#Turnkey execution of Coal Handling Systems

Explore tagged Tumblr posts

Text

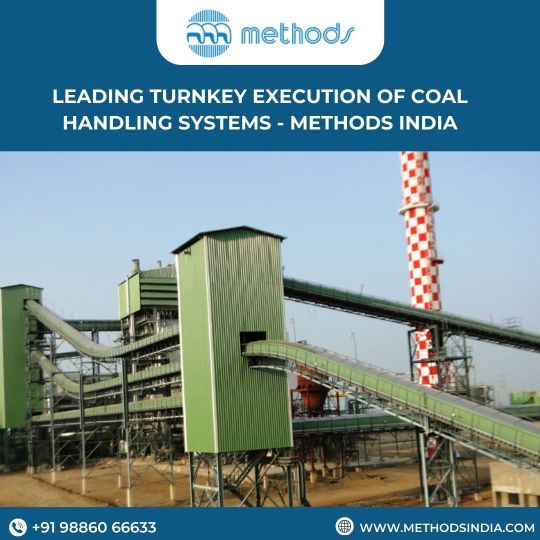

Leading Turnkey Execution of Coal Handling Systems - Methods India

In the realm of material handling, Methods India stands out as a leader in providing Turnkey execution of Coal Handling Systems. The products from Methods India are made with a focus on efficiency, safety, and simplicity. This allows for simple maintenance, which guarantees smooth operation. These turnkey solutions are designed to make moving and storing bulk materials easier.

The organization's dedication to quality has secured its standing as one of the top players in the bulk material handling sector. Find out how Methods India's innovative ideas can help you streamline your coal handling operations.

To contact us, Click on the link below- https://methodsindia.com/contact-information/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Independent Design House#Bagasse Handling Systems#Bulk material handling equipment manufacturers in Bangalore

2 notes

·

View notes

Text

Indian coal handling plants

The Indian coal sector is witnessing heightened competition as a ₹200 crore coal handling plant project advances to the technical pre-qualification stage. With major players vying for a spot, the latest tender is setting new standards for turnkey project execution and advanced handling technology. This surge of interest underscores the growing importance of the coal handling plant in India segment, as utilities and developers look to upgrade infrastructure for improved efficiency, safety, and reliability. Unlike previous procurement rounds, this project’s pre-qualification process places strong emphasis on proven technical expertise and a track record in executing large-scale, integrated systems. As a result, only companies with substantial experience in the coal handling plant in India domain are making it to the shortlist, raising the bar for future projects. This focus on advanced technology is expected to drive innovation and improve operational outcomes across the sector. Moreover, the project serves as a bellwether for upcoming tenders in the coal handling plant in India space, as stakeholders increasingly prioritize automation, dust suppression, and environment-friendly logistics. The move toward turnkey execution models is designed to streamline project delivery, minimize delays, and ensure seamless integration with existing power generation assets. As the coal handling plant in India market continues to mature, successful bidders on marquee projects like this will likely play a pivotal role in shaping industry best practices and setting benchmarks for technology adoption, safety, and project management across the Indian coal supply chain, Indian Coal Prices, Coal Market India, Indian coal handling plants, Energylineindia.

0 notes

Text

Operation and Maintenance India, Thermal Power Plant Maintenance, Dairy Plant, Railway Track Laying and Mining Companies in India

Laxyo Energy Limited is the leading firm of operation and maintenance india provides support and turnkey, full-service delivery across a variety of market sectors, from transportation to buildings and facilities and from water to power and energy. We have entered into the field of O and M services by giving particular dedicated work in the field of O&M administrations of Power Plant, Steel Plant, Ash Handling System, Coal Handling System, Bulk Material Handling System, Water Distribution and Electrical Works as Job Outsource, as indicated by the customer Planning and Designing. We provide reasonable Experts Manpower-Support to Operation and Maintenance Services on a turnkey preface. Near the above, we in like manner base on roduction/Maintenance/Quality Job Outsource for Industry. Our need is to keep up the most noteworthy conceivable execution as far as wellbeing and security, accessibility, effectiveness and resource honesty for Thermal power plant maintenance support. We focus on minimizing maintenance costs and drive through settled systems, Standardize Procedures and Manuals. We also stretch out our support services to Pre-appointing, Erection Stage and Annual Operation & Maintenance Services. We comprehend that long after development groups have finished their work, the maintainability and profit for a foundation venture are reliant on suitable and adequate tasks and upkeep over short, medium and long term timelines. Here we are expanding our O&M services by adding more Balance of Plant packages such as Ash Handling, Lignite Handling and Water Systems, O & M of complete power plant of small size, and extending O&M services in Mining & Port Handling.

Our operation and maintenance of dairy plant conveyance arrangements draw on a total scope of ability from a solitary source, tending to the whole esteem chain and life cycle of the benefit. The solutions can be applied to a single site or a complete portfolio of assets. Procedures in little dairies were administered and controlled by a couple of talented individuals, who completed most tasks physically and furthermore cleaned the hardware by hand toward the end of each run. As dairies extended, both the number and size of the machines developed, as did the quantity of manual activities required. Cleaning, in particular, was a laborious business – every machine that had been in contact with the product had to be disassembled and cleaned by hand at least once a day.

Laxyo group is today one of the oldest railway track laying contractors in India with the experience of having completed assignments across diverse terrains for Eastern Railway, North Eastern Railway, South Eastern Railway and Northeast Frontier Railway. Laying tracks utilizing the ceaseless activity, mechanical production system technique has ended up being the most cost-effective strategy for work. The whole supply of new sleepers and rails inside the track being laid is by motorized activity. We also offer particular services crosswise over mining industry from investigation, readiness of geographical report alongside topographical models, arrangement of mine arrangement and venture report including the Mine Modeling with Mine closure plan and mining of minerals as the leading Mining companies in india.

#operation and maintenance india#Thermal power plant maintenance#operation and maintenance of dairy plant#railway track laying#Mining companies in india

0 notes

Text

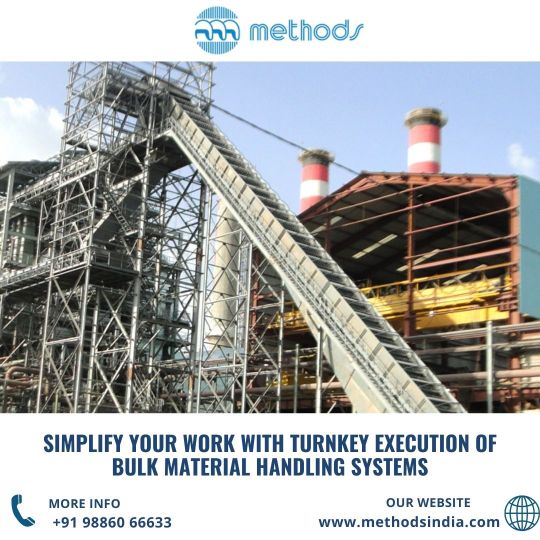

Simplify Your Work with Turnkey Execution of Coal Handling Systems

Simplify your industrial operations with Methods India's turnkey execution of Coal Handling Systems systems. Our comprehensive solutions make bulk material handling more efficient and reliable. We manage the entire project from start to finish, including design, procurement, installation, and commissioning. With our expertise and cutting-edge technology, we provide tailored solutions to your specific needs. To Learn more - https://methodsindia.com/contact-information/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Bagasse Handling Systems#Biomass Handling Systems#Cross Country Conveyors#Sugar Elevators

0 notes

Text

Effortless Implementation with Turnkey Execution of Coal Handling Systems

Methods India offers effortless implementation through Turnkey execution of Coal Handling Systems. Our products are designed and built to be simple, safe, and efficient to operate.

Our solutions can help you streamline your operations and achieve seamless performance in coal handling.Trust Methods India for reliable and efficient coal handling solutions tailored to your needs.

To Learn more - https://methodsindia.com/contact-information/

#Sugar Elevators#Cross Country Conveyors#Biomass Handling Systems#Bagasse Handling Systems#Turnkey execution of Bulk Material Handling Systems#Turnkey execution of Coal Handling Systems

1 note

·

View note

Text

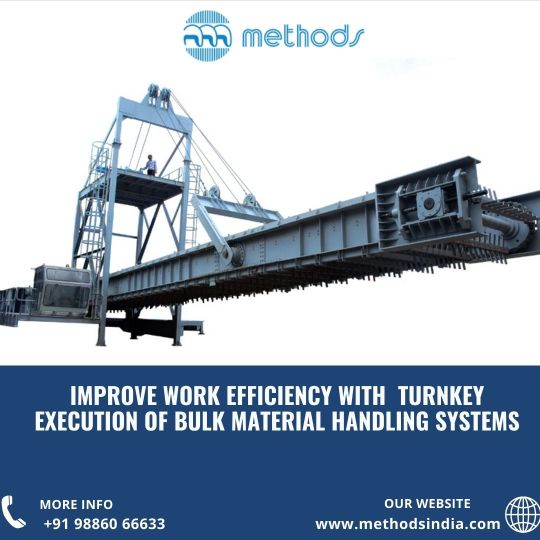

Boost Your Business with Turnkey Execution of Coal Handling Systems

Enhance your business operations with Methods India's Turnkey execution of Coal Handling Systems. Our comprehensive solutions are designed to maximize efficiency and productivity, ensuring that coal is handled smoothly from beginning to end.

With our expertise and cutting-edge technology, we provide tailored solutions to meet your specific needs. Methods India can help you grow your business with dependable and efficient coal handling systems that streamline operations and maximize productivity.

For more information , Click on the link - https://methodsindia.com/methods-india-leading-structural-design-fabrication-bulk-material-handling-company/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Bagasse Handling Systems#Biomass Handling Systems#Cross Country Conveyors#Sugar Elevators

1 note

·

View note

Text

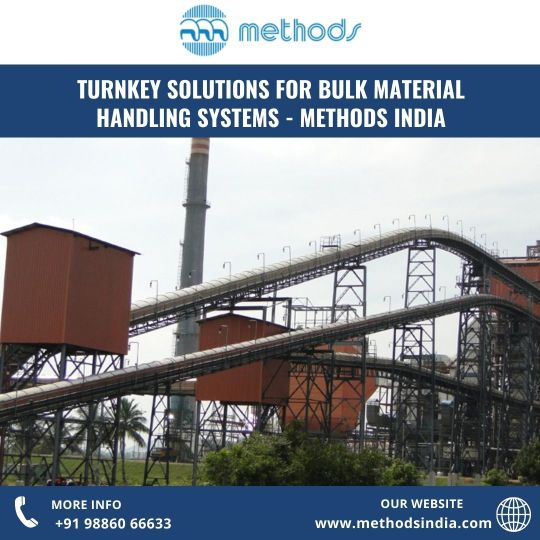

Expert Turnkey Execution for Coal Handling Systems - Methods India

Methods India specializes in expert Turnkey Execution for Coal Handling Systems, Providing full solutions from concept through execution. Our products are designed and built for easy maintenance, focusing on simplicity, safety, and efficiency.

Our solutions are designed for quick functionality and ensure smooth operations when moving and storing bulk materials. Methods India has become a leader in the field of bulk material handling by consistently supplying high-quality products and turnkey solutions tailored to each project's specific requirements.

For more details , click on the link - https://methodsindia.com/methods-india-leading-structural-design-fabrication-bulk-material-handling-company/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Bagasse Handling Systems#Biomass Handling Systems#Bagasse Dryers#Bulk Reception Unit

1 note

·

View note

Text

Bulk Material Handling Systems in India: Trends, Innovations & Future

Imagine a massive port where thousands of tonnes of coal, grain, or cement are being loaded, stored, or transported every hour. Or picture a sugar mill or cement plant running smoothly without ever pausing to move raw materials. Behind all this seamless action lies the unsung hero of industrial efficiency — Bulk Material Handling Systems. In India, where infrastructure, mining, and manufacturing industries are booming, the need for smarter, faster, and cleaner ways to handle bulk materials has never been more urgent. Whether it’s transporting limestone across a quarry or managing biomass for a power plant, bulk handling systems are the invisible engines powering productivity. This blog dives deep into the evolution of Bulk Material Handling Systems in India, spotlighting the latest trends, cutting-edge equipment innovations, and what the future holds. We’ll also look at how Indian pioneers like Methods India Pvt. Ltd. are leading the charge in transforming how industries move and manage materials — safely, sustainably, and at scale.

What Are Bulk Material Handling Systems?

Bulk Material Handling Systems are engineered solutions used to transport, process, store, and manage bulk materials like coal, limestone, iron ore, sugar, biomass, and fertilizers. These systems include conveyors, stackers, reclaimers, hoppers, silos, feeders, and dust control equipment. From quarry to processing and packaging, these systems are integral to industrial performance.

Emerging Trends in Bulk Material Handling Systems in India:

As India pushes forward with ambitious infrastructure and industrial growth targets, the bulk material handling industry is evolving rapidly to keep pace. Traditional systems are giving way to smarter, greener, and more integrated solutions that not only enhance productivity but also address environmental and operational challenges. From automation and digitization to energy-efficient designs and turnkey project execution, the emerging trends in bulk material handling systems in India reflect a bold shift toward innovation and sustainability. Let’s take a closer look at the key developments shaping the future of this critical sector.

Automation & Smart Handling:

IoT-enabled sensors, programmable logic controllers (PLCs), and SCADA systems are increasingly being used to monitor, automate, and optimize handling systems.

Predictive maintenance and real-time monitoring are reducing downtime and increasing safety.

Sustainability and Environmental Compliance:

New designs emphasize dust suppression, energy efficiency, and lower carbon footprints.

India’s tightening environmental laws have pushed the demand for pollution control-integrated systems.

Customized & Turnkey Solutions:

Companies like Methods India offer end-to-end design, manufacturing, installation, and commissioning of tailor-made bulk handling systems to suit specific industry needs.

This trend is reshaping the competitive landscape by emphasizing project-specific efficiency.

Growth of Biomass & Renewable Integration

With increasing emphasis on green energy, bulk handling systems are now designed to process biofuels and biomass.

Boilers and dryer solutions are being integrated into the handling system for seamless operation.

Also Read: Turnkey Execution of Coal Handling Systems

Innovations in Bulk Material Handling Equipment:

Gone are the days when bulk material handling relied solely on basic belts and conveyors. Today, the industry is witnessing a wave of innovation, with equipment designed to be smarter, safer, and more efficient than ever before. With increasing demands for automation, space optimization, and environmental compliance, manufacturers are developing advanced machinery that can handle complex materials and challenging environments with ease. These innovations in bulk material handling equipment are not only improving performance but also redefining what’s possible across industries like mining, cement, power, and agriculture.

Pipe Conveyors: Ideal for long-distance and environmentally sensitive zones; they minimize spillage and are more flexible in routing.

Cross Country Conveyors: Used extensively in mining and cement sectors for long-haul material transfer.

Dense Phase Pneumatic Conveyors: Suited for fine powders and fragile materials, minimizing degradation and dust.

High-Capacity Stacker-Reclaimers: Essential for ports and large storage yards, with smart positioning and stacking algorithms.

Methods India is at the forefront of these innovations, offering proprietary designs and in-house fabrication of everything from conveyors to storage hoppers with a keen focus on efficiency and safety. Industries Driving Demand: The demand for bulk material handling systems doesn’t arise in isolation — it’s powered by the heartbeat of India’s industrial engine. From the towering chimneys of thermal power plants to the fast-paced operations of cement factories, and from bustling ports to sprawling mining sites, multiple sectors rely heavily on efficient material handling to stay productive and profitable. As these industries scale up to meet the country’s growing infrastructure and energy needs, the role of bulk material handling systems has become more mission-critical than ever. Let’s explore the key sectors fueling this rising demand.

Cement & Mining

Power & Renewable Energy

Sugar Processing

Steel and Metallurgy

Ports & Terminals

Fertilizers & Agro-processing

With over 1,000 projects across 36 countries, Methods India Pvt. Ltd. exemplifies India’s engineering leadership in this space. Also Read: The Role of Bulk Reception Units (BRUs)

The Future of Bulk Material Handling in India:

The future of bulk material handling systems in India lies in the convergence of automation, green technologies, and modular, scalable design. Key developments on the horizon include:

AI-driven material flow optimization.

Autonomous handling systems with minimal human intervention.

Increased use of composite materials for lighter, corrosion-resistant equipment.

Digital twins and simulations for error-free commissioning and maintenance planning.

The government’s focus on “Make in India,” rapid urbanization, and massive infrastructure investments will continue to fuel this industry’s growth. Players like Methods India are well-poised to meet this demand with decades of domain expertise, in-house R&D, and a strong commitment to sustainability and innovation.

Why Choose Methods India?

When it comes to reliable, customized, and future-ready bulk material handling systems, Methods India Pvt. Ltd. stands out as a trusted industry leader. With over four decades of experience and a strong track record across diverse sectors — power, cement, sugar, ports, and more — Methods India brings engineering excellence, innovation, and precision to every project. Their ability to offer turnkey solutions, from design and manufacturing to installation and commissioning, ensures clients get end-to-end support with unmatched quality and performance. Backed by a deep understanding of industry challenges and a commitment to sustainable engineering, Methods India is not just a vendor — they’re a strategic partner in building India’s industrial future.

Turnkey Expertise: From concept to commissioning, everything is handled in-house.

In-House Manufacturing: Full control over quality and delivery.

Sustainability-Driven: Integrated pollution control, water conservation, and CSR-focused operations.

Proven Track Record: Trusted by major industrial players in India and abroad.

Conclusion:

As India moves toward becoming a global manufacturing hub, Bulk Material Handling Systems will remain the backbone of industrial logistics and processing. With innovation, customization, and sustainability at the core, companies like Methods India are not just meeting industry needs — they’re defining the future of bulk material handling in India.

#bulkmaterialhandling#bulkmaterialhandlingsystems#bulkmaterialhandlingequipmentmanufacturersinindia#bulkmaterialmanufactuersinindia#bulkmaterialhandlingsystemsinindia#methodsindia

0 notes