a proper toilet paper roll.

The Emergence of Modern Toilet Paper

Despite the fact that toilet paper was invented at the end of the 14th century, it was not mass-produced until the late 19th century.

Joseph Gayetty created his own aloe-infused hemp toilet paper line in 1857. The concept impressed Gayetty so much that he printed his last name on any sheet! Unfortunately, most Americans preferred to wipe with pages from the - free – Sears Roebuck catalog, thus only a small percentage of the population purchased his toilet paper.

Two brothers, Clarence and Irvin Scott, then began producing toilet paper around 1890 on a roll. In the 1930s retailers started selling roller packs of toilet paper, and Charmin started marketing roller toilet paper.

Americans had become completely reliant on toilet paper by 1970, yet toilet paper invention was far from finished. As we progressed into the twenty-first century, we began to notice the emergence of environmentally-friendly toilet paper options. Reel Paper, in particular, has revolutionized the toilet paper industry by providing soft, environmentally friendly bamboo toilet paper.

What are the advantages of using eco-friendly toilet paper?

Let's take a look at why you should convert from ordinary toilet paper to sustainable toilet paper before we get into the finest eco-friendly toilet paper on the market.

The majority of conventional toilet paper is created from virgin softwood pulp supplied straight from the forests' trees.

When you consider that the average American uses around 140 rolls of toilet paper per year, the number of trees cut down and the energy consumed to make their reveals we have a problem!

Trees not only supply the oxygen that humans breathe but defend our globe against climate change as well.

Not only are trees to be concerned, but there is also a threat to the existence of other creatures in the numerous ecosystems that are lost. The influence on the land of indigenous peoples is equally harmful.

37 liters of water and 1,3 kWh of power are used to make one roll of toilet paper. We should be very cautious about the toxin in the chlorine used for paper pulp production!

These causes have led us to this point; we are dedicated to eliminating waste, from bamboo toothbrushes to environmentally friendly toilet paper. So let's discover the best environmentally-friendly toilet paper without further ado!

The Choice Of Toilet Paper

You should also know the product to be cleaned properly, as you have learned how to use toiletries. But that could be hard as numerous companies sell toilet paper in different ways.

Here are the characteristics of fine toilet paper.

Free of Toxic Chemicals

To make their toilet paperwhite, most companies utilize chlorine. These goods produce chemicals that are detrimental to the health and the environment after being used. Fortunately, some brands sell chlorine-free toilet paper; choose one of these products.

Made From Eco-Friendly Paper

Use toilet paper made from recycled stationary or trees harvested from tree farms. At the end of the day, you'll be helping to save the ecosystem and older forests' trees.

Convenient to Use

A decent toilet paper is soft and pleasant. It should also not leave any lint, especially after wiping you behind.

Strong

A clean-up consists of fluids that can break up poor toilet paper. However, if you choose a long-lasting product, you won't have to worry about smearing your fingertips.

Simple to Flush

As previously said, you should use high-quality toilet paper that can withstand dampness. It should, however, be able to pass through the pipes without becoming clogged.

What is the Composition of Toilet Paper?

Although toilet paper is a common home item, how many of us have ever wondered what our favorite brand is made up of? To know exactly what we use in our most sensitive areas enables us to decide actively and informedly rather than merely to take whatever brand is on sale.

As with most paper products, traditional toilet paper comes from trees. Indeed, in 1930 the first-ever guaranteed splinter-free toilet paper was announced by a business called Northern Tissue!

Thankfully, modern toilet paper produced by Toilet Paper Rolls Manufacturer in UAE is splinter-free and created from one of two types of pulp: virgin or recycled.

To produce toilet paper, the virgin pulp is harvested directly from a tree. Recycled pulp, on the other hand, is derived from previously used paper goods; in fact, the recycled pulp may have been used multiple times before becoming toilet paper.

There are, fortunately, other toilet paper options available. Switching to bamboo toilet paper offered by the Toilet Paper Rolls Manufacturer in UAE is one of the best things you can do for both your behind and the earth!

What is the Process of Making Toilet Paper?

Depending on whether they are making virgin or recycled toilet paper, toilet paper manufacturers use two different manufacturing procedures.

Using Virgin Pulp for Toilet Paper

Producing toilet paper from virgin pulp is a one-of-a-kind procedure. The Toilet Paper Rolls Manufacturer in UAE begins by cutting the tree, removing its bark, and chipping the wood into little pieces. The wood chips are then pressure cooked to make a pulp.

The pulp is then washed and bleached until it is colorless, mixed with water, strained, pressed, and dried to its final moisture level.

The pulp is perforated and rolled into a long paper log once it has dried. Finally, the log is split into smaller rolls and packaged for customer consumption.

Using Recycled Pulp for Toilet Paper

In contrast to the virgin pulp method, the recycled toilet paper process begins with a load of recycled paper being placed in a container filled with warm water. The water is then aerated to remove any remaining ink from the paper before bleaching and sanitizing it.

Before being embossed to strengthen, the pulp is squeezed and dried onto a large, flat surface. They pass the blend in a machine, which collects the sheets together to make a two-fold roll.

Finally, they cut the rolls using a circular saw and wrapped them for individual sale.

Paper Link is the best Toilet Paper Rolls Manufacturer in UAE, offering a diverse selection of high-quality tissue products such as facial tissue, kitchen towels, aluminum foil, toilet paper, and more!

As being a leading Tissue Paper Manufacturers in UAE, we strive to manufacture our products from high-quality raw ingredients that ensure the end-user's safety and hygiene. We are dedicated to aiding our clients by providing a diverse range of services, lucrative deals, and well-managed supply-chain capabilities. Our organization and its affiliates believe in manufacturing high-quality items while also ensuring that our clients' hygiene is taken care of.

With this level of attention and focus, we are continually acquiring the trust and confidence of our loyal consumers. As a result, our commitments have increased, motivating us to continue improving and creating products for our customers.

Our commitment to providing the finest to our customers has helped us become one of the fastest-growing Toilet Paper Rolls manufacturers in UAE's premium sectors.

0 notes

Text

MODERN WORLD OF DIGITAL PRINTING

High Quality, Color Digital Outputs with the newest in equipment & technology

Digital printing gives you cost-effective, high-quality, short-run colour printing within the tightest imaginable timeframes with all the customization you'll imagine, and adaptability to print the precise quantities of materials you would like once you need it. Business Cards | Flyers | Brochures | Postcards | Door Hangers | Pull up Banners | Roll up Banners | fair Banners | Vinyl Banner Inside | Vinyl Banners Posters | Large Format Posters | Books | Car Magnets | Pocket Folders | purchasable Signs | party Signs | T-Shirts Printing.

Digital T-Shirt Printing

• Suitable for Full colour complex designs with gradients and tones

• Ideal for a coffee order quantity

• Custom digital images or photos

• For numerous logos/designs to print per garment

• Can be processed quickly if you've got a decent deadline.

Digital t-shirt printing Dubai is employed for multi-colour artwork with complex gradients and tones and photographic imagery.

The digital printing is performed by printing the digital-based image on to a vinyl base, which is then machine cut and processed by hand to be positioned on to the garment before applying heat and pressure to transfer to the merchandise.

Transfer printing

• One-off samples for client meetings or press events

• Multicolored logos that require seeming bright and bold

• Nylon fabrics – waterproofs, umbrellas Sports, hi-vis jackets, sponsors for sports kits

Transfer printing is extremely popular and most suited to smaller orders and print runs of up to around 100 units. a way which involves heat pressing plastisol, foil, flock or CAD-cut vinyl onto garments.

Transfer printing will outlive the garment it's printed on!! Once printed the clothes are often washed at up to 40 degrees.

Business Cards

Digital Signs & Printing provides the very best quality grade of cardstock and different options, starting at 12pt up to 16pt double-sided full-color printing. Also offer embossing and foil while other options are available. Provide a hassle free and quick turnaround on small batches of business card printing and lots of different options for printing your cards in various quantities to satisfy your budget.

Door Hanger

Door Hanger design requires a special touch. Design an attractive door hanger for your business or brand promotion.

Studies show that 80% of your marketing success depends on the deal offered and therefore the distribution. That leaves 20% for copy, design, and printing.

While strong copy and compelling design appear to be a no brainer, it’s equally important to recollect that the print quality of your door hanger plays a neighbourhood in how customers view your company.

Here are some tips to stay in mind with door hanger printing:

• Stick to full-colour, double-sided custom hangers that allow you to incorporate all necessary information

• Print as many customs hangers as you'll afford to chop down on overhead.

Printed door hangers still, be an economical marketing tool that's often ignored when marketing a business, product or service. But, their rock-bottom printing costs make them a beautiful marketing prospect for cash-strapped businesses.

Local businesses like restaurants, dry cleaners, beauty salons, and convenience stores find them to be an efficient thanks to market promotions and an excellent thanks to pushing for holiday sales. Service-based businesses can advertise monthly maintenance packages and repair contracts.

Every marketing plan should find a home for them because:

• People can’t ignore them

• Versatility: small, local businesses and more massive franchises can use custom door hangers for general purposes or specific promotions

• Laser-focused geographic targeting

Printed paper bags

Printed paper bags became a standing symbol in today’s market. They provide many benefits to their users and also gain importance thanks to being 100% reusable, biodegradable, recyclable and environmentally friendly. They’re also preferred because they're neat, easy to hold, can hold many items and are used for various purposes.

Because of the rise in demand for a personalized paper bag, businesses are designing them in line with their brand as a sort of free advertisement, endorsement and brand awareness. People get to understand about you, your brand, and company and therefore the benefits and repair they will get from it.

Customizing a printed gift bag may be a highly cost-effective marketing tool that each one business got to adopt as how of selling their brand. It’s a useful and robust way of promoting businesses by providing an honest picture of your product and a high level of service to your customers. It creates a conscious bond between your business and customers.

By the top of this post, you’ll understand 3 ways in which brands can make their bags stand out for Easter promotions with printed tissue, printed ribbon and tips for an attention-grabbing design.

0 notes

Text

Embossing Machine Market Potential Growth, Attractive Valuation Make It Is A Long-Term Investment

Embossing is considered one of the highly sought after process to add a finishing touch to packaging. One of the core purposes of embossing is to add an aesthetic appeal to a product. Embossing machines are specially designed for growing or embossing the rolls for applying a coarse surface to plastic sheets paper and foils. The global market for embossing is expected to grow with the increasing trend among manufacturers and brand owners to do promotions, advertisement, and branding the image of the company symbol on various products. Embossing machines are designed to cater to specific surfaces and materials such as paper, foil, tissue, rubber, and plastic. Embossing machines are used in various ends use industries such as pharmaceutical, food & beverage, consumer goods, and others. Therefore, the outlook for the growth of the global embossing machine market is expected to be largely positive during the forecast period.

Looking for exclusive market insights from business experts? Request a Sample Report

Global Embossing machine market: Dynamics

The need for improving the aesthetic appearance of packaging for attracting more consumers and creating a unique identity among other brands is the key driver for embossing machine market. The ability of embossing machines to convert around 2500 pcs per hour is another factor supporting the growth in embossing machine market. The trend for using embossed aluminum foils, especially in luxury packaging may boost the growth in embossing machine market. Compatibility of embossing machines with aluminum, paper, and films has widened the area of application for embossing machines and significantly strengthened embossing machine market. Embossing machines are available with various customizations for suiting the application requirement of consumers. However, improved performance of printing machines may hamper the growth in embossing machines market.

For more press relaese: https://www.prnewswire.com/news-releases/lithium-ion-battery-market-to-expand-at-growth-rate-of–11-compounded-annually-from-2019-to-2027-to-reach-15-764-89-million-units-by-2027-transparency-market-research-300997555.html

0 notes

Text

Check the Details of Paper Converting Companies

Every person has different requirements and people look for the option as per the requirement. There are different requirements by the people, so whenever a person has some requirements, then he or she looks for the products as per the requirement of the situation or place. Due to the requirement from the people, there are many vendors and companies available who are offering the different types of products and services which will satisfy a person’s requirement. There are many people who are looking for the upholstery service, but what is upholstery? Thus, it is the work of providing the furniture, especially the seat with the webbing, padding, fabric, and springs or sometimes with the leather covers. If you are also looking for the upholstery service, then you can check the details of upholstery services near me, you can take the help of the internet to find the details about the upholstery service provider. If you are not able to visit their place, then you can call them at your place and discuss your specific requirements. They will provide a free estimate which will be according to material cost, fabrics, labor, and equipment that will be utilized while performing the upholstery work. Most of the companies have an online website, so it will be good to visit their website and check all the details offered by them. Upholstery is a great way to change the look of the chair, sofa, seat, and more. When the good quality material is used then you will get more comfortable. There are many different services required and due to that people look for the companies that can offer the service, if you are looking for paper converting companies then you can check it on the internet. There are companies that specialize in the design and manufacture of converting the machinery for the tissue, flexographic, and nonwovens printing industries. In the market, there are many companies that offer the converting services; there are many companies that have a custom converter who are specialized in converting the papers and films and sliding narrow width, short-run papers, and films. You can check the details about the companies on the internet. The companies are experienced and have a license, so they serve the best service due to their experience and skills. The companies have experienced professionals as well as they also have all the required equipment which is required for the paper converting work. In the paper converting industry, there are many machines used which include the embossing, renting, laminating, packaging and perforating equipment to produce the multi-ply bathroom household towels, tissues, away from home rolled and table napkins products. You can check out the range of items and the services offered by the companies. If you don't know about the companies, then you can search it on the internet, there are many companies available that offer the service in the paper industry, so you have to find the right one.

0 notes

Text

Sales Revenue of Paper Napkin Converting Lines Market to Soar in the Near Future Owing to Growing Consumer Adoption

Paper Napkin Converting Lines Market: Overview

Paper napkin is a widely used product across the globe, and its demand is continuously growing. Paper napkin converting lines help in paving the bridge between demand-supply of paper napkins. With changing lifestyle and increasing modernization, consumer base is shifting from generalized to premium products, especially when it comes to hygiene. Paper napkin converting lines helps in conversion of the large size paper rolls into rectangular and square paper napkins. The paper napkin converting lines also perform embossing, color printing, folding, and counting. Paper napkin converting lines include machines for different purposes such as paper napkin printing machines, paper napkin cutting machines and paper napkin folding machines. These paper napkins are then used as tissues, wipes or for other sanitary purposes. Due to growing popularity, many tissue paper manufacturers are investing in paper napkins production. Overall, the outlook for the paper napkin converting lines market is expected to be positive throughout the forecast period.

Request Sample of Report with important Figures @ https://www.futuremarketinsights.com/reports/sample/rep-gb-8536

Paper Napkin Converting Lines Market: Dynamics

The major portion of the global population is shifted from poverty to the middle class. The rising awareness among people regarding health and hygiene coupled with increasing disposable income is expected to boost the demand for paper napkins and other hygiene products. These factors are supposed to fuel the demand for paper napkin converting lines during the forecast period. Shifting of tissue paper manufacturers towards the production of paper napkins also fuels the market growth shortly. The throughput of paper napkin converting lines is monitored with the help of an electronic counter. This feature eases the production process of paper napkins for the manufacturers. Also, the printing unit in paper napkin converting lines is equipped with back and forth adjustment, automatically adjustable resolution, and other features. These factors are expected to drive the global paper napkin converting lines market during the forecast period during the next decade. The growing initiatives by schools, government, and non-government organizations regarding health and hygiene helps in the rising demand of paper napkins, which in turn fuels the demand for paper napkin converting lines during the forecast period. Paper napkin converting lines produced paper napkins with varying speeds ranging from 250 to 800 sheets per minute. The paper napkin converting lines market is expected to witness favorable growth prospects during the forecast period.

Paper Napkin Converting Lines Market: Segmentation

Globally, the paper napkin converting lines market has been segmented on the basis of product type, speed and region:

On the basis of product type, the global paper napkin converting lines market has been segmented as:

Semi-automatic & Automatic

Request Report for Table of Contents @ https://www.futuremarketinsights.com/toc/rep-gb-8536

On the basis of speed, the global paper napkin converting lines market has been segmented as:

150 to 250 sheets/min,250 to 500 sheets/min,500 to 750 sheets/min,750 sheets/min & above

Regional Outlook

In APEJ region, China is supposed to be the leading market for paper napkin converting lines. It is attributed to the fact that China is specialized in the production of low-cost paper napkin converting lines in the global marketplace. China is followed by the U.S., where the consumption of paper napkin is extensively high. European countries including the U.K., France, and Germany are expected to be the key consumers of paper napkin converting lines. It is attributed to the high living standards and high disposable income of the people who invests more on hygiene products. The countries are expected to witness above-average growth rate in the paper napkin converting lines market. Japan is expected to witness stagnant growth rate in the paper napkin converting lines market due to the availability of various manufacturers in the country.

Paper Napkin Converting Lines Market: Key Players

Some of the leading players operating in the global paper napkin converting lines market are:

Jiuhyan Precision Machinery Co., Ltd.,Gambini S.p.A.,Kuo's Gang Precision Machinery,Birla Hi Tech Machines,Foshan Nanhai Dechangyu Paper Machinery Manufacturing Co., Ltd.,Foshan Baosuo Machinery Manufacturing Co., Ltd.

Request to Report Methodology @ https://www.futuremarketinsights.com/askus/rep-gb-8536

0 notes

Text

Full Range of Non woven Wipes

yes, it is value to read this blog: here we will show you the full range of the non woven dry wipes and how to buy the quality non woven wipes from china manufacturer.

WIPES TYPES

Wipes can be a paper, tissue or nonwoven. Here we talk about non woven Wipes.

Also, for the globe demand of wipes: wet wipes is about 70% and dry wipes is 30%.Because personal care wipes used more for other functional wipes. You can also use the non woven dry wipes in these industries: Foodservice, Building care, Industrial, Healthcare, Automotive and Aerospace etc.

The non woven wipes are clean, fresh and can be precut to convenient sizes and shapes, it mainly packed by 2 ways: Polybag or Roll like this.

For the polybag packed, the fabric usually flat or folded(1/2,1/4,1/8,C, Z folded etc).

You can use printing polybag or put a printing paper card to private label your wipes.

Sometime you can also packed by the paper card on the head to wholesale your wipes.

For the roll, it usually perforated so that you can tear easy sheet by sheet.You can choose with or without core.

SPUNLACE WIPES

Spunlace Fabric is the most suitable fabric material for wipes, you can check to read this blog to learn more about spunlace non woven fabric. From the report, nearly half of the wipes are made by spunlace non woven material.

As spunlace is made by viscose,polyester,microfiber, cotton, bamboo fiber etc. The soft hand feeling made the spunlace fabric is the most suitable for wipes. Almost all the wet wipes is made by spunlace material, but also the dry wipes can mainly made by spunlace.

A white soft spunlace wipes is good used as Beauty towel and hospital wipes.

Also,with the printing on line and embossing cylinders, spunlace wipes have a lot of different patterns:

Only 35 patterns? In fact, spunlace have far more than hundreds of embossing and popular printing. Do you find your loving pattern?If not no problem, contact us for more photo options. You can also design a pattern as well.

You can not always ignore the woodpulp spunlace for wiping cloths, as many famous company such as Dupont Brand – Sontara, Kimberly Clark Brand -WYPALL , SCA brand – Tork etc. The high quality woodpulp non woven wipes is good for industrial wipes. The important specification for woodpulp wipes is Low Linting or even linting free.

The woodpulp spunlace also have various of the printing and embossing (also sometime creped).Even sometimes the price is cheaper so it can be another option for your wipes.

CHEMICAL BOND WIPES

Wiping cloths made by chemical bonded non woven fabric, it is a light weight, disposable cloth which good for cleaning surfaces.

The Wipes is thin and economical. Popular used in UK, Ireland and some other Europe countries. Available in rolls(popular in twin rolls) and quarter fold formats.

PP NON WOVEN WIPES

Wiping Cloths can also made by spunbond, melt-blown etc PP non woven fabric. Such as PP spunbond non woven fabric with soft version is very good for floor wipes. The heavy weight meltblown polypropolyne material can absorbs oil, grease, inks, solvents and chemicals, it is good DEGREASING WIPES. The PP wipes is suitable to wiping machine, hard surfaces working etc.

NEEDLE PUNCHED WIPES

Wipes made by needle punched non woven fabric is thick and good absorbent.

It is an ideal cloths for household.

Available in folded cloth and wiping rolls.

NON WOVEN WIPES MANUFACTURERS IN CHINA

According to reports, China represents more than 33% of the world’s spunlace production, growing more than 33% between 2008 and 2009, and even now the output is still in growing.

China local consumer market do not use the wipes in big quantity, most of the China produced wipes are exported, the price is very competitive.

When you import the wipes from China, we have 3 tips for you:

1) Wipes manufacturers are mostly local in Zhejiang Province,several local in Shangdong, Guangdong and Shanghai. If you buy from other province you must be imported from a trading company.

2) If you want to have a better price, it is good to buy from a non woven material manufacturer who has own converting workshop. Then you can get the best price.

3)Take care of your quality, if you received your wipes which is lower weight, wrong composition, weak package etc, then your supplier is not a trust company and you’d better to change another supplier.

To import your wipes from China is a wise option. You can work with us for your wipes business and we can not only provide you the competitive prices but we manage your quality, you can get a lot of help with your import wipes.

0 notes

Text

Tissue Paper Packaging Machines Market Set to Reach US$ 433.7 Million by 2032

Tissue paper products such as toilet paper, facial tissues, and paper towels play an essential role in maintaining personal hygiene and cleanliness. Tissue paper packaging machines are instrumental in the efficient production and packaging of these essential products, ensuring quality, consistency, and cost-effectiveness in manufacturing operations. The global tissue paper packaging machines market, valued at US$ 273.8 million in 2023, is estimated to grow at a robust CAGR of 5.2% from 2024 to 2032, reaching a valuation of US$ 433.7 million by the end of 2032.

Market Overview:

Tissue paper packaging machines are designed to handle various aspects of tissue paper production and packaging, including cutting, folding, embossing, and wrapping. These machines are used by tissue paper manufacturers to automate and streamline their production processes, increasing efficiency, reducing labor costs, and ensuring product quality and consistency. With the growing demand for tissue paper products driven by factors such as population growth, urbanization, and increasing awareness of personal hygiene, the tissue paper packaging machines market is witnessing significant growth worldwide.

Request Sample Copy of Market Research Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=38441

Market Size and Growth:

The global tissue paper packaging machines market is experiencing robust growth, fueled by factors such as the expanding tissue paper industry, technological advancements in packaging machinery, and increasing demand for hygiene products. As consumers prioritize cleanliness and sanitation, the demand for tissue paper products is expected to continue rising, driving investments in production and packaging infrastructure. Moreover, the adoption of eco-friendly packaging materials and sustainable manufacturing practices is further driving market growth.

Market Segmentation:

The global tissue paper packaging machines market can be segmented based on various factors, including machine type, operation type, technology type, end-user, and region.

Regional Analysis:

Geographically, Asia Pacific is expected to dominate the global tissue paper packaging machines market, driven by the presence of major tissue paper manufacturing hubs in countries such as China, India, and Indonesia. The region’s rapid economic growth, expanding population, and increasing hygiene awareness are fueling market growth. Moreover, North America and Europe are witnessing steady demand for tissue paper packaging machines, supported by established tissue paper industries and stringent hygiene standards. Additionally, Latin America and the Middle East & Africa are emerging as lucrative markets for tissue paper packaging machines, driven by urbanization, changing consumer lifestyles, and investments in hygiene infrastructure.

Market Drivers and Challenges:

Key drivers influencing the growth of the global tissue paper packaging machines market include:

However, the market also faces challenges such as high initial investment costs, complex regulatory requirements, and competition from alternative packaging formats.

Market Trends:

Several trends are shaping the future of the global tissue paper packaging machines market, including:

Future Outlook:

With the increasing emphasis on personal hygiene, sanitation, and sustainability, the global tissue paper packaging machines market is poised for significant growth in the coming years. As tissue paper manufacturers invest in expanding production capacities, improving operational efficiency, and meeting evolving consumer demands, the demand for advanced packaging machinery is expected to remain strong, presenting opportunities for market players.

About Us Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. The firm scrutinizes factors shaping the dynamics of demand in various markets. The insights and perspectives on the markets evaluate opportunities in various segments. The opportunities in the segments based on source, application, demographics, sales channel, and end-use are analysed, which will determine growth in the markets over the next decade.

Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers, made possible by experienced teams of Analysts, Researchers, and Consultants. The proprietary data sources and various tools & techniques we use always reflect the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in all of its business reports.

Contact:

Transparency Market Research Inc.

Advertisement

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

0 notes

Text

Best 15 Paper Business Ideas - Low Cost Small Manufacturing Business

Today I am going to present a list of 15 exciting paper business ideas. If you are really interested to work with recyclable material like paper and willing to start your career with it, then these opportunities will definitely lead you to gain financial stability as well as establish you as a green entrepreneur. Actually the paper industry in the world is booming and so as the employment opportunities for the local population. The industry is not restricted to produce newsprint only; diversified products like paper bags, paper cups and plates, handmade paper boxes, albums and diaries are manufactured and exported all over the world. Do you want to invest in paper products manufacturing businesses? Government has made it easier for individuals to operate on a small-scale basis as either sole proprietors or joint ventures. This is a contemporary economic trend in the nation because of its viability, productivity, and usability.

Due to much utility of paper products as domestically and commercially essential commodity, there is a great demand for these products. Some of the products you can get from paper production are packaging boxes or cartons, paper jewelries, paper bags, paper cups, exercise books, paper plates, invitation cards, tissue papers, face wipes, envelops, files,and more.

1. Paper bag making business

The disposable nature of paper bags has made them essential and much demanded packaging materials in the market. Traders and vendors prefer to use them in packaging their goods for sales, due to the ban on plastic bags in various countries. The manufacturing of these bags involves the application of simple technological processes. Some of the machines you can use are paper bag making machine, stereo press, stereo grinder, rolls slitter motorized machine, eye letting machine, bag cutting machine, and scale or testing instrument. Moreover, the fuel consumption is minimal and the water utilization is moderate. Learn More About: Paper bag making business

2. Paper jewelry making

You can also use papers to make jewelries using your fine skills. Some of the jewelries you can make with paper are necklaces, bracelets, brooches, and bangles. The raw materials you need to make these products are tissue papers or other recycled paper stripes, a needle-like tool, glue, acrylic paints and other basic jewelry making material. You can create a good livelihood by selling these paper jewelries. Learn More About: Paper jewelry making Business

3. Paper cup making business

Are you ready to make extra income with your talent and abilities? Paper cup making business is an opportunity for you to realize your dreams. The cup is a disposable item made with plastic linings to prevent the liquid from leaking out. You can use the PE coated paper roll for this production. Learn More About: Paper cup making business 4. Envelop making business: Envelopes are needed in offices, academic institutions, and even in the homes. You can run this business as a sole proprietor on a small-scale basis using manual or automatic machines. The raw materials you need to make your envelopes are papers, glue, and gum. The types of papers you need to handle this project effectively are scrap of papers, map litho papers, and useless papers.The GSM of paper you utilized determines the quality and output of envelops you will produce. You can make colored envelopes, envelopes printed with details on it, and plain envelopes. Learn More About: Envelop making business 5. Exercise book making business: You can begin this business with little capital and it is very simple to operate. As an office and educational stationary material, there is an increasing demand for exercise books and notebooks. The materials you need in this manufacturing process are printing ink, cover sheet, grey board sheet, gum, and stitching wire. The machinery involved are semi-auto paper cutting machine, disc ruling machine, book pressing machine, three knife trimming machine, perforating machine, and book stitching machine. Learn More About: Exercise book making business

6. Paper plate making business

This is a business you can do in order to be making some extra income regularly because paper plates are needed to serve foods in parties, picnics, and other occasions. You can make different shapes, sizes, and designs. The materials you need to produce your plates are layers of paper, polythene sheets, dies, and machinery that operate using hydraulics. Learn More About: Paper plate making business

7. Packaging box manufacturing

You can start this small-scale business with little capital. Moreover, there is a huge demand for packaging materials all over world. Learn More About: Packaging box manufacturing

8. Tissue paper production

There are wide range of tissues you can produce like paper towels, facial tissues, and tissue papers. You need some simple machinery like band saw cutter, rewinding machine, embossing and perforating units to make this cost effective and profitable household paper. Read More about Tissue Paper Making Business

9. Hand Made paper making

Generally, handmade paper has a great demand among the students as they make various crafts and project works with this paper. Examples of this paper are drawing sheets, watermark, and filter paper. If you are from rural area, you can start this handmade paper making business easily since most of the raw materials are naturally abundant and there is Rural Employment Generation Program under which the government sanctions loans to promising entrepreneurs to start their small handmade paper units. Read More About Hand Made paper making Business

10. Invitation card making

If you are creative and talented in design making, this is an avenue to convert your creativity into money making venture through the production of invitation cards.

11. Waste paper recycling

Waste paper recycling is a productive venture that does not require huge capital investment. You need to locate the source of your waste papers like sports arenas, paper vendors, and recreation clubs. Then, locate another source that could accept the waste papers for processing and recycling. 12. Paper shredding business

This is regarded as a section of paper recycling business. You can make a living through paper shredding as a start-up or already existing entrepreneur. The equipment you need are a shredder, paper baler, pallets, pallet jacket, paper bins, truck or a van that can help you to be move around. You do not necessarily need an office for this business.

13. Mini paper mill

You can make fortunes through this business, although it needs huge capital investment. The location of your business is very important because of the source of raw materials, which are basically forestry products.

14. Paper flower making

Do you know papers flowers that you make in your spare time can give you a stable source of income? You can achieve this by investing in paper flower making business. Some of the items you can produce with this creativity are wrist corsages, bouquets, paper roses, and more. Learn More About: Paper flower making

15. File manufacturing

With the aid of simple mechanisms, you can start up a file manufacturing unit. Files are needed in offices and educational institutions. You have the flat file and cover file with band on it.All the above paper business ideas are profitable enough if started after doing a thorough market research. Depending on your skills and interest in a specific niche, investment capacity, availability of the raw material and finally the market demand of the end product, you should choose a paper business idea. Hope this post will help you to achieve your goal in paper business.

This article originally posted on https://www.homebusinessideascenter.com/15-paper-business-ideas-low-cost/

0 notes

Text

Tissue Paper Embosser Machine Market Size, Analysis, and Forecast Report 2017-2027

Tissue Paper Embosser Machine market: Introduction

Globally, the tissue paper market is growing substantially due to rise in consumer inclination towards hygienic products. The tissue papers are first embossed and then sold to the end consumers. The commercial embosser machines performs the embossing operation for the industrial production. Embossing of a tissue is a very delicate process which needs to be handled very carefully. There are several factors which need to be considered while performing embossing on a tissue paper are ply bond, bulk, softness, attractive design, paper and basis weight, etc. In general terms, embossing is a technique to change the flat surface of any thin material to a shaped or three-dimensional surface. The embossing is sometimes done for the designing purpose. However, in most of the cases, it is done to change the physical characteristics of the material. The embossing of tissue paper is performed to improve absorbency and flexibility but at the expense of the strength. Most tissue papers are embossed by the application of force which significantly affects the mechanical properties of the material.

Tissue Paper Embosser Machine: Market Dynamics

It is noticed that the tissue paper embosser machine market has gained traction in recent years due to the rise in disposable incomes of the middle-class households to spend more on the hygienic products. It is a mandatory process to be performed on the tissue paper to enhance its physical properties. Increasing demand for tissue paper is driving the tissue paper embosser machine market globally. In recent years, it is observed that there has been a substantial increase in the number of tissue paper manufacturers across the world which further boosts the demand for tissue paper embosser machines. The main restraint in the tissue paper embosser machine market is the introduction of the alternative technology to enhance the properties of the tissue papers. Also, the machine is unaffordable to most of the small tissue paper manufacturers due to high installation and maintenance cost. The latest trend observed in the tissue paper embosser machines market is the innovation in its design to increase suitability and performance of the machine. It is also noticed that there are lots of opportunities available for the tissue paper embosser machine manufacturers in the developing region where the trend for hygienic products is growing like anything. The manufacturers could target these regions to increase their market share and footprint to remain competitive in the market.

Tissue Paper Embosser Machine: Market Segmentation

Tissue Paper Embosser Machine market is segmented as follows-

Tissue Paper Embosser Machine market segmentation by product type–

Jaws Style Embossers

Single Station Embossers

Compact Unwind Embossers

Two Station Embossers

Three Roll Embossers

Thermoformed Embossers

Others

Request to Sample Report - https://www.futuremarketinsights.com/reports/sample/rep-gb-5929

Tissue Paper Embosser Machine Market: Regional outlook

Geographically, the global tissue paper embosser machine market is segmented into following regions- North America, Eastern Europe, Asia-Pacific Excluding Japan, Japan, Western Europe, Latin America, Middle East and Africa. It is estimated that Europe followed by North America is the largest market for the tissue paper embosser machines. The Western European market is dominated by the German and Italian companies. The companies based in these countries has noticeable market share in the tissue paper embosser machines market. Due to the high penetration of the tissue papers in the North American region, the demand for tissue paper embosser machines is growing at a decent rate. In Asia Pacific region, the demand for hygienic products is increasing at a good CAGR value which will further increase the demand for these machines in the region. China and India are expected to dominate the region throughout the forecast period. The MEA and Latin America also offer untapped growth potential for the tissue paper embosser machine market in the coming years.

Tissue Paper Embosser Machine Market: Key players

Some of the key players in the global tissue paper embosser machine market are Barry-Wehmiller Companies, FABIO PERINI S.P.A., Cavalleri S.r.l., Industrial Engraving, LLC, American Thermoform Company, HCI Converting Equipment Company Ltd., Wenzhou Kingsun Machinery Industrial Ltd. and Margreiter-Technik Hans Hilscher GmbH.

Request Report TOC @ https://www.futuremarketinsights.com/toc/rep-gb-5929

0 notes