#UltraCleanTubeCleaner

Explore tagged Tumblr posts

Text

Top Benefits of Using an Ultra Clean Tube Cleaner for Hydraulic Maintenance | Ultra Clean Technologies

Maintaining clean hydraulic lines is critical for system performance, reliability, and longevity. In industries where contamination control is non-negotiable—such as aerospace, heavy equipment, and manufacturing—the Ultra Clean tube cleaner stands out as a reliable, efficient, and industry-approved solution for cleaning fluid-carrying tubes and pipes.

What Is the Ultra Clean Tube Cleaner?

The Ultra Clean tube cleaner is a high-performance cleaning system designed to remove dust, dirt, metal particles, moisture, and other contaminants from the interior of tubes and pipes. It uses a patented foam projectile system, which is propelled through the tube using compressed air. The projectile scrapes the internal surfaces clean without causing damage, leaving behind a contamination-free line ready for use.

Key Features and Benefits

Fast and Effective Cleaning The cleaning process takes seconds per tube, significantly reducing labor time and production delays.

Safe on All Tube Types Whether it's stainless steel, aluminum, or copper tubing, the Ultra Clean tube cleaner provides safe, non-abrasive internal cleaning.

Prevents System Failures Removing contaminants from fluid systems helps prevent premature wear, corrosion, and blockages in valves, pumps, and actuators.

ISO Cleanliness Compliance Ensures your tubing meets required ISO 4406 cleanliness levels—essential for modern hydraulic and fluid systems.

Reusable and Cost-Effective With interchangeable parts and durable construction, the cleaner offers long-term value and reduced maintenance costs.

Ideal Applications

The Ultra Clean tube cleaner is used across various industries where fluid integrity and performance are critical:

Hydraulic and pneumatic systems

OEM and assembly operations

Aerospace and defense manufacturing

Agricultural and construction equipment

Oil & gas and marine systems

Whether used in production or field service, it plays a vital role in contamination control.

How It Works?

The process is simple:

Load the appropriate foam projectile into the launcher.

Insert the nozzle into the tube or pipe.

Fire the projectile using compressed air.

The projectile expands and cleans the tube’s interior as it passes through.

Use a projectile catcher for safe disposal and inspection.

For best results, Ultra Clean also offers heat-shrink caps to seal cleaned tubes and prevent recontamination before installation.

Final Thoughts

In hydraulic systems, cleanliness equals reliability. The Ultra Clean tube cleaner is a proven tool that delivers precision cleaning with minimal effort, helping industries maintain system integrity, reduce equipment failures, and ensure long-term performance.

Looking to improve your tube cleaning process? Invest in the Ultra Clean tube cleaner today and bring your contamination control to a whole new level.

Contact us today to schedule your service and keep your systems running at their best.

Call: +1 856 451 2176

E Mail Us: [email protected]

Visit: https://ultracleantech.com/

Stay in touch with the latest developments and company news:

LinkedIn

Facebook

Youtube

#UltraCleanTubeCleaner#TubeCleaningSystem#HydraulicTubeCleaning#ContaminationControl#FluidSystemCleaning#CleanTubeTechnology#IndustrialTubeCleaner#ISOCleanlinessTools#PneumaticTubeCleaning#HydraulicMaintenance#CleanFluidLines#TubeCleaningProjectiles#CleanHydraulicTubes#UltraCleanEquipment#PrecisionTubeCleaning

1 note

·

View note

Text

Top Benefits of Using an Ultra Clean Tube Cleaner for Hydraulic Maintenance | Ultra Clean Technologies

Maintaining clean hydraulic lines is critical for system performance, reliability, and longevity. In industries where contamination control is non-negotiable—such as aerospace, heavy equipment, and manufacturing—the Ultra Clean tube cleaner stands out as a reliable, efficient, and industry-approved solution for cleaning fluid-carrying tubes and pipes.

What Is the Ultra Clean Tube Cleaner?

The Ultra Clean tube cleaner is a high-performance cleaning system designed to remove dust, dirt, metal particles, moisture, and other contaminants from the interior of tubes and pipes. It uses a patented foam projectile system, which is propelled through the tube using compressed air. The projectile scrapes the internal surfaces clean without causing damage, leaving behind a contamination-free line ready for use.

Key Features and Benefits

Fast and Effective Cleaning The cleaning process takes seconds per tube, significantly reducing labor time and production delays.

Safe on All Tube Types Whether it's stainless steel, aluminum, or copper tubing, the Ultra Clean tube cleaner provides safe, non-abrasive internal cleaning.

Prevents System Failures Removing contaminants from fluid systems helps prevent premature wear, corrosion, and blockages in valves, pumps, and actuators.

ISO Cleanliness Compliance Ensures your tubing meets required ISO 4406 cleanliness levels—essential for modern hydraulic and fluid systems.

Reusable and Cost-Effective With interchangeable parts and durable construction, the cleaner offers long-term value and reduced maintenance costs.

Ideal Applications

The Ultra Clean tube cleaner is used across various industries where fluid integrity and performance are critical:

Hydraulic and pneumatic systems

OEM and assembly operations

Aerospace and defense manufacturing

Agricultural and construction equipment

Oil & gas and marine systems

Whether used in production or field service, it plays a vital role in contamination control.

How It Works?

The process is simple:

Load the appropriate foam projectile into the launcher.

Insert the nozzle into the tube or pipe.

Fire the projectile using compressed air.

The projectile expands and cleans the tube’s interior as it passes through.

Use a projectile catcher for safe disposal and inspection.

For best results, Ultra Clean also offers heat-shrink caps to seal cleaned tubes and prevent recontamination before installation.

Final Thoughts

In hydraulic systems, cleanliness equals reliability. The Ultra Clean tube cleaner is a proven tool that delivers precision cleaning with minimal effort, helping industries maintain system integrity, reduce equipment failures, and ensure long-term performance.

Looking to improve your tube cleaning process? Invest in the Ultra Clean tube cleaner today and bring your contamination control to a whole new level.

Contact us today to schedule your service and keep your systems running at their best.

Call: +1 856 451 2176

E Mail Us: [email protected]

Visit: https://ultracleantech.com/

Stay in touch with the latest developments and company news:

LinkedIn

Facebook

Youtube

#UltraCleanTubeCleaner#TubeCleaningSystem#HydraulicTubeCleaning#ContaminationControl#FluidSystemCleaning#CleanTubeTechnology#IndustrialTubeCleaner#ISOCleanlinessTools#PneumaticTubeCleaning#HydraulicMaintenance#CleanFluidLines#TubeCleaningProjectiles#CleanHydraulicTubes#UltraCleanEquipment#PrecisionTubeCleaning

1 note

·

View note

Text

Top Benefits of Using an Ultra Clean Tube Cleaner for Hydraulic Maintenance | Ultra Clean Technologies

Maintaining clean hydraulic lines is critical for system performance, reliability, and longevity. In industries where contamination control is non-negotiable—such as aerospace, heavy equipment, and manufacturing—the Ultra Clean tube cleaner stands out as a reliable, efficient, and industry-approved solution for cleaning fluid-carrying tubes and pipes.

What Is the Ultra Clean Tube Cleaner?

The Ultra Clean tube cleaner is a high-performance cleaning system designed to remove dust, dirt, metal particles, moisture, and other contaminants from the interior of tubes and pipes. It uses a patented foam projectile system, which is propelled through the tube using compressed air. The projectile scrapes the internal surfaces clean without causing damage, leaving behind a contamination-free line ready for use.

Key Features and Benefits

Fast and Effective Cleaning The cleaning process takes seconds per tube, significantly reducing labor time and production delays.

Safe on All Tube Types Whether it's stainless steel, aluminum, or copper tubing, the Ultra Clean tube cleaner provides safe, non-abrasive internal cleaning.

Prevents System Failures Removing contaminants from fluid systems helps prevent premature wear, corrosion, and blockages in valves, pumps, and actuators.

ISO Cleanliness Compliance Ensures your tubing meets required ISO 4406 cleanliness levels—essential for modern hydraulic and fluid systems.

Reusable and Cost-Effective With interchangeable parts and durable construction, the cleaner offers long-term value and reduced maintenance costs.

Ideal Applications

The Ultra Clean tube cleaner is used across various industries where fluid integrity and performance are critical:

Hydraulic and pneumatic systems

OEM and assembly operations

Aerospace and defense manufacturing

Agricultural and construction equipment

Oil & gas and marine systems

Whether used in production or field service, it plays a vital role in contamination control.

How It Works?

The process is simple:

Load the appropriate foam projectile into the launcher.

Insert the nozzle into the tube or pipe.

Fire the projectile using compressed air.

The projectile expands and cleans the tube’s interior as it passes through.

Use a projectile catcher for safe disposal and inspection.

For best results, Ultra Clean also offers heat-shrink caps to seal cleaned tubes and prevent recontamination before installation.

Final Thoughts

In hydraulic systems, cleanliness equals reliability. The Ultra Clean tube cleaner is a proven tool that delivers precision cleaning with minimal effort, helping industries maintain system integrity, reduce equipment failures, and ensure long-term performance.

Looking to improve your tube cleaning process? Invest in the Ultra Clean tube cleaner today and bring your contamination control to a whole new level.

Contact us today to schedule your service and keep your systems running at their best.

Call: +1 856 451 2176

E Mail Us: [email protected]

Visit: https://ultracleantech.com/

Stay in touch with the latest developments and company news:

LinkedIn

Facebook

Youtube

#UltraCleanTubeCleaner#TubeCleaningSystem#HydraulicTubeCleaning#ContaminationControl#FluidSystemCleaning#CleanTubeTechnology#IndustrialTubeCleaner#ISOCleanlinessTools#PneumaticTubeCleaning#HydraulicMaintenance#CleanFluidLines#TubeCleaningProjectiles#CleanHydraulicTubes#UltraCleanEquipment#PrecisionTubeCleaning

1 note

·

View note

Text

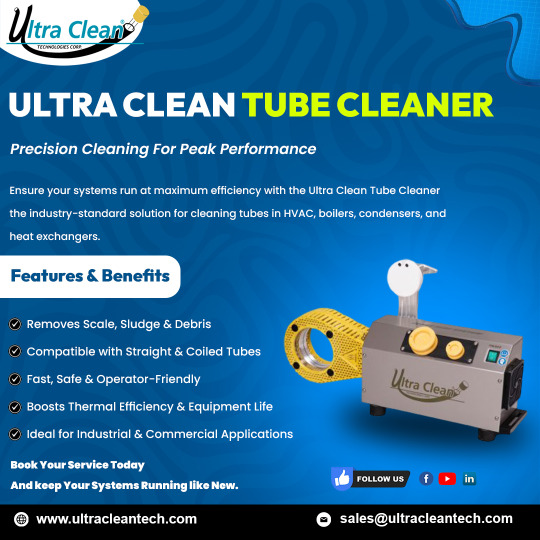

Ultra Clean Tube Cleaner – Precision Cleaning for Peak Performance | UCT

Ensure your systems run at maximum efficiency with the Ultra Clean Tube Cleaner — the industry-standard solution for cleaning tubes in HVAC, boilers, condensers, and heat exchangers.

Features & Benefits:

Removes Scale, Sludge & Debris

Compatible with Straight & Coiled Tubes

Fast, Safe & Operator-Friendly

Boosts Thermal Efficiency & Equipment Life

Ideal for Industrial & Commercial Applications

Whether for routine maintenance or performance restoration, Ultra Clean delivers powerful results with minimal downtime.

Take control of hydraulic contamination today—discover how the Ultra Clean Tube Cleaner can extend equipment life, improve performance, and simplify your maintenance routine. Contact us now to get started.

Please email us: [email protected]

Visit us: www.ultracleantech.com

Phone: +1 856 451 2176

Stay in touch with the latest developments and company news:

LinkedIn

Facebook

Youtube

#UltraCleanTubeCleaner#HydraulicCleaning#TubeCleaningSystem#ContaminationControl#EquipmentMaintenance#CleanHydraulics#IndustrialTubeCleaner#MaintenanceSolutions#ExtendEquipmentLife#HydraulicSystemCare#CleanTubeTechnology#FluidPowerCleaning#PreventContamination#SystemEfficiency#IndustrialMaintenance#MaintenanceSimplified#TubeCleaningTool#PerformanceBoost#CleanHydraulicSystems#UltraCleanTechnology

1 note

·

View note

Text

Ultra Clean Tube Cleaner – Precision Cleaning for Peak Performance | UCT

Ensure your systems run at maximum efficiency with the Ultra Clean Tube Cleaner — the industry-standard solution for cleaning tubes in HVAC, boilers, condensers, and heat exchangers.

Features & Benefits:

Removes Scale, Sludge & Debris

Compatible with Straight & Coiled Tubes

Fast, Safe & Operator-Friendly

Boosts Thermal Efficiency & Equipment Life

Ideal for Industrial & Commercial Applications

Whether for routine maintenance or performance restoration, Ultra Clean delivers powerful results with minimal downtime.

Take control of hydraulic contamination today—discover how the Ultra Clean Tube Cleaner can extend equipment life, improve performance, and simplify your maintenance routine. Contact us now to get started.

Please email us: [email protected]

Visit us: www.ultracleantech.com

Phone: +1 856 451 2176

Stay in touch with the latest developments and company news:

LinkedIn

Facebook

Youtube

#UltraCleanTubeCleaner#HydraulicCleaning#TubeCleaningSystem#ContaminationControl#EquipmentMaintenance#CleanHydraulics#IndustrialTubeCleaner#MaintenanceSolutions#ExtendEquipmentLife#HydraulicSystemCare#CleanTubeTechnology#FluidPowerCleaning#PreventContamination#SystemEfficiency#IndustrialMaintenance#MaintenanceSimplified#TubeCleaningTool#PerformanceBoost#CleanHydraulicSystems#UltraCleanTechnology

1 note

·

View note

Text

Ultra Clean Tube Cleaner – Precision Cleaning for Peak Performance | UCT

Ensure your systems run at maximum efficiency with the Ultra Clean Tube Cleaner — the industry-standard solution for cleaning tubes in HVAC, boilers, condensers, and heat exchangers.

Features & Benefits:

Removes Scale, Sludge & Debris

Compatible with Straight & Coiled Tubes

Fast, Safe & Operator-Friendly

Boosts Thermal Efficiency & Equipment Life

Ideal for Industrial & Commercial Applications

Whether for routine maintenance or performance restoration, Ultra Clean delivers powerful results with minimal downtime.

Take control of hydraulic contamination today—discover how the Ultra Clean Tube Cleaner can extend equipment life, improve performance, and simplify your maintenance routine. Contact us now to get started.

Please email us: [email protected]

Visit us: www.ultracleantech.com

Phone: +1 856 451 2176

Stay in touch with the latest developments and company news:

LinkedIn

Facebook

Youtube

#UltraCleanTubeCleaner#HydraulicCleaning#TubeCleaningSystem#ContaminationControl#EquipmentMaintenance#CleanHydraulics#IndustrialTubeCleaner#MaintenanceSolutions#ExtendEquipmentLife#HydraulicSystemCare#CleanTubeTechnology#FluidPowerCleaning#PreventContamination#SystemEfficiency#IndustrialMaintenance#MaintenanceSimplified#TubeCleaningTool#PerformanceBoost#CleanHydraulicSystems#UltraCleanTechnology

1 note

·

View note

Text

Enhancing Industrial Maintenance Efficiency with Ultra Clean Tube Cleaner Technology | Ultra Clean Technologies

In high-performance industrial environments, equipment reliability is critical. One of the key challenges across sectors like HVAC, power generation, chemical processing, and food manufacturing is keeping tubes clean and free from blockages. That’s where the Ultra Clean Tube Cleaner plays a vital role in preventative maintenance and operational efficiency.

An ultra clean tube cleaner is a specialized tool designed to thoroughly remove scale, sludge, and other contaminants from the inside of heat exchanger tubes, condensers, boilers, and chillers. These systems are engineered to provide high-pressure, precision cleaning without damaging delicate internal surfaces — ensuring optimal heat transfer and energy efficiency.

The buildup of debris in tube systems not only reduces performance but also increases energy consumption and operational costs. Traditional cleaning methods can be time-consuming and sometimes ineffective. The ultra clean tube cleaner, however, uses advanced mechanical or pneumatic technology that allows maintenance teams to complete the job faster, safer, and more effectively.

One of the key benefits of using an ultra clean system is that it minimizes downtime. With portable and easy-to-operate designs, these cleaners can be deployed on-site with minimal training. Whether it’s routine maintenance or an emergency situation, they provide a dependable solution to maintain the cleanliness and functionality of critical equipment.

In industries where cleanliness is regulated — such as pharmaceutical, food, and beverage manufacturing — an ultra clean tube cleaner ensures compliance with hygiene standards. By removing microbial build-up and residues, companies can avoid contamination risks and maintain production quality.

Moreover, using an ultra clean tube cleaner as part of a regular maintenance program helps extend equipment life, reduce costly repairs, and prevent unplanned shutdowns. It’s a proactive investment that pays off in both performance and reliability.

If you are a facility manager, plant operator, or maintenance professional, investing in modern tube cleaning technology is no longer optional — it’s essential. The ultra clean tube cleaner represents the next generation of industrial cleaning tools, combining power, precision, and practicality.

Ready to Keep Your Equipment Performing at Its Best? Contact us today to learn more about the Ultra Clean Tube Cleaner — the smart solution for efficient, reliable maintenance.

Call Now: 856 451 2176

Email: [email protected] Website: www.UltraCleanTubeCleaner.com

Follow Us for Updates & Offers: Facebook: https://www.facebook.com/ultracleantech Youtube: https://www.youtube.com/user/ultracleantech LinkedIn: https://www.linkedin.com/company/ultra-clean-technologies-corp-/

#UltraCleanTubeCleaner#IndustrialTubeCleaning#HeatExchangerMaintenance#BoilerTubeCleaning#CondenserCleaningTools#PneumaticTubeCleaner#HVACMaintenanceEquipment#PlantMaintenanceTools#SludgeRemovalSystem#ScaleRemovalCleaner#PreventiveMaintenanceTools#PharmaceuticalEquipmentCleaning#FoodIndustryMaintenance#MechanicalTubeCleaningSystem#IndustrialCleaningTechnology

1 note

·

View note

Text

Enhancing Industrial Maintenance Efficiency with Ultra Clean Tube Cleaner Technology | Ultra Clean Technologies

In high-performance industrial environments, equipment reliability is critical. One of the key challenges across sectors like HVAC, power generation, chemical processing, and food manufacturing is keeping tubes clean and free from blockages. That’s where the Ultra Clean Tube Cleaner plays a vital role in preventative maintenance and operational efficiency.

An ultra clean tube cleaner is a specialized tool designed to thoroughly remove scale, sludge, and other contaminants from the inside of heat exchanger tubes, condensers, boilers, and chillers. These systems are engineered to provide high-pressure, precision cleaning without damaging delicate internal surfaces — ensuring optimal heat transfer and energy efficiency.

The buildup of debris in tube systems not only reduces performance but also increases energy consumption and operational costs. Traditional cleaning methods can be time-consuming and sometimes ineffective. The ultra clean tube cleaner, however, uses advanced mechanical or pneumatic technology that allows maintenance teams to complete the job faster, safer, and more effectively.

One of the key benefits of using an ultra clean system is that it minimizes downtime. With portable and easy-to-operate designs, these cleaners can be deployed on-site with minimal training. Whether it’s routine maintenance or an emergency situation, they provide a dependable solution to maintain the cleanliness and functionality of critical equipment.

In industries where cleanliness is regulated — such as pharmaceutical, food, and beverage manufacturing — an ultra clean tube cleaner ensures compliance with hygiene standards. By removing microbial build-up and residues, companies can avoid contamination risks and maintain production quality.

Moreover, using an ultra clean tube cleaner as part of a regular maintenance program helps extend equipment life, reduce costly repairs, and prevent unplanned shutdowns. It’s a proactive investment that pays off in both performance and reliability.

If you are a facility manager, plant operator, or maintenance professional, investing in modern tube cleaning technology is no longer optional — it’s essential. The ultra clean tube cleaner represents the next generation of industrial cleaning tools, combining power, precision, and practicality.

Ready to Keep Your Equipment Performing at Its Best? Contact us today to learn more about the Ultra Clean Tube Cleaner — the smart solution for efficient, reliable maintenance.

Call Now: 856 451 2176

Email: [email protected] Website: www.UltraCleanTubeCleaner.com

Follow Us for Updates & Offers: Facebook: https://www.facebook.com/ultracleantech Youtube: https://www.youtube.com/user/ultracleantech LinkedIn: https://www.linkedin.com/company/ultra-clean-technologies-corp-/

#UltraCleanTubeCleaner#IndustrialTubeCleaning#HeatExchangerMaintenance#BoilerTubeCleaning#CondenserCleaningTools#PneumaticTubeCleaner#HVACMaintenanceEquipment#PlantMaintenanceTools#SludgeRemovalSystem#ScaleRemovalCleaner#PreventiveMaintenanceTools#PharmaceuticalEquipmentCleaning#FoodIndustryMaintenance#MechanicalTubeCleaningSystem#IndustrialCleaningTechnology

1 note

·

View note

Text

Enhancing Industrial Maintenance Efficiency with Ultra Clean Tube Cleaner Technology | Ultra Clean Technologies

In high-performance industrial environments, equipment reliability is critical. One of the key challenges across sectors like HVAC, power generation, chemical processing, and food manufacturing is keeping tubes clean and free from blockages. That’s where the Ultra Clean Tube Cleaner plays a vital role in preventative maintenance and operational efficiency.

An ultra clean tube cleaner is a specialized tool designed to thoroughly remove scale, sludge, and other contaminants from the inside of heat exchanger tubes, condensers, boilers, and chillers. These systems are engineered to provide high-pressure, precision cleaning without damaging delicate internal surfaces — ensuring optimal heat transfer and energy efficiency.

The buildup of debris in tube systems not only reduces performance but also increases energy consumption and operational costs. Traditional cleaning methods can be time-consuming and sometimes ineffective. The ultra clean tube cleaner, however, uses advanced mechanical or pneumatic technology that allows maintenance teams to complete the job faster, safer, and more effectively.

One of the key benefits of using an ultra clean system is that it minimizes downtime. With portable and easy-to-operate designs, these cleaners can be deployed on-site with minimal training. Whether it’s routine maintenance or an emergency situation, they provide a dependable solution to maintain the cleanliness and functionality of critical equipment.

In industries where cleanliness is regulated — such as pharmaceutical, food, and beverage manufacturing — an ultra clean tube cleaner ensures compliance with hygiene standards. By removing microbial build-up and residues, companies can avoid contamination risks and maintain production quality.

Moreover, using an ultra clean tube cleaner as part of a regular maintenance program helps extend equipment life, reduce costly repairs, and prevent unplanned shutdowns. It’s a proactive investment that pays off in both performance and reliability.

If you are a facility manager, plant operator, or maintenance professional, investing in modern tube cleaning technology is no longer optional — it’s essential. The ultra clean tube cleaner represents the next generation of industrial cleaning tools, combining power, precision, and practicality.

Ready to Keep Your Equipment Performing at Its Best?

Contact us today to learn more about the Ultra Clean Tube Cleaner — the smart solution for efficient, reliable maintenance.

Call Now: 856 451 2176

Email: [email protected] Website: www.UltraCleanTubeCleaner.com

Follow Us for Updates & Offers: Facebook: https://www.facebook.com/ultracleantech Youtube: https://www.youtube.com/user/ultracleantech LinkedIn: https://www.linkedin.com/company/ultra-clean-technologies-corp-/

#UltraCleanTubeCleaner#IndustrialTubeCleaning#HeatExchangerMaintenance#BoilerTubeCleaning#CondenserCleaningTools#PneumaticTubeCleaner#HVACMaintenanceEquipment#PlantMaintenanceTools#SludgeRemovalSystem#ScaleRemovalCleaner#PreventiveMaintenanceTools#PharmaceuticalEquipmentCleaning#FoodIndustryMaintenance#MechanicalTubeCleaningSystem#IndustrialCleaningTechnology

1 note

·

View note