#VacuumSystem

Explore tagged Tumblr posts

Text

Vacuum Tank: Reliable and Efficient Pressure Control for Plywood Machinery

In the industry of plywood production, efficiency and accuracy are the determinants of quality output. One of the critical parts that are indispensable in the process is the vacuum tank. Being a top player in the production of plywood equipment, we recognize the significance of efficient and stable pressure control in maximizing production and maintaining smooth operations.

What is a Vacuum Tank?

A vacuum tank is a key component in plywood production used to control and keep the pressure constant throughout different production steps. It is mainly applied to extract air, gases, and moisture, with the aim of making materials bond properly and gain superior durability. Vacuum tanks help keep equipment in a controlled vacuum environment, thus ensuring that plywood machinery runs without any issues and lowering defects and inconsistency in products.

Why Vacuum Tanks are Necessary for Plywood Machinery

1. Better Adhesion & Bonding

In plywood manufacturing, adhesives are important in achieving maximum bonding between layers. A vacuum tank efficiently removes entrapped air and moisture, enabling adhesives to penetrate uniformly, leading to improved adhesion and a stronger end product.

2.Improved Drying Process

Accurate drying is necessary to preserve the structural integrity of plywood. Vacuum tanks assist in removing excess moisture from the wood, speeding up the drying process without warping or cracking. This avoids defects and increases the life of the plywood.

3. Optimized Pressure Control

Producing the ideal pressure balance is crucial for consistent production quality. The vacuum tank provides a consistent pressure regulation, minimizing production errors and material wastage. This results in cost savings and better efficiency in production.

4. Energy Efficiency & Cost-Effectiveness

New vacuum tanks are made to be energy-efficient while giving maximum performance. Through the inclusion of sophisticated technology, producers can minimize cost of operation and enhance productivity, thus being a worthy investment for plywood plants.

Selecting the Ideal Vacuum Tank for Your Plywood Equipment

As a reputable producer of plywood equipment, we provide customized vacuum tanks best suited to your unique production requirements. In picking a vacuum tank, take into consideration:

✔ Capacity & Size: Select a vacuum tank with the same capacity as your production level to maintain efficiency.

✔ Material Quality: Use tanks of high-grade stainless steel for strength and longevity.

✔ Automation Features: Select intelligent control systems to automate pressure controls for improved accuracy.

✔ Maintenance & Durability: Use a design that is simple to maintain and corrosion-resistant.

Increase Your Plywood Production with Efficient Vacuum Tanks

Incorporating a high-performance vacuum tank into the operations of plywood makers is a game-seller when it comes to upgrading the quality and efficiency of production. Through accurate pressure control, improved adhesion, and energy conservation, these tanks help make manufacturing processes trouble-free.

Here at DNH Engineers, we are experts in top-of-the-line plywood equipment, including vacuum tanks designed for optimal performance. Reach out to us today to learn how our cutting-edge solutions can help advance your production!

Get in Touch for the Best Vacuum Tanks in the Industry!

By integrating superior quality vacuum tanks into your manufacturing process, you guarantee better plywood quality, greater efficiency, and cost savings over the long run. Upgrade your equipment today and lead the competitive plywood market! Visit www.dnhengineers.com to know more.

#VacuumTank#PressureControl#ReliableTechnology#EfficientPerformance#IndustrialSolutions#VacuumSystem#FluidControl#EngineeringExcellence#ProcessOptimization#Automation#SustainableTechnology#ManufacturingEfficiency#Pneumatics#VacuumEngineering#TechInnovation#ReliabilityFirst#PressureManagement#EfficiencyMatters#VacuumPressure

0 notes

Text

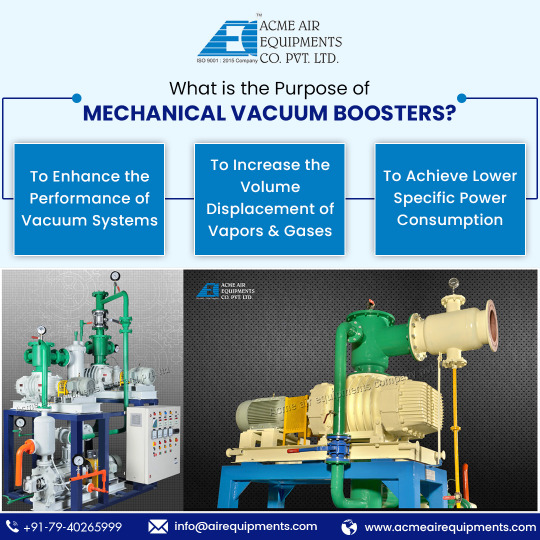

Our vacuum system is ideal for distilling re-used oil. The design and construction of the vacuum booster compressor include two counter-rotating impellers with a unique contour. These vacuum compressors rotate with an exact and sharp clearance, without making any physical contact. The design variations offer Twin or Tri lobe Boosters in air-cooled or water-cooled configurations. The Vacuum Boosters are designed to handle vapors and gases with lower power consumption.

For more detailed information visit: https://www.acmeairequipments.com/product/mechanical-vacuum-boosters/

0 notes

Text

Take control of your lab setup with the Labasics Vacuum Glass 3-Way Flow Control Adapter! 💨 Made from borosilicate glass, this adapter features a standard 24/40 taper joint and a PTFE stopcock for precise flow regulation. Ideal for laboratory use, it provides reliable and durable performance, helping you manage your experiments with ease. 🔧⚗️

Get yours now for $25.99 and enhance your lab efficiency! 🛒💰

#labasicsstore #vacuumsystems #flowcontrol #labadapters

0 notes

Photo

Selecting the Right Vacuum pumping system for vacuum furnace.

Vacuum pumping systems:

1. Rough vacuum systems

2. Diffusion pumping systems

3. Turbo pumping systems

4. Ion / cryogenic pumping systems

Pumping systems include all needed valves, sensors and controls.

Systems come fully tested and leak checked prior to shipping.

Basic vacuum furnaces come with a mechanical vacuum pump that can reach ultimate pressures in the 10-3 torr range

Allows vacuum levels to 10-6 Torr (mBar) range. Adds a diffusion pump, baffle and additional valves to our Standard rough vacuum system. An optional holding pump and valve can also be added to this pumping system.

Allows vacuum levels to 10-7 Torr (mBar) range with an oil free pumping system for ultra clean environments. Adds a Turbo pump, additional valves and controls to our Standard rough vacuum system. “Dry” or oil free roughing pumps can substitute standard dual stage rotary vane pumps which rely on oil for lubrication.

Need further information, a quotation or to place an order?

Please contact us [email protected] , www.souzvac.com

1 note

·

View note

Photo

Just received my new POMODORO VACUUM FOOD CONTAINERs #complimentary from @urbanlab.globe. Two 27.1oz containers and one 47.3oz container. They so easy to use and keep food fresh long time , because : UrbanLab containers comes with a portable automatic vacuum pump that can removes the oxygen at the push of a button. The containers are BPA free, durable & stackable; it keeps my food fresh and even taste better. All features: 1. One touch automatical vacuum pump 2. Rechargeable lithium-ion battery 3. BPA free & transparent container, I always can know what food and in which container I store inside. 4. Stackable & save space 5. Freezer safe 6. Quick seal marinator 7. Visual indicator securely seals freshness 8. Silicon gasket and valve prevent leakage 🧺🍅 Get yours with 10% off at https://dealspotr.com/getcode/iBqtI MILENANARCISO-10 🧺🍅 #UrbanLab #urbanlabcontainers #vacuumcontainers #keepitfresh #POMODORO #healthy #freshness #foodorganization #foodcontainers #vacuumsystem #vacuumstorage #stayfresh #leakproofseal #reviews #review #honestreview #bestseller #shoponline #10off #saving #discount #healthylifestyle #lifestyle #lifestyleblog #lifestyleblogger (at Miami, Florida) https://www.instagram.com/p/CNYNbdrHXAx/?igshid=no3k8jabbn1j

#complimentary#urbanlab#urbanlabcontainers#vacuumcontainers#keepitfresh#pomodoro#healthy#freshness#foodorganization#foodcontainers#vacuumsystem#vacuumstorage#stayfresh#leakproofseal#reviews#review#honestreview#bestseller#shoponline#10off#saving#discount#healthylifestyle#lifestyle#lifestyleblog#lifestyleblogger

0 notes

Text

Vacuum Tank: Reliable and Efficient Pressure Control for Plywood Machinery

In plywood production, precision and efficiency are the key to sustaining high-quality production. One of the most important components that facilitate smooth operation in plywood machinery is the vacuum tank. A vacuum tank is an essential component that controls pressure to achieve optimal performance, energy efficiency, and machine durability.

What is a Vacuum Tank?

A vacuum tank is a vital unit employed in industrial equipment to provide and sustain a controlled vacuum state. It facilitates pressure control, evacuation of surplus air, and stabilization of the manufacturing process for increased efficiency. In plywood manufacturing, vacuum tanks ensure improved adhesion, drying, and finishing of plywood panels.

Why a Vacuum Tank is Necessary in Plywood Machinery?

There are several processes involved in producing plywood, such as gluing, pressing, and drying, where pressure control becomes a critical factor. Here's why an efficient and reliable vacuum tank is essential for plywood equipment:

1. Better Adhesion and Bonding

Vacuum tanks facilitate the appropriate pressure environment, making the adhesives spread uniformly and bond well between veneers of wood. This makes the overall strength and durability of plywood sheets stronger.

2. Better Drying Efficiency

Moisture control is essential in plywood production. A vacuum tank ensures removal of excess moisture from the wood, saving drying time and avoiding flaws such as warping and delamination.

3. Uniform Pressure Control

A well-performing vacuum tank ensures constant pressure rates, facilitating efficient and even plywood processing. This avoids pressure fluctuations that may result in production faults and material losses.

4. Cost and Energy Efficiency

New vacuum tanks are made to use less energy and provide maximum performance. By cutting down on energy usage, companies can reduce operational expenses and increase profitability.

5. Longer Machinery Life

Controlling pressure optimally minimizes wear and tear on plywood equipment. A quality vacuum tank reduces mechanical stress, prolonging the life of your equipment and minimizing maintenance expenses.

Selecting the Right Vacuum Tank for Your Plywood Machinery

In order to facilitate smooth production, it is important to invest in a high-quality vacuum tank from a reliable manufacturer. The following are some of the considerations to make when choosing the appropriate vacuum tank:

•Capacity & Size: Select a vacuum tank that suits your machinery capacity and production needs.

��Material Quality: Stainless steel or corrosion-resistant materials guarantee durability and longevity.

•Energy Efficiency: Select vacuum tanks with energy-saving capabilities to minimize operational costs.

•Automation & Control Features: New vacuum tanks have digital controls for accurate pressure control.

Why Choose a Leading Plywood Machinery Manufacturer?

When you purchase a vacuum tank, choosing a top plywood machinery manufacturer guarantees that you get quality, long-lasting, and efficient equipment. Industry leaders provide personalized solutions, after-sales services, and cutting-edge technology to increase your production efficiency.

Final Thoughts

A vacuum tank is an indispensable component in plywood machinery, delivering reliable and efficient pressure control for high-quality production. Investing in the right vacuum tank improves adhesion, accelerates drying, saves energy, and extends machinery life.

For plywood businesses, using a reputable plywood machinery manufacturer guarantees that you are equipped with top-of-the-line equipment meeting industry standards, improving efficiency, and increasing profitability.

Need the finest vacuum tank for your plywood equipment? Deal with DNH Engineers number one plywood equipment manufacturer today and upgrade your output to a new level!. Go and check out our website www.dnhengineers.com for more details.

#VacuumTank#PressureControl#ReliableEfficiency#IndustrialVacuum#VacuumSystem#EngineeringSolutions#EfficientVacuum#ProcessControl#VacuumTechnology#ManufacturingExcellence#VacuumBenefits#PressureManagement#FluidDynamics#EnergyEfficiency#InnovativeEngineering#EquipmentReliability#ProductionOptimization#IndustrialSolutions#VacuumExperts

0 notes

Text

Acme Air Equipments Co. Pvt. Ltd. offers state-of-the-art Mechanical Vacuum Boosters designed for exceptional performance in re-used oil distillation and various industrial applications. Engineered with twin or tri-lobe boosters and available in both air-cooled and water-cooled executions, our vacuum systems provide precise, constant volume displacement at reduced energy consumption. With pumping speeds up to 321,000 LPM and pressure differentials from 50 to 100 mbar, our systems are tailored for processes like distillation, degassing, refining, and vacuum impregnation.

For more details, visit- https://www.acmeairequipments.com/product/mechanical-vacuum-boosters/

#AcmeAirEquipments#MechanicalVacuumBooster#TwinLobeBooster#TriLobeBooster#VacuumSystem#IndustrialApplications#distillation#degassing#coating

0 notes

Text

Top 9 Loai May Hut Chan Khong Khong Ken Tui Dang Dung Nhat Hien Nay

Bảo quản thực phẩm luôn là một mối quan tâm lớn trong mỗi gia đình, đặc biệt khi mọi người đều muốn giữ thực phẩm tươi ngon lâu mà vẫn đảm bảo dưỡng chất. Máy hút chân không không kén túi là một giải pháp hiệu quả, giúp kéo dài thời gian bảo quản mà không làm ảnh hưởng đến chất lượng thực phẩm. Trong bài viết này, chúng tôi sẽ giới thiệu 9 mẫu máy hút chân không không kén túi chất lượng và phù hợp với nhiều nhu cầu sử dụng.

Những Máy Hút Chân Không Không Kén Túi Đáng Mua Nhất

1. Máy Hút Chân Không DZ-300A

Máy hút chân không DZ-300A là sự lựa chọn lý tưởng cho các gia đình có diện tích nhỏ. Với thiết kế gọn nhẹ và công suất 220W, máy có khả năng hút chân không nhanh chóng cho cả thực phẩm khô lẫn ướt. Đặc biệt, máy có tính năng tự động niêm phong sau khi hút, giúp tiết kiệm thời gian và công sức.

2. Máy Hút Chân Không P290

Máy hút chân không P290 là sự lựa chọn phù hợp cho các gia đình có nhu cầu bảo quản thực phẩm hàng ngày. Máy này có khả năng hút nhanh chóng chỉ trong vòng 10 giây, giúp loại bỏ không khí hoàn toàn khỏi túi. Thêm vào đó, với tính năng điều chỉnh độ dài túi tự động, máy đem lại hiệu quả tối ưu và dễ sử dụng.

3. Máy Hút Chân Không Công Nghiệp DZ-400

Dành cho các hộ kinh doanh hoặc doanh nghiệp nhỏ, máy hút chân không DZ-400 sở hữu công suất mạnh mẽ lên đến 900W, phù hợp với nhu cầu đóng gói số lượng lớn. Máy có thể xử lý cả thực phẩm khô và ướt, đảm bảo chất lượng sản phẩm sau khi bảo quản.

4. Máy Hút Chân Không Bluestone VSB-2735

Bluestone VSB-2735 là dòng máy hút chân không mini sở hữu thiết kế hiện đại, bền bỉ và hiệu suất cao. Máy giúp bảo quản thực phẩm tươi lâu hơn và dễ dàng sử dụng, phù hợp cho gia đình hiện đại.

5. Máy Hút Chân Không Ronegye 5200

Máy hút chân không Ronegye 5200 nổi bật với khả năng xử lý đa dạng thực phẩm như rau củ, thịt cá. Máy hoạt động êm ái, tiết kiệm năng lượng và dễ sử dụng, là lựa chọn lý tưởng cho những ai cần một giải pháp bảo quản thực phẩm tiện lợi.

6. Máy Hút Chân Không Elip DZ-500

Với công suất 500W, Elip DZ-500 rất thích hợp cho hộ gia đình và cửa hàng nhỏ. Máy có khả năng hút chân không nhanh chóng, giữ thực phẩm lâu dài và ngăn ngừa vi khuẩn phát triển, đảm bảo độ tươi ngon.

7. Máy Hút Chân Không Sunhouse SHD5812

Sunhouse SHD5812 là lựa chọn phù hợp cho các gia đình có không gian bếp nhỏ. Máy này có công nghệ hút chân không tiên tiến giúp bảo quản thực phẩm mà không cần tủ đông, đồng thời tiết kiệm điện năng và diện tích.

8. Máy Hút Chân Không Caso VC10

Caso VC10 với công suất mạnh mẽ là lựa chọn tối ưu cho gia đình hoặc cửa hàng. Máy có thể hút chân không nhanh chóng, giữ thực phẩm lâu tươi mà không làm mất đi chất lượng.

9. Máy Hút Chân Không Freshpack Pro

Máy hút chân không Freshpack Pro là lựa chọn hoàn hảo cho những gia đình có không gian hạn chế. Với thiết kế mini và tính năng dễ vận hành, máy này tương thích với nhiều loại túi và đảm bảo bảo quản thực phẩm hiệu quả.

Kinh Nghiệm Lựa Chọn Máy Hút Chân Không

Khi chọn mua máy hút chân không, bạn cần cân nhắc một số yếu tố như nhu cầu sử dụng, tính năng của máy (hút được cả thực phẩm khô và ướt), công suất máy, chất liệu và độ bền. Hãy ưu tiên chọn máy từ các thương hiệu uy tín để đảm bảo chất lượng và độ bền lâu dài.

Những Điều Cần Lưu Ý Khi Sử Dụng Máy Hút Chân Không

Để đảm bảo máy hoạt động tốt và kéo dài tuổi thọ, bạn cần vệ sinh máy thường xuyên, kiểm tra túi hút trước khi sử dụng để tránh rách và bảo quản máy ở nơi khô ráo. Ngoài ra, luôn đọc kỹ hướng dẫn sử dụng để đảm bảo hiệu quả khi vận hành.

Kết Luận

Máy hút chân không không kén túi là giải pháp bảo quản thực phẩm hiệu quả, giúp thực phẩm tươi lâu mà không mất đi dưỡng chất. Tùy vào nhu cầu sử dụng, bạn có thể lựa chọn dòng máy phù hợp, từ các máy mini cho gia đình đến các máy công nghiệp cho doanh nghiệp. Để có sự lựa chọn tốt nhất, hãy chọn sản phẩm từ các thương hiệu uy tín và đại lý chính hãng để đảm bảo chất lượng và dịch vụ hỗ trợ.

Bài viết liên quan:

Địa chỉ: 41 Đường số 40, Khu định cư Tân Quy Đông, tổ 8, Khu phố 2, Phường Tân Phong, Quận 7, Thành phố Hồ Chí Minh

Social:

0 notes

Photo

Central vacuum system known as built-in vacuum system. We offer everythong what your installation need and we are doing everything what need to be done. Https://centralvacuumstore.co.uk #centralvacuumsystem #builtinvacuumcleaner #vacuumsystem #home #unitedkingdom (w: United Kingdom) https://www.instagram.com/p/B5PfL0MhOMt/?igshid=1xi0bcd7vhdf2

1 note

·

View note

Link

#vacuum#vacuumEjectors#vacuumEjector#VacuumEjectorManufactures#vacuumEjectorSuppliers#vacuumEjectorSupplier#VacuumSystem#manufactures#suppliers#manufactureIndustry#manufactruringinIndia#ManufacturingCompanyNashik

0 notes

Photo

New Vac Truck Coleman Vacuum Systems Phone: 1 (800) 645-1136 Serving: United States of America Email: [email protected] #NewTank #NewTruck #VacuumTruck #Coleman #VacuumSystems #VacuumTank #VTM #WeBuildWhatYouNeed #GetAQuoteOnANewTruck #PortableToilet #SkidUnit #SepticTruck #JetVac #CombinationTruck #FrackingTruck #EnvironmentalTruck #CodedTank #RollOffTankUnits #DumpTanks #Trailers #TankTruck #Tanker #PottyTruck #HoneyWagon #VacTruck #SepticHauler #LiquidWaste #Pumper (at Michigan) https://www.instagram.com/p/BvN17MgH0i-/?utm_source=ig_tumblr_share&igshid=ub72dlponxi4

#newtank#newtruck#vacuumtruck#coleman#vacuumsystems#vacuumtank#vtm#webuildwhatyouneed#getaquoteonanewtruck#portabletoilet#skidunit#septictruck#jetvac#combinationtruck#frackingtruck#environmentaltruck#codedtank#rollofftankunits#dumptanks#trailers#tanktruck#tanker#pottytruck#honeywagon#vactruck#septichauler#liquidwaste#pumper

1 note

·

View note

Photo

CVS1*20 vacuum system for vacuum forming process. It can be customized by your request. #vacuum #vacuumpumps #souzvacuumpump #vacuumsystem #plastic https://www.instagram.com/p/CrdF5PfxPmB/?igshid=NGJjMDIxMWI=

0 notes

Photo

LIQUID RING VACUUM PUMPS

Toshniwal’s range of Liquid Range Vacuum Pumps are manufactured by Pompetravaini- Italy, known worldwide for their quality and unique pump design. The LRVP range includes Single-stage, Double-stage and a unique TRVX Variport variant which covers most rough vacuum applications. Coupled with Toshniwal’s unique system design expertise, the Hybrid LRVP systems (LRVP with ROOTS and condenser) can give a very reliable and efficient Vacuum for most applications. Pompetravaini LRVP is known for delivering higher performance at reduced body profiles and weight. With a large series of materials of construction to choose from, the LRVP range is very versatile and suited for most applications.

FEATURES

Pumping Capacity Range: 3m3/hr to 3500m3/hr

Ultimate Pressure: 33 mbar

Excellent quality and reliability

Very compact pump size with no compromise on performance

High quality materials of construction for accommodating challenging applications

Hydropac option available. (Closed loop water re-circulation for optimum performance and to avoid pollution)

The liquid ring enables easy handling of condensable vapors

Full SS body and impeller construction available for highly corrosive vapor handling

Applications

The Liquid Ring Vacuum Pump is a great solution for those applications for which the condensable vapor load is high. The LRVP is a perfect fit for most Chemical and Pharmaceutical applications such as:

Vacuum distillation

Vacuum Tray Drying (VTD)

Rotary Vacuum Dryer (RVD)

Solvent extraction and Concentration

Recovery of Condensates

0 notes

Video

instagram

#rhodiumplating #royaldiademjewelers with the stirring platform just a bit too fast #livingontheedge #royaldiademjewelers #vacuumsystem sounds weird in the video 😳 (at Royal Diadem Jewelers) https://www.instagram.com/p/B5g7yzHlRuK/?igshid=k4m5hkneoa3o

0 notes

Text

CENTRAL VACUUM

Keeping your residential house clean is an essential aspect that must be fulfilled in order to lead a healthy life.

To Know More Visit Our Website: https://www.atss.in/central-vacuum-cleaner/

#vacuumsystems #vacuumsystem #centralisedvacuumsystem #centralisedvacuumcleaner #centralvacuuminstallersnearme #centralvacuum #centralcleaners #atss

1 note

·

View note

Text

Mechanical Vacuum Boosters are designed to enhance the performance of vacuum systems by increasing the volume displacement of vapors and gases while maintaining lower specific power consumption. This advanced technology boosts efficiency, making vacuum systems more effective and energy-efficient.

For more details, visit- https://www.acmeairequipments.com/product/mechanical-vacuum-boosters/

#AcmeAirEquipments#VacuumSystem#EnergyEfficiency#IndustrialEfficiency#VacuumBoosters#MechanicalBoosters#AdvancedTechnology#EnergySaving#IndustrialEquipment#PerformanceBoost

0 notes